Size Control of Carbon Xerogel Spheres as Key Factor Governing the H2O2 Selectivity in Metal-Free Bifunctional Electro-Fenton Catalysts for Tetracycline Degradation

Abstract

1. Introduction

2. Results and Discussion

2.1. Morphological and Textural Characterization

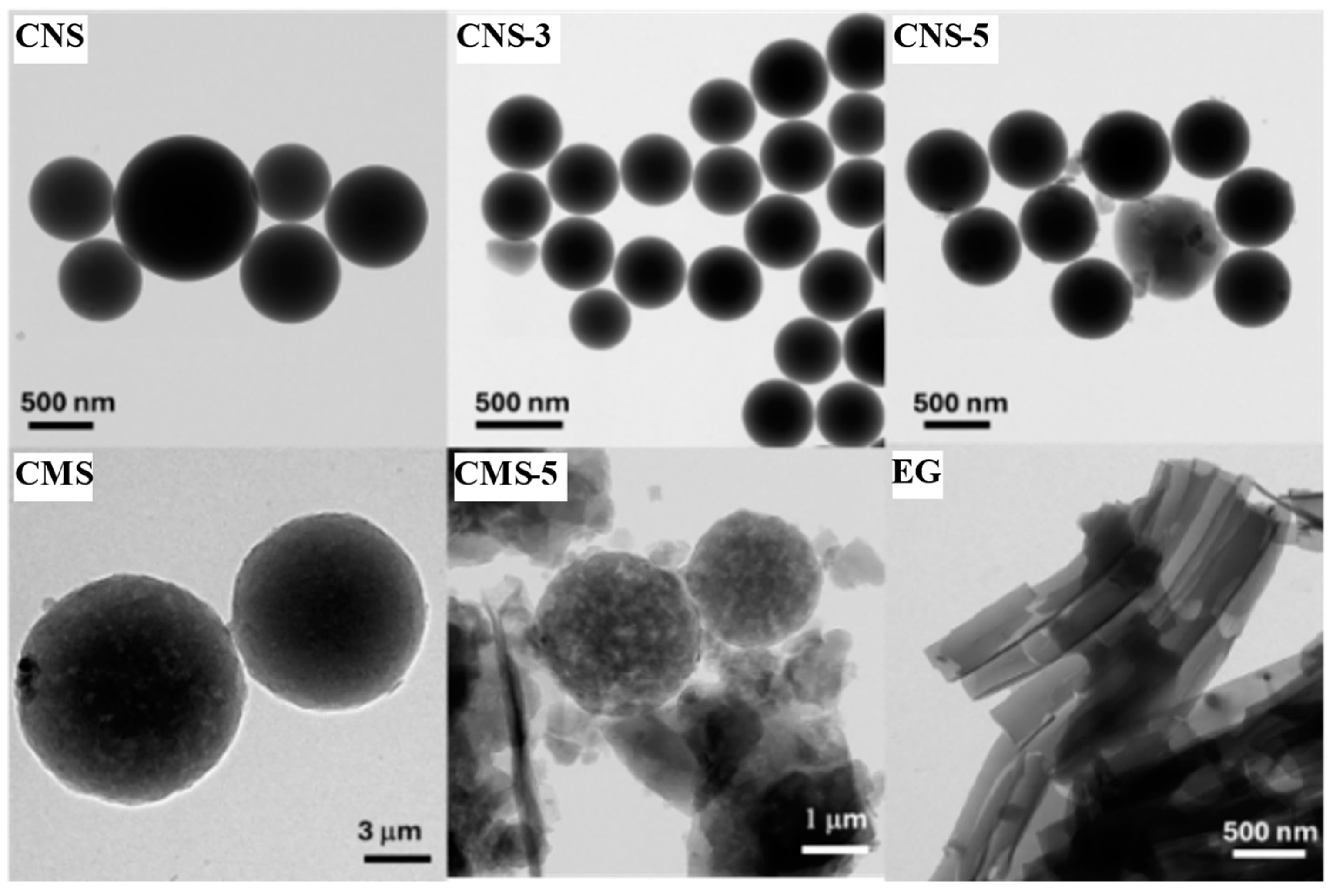

2.1.1. Morphology

2.1.2. Textural Characterization

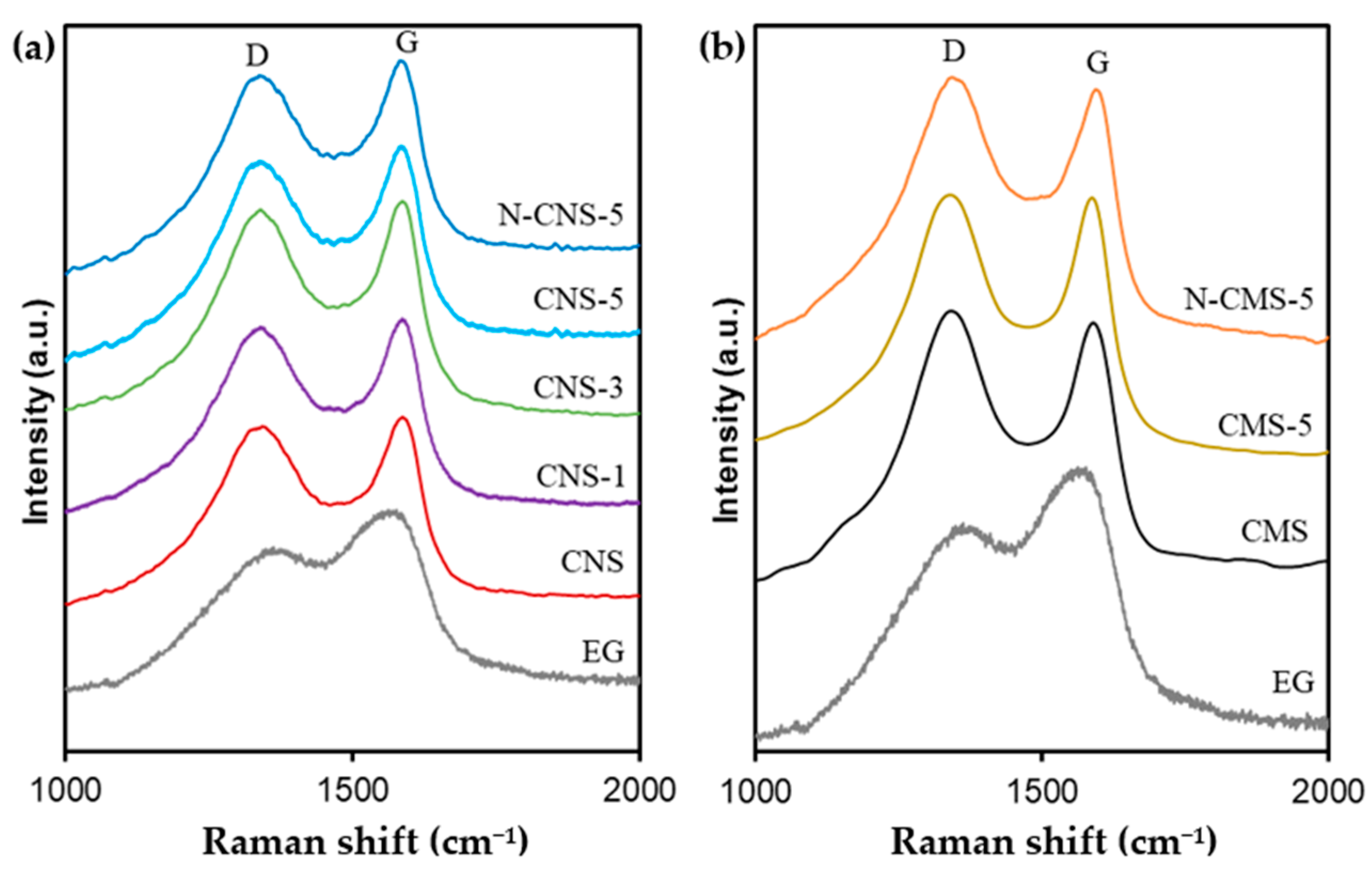

2.1.3. Raman Characterization

2.2. Elemental Analysis and XPS Characterization

2.2.1. Elemental Analysis

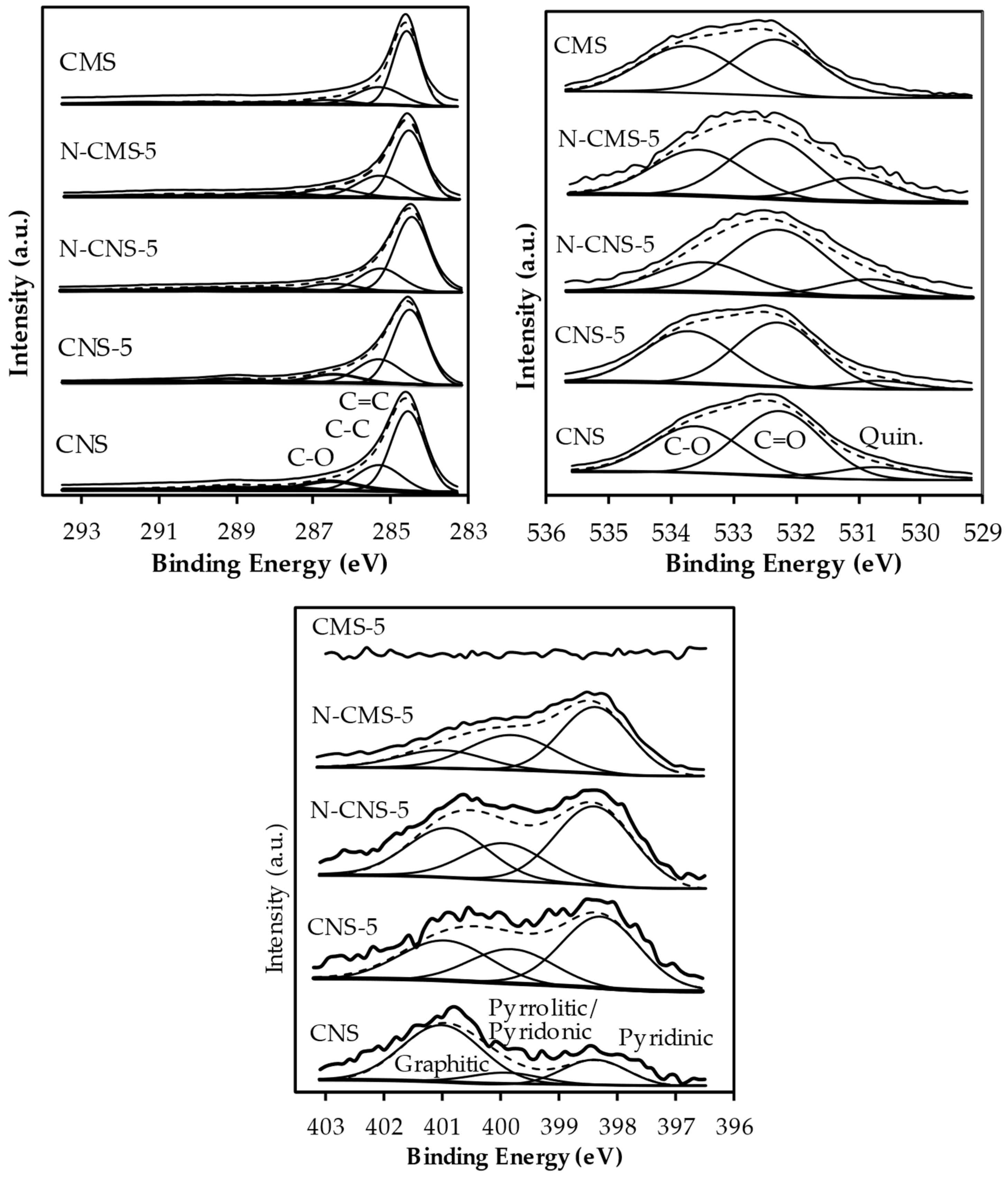

2.2.2. XPS Characterization

2.3. Electrochemical Characterization

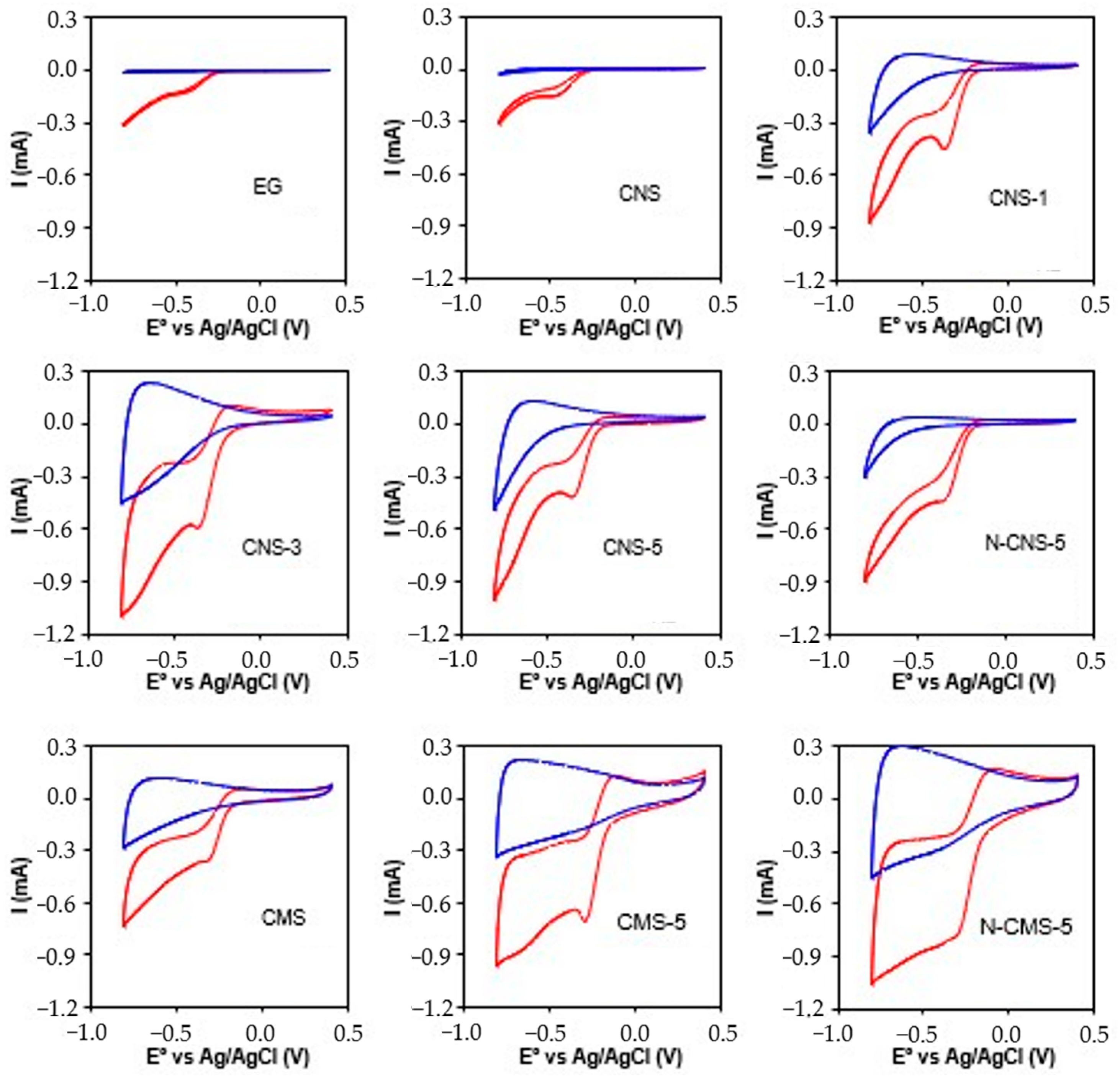

2.3.1. Voltammetries

2.3.2. Size Effect of N-CS in the Catalytic Activity

3. Conclusions

4. Materials and Methods

4.1. Synthesis of Materials

4.1.1. Eco-Graphene (EG)

4.1.2. Carbon Xerogel Spheres (CS)

4.1.3. N-Doped Carbon Xerogel Spheres (N-CS)

4.2. Characterization

4.2.1. Chemical and Textural Characterization

4.2.2. Electrochemical Characterization

4.3. Electro-Fenton Processes

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Song, Y.; Meng, C.; Lyu, Y.; Liu, Y.; Li, Y.; Jiang, Z.; Jiang, K.; Hu, C. Self-Cleaning Foulant Attachment on near-Infrared Responsive Photocatalytic Membrane for Continuous Dynamic Removing Antibiotics in Sewage Effluent Environment. Water Res. 2024, 248, 120867. [Google Scholar] [CrossRef]

- Fang, Y.; Lin, G.; Liu, Y.; Zhang, J. Advanced Treatment of Antibiotic-Polluted Wastewater by a Consortium Composed of Bacteria and Mixed Cyanobacteria. Environ. Pollut. 2024, 344, 123293. [Google Scholar] [CrossRef] [PubMed]

- Chen, A.; Wang, H.; Zhan, X.; Gong, K.; Xie, W.; Liang, W. Applications and Synergistic Degradation Mechanisms of NZVI-Modified Biochar for the Remediation of Organic Polluted Soil and Water: A Review. Sci. Total Environ. 2024, 911, 168548. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Gao, M.; Dong, H.; Jiang, Y.; Liang, W.; Jiang, J.; Ho, S.H.; Li, F. Deciphering the Fate of Antibiotic Resistance Genes in Norfloxacin Wastewater Treated by a Bio-Electro-Fenton System. Bioresour. Technol. 2022, 364, 128110. [Google Scholar] [CrossRef] [PubMed]

- Zhong, D.; Zhang, J.; Huang, J.; Ma, W.; Li, K.; Li, J.; Zhang, S.; Li, Z. Accelerated Electron Transfer Process via MOF-Derived FeCo/C for Enhanced Degradation of Antibiotic Contaminants towards Heterogeneous Electro-Fenton System. Chemosphere 2023, 335, 138994. [Google Scholar] [CrossRef]

- Hu, J.; Cheng, W.; Zhao, Y.; Song, Y.; Xu, H.; Zhou, H.; Yang, H.; Sun, J.; Chi, R. The Synergistic Effect of Oxygen Vacancies and Acidic Properties of SO42−/CexZr1−xO2 on Enhancing the Electro-Fenton Performance in Antibiotics Wastewater Treatment. Sep. Purif. Technol. 2024, 330, 125233. [Google Scholar] [CrossRef]

- Xu, A.; Liu, W.; Yang, Z.; Cao, L.; Sirés, I.; Zhang, Q.; Zhang, Y. Waste Tire Upcycling for the Efficient Electrogeneration of H2O2 in Advanced Degradation of the Antibiotic Tinidazole by Electro-Fenton Process. J. Clean. Prod. 2023, 430. [Google Scholar] [CrossRef]

- Lu, W.; Chen, N.; Feng, C.; Deng, Y.; Feng, Z.; Hu, Y.; Liu, T.; Hu, W. A Bifunctional Graphene-Based Cathode for Wastewater Treatment in Heterogeneous Electro-Fenton: Taking Textile, Old Landfill Leachate and Simulated Antibiotic Wastewater as Examples. Chem. Eng. J. 2023, 468, 143780. [Google Scholar] [CrossRef]

- Lai, S.; Zhao, H.; Qu, Z.; Tang, Z.; Yang, X.; Jiang, P. Promotion of Formaldehyde Degradation by Electro-Fenton: Controlling the Distribution of ⋅ OH and Formaldehyde near Cathode to Increase the Reaction Probability. Chemosphere 2022, 307, 135776. [Google Scholar] [CrossRef]

- Li, Y.; Yao, B.; Chen, Y.; Zhou, Y.; Duan, X. Metal-Organic Frameworks (MOFs) as Efficient Catalysts for Electro-Fenton (EF) Reactions: Current Progress and Prospects. Chem. Eng. J. 2023, 463, 142287. [Google Scholar] [CrossRef]

- Robles, I.; Martínez, R.J.; Banda-alem, J.A.; Salazar-l, M.L.; Manríquez, J.; García-espínoza, D.; Godínez, L.A. Surface Oxidation Pre-Treatment on Activated Carbon: Effect on Its Cathode Performance in Electro-Fenton Processes. Mater. Today Commun. 2023, 34, 105290. [Google Scholar] [CrossRef]

- Zhou, W.; Rajic, L.; Chen, L.; Kou, K.; Ding, Y.; Meng, X.; Wang, Y.; Mulaw, B.; Gao, J.; Qin, Y.; et al. Activated Carbon as Effective Cathode Material in Iron-Free Electro-Fenton Process: Integrated H2O2 Electrogeneration, Activation, and Pollutants Adsorption. Electrochim. Acta 2019, 296, 317–326. [Google Scholar] [CrossRef]

- Babaei-sati, R.; Parsa, J.B. Electrogeneration of H 2 O 2 Using Graphite Cathode Modi Fi Ed with Electrochemically Synthesized Polypyrrole / MWCNT Nanocomposite for Electro-Fenton Process. J. Ind. Eng. Chem. 2017, 52, 270–276. [Google Scholar] [CrossRef]

- Rivera-vera, C.; Rodrigo-rodrigo, M.A.; Saez, C.; Thiam, A.; Salazar-gonz, R. Electrogeneration of H2O2 through Carbon-Based Ink on Al Foam for Electro-Fenton Treatment of Micropollutants in Water. Chemosphere 2024, 348, 140764. [Google Scholar] [CrossRef]

- Trench, A.B.; Moura, J.P.C.; Antonin, V.S.; Gentil, T.C.; Lanza, M.R.V.; Santos, M.C. Using a Novel Gas Diffusion Electrode Based on Vulcan XC-72 Carbon Modified with Nb2O5 Nanorods for Enhancing H2O2 Electrogeneration. J. Electroanal. Chem. 2023, 946. [Google Scholar] [CrossRef]

- Hu, X.; Wang, J.; Jin, T.; Li, Z.; Tsang, Y.F.; Liu, B. Efficient H2O2 Generation and Bisphenol A Degradation in Electro-Fenton of O-Doped Porous Biochar Cathode Derived from Spirit-Based Distiller’s Grains. Process Saf. Environ. Prot. 2022, 166, 99–107. [Google Scholar] [CrossRef]

- Wang, W.; Li, W.; Li, H.; Xu, C.; Zhao, G.; Ren, Y. Kapok Fiber Derived Biochar as an Efficient Electro-Catalyst for H2O2 in-Situ Generation in an Electro-Fenton System for Sulfamethoxazole Degradation. J. Water Process Eng. 2022, 50, 103311. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhan, L.; Hu, L.; Fan, G. Oxygen-Assisted One-Step Fabrication and Concomitant Regulation of Hierarchical Carbon Nanosheet Assemblies with Conjugated Binding Configurations for Promoted H2O2 Electrosynthesis. Fuel 2023, 354. [Google Scholar] [CrossRef]

- Wu, F.; Nan, J.; Wang, T.; Ge, Z.; Liu, B.; Chen, M.; Ye, X. Highly Selective Electrosynthesis of H2O2 by N, O Co-Doped Graphite Nanosheets for Efficient Electro-Fenton Degradation of p-Nitrophenol. J. Hazard. Mater. 2023, 446, 130733. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Liu, Y.; Liu, Z.; Li, Z.; Zhang, T.; Cheng, Y.; Lei, L.; Yang, B.; Hou, Y. Highly Efficient Electrosynthesis of H2O2 in Acidic Electrolyte on Metal-Free Heteroatoms Co-Doped Carbon Nanosheets and Simultaneously Promoting Fenton Process. Chinese Chem. Lett. 2023, 108926. [Google Scholar] [CrossRef]

- Wang, Y.; Waterhouse, G.I.N.; Shang, L.; Zhang, T. Electrocatalytic Oxygen Reduction to Hydrogen Peroxide: From Homogeneous to Heterogeneous Electrocatalysis. Adv. Energy Mater. 2021, 11, 1–27. [Google Scholar] [CrossRef]

- Yang, Y.; He, F.; Shen, Y.; Chen, X.; Mei, H.; Liu, S.; Zhang, Y. A Biomass Derived N/C-Catalyst for the Electrochemical Production of Hydrogen Peroxide. Chem. Commun. 2017. [Google Scholar] [CrossRef]

- Han, S.; Wang, Z.; Pi, X.; Wu, C.; Wang, X.; Wang, Y.; Liu, X.; Zhao, H. Promotion of Tetracycline Degradation by Electro-Fenton: Controlling the Reaction Zone by N-Doped Modified Activated Carbon Cathode. J. Clean. Prod. 2022, 370, 133524. [Google Scholar] [CrossRef]

- Zhu, Y.; Qiu, S.; Deng, F.; Ma, F.; Zheng, Y. Degradation of Sulfathiazole by Electro-Fenton Using a Nitrogen-Doped Cathode and a BDD Anode: Insight into the H2O2 Generation and Radical Oxidation. Sci. Total Environ. 2020, 722, 137853. [Google Scholar] [CrossRef]

- Sun, Y.; Li, S.; Jovanov, Z.P.; Bernsmeier, D.; Wang, H.; Paul, B.; Wang, X.; Kühl, S.; Strasser, P. Structure, Activity, and Faradaic Efficiency of Nitrogen-Doped Porous Carbon Catalysts for Direct Electrochemical Hydrogen Peroxide Production. ChemSusChem 2018, 11, 3388–3395. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, G.; Jin, S.; Zhou, Y.; Ji, Q.; Lan, H. Graphitic N in Nitrogen-Doped Carbon Promotes Hydrogen Peroxide Synthesis from Electrocatalytic Oxygen Reduction. Carbon N. Y. 2020, 163, 154–161. [Google Scholar] [CrossRef]

- Tian, M.; Zhu, Y.; Zhang, D.; Wang, M.; Chen, Y.; Yang, Y.; Gao, S. Pyrrolic-Nitrogen-Rich Biomass-Derived Catalyst for Sustainable Degradation of Organic Pollutant via a Self-Powered Electro-Fenton Process. Nano Energy 2019, 64, 103940. [Google Scholar] [CrossRef]

- Chen, J.; Wang, X.; Cui, X.; Yang, G.; Zheng, W. Amorphous Carbon Enriched with Pyridinic Nitrogen as an Efficient Metal-Free Electrocatalyst for Oxygen Reduction Reaction. 2014, 557–559. [CrossRef]

- Quílez-Bermejo, J.; Melle-Franco, M.; San-Fabián, E.; Morallón, E.; Cazorla-Amorós, D. Towards Understanding the Active Sites for the ORR in N-Doped Carbon Materials through Fine-Tuning of Nitrogen Functionalities: An Experimental and Computational Approach. J. Mater. Chem. A 2019, 7, 24239–24250. [Google Scholar] [CrossRef]

- Zhe-lun, P.; Xu-fang, Q. Porous Carbons for Use in Electro-Fenton and Fenton-like Reactions. NEW CARBON Mater. 2022, 37, 180–195. [Google Scholar] [CrossRef]

- Tan, Z.; Qin, X.; Cao, P.; Chen, S.; Yu, H.; Su, Y.; Quan, X. Enhanced Electrochemical-Activation of H2O2 to Produce •OH by Regulating the Adsorption of H2O2 on Nitrogen-Doped Porous Carbon for Organic Pollutants Removal. J. Hazard. Mater. 2023, 458, 131925. [Google Scholar] [CrossRef]

- Tan, L.; Liu, Y.; Zhu, G.; Fan, X.; Quan, X. Metal-Free Electro-Fenton Degradation of Perfluorooctanoic Acid with Efficient Ordered Mesoporous Carbon Catalyst. Sci. Total Environ. 2023, 875, 162725. [Google Scholar] [CrossRef]

- Yang, Q.; Chu, L.; Wu, T.; Zhou, Y.; Liu, C.; Cang, L. Investigation of Dual-Functional Carbon Cathode Catalysts from Agricultural Wastes in the Heterogeneous Electro-Fenton Process. Appl. Catal. B Environ. 2023, 337, 123018. [Google Scholar] [CrossRef]

- Barranco Lopez, A.; Morales-Rodríguez, A.I.; Fajardo-Puerto, E.; Elmouwahidi, A.; Bailón-García, E. Highly Graphitic Fe-Doped Carbon Xerogels as Dual-Functional Electro-Fenton Catalysts for the Degradation of Tetracycline in Wastewater. Environ. Res. 2023, 228. [Google Scholar] [CrossRef]

- Ramírez-Valencia, L.D.; Bailón-García, E.; Moral-Rodríguez, A.I.; Carrasco-Marín, F.; Pérez-Cadenas, A.F. Carbon Gels–Green Graphene Composites as Metal-Free Bifunctional Electro-Fenton Catalysts. Gels 2023, 9. [Google Scholar] [CrossRef]

- Alegre, C.; Sebastián, D.; Lázaro, M.J. Carbon Xerogels Electrochemical Oxidation and Correlation with Their Physico-Chemical Properties. Carbon N. Y. 2019, 144, 382–394. [Google Scholar] [CrossRef]

- Zhao, M.; Ma, X.; Yan, S.; Xiao, H.; Li, Y.; Hu, T.; Zheng, Z.; Jia, J.; Wu, H. Solvothermal Synthesis of Oxygen-Incorporated MoS2-x Nanosheets with Abundant Undercoordinated Mo for Efficient Hydrogen Evolution. Int. J. Hydrogen Energy 2020, 45, 19133–19143. [Google Scholar] [CrossRef]

- Dibale, A.A.; Su, W.-N.; Tamirat, A.G.; Pan, C.-J.; Aragaw, B.A.; Chen, H.-M.; Chen, C.H.; Hwang, B.-J. The Synergetic Effect of Graphene on Cu2O Nanowire Arrays as a Highly Efficient Hydrogen Evolution Photocathode in Water Splitting. Mater. Chem. A 2014, 18383–18397. [Google Scholar] [CrossRef]

- Wassner, M.; Eckardt, M.; Reyer, A.; Diemant, T.; Elsaesser, M.S.; Behm, R.J.; Hüsing, N. Synthesis of Amorphous and Graphitized Porous Nitrogen- Doped Carbon Spheres as Oxygen Reduction Reaction Catalysts. 2020, 1–15. [CrossRef]

- Hunter, R.D.; Hayward, E.C.; Smales, G.J.; Kulak, A.; De, S.G.; Schnepp, Z. The Effect of Nitrogen on the Synthesis of Porous Carbons by Iron-Catalyzed Graphitization. Mater. Adv. 2023, 2070–2077. [Google Scholar] [CrossRef]

- Gong, Y.; Shi, G.; Zhang, Z.; Zhou, W.; Jung, J.; Gao, W.; Ma, L.; Yang, Y.; Yang, S.; You, G.; et al. Direct Chemical Conversion of Graphene to Boron- and Nitrogen- and Carbon-Containing Atomic Layers. Nat. Commun. 2014. [Google Scholar] [CrossRef]

- Elmouwahidi, A.; Bailón-García, E.; Pérez-Cadenas, A.F.; Castelo-Quibén, J.; Carrasco-Marín, F. Carbon-Vanadium Composites as Non-Precious Catalysts for Electro-Reduction of Oxygen. Carbon N. Y. 2019, 144, 289–300. [Google Scholar] [CrossRef]

- Rufford, T.E.; Hulicova-jurcakova, D.; Zhu, Z.; Lu, G.Q. Empirical Analysis of the Contributions of Mesopores and Micropores to the Double-Layer Capacitance of Carbons. J. Phys. Chem. 2009, 19335–19343. [Google Scholar] [CrossRef]

- Vallerot, J.; Bourrat, X.; Mouchon, A.; Chollon, G. Quantitative Structural and Textural Assessment of Laminar Pyrocarbons through Raman Spectroscopy, Electron Diffraction and Few Other Techniques. Carbon N. Y. 2006, 44, 1833–1844. [Google Scholar] [CrossRef]

- Elmouwahidi, A.; Bailón-garcía, E.; Pérez-cadenas, A.F.; Maldonado-hódar, F.J.; Carrasco-marín, F. Activated Carbons from KOH and H3PO4 Activation of Olive Residues and Its Application as Supercapacitor Electrodes. Electrochim. Acta 2017, 229, 219–228. [Google Scholar] [CrossRef]

- Canal-rodríguez, M.; Arenillas, A.; Men, J.A.; Ramos-fern, G.; Rodríguez-pastor, I.; Martin-gullon, I. Determinant in Fluence of the Electrical Conductivity versus Surface Area on the Performance of Graphene Oxide-Doped Carbon Xerogel Supercapacitors. Carbon N. Y. 2018, 126, 456–463. [Google Scholar] [CrossRef]

- Zhao, P.; Shen, B.; Yang, M.; Chen, L.; Shi, G.; Lu, F. Effect of Nitrogen Species on Electrochemical Properties of N-Doped Carbon Nanotubes Derived from Co-Pyrolysis of Low-Density Polyethylene and Melamine. J. Energy Storage 2023, 67, 107569. [Google Scholar] [CrossRef]

- Tian, K.; Wang, J.; Cao, L.; Yang, W.; Guo, W.; Liu, S.; Li, W.; Wang, F.; Li, X.; Xu, Z.; et al. Single-Site Pyrrolic-Nitrogen-Doped Sp2-Hybridized Carbon Materials and Their Pseudocapacitance. Nat. Commun. 2020, 11, 3884. [Google Scholar] [CrossRef]

- Qin, X.; Zhao, K.; Quan, X.; Cao, P.; Chen, S.; Yu, H. Highly Efficient Metal-Free Electro-Fenton Degradation of Organic Contaminants on a Bifunctional Catalyst. J. Hazard. Mater. 2021, 416, 125859. [Google Scholar] [CrossRef]

- Noël, J.; Latus, A.; Lagrost, C.; Volanschi, E.; Hapiot, P. Evidence for OH Radical Production during Electrocatalysis of Oxygen Reduction on Pt Surfaces: Consequences and Application. Am. Chem. Soc. 2012, 2835–2841. [Google Scholar] [CrossRef]

- Miao, F.; Gao, M.; Yu, X.; Xiao, P.; Wang, M.; Wang, Y.; Wang, S.; Wang, X. TiO2 Electrocatalysis via Three-Electron Oxygen Reduction for Highly Efficient Generation of Hydroxyl Radicals. Electrochem. commun. 2020, 113, 106687. [Google Scholar] [CrossRef]

- Xie, L.; Wang, P.; Zheng, W.; Zhan, S.; Xia, Y.; Liu, Y.; Yang, W.; Li, Y. The Strong Metal–Support Interactions Induced Electrocatalytic Three-Electron Oxygen Reduction to Hydroxyl Radicals for Water Treatment. Environ. Sci. 2023, 120, 1–8. [Google Scholar] [CrossRef]

- Skorupska, M.; Ilnicka, A.; Lukaszewicz, J.P. The Effect of Nitrogen Species on the Catalytic Properties of N-Doped Graphene. Sci. Rep. 2021, 11, 1–11. [Google Scholar] [CrossRef]

- Su, P.; Zhou, M.; Song, G.; Du, X.; Lu, X. Efficient H2O2 Generation and Spontaneous [Rad]OH Conversion for in-Situ Phenol Degradation on Nitrogen-Doped Graphene: Pyrolysis Temperature Regulation and Catalyst Regeneration Mechanism. J. Hazard. Mater. 2020, 397, 122681. [Google Scholar] [CrossRef]

- Li, Y.; Cao, W.X.; Zuo, X.J. O- and F-Doped Porous Carbon Bifunctional Catalyst Derived from Polyvinylidene Fluoride for Sulfamerazine Removal in the Metal-Free Electro-Fenton Process. Environ. Res. 2022, 212, 113508. [Google Scholar] [CrossRef]

- Yang, W.; Zhou, M.; Mai, L.; Ou, H.; Oturan, N.; Oturan, M.A.; Zeng, E.Y. Generation of Hydroxyl Radicals by Metal-Free Bifunctional Electrocatalysts for Enhanced Organics Removal. Sci. Total Environ. 2021, 791, 148107. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, M.A.A.; Elessawy, N.A.; Carrasco-Marín, F.; Hamad, H.A.F. A Novel One-Pot Facile Economic Approach for the Mass Synthesis of Exfoliated Multilayered Nitrogen-Doped Graphene-like Nanosheets: New Insights into the Mechanistic Study. Phys. Chem. Chem. Phys. 2019, 21, 13611–13622. [Google Scholar] [CrossRef] [PubMed]

- Moreno-castilla, C.; García-rosero, H.; Carrasco-marín, F. Synthesis and Characterization of Solid Polymer and Carbon Spheres Derived from an Emulsion Polymerization Reaction of Different Phenolic Compounds with Formaldehyde. Colloids Surfaces A Physicochem. Eng. Asp. 2017, 520, 488–496. [Google Scholar] [CrossRef]

| Sample | N2-Isotherm | CO2 Isotherm | Raman | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SBET | W0 | L0 | V0.95 | Vmeso | W0 | L0 | ID/IG | D Position | G Position | |

| m2g−1 | cm3g−1 | nm | cm3g−1 | cm3g−1 | cm3g−1 | nm | n.a. | cm−1 | cm−1 | |

| EG | 1 | 0.00 | - | 0.00 | 0.00 | - | - | 0.78 | 1363 | 1563 |

| CNS | 560 | 0.23 | 0.51 | 0.27 | 0.00 | 1.00 | 1344 | 1588 | ||

| CNS-1 | - | - | - | - | - | - | - | 0.98 | 1340 | 1587 |

| CNS-3 | - | - | - | - | - | - | - | 0.98 | 1341 | 1587 |

| CNS-5 | 0.97 | 1341 | 1585 | |||||||

| N-CNS-5 | 0.98 | 1338 | 1583 | |||||||

| CMS | 501 | 0.20 | 1.19 | 0.23 | 0.03 | 0.26 | 0.56 | 1.05 | 1343 | 1590 |

| CMS-5 | 555 | 0.23 | 0.86 | 0.41 | 0.18 | 0.24 | 0.56 | 1.00 | 1340 | 1587 |

| N-CMS-5 | 260 | 0.11 | 1.60 | 0.32 | 0.21 | 0.24 | 0.56 | 1.01 | 1343 | 1590 |

| Sample | Elemental Composition (wt.%) | |||

|---|---|---|---|---|

| C | H | O | N | |

| CNS | 95.46 | 0.34 | 4.15 | 0.05 |

| N-CNS | 87.15 | 0.95 | 8.67 | 3.23 |

| CNS-1 | 95.38 | 0.33 | 4.20 | 0.09 |

| CNS-3 | 95.00 | 0.33 | 4.53 | 0.14 |

| CNS-5 | 95.93 | 0.35 | 3.51 | 0.21 |

| N-CNS-5 | 89.18 | 0.67 | 7.74 | 2.41 |

| CMS | 95.96 | 0.33 | 3.71 | 0.00 |

| CMS-5 | 96.00 | 0.35 | 3.42 | 0.23 |

| N-CMS-5 | 90.10 | 0.25 | 3.57 | 6.08 |

| Sample | C1s | O1s | N1s | CXPS (%) | OXPS (%) | NXPS (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BE (eV) | % Peak | Assign. | BE (eV) | % Peak | Assign. | BE (eV) | % Peak | Assign. | ||||

| CMS | 284.6 | 59.3 | C=C | 532.4 | 54.1 | C=O | 96.1 | 3.9 | - | |||

| 285.3 | 23.1 | C–C | 533.8 | 45.9 | C-O | |||||||

| 286.6 | 8.0 | C–O | ||||||||||

| 288.1 | 3.3 | C=O | ||||||||||

| 289.8 | 4.1 | COO− | ||||||||||

| 291.4 | 2.2 | π−π* | ||||||||||

| N-CMS-5 | 284.6 | 55.2 | C=C | 530.8 | 12.2 | Quin. | 398.4 | 56.6 | Pyridinic | 92.4 | 2.5 | 5.1 |

| 285.3 | 23.4 | C–C | 532.3 | 50.3 | C=O | 399.8 | 28.1 | Pyrrolitic/Pyridonic | ||||

| 286.6 | 9.7 | C–O | 533.5 | 37.5 | C-O | 401.0 | 15.3 | Graphitic | ||||

| 288.0 | 4.9 | C=O | ||||||||||

| 289.9 | 4.2 | COO− | ||||||||||

| 291.5 | 2.6 | π−π* | ||||||||||

| CNS | 284.6 | 56.6 | C=C | 530.7 | 8.1 | Quin. | 398.4 | 23.7 | Pyridinic | 92.3 | 7.1 | 0.6 |

| 285.3 | 23.7 | C–C | 532.3 | 53.2 | C=O | 399.9 | 11.1 | Pyrrolitic/Pyridonic | ||||

| 286.6 | 9.4 | C–O | 533.6 | 38.7 | C-O | 401.0 | 65.2 | Graphitic | ||||

| 288.0 | 4.2 | C=O | ||||||||||

| 289.3 | 3.9 | COO− | ||||||||||

| 290.9 | 2.2 | π−π* | ||||||||||

| CNS-5 | 284.6 | 55.8 | C=C | 530.7 | 6.2 | Quin. | 398.4 | 47.4 | Pyridinic | 90.9 | 8.7 | 0.4 |

| 285.4 | 23.1 | C–C | 532.3 | 50.1 | C=O | 399.9 | 22.7 | Pyrrolitic/Pyridonic | ||||

| 286.6 | 10.9 | C–O | 533.7 | 43.7 | C-O | 400.9 | 29.9 | Graphitic | ||||

| 288.0 | 4.4 | C=O | ||||||||||

| 289.3 | 3.9 | COO− | ||||||||||

| 290.9 | 1.9 | π−π* | ||||||||||

| N-CNS-5 | 284.6 | 57.8 | C=C | 530.8 | 13.8 | Quin. | 398.3 | 39.5 | Pyridinic | 85.6 | 5.2 | 9.1 |

| 285.4 | 22.2 | C–C | 532.3 | 59.3 | C=O | 399.8 | 24.8 | Pyrrolitic/Pyridonic | ||||

| 286.6 | 8.9 | C–O | 533.5 | 26.8 | C-O | 401.0 | 35.7 | Graphitic | ||||

| 288.2 | 5.2 | C=O | ||||||||||

| 289.8 | 3.4 | COO− | ||||||||||

| 291.5 | 2.5 | π−π* | ||||||||||

| Eco-G | 284.5 | 72.8 | C=C | 530.6 | 30.9 | Quinone | 398.4 | 47.4 | Pyridinic | 75.7 | 11.3 | 13.1 |

| 285.7 | 20.9 | C–C | 532.0 | 69.1 | C=O | 399.6 | 47.2 | Pyrrolitic/Pyridonic | ||||

| 286.9 | 6.3 | C–O | 401.8 | 5.4 | Graphitic | |||||||

| Sample | Eonset (V) | Jk mAcm−2 | n | H2O2 (%) | |||

|---|---|---|---|---|---|---|---|

| −0.8 V | −0.4 V | −0.8 V | −0.4 V | −0.8 V | −0.4 V | ||

| EG | −0.26 | 5.27 | 0.67 | 2.31 | 2.12 | 84.72 | 94.10 |

| CNS | −0.28 | 1.90 | 0.28 | 2.65 | 2.58 | 67.36 | 70.76 |

| CNS-1 | −0.23 | 9.62 | 2.89 | 2.87 | 2.54 | 56.63 | 78.24 |

| CNS-3 | −0.23 | 10.05 | 2.95 | 3.13 | 2.63 | 43.28 | 68.60 |

| CNS-5 | −0.23 | 10.81 | 3.07 | 3.18 | 2.69 | 40.99 | 65.27 |

| N-CNS-5 | −0.22 | 14.13 | 3.96 | 3.18 | 2.64 | 41.10 | 68.05 |

| CMS | −0.19 | 4.60 | 1.99 | 2.54 | 2.34 | 73.04 | 83.18 |

| CMS-5 | −0.18 | 14.16 | 8.66 | 2.83 | 2.47 | 58.47 | 76.72 |

| N-CMS-5 | −0.15 | 16.10 | 9.45 | 3.10 | 2.91 | 45.62 | 54.43 |

| Catalyst | n | Pollutant | Experiment Conditions | Time (min) | %Degradation | Ref |

|---|---|---|---|---|---|---|

| OCNT-80 (O-doped carbon nanotubes) | 2.5 to 2.6 (−0.3 to −1.0V vs. SCE) | Phenol | −0.4V vs. SCE, pH = 6.5 | 60 | 99.2 | [49] |

| NGE (Nitrogen-doped Graphene) | 2.1 to 2.5 (−0.6 to −1.2V vs. Ag/AgCl) | Phenol | pH neutral | 180 | 93.6 | [54] |

| PPC (O and F doped porous carbon) | 2.1 to 2.2 (−0.4 to −1.6V vs. Ag/AgCl) | Sulfamerazine | −1.5V vs. Ag/AgCl, pH = 3 | 180 | 90.1 | [55] |

| ACSS (Activated carbon wrapped with stainless steel) | ----- | RB19 | 100 mA, pH = 7 | 720 | 61.5 | [12] |

| N,S-EEGr (Nitrogen and sulfur co-doped graphene) | 2.22 to 2.27 (−1.0 to 0.0V vs. SCE) | Phenol | 6.25 mA cm−2, pH = 7 | 15 | 100 | [56] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fajardo-Puerto, E.; López-García, N.; Elmouwahidi, A.; Bailón-García, E.; Carrasco-Marín, F.; Ramírez-Valencia, L.D.; Pérez-Cadenas, A.F. Size Control of Carbon Xerogel Spheres as Key Factor Governing the H2O2 Selectivity in Metal-Free Bifunctional Electro-Fenton Catalysts for Tetracycline Degradation. Gels 2024, 10, 306. https://doi.org/10.3390/gels10050306

Fajardo-Puerto E, López-García N, Elmouwahidi A, Bailón-García E, Carrasco-Marín F, Ramírez-Valencia LD, Pérez-Cadenas AF. Size Control of Carbon Xerogel Spheres as Key Factor Governing the H2O2 Selectivity in Metal-Free Bifunctional Electro-Fenton Catalysts for Tetracycline Degradation. Gels. 2024; 10(5):306. https://doi.org/10.3390/gels10050306

Chicago/Turabian StyleFajardo-Puerto, Edgar, Nerea López-García, Abdelhakim Elmouwahidi, Esther Bailón-García, Francisco Carrasco-Marín, Lilian D. Ramírez-Valencia, and Agustín F. Pérez-Cadenas. 2024. "Size Control of Carbon Xerogel Spheres as Key Factor Governing the H2O2 Selectivity in Metal-Free Bifunctional Electro-Fenton Catalysts for Tetracycline Degradation" Gels 10, no. 5: 306. https://doi.org/10.3390/gels10050306

APA StyleFajardo-Puerto, E., López-García, N., Elmouwahidi, A., Bailón-García, E., Carrasco-Marín, F., Ramírez-Valencia, L. D., & Pérez-Cadenas, A. F. (2024). Size Control of Carbon Xerogel Spheres as Key Factor Governing the H2O2 Selectivity in Metal-Free Bifunctional Electro-Fenton Catalysts for Tetracycline Degradation. Gels, 10(5), 306. https://doi.org/10.3390/gels10050306