Abstract

The study aimed at the evaluation of the physical properties of apple juice powders mixed with different concentration of maltodextrin obtained by freeze-, vacuum and spray drying methods. Due to the chemical composition of apple juice there was a possibility to obtain apple juice powders by freeze-, spray and vacuum drying, excluding vacuum drying at 40 °C when 15% and 20% of maltodextrin were added. The moisture content of powders was more dependent on the drying method than on the quantity of maltodextrin added. The spray drying process in the context of an increase in maltodextrin quantity resulted in a decrease in the water activity of apple powders, whereas low temperature processes increased its values. Lower values of true density were observed after spray drying in comparison to freeze- and vacuum drying processes. The application of selected drying methods resulted in the formation of different particles’ size of apple powders influencing the bulk density of the products. The highest values of bulk density were indicated for powders obtained by vacuum drying due to the bigger size of the particles (crystalized structure). The porosity of apple juice powders was strictly related to the bulk density. Colour parameters of powders were more influenced by drying techniques than the quantity of maltodextrin (15% up to 35%) added.

1. Introduction

Apples rank second after bananas in terms of production volume worldwide. In 2014, the highest apple production was noted for China, followed by United States and Poland [1]. The global average percentage of apples marked fresh is estimated at approx. 82%, whereas the remaining 18% is processed [2]. Apple juice is one of the most popular products obtained after apple processing. Distribution of this beverage worldwide might be expensive due to the high transportation costs. Thus, fruit juice powders could be a more practical form than their liquid counterpart. Fruit juice powders, by virtue of their reduced weight and volume, are easier to handle, diminish the transportation costs and prolong the shelf life of the juice products [3]. The transformation of juice into powders has gained special attention due to the complexity of the process. The chemical composition of fruit juices, mainly due to the low glass transition temperature of the main juice components, that is, organic acids and low molecular weight sugars, make it almost impossible to obtain powders without carriers that are added in a relatively huge quantities [4,5,6]. What is more, different types of carrier agents might be applied, namely, maltodextrins, gum arabic, waxy starch, inulin and cellulose, among which the most popular are maltodextrins [7]. Taking into account the application of carriers before drying process of fruit juices, the quality of the final products considered in terms of chemical properties is significantly altered [6,8,9]. The influence of the quantity of the carrier added into the fruit juices has an influence on the final product properties [9,10]. Those properties of fruit powders also strongly depended on the drying methods and the parameters applied for their dehydration [11,12,13,14,15]. According to Chopda and Barret [16], the recommended methods for fruit juice production are, for example, freeze-drying, foam mat drying and spray drying, however, the economic aspect should be taken into account. The production of fruit powders requires a thorough examination of the mixture composition (carrier and juice) as, in general, a higher bulk density and a lower moisture content are desirable parameters for food powders. To date, there is no information available about the quantity of carrier added in terms of physical properties of apple juice powders and whether there are any relationships between the addition of carrier and moisture content, water activity, true and bulk density, porosity and the colour parameters. Thus, taking above into consideration, the aim of the study was to examine the possibility of apple juice powders preparation with the addition of carrier and to explore the physical properties of products obtained.

2. Materials and Methods

2.1. Materials

Apples cv. Champion (20 kg) were purchased from the local market in 2015. The fruits were washed, cut and pressed by a hydraulic press (SRSE, Warsaw, Poland). The juice obtained was centrifuged (5000× g, 15 min, room temperature) and portioned. Each part (12.9 ± 0.1° Brix) was mixed with 15%, 20%, 25%, 30% and 35% (w/w) commercial maltodextrin (the ratio of juice solids to carrier was: 1:1.38; 1:1.95; 1:2.60; 1:3.35; 1:4.21, respectively) with dextrose equivalent of dextrose equivalent (DE) 20–30. Apple juice with selected addition of maltodextrin was subjected to different drying techniques.

2.2. Methods

2.2.1. Drying Processes

The freeze-drying (FD) process of apple juice with a different quantity of maltodextrin (100 mL) was made in OE-950 freeze dryer (Labor, MIM, Budapest, Hungary) at a reduced pressure of 65 Pa for 24 h with the temperature in the drying chamber −60 °C and 30 °C of the heating plate. Freeze drying process for each sample was performed in triplicate (n = 3).

Spray drying (SD) of the apple juice with a selected quantity of maltodextrin (100 mL) was performed by Mini Buchi Spray-dryer (Buchi, Flawil, Switzerland). The juice temperature before loading on spray dryer was 23 °C and the rate of feeding was 40 mL min−1. The spray dryer was operated at an inlet temperature of 180 °C. The process was made in triplicate.

Vacuum drying at 40 °C, 60 °C and 80 °C of apple juice (200 mL) was made in a vacuum dryer (SPT-200, ZEAMiL, Horyzont, Kraków, Poland) at a pressure of 1 kPa for, respectively, 72 h, 48 h and 24 h. The process was made in duplicate.

2.2.2. Moisture Content (Mc)

The moisture content of powders obtained was made at 80 °C for 72 h at the pressure of 100 Pa performed in a vacuum oven (SPT-200, ZEAMiL, Horyzont, Kraków, Poland). The measurements were done in triplicate.

2.2.3. Water Activity

The water activity (aw) was done using water activity meter AquaLab DewPoint 4Te (Decagon Devices Inc., Pullman, WA, USA) at 25 °C ± 0.5. Three readings were made for each sample.

2.2.4. True Density, Bulk Density and Porosity

True density was determined by calculating the ratio of the mass of the dry solids (m) to the total volume (Vs) of the sample, excluding the air pores according to Equation (1), and was expressed as g cm−3:

The apple powders were weighed with an analytical balance (XA 60/220/X Radwag, Radom, Poland), while the total volume excluding the air (Vs) was measured with an HumiPyc™/model 2 Gas Pycnometer (InstruQuest Inc., Coconut Creek, FL, USA).

Bulk density of the apple powders was calculated by the ratio of their mass (m) to their bulk volume (Vb), and was expressed as g cm−3:

The apple powders were weighed with an analytical balance with an accuracy of 0.0001 g (XA 60/220/X Radwag, Radom, Poland), while the bulk volume (Vb) was measured with a 10 ± 0.5 mL graduated cylinder. The container was filled with the samples and then gently shaken to obtain the smallest volume of the samples. The measurements were done in duplicate.

Porosity of the powders was calculated using the relationship between the bulk (ρb) and the true density (ρt) of the powder as in Equation (3) [17]:

2.2.5. Statistical Analysis

Statistical analyses were done using STATISTICA 10 (Statsoft, CA, USA). One-way analysis of variance ANOVA and the least significance test HSD Tukey was carried out to compare the samples and the significance was defined at p < 0.05. Table Curve 2D v 5.01 (Systat Software, San Jose, CA, USA) enabled fitting the mathematical model to experimental points with the highest possible values of the determination coefficient R2 and the lowest values of root mean square error (RMSE).

3. Results and Discussion

Drying methods applied in the current study, that is, freeze-drying (FD), vacuum drying (VD) and spray drying (SD), allowed to obtained powders, excluding VD at 40 °C when 15% and 20% of maltodextrin was used. The chemical composition of apple juice mainly the presence of organic acids and sugars [4], made it almost impossible to perform drying processes as the glass transition temperature of those constituents is lower than the operating temperature of the drying methods applied. Thus, addition of carriers into the apple juice is necessary to perform those processes [4]. Nevertheless, when preparing the apple juice powders not only the drying parameters should be taken into account but also the quantity of the carrier added as relatively low temperature during vacuum drying (40 °C) enable to perform the process only when addition above 25% (w/w) of maltodextrin was done.

3.1. The Physical Properties of Apple Juice Powders

The moisture content (Mc) of apple juice powders ranged from 1.1% up to 5.6% and was within the range obtained by Boonyai et al. [4]. In the current study, the moisture content was dependent on the parameters of drying methods as well as on the percentage of the maltodextrin added into the apple juice. In general, the highest average value of Mc was noticed after freeze drying process (Table 1), whereas the lowest was indicated after SD during which the highest temperature among the drying methods was used. The differences between Mc in powders analysed might result also from their different sorption capacity. The experimental part aimed at gaining the powdered form of apple juice; however, in order to obtain fine powders the different times of drying were used. Thus, the samples may differ in terms of the moisture content. Similar observation was made in case of powders gained from yacon juice drying where the Mc was dependent of the drying conditions [18].

Table 1.

Physical properties of apple juice powders (n = 3; average ± SD).

The determination of water activity (aw) in food powders is an important issue as this parameter influences their stability—both chemical and microbial. Both factors are connected with the quality of the dried products as the rate of its decrease begins above 0.3 for some chemical reactions [19]. In the current study, the water activity (aw) of all apple juice powders was below 0.4, indicating the possible inhibition of microbial growth in the samples obtained [20]. When the selected drying methods were concerned, the lowest average values of water activity were noted after spray drying, whereas the highest average values of aw were indicated when freeze drying process was applied, regardless of the quantity of maltodextrin added. This may be connected with the different structure of powders obtained by selected methods. In the case of the freeze-drying process, a more porous structure was formed, which resulted in higher moisture content and water activity values [19]. It was observed that the water activity was strongly correlated with the moisture content (r = 0.861) (Table 1). A similar relation was observed in case of orange juice powder [14] and carrot powder [21].

The values of true density were not statistically significantly different between the apple juice powders, excluding those obtained by spray drying (Table 1). The application of this drying method significantly reduced the true density of apple powders. During the SD process a relatively high temperature was used, thus it could cause a degradation of selected components or it could lead to the formation of a new compounds [10], which might have a relatively lower values of true density.

The values of bulk density of apple juice powders are presented in Table 1. In general, the highest values of bulk density were noted after vacuum drying when compared to freeze and spray drying processes. The bulk density was influenced by the powders’ grain state that differed due to the structure obtained by different drying methods applied. The more crystalized structure obtained after vacuum drying resulted in lower values of the bulk density as it has lower volume contrary to more powdered form obtained after spray and freeze-drying. This was due to the fact that the crystalized structure contain bigger particles [22].

The porosity of the apple juice powders was indicated in Table 1. Among processes applied, the highest porosity of powders was observed after spray drying. It was strongly correlated with the bulk density (r= −0.947); however, no influence of the true density was noticed as this parameter was at the comparable level among all the samples, except for spray drying (Table 1).

The differences between the colour attributes of the apple juice powders gained after different drying processes were presented in Table 2. In general, lower values of coordinate L* were noted when vacuum drying was applied, regardless of the temperature used when compared to freeze- and spray-dried samples. In general, the FD and SD processes resulted in lighter products than those obtained by VD. Similar observation was made in case of chokeberry powders [12], pointing out that the selection of drying method had a strong impact of the final colour of the powders obtained. Among all powders analysed, the lowest values of attribute a* were noted when the freeze-drying process was applied, indicating the tendency to greenish colour. A strong influence of the drying method and the addition of maltodextrin was noted in case of colour attribute b*. Among the powders analysed, the strongest yellowness was noted when VD at 80 °C was applied, whereas the lowest values of coordinate b* were noted after the SD process. The increase of the temperature from 40 °C up to 80 °C during vacuum drying resulted in an increase in coordinate b* values, pointing to the probable presence of newly formed compounds [23]. Chroma (C*) indicate the colour intensity of the samples [23] and the highest values were noted for powders obtained after vacuum drying at 80 °C (Table 2), whereas the lowest were obtained when the SD process was applied. The C* values were strongly correlated with the coordinate b* (r = 0.999), pointing to the dominant yellow colour of the samples. The hue angle (h*) is used to described the differences of a certain colour [23], and the values obtained in the current study are in agreement with the observations that an angel of approx. 90° represents yellow [24]. Among the drying methods applied, the lowest h* values were noted for powders obtained after freeze-drying process, whereas the lowest were after vacuum drying at 40 °C, suggesting a strong influence on the drying techniques on the colour of the apple juice powders.

Table 2.

The colour parameters (CIE L* a* b*, C* and h*) of apple juice powders (n = 5; average ± SD).

3.2. Funtional Relationships

The study focused on the influence of the addition of maltodextrin on the selected physical properties of the apple juice powders. Table 3 showed the models describing the relationship between quantity of maltodextrin added and selected physical parameters of apple juice powders. The types of functions were established considering the highest possible values of correlation coefficient (R2).

Table 3.

Fitting models.

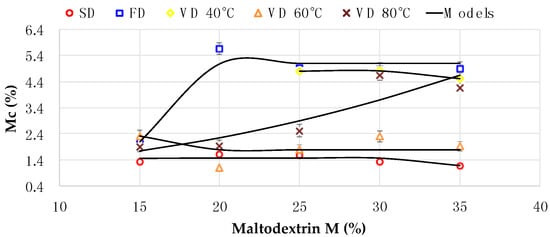

Figure 1 showed the influence of the maltodextrin addition on the moisture content of the apple powders obtained by different drying techniques.

Figure 1.

Functional relationships between the percentage addition of maltodextrin (M) and the moisture content (Mc) of apple powders obtained by different drying methods (SD—spray drying; FD—freeze-drying; VD—vacuum drying).

The relationship between the percentage of the carrier addition and Mc was described by exponential function for drying methods applied, except VD 80 °C that was described by a power function. A high coefficient of the determination of the fitting model was noted only for VD 40 °C (R2 = 0.9989) and FD (R2 = 0.9404) (Table 3).

It was observed that the Mc of powders obtained was only at the comparable level when less than 20% of maltodextrin was added. It might be concluded that Mc was more depended on the drying method applied than on the maltodextrin addition. Indeed, Goula and Adampoulus [25] observed an increase in Mc in powders within an increase in maltodextrin addition, whereas Jittanit et al. [26] observed a decrease in moisture content within the increase in maltodextrin addition during pineapple spray drying process. The final Mc of powders might depend on numerous factors, namely, the drying conditions [27], as well as on the drying technique applied [13], thus low correlation coefficients between those parameters were noted.

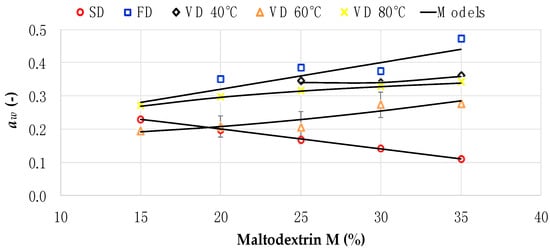

In case of water activity, the relationship between aw and maltodextrin addition was described by linear function in case of FD and SD, by exponential function for VD at 40 °C, and by power function for VD at 60 °C and 80 °C (Table 3, Figure 2). In all cases, the correlation coefficient R2 of fitting models were above 0.85, pointing to a strong relationship between aw and maltodextrin addition. Going into the details, it was observed that the higher the maltodextrin addition, the higher the values of aw for freeze-drying and vacuum drying, regardless of the temperature applied. When the SD process was concerned, the aw values decrease within the increase in the maltodextrin quantity present in the powders. This might be due to the binding capacity of powders connected with a structure of the material formed during spray drying that was trapping the water molecules. A similar observation was made during spray drying of Gac fruit, during which an increase in maltodextrin quantity resulted in decrease in aw values [28]. On the other hand, during the spray drying of bayberry juice an increase in addition of maltodextrin did not change the water activity values of the powders obtained [29]. Similar results were gained during spray and freeze-drying of watermelon juice [30].

Figure 2.

Functional relationships between the water activity (aw) and maltodextrin (M) addition in apple juice powders obtained by different drying methods (SD—spray drying; FD—freeze-drying; VD—vacuum drying).

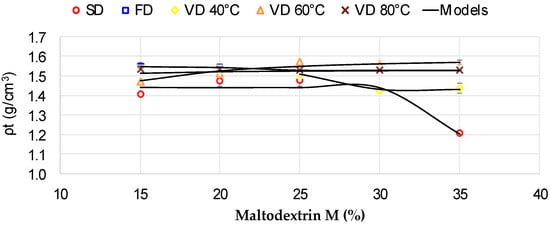

Figure 3 indicated the influence of maltodextrin addition on the true density of apple juice powders obtained by selected drying methods. The relationships between those parameters were described by exponential function for SD and VD at 40 °C with a correlation coefficient 0.6637 and 0.8584, respectively (Table 3). The power function was used for the description of relationships between mention above parameters for the rest of the drying methods with a coefficient of the determination of the fitting model above 0.9. The increased quantity of maltodextrin added into the juice did not significantly influence the true density of the samples, regardless of the methods applied. This might be explained by the fact that the true density of maltodextrin is approx. 1.5 g cm−3 [31]. Taking this into account, the increase in the quantity of maltodextrin generally had no statistically significant influence on the true density of the powders obtained. Thus, the drying process itself and the parameters applied had stronger influence on true density than the addition of maltodextrin into the apple juice. It was observed that only significant influence of the addition of maltodextrin above 30% into the juice was observed in case of spray drying process. It was assumed that the relatively high temperature applied during spray drying process might have caused the chemical changes between the compounds present in apple juice, resulting in the structural alteration of the material. Thus, lower values of true density were observed. Taking into account the water activity values, there is a probability that lower aw of powder obtained after 30% addition of maltodextrin influence the true density as less water was present in the sample. Similar results were obtained during spray drying of pitaya fruits at a relatively high temperature (175 °C) in which the increase in quantity of maltodextrin from 20% up to 30% resulted in a significant decrease in true density values [32].

Figure 3.

Functional relationships between the true density and maltodextrin (M) addition in apple juice powders obtained by different drying methods (SD—spray drying; FD—freeze-drying; VD—vacuum drying).

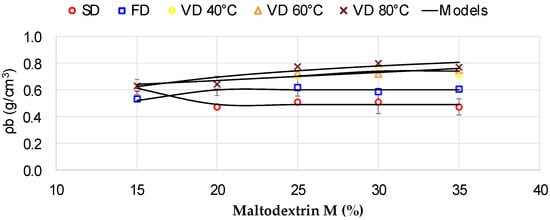

The relationship between the bulk density and the quantity of maltodextrin present in apple powders is shown in Figure 4, and the fitting models are presented in Table 3. The relationship was described by exponential function for FD and SD with correlation coefficient above 0.85 (Table 3). In the case of VD at 60 °C, the linear function was used to describe this relationship, and in the case of VD 80 °C power function best described the relationship between those parameters. No statistically significant relation was found between the bulk density and the quantity of maltodextrin added during vacuum drying at 40 °C. Moreover, the higher concentration of maltodextrin, that is, above 15%, the stronger the influence of the drying processes and parameters applied on the bulk density of apple powders. A similar observation was made during freeze- and spray drying of black glutinous rice bran and maltodextrin composition [33]. In the following study, the spray drying process performed at 180 °C resulted in a decrease in bulk density, whereas the application of the freeze-drying process caused an increase in bulk density values.

Figure 4.

Functional relationships between the bulk density and maltodextrin (M) addition in apple juice powders obtained by different drying methods (SD—spray drying; FD—freeze-drying; VD—vacuum drying).

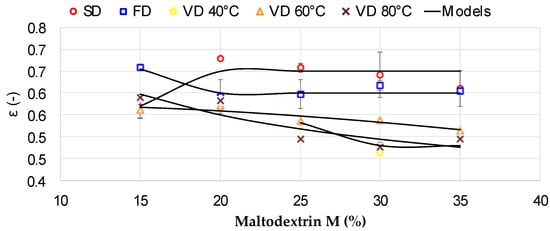

Figure 5 indicated the influence of the maltodextrin content on the porosity of apple juice powders obtained after different drying methods. The relationship between the addition of maltodextrin and the porosity of apple powders obtained was described by exponential function for freeze-, spray and vacuum drying at 40 °C, whereas the power function was used to describe the relationship for vacuum drying at 60 °C and 80 °C. The models were presented in Table 3. It was concluded that porosity decreased within the increase of maltodextrin content for drying methods applied, except for the spray drying process. It might be connected to a greater extent with the properties of apple juice subjected to the drying processes than the addition of maltodextrin. Similar observation was made in the case of mango powders gained after FD and SD processes, after which the highest values of porosity were noticed [22].

Figure 5.

Functional relationships between the porosity (ε) and maltodextrin (M) addition in apple juice powders obtained by different drying methods (SD—spray drying; FD—freeze-drying; VD—vacuum drying).

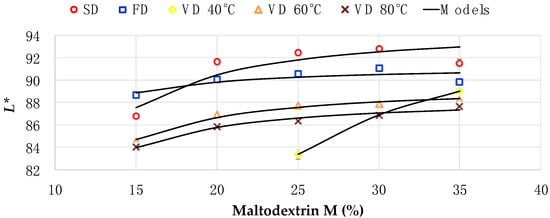

The relationship between the addition of maltodextrin and values of the coordinate L* in relation to selected drying methods was shown in Figure 6. The L* parameter was described by power function for all drying methods used in the current study, and the model equations were presented in Table 3. It can be assumed that the increase in maltodextrin concentration resulted in the lighter products (higher values of L*), regardless of the drying method applied for apple juice powder preparation. The addition of maltodextrin from 15% up to 35% influenced the lightness described by coordinate L* of the powders obtained by selected drying methods. A similar observation was made in the case of mango [22], orange peel [34] and sumac extract [35] powders. When FD and SD were applied, the addition of more than 30% maltodextrin resulted in a decrease in coordinate L* values. No relationship was found between the temperature of vacuum drying and the L* values.

Figure 6.

Functional relationships between the colour attribute L* and maltodextrin (M) addition in apple juice powders obtained by different drying methods (SD—spray drying; FD—freeze-drying; VD—vacuum drying).

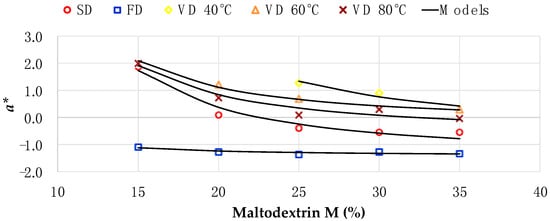

Figure 7 indicated the relationships between the quantity of maltodextrin and a* colour parameter of apple juice powders obtained by selected drying methods. The coordinate a* was described by power function for all methods applied and the models are presented in Table 3. It was observed that the higher the quantity of maltodextrin in the powders, the lower the values of a*, regardless of the drying method applied. Among all methods applied, the freeze-drying process resulted in the lowest alterations in a* values, regardless of the quantity of maltodextrin added. It might be connected with the influence of combination of both aspects, that is, the relatively low temperature during FD and the addition of maltodextrin that protect the molecules responsible for the red colour.

Figure 7.

Functional relationships between the colour attribute a* and maltodextrin (M) addition in apple juice powders obtained by different drying methods (SD—spray drying; FD—freeze-drying; VD—vacuum drying).

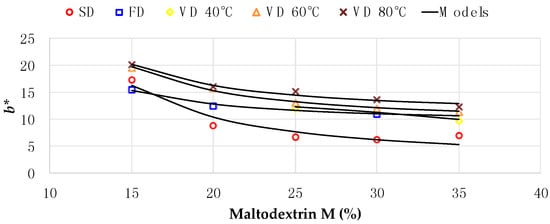

Figure 8 showed the functional relationships between the colour coordinate b* and maltodextrin quantity in apple juice powders obtained by different drying methods. The parameter b* was described by power function for all drying methods applied and models are indicated in Table 3. The strongest influence of maltodextrin addition on the yellowness of the apple powders was noted when maltodextrin below 20% was added, regardless of the drying method applied.

Figure 8.

Functional relationships between the colour attribute b* and maltodextrin (M) addition in apple juice powders obtained by different drying methods (SD—spray drying; FD—freeze-drying; VD—vacuum drying).

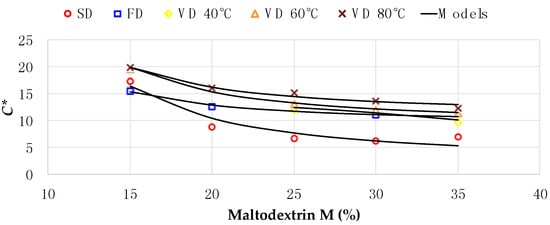

The power function was also used to describe the relationships between the quantity of maltodextrin added into the apple juice and the parameter C* (Figure 9) and the fitting models are indicated in Table 3. The functional relationships were similar to those observed for parameter b* as this coordinate was responsible for the powders’ colour. Similar to Caliskan and Dirim [35], the higher the content of maltodextrin in the powders, the lower the chroma values.

Figure 9.

Functional relationships between the chroma (C*) and maltodextrin (M) addition in apple juice powders obtained by different drying methods (SD—spray drying; FD—freeze-drying; VD—vacuum drying).

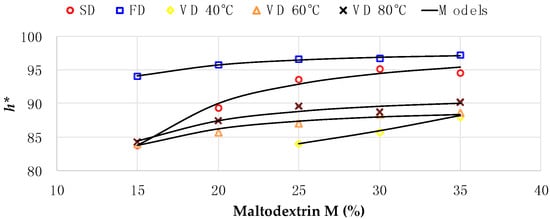

Figure 10 showed the relationships between the hue angle (h*) parameter and the quantity of maltodextrin added in apple powders obtained by selected drying methods. Those relationships were described by power functions for all methods applied (Table 3). In general, the 15% addition of maltodextrin resulted in comparable h* values for the powders obtained by spray and vacuum drying. Higher content of the carrier in the apple juice resulted in higher values of hue angle.

Figure 10.

Functional relationships between the hue angle (h*) and maltodextrin (M) addition in apple juice powders obtained by different drying methods (SD—spray drying; FD—freeze-drying; VD—vacuum drying).

4. Conclusions

The addition of a carrier during apple juice powders’ preparation is an essential step in order to obtain powdered products, however, the quantity of the carrier should be considered, taking into account the drying method. Due to the chemical composition of apple juice there was a possibility to obtain apple juice powders by freeze-drying, spray drying and vacuum drying, excluding VD at 40 °C when 15% and 20% of maltodextrin was used. The moisture content of the powders obtained was more dependent on the drying method applied than on the addition of maltodextrin. High temperature drying processes, that is, spray drying within an increase in maltodextrin quantity, resulted in a decrease in the water activity, whereas low temperature processes increase its values in apple juice powders. The application of the spray drying process caused a significant chemical changes in apple juice powders towards lower values of true density in comparison to freeze- and vacuum drying. The different size of the particles formed in dependence on the drying method used in the study influenced the bulk density of the final products. The higest values of bulk density were indicated for powders obtained by vacuum drying due to the bigger size of the particles that form a crystalized structure. The porosity of apple juice powders was strictly related to bulk density. The colour parameters of the apple juice powders were more influenced by drying techniques than the quantity of maltodextrin (15% up to 35%) added. Taking into account the relatively comparable physical properties of apple juice powders obtained in the current study, the spray drying process can be recommended for apple juice powder preparation with the addition of 20% and greater quantities of maltodextrin during its production due to the effectiveness and economic aspects of the process.

Acknowledgments

The study was funded by the National Science Centre—Poland for the post-doctoral internship (FUGA 3) granted to Anna Michalska (Ph.D.) based on decision number 2014/12/S/NZ9/00754.

Author Contributions

Anna Michalska conceived and designed the experiments; Anna Michalska and Krzysztof Lech performed the experiments and analyzed the data; Anna Michalska wrote the paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Food and Agriculture Organization. Food and Agriculture Organization of the United Nations. Food and Agriculture Organization, 2017. Available online: http://www.fao.org/3/a-i5527e.pdf (accessed on 8 December 2017).

- Rabetafika, H.N.; Bchir, B.; Blecker, C.; Richel, A. Fractionation of apple by-products as source of new ingredients: Current situation and perspectives. Trends Food Sci. Technol. 2014, 40, 99–114. [Google Scholar] [CrossRef]

- Bhandari, B. 1-Introduction to food powders. In Handbook of Food Powders; Woodhead Publishing Series in Food Science, Technology and Nutrition; Woodhead Publishing: Cambridge, UK, 2013; pp. 1–25. ISBN 978-0-85709-513-8. [Google Scholar]

- Boonyai, P.; Howes, T.; Bhandari, B. Applications of the cyclone stickiness test for characterization of stickiness in food powders. Dry. Technol. 2006, 24, 703–709. [Google Scholar] [CrossRef]

- Jiang, H.; Zhang, M.; Adhikari, B. 21-Fruit and vegetable powders. In Handbook of Food Powders; Woodhead Publishing Series in Food Science, Technology and Nutrition; Woodhead Publishing: Cambridge, UK, 2013; pp. 532–552. ISBN 978-0-85709-513-8. [Google Scholar]

- Tonon, R.V.; Brabet, C.; Hubinger, M.D. Anthocyanin stability and antioxidant activity of spray-dried açai (Euterpe oleracea Mart.) juice produced with different carrier agents. Food Res. Int. 2010, 43, 907–914. [Google Scholar] [CrossRef]

- Phisut, N. Spray drying technique of fruit juice powder: Some factors influencing the properties of product. Int. Food Res. J. 2012, 19, 1297–1306. [Google Scholar]

- Michalska, A.; Wojdyło, A.; Honke, J.; Ciska, E.; Andlauer, W. Drying-induced physico-chemical changes in cranberry products. Food Chem. 2018, 240, 448–455. [Google Scholar] [CrossRef] [PubMed]

- Michalska, A.; Wojdyło, A.; Łysiak, G.P.; Figiel, A. Chemical composition and antioxidant properties of powders obtained from different plum juice formulations. Int. J. Mol. Sci. 2017, 18, 176. [Google Scholar] [CrossRef] [PubMed]

- Quek, S.Y.; Chok, N.K.; Swedlund, P. The physicochemical properties of spray-dried watermelon powders. Chem. Eng. Proc. Process Intensif. 2007, 46, 386–392. [Google Scholar] [CrossRef]

- Michalska, A.; Wojdyło, A.; Lech, K.; Łysiak, G.P.; Figiel, A. Effect of different drying techniques on physical properties, total polyphenols and antioxidant capacity of blackcurrant pomace powders. LWT Food Sci. Technol. 2017, 78, 114–121. [Google Scholar] [CrossRef]

- Horszwald, A.; Julien, H.; Andlauer, W. Characterisation of Aronia powders obtained by different drying processes. Food Chem. 2013, 141, 2858–2863. [Google Scholar] [CrossRef] [PubMed]

- Franceschinis, L.; Salvatori, D.M.; Sosa, N.; Schebor, C. Physical and functional properties of blackberry freeze- and spray-dried powders. Dry. Technol. 2014, 32, 197–207. [Google Scholar] [CrossRef]

- Islam, M.Z.; Kitamura, Y.; Yamano, Y.; Kitamura, M. Effect of vacuum spray drying on the physicochemical properties, water sorption and glass transition phenomenon of orange juice powder. J. Food Eng. 2016, 169, 131–140. [Google Scholar] [CrossRef]

- Tontul, I.; Topuz, A. Spray-drying of fruit and vegetable juices: Effect of drying conditions on the product yield and physical properties. Trends Food Sci. Technol. 2017, 63, 91–102. [Google Scholar] [CrossRef]

- Chopda, C.A.; Barrett, D.M. Optimization of guava juice and powder production. J. Food Process. Preserv. 2001, 25, 411–430. [Google Scholar] [CrossRef]

- Bhusari, S.N.; Muzaffar, K.; Kumar, P. Effect of carrier agents on physical and microstructural properties of spray dried tamarind pulp powder. Powder Technol. 2014, 266, 354–364. [Google Scholar] [CrossRef]

- Franco, T.S.; Perussello, C.A.; Ellendersen, L.N.; Masson, M.L. Effects of foam mat drying on physicochemical and microstructural properties of yacon juice powder. LWT Food Sci. Technol. 2016, 66, 503–513. [Google Scholar] [CrossRef]

- Rahman, M.S.; Labuza, T.P. Water activity and food preservation. In Handbook of Food Preservation; Rahman, S., Ed.; CRC Press, Taylor & Trancis Group: Boca Raton, FL, USA, 2007; pp. 447–476. [Google Scholar]

- Beuchat, L. Microbial stability as affected by water activity. Cereal Foods World 1981, 26, 345–349. [Google Scholar]

- Janiszewska-Turak, E.; Dellarosa, N.; Tylewicz, U.; Laghi, L.; Romani, S.; Dalla Rosa, M.; Witrowa-Rajchert, D. The influence of carrier material on some physical and structural properties of carrot juice microcapsules. Food Chem. 2017, 236, 134–141. [Google Scholar] [CrossRef] [PubMed]

- Caparino, O.A.; Tang, J.; Nindo, C.I.; Sablani, S.S.; Powers, J.R.; Fellman, J.K. Effect of drying methods on the physical properties and microstructures of mango (Philippine ‘Carabao’ var.) powder. J. Food Eng. 2012, 111, 135–148. [Google Scholar] [CrossRef]

- Pathare, P.B.; Opara, U.L.; Al-Said, F.A.-J. Colour measurement and analysis in fresh and processed foods: A review. Food Bioprocess Technol. 2013, 6, 36–60. [Google Scholar] [CrossRef]

- Lopez, A.; Pique, M.T.; Boatella, J.; Parcerisa, J.; Romero, A.; Ferra, A.; Garci, J. Influence of drying conditions on the hazelnut quality. III. Browning. Dry. Technol. 1997, 15, 989–1002. [Google Scholar] [CrossRef]

- Goula, A.M.; Adamopoulos, K.G. Effect of maltodextrin addition during spray drying of tomato pulp in dehumidified air: I. drying kinetics and product recovery. Dry. Technol. 2008, 26, 714–725. [Google Scholar] [CrossRef]

- Jittanit, W.; Niti-Att, S.; Techanuntachikul, O. Study of spray drying of pineapple juice using maltodextrin as an adjunct. Chiang Mai J. Sci. 2010, 37, 498–506. [Google Scholar]

- Fazaeli, M.; Emam-Djomeh, Z.; Kalbasi Ashtari, A.; Omid, M. Effect of spray drying conditions and feed composition on the physical properties of black mulberry juice powder. Food Bioprod. Process. 2012, 90, 667–675. [Google Scholar] [CrossRef]

- Kha, T.C.; Nguyen, M.H.; Roach, P.D. Effects of spray drying conditions on the physicochemical and antioxidant properties of the Gac (Momordica cochinchinensis) fruit aril powder. J. Food Eng. 2010, 98, 385–392. [Google Scholar] [CrossRef]

- Fang, Z.; Bhandari, B. Comparing the efficiency of protein and maltodextrin on spray drying of bayberry juice. Food Res. Int. 2012, 48, 478–483. [Google Scholar] [CrossRef]

- Oberoi, D.P.S.; Sogi, D.S. Effect of drying methods and maltodextrin concentration on pigment content of watermelon juice powder. J. Food Eng. 2015, 165, 172–178. [Google Scholar] [CrossRef]

- Takeiti, C.Y.; Kieckbusch, T.G.; Collares-Queiroz, F.P. Morphological and physicochemical characterization of commercial maltodextrins with different degrees of dextrose-equivalent. Int. J. Food Prop. 2010, 13, 411–425. [Google Scholar] [CrossRef]

- Tze, N.L.; Han, C.P.; Yusof, Y.A.; Ling, C.N.; Talib, R.A.; Taip, F.S.; Aziz, M.G. Physicochemical and nutritional properties of spray-dried pitaya fruit powder as natural colorant. Food Sci. Biotechnol. 2012, 21, 675–682. [Google Scholar] [CrossRef]

- Laokuldilok, T.; Kanha, N. Effects of processing conditions on powder properties of black glutinous rice (Oryza sativa L.) bran anthocyanins produced by spray drying and freeze drying. LWT Food Sci. Technol. 2015, 64, 405–411. [Google Scholar] [CrossRef]

- Barbosa, J.; Borges, S.; Amorim, M.; Pereira, M.J.; Oliveira, A.; Pintado, M.E.; Teixeira, P. Comparison of spray drying, freeze drying and convective hot air drying for the production of a probiotic orange powder. J. Funct. Foods 2015, 17, 340–351. [Google Scholar] [CrossRef]

- Caliskan, G.; Nur Dirim, S. The effects of the different drying conditions and the amounts of maltodextrin addition during spray drying of sumac extract. Food Bioprod. Process. 2013, 91, 539–548. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).