Abstract

This review aims to create a communication tool for low-alcohol and nonalcoholic wine production, catering to scientists, educators, students, and wine producers in the field. With health concerns regarding alcohol consumption, the need for information on low-alcohol wines is essential. This paper outlines the methods for the pre-fermentation (leaf area reduction, early grape harvest, grape must dilution, filtration of grape juice and addition of glucose oxidase), mid-fermentation (employing non-saccharomyces yeasts, using genetically modified yeasts through metabolic engineering, and controlling yeast nutrition), and post-fermentation (nanofiltration and reverse osmosis, osmotic distillation, pervaporation, spinning cone column, vacuum distillation, and multi-stage membrane-based systems) stages and their effects on wine quality. It also presents evidence of the impact of alcoholic, low-alcohol, and nonalcoholic wines on cardiovascular health. Finally, the potential market for low-alcohol and nonalcoholic wines is discussed. Key findings indicate a shift toward low-alcohol alternatives due to health, economic, and social factors and consumer interest in healthier lifestyles. Low-alcohol and nonalcoholic wines offer health benefits, particularly cardiovascular health, presenting an opportunity for winemakers to cater to a health-conscious market. From an economic perspective, the low-alcohol and nonalcoholic wine market is poised to grow and diversify its revenue streams. The development of high-quality low-alcohol and nonalcoholic wines, which can command premium prices, enhances profitability. The changing regulatory landscape in Europe, with a focus on transparency in alcohol labeling and nutritional information, aligns with the new consumer preferences and regulatory standards.

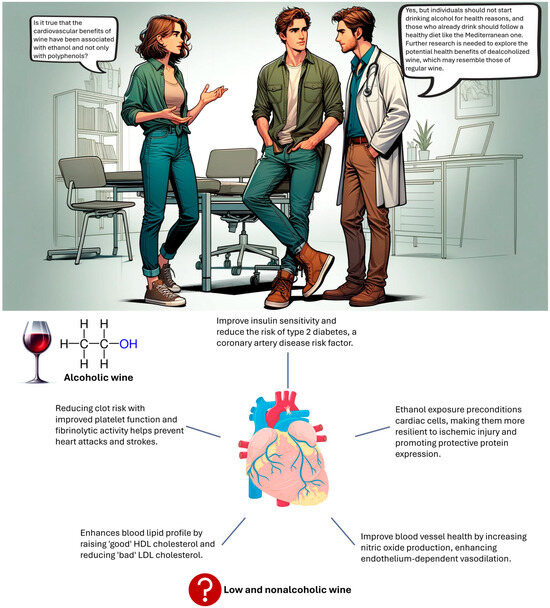

1. Introduction

The growing concern about the increasing alcohol content in wine within the viticulture industry and among health professionals is driven not only by evolving consumer preferences but also by significant shifts in climate patterns. Wines, particularly those from warmer regions, exhibit higher alcohol levels owing to earlier ripening and increased sugar content in grapes [1]. This trend poses health risks because higher alcohol consumption is linked to various adverse health effects, including an increased risk of chronic diseases [2,3,4]. Additionally, wines with elevated alcohol content can experience altered sensory profiles, which may affect consumer satisfaction and the economic stability of wineries [5]. Therefore, the need to reduce the alcohol content in wines is clear, motivated by both public health interests and the need to adapt to climate change-induced viticultural challenges.

The global market for nonalcoholic wine production has demonstrated growing demand, as evidenced by an anticipated annual growth rate of 10% from 2023 to 2033, with the industry projected to reach USD 5.2 billion by 2033 [6]. This demand has been driven by health concerns related to alcohol consumption and an increasing trend toward healthier lifestyles. Advances in technology, such as pervaporation, have enabled the production of nonalcoholic wines that retain the sensory qualities of traditional wines [7]. However, the acceptance of nonalcoholic wines faces challenges, including consumer reluctance to try these products and pricing structures that exceed expectations [8]. While nonalcoholic wines are gaining popularity, studies have suggested that the health benefits associated with moderate red wine consumption, such as improved endothelial function and cardiovascular health, may not extend to their nonalcoholic counterparts [9]. Additionally, the presence of trace amounts of ethanol in “nonalcoholic” beverages poses minimal health risks, according to current physiological and psychocultural knowledge [10]. Therefore, the study of low-alcohol and nonalcoholic wine production is essential owing to its increasing market demand and potential health benefits. Understanding consumer behavior, technological challenges, and health implications of low-alcohol wine consumption is crucial for the beverage industry and policymakers. This research is vital for informing strategies that will increase consumer acceptance and address market challenges, ultimately supporting the growth of this emerging sector.

Narrative reviews are powerful tools for disseminating complex information across a broad spectrum of audiences, including scientists dedicated to viticulture and enology research, educators and students involved in these fields, policymakers shaping industry standards, and wine producers adjusting to market demands and climatic realities. The utility of narrative reviews lies in their ability to compile and synthesize extensive research into coherent stories, highlighting gaps, controversies, and consensus within the literature [11,12]. To be effective, especially in a multidisciplinary context, narrative reviews should be written in a language that is accessible to non-specialists [12]. This approach not only facilitates the dissemination of knowledge but also ensures that reviews can effectively contribute to the advancement of practice and research [12]. A clear and understandable prose expands the reach and impact of scientific findings, ensuring that stakeholders at all levels can make informed decisions based on the latest evidence. This review is prompted by the pressing concerns regarding rising alcohol levels in wine due to climate change and attendant health repercussions. By evaluating the current methods for wine alcohol reduction and their efficacy, this review endeavors to provide a comprehensive survey of the domain. It seeks to bridge the knowledge gap for a diverse readership, fostering a holistic comprehension that promotes informed decision-making and encourages further research into sustainable and health-focused winemaking practices. In this paper, it was not only used as an accessible language but also incorporated illustrations reminiscent of comic strips to enhance the effectiveness of the document as a communication tool. Comics and illustrations are crucial in narrative reviews because of their historical significance, educational value, and unique narrative structures. They serve as a hybrid art form that can express complex ideas and emotions while also being accessible and engaging to a wide audience. The interplay of visual and textual elements in comics provides a rich and immersive experience, making them an important subject of academic study and cultural appreciation [13].

2. What Is the Best Way to Reduce Alcohol Content?

The primary source of alcohol in wine is the fermentation of sugars, particularly the glucose and fructose found in grapes. During grape ripening, these sugars accumulate in the cellular medium, especially in the vacuoles. Glucose plays a crucial role in this process, accounting for half of the total fermentable sugars in grape juice. It is the primary substrate for the conversion of yeast into alcohol during fermentation. Thus, the glucose concentration in grapes at the time of harvest directly affects the potential alcohol content of wine [14]. Thus, winemakers can employ strategies to control or modify the sugar content of grapes, thereby influencing the final alcohol level in their wines.

2.1. Pre-Fermentation Strategies

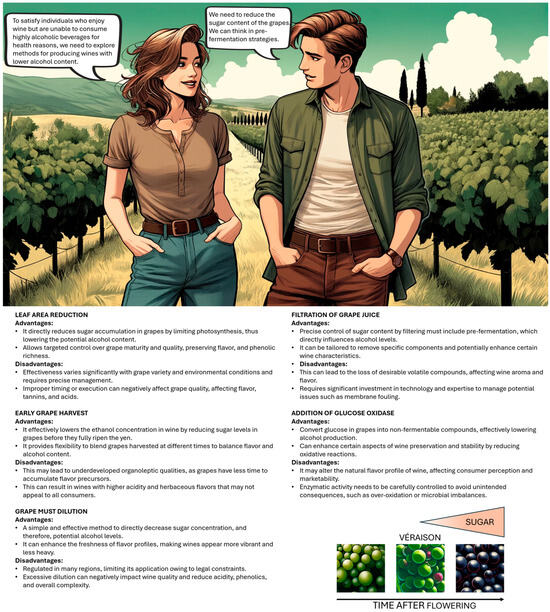

2.1.1. Leaf Area Reduction

Leaf area reduction is a viable strategy for effectively managing the alcohol content of wine by influencing sugar accumulation in grape berries. Leaves play a crucial role in photosynthesis, the process by which sunlight is converted into sugars in vineyards. These sugars are then transformed into alcohol by the yeast during fermentation. Consequently, the sugar content of grapes at harvest is a key factor in determining the potential alcohol content of wine [15,16]. Maintaining an optimal leaf area to fruit ratio, generally between 0.8 and 1.2 m2/kg, is essential for achieving the right sugar levels in grapes while preserving the wine’s flavor and phenolic content [17]. By strategically pruning or trimming leaves, winemakers can limit the vine’s capacity for photosynthesis, thereby controlling grape sugar levels and ultimately producing wines with a lower alcohol content [18]. Therefore, the timing and methods of leaf area reduction are critical. It is important for winemakers to manage this process to slow down sugar accumulation at particular stages of grape development without adversely affecting other important grape characteristics, such as flavor, tannins, and acids. The effectiveness of this technique can vary depending on the grape variety and environmental conditions, highlighting the importance of winemakers and viticulturists to deeply understand their specific vineyard conditions and how different canopy management practices impact their vines. For example, studies involving Shiraz grapes have demonstrated that apical defoliation, which involves removing leaves from the top of the vine, can delay sugar accumulation and reduce the final alcohol content of wine without compromising its aromatic qualities [19]. Similarly, mechanical leaf removal after veraison, or the onset of ripening, has been shown to effectively reduce sugar content in Sangiovese grapes, resulting in wines with lower alcohol levels while maintaining their characteristic flavor profiles [20]. However, these results are not universal across all grape varieties. In varieties such as Carot Noir [21] and Cabernet Sauvignon [22], shoot thinning was found to increase both soluble solids and alcohol content in wines, suggesting a complex interaction between viticultural practices and biochemical processes within different grape types. These findings underscore the need for a customized approach to canopy management tailored to the unique characteristics and needs of each grape variety to achieve desired wine profiles. The effectiveness of practices such as shoot thinning and leaf area reduction varies significantly with grape variety. Thus, meticulous planning and precise implementation of these techniques are crucial, as they substantially influence the alcohol content, flavor profile, and overall quality of the final wine product. This approach requires a comprehensive understanding of viticulture as well as an appreciation of the nuances of each grape variety and the desired characteristics of wine (Figure 1) [23].

Figure 1.

Pre-fermentation strategies to reduce the wine alcohol content. (Artificial intelligence and Adobe Illustrator were used to produce the elements depicted in this image).

2.1.2. Early Grape Harvest

Managing the harvest date is a pre-fermentation strategy that is used to reduce the alcohol content in wine and is applicable to both red and white grape varieties. This approach generally includes either early harvesting of grapes or blending grapes that are mature with those harvested early [24,25,26,27,28,29]. Research has indicated that such practices can significantly lower ethanol concentration in wine by approximately 3% v/v [26]. One specific method, known as the double-harvest approach, precisely timed two separate harvests. This includes determining the optimal quantity of grapes to be collected at each harvest and selecting the best method to preserve the harvested grapes, either in the form of must or wine. This method requires experimental adjustments to fine-tune the variables [18,30]. However, early harvesting of grapes can sometimes result in wines that have not fully developed their organoleptic properties, as the grapes may not have had sufficient time to accumulate all the flavor precursors typically garnered before harvest. Additionally, wines from early-harvested grapes might present organoleptic defects, such as herbaceous flavors, and higher than usual acidity levels [31]. An interesting study investigated the effects of grape juice from two red grape varieties, Pinot Noir and Tannat, harvested at different maturity levels. This was carried out to produce red wines with reduced alcohol content and pH while enhancing the color and phenolic compound concentrations [29]. The wines produced exhibited lower alcohol content and total acidity without significant changes in other wine components. Furthermore, the study examined the impact of early harvesting on the alcohol content and aromatic qualities of Barbera and Pinot Noir wines. The results showed that early harvesting reduced the alcohol content in wines by approximately 3.2% v/v, particularly in Barbera wines, while still maintaining an optimal aromatic profile (Figure 1) [29].

2.1.3. Grape Must Dilution

The practice of adding water to grapes to reduce their sugar concentrations is subject to regulation in many wine-producing regions. For example, in Australia, the permissible limit for adding water to wine as a fining agent is 7% (v/v). This addition could potentially lower the alcohol concentration by approximately 1% v/v [32]. However, this method impacts not only the sugar and ethanol levels but also other critical wine parameters such as total acidity, color, tannins, and the overall flavor profile of the wine [32]. Adding water to Merlot grapes resulted in a wine that contained 2% v/v less ethanol than the control wine, and it featured an enhanced fresh fruit flavor. There were no significant differences in the perceived heat (hotness) of wine compared with untreated wines. Similarly, wines made from diluted Cabernet Sauvignon must also show a reduction in alcohol content, similar to wines produced from early-harvested grapes [33]. However, it is important to note that excessive water addition can reduce acidity, diminish phenolic and tannin concentrations, and adversely affect wine appearance and sensory qualities [34,35,36,37]. Therefore, careful management of water addition is essential for maintaining the desired quality and characteristics of wine (Figure 1).

2.1.4. Filtration of Grape Juice

Another approach to reducing the alcohol content in wine involves decreasing the sugar content in musts using membrane techniques. Initially, this method was not permitted in Europe, but in 2012, the International Organisation of Vine and Wine authorized the use of membrane coupling, specifically ultrafiltration (UF) and nanofiltration (NF), for this purpose (Resolution OIV-OENO 450B-2012) [38]. This technology is commercialized under the brand REDUX®, which employs an initial UF step to filter the must. The UF process yields a permeate containing water, sugars, acids, minerals, and traces of anthocyanins and tannins. This permeate is then processed through the NF, producing a sugar-rich viscous filtrate. The NF permeate, primarily comprising water, acids, and minerals, is reintegrated with the UF filtrate, which is rich in polysaccharides, proteins, anthocyanins, and tannins, back into the treated must. Wines crafted from this reconstituted must show a reduction in alcohol content of 1–2% v/v when treating 20–25% of the grape must using the REDUX® process (Figure 1) [39].

This dual-stage membrane process is preferred over single-step NF treatment because the UF stage alleviates osmotic pressure and reduces the content of macromolecules, which facilitates a more efficient sugar concentration by the NF and minimizes volume loss. Studies have shown varying effects on wine properties, depending on the method used. For instance, experiments with Verdejo and Tinta de Toro musts using both single- and dual-step NF processes resulted in alcohol reductions of up to 3.3% v/v but also caused slight reductions in wine color intensity and altered the perception of specific volatile compounds, as well as floral and fruity aromas [40]. Similarly, experiments using a singular and two-stage NF process with a 200 Da membrane on white and red musts led to reductions in wine alcohol content by 1–2% v/v compared to control wines, with minimal impact on sensory characteristics [41]. Additionally, the application of reverse osmosis (RO) to filter the musts of Tinta Roriz, Syrah, and Alicante Bouschet achieved up to a 5% reduction in alcohol v/v. However, this process influences color intensity, polyphenols, and anthocyanins, thereby affecting the sensory properties of wine [42]. Given that musts are complex colloidal liquids, challenges such as membrane fouling can occur during filtration, making the selection of appropriate membranes and optimal operational conditions crucial for preserving the desired flavors and aromas of wine.

2.1.5. Addition of Glucose Oxidase

Glucose oxidase (Gox) is primarily produced by fungi, particularly Aspergillus and Penicillium strains. However, the industrial production of fungal enzymes often encounters issues such as low efficiency, generation of unwanted byproducts, and sensitivity to metal ions. To address these challenges, biotechnological advancements have been applied to enhance Gox production. A notable development is the heterologous expression of Gox genes, which has been achieved by modifying genes from Aspergillus niger for expression in Pichia pastoris, leading to significantly increased yields of Gox [43]. Additionally, research has shown that expressing the Gox gene in Yarrowia lipolytica using a hybrid promoter and secretion system substantially boosts Gox activity, particularly under controlled pH and temperature conditions [44]. This method highlights the potential of Yarrowia lipolytica as a reliable host for producing recombinant enzymes, overcoming traditional limitations of fungal enzyme production (Figure 1).

The Gox has valuable applications in the wine industry. This enzyme catalyzes the conversion of glucose in grape must to gluconic acid through a two-step oxidation process. This transformation not only reduces the sugar available for alcohol production but also directly influences the final alcohol content of wine. For instance, Gox was used to significantly lower glucose levels in Riesling grape juice, which in turn reduced the alcohol content after fermentation [45]. The use of Gluzyme, a commercial Gox product derived from Aspergillus oryzae, has also been observed to modestly decrease ethanol content while impacting other characteristics of wine, such as acidity and sensory properties [46]. Further studies have demonstrated the complex relationship between Gox application and wine quality, illustrating how repeated enzyme additions can affect not only the alcohol content but also the acidity and overall flavor profile of wine [47]. The role of Gox extends beyond fermentation; it remains active in wine and participates in reactions that can influence the formation of new compounds under acidic conditions. These interactions may alter the visual and sensory qualities of wine, which can be particularly significant in white wine varieties where such changes might be less desirable [48]. Additionally, research has indicated the potential of Gox to inhibit undesirable browning in wines, suggesting a dual function of the enzyme in both preserving color quality and managing chemical transformations during wine storage [49]. Cumulative research on Gox underscores its dual utility in enhancing industrial enzyme production and refining wine production processes.

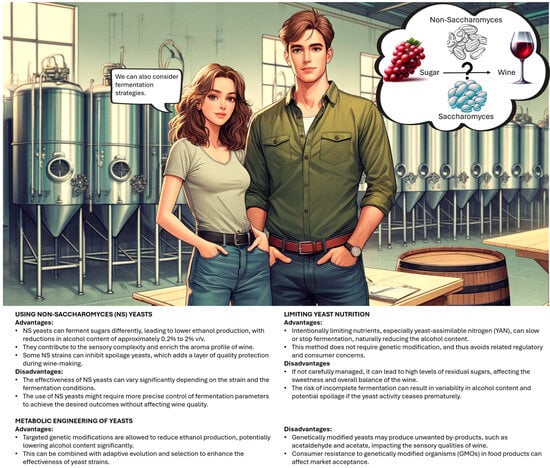

2.2. Fermentation Strategies

Various innovative fermentation techniques have been developed to produce wines with reduced alcohol content, with a focus mainly on yeast management. These methods include using different yeast strains and genetically engineered yeasts and adjusting the nutritional intake of the yeast during fermentation. Employing non-Saccharomyces (NS) yeasts, using genetically modified yeasts through metabolic engineering, and controlling yeast nutrition are effective strategies for reducing alcohol levels in wines. Each approach has its unique benefits and challenges, significantly influencing the fermentation process, sensory characteristics of the wine, and overall alcohol content (Figure 2) [23].

Figure 2.

Fermentation strategies to reduce the wine alcohol content. (Artificial intelligence and Adobe Illustrator were used to produce the elements depicted in this image).

The use of NS yeasts has gained interest among researchers and winemakers for their ability to ferment sugars differently or divert carbon metabolism to pathways that produce less ethanol [50]. The effectiveness of NS yeasts in decreasing ethanol levels, which can range from 0.2% to 2% v/v, has been demonstrated through various fermentation techniques, such as single-strain, mixed, and sequential fermentation, alongside Saccharomyces cerevisiae [51,52,53,54,55,56,57,58,59]. NS yeasts not only help to modestly reduce ethanol content but also enhance the fermentation process, contribute to the wine’s sensory complexity, and enrich its aroma profile [53,57,58]. Some NS yeast species or strains have the potential to inhibit spoilage yeasts, adding an additional benefit [59].

Metabolic engineering uses techniques such as gene editing, adaptive evolution, and selection to create yeast strains capable of reducing ethanol levels during fermentation [60,61,62,63]. The relative simplicity of the yeast genome enables targeted modifications to reduce ethanol production. Limiting the activity of alcohol dehydrogenase (ADH), the enzyme responsible for the final step of ethanol production, is a common strategy. However, deleting ADH proved impractical, as these strains could not thrive under anaerobic conditions and produced high levels of acetic acid and acetaldehyde [64]. Therefore, researchers are exploring other metabolic targets to reroute yeast metabolism from ethanol to other end-products [55], ensuring that these changes do not compromise wine quality [50]. Although these genetically engineered strains can effectively lower alcohol content, they may also produce compounds such as acetate, acetaldehyde, and acetoin, which could negatively impact the sensory quality of wine [63]. Additionally, there is considerable consumer hesitancy regarding the use of genetically modified organisms for food and beverage production. As an alternative, non-genetic methods, such as adaptive evolution and selection, along with using naturally lower ethanol-yielding yeasts, are also employed, potentially reducing wine alcohol content by up to 3% (v/v) without sacrificing quality (Figure 2) [31,65].

Another effective winemaking technique for producing low-alcohol wines involves intentionally limiting yeast nutrition, primarily by managing the availability of yeast-assimilable nitrogen (YAN), which comes from sources such as ammonium and amino acids [66]. Although grapes naturally contain some YAN, supplemental nitrogen is often added to prevent yeast starvation [66]. By setting lower YAN targets or withholding supplemental nitrogen, fermentation can be naturally slowed or stopped, although this may lead to variability in the final alcohol content and potentially high levels of residual sugars [67,68]. In addition to nutrient control, arrested fermentation can also be achieved through temperature manipulation or sterilization techniques. Research indicates that fermentation temperatures between 15 °C and 25 °C are more effective at converting sugars into ethanol, leading to a higher alcohol content. Conversely, fermentation at higher temperatures, such as 30–35 °C, tends to slow yeast growth and sugar consumption [69]. Nutrient limitation combined with temperature or chemical intervention is a viable strategy for managing fermentation processes aimed at producing wines with lower alcohol content. However, these methods must be carefully managed to ensure the quality of wine, particularly in terms of balancing residual sugars and developing a desirable aroma profile [70,71].

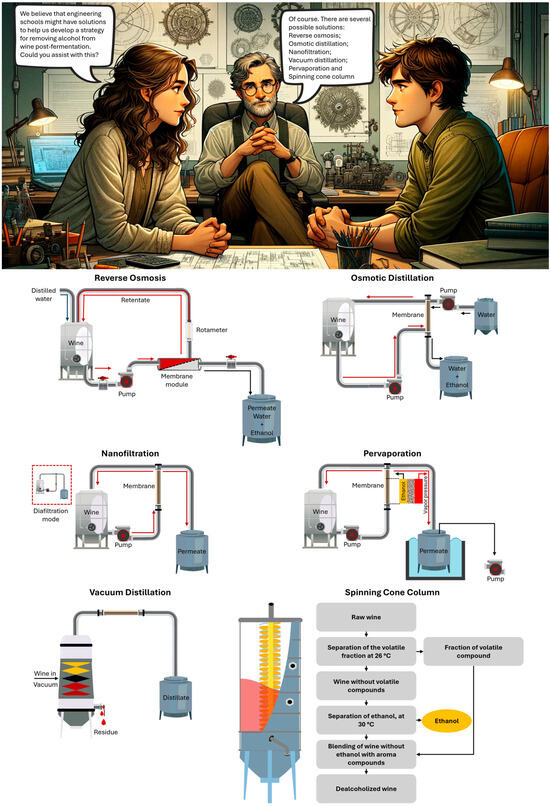

2.3. Post-Fermentation Strategies

2.3.1. Nanofiltration and Reverse Osmosis

One of the major challenges in winemaking is reducing the alcohol content of wine without compromising its quality. Advanced membrane technologies such as NF and RO offer effective solutions for removing ethanol while preserving the essential components and bioactive compounds of wine [23]. The use of RO in the alcohol reduction of beverages dates back to 1975, when a German brewing company obtained a patent to use RO to remove alcohol from beer and wine, marking a significant advancement in nonthermal beverage processing [72]. RO operates by pushing water and ethanol through a dense membrane, driven by a pressure differential that exceeds the osmotic pressure across the membrane. RO is often paired with column distillation to boost efficiency and minimize volume loss, allowing for the recirculation of distilled water back into the wine [73]. It has been observed that wines processed through RO maintain taste and aroma profiles similar to those produced via traditional methods like distillation or spinning cone technology [74]. In one case, RO was used to reduce the ethanol content in apple cider by 75% v/v at pressures ranging from 1.0 MPa to 5.0 MPa at 15 °C, effectively preserving key aroma compounds [75,76]. Another study on the partial dealcoholization of red wines found that wines dealcoholized by 1 and 2 vol percent using RO had compositions similar to those of the control wines, showcasing RO as a suitable method for partial dealcoholization with minimal impact on wine composition and sensory attributes [77]. However, some negative effects were noted on the sensory qualities of Merlot and Shiraz wines dealcoholized using RO, emphasizing the need for careful balance during the dealcoholization process [78]. Despite RO’s energy efficiency and “clean” technology status owing to its lower operating temperatures, it requires precise management to avoid diluting and altering the authentic characteristics of the beverage [7]. Recent advances have combined RO with other technologies, such as osmotic distillation (OD), to achieve dealcoholization without significantly affecting the aroma and flavor profiles of wine, demonstrating the potential of integrated membrane technologies in modern winemaking (Figure 3) [79,80].

Figure 3.

Post-fermentation strategies to reduce the wine alcohol content. (Artificial intelligence and Adobe Illustrator were used to produce the elements depicted in this image).

NF, a separation process using semi-permeable membranes with pore sizes ranging from 1 to 10 nm, can operate at pressures of up to approximately 75 bar [81,82]. These membranes are known to have higher permeate fluxes than RO membranes and can effectively reject smaller molecules, such as sugars, peptides, and proteins. NF has been used both in the pre-fermentation stage to reduce the sugar content required to produce low-alcohol wine [40,42,83,84] and directly on finished wines to achieve similar reductions [85,86,87,88,89]. A previous study demonstrated the use of an NF TriSep flat sheet membrane (type XN45) to concentrate valuable red wine components while reducing the ethanol content from 12.8% to 9.8%, although there was a slight loss of aroma [90]. Comparative studies on various NF membranes have shown that they provide higher permeate flux and adequate ethanol rejection, resulting in dealcoholized wine samples with more promising organoleptic properties than those processed by RO (Figure 3) [85].

Researchers have found that NF not only effectively reduces alcohol content but also preserves the organoleptic characteristics vital to wine quality [91]. Although RO membranes have lower ethanol rejection and permeate fluxes, NF membranes generally display high permeate fluxes and are effective for ethanol rejection and aroma compound removal. One significant advantage of NF over RO is its ability to enrich the ethanol content in the permeate, thus enhancing the dealcoholization efficiency. The lower transmembrane pressure required for NF also makes it more cost-effective than other methods, with the potential for nearly zero alcohol retention, making NF highly efficient in producing nonalcoholic or significantly lower alcohol wines without compromising crucial wine characteristics [90].

2.3.2. Osmotic Distillation

Osmotic distillation (OD) is an advanced membrane-based technique used predominantly at atmospheric pressure and ambient temperature to selectively extract water and other solvents from aqueous solutions [92]. This process is distinctive because it does not rely on pressure gradients but instead uses a hydrophobic polymeric membrane, making it highly effective for applications such as wine dealcoholization. The materials commonly used for these membranes include polypropylene, polyvinylidene fluoride, polyethylene, and polytetrafluoroethylene, which are chosen for their low surface tension properties. The application of OD for wine dealcoholization was significantly advanced by pioneering studies that demonstrated its ability to reduce alcohol levels by up to 6% at operating temperatures between 10 °C and 20 °C using water as the stripping agent [93]. In this setup, a microporous membrane with a pore size of approximately 0.2 μm acts as a vapor barrier between the wine and a water-based solution, allowing for a countercurrent flow that enhances the mass transfer of ethanol from the wine to the water without mixing the two phases. This selective removal of ethanol effectively lowers the alcohol content of wine while preserving its essential aromatic and flavor components. The process of ethanol removal from OD consists of three main stages: evaporation, diffusion, and condensation. Evaporation occurs when ethanol vaporizes at the wine-membrane interface, diffusion occurs as ethanol vapor moves through the membrane pores, and condensation occurs when ethanol vapor condenses into the stripping solution (Figure 3) [94].

Further studies have investigated the effects of different stripping solutions and operational parameters, such as the speed of feed and stripper flows and temperature changes, on the efficiency of ethanol removal [94]. Using water as the stripping agent led to a 34% reduction in ethanol content. However, increasing the operational temperature from 25 °C to 45 °C increased the ethanol flux but also resulted in significant losses of aroma compounds, likely due to their co-extraction with ethanol because of shared affinities. Research has shown that adjusting the operational conditions can optimize ethanol removal from the solution. Under laminar flow conditions for both the feed and stripper streams, there was a notable decrease in ethanol transport rates with increasing ethanol concentrations, which was attributed to saturation effects. It was also observed that higher temperatures could accelerate the dealcoholization process, although this might negatively impact the sensory attributes of wine [95]. In a specific study, a large-scale hollow-fiber contactor was used for the partial dealcoholization of Garnacha, Xarelo, and Tempranillo wines. This system, featuring a 20 square meter membrane area and variable feed and stripping flow rates between 600 L/h and 300 L/h, demonstrated that the alcohol content could be reduced by 1.3% to 5% by volume. This method was particularly effective in preserving the aromatic integrity of wines, with only approximately 20% loss in aroma compounds [96]. Further investigations assessed the impact of partially dealcoholized red wine by OD, and it was found that wines with a 2% reduction in alcohol content, the wines were sensorially indistinguishable from standard wines, whereas a 5% reduction led to significant sensory changes, notably diminishing the presence of “Red fruits”, “Cherry”, and “Spicy” notes. Further reductions led to an increase in grass and cooked notes as well as astringency and bitterness when the reduction reached 3% v/v [97]. Subsequent research reported minimal changes in acidity, organic acids, phenolics, and flavonoids in treated wines. However, extensive dealcoholization results in significant alterations in wine color, tonality, and volatile compounds, with reductions of over 98% in completely dealcoholized wines [98,99]. Another study confirmed that reductions in alcohol content to 4.9% and 6.3% retained 84% and 82% of the esters, respectively, highlighting the selective preservation of some aromatic compounds. This modification increased acidity and astringent sensations, along with changes in the aromatic profile of the wine, which includes notes of red fruits and spices [100]. These findings underscore the utility of OD in effectively reducing the ethanol content while maintaining key wine characteristics. However, challenges remain in fully preserving the aromatic profile during extensive dealcoholization processes, indicating a need for careful management of operational parameters to balance ethanol removal with sensory quality preservation.

2.3.3. Pervaporation

Pervaporation (PV) is recognized as one of the most selective membrane technologies, providing substantial benefits for the dealcoholization of wine. This method uses organophilic membranes that efficiently transport ethanol molecules while restricting water molecules, making it particularly effective in systems such as wine, where ethanol is a minor component compared with water [23,101]. PV is not only energy-efficient but also easier to manage than traditional distillation methods, offering high selectivity for ethanol separation. For instance, at a temperature of 40 °C, PV can reduce the ethanol content in wine from an initial 11.5% to between 3% and 7% with a permeate rate of 1.5 kg/m2h [102]. Further enhancements were observed using a commercial organophilic PERVAP Sulzer 1060 membrane, which effectively dealcoholized the Hungarian Tokaji Harslevelu wine. An increase in temperature from 40 °C to 70 °C increased the permeation rate from 0.287 to 1.2 kg/m2h, though it decreased separation efficiency and adversely affected the preservation of aroma compounds essential for maintaining the wine’s organoleptic properties (Figure 3) [7].

To address the issue of aroma loss, innovative applications of PV have been developed to extract aroma compounds before dealcoholization. For example, the use of polyoctylmethylsiloxane-based (POM) membranes has proven effective in recovering esters from dealcoholized wine [85]. Similarly, PV was initially applied to extract aroma compounds from must, which were then blended back into dealcoholized wine, enhancing the wine with its original aromatic profile while preserving crucial aroma compounds such as isoamyl alcohol, hexanal, 2-phenylethanol, and benzaldehyde because of the organophilic properties of the POM membrane [103]. Recent advancements have extended PV applications to other areas of the wine industry. For instance, a recent study explored the use of hydrophobic (PDMS or zeolite silicalite-1) and hydrophilic (zeolite mordenite or faujasite) membranes to extract water from dealcoholized wine via osmotic distillation. This innovative approach successfully recovered bioethanol, capturing 88% of the ethanol removed from the wine and producing a 99.4 wt% water product. This highly purified water exhibited physicochemical properties suitable for reuse in subsequent osmotic distillation processes, underscoring the versatility and potential of PV for fostering sustainable wine production practices [104].

2.3.4. Spinning Cone Column

Spinning Cone Column (SCC) is widely recognized for its remarkable efficiency and cost-effectiveness in the food industry, particularly because of its ability to retain volatile aroma compounds in slurries or liquids [73]. The use of SCC is prevalent in the wine industry for several essential processes, including grape must concentration, sulfur dioxide removal from grape must, recovery of volatile aroma compounds, and reduction of ethanol levels in wines [23,73]. SCC features a rotating vertical shaft with vertically arranged cones that operate as falling-film contactors [73,105,106]. SCC is a two-stage process used to dealcoholize wine. In the first stage, wine is treated under a low vacuum pressure (0.04 atm) at approximately 28 °C, which aids in capturing volatile wine aromas in approximately 1% of the total product volume. In the second stage, the process intensifies with a higher vacuum pressure and a temperature of approximately 38 °C to efficiently remove the alcohol. After the alcohol was removed, the dealcoholized wine was blended with the recovered aromatic fractions to obtain the final dealcoholized wine product [73,107]. Previous studies have explored the use of SCC for continuous ethanol removal from fermenting yeast broth, achieving up to 85% ethanol removal. However, it has been observed that the vacuum conditions used during SCC operations could negatively impact yeast productivity, affecting cell size and morphology [106]. This technology remains pivotal in the wine industry because of its ability to modify alcohol content while preserving or even enhancing the aromatic and flavor profiles of wines (Figure 3).

2.3.5. Vacuum Distillation

Vacuum distillation (VD) is a thermal process widely employed in winemaking that operates under vacuum conditions to facilitate evaporation, distillation, and condensation [108,109]. This technique is primarily used for the self-enrichment of must and for adjusting the alcohol content in wine, with many wineries equipped to perform VD because of its efficacy in extracting most of the alcohol from wine or in separating it from less volatile components [110,111]. A significant advantage of VD is its ability to operate at low temperatures, typically reducing the evaporation temperature of ethanol to between 15 and 20 °C and under pressures below 0.1 bar. These conditions are particularly beneficial, as they help minimize the loss of volatile compounds that are crucial for the flavor and aroma of wine [112]. During the distillation process, the initial portion of the distillate, which is rich in aromatic compounds, can be captured and later reintegrated with the dealcoholized wine, further preserving its aromatic qualities. However, while VD is effective in enhancing certain volatile compounds, research indicates that it may lead to a notable reduction in esters, alcohols, and terpenes [109]. These components are vital for the aromatic complexity and sensory profile of the wine, and their reduction can alter the overall characteristics of the wine. This underscores the importance of carefully managing distillation parameters to balance alcohol removal while preserving key sensory attributes (Figure 3).

2.3.6. Multi-Stage Membrane-Based Systems

Advancements in multi-stage membrane-based systems have shown significant promise in reducing the alcohol content of beverages such as wine and beer while also addressing challenges such as the loss of desirable volatile aroma compounds often associated with single-membrane methods such as NF, RO, and OD [14,79,80,82,103,113]. These sophisticated systems use the strengths of multiple processes to maintain the integrity of the flavor and aroma profiles. For example, in the brewing industry, a combination of PV and distillation units has been successfully used to produce low-alcohol beers. This approach not only extracts alcohol but also recovers and reincorporates aroma compounds, resulting in a beer with only 0.5% v/v ethanol and a desirable flavor profile [114]. In the wine sector, a pilot-scale nanofiltration-pervaporation (NF-PV) system was explored to produce full-flavored, low-alcohol white wine. The process involved reducing the sugar content of the must using a two-stage NF system, followed by the use of PV to extract aroma precursors that were then reintegrated with the reduced-sugar must, yielding a wine that maintained a similar aroma profile to that of the original must [103]. A study investigated the effects of partial dealcoholization on Cabernet Sauvignon wines using an RO-evaporative perstraction (RO-EP) method. This technique involves blending control and dealcoholized wines to examine the sensory changes that result from such modifications. Remarkably, the study found no significant differences in overall aroma intensity between the reconstituted and control wines, showing the RO-EP system’s ability to operate with low energy consumption and minimal thermal impact on wine components, effectively preserving key wine qualities under ambient temperature and atmospheric pressure conditions [79,94]. However, this system also has the potential to reduce critical odor-active volatiles, such as ethyl acetates, esters, and monoterpenes, which are crucial for the sensory attributes of wine [98]. Although multi-stage processes have shown an enhanced capacity to preserve wine aromas and taste to a certain degree, they also have limitations. Important aroma compounds can still be lost, highlighting the need for additional improvements in aroma profile enhancement after dealcoholization. Implementing such enhancements could help wine producers minimize undesirable effects and increase consumer acceptance of low-alcohol wines.

3. How Do Dealcoholization Techniques Influence Wine Composition?

The phenolic composition of wine includes both flavonoid and non-flavonoid elements. Flavonoids are divided into several groups: flavones, flavanols (notably (+)-catechin and (−)-epicatechin), flavonols (such as quercetin, myricetin, kaempferol, and rutin), anthocyanins, and proanthocyanidins. The non-flavonoid phenolic compounds mainly consist of stilbenes (including cis and trans forms of resveratrol and piceid), hydroxybenzoic acids (including p-hydroxybenzoic, vanillic, syringic, gallic, gentisic, salicylic, and protocatechuic acids), and hydroxycinnamates (cis and trans forms of caftaric, coutaric, and fertaric acid). Free hydroxycinnamic acids are present in low concentrations. These compounds are essential for wine quality, particularly in red wines, where they contribute to organoleptic characteristics, including astringency and color [2]. Dealcoholization techniques have been shown to variably influence the phenolic composition of wines, impacting both the sensory qualities and the potential health benefits attributed to wines. The bouquet and palate of wine are significantly shaped by their volatile compound profile [115]. With more than a thousand different volatiles spanning classes, such as alcohols, esters, fatty acids, aldehydes, terpenes, ketones, and sulfur-containing compounds, the complexity of wine aroma is substantial. Fermentation contributes to this complexity by producing approximately 400 volatile compounds [115].

3.1. Pre-Fermentation Strategies

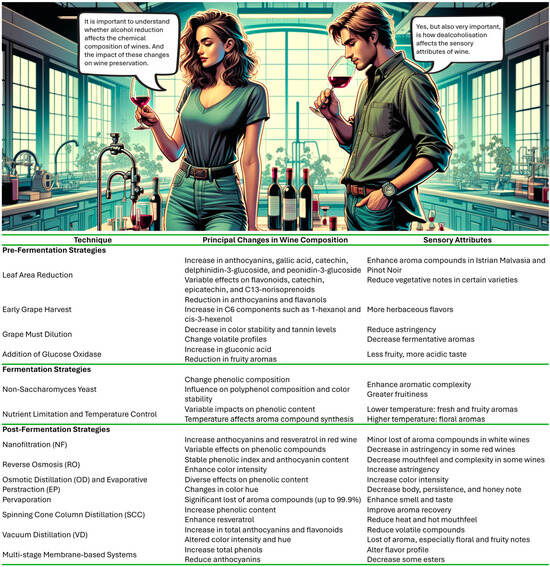

3.1.1. Leaf Area Reduction

Leaf removal is a fundamental technique in vineyard management that enhances the quality of grapes and affects the characteristics of wine. This process can be carried out manually or by using mechanical methods, each of which has different implications for labor costs and sensory attributes of wine. Studies have produced varying results on the impact of defoliation on the phenolic composition of wine, which is influenced by factors such as the timing and method of leaf removal and local climate conditions. For instance, a study in La Rioja, Spain, revealed noticeable differences in wine aroma between manually and mechanically defoliated vines [116]. Another study in Italy found that mechanical defoliation did not significantly change phenolic compounds in Barbera grapes but was helpful in managing vine health in moderate climates [117]. In New Zealand, research on Pinot Noir showed that the timing of leaf removal significantly affects the tannin levels in wine [118]. Additionally, a study investigated the impact of fruit zone leaf removal on the volatile and anthocyanin composition of Pinot Noir wine across two growing seasons. Generally, cluster zone leaf removal enhanced anthocyanins in the resulting wines, reflecting changes observed in the grape composition [119]. Another study on Istrian Malvasia grapes discovered that mechanical defoliation at the pea-size stage significantly increased certain aroma compounds, although it reduced other phenolics, such as hydroxycinnamates [120]. Defoliation has been demonstrated to increase the concentration of anthocyanins, which are essential for wine color and sensory properties, although the outcomes are not always consistent. A two-year study was conducted to evaluate the influence of leaf removal and red geotextile reflective mulch on the phenolic composition of wines from three red wine grape cultivars, Merlot, Teran, and Plavac Mali. The study entailed separate and combined applications of leaf removal and reflective mulch, which comprised a weave of aluminum platelets covered by a transparent film and stitched with red polypropylene threads on the vines of these cultivars during the 2009 and 2010 growing seasons, in comparison to untreated controls. All treatments were implemented during the veraison stage. These findings indicated that leaf removal had the most substantial impact on the phenolic composition of the wines, especially in increasing the levels of gallic acid, catechin, malvidin-3-glucoside, delphinidin-3-glucoside, and peonidin-3-glucoside. The combination of leaf removal and reflective mulch resulted in higher concentrations of gallic acid and malvidin-3-glucoside [121]. Despite some studies having indicated an increase in total phenolics, others have not reported any significant changes [122,123,124]. The significance of defoliation on wine phenolics and aromas highlights the necessity of adopting vineyard practices tailored to local conditions and grape variety. Although defoliation can be used to reduce alcohol content, it is crucial to carefully evaluate its impact on wine quality, as it may not always meet quality expectations based on the specifics of the vineyard (Figure 4).

Figure 4.

Principal changes in wine composition and sensory attributes after the application of different techniques to reduce alcohol content of the wine. (Artificial intelligence and Adobe Illustrator were used to produce the elements depicted in this image).

Defoliation can affect various aroma molecules in the bunch zone, including free-aroma volatiles, glycosylated aroma precursors, C13-norisoprenoids, methoxypyrazines, and terpenes [119,125]. For instance, removing the five basal leaves from each shoot at veraison in Riesling italico and Traminer grape varieties significantly enhanced the flavonoid content of the grapes. Grapes that were not treated generally had lower levels of hydroxybenzoic acid, catechin, epicatechin, and flavor [121]. In contrast, Sun-exposed Riesling bunches showed increased C13-norisoprenoid concentrations in both berries and wines. While β-damascenone levels remained unchanged, there was a noted increase in 1,1,6-trimethyl-1,2-dihydronaphthalene (TDN) in defoliated vines [126]. Additional research has indicated that higher sunlight exposure positively impacts free and bound aroma compounds, such as linalool, geraniol, hexen-1-ol, α-terpineol, and β-damascenone [127]. In the Isonzo region of Friuli, Italy, a study was conducted to investigate the effects of leaf removal on Sauvignon Blanc after berry set. Researchers have found that increased sunlight exposure early in berry development leads to a decrease in the concentrations of certain methoxypyrazines, such as 2-methoxy-3-isobutylpyrazine and 3-isopropyl-2-methoxypyrazine. However, no significant differences were observed at harvest time [128]. Additionally, leaf removal conducted two weeks prior to veraison resulted in an increase in the concentrations of both free and bound monoterpenes in Sauvignon Blanc grapes [129]. For Muscat grapes, it was discovered that berries that were shaded by foliage had higher levels of certain volatile compounds, such as hexanal and E-2-hexenal, than Sun-exposed berries. However, the total amount of terpenols is lower in shaded berries [130]. These variations in terpenol levels may be attributed to differences in cluster temperature, which can affect phytochrome activity and subsequently influence monoterpene biosynthesis [131,132,133]. Finally, in Istrian Malvasia vines, both hand and mechanical leaf removal increased the composition of hydroxycinnamates and aromatic thiol precursors in the berries, enhancing the aroma and flavor of the resulting wines compared with untreated vines (Figure 4) [120,134].

3.1.2. Early Grape Harvest

The composition of phenolic compounds in grapes, particularly anthocyanins and flavanols, is essential for determining the quality of wine, and numerous studies have investigated their evolution during berry ripening to determine the optimal harvest time. Anthocyanins, synthesized via the flavonoid pathway in grape berries, accumulate in the vacuoles of skin cells beginning at veraison and reaching their peak toward the end of ripening [135]. This accumulation may fluctuate based on environmental factors and grape variety and sometimes decreases under high temperatures [136,137]. These compounds undergo glycosylation, methylation, and acylation to enhance their stability and facilitate storage [138]. For instance, some anthocyanins in grapes, such as Pinot Noir, do not form acylated derivatives [139]. Flavanols, present in both grape skins and seeds, reach their highest concentrations at the onset of ripening but may decline due to berry expansion and the oxidative linking of polymers [140,141]. This decline sometimes stabilizes immediately before harvest [142,143]. Notably, skin flavanols such as epigallocatechin have been observed to increase during ripening [144,145]. The relationship between the total skin and seed flavonoids of grapes during ripening and wine color characteristics is strong but not with wine flavanols or their sensory traits. This indicates that the extractability of these compounds from the skin and seeds varies, which suggests a complexity in assessing phenolic maturity based solely on these measures [24,146]. Harvest timing is critical for determining the composition and sensory profile of wine, especially for varieties such as Cabernet Sauvignon. Grapes harvested later tend to have fuller flavors and less vegetative characteristics, which can influence consumer preferences for wines with more mature fruit flavors [24,146]. However, studies have shown that consumer preferences do not necessarily increase with grape maturity, suggesting that earlier-harvested grapes can produce equally preferred wines with lower alcohol contents [24,146]. Similar trends have been observed in studies of Shiraz grapes, indicating that these findings could be extended to other grape varieties as well. This comprehensive understanding of how phenolic compounds evolve and how they influence wine attributes highlights the importance of precise harvest timing to achieve desired wine characteristics. Harvesting grapes prematurely often leads to wines with fewer desirable aromatic compounds, such as esters, and an increased presence of grape-derived C6 components, including 1-hexanol and cis-3-hexenol. These compounds can impart unwanted herbaceous flavors to wine (Figure 4) [146].

The use of the double harvest technique in winemaking resulted in noticeable differences in alcohol content, which was influenced by the extent of racking. The analysis did not reveal any notable disparities in essential quality aspects, such as color intensity and total phenols. Additionally, the sensory attributes of the wines were unaffected, as no unfavorable descriptors were observed during the first year of trials. Nevertheless, a more pronounced green taste was detected in the second year, suggesting the need for further examination of this trend. This method presents a diverse range of possibilities, including adjusting the proportion of replaced must and modifying the ripeness levels of grapes used in cluster thinning and the second harvest [30].

3.1.3. Grape Must Dilution

Replacing water, particularly at lower and intermediate rates, could improve or maintain the color stability of Cabernet Sauvignon better than control wines. However, higher rates of water substitution generally led to a decrease in the concentration of wine volatiles. In the case of Shiraz, more significant changes were observed, particularly in the non-volatile wine characteristics. Using water (up to 25%) and GHW (up to 40%) led to a decrease in color stability and tannin levels, which has implications for wine aging potential and perceptions of astringency. Furthermore, Shiraz wines demonstrated major changes in their volatile profiles, particularly when water was used, showing a decrease in fermentative aromas relative to grape-derived aromas. This study highlights the need for further research to explore varietal responses to pre-fermentative juice substitution and address inconsistencies with control wines. Expanding research into different vintage conditions and ripening stages could provide deeper insights into how these practices affect wine quality parameters, aiding in the prediction and crafting of desired wine styles. Additionally, consumer studies would be valuable to assess the market reception of lower alcohol wines and to determine whether simpler methods, such as direct water addition before fermentation, could suffice to maintain the desired juice ratios and simplify production processes (Figure 4) [28].

3.1.4. Addition of Glucose Oxidase

Glucose oxidase, an enzyme that converts glucose into gluconic acid, can be used to decrease the ethanol content in wines. This reaction requires molecular oxygen as a co-substrate and generates hydrogen peroxide as a by-product. One specific approach involves adjusting the acidity of grapes to optimize the pH for the enzyme, coupled with aeration during the enzymatic process. Catalase is also added alongside glucose oxidase to eliminate the hydrogen peroxide generated, enhancing both yeast survival and enzyme effectiveness. Applying this method, a 3.7% reduction in alcohol content was achieved in treated Riesling grape juice [147]. However, the resulting increase in gluconic acid adversely affects the taste of wine, diminishing the intensity and longevity of fruity aromas [148]. To mitigate these effects, further deacidification or sweetening has been suggested [149]. Further studies, such as those by Röcker et al. [47], explored various deacidification techniques following glucose oxidase treatment, yet these wines were found to be more acidic and less fruity than controls. Additionally, other researchers have used encapsulated enzymes to enhance the activity of glucose oxidase without the need for initial pH adjustments [46,150]. This method resulted in a modest reduction of 0.68% in ethanol content after juices were treated for two days (Figure 4) [46].

3.2. Fermentation Strategies

The influence of non-Saccharomyces yeast on the phenolic composition and sensory features of wine is multifaceted and significant. These yeasts, naturally present in grapes, play a crucial role in the transformation of phenolic compounds during winemaking, ultimately affecting the quality and sensory attributes of the final product [151]. They contribute to the aroma and flavor of wine by producing volatile aromatic compounds and modifying the phenolic profile through metabolic activities [152]. While some studies have suggested that non-Saccharomyces yeasts can be a source of microbial spoilage, substantial evidence supports their positive impact on wine quality [153]. Non-Saccharomyces yeasts have been shown to enhance the aroma profile, add complexity, and influence the polyphenol composition and color stability of red wines [56]. Moreover, the use of indigenous non-Saccharomyces yeasts has been associated with the preservation of the natural varietal characteristics of grapes [154]. In summary, non-Saccharomyces yeasts have a considerable effect on the phenolic and sensory characteristics of wine. Their metabolic activity during fermentation can enhance the complexity and aromatic quality of wine, contributing to a more desirable sensory profile. The interaction between non-Saccharomyces and Saccharomyces yeasts during mixed fermentation is particularly important for the development of wines with improved aroma and flavor [155,156]. Future research should explore the potential of these yeasts to improve wine quality and guide the development of new fermentation strategies [151]. Non-Saccharomyces yeasts play a critical role in shaping the profile of volatile compounds and sensory attributes of wine. These yeasts release hydrolytic enzymes and produce metabolites that not only improve wine quality but also contribute to their aromatic complexity [155,157]. The utilization of non-Saccharomyces yeasts in winemaking has led to the production of wines with more diverse and desirable volatile compound compositions, including higher alcohols, acetate, and ethyl esters, which are significant contributors to the aroma of wine [158]. However, non-Saccharomyces yeasts exhibit limited fermentative power and survival post-fermentation compared with Saccharomyces cerevisiae [157]. This can result in longer fermentation periods and variations in ethanol and acid contents, which in turn affect the sensory attributes of the wine [159]. Furthermore, the specific metabolic pathways of non-Saccharomyces yeasts are crucial for the synthesis of aromatic compounds, and their activity is essential for the final wine aroma profile [155]. In conclusion, non-Saccharomyces yeasts have a significant impact on the composition of volatile compounds and sensory characteristics of wine. They contribute to primary and secondary aromas, and their metabolic products enhance wine’s complexity and appeal [152,160]. The selection and use of these yeasts in winemaking practices can lead to the production of wines with distinct and improved sensory profiles, offering a promising avenue for the diversification and enhancement of wine quality (Figure 4) [154,161].

Nutrient limitation, along with temperature or chemical intervention, is a strategy employed to manage fermentation processes, including the aim of reducing ethanol levels. However, the effects of such interventions on wine phenolic content are multifaceted and can vary depending on the specific conditions and methods applied. Studies have shown that temperature control during fermentation can significantly influence the phenolic composition of wine. For instance, low-temperature maceration treatments have been investigated for their effects on wine phenolic composition, with some findings indicating that pre-fermentation maceration at lower temperatures can result in wines with increased vitamin A content [162]. Additionally, the review by Setford et al. (2017) [163] highlights the role of temperature as a process variable that influences the extraction of phenolic compounds during maceration. Conversely, Yabo and Casenave (2023) [164] emphasize the trade-off between energy consumption for temperature regulation and the synthesis of aroma compounds, which are also related to wine quality. The fermentation temperature is a critical factor influencing the production of yeast-derived aroma compounds, with lower temperatures generally favoring the formation of compounds associated with fresh and fruity aromas [164]. Conversely, higher fermentation temperatures can lead to increased concentrations of flowery-related aromatic compounds [164]. Additionally, the presence of ethanol has been shown to significantly reduce the headspace concentration of volatile aroma compounds, potentially suppressing the fruit aroma attributes in wine (Figure 4) [165].

3.3. Post-Fermentation Strategies

3.3.1. Nanofiltration and Reverse Osmosis

In a study where NF was used to lower the alcohol content from 12.0% v/v to a range between 6.0% and 4.0% v/v, the technique proved highly effective not only in reducing alcohol levels but also in significantly enhancing the wine phenolic composition. The reduction in alcohol volume led to a notable increase in key bioactive compounds, specifically anthocyanins and resveratrol, with the concentration of these phenolics in wine concentrates increasing by a factor of 2.5 to 3 times. This outcome demonstrates NF’s ability to not only decrease alcohol content but also potentially improve the nutritional and sensory attributes of red wine due to the enhanced presence of these health-promoting and quality-defining phenolic compounds (Figure 4) [87].

Using a specialized filter, the TORAY-UB70 membrane, in conjunction with cold conditions and high pressure, it was possible to reduce the alcohol content in white model wine from 12% to 8.4%. Although this process resulted in a slight loss of certain aroma compounds, such as diethyl succinate and 2-phenyl-ethanol, the decrease was relatively minor, amounting to between 2.4% and 12.6% of the original content [91]. When employing a similar method on a red wine using the Alfa Laval polyamide NF9 membrane, the alcohol content decreased from 12% to 9.1%, but a more substantial loss of the wine’s aroma, amounting to approximately 30%, was observed [85]. These findings suggest that while methods for reducing alcohol content can be effective, they may also result in a loss of wine aroma and flavor, which are crucial elements of wine quality. The extent of these changes depends on factors such as the temperature, pressure, and type of filter used. For winemakers aiming to produce wine with a lower alcohol content while preserving its flavor, it is essential to carefully select the appropriate filter and optimize the process to achieve the desired outcome (Figure 4).

On the contrary, when RO was applied to a blend of Cabernet Sauvignon, Merlot, and Tempranillo red wines, no significant differences were observed in the total anthocyanins and phenolic compounds between the original and dealcoholized wines. However, the color intensity of the dealcoholized wines increased by approximately 20%, likely due to the concentration effect of ethanol removal and retention of anthocyanins by the membrane, whereas tonality decreased by approximately 15% [166]. Further research on Cabernet Sauvignon red wine processed through RO revealed that the total phenolic index, total proanthocyanidins, and percentages of procyanidins, prodelphinidins, and galloylation in partially dealcoholized wines remained nearly unchanged compared to the control, with no significant color differences observed [77]. Similar results were found in Grenache–Carignan red wine, where the total phenolic index and total proanthocyanidins remained stable, although slight but significant differences were observed in the percentages of procyanidins, prodelphinidins, and galloylation during alcohol reduction [77]. These findings highlight the distinct effects of NF and RO on the phenolic profile and sensory characteristics of red wines, reflecting their differing mechanisms and effects on the dealcoholization process (Figure 4).

When the Osmionics-SE membrane filter is applied at low temperature and high pressure to a model wine, the alcohol content can be reduced from 12% to 8.4%. Although this process has a slight impact on the wine’s odor and taste, it reduces certain key aroma compounds, such as diethyl succinate and 2-phenyl-ethanol, by a small amount, ranging from less than 1% to approximately 18% [91]. This finding was determined using a highly sensitive scent detection method known as HS/SPME-GC/MS, which is effective in identifying even minor changes in complex liquids, such as wine. When a red wine was filtered using a cellulose acetate CA99SPE membrane at a warmer temperature and similar pressure to reduce its alcohol content from 12% to 8.4%, the scent compounds in the wine decreased by 90%, as measured by the GC-FID technique, indicating a significant change in the wine’s natural aroma [85]. For Montepulciano d’Abruzzo, a red wine, using another RO filter at a lower pressure for a shorter duration resulted in a decrease in the alcohol content from 13.2% to 9.0%. This decrease was accompanied by a reduction in various aroma components, including alcohols, acids, esters, phenols, and lactones, as determined by SPME-GC/MS [80]. This information indicates that while reverse osmosis is effective in reducing the alcohol content of wine, it can also significantly alter the wine’s bouquet of aroma and taste. The extent of the loss depends on factors such as the type of filter used, method of application, and initial composition of the wine. It is crucial for winemakers to consider these factors to maintain the desirable taste and aroma of wine, even after reducing the alcohol content. Therefore, careful consideration must be given to the application of RO to achieve a correct balance (Figure 4).

Research on the effects of RO ethanol removal on wine sensory characteristics has primarily focused on the dealcoholization processes and their impact on Syrah and Merlot red wines [78]. The decrease in ethanol content led to a decline in the wine’s perceived length of mouth and an increase in red fruit flavors, followed by woody and blackcurrant perceptions. These sensory changes are directly related to the removal of ethanol using Thermal Distillation Systems (TDS) and RO. Additionally, a reduction in both heat and sweetness intensity was observed, which is particularly significant, as these attributes are often associated with the ethanol content of the wine. These alterations also affected the perception of red fruit intensity, suggesting a sensory shift toward other flavor components [78]. Similarly, an RO process was applied to Merlot red wine, which had an initial ethanol concentration of 13.4% (v/v), resulting in a reduction to a range of 11.8–10.2% (v/v). This decrease in ethanol concentration was found to decrease wine length in the mouth while increasing astringency and fruity perceptions. The use of TDS in conjunction with RO also resulted in decreased heat and texture intensity, again highlighting the influence of ethanol content on these sensory attributes. An increase in acid intensity was also noted, which may have contributed to the perceived balance and complexity of the wine profile [78]. A study on Syrah red wine with an initial ethanol concentration of 13.4% (v/v) observed a decrease in ethanol content to 11.4–7.9% (v/v) through RO. This reduction in ethanol led to a decrease in persistence, complexity, and number of aromas; however, there was an increase in balance, harmony, and familiarity [167]. However, the study noted a decrease in familiarity and harmony after the RO process, which suggests that the initial improvement in these aspects may not persist over time or through the RO process [167]. These findings emphasize the significant impact of ethanol content on the sensory experience of wine and underscore the need for winemakers to carefully consider the effects of dealcoholization techniques on flavor and aroma profiles. Further research is necessary to explore the long-term effects of these processes on wine quality (Figure 4).

3.3.2. Osmotic Distillation and Evaporative Perstraction

Studies investigating the effects of OD and EP on the phenolic profiles of various wines have highlighted that these dealcoholization techniques can have differing impacts based on the wine variety and processing conditions applied. The alterations in the phenolic content of some wines due to dealcoholization have been observed to be significant. For example, Aglianico red wine, after undergoing OD/EP, showed a substantial 49% reduction in total monomeric anthocyanins, although the total anthocyanins and vanillin-reactive flavans remained largely unaffected, reflecting the selective nature of these processes. This significant reduction resulted in a decrease in the wine sweet and solvent aroma series, which are key characteristics of wine [168]. Merlot red wine exhibited a significant 57% decrease in total phenolics after dealcoholization, with monomeric anthocyanins remaining unchanged, illustrating the varietal-dependent impact of these techniques [169]. In other varieties, such as Barbera red wine, notable changes in phenolic composition were observed. The total flavonoids were significantly affected, and the color hue of the wine shifted toward orange, indicating a pronounced impact of the dealcoholization process on its phenolic structure [110]. Similarly, Langhe Rosé and Verduno Pelaverga red wines experienced an increase in total anthocyanins and other tannins, altering the color toward orange hues after the alcohol content was reduced to 5.0% v/v [110]. In contrast, the other varieties demonstrated remarkable resilience of their phenolic composition to the dealcoholization process. Specifically, Pedro Ximenez wine retained its phenolic profile post-dealcoholization, with no significant changes observed compared to untreated wine [169]. Likewise, Montepulciano d’Abruzzo red wine maintained its total phenolic and anthocyanin contents with little to no difference despite considerable alcohol reduction [80]. Additionally, Falanghina white wine showed that dealcoholization could occur without significant changes in the total phenols and flavonoids, maintaining its phenolic profile post-dealcoholization [36]. Consistent retention of phenolic compounds was also noted for Montepulciano d’Abruzzo red wine, which underwent alcohol reduction with minimal impact on total phenols and anthocyanins [80]. The differing effects of dealcoholization techniques on wine phenolics may be explained by the specific properties of the membranes used, the initial phenolic composition of each wine, and the operational conditions of the dealcoholization process. These factors determine the extent to which phenolic compounds are preserved or altered during alcohol reduction. Consequently, the phenolic outcomes of dealcoholization stress the necessity of customizing the process for each wine variety to effectively preserve or enhance the sensory and quality attributes of the wine (Figure 4).

Using a specific filter, it was possible to reduce the alcohol content in the test wine from 13% to 8.1%. However, this resulted in a reduction of 40% to 80.7% in important flavor elements, such as isoamyl alcohol. The removal of alcohol did not substantially affect the sensory notes, including floral, fruity, and vegetable tones, nor the acidity, salinity, and bitterness; however, there was a decrease in the wine’s body, persistence, and honey notes [170]. When applying the same method to a white wine called Falanghina, it was observed that some flavors decreased slightly, whereas others almost entirely disappeared, such as hexanoic acid, which lost between 21.5% and 99.2% of its original amount. This process led to a decrease in odor, sweetness, and body, making the wine unbalanced and resulting in an unpleasant aftertaste, as cited in reference [99]. This demonstrates that the wine type can significantly affect the amount of flavor loss. Moreover, it was found that different filters and conditions had varying effects on Aglianico red wine. The alcohol content decreased from 13.8% to 11.6% and 8.8%, and flavors such as benzaldehyde were significantly reduced [171]. Reducing the alcohol content in Merlot red wine led to an increase in certain flavors, such as ethyl lactate, by 13.7 percent [172]. This suggests that decreasing the alcohol content does not always result in loss of flavor, as some flavors may become more concentrated. Similarly, Barbera red and Tempranillo wines also experienced significant changes in both alcohol and flavor after applying these methods [96,110]. For Montepulciano d’Abruzzo red wine, the alcohol level dropped significantly, resulting in changes in the levels of flavors such as ethyl esters and aldehydes [80]. Overall, our research has shown that reducing alcohol in wine can have a significant impact on its taste and aroma, depending on the type of wine, filtration method used, and degree of alcohol removal. It is essential for winemakers to carefully consider these factors to ensure that wine maintains its quality and flavor, even with a lower alcohol content (Figure 4).

3.3.3. Pervaporation

In the instance of Tokaji Hárslevelű white wine, a PERVAP.Sulzer 1060 PDMS membrane was used, operating under the “Carrier gas mode” at normal atmospheric pressure and temperatures ranging between 40 and 70 °C. This method effectively reduced the alcohol content from 13.1% v/v to 0.1% v/v. However, this considerable reduction in alcohol content was accompanied by a loss of approximately 70% of the total volatile aroma of wine, as determined by a sophisticated testing method that combines distillation and gas chromatography–mass spectrometry (LE-GC/MS) [7]. Similarly, Cabernet Sauvignon red wine was exposed to a pervaporation (PV) process using a JS-WSM-8040 PDMS membrane operated at 45 °C under slight vacuum pressure. The alcohol level was reduced from 12.5% to 0.5% (v/v). This process also resulted in considerable losses of significant aroma-contributing compounds, such as alcohols, acids, and esters, with certain elements experiencing a reduction of up to 99.9%, as analyzed by GC/MS. Sensory evaluation of the treated wine revealed a high retention of fruit aroma, leading to a product with an enhanced smell and taste (Figure 4) [173].

3.3.4. Spinning Cone Column Distillation

SCC is particularly notable for its ability to efficiently reduce alcohol content while maintaining the integrity of volatile compounds. In red, rose, and white wines with an initial alcohol concentration of 14.0% v/v, the SCC process reduced the alcohol content to less than 0.3% v/v. The process resulted in an increase in phenolic compounds, including phenolic, flavonol, tartaric ester, and anthocyanin contents, by approximately 24% across all three wine types [107]. Notably, the content of resveratrol, a significant antioxidant, was higher in dealcoholized wines than in the original wines. The uniform increase in phenolic compounds after dealcoholization suggests that the SCC process can concentrate these important bioactive compounds because of the reduction in volume from alcohol removal. The enhancement of phenolic content can potentially improve the health benefits and sensory attributes of wines, given that phenolic compounds contribute to the taste, color, and mouthfeel of wine. This significant retention and concentration of phenolic substances after SCC treatment demonstrates the potential of this technique for reducing alcohol content and potentially augmenting the nutritional value of wines. These findings underscore the relevance of the SCC method as a viable option for producing low-alcohol wines while potentially improving their phenolic profile, which is beneficial from both the winemaker’s and consumer’s perspectives [107]. Another study demonstrated that SCC could remove 2% v/v ethanol from Chardonnay grapes during mid-fermentation, but this resulted in a 45% reduction in fusel alcohols and a 25% reduction in volatile compounds [174]. To improve the aroma recovery in red wine (cv. Tempranillo), rosé wine (cv. Cabernet Sauvignon), and white wine (cv. Chardonnay) during dealcoholization, adjustments were made to the aromatic extraction percentage and flow rate, successfully recovering 97–100% of the total aroma fraction from these wines [108]. Despite its benefits, the primary drawbacks of using SCC include the high costs associated with the equipment and operational expenses [175]. A study explored the use of SCC as a means of reducing alcohol content in Chardonnay white wine. The initial alcohol concentration of the wine was 14.9% (v/v), and after undergoing the SCC process, the alcohol content was reduced to a range of 14.6-12.9% (v/v). This decrease in alcohol content resulted in a decrease in the intensity of wine aroma and the sensation of heat and a hot mouthfeel, which are typical sensory characteristics associated with a higher ethanol content in wines. These findings suggest that the SCC process can moderately reduce alcohol content without significantly altering the organoleptic properties of wine (Figure 4) [176].

3.3.5. Vacuum Distillation

VD application as a dealcoholization process has been studied for its effects on the phenolic composition of wine. Recent studies focusing on Langhe Rosé, Barbera red, and Verduno Pelaverga red wines have demonstrated changes in phenolic profiles following VD dealcoholization. In each of these wines, the alcohol content was significantly reduced from the initial concentrations ranging from 13.2% to 15.2% v/v to a uniform 5.0% v/v [110]. One consistent observation across these studies is the increase in total anthocyanins and total flavonoids in wine following dealcoholization. This could be due to the concentration effect as the alcohol is removed, which may cause a relative increase in the concentrations of these phenolic compounds. Interestingly, despite the increase in phenolic concentrations, changes in wine color intensity and hue were noted. Specifically, there was a decrease in orange tones in the hues of wines, which might be attributed to the relative increase in anthocyanin and flavonoid content after dealcoholization. The shift in phenolic content and its effects on wine coloration after VD dealcoholization suggests a complex interplay between the removal of alcohol and alterations in the wine’s phenolic makeup. The results indicate that, while VD can effectively reduce alcohol content in wines, it can also alter phenolic compounds that are crucial for the color and overall sensory attributes of wine. These findings highlight the nuanced impacts of dealcoholization processes on wine composition, emphasizing the importance of careful process control to achieve the desired balance between alcohol reduction and preservation of phenolic integrity. The specific effects of VD on the phenolic composition and sensory profile of wine call for tailored approaches to dealcoholization that consider the initial phenolic makeup of the wine and the intended sensory outcomes (Figure 4) [110].