Biodegradable Polymeric Substances Produced by a Marine Bacterium from a Surplus Stream of the Biodiesel Industry

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Chemicals

2.1.2. Growth and Maintenance of Bacillus licheniformis

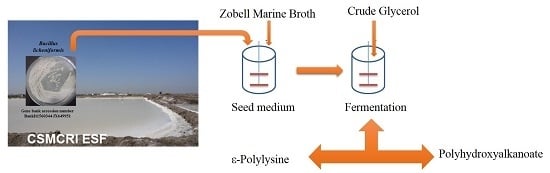

2.2. Fermentation

2.2.1. Culture Media

2.2.2. Inoculum Development

2.2.3. Simultaneous Production of ε-Polylysine and PHA

2.2.4. Analysis of ε-Polylysine

2.2.5. Percentage Carbon Utilization of Bacillus licheniformis PL26

2.2.6. Extraction and Purification of PHA

2.3. Purification of ε-Polylysine

2.3.1. Precipitation of Polycationic ε-PL with TPB− Anion from the Supernatant

2.3.2. Analytical Methods

3. Results and Discussions

3.1. Simultaneous ε-Polylysine and PHA Production by B. licheniformis PL26

3.2. Percentage Carbon Utilization of Bacillus licheniformis PL26

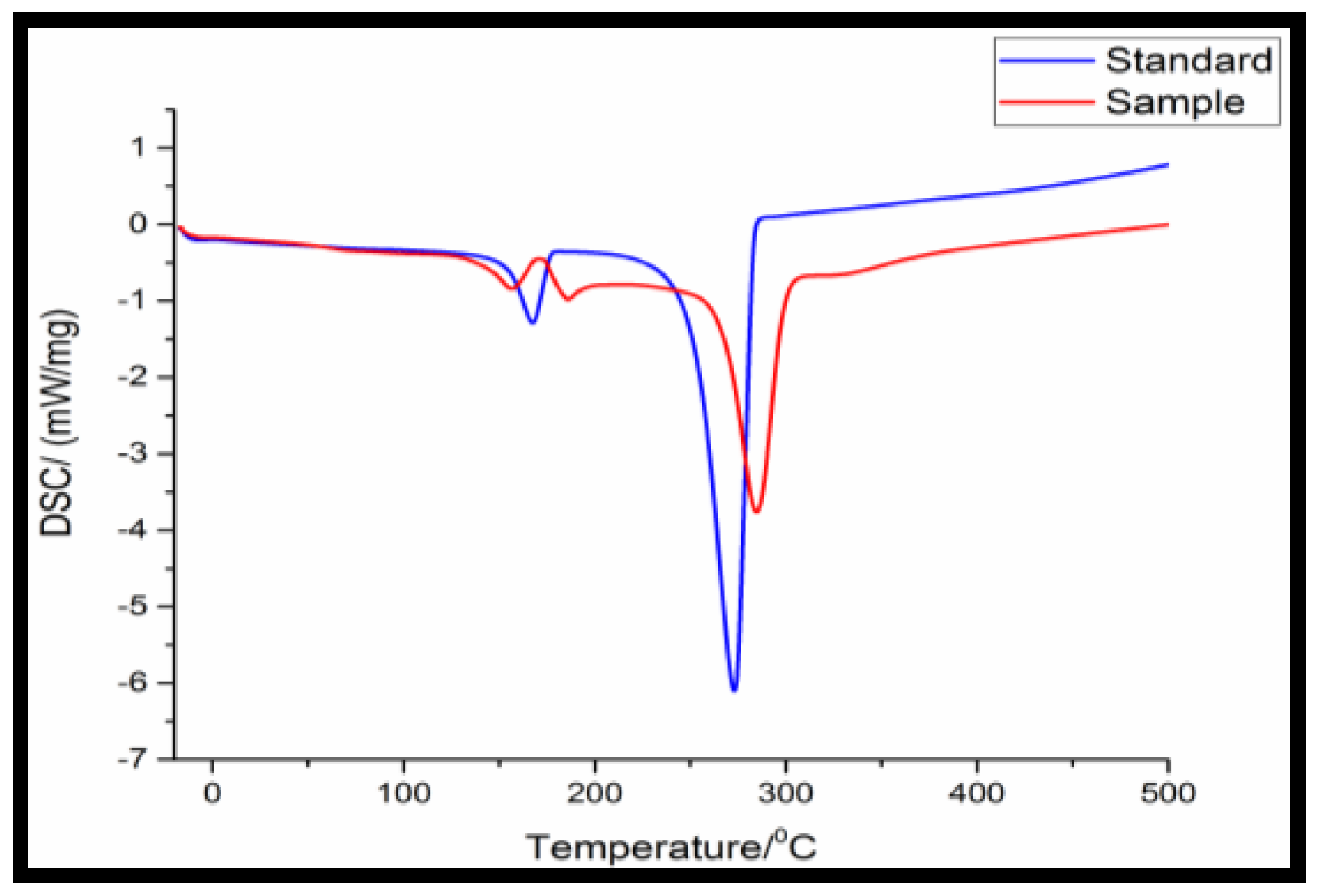

3.3. Characterization of Purified PHA

3.4. Characterization of ε-Polylysine

1H NMR of ε-Polylysine in D2O Isolated from B. licheniformis PL26

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References and Notes

- Campbell, C.J.; Laherrère, J.H. The end of cheap oil. Sci. Am. 1998, 3, 78–83. [Google Scholar] [CrossRef]

- Sheehan, J.; Camobreco, V.; Duffield, J.; Graboski, M.; Shapouri, H. Life Cycle Inventory of Biodiesel and Petroleum Diesel for Use in an Urban Bus. Available online: http://www.nrel.gov/docs/legosti/fy98/24089.pdf (accessed on 17 January 2016).

- Nerve, Z. Upgrading of Biodiesel-Derived Glycerol in the Biosynthesis of ε-poly-l-Lysine: An Integrated Biorefinery Approach. Available online: http://wiredspace.wits.ac.za/handle/10539/9253?show=full (accessed on 17 January 2016).

- Vasudevan, P.T.; Briggs, M. Biodiesel production—Current state of the art and challenges. J. Ind. Microbiol. Biotechnol. 2008, 35, 421–430. [Google Scholar] [CrossRef] [PubMed]

- Adhikari, S.; Fernando, S.D.; To, S.D.F.; Bricka, R.M.; Steele, P.H.; Haryanto, A. Conversion of glycerol to hydrogen via a steam reforming process over nickel catalysts. Energy Fuels 2008, 22, 1220–1226. [Google Scholar] [CrossRef]

- Wirawan, S.S.; Tambunan, A.H. The current status and prospects of biodiesel development in Indonesia: A review. In Proceedings of the Third Asia Biomass Workshop, Tsukuba, Japan, 16 November 2006.

- Marchetti, J.M.; Miguel, V.U.; Errazu, A.F. Possible methods for biodiesel production. Renew. Sustain. Energy Rev. 2007, 11, 1300–1311. [Google Scholar] [CrossRef]

- Johnson, D.T.; Taconi, K.A. The glycerin glut: Options for the value-added conversion of crude glycerol resulting from biodiesel production. Environ. Prog. 2007, 26, 338–348. [Google Scholar] [CrossRef]

- Thompson, J.C.; He, B.B. Characterization of crude glycerol from biodiesel production from multiple feedstock. Appl. Eng. Agric. 2006, 22, 261–265. [Google Scholar] [CrossRef]

- Dasari, M.A.; Kiatsimkul, P.P.; Sutterlin, W.R.; Suppes, G.J. Low-pressure hydrogenolysis of glycerol to propylene glycol. Appl. Catal. A Gen. 2005, 281, 225–231. [Google Scholar] [CrossRef]

- Lemke, D. Volumes of Versatility. Auri Ag Innovation News.

- Gallan, M.; Bonet, J.; Sire, R.; Reneaume, J.; Plesu, A.E. From residual to useful oil: Revalorization of glycerine from the biodiesel synthesis. Bioresour. Technol. 2009, 100, 3775–3778. [Google Scholar] [CrossRef] [PubMed]

- McCoy, M. Glycerin surplus. Chem. Eng. News 2006, 84, 7–8. [Google Scholar] [CrossRef]

- Yazdani, S.S.; Gonzalez, R. Anaerobic fermentation of glycerol: A path to economic viability for the biofuels industry. Curr. Opin. Biotechnol. 2007, 18, 213–219. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, P.K.; Mishra, S.C.P.; Gandhi, M.R.; Upadhyay, S.C.; Paul, P.; Anand, P.S.; Popat, K.M.; Shrivastav, A.V.; Mishra, S.K.; Ondhiya, N.; et al. Integrated Process for the Production of Jatropha Methyl Ester and by Products. EU Patent 2,475,754, 18 July 2012. [Google Scholar]

- Yang, F.; Hanna, M.A.; Sun, R. Value-added uses for crude glycerol—A byproduct of biodiesel production. Biotechnol. Biofuels 2012, 5, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Ito, T.; Nakashimada, Y.; Senba, K.; Matsui, T.; Nishio, N. Hydrogen and ethanol production from glycerol-containing wastes discharged after biodiesel manufacturing process. J. Biosci. Bioeng. 2005, 100, 260–265. [Google Scholar] [CrossRef] [PubMed]

- Shrivastav, A.; Mishra, S.K.; Shethia, B.; Pancha, I.; Jain, D.; Mishra, S. Isolation of promising bacterial strains from soil and marine environment for polyhydroxyalkanoates (PHAs) production utilizing Jatropha biodiesel byproduct. Int. J. Biol. Macromol. 2010, 47, 283–287. [Google Scholar] [CrossRef] [PubMed]

- Rymowicz, W.; Rywińska, A.; Marcinkiewicz, M. High-yield production of erythritol from raw glycerol in fed-batch cultures of Yarrowia lipolytica. Biotechnol. Lett. 2009, 31, 377–380. [Google Scholar] [CrossRef] [PubMed]

- Tang, S.; Boehme, L.; Lam, H.; Zhang, Z. Pichia pastoris fermentation for phytase production using crude glycerol from biodiesel production as the sole carbon source. Biochem. Eng. J. 2009, 43, 157–162. [Google Scholar] [CrossRef]

- Volpato, G.; Rodrigues, R.C.; Heck, J.X.; Ayub, M.A.Z. Production of organic solvent tolerant lipase by Staphylococcus caseolyticus EX17 using raw glycerol as substrate. J. Chem. Technol. Biotechnol. 2008, 83, 821–828. [Google Scholar] [CrossRef]

- Scholten, E.; Renz, T.; Thomas, J. Continuous Cultivation Approach for Fermentative Succinic Acid Production from Crude Glycerol by Basfia succiniciproducen DD1. Biotechnol. Lett. 2009, 31, 1947–1951. [Google Scholar] [CrossRef] [PubMed]

- Ethier, S.; Woisard, K.; Vaughan, D.; Wen, Z.Y. Continuous culture of the microalgae Schizochytrium limacinum on biodiesel-derived crude glycerol for producing docosahexaenoic acid. Bioresour. Technol. 2011, 102, 88–93. [Google Scholar] [CrossRef] [PubMed]

- Athalye, S.K.; Garcia, R.A.; Wen, Z.Y. Use of biodiesel-derived crude glycerol for producing eicosapentaenoic acid (EPA) by the fungus Pythium Irregular. J. Agric. Food. Chem. 2009, 57, 2739–2744. [Google Scholar] [CrossRef] [PubMed]

- Choi, W.J.; Hartono, M.R.; Chan, W.H.; Yeo, S.S. Ethanol Production from Biodiesel-Derived Crude Glycerol by Newly Isolated Kluyvera Cryocrescen. Appl. Microbiol. Biotechnol. 2011, 89, 1255–1264. [Google Scholar] [CrossRef] [PubMed]

- Oh, B.R.; Seo, J.W.; Heo, S.Y.; Hong, W.K.; Luo, L.H.; Joe, M.; Park, D.H.; Kim, C.H. Enhancement of ethanol production from glycerol in a Klebsiella pneumoniae mutant strain by the inactivation of lactate dehydrogenase. Bioresour. Technol. 2011, 102, 3918–3922. [Google Scholar] [CrossRef] [PubMed]

- Taconi, K.A.; Venkataramanan, K.P.; Johnson, D.T. Growth and solvent production by Clostridium pasteurianum ATCC® 6013™ utilizing biodiesel-derived crude glycerol as the sole carbon source. Environ. Prog. Sustain. Energy 2009, 28, 100–110. [Google Scholar] [CrossRef]

- Poblete-Castro, I.; Binger, D.; Oehlert, R.; Rohde, M. Comparison of mcl-Poly (3-hydroxyalkanoates) synthesis by different Pseudomonas putida strains from crude glycerol: Citrate accumulates at high titer under PHA-producing conditions. BMC Biotechnol. 2014, 14, 962. [Google Scholar] [CrossRef] [PubMed]

- Moita, R.; Freches, A.; Lemos, P.C. Crude glycerol as feedstock for polyhydroxyalkanoates production by mixed microbial cultures. Water Res. 2014, 58, 9–20. [Google Scholar] [CrossRef] [PubMed]

- Hermann-Krauss, C.; Koller, M.; Muhr, A.; Fasl, H.; Stelzer, F.; Braunegg, G. Archaeal production of polyhydroxyalkanoate (PHA) co-and terpolyesters from biodiesel industry-derived by-products. Archaea 2013, 2013, 129268. [Google Scholar] [CrossRef] [PubMed]

- González-Pajuelo, M.; Andrade, J.C.; Vasconcelos, I. Production of 1,3-propanediol by Clostridium butyricum VPI 3266 using a synthetic medium and raw glycerol. J. Ind. Microbiol. Biotechnol. 2004, 31, 442–446. [Google Scholar] [CrossRef] [PubMed]

- Bera, A.; Dubey, S.; Bhayani, K.; Mondal, D.; Mishra, S.; Ghosh, P.K. Microbial synthesis of polyhydroxyalkanoate using seaweed-derived crude levulinic acid as co-nutrient. Int. J. Biol. Macromol. 2015, 72, 487–494. [Google Scholar] [CrossRef] [PubMed]

- Chheda, A.H.; Vernekar, M.R. Improved production of natural food preservative ε-poly-l-lysine using a novel producer Bacillus cereus. Food Biosci. 2014, 30, 56–63. [Google Scholar] [CrossRef]

- Itzhaki, R.F. Colorimetric method for estimating polylysine and polyarginine. Anal. Biochem. 1972, 50, 569–574. [Google Scholar] [CrossRef]

- Dhangdhariya, J.H.; Dubey, S.; Trivedi, H.B.; Pancha, I.; Bhatt, J.K.; Dave, B.P.; Mishra, S. Polyhydroxyalkanoate from marine Bacillus megaterium using CSMCRI’s Dry Sea Mix as a novel growth medium. Int. J. Biol. Macromol. 2015, 76, 254–261. [Google Scholar] [CrossRef] [PubMed]

- Chheda, A.H.; Vernekar, M.R. Enhancement of ε-poly-l-lysine (ε-PL) production by a novel producer Bacillus cereus using metabolic precursors and glucose feeding. 3 Biotech 2015, 5, 839–846. [Google Scholar] [CrossRef]

- Koller, M.; Chiellini, E.; Braunegg, G. Study on the Production and Re-use of Poly (3-hydroxybutyrate-co-3-hydroxyvalerate) and Extracellular Polysaccharide by the Archaeon Haloferax mediterranei Strain DSM 1411. Chem. Biochem. Eng. Q. 2015, 29, 87–98. [Google Scholar] [CrossRef]

- Moralejo-Gárate, H.; Palmeiro-Sánchez, T.; Kleerebezem, R.; Mosquera-Corral, A.; Campos, J.L.; van Loosdrecht, M. Influence of the cycle length on the production of PHA and polyglucose from glycerol by bacterial enrichments in sequencing batch reactors. Biotechnol. Bioeng. 2013, 110, 3148–3155. [Google Scholar] [CrossRef] [PubMed]

- Jia, S.; Fan, B.; Dai, Y.; Wang, G.; Peng, P.; Jia, Y. Fractionation and Characterization of ε-poly-l-lysine from Streptomyces albulus CGMCC 1986. Food. Sci. Biotechnol. 2010, 19, 361–366. [Google Scholar] [CrossRef]

| Parameter | Concentration |

|---|---|

| Total Carbon content in fermentation medium | 0.7% |

| Total Carbon left in the supernatant after complete fermentation (96 h production age) | 0.41% |

| Carbon present in the biomass | 0.21% |

| Percentage carbon utilized | 30% |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bhattacharya, S.; Dubey, S.; Singh, P.; Shrivastava, A.; Mishra, S. Biodegradable Polymeric Substances Produced by a Marine Bacterium from a Surplus Stream of the Biodiesel Industry. Bioengineering 2016, 3, 34. https://doi.org/10.3390/bioengineering3040034

Bhattacharya S, Dubey S, Singh P, Shrivastava A, Mishra S. Biodegradable Polymeric Substances Produced by a Marine Bacterium from a Surplus Stream of the Biodiesel Industry. Bioengineering. 2016; 3(4):34. https://doi.org/10.3390/bioengineering3040034

Chicago/Turabian StyleBhattacharya, Sourish, Sonam Dubey, Priyanka Singh, Anupama Shrivastava, and Sandhya Mishra. 2016. "Biodegradable Polymeric Substances Produced by a Marine Bacterium from a Surplus Stream of the Biodiesel Industry" Bioengineering 3, no. 4: 34. https://doi.org/10.3390/bioengineering3040034

APA StyleBhattacharya, S., Dubey, S., Singh, P., Shrivastava, A., & Mishra, S. (2016). Biodegradable Polymeric Substances Produced by a Marine Bacterium from a Surplus Stream of the Biodiesel Industry. Bioengineering, 3(4), 34. https://doi.org/10.3390/bioengineering3040034