Abstract

Agriculturally derived biowastes can be transformed into a diverse range of materials, including powders, fibers, and filaments, which can be used in additive manufacturing methods. This review study reports a study that analyzes the existing literature on the development of novel materials from agriculturally derived biowastes for additive manufacturing methods. A review was conducted of 57 selected publications since 2016 covering various agriculturally derived biowastes, different additive manufacturing methods, and potential large-scale applications of additive manufacturing using these materials. Wood, fish, and algal cultivation wastes were also included in the broader category of agriculturally derived biowastes. Further research and development are required to optimize the use of agriculturally derived biowastes for additive manufacturing, particularly with regard to material innovation, improving print quality and mechanical properties, as well as exploring large-scale industrial applications.

1. Introduction

Additive manufacturing (AM) can produce products from 3D model data by applying a layer-by-layer approach, distinct from formative and subtractive manufacturing methods [1]. The main advantages of AM include producing products with complex geometries from different materials (such as polymers, ceramics, and metals), energy efficiency, product personalization, small-scale productions, and the potential to implement a distributed network of affordable equipment in local communities [2]. The importance of AM in fostering a more sustainable economic system is becoming more apparent in light of its numerous advantages and its expanding applications [3]. AM has been recently used for valorization of various resources at their end of life (EoL), such as recycled plastics [4], biomaterials for construction sectors [5], and electronic wastes [6]. AM promotes the use of agriculturally derived wastes. Additionally, AM can reduce pollution brought on by wastes (biomass) created during traditional industrial transformation of agricultural products.

According to FAOSTAT [7], currently, the agricultural industry worldwide utilizes almost one third of the earth’s land surface and generates a significant amount of biowastes such as rice husk/bran, millet stoves, sugarcane bagasse/tops/molasses [8], wheat bran/straw, and oat straw [9]. When handling agricultural biowastes, it is important to consider that they contain substantial quantities of carbon (C) and plant nutrients. These biowastes are precursors to greenhouse gases (GHGs), ammonia (NH3), pollution of surface water, offensive odor, and particles [10,11,12,13]. The management of agricultural biowastes has a significant impact on the extent of the resulting emissions. When devising sustainable methods for recycling and utilizing agricultural biowastes, it is important to consider the risk of disease transmission [14], heavy metal, and biogenic contamination of the soil [15], as well as the pollution caused by excessive nutrient use and gaseous emissions.

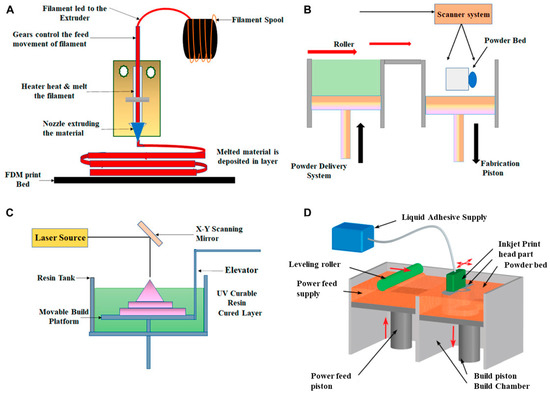

Combining AM with biowastes demonstrates the potential to encourage the application of eco-friendly design, such as designing of products by upcycling or recycling biowastes [16,17]. FDM (Fused Deposition Modeling), also known as Fused Filament Fabrication (FFF) [18], Direct Ink Writing (DIW), also known as liquid deposition modeling (LDM) [19,20], stereolithography [21], and binder jetting AM [22] methods are used for 3D printing of agriculturally derived biowastes (Figure 1).

Figure 1.

Illustrations of (A) fused deposition modeling, (B) selective laser sintering, (C) stereolithography, and (D) binder jetting (redrawn from [23,24]).

A recently published paper contained a thorough evaluation of the literature on biomass materials—either wastes or byproducts—for FDM and LDM [2]. However, this evaluation did not cover other additive manufacturing methods and was not exclusively focused on the newly developed novel biowaste materials. Another review paper discussed biopolymeric sustainable materials and their emerging applications [25]. However, its focus was not on agriculturally derived biowastes. It mentioned additive manufacturing but did not exclusively focus on additive manufacturing.

There are several reasons to write a literature review that places particular emphasis on different additive manufacturing methods that utilize agriculturally derived biowastes. Firstly, it promotes sustainability by utilizing agricultural biowastes, reducing reliance on traditional petrochemical-based materials and minimizing environmental impact. Secondly, it facilitates the development of novel materials with unique properties, fostering innovation in product design and expanding the range of applications. Additionally, the incorporation of biowastes in large-scale industrial applications brings economic advantages, contributing to the establishment of a bio-circular economy and promoting a more sustainable and efficient approach to manufacturing.

Therefore, this systematic review includes different AM methods used for printing agriculturally derived biowastes, novel materials developed for printing biowastes, important printing parameters and printing technology considered for printing these biowastes, characterizations required for evaluating the mechanical properties of these biowastes, potential applications and limitations of incorporating these biowastes into large-scale applications and future research opportunities focused on improving print quality and enhancing mechanical/thermal properties for large-scale production integrating biowastes.

This study reports a thorough evaluation of the literature on novel materials made from agriculturally derived biowastes—either wastes or byproducts—for various AM methods. The main research questions (RQ) are as following:

RQ1: What is the state-of-the-art research regarding AM of agriculturally derived biowastes?

RQ2: What are the types of agriculturally derived biowastes, novel 3D printable materials incorporating biowastes, commonly used AM methods, and important printing parameters?

RQ3: What are the potential applications, as well as constraints, in the context of using agriculturally derived biowastes for AM methods in large-scale production?

RQ4: What are the common mechanical characterization tests performed on these biowaste materials?

RQ5: What are future research opportunities?

A total of 57 papers are included in this study after screening, and the screening process is described in the methodology. All these papers are presented in a table to show the list of recent research studies (RQ1). These papers are analyzed based on the agriculturally derived biowastes, novel 3D printable materials, and types of AM methods (RQ2). Beginning with the possible applications of these materials, various limitations in the context of using AM methods in large-scale applications integrating these biowastes are considered (RQ3). Then, common mechanical characterization tests are analyzed for these biowastes (RQ4), and lastly, future research opportunities are described (RQ5). This review aims to provide an overview of agriculturally derived biowastes and their potential applications in AM for large-scale applications.

2. Methodology

This study represents a systematic literature review in accordance with the PRISMA systematic review statement [26]. PRISMA 2020 implementation could be advantageous for authors, editors, and peer reviewers of systematic reviews. Readers can evaluate the applicability of the methodologies and, consequently, the veracity of the conclusions. The goal of this PRISMA statement is to increase the completeness, accuracy, and transparency of systematic reviews. PRISMA primarily comprises a checklist and a flow diagram that depict the workflow for the search, identification, screening, and analysis procedures and aid in determining whether the information is exhaustive [27].

Table 1 summarizes the criteria of eligibility, search library, and binary strings (selected based on [28]) for query used to select papers that are included in this study. This study does not include review and meta-analyses papers. All the papers included have an experimental component connected to different types of AM methods. A preliminary screening revealed no papers published prior to 2016. Hence, a timeframe of 2016 to 2023 was decided upon. Since the study explores agriculturally derived biowastes in relation to the AM methods, papers related to wastes from chemicals or other industrial systems were excluded. Papers on biowastes obtained from wood (forestry industry), fish, and algal cultivation were included for this review. All these biowastes are mentioned as agriculturally derived biowastes throughout the review. Lastly, the papers lacking a description of the AM methods, such as the type of printer, type of materials, or newly developed materials, were excluded. The search was conducted using TAMU (Texas A&M University College Station) library and Web of Science (WoS) library.

Table 1.

Criteria of eligibility, search library and binary strings for query for selecting papers to be included.

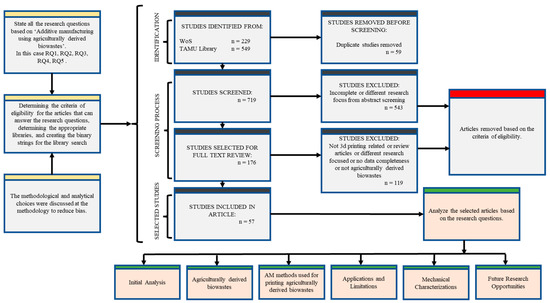

First, duplicates and inaccessible works were removed from search results. In order to choose the records that would be included and removed, the screening process began with a check of the titles, abstracts, and keywords. The papers selected from the first screening were then taken into a full text review based on agriculturally derived biowastes, AM methods, and novel materials incorporating biowastes. By thoroughly reading the full texts, two further screenings were conducted. Then, at the data extraction stage, data columns of paper categories, links, keywords, material specifications, suppliers, sources, AM methods, applications and limitations, and future research opportunities were created (Figure 2). These data were extracted using full texts, as well as some websites and source sites. On some occasions, the data for comparison with the other articles such as printing parameters were normalized based on units.

Figure 2.

Flow chart of the systematic review.

3. Results and Discussion

The screening described in the previous section resulted in 57 papers. The analysis of these 57 papers is presented in this section.

3.1. Initial Analysis

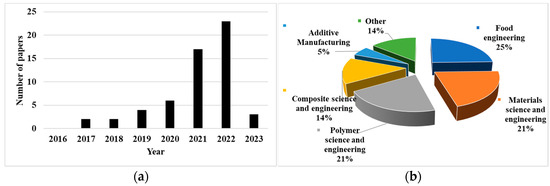

Figure 3a and Table 2 show that the number of research papers on 3D printing using agriculturally derived biowastes became higher after 2019. There were 23 articles in year 2022, which equals to the number of papers in year 2021 and 2020 combined.

Figure 3.

Initial analysis results: (a) number of papers in each year, (b) percentage of selected papers in each research area.

Table 2.

A list of selected papers organized by research area and year of publication.

These papers were classified according to research areas (Figure 3b). To evaluate this aspect, the following factors were considered in detail: the journal’s research field, the specific papers’ keywords, and the research contents. For visual purposes, the principal research areas that had only one publication were mentioned as “Others” in Figure 3b. There were four main research areas: food engineering, materials science and engineering, polymer science and engineering, and composite science and engineering. About 81% of papers were from these four areas. If three research areas (polymer science and engineering, materials science for specific sectors, and composite science and engineering) are considered as subsets of materials science and engineering, around 58% of selected papers are from the materials research area.

3.2. Agriculturally Derived Biowastes

This subsection provides an overview of the biowastes that have been employed in additive manufacturing, including their types and sources. It also discusses the particle size and shape that are typically utilized in various AM methods, as well as matrix materials and additives employed in formulating printable filaments, powders, or inks. Finally, this subsection shows the maximum weight percentages at which biowastes, used as biofillers, can be incorporated into printable filaments, powders, or inks based on different additive manufacturing methods, as well as advantages and challenges of using biowastes as biofillers.

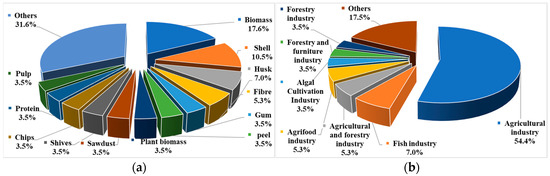

Table 3 lists the types of materials used in selected papers. Mostly used biowastes are biomass, shell, husk, and fiber (Figure 4a). All the definitions of the biowastes mentioned in Figure 4 are taken from the cited references in Table 3. These biowastes originate from various sources such as wood, rice, nuts, algae, fungi, vegetables, fish, and crabs.

Table 3.

List of selected papers by Biowaste Types, Biowaste Sources, Biowaste, Matrix, and Weight Percentages.

Figure 4.

Analysis results showing percentage of selected papers based on (a) types of the agriculturally derived biowastes and (b) sources of agriculturally derived biowastes.

In this review, the sources of the materials are agricultural industry (wheat, corn, rice, plants, vegetables, banana, nuts, etc.), forestry and furniture industry (wood), and fish industry (crab, cod, salmon, etc.). Figure 4b shows that around 54% of the materials in the selected papers are from the agricultural industry and around 67% are from the agricultural and forestry industry combined. Another important source is the food industry related to agrifood, algal cultivation, and fish. A total of 15% of the materials in the selected papers are from the food industry.

Particle size affects printability of the filaments, powders or inks, and mechanical properties of printed parts [53,81], printing resolution, surface roughness of the printed parts, material homogeneity, and nozzle clogging and blockage [38,45,52,53,81,82]. These biowastes were usually ground, sieved, and milled to obtain the required particle sizes [37,42,65,69,72]. For wood powders, particle sizes of 0.6 to 1.25 mm were used in binder jetting printing [74]. For FDM, particle sizes are typically less than 0.65 mm. For instance, buckwheat husk was used for 3D printing filament fabrication, where the particle sizes were mostly 0.2 mm [37]. Different particle sizes (0.02 to 0.65 mm) of flax fiber were used in another paper for a similar FDM method [72]. Mostly, particle sizes ranged between 0.02 and 0.65 mm for FDM methods [29,42,59,67,75,79]. There was one paper that used a 0.009 mm particle size for Miscanthus biomass powder [65]. In most cases, smaller particle sizes were chosen to avoid nozzle clogging during extrusion.

Particle size used for LDM printing methods can be categorized into two groups: smaller than 0.125 mm and larger or equal to 0.125 mm. For example, banana peel, beechwood sawdust, potato peel, and okara powder used in LDM printing had a particle size less than 0.125 mm [38,45,46,51]. In some selected papers, larger particles (>0.125 mm) of Nostoc sphaeroides, okara, and banana peel were used along with smaller particles [32,51,52].

For selective laser sintering, peanut husk and walnut shell powder were used with particle sizes of less than 0.125 mm [30,60]. For stereolithography, three ranges of particle sizes (<0.045 mm, 0.045–0.125 mm, and >0.125 mm) were used. Additionally, the characteristics of the material depend on the size of the fibers. Larger fiber diameters result in more flaws at the resin-biomass contact in terms of structural characteristics. Larger fibers have demonstrated better performances in relation to the thermal stability of the photo-curable composites due to the higher lignin content [53].

One of the selected papers provided evidence that the choice of the matrix is an important parameter to control the mechanical performance of the printed objects [72]. According to Table 3, around 21% of selected papers used poly lactic acid (PLA) as a matrix, which makes it the most popular matrix material for FDM printing. In some selected papers, acrylonitrile butadiene styrene (ABS) [59,70,77], Mater- Bi® EF51L (MB) [42,79], poly(3-hydroxybutyrate-co-hydroxy valerate) (PHBV), hydroxy valerate (HV) [66], poly-(butylene-terephthalate) (PBAT) [76], and recycled polypropylene [3,78] were used. For the LDM printing method, mostly water was used as a matrix for creating printable pastes. In some selected papers, the Na-alginate solution [50], Guar gum (GG), Xanthan gum (XG), wheat flour [44], and glacial acetic acid [83] were used along with water. In selective laser sintering, stereolithography, and binder jetting, various compositions of materials were used, such as epoxy resin, paraffin wax, stearic acid, polyether sulfone, polyamide, methacrylated ethyl cellulose macromonomer (ECM), hexamethylene diisocyanate (HDI), rosin-derived monomers (DAGMA), and 2-hydroxyethyl acrylate (HEA). In a few selected papers, psyllium husk, wheat, water, and fungi were used as matrix [41,84].

Table 3 also shows that a maximum of 30% [34,72] of biowastes were used as biofillers for developing 3D printable filaments for FDM. In all the other FDM-based papers, the percentages were less than 20%. However, a higher amount of biowastes in the matrix may have a negative impact on the mechanical properties of the printed parts. For LDM, the biowaste material content used varied from 0% to 90% for making printable pastes/inks/gels. Most matrix materials are used to change the rheological behavior of the pastes so that printable gels/pastes can be made. Researchers are trying to use various combinations so that printability can be improved [33,49,51,84].

Using biowastes in printable filaments, pastes/gels/inks, and powders can reduce the cost of printed products and also increase their sustainability and biodegradability [51]. However, integrating biowastes into filaments or inks for 3D printing can give rise to certain challenges and difficulties, including altering material properties, potentially affecting the filament’s mechanical and thermal characteristics [30,40,42,48,58,68,69]. This alteration can impact print quality, resulting in reduced strength, increased brittleness, or changes in dimensional stability. High biowaste content can impair interlayer bonding, causing weaker printed parts and delamination. Moreover, complex geometries may suffer from reduced printability, accuracy, and resolution when biowaste content is increased [3,29,42,65,70,72,77].

3.3. AM Methods Used for Printing Agriculturally Derived Biowastes

This subsection describes the different AM methods that have used biowastes. It also shows what types of printers are used, the important printing parameters (such as nozzle size, printing speed, layer height, pressure, laser power, scan speed, hatching distance, and temperature) considered for printing materials incorporating biowastes.

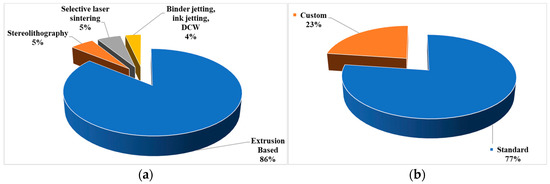

Figure 5a shows the percentages of the selected papers using different AM methods. A total of 86% of these selected papers are based on extrusion-based AM methods including FDM and LDM. Only three papers used stereolithography, three papers used selective laser sintering, and two papers used binder jetting (including one paper that used ink jetting, direct cryo writing (DCW) along with binder jetting). About 23% of the selected papers used custom-made printers not available commercially (Figure 5b).

Figure 5.

Analysis results showing percentage of selected papers based on (a) different AM methods and (b) standard or custom 3D printers.

3.3.1. Extrusion-Based AM Methods

In extrusion-based AM methods, the final product is produced by extruding materials via a nozzle. These methods are under the “Material Extrusion” category of AM as defined by ASTM [1]. FFF (or FDM) and LDM (or DIW) are in this group. Table 4 shows that 49 papers out of the 57 selected papers used extrusion-based AM methods for printing. The printers are small and inexpensive and can print a variety of materials using filaments or pastes.

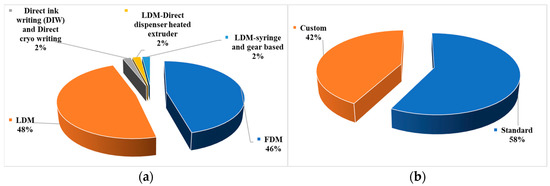

FDM printers are easily accessible to a wider range of users, ranging from affordable desktop-size devices to massive industrial equipment. Hence, developing novel materials for FDM is appropriate for scaling up in the short- and mid-term, allowing the proliferation of new applications [85]. This is especially true for biowastes from agriculturally derived materials, as 46% of the 49 papers selected for this subsection are based on FDM (Figure 6a).

Figure 6.

Analysis results showing percentages of selected papers based on (a) different types of extrusion-based AM methods and (b) standard or custom 3D printers for LDM.

LDM is another extrusion-based printing method. Figure 6a shows that approximately 46% of the selected papers used the LDM method. LDM can handle a large variety of materials. Processing various material types also implies dealing with a range of potential applications. Compared to papers based on FFF, the papers based on LDM exhibit a more pronounced customization in the 3D printer type. LDM is a more adaptable method for agriculturally derived biowastes with a wider range of applications, including large building structure printers and small bioprinters. Figure 6b shows that around 42% of the selected papers based on the LDM printing method used a customized setup for printing agriculturally derived biowastes. In order to better control the LDM printing parameters for these novel materials, customized systems were developed. In these papers, viscous pastes were printed at room temperature (except one of the selected papers, in which heating during LDM printing was used [64]) by using screw extruders or pump systems on robot arms or customizing existing 3D printers [38,41,58,80,83]. Though a lot of pre-processing or post-processing might be required with LDM, without the need for heating (while printing), LDM use less energy and are more environmentally friendly.

As shown in Table 4, nozzle diameter for FDM printing is typically 0.4 to 1.00 mm. These nozzles are available commercially, and 0.4 mm, 0.6 mm, 0.8 mm, and 1 mm nozzles are the most common ones. However, one of the selected papers used a 1.3 mm nozzle for FDM printing to avoid nozzle clogging because a larger ramie fiber size was used as a filler material [75]. However, in LDM, a larger variety of nozzles is observed. Most of the nozzles used in LDM are larger than 1 mm. Some customized nozzle diameters are even larger than 20 mm [33,68]. Bigger nozzles, along with thicker layers, are common in DIW, making them more suitable for large-scale printing applications such as construction, food, and furniture [86]. Some papers used modified extrusion-based (syringe-based and gear-based LDM) printing methods for specific applications [53,64].

Table 4 also shows a significant difference in printing speed between FDM and LDM-DIW. The printing speed in FDM is usually higher, ranging from 35 to 150 mm/s (mostly 35, 45, 50, and 65 mm/s). Only one paper on FDM used a printing speed range of 1.67 to 8.36 mm/s [75]. On the other hand, the printing speed in all the selected papers that used LDM ranged from 1.67 to 30 mm/s. Only one of the selected papers used a printing speed of 25 to 58.33 mm/s [33].

Table 4 also shows a clear difference in layer height between FDM and LDM. Layer height in FDM normally ranged from 0.1 mm to 1.00 mm, but LDM had a much wider range, up to far more than 1 mm [41]. Another critical parameter in LDM is pressure, with typical values of 2 bar to 6 bar.

Table 4.

List of the selected papers by Extrusion-based AM methods, Printer Size, 3D Printer Name, 3D Printer Type, Nozzle Diameter, Speed, Layer Height, and Pressure.

Table 4.

List of the selected papers by Extrusion-based AM methods, Printer Size, 3D Printer Name, 3D Printer Type, Nozzle Diameter, Speed, Layer Height, and Pressure.

| AM Methods | Printer Size | References | 3D Printer Name | 3D Printer Type | Nozzle Diameter (mm) | Speed (mm/s) | Layer Height (mm) | Pressure (Bar) |

|---|---|---|---|---|---|---|---|---|

| FDM | Small | [39] | // | Extrusion-based printer (standard) | // | // | // | // |

| [59] | Leapfrog Creatr 3D | Extrusion-based printer (standard) | 0.50 | // | // | // | ||

| [72] | Prusa i3 Rework 3D printer | Extrusion-based printer (standard) | 1.00 | 50 to 150 | 0.6 to 1.0 | // | ||

| [29] | // | Extrusion-based printer (standard) | 0.60 | 60.00 | 0.25 | // | ||

| [73] | ENDER-3S | Extrusion-based printer (standard) | 0.40 | 50.00 | 0.20 | // | ||

| [34] | CREALITY CR-10 3D printer | Extrusion-based printer (standard) | 0.40 | 35.00 | 0.20 | // | ||

| [37] | Prusa i3 MK3 | Extrusion-based printer (standard) | 0.80 | 50 and infill 80 | 0.15 | // | ||

| [75] | Combot-200 printer | Extrusion-based printer along with dry fiber deposition mechanism | 1.30 | 1.67 to 8.36 | 0.60 | // | ||

| [65] | Lulzbot Taz 6 | Extrusion-based printer (standard) | 0.50 | 35.00 | 0.30 | // | ||

| [4] | Lulzbot Taz 6 | Extrusion-based printer (standard) | 0.50 | 35.00 | 0.30 | // | ||

| [66] | Ender 5 Pro | Extrusion-based printer (standard) | 0.40 | 65.00 | 0.25 | // | ||

| [76] | Ultimaker 3 | Extrusion-based printer (standard) | 0.80 | // | 0.20 | // | ||

| [77] | Prusa i3 MK3S | Extrusion-based printer (standard) | 0.60 | 60.00 | 0.30 | // | ||

| [3] | 3D FF-STD Doppia machine | Extrusion-based printer (standard) | 0.80 | 60.00 | 0.25 | // | ||

| [78] | 3D FF-STD Doppia machine | Extrusion-based printer (standard) | 0.80 | 60.00 | 0.25 | // | ||

| [79] | Sharebot Next Generation | Extrusion-based printer (standard) | 0.40 | 45.00 | 0.10 | // | ||

| [67] | FDM printer | Extrusion-based printer (standard) | // | // | // | // | ||

| [69] | FDM printer | Extrusion-based printer (standard) | // | // | // | // | ||

| [70] | 3D printing pen | Extrusion-based printer (standard) | // | // | // | // | ||

| [40] | Ultimaker 3 | Extrusion-based printer (standard) | 0.60 | 50.00 | 0.10 | // | ||

| [42] | Sharebot Next Generation | Extrusion-based printer (standard) | // | 45.00 | 0.10 | // | ||

| [71] | FS-200 3D printer | Extrusion-based printer (standard) | 0.40 | 50.00 | 0.10 | // | ||

| [82] | Sharebot Next Generation | Extrusion-based printer (standard) | 0.40 | 50.00 | 0.10 | // | ||

| LDM | Small | [32] | Model FSE 2 | Extrusion-based printer (standard) | 2.00 | // | 3.00 | // |

| [64] | 3D discovery™ Evolution printer | Extrusion-based printer (standard) | 0.60 | 2.50 | 0.20 | 4 bars | ||

| Medium | [68] | Custom-built/in-house printer | Extrusion-based printer with 6 nozzles custom built | 225 to 400 mm2 for 6 different types of nozzles | // | // | // | |

| Small | [43] | Foodini 3D food printer | Extrusion-based printer (standard) | 4.00 | // | // | // | |

| [83] | Custom printer Arduino Mega2560 coupled with a RAMPS 1.4; the software used was Marlin™ | Extrusion-based printer (custom) | 0.19 | // | // | // | ||

| [36] | Delta Wasp 2040 | Extrusion-based 3D printer with custom nozzle and extrusion system | 6.00 | 15.00 | 6.00 | 3.5 bars | ||

| [44] | Focus 3D food printer | Extrusion-based printer (standard) | 1.60 | 10.00 | 1.12 | // | ||

| [63] | Creality Ender 5 Pro | Extrusion-based printer with Custom Nozzle system for ink deposition | 0.60 | 10 to 20 | 0.1 to 1 | 2 to 3 bars | ||

| [45] | Shotmini 200 Sx DIW printer | Extrusion-based printer with 50 mL Luer lock dispensing syringe | 0.90 | 50.00 | 0.40 | 0.9 bar | ||

| [46] | 3D food printer CARK (controlled additive manufacturing robotic kit) | Extrusion-based printer custom printer for 3D food printing | 0.5 to 1.28 | 5 to 20 | // | 4 bars | ||

| [47] | Foodini 3D food printer | Extrusion-based printer (standard) | 1.50 | // | // | // | ||

| [48] | M4 3D printer [87] | Custom printer with seven printheads (two FFF heads, two DIW heads, two IJ heads, and one AJ head), two in situ curing modules (photonic and UV), and two robotic arms | 1.194, 0.838, 0.603 | // | 0.40 | // | ||

| [49] | System 60 M | Extrusion-based printer (standard) | 0.70 | 20.00 | 0.50 | // | ||

| [50] | 3D printer 3.0 developed by Felix | Extrusion-based printer (standard) | 1.55 | 10 | 0.60 | // | ||

| [38] | KUKA KR 15/2 6-axis industrial robot | Custom extrusion-based printer with a single extruder attached to the robotic arm | 5 to 25 | 20 to 30 | // | 1.6 to 2 bars | ||

| [80] | 3D4E | Extrusion-based custom-made printer capable of printing pastes, gels and highly viscous liquids | 0.68 | // | // | // | ||

| [58] | Custom LDM printer with syringe-based extrusion system | Extrusion-based custom-made printer | 0.61 | 10.00 | 0.40 | // | ||

| [33] | Foodini 3D food printer | Extrusion-based printer (standard) | 8, 15, 40 | 25 to 58.33 | 0.7 to 2.8 | // | ||

| [57] | Foodini 3D food printer | Extrusion-based printer (standard) | // | 33.33 | 1.95 | // | ||

| [52] | 3D food printer CARK (controlled additive manufacturing robotic kit) | Extrusion-based printer custom printer for 3D food printing | 1.20 | 1.67 to 10 | 0.45 to 1.07 | 2 to 6 bars | ||

| [51] | 3D food printer CARK (controlled additive manufacturing robotic kit) | Extrusion-based printer custom printer for 3D food printing | 1.20 | 6.67 to 11.67 | 0.31 to 1.34 | 3.2 bars | ||

| [41] | Delta Wasp 2040 | Extrusion-based 3D printer with custom nozzle and extrusion system | 6.00 | 15.00 | 6.00 | 3.5 bars | ||

| [54] | Shinnove-E Pro | Extrusion-based printer (standard) | 0.84 | 25.00 | 0.60 | // | ||

| [55] | Shinnove-E Pro | Extrusion-based printer (standard) | 0.84 | 25.00 | 0.60 | // | ||

| [56] | Foodbot-D2 | Extrusion-based printer (standard) | 1.20 | 20.00 | // | // | ||

| LDM-Syringe and gear based | Small | [53] | Syringe-based 3D printer 3.0 Felix and gear-based 3D printer L3D Extruder Kit | Extrusion-based printer (standard) | 1.55 for syringe-based and 0.5 for gear-based printing | 10.00 | 0.60 | // |

3.3.2. Selective Laser Sintering AM method

Selective laser sintering is an additive manufacturing method that fabricates three-dimensional objects by successive layers made by laser sintering [60]. In total, 3 of the 57 selected papers were based on SLS and used the AFS-360 rapid prototyping equipment, a commercially available large printer (Table 5). The choice of feedstock materials has a significant impact on the mechanical strength and the surface quality of the sintered or printed object. Currently, SLS feedstock materials are focused on metal, ceramic, polymers, and their corresponding composites. However, the growth of SLS is very limited because of high price and lack of diversity of these feedstock materials. Therefore, there is an urgent need to develop environmentally friendly, cost-effective, and sustainable materials suitable for SLS [30,60,61].

Table 5.

List of the selected papers by 3D Printer Name, 3D Printer Type, Layer Height, Specifications for SLS.

Values of layer height used in SLS printing were between 0.1 to 0.15 mm. Laser power, scanning speed, and scan spacing are important printing parameters for SLS printing. In one of the selected papers, preheating of the powder materials was performed to obtain better print quality [30].

3.3.3. Stereolithography AM Method

Stereolithography (SLA) involves curing a photocurable liquid resin in a tank by the action of an ultraviolet (UV) laser, whose length in commercial systems is typically 405 nm. Stereolithography is different from FFF because it is more accurate and has higher resolution [81]. Table 6 shows that three papers used stereolithography printing. Stereolithography printers are small in size. Irradiation dose, intensity, exposure time, and layer height are important parameters for stereolithography printing. Ethyl cellulose macromonomer (ECM) and rosin-based monomer (DAGMA), photocurable resin, and soyabean oil epoxidized acrylate are used for printing, and the printability of these materials incorporating biowastes was investigated [31,35,81]. The reported studies show that post-processing is required for SLS printing [31].

Table 6.

List of the selected papers by 3D Printer Name, 3D Printer Type, Specifications for Stereolithography Printing.

3.3.4. Binder Jetting, Ink Jetting, and DCW AM Methods

Individual layer fabrication (ILF) involves constructing parts by layering solid materials in a laminated manner. The individual panels are produced separately using a technique called binder jetting. This enables the application of pressure to these panel-like components, similar to the manufacturing process of traditional wood composite boards. Depending on the chosen binder, either hot or cold pressing methods can be employed [88]. The Direct Cryo Writing (DCW) combines 3D printing and cryotemplating, in which ink is extruded onto a cold plate and carefully frozen. All these printing methods, along with the ink jetting method, were used for printing wood powder or chips. Table 7 shows the printers used, printer types, nozzle sizes, and parameters important for different printing methods.

Table 7.

List of the selected papers by AM Methods, Printer Size, 3D Printer Name, 3D Printer Type, Nozzle Sizes for DIW and DCW (mm), Specifications for Ink Jet Printing, and Specifications for Binder Jet Printing.

3.4. Applications and Limitations

The primary objective of the selected papers was to develop printable filaments, inks, or powders that exhibit mechanical and thermal properties comparable to those of commercially available materials. Therefore, this section emphasizes the sectors in which the incorporation of these biowastes can effectively mitigate the reliance on petrochemical-based materials. Additionally, the section addresses the limitations that currently impede the widespread utilization of biowastesin large-scale applications using additive manufacturing methods.

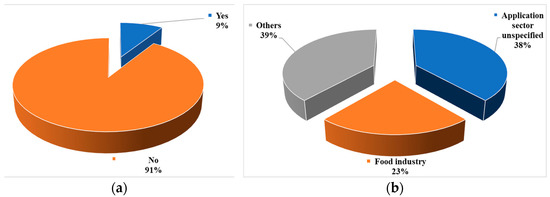

Approximately 91% of the selected papers in this systematic review focused on material composites that had not been previously utilized (Figure 7a). Conversely, about 9% of the papers explored materials that had been employed in other sectors but had not yet been applied using additive manufacturing methods (Figure 7a). All of these materials have potential applications across various sectors. Selected papers that have not mentioned any potential application sector are mentioned as “Application sector unspecified” in Table 8. Those papers were more focused on developing sustainable filaments, inks, or powders instead of focusing on specific application sectors. Figure 7b presents a breakdown of the sectors. The food industry emerged as the most common area where AM methods could be employed for production utilizing agriculturally derived biowastes. About 38% of the selected papers did not mention specific application sectors, while 23% indicated future applications in the food industry.

Figure 7.

Analysis results showing the percentages of reported papers: (a) whether the materials are already used or not, and (b) application sectors of biowaste-incorporated materials.

Table 8.

List of the selected papers by AM Methods, Application Sectors, New Materials, and Product Applications.

According to Table 8, most of the papers that used FDM for printing were focused on developing sustainable, recyclable, and biodegradable 3D printable filaments with biowastes. Some of the papers have shown good results in developing cheaper filaments, lightweight filaments, filaments that can be used in biomedical devices [29], fluorescent emitting 3D printing filaments [76], and filaments that can be customizable and used for producing non-structural components in electrical and automotive industries [65].

Table 8 also shows that the papers using LDM are focused on developing 3D printable ink in food [46,57]. Some of the papers successfully developed printable materials for LDM, which can be used for bone tissue generation [64], food packaging [51], construction sectors [52], waste water treatment plants [83], electrical, pharmaceutical parts production [63], furniture [32,38], and automotive industries [35]. Papers that used SLS were more focused on developing sustainable, low-cost, and environmentally friendly feedstock. Similarly, the papers using the stereolithography method were focused on developing environmentally friendly materials by replacing petrochemical-based materials.

There are several challenges associated with utilizing agriculturally derived biowastes in large-scale industrial settings using various AM methods.

- Energy consumption increases when using AM methods compared to other manufacturing methods when the preprocessing (milling, chemical processing, using single or dual screw extruders) and post-processing (polishing, curing, heating, and cooling) steps required for processing agriculturally derived biowastes are included [2,39,60].

- Particle sizes and fiber sizes of the biowastes can negatively impact the mechanical and thermal properties of the printed products and adversely affect the printing process, i.e., larger fiber degrade elastic modulus, tensile strength [67,69,81,82].

- Printability window for printable biowastes is narrow in some cases [41,43].

- An additional notable issue involves the possibility of biowastes undergoing biodegradation or decay over time. Due to the organic components present in biowastes, they can be prone to microbial growth, moisture absorption, and degradation. Consequently, the long-term durability and stability of printed objects may be compromised, thereby constraining their suitability for applications that demand extended lifespans [42].

3.5. Mechanical Characterizations

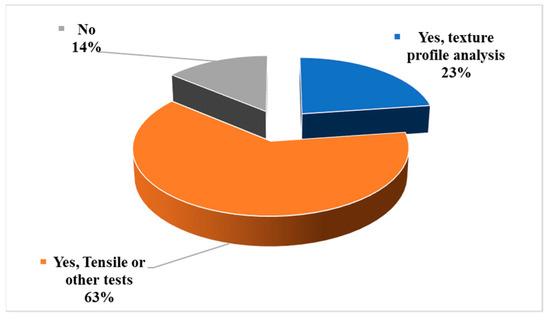

Figure 8 shows that around 14% of the selected papers did not conduct any mechanical characterizations. About 23% of selected papers used texture profile analysis (TPA). TPA is mainly conducted on food materials so that the yield stress, adhesiveness, hardness, compressibility, and springiness can be measured. But in some cases, TPA has been used to characterize viscoelastic materials for AM methods that might be used in construction, packaging, and furniture industry. Approximately 63% of the selected papers conducted tensile, compression, impact Charpy, flexural, and three-point bending tests. One of the papers showed that in the case of flexural and impact tests, the filler efficiently served as reinforcement; for polylactic acid (PLA)/Mater–Bi® EF51L (MB), the inclusion of anchovy fishbone powder (EE) results in an increase in flexural modulus by roughly 23% and 32%, respectively [42]. Another paper showed that the tensile strength of the 3D printed samples was kept or even improved upon increasing the plant waste content as a biofiller. The elastic modulus was enhanced and only a small reduction in the elongation at break was found [82]. In another paper, white marble powder, eggshell powder, and walnut shell powder were added in PLA. It has shown that the inclusion of eggshell and white marble powder negatively impacted tensile strength. The tensile strength of composites made of biowaste can be increased by mixing walnut shell powder with additional fillers [69]. Another paper showed that the CSP/PLA composites have significantly higher mechanical strength and toughness than pure PLA [71]. Another paper showed that HEMP and WEED compounds improved their performance in terms of mechanical properties and weight reduction compared to conventional thermoplastic materials [29]. According to the data of another paper, nanosized hydroxyapatite (bio-HA) from natural sources is a promising material to utilize in the 3D printing scaffolds with regulated porosity for bone tissue engineering. Pure poly(ε-caprolactone) (PCL) components have a lower modulus (177 MPa), highlighting the stiffening effect of the bio-HA nanoparticles. Moreover, compared to pure PCL, the PCL/bio-HA scaffolds have higher bioactivity. Among these, it was discovered that mussel-shell-derived HA had improved cell adhesion, activation, and proliferation [64].

Figure 8.

Analysis results showing the percentages of reported papers: whether mechanical characterizations were conducted or not.

Effective material characterization is essential for ensuring the quality and performance of 3D printed parts [59,60]. Through a comprehensive understanding of material properties, including tensile strength, elasticity, and thermal behavior, manufacturers can optimize printing parameters and enhance mechanical properties to meet specific requirements [29,34,61,62,72,73]. Furthermore, material characterization aids in addressing potential challenges like warping, shrinkage, or poor layer adhesion, enabling adjustments during the printing process to mitigate these issues [3,41]. Ultimately, meticulous material characterization results in reliable and predictable 3D printed parts using biowastes, offering superior quality, durability, and functionality across diverse applications.

3.6. Future Research Opportunities

Section 3.6.1, Section 3.6.2, Section 3.6.3, Section 3.6.4 and Section 3.6.5 describe future research opportunities for improving the print quality, mechanical and thermal properties.

3.6.1. Rheological Studies

Rheology is a scientific discipline concerned with the study of the flow and deformation of matter and is of utmost importance in 3D printing because it governs the flow of material through the nozzle, its deposition onto the build platform, and its solidification into a finished product [96,97]. A thorough understanding of the viscoelastic properties of the material is required to understand its thixotropic behavior, optimize the printing parameters, and identify potential issues [98].

The ability of some materials to become less viscous over time when subjected to mechanical stress, such as stirring or shaking, is known as thixotropy. A few models are used to explain the viscosity behavior of thixotropic materials, such as the Power law model [99], the Hershel–Bulkley model [100], the Cross model [101], and the Carreau–Yasuda model [102]. Rheology can be used to assess the material’s thixotropic behavior and make sure it is appropriate for 3D printing. For instance, a material with poor flow characteristics might not be appropriate for use in a specific printer or for a specific application [103]. Early detection of these problems (such as viscosity variations, low yield stress, flow instabilities, strain recovery and thixotropy) enables the avoidance of time and money lost on unsuccessful prints.

Some of the selected papers selected for this study did not conduct rheological studies [33,37,59,69,70,71,73]. Rotational and capillary rheometers can both be used to evaluate the validity of the Cox–Merz rule [104]. Two commonly used rheological tests for determining the viscoelastic properties of complex fluids are the incremental deformation test and the oscillatory deformation test. In the incremental deformation test, the fluid is subjected to a constant shear rate, causing it to reach a steady state deformation. The resulting shear stress, τ, is measured, providing information about the steady state viscosity, . In the oscillatory deformation test, the fluid is deformed by applying either shear stress, τ(t), or shear strain, γ(t), induced by harmonic periodic oscillations of frequency ω. This test aims to obtain the transfer function, , which can be expressed as G*(ω) = G′(ω) + G″(ω)j. Here, G′(ω) represents the elastic modulus (storage modulus), and G″(ω) represents the viscous modulus (loss modulus). According to Cox and Merz’s study [105], the steady state viscosity and the complex viscosity defined as , where is the magnitude of G*(ω), share a similarity in a sense that In later research [106], they applied the Cox–Merz rule (CMR) to food materials and observed that the dynamic viscosity (η ∗ (ω)) is often significantly greater than the steady viscosity (η). This finding suggests a nonlinear behavior in the response of biomaterials. Several examples and a modified CMR have been provided in a recent article [107].

Rotational rheometers are suitable for measuring the viscoelastic properties of fluids over a wide range of frequencies, whereas capillary rheometers are useful for measuring the shear viscosity of fluids under high shear rates. The choice of rheometer depends on the particular characteristics of the fluid to be measured and the kind of rheological data needed.

3.6.2. Printing Parameter Optimization

An important step to enhance the mechanical properties of FFF printed parts is the optimization of printing parameters [108,109,110,111]. Layer height, air gaps (both within and between layers), infill density, temperature, and printing speed are the most important printing parameters for optimization [112,113]. However, these parameters must be examined together because of the intricate interplay between them [114]. To this end, various design of experiment (DOE) procedures are available in the open literature, with the Taguchi method being one of the most widely utilized along with factorial design, as well as the Box–Behnken design [115].

The majority of the selected papers focused on developing novel 3D printable materials, and, as a result, none of the papers comprehensively optimized the printing parameters [39,42,61,63,67,68,69,70,71,72,73,74,75,76,77,78,79,82]. To facilitate the large-scale production use of these biowastes, it is imperative that these printing parameters are optimized.

3.6.3. Material Composition Optimization

The surface finish, accuracy, and resolution of the printed object are all affected by the composition of the materials used for printing [116,117,118,119]. Properties including heat conductivity, electrical conductivity, and chemical resistance vary amongst different materials. It is feasible to produce parts with specified qualities to satisfy the requirements of particular applications by optimizing the material composition. The material composition can be optimized to strike a balance between performance and cost. Using less expensive materials, for instance, could result in lower prices but also lesser strength or durability in the printed products [51,57,60,78].

The selected papers analyzed in this review study commonly employed PLA and ABS as matrix materials for FDM printing [34,59,62,73]. For food printing, Xanthan gum, Guar gum, psyllium husk, Na-alginate have been used as matrix materials. Different matrix materials at different compositions were used. Different additives can also be introduced to the materials to reduce production costs, enhance material strength, improve printing accuracy, or produce specialized printed parts for specific applications. For biomass–fungi composites, some substrates, along with Ganoderma fungi, have been tested, but different fungi along with different substrates are yet to be investigated. Some selected papers have shown potential application of biowastes in the biomedical sector (producing scaffolds for bone tissue generation, producing parts with antimicrobial properties) [29,64,66,71]. Different hydrocolloids can be used, too. All these different additives need to be investigated along with different compositions, which provides a vast region of research opportunities and potentially inventing new materials for 3D printing.

3.6.4. Numerical Simulations

Numerical simulations can improve the efficiency of the 3D printing procedure by spotting potential issues in advance. Designers and engineers can choose the best printing settings, such as layer thickness, printing speed, and temperature, by modeling the process [120,121]. Numerical simulations can shed light on the behavior of the material during printing. This knowledge is essential for creating novel materials and figuring out their limitations [122,123,124,125]. The price of 3D printing can be reduced with the aid of numerical simulations. Users can find solutions to reduce material waste, cut down on printing time, and boost printing productivity by simulating the printing, which eventually lowers the cost of production as a whole.

Numerical simulations for 3D printing these new biowastes are still an unexplored region. They enable engineers and new researchers to enhance the quality of the printed product, decrease material waste, boost productivity, and optimize the 3D printing process [126,127].

3.6.5. Life Cycle Analysis

Life cycle analysis (LCA) of these biowastes is missing in all the selected papers except one [70]. That paper showed that palm fiber filament composite used less polymer resin and also reduced the volume of Australian royal palm waste that would otherwise be disposed of in the environment, which could have negative effects on the ecosystem. More LCA studies are required for these novel materials so that the environmental impact of these materials can be assessed.

The agriculturally derived biowastes have a great potential for industrial applications. Furthermore, because European standards call for 20% biobased materials, the secondary thermoplastic industry sectors can effectively utilize these new agricultural derived biowastes. Biodegradability, sustainability, environmental and social impacts of these materials need to be investigated and AM methods need to be developed more for industrial sectors. This research can effectively provide a path towards bio-circular economy.

4. Conclusions

Papers addressing novel materials made from agriculturally derived biowastes were gathered using a systematic process. The primary goal of this systematic review was to assess the current state of the art with regard to issues related to the particular emphasis on the novel 3D printable materials derived from biowastes, the specifics of 3D printing, and potential applications. Around 58% of the selected papers are from the materials research area.

The majority of biowastes and by-products are derived from agricultural, fishery, forestry, and agrifood industries. A limited number of novel materials have been developed for additive manufacturing thus far. However, researchers are actively exploring new sources of biowaste. A few feedstock materials have been investigated for producing printable filaments, inks, and powders. A large number of selected papers have studied the particle sizes of biowaste for achieving desired printability. Moreover, the size and shape of these particles can affect nozzle clogging, surface roughness, and the presence of defects in the printed parts. PLA was the most used matrix for biowaste-reinforced composites. Guar gum, Xanthan gum, psyllium husk, and other gels were used for creating 3D printable inks. However, this integration poses challenges due to the alteration of material properties, potentially impacting mechanical and thermal characteristics of the printed products. These challenges include reduced strength, increased brittleness, changes in dimensional stability, impaired layer adhesion, interlayer bonding issues, and decreased printability, accuracy, and resolution of complex geometries.

Mechanical and rheological characterizations were conducted in most of the selected papers. Comparable results were found in some cases, whereas favorable results were not obtained in many cases. Material characterization is vital for ensuring the quality and performance of 3D printed parts. By understanding material properties and behavior, manufacturers can optimize printing parameters and enhance mechanical properties. Thorough material characterization enables the identification and mitigation of potential issues, resulting in reliable and high-quality 3D printed parts for various applications.

The majority of selected papers (91%) focused on novel material composites. These materials show potential for various sectors, with the food industry being the most common areas for AM production utilizing agriculturally derived biowastes. Here, 38% of the selected papers did not mention specific application sectors, while 23% indicated future applications in the food industry. The papers using FDM primarily focused on developing sustainable and biodegradable filaments, while the papers using LDM aimed to develop printable ink for food, construction, packaging, and biomedical sectors. Papers using SLS and stereolithography focused on developing sustainable feedstock.

There are limitations to promote the use of agriculturally derived biowastes and different additive manufacturing methods in large-scale settings. These include higher energy consumption due to pre-processing and post-processing steps, the time-intensive nature of most AM methods, higher material costs compared with other manufacturing methods, variability in biowastes impacting product properties and the printing process, a narrow printability window for many biowastes. Resolving these limitations is crucial for a wider adoption of agriculturally derived biowastes and AM in large-scale applications.

Many of the selected papers mentioned few potential markets for these novel materials. Using biowastes through additive manufacturing has a wide range of applications. The purpose of this review is to encourage more research to utilize agriculturally derived biowastes in the actual world using AM.

Author Contributions

Methodology, A.M.R.; formal analysis, A.M.R. and T.T.R.; investigation, A.M.R.; writing—original draft preparation, A.M.R.; writing—review and editing, A.M.R., Z.P., T.T.R., C.O.U., J.L. and A.E.; supervision, Z.P. All authors have read and agreed to the published version of the manuscript.

Funding

This material is based upon work supported by the National Science Foundation under Grant No. 2308575.

Data Availability Statement

The authors confirm that the data to support the findings of this study are available within the article or upon request to the corresponding author.

Conflicts of Interest

The authors declare that they have no known competing financial interest or personal relationships that could have appeared to influence the work reported in this study.

Nomenclature

| ABS | Acrylonitrile buta-diene styrene |

| AM | Additive manufacturing |

| CBS | Cocoa bean shell |

| CMR | Cox–Merz rule |

| copes | Copolyester hot melt adhesive |

| CSP | Crab shell powder |

| DAGMA | Rosin-based monomer |

| DIW | Direct Ink Writing |

| EALNSs | Ethyl acetate treated lignin nanospheres |

| ECM | Ethyl cellulose macromonomer |

| EE | Engraulis encra-sicolus |

| EoL | End of life |

| FA | Fly ash |

| FDM | Fused Deposition Modeling |

| FFF | Fused Filament Fabrication |

| FG-FS | Fluorescent rafted flax shives |

| FS | Flax shives |

| GHGs | Greenhouse gases |

| HA | Nanometric hydroxyapatite |

| HDPE | High-density poly-ethylene |

| HEA | 2-hydroxyethyl acrylate |

| HPMC | Hydroxypro-pyl methylcellulose |

| HV | Hydroxyvalerate |

| ILD | Individual layer fabrication |

| KGM | Konjac gum |

| LCA | Life cycle analysis |

| LDM | Liquid deposition modeling |

| MB | Mater-Bi® EF51L |

| PBAT | Poly-(butylene-terephthalate) |

| PCL | Poly(ε-caprolactone) |

| PHB | Polyhydroxybutyrate |

| PHBV | Poly(3-hydroxybutyrate-co-hydroxy valerate) |

| PLA | Polylactic acid |

| PP | Polypropylene |

| PPP | Purple sweet potato |

| PUL | Pullulan |

| RQ | Research questions |

| SLA | Stereolithography |

| SLS | Selective laser sintering |

| SPI | Soy protein isolate |

| TAMU | Texas A&M University |

| UV | Ultraviolet |

| WoS | Web of Science |

| XG | Xanthan gum |

References

- ASTM52900-15; Standard Terminology for Additive Manufacturing—General Principles—Terminology. ASTM International: West Conshohocken, PA, USA, 2015; Volume 3, p. 5.

- Romani, A.; Suriano, R.; Levi, M. Biomass waste materials through extrusion-based additive manufacturing: A systematic literature review. J. Clean. Prod. 2023, 386, 135779. [Google Scholar] [CrossRef]

- Morales, M.A.; Martinez, C.L.A.; Maranon, A.; Hernandez, C.; Michaud, V.; Porras, A. Development and Characterization of Rice Husk and Recycled Polypropylene Composite Filaments for 3D Printing. Polymers 2021, 13, 1067. [Google Scholar] [CrossRef]

- Maldonado-García, B.; Pal, A.K.; Misra, M.; Gregori, S.; Mohanty, A.K. Sustainable 3D printed composites from recycled ocean plastics and pyrolyzed soy-hulls: Optimization of printing parameters, performance studies and prototypes development. Compos. Part C Open Access 2021, 6, 100197. [Google Scholar] [CrossRef]

- Attias, N.; Danai, O.; Abitbol, T.; Tarazi, E.; Ezov, N.; Pereman, I.; Grobman, Y.J. Mycelium bio-composites in in-dustrial design and architecture: Comparative review and experimental analysis. J. Clean. Prod. 2020, 246, 119037. [Google Scholar] [CrossRef]

- Mikula, K.; Skrzypczak, D.; Izydorczyk, G.; Warchoł, J.; Moustakas, K.; Chojnacka, K.; Witek-Krowiak, A. 3D printing filament as a second life of waste plastics—A review. Environ. Sci. Pollut. Res. 2020, 28, 12321–12333. [Google Scholar] [CrossRef]

- FAOSTAT. 2014. Available online: https://www.fao.org/sustainability/news/detail/en/c/1274219 (accessed on 5 April 2023).

- Phonbumrung, T.; Khemsawas, C. Agricultural crop residue. In Proceedings of the Sixth Meeting of Regional Working Group on Grazing and Feed Resources for Southeast Asia, Legaspi, Philippines, 5–9 October 1998. [Google Scholar]

- Arvanitoyannis, I.S.; Tserkezou, P. Wheat, barley and oat waste: A comparative and critical presentation of methods and potential uses of treated waste. Int. J. Food Sci. Technol. 2008, 43, 694–725. [Google Scholar] [CrossRef]

- Nagendran, R. Chapter 24—Agricultural Waste and Pollution. In Waste; Letcher, T.M., Vallero, D.A., Eds.; Academic Press: Boston, MA, USA, 2011; pp. 341–355. [Google Scholar]

- Sommer, S.G.; Olesen, J.E.; Petersen, S.O.; Weisbjerg, M.R.; Valli, L.; Rodhe, L.; Béline, F. Region-specific assessment of greenhouse gas mitigation with different manure management strategies in four agroecological zones. Glob. Chang. Biol. 2009, 15, 2825–2837. [Google Scholar] [CrossRef]

- FAO. 2006. Available online: https://www.fao.org/3/a0701e/a0701e00.htm (accessed on 5 April 2023).

- Sutton, M.A.; Oenema, O.; Erisman, J.W.; Leip, A.; van Grinsven, H.; Winiwarter, W. Too much of a good thing. Nature 2011, 472, 159–161. [Google Scholar] [CrossRef] [PubMed]

- Vinnerås, B. Sanitation and hygiene in manure management. In Animal Manure Recycling: Treatment and Management; Wiley: Hoboken, NJ, USA, 2013; pp. 91–104. [Google Scholar]

- Syakti, A.D.; Asia, L.; Kanzari, F.; Umasangadji, H.; Lebarillier, S.; Oursel, B.; Garnier, C.; Malleret, L.; Ternois, Y.; Mille, G.; et al. Indicators of terrestrial biogenic hydrocarbon contamination and linear alkyl benzenes as land-base pollution tracers in marine sediments. Int. J. Environ. Sci. Technol. 2013, 12, 581–594. [Google Scholar] [CrossRef]

- Holden, N.M.; Neill, A.M.; Stout, J.C.; O’brien, D.; Morris, M.A. Biocircularity: A Framework to Define Sustainable, Circular Bioeconomy. Circ. Econ. Sustain. 2022, 3, 77–91. [Google Scholar] [CrossRef]

- Rai, P.; Mehrotra, S.; Priya, S.; Gnansounou, E.; Sharma, S.K. Recent advances in the sustainable design and applications of biodegradable polymers. Bioresour. Technol. 2021, 325, 124739. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Meng, F.; Ferraris, E. Temperature gradient at the nozzle outlet in material extrusion additive manufacturing with thermoplastic filament. Addit. Manuf. 2023, 73, 103660. [Google Scholar] [CrossRef]

- Bi, X.; Huang, R. 3D printing of natural fiber and composites: A state-of-the-art review. Mater. Des. 2022, 222, 111065. [Google Scholar] [CrossRef]

- Li, Y.; Ren, X.; Zhu, L.; Li, C. Biomass 3D Printing: Principles, Materials, Post-Processing and Applications. Polymers 2023, 15, 2692. [Google Scholar] [CrossRef]

- Kumar, H.; Kim, K. Stereolithography 3D Bioprinting. In 3D Bioprinting: Principles and Protocols; Crook, J.M., Ed.; Springer: New York, NY, USA, 2020; pp. 93–108. [Google Scholar]

- Yilmaz, B.; Al Rashid, A.; Mou, Y.A.; Evis, Z.; Koç, M. Bioprinting: A review of processes, materials and applications. Bioprinting 2021, 23, e00148. [Google Scholar] [CrossRef]

- Moritz, T.; Maleksaeedi, S. 4—Additive manufacturing of ceramic components. In Additive Manufacturing; Zhang, J., Jung, Y.-G., Eds.; Butterworth-Heinemann: Oxford, UK, 2018; pp. 105–161. [Google Scholar]

- Prabhakar, P.; Sen, R.K.; Dwivedi, N.; Khan, R.; Solanki, P.R.; Srivastava, A.K.; Dhand, C. 3D-Printed Microfluidics and Potential Biomedical Applications. Front. Nanotechnol. 2021, 3. [Google Scholar] [CrossRef]

- Arif, Z.U.; Khalid, M.Y.; Sheikh, M.F.; Zolfagharian, A.; Bodaghi, M. Biopolymeric sustainable materials and their emerging applications. J. Environ. Chem. Eng. 2022, 10, 108159. [Google Scholar] [CrossRef]

- Sarkis-Onofre, R.; Catalá-López, F.; Aromataris, E.; Lockwood, C. How to properly use the PRISMA Statement. Syst. Rev. 2021, 10, 117. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. Int. J. Surg. 2021, 88, 105906. [Google Scholar] [CrossRef]

- Bramer, W.M.; De Jonge, G.B.; Rethlefsen, M.L.; Mast, F.; Kleijnen, J. A systematic approach to searching: An efficient and complete method to develop literature searches. J. Med. Libr. Assoc. 2018, 106, 531–541. [Google Scholar] [CrossRef]

- Calì, M.; Pascoletti, G.; Gaeta, M.; Milazzo, G.; Ambu, R. New filaments with natural fillers for FDM 3D printing and their applications in biomedical field. Procedia Manuf. 2020, 51, 698–703. [Google Scholar] [CrossRef]

- Idriss, A.I.; Li, J.; Guo, Y.; Wang, Y.; Elfaki, E.A.; Ahmed, E.A. Improved Sintering Quality and Mechanical Properties of Peanut Husk Powder/Polyether Sulfone Composite for Selective Laser Sintering. 3D Print. Addit. Manuf. 2023, 10, 111–123. [Google Scholar] [CrossRef] [PubMed]

- Barkane, A.; Jurinovs, M.; Briede, S.; Platnieks, O.; Onufrijevs, P.; Zelca, Z.; Gaidukovs, S. Biobased Resin for Sustainable Stereolithography: 3D Printed Vegetable Oil Acrylate Reinforced with Ultra-Low Content of Nanocellulose for Fossil Resin Substitution. 3D Print. Addit. Manuf. 2022. [Google Scholar] [CrossRef]

- An, Y.-J.; Guo, C.-F.; Zhang, M.; Zhong, Z.-P. Investigation on characteristics of 3D printing using Nostoc sphaeroides biomass. J. Sci. Food Agric. 2018, 99, 639–646. [Google Scholar] [CrossRef]

- Letras, P.; Oliveira, S.; Varela, J.; Nunes, M.; Raymundo, A. 3D printed gluten-free cereal snack with incorporation of Spirulina (Arthrospira platensis) and/or Chlorella vulgaris. Algal Res. 2022, 68, 102863. [Google Scholar] [CrossRef]

- Sun, Y.; Lee, D.; Wang, Y.; Li, S.; Ying, J.; Liu, X.; Xu, G.; Gwon, J.; Wu, Q. Effect of infill value on decay resistance, thermal, and mechanical properties of 3D printed polylactic acid composites filled with wood fibers. Bioresources 2020, 15, 6724–6734. [Google Scholar] [CrossRef]

- Lu, C.; Wang, C.; Yu, J.; Wang, J.; Chu, F. Two-Step 3 D-Printing Approach toward Sustainable, Repairable, Fluorescent Shape-Memory Thermosets Derived from Cellulose and Rosin. ChemSusChem 2020, 13, 893–902. [Google Scholar] [CrossRef]

- Bhardwaj, A.; Vasselli, J.; Lucht, M.; Pei, Z.; Shaw, B.; Grasley, Z.; Wei, X.; Zou, N. 3D Printing of Biomass-Fungi Composite Material: A Preliminary Study. Manuf. Lett. 2020, 24, 96–99. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Grad, K.; Wiśniewski, W.; Szulc, J. The Use of Agricultural Waste in the Modification of Poly(lactic acid)-Based Composites Intended for 3D Printing Applications. The Use of Toughened Blend Systems to Improve Mechanical Properties. J. Compos. Sci. 2021, 5, 253. [Google Scholar] [CrossRef]

- Elsacker, E.; Peeters, E.; De Laet, L. Large-scale robotic extrusion-based additive manufacturing with living mycelium materials. Sustain. Futures 2022, 4, 100085. [Google Scholar] [CrossRef]

- Long, H.; Hu, L.; Yang, F.; Cai, Q.; Zhong, Z.; Zhang, S.; Guan, L.; Xiao, D.; Zheng, W.; Zhou, W.; et al. Enhancing the performance of polylactic acid composites through self-assembly lignin nanospheres for fused deposition modeling. Compos. Part B Eng. 2022, 239, 109968. [Google Scholar] [CrossRef]

- Ohaeri, O.; Cree, D. Development and Characterization of PHB-PLA/Corncob Composite for Fused Filament Fabrication. J. Compos. Sci. 2022, 6, 249. [Google Scholar] [CrossRef]

- Rahman, A.M.; Bhardwaj, A.; Pei, Z.; Ufodike, C.; Castell-Perez, E. The 3D Printing of Biomass–Fungi Composites: Effects of Waiting Time after Mixture Preparation on Mechanical Properties, Rheological Properties, Minimum Extrusion Pressure, and Print Quality of the Prepared Mixture. J. Compos. Sci. 2022, 6, 237. [Google Scholar] [CrossRef]

- Scaffaro, R.; Citarrella, M.C.; Catania, A.; Settanni, L. Green composites based on biodegradable polymers and anchovy (Engraulis encrasicolus) waste suitable for 3D printing applications. Compos. Sci. Technol. 2022, 230, 109768. [Google Scholar] [CrossRef]

- Gudjónsdóttir, M.; Napitupulu, R.J.; Petty Kristinsson, H.T. Low field NMR for quality monitoring of 3D printed surimi from cod by-products: Effects of the pH-shift method compared with conventional washing. Magn. Reson. Chem. 2019, 57, 638–648. [Google Scholar] [CrossRef]

- Vieira, M.V.; Oliveira, S.M.; Amado, I.R.; Fasolin, L.H.; Vicente, A.A.; Pastrana, L.M.; Fuciños, P. 3D printed functional cookies fortified with Arthrospira platensis: Evaluation of its antioxidant potential and physical-chemical characterization. Food Hydrocoll. 2020, 107, 105893. [Google Scholar] [CrossRef]

- Lee, C.P.; Takahashi, M.; Arai, S.; Lee, C.-L.K.; Hashimoto, M. 3D Printing of Okara Ink: The Effect of Particle Size on the Printability. ACS Food Sci. Technol. 2021, 1, 2053–2061. [Google Scholar] [CrossRef]

- Muthurajan, M.; Veeramani, A.; Rahul, T.; Gupta, R.K.; Anukiruthika, T.; Moses, J.A.; Anandharamakrishnan, C. Valorization of Food Industry Waste Streams Using 3D Food Printing: A Study on Noodles Prepared from Potato Peel Waste. Food Bioprocess Technol. 2021, 14, 1817–1834. [Google Scholar] [CrossRef]

- Wang, R.; Li, Z.; Shi, J.; Holmes, M.; Wang, X.; Zhang, J.; Zhai, X.; Huang, X.; Zou, X. Color 3D printing of pulped yam utilizing a natural pH sensitive pigment. Addit. Manuf. 2021, 46, 102062. [Google Scholar] [CrossRef]

- Armstrong, C.D.; Yue, L.; Deng, Y.; Qi, H.J. Enabling direct ink write edible 3D printing of food purees with cellulose nanocrystals. J. Food Eng. 2022, 330, 111086. [Google Scholar] [CrossRef]

- Carvajal-Mena, N.; Tabilo-Munizaga, G.; Pérez-Won, M.; Lemus-Mondaca, R. Valorization of salmon industry by-products: Evaluation of salmon skin gelatin as a biomaterial suitable for 3D food printing. LWT 2021, 155, 112931. [Google Scholar] [CrossRef]

- Chen, J.; Sun, H.; Mu, T.; Blecker, C.; Richel, A.; Richard, G.; Jacquet, N.; Haubruge, E.; Goffin, D. Effect of temperature on rheological, structural, and textural properties of soy protein isolate pastes for 3D food printing. J. Food Eng. 2022, 323, 110917. [Google Scholar] [CrossRef]

- Nida, S.; Moses, J.A.; Anandharamakrishnan, C. 3D Extrusion Printability of Sugarcane Bagasse Blended with Banana Peel for Prospective Food Packaging Applications. Sugar Tech 2022, 24, 764–778. [Google Scholar] [CrossRef]

- Nida, S.; Moses, J.A.; Anandharamakrishnan, C. Converting fruit waste to 3D printed food package casings: The case of banana peel. Circ. Econ. 2023, 2, 100023. [Google Scholar] [CrossRef]

- Shi, Z.; Blecker, C.; Richel, A.; Wei, Z.; Chen, J.; Ren, G.; Guo, D.; Yao, Y.; Haubruge, E. Three-dimensional (3D) printability assessment of food-ink systems with superfine ground white common bean (Phaseolus vulgaris L.) protein based on different 3D food printers. LWT 2021, 155, 112906. [Google Scholar] [CrossRef]

- Yu, J.; Wang, X.-Y.; Li, D.; Wang, L.-J.; Wang, Y. Development of soy protein isolate emulsion gels as extrusion-based 3D food printing inks: Effect of polysaccharides incorporation. Food Hydrocoll. 2022, 131, 107824. [Google Scholar] [CrossRef]

- Yu, J.; Li, D.; Wang, L.-J.; Wang, Y. Improving freeze-thaw stability and 3D printing performance of soy protein isolate emulsion gel inks by guar & xanthan gums. Food Hydrocoll. 2023, 136, 108293. [Google Scholar] [CrossRef]

- Yu, X.; Wang, Y.; Zhao, W.; Li, S.; Pan, J.; Prakash, S.; Dong, X. Hydrophilic colloids (Konjac gum/Xanthan gum) in 3D printing of transitional food from fish paste. Food Hydrocoll. 2023, 137, 108333. [Google Scholar] [CrossRef]

- Liu, P.; Dang, X.; Woo, M.W.; Chattha, S.A.; An, J.; Shan, Z. Feasibility Study of Starch-Based Biomass Incorporated 3D Printed Beef. Starch–Stärke 2022, 74, 2200030. [Google Scholar] [CrossRef]

- Islam, M.N.; Jiang, Y. 3D Printable Sustainable Composites with Thermally Tunable Properties Entirely from Corn-Based Products. ACS Sustain. Chem. Eng. 2022, 10, 7818–7824. [Google Scholar] [CrossRef]

- Girdis, J.; Gaudion, L.; Proust, G.; Löschke, S.; Dong, A. Rethinking Timber: Investigation into the Use of Waste Macadamia Nut Shells for Additive Manufacturing. JOM 2016, 69, 575–579. [Google Scholar] [CrossRef]

- Yu, Y.; Guo, Y.; Jiang, T.; Li, J.; Jiang, K.; Zhang, H. Study on the Ingredient Proportions and After-Treatment of Laser Sintering Walnut Shell Composites. Materials 2017, 10, 1381. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.; Guo, Y.; Jiang, T.; Li, J.; Jiang, K.; Zhang, H.; Zhuang, Y. Study on the Characteristics of Walnut Shell/Co-PES/Co-PA Powder Produced by Selective Laser Sintering. Materials 2018, 11, 784. [Google Scholar] [CrossRef]

- Kam, D.; Layani, M.; BarkaiMinerbi, S.; Orbaum, D.; Abrahami Benharush, S.; Shoseyov, O.; Magdassi, S. Additive Manufacturing of 3D Structures Composed of Wood Materials. Adv. Mater. Technol. 2019, 4, 1900158. [Google Scholar] [CrossRef]

- Adams, D.; Ounaies, Z.; Basak, A. Printability Assessment of Ethyl Cellulose Biopolymer Using Direct Ink Writing. JOM 2021, 73, 3761–3770. [Google Scholar] [CrossRef]

- Cestari, F.; Petretta, M.; Yang, Y.; Motta, A.; Grigolo, B.; Sglavo, V.M. 3D printing of PCL/nano-hydroxyapatite scaffolds derived from biogenic sources for bone tissue engineering. Sustain. Mater. Technol. 2021, 29, e00318. [Google Scholar] [CrossRef]

- Diederichs, E.; Picard, M.; Chang, B.P.; Misra, M.; Mohanty, A. Extrusion Based 3D Printing of Sustainable Biocomposites from Biocarbon and Poly(trimethylene terephthalate). Molecules 2021, 26, 4164. [Google Scholar] [CrossRef]

- Martins, L.S.; Cortat, L.I.; Zanini, N.C.; Barbosa, R.F.; de Souza, A.G.; Medeiros, S.F.; Rosa, D.S.; Mulinari, D.R. A versatile filler in polyhydroxyalcanoates filaments for FDM: A diverse panorama for pullulan application. Mater. Today Commun. 2021, 28, 102690. [Google Scholar] [CrossRef]

- Giani, N.; Mazzocchetti, L.; Benelli, T.; Bovo, M.; Gazzotti, S.; Torreggiani, D.; Tassinari, P.; Giorgini, L. A New Biocomposite Material Based on Wheat Waste and Suitable for 3D Printing Applications. Macromol. Symp. 2022, 405, 2100235. [Google Scholar] [CrossRef]

- Kong, X.; Dai, L.; Wang, Y.; Qiao, D.; Hou, S.; Wang, S. Influence of kenaf stalk on printability and performance of 3D printed industrial tailings based geopolymer. Constr. Build. Mater. 2021, 315, 125787. [Google Scholar] [CrossRef]

- Lohar, D.; Nikalje, A.; Damle, P. Development and testing of hybrid green polymer composite (HGPC) filaments of PLA reinforced with waste bio fillers. Mater. Today Proc. 2022, 62, 818–824. [Google Scholar] [CrossRef]

- Marton, A.M.; Monticeli, F.M.; Zanini, N.C.; Barbosa, R.F.; Medeiros, S.F.; Rosa, D.S.; Mulinari, D.R. Revalorization of Australian royal palm (Archontophoenix alexandrae) waste as reinforcement in acrylonitrile butadiene styrene (ABS) for use in 3D printing pen. J. Clean. Prod. 2022, 365, 132808. [Google Scholar] [CrossRef]

- Yang, F.; Ye, X.; Zhong, J.; Lin, Z.; Wu, S.; Hu, Y.; Zheng, W.; Zhou, W.; Wei, Y.; Dong, X. Recycling of waste crab shells into reinforced poly (lactic acid) biocomposites for 3D printing. Int. J. Biol. Macromol. 2023, 234, 122974. [Google Scholar] [CrossRef] [PubMed]

- Badouard, C.; Traon, F.; Denoual, C.; Mayer-Laigle, C.; Paës, G.; Bourmaud, A. Exploring mechanical properties of fully compostable flax reinforced composite filaments for 3D printing applications. Ind. Crops Prod. 2019, 135, 246–250. [Google Scholar] [CrossRef]

- Jiang, G.; Yang, T.; Xu, J.; Tao, D.; Luo, C.; Wang, C.; Dong, Q.; Wang, Y. Investigation into hydroxypropyl-methylcellulose-reinforced polylactide composites for fused deposition modelling. Ind. Crops Prod. 2020, 146, 112174. [Google Scholar] [CrossRef]

- Buschmann, B.; Henke, K.; Talke, D.; Saile, B.; Asshoff, C.; Bunzel, F. Additive Manufacturing of Wood Composite Panels for Individual Layer Fabrication (ILF). Polymers 2021, 13, 3423. [Google Scholar] [CrossRef]

- Cheng, P.; Wang, K.; Chen, X.; Wang, J.; Peng, Y.; Ahzi, S.; Chen, C. Interfacial and mechanical properties of continuous ramie fiber reinforced biocomposites fabricated by in-situ impregnated 3D printing. Ind. Crops Prod. 2021, 170, 113760. [Google Scholar] [CrossRef]

- Mayer-Laigle, C.; Foulon, L.; Denoual, C.; Pernes, M.; Rondet, E.; Magueresse, A.; Barron, C.; Habrant, A.; Bourmaud, A.; Paës, G. Flax shives-PBAT processing into 3D printed fluorescent materials with potential sensor functionalities. Ind. Crops Prod. 2021, 167, 113482. [Google Scholar] [CrossRef]

- Mohan, D.; Bakir, A.N.; Sajab, M.S.; Bakarudin, S.B.; Mansor, N.N.; Roslan, R.; Kaco, H. Homogeneous distribution of lignin/graphene fillers with enhanced interlayer adhesion for 3D printing filament. Polym. Compos. 2021, 42, 2408–2421. [Google Scholar] [CrossRef]

- Morales, M.A.; Maranon, A.; Hernandez, C.; Porras, A. Development and Characterization of a 3D Printed Cocoa Bean Shell Filled Recycled Polypropylene for Sustainable Composites. Polymers 2021, 13, 3162. [Google Scholar] [CrossRef] [PubMed]

- Scaffaro, R.; Maio, A.; Gulino, E.F.; Alaimo, G.; Morreale, M. Green Composites Based on PLA and Agricultural or Marine Waste Prepared by FDM. Polymers 2021, 13, 1361. [Google Scholar] [CrossRef]

- Bahcegul, E.G.; Ozkan, N. 3D printing of crude lignocellulosic biomass extracts containing hemicellulose and lignin. Ind. Crops Prod. 2022, 186, 115234. [Google Scholar] [CrossRef]

- Romero-Ocaña, I.; Delgado, N.F.; Molina, S.I. Biomass waste from rice and wheat straw for developing composites by stereolithography additive manufacturing. Ind. Crops Prod. 2022, 189, 115832. [Google Scholar] [CrossRef]

- Scaffaro, R.; Citarrella, M.C.; Morreale, M. Green Composites Based on Mater-Bi® and Solanum lycopersicum Plant Waste for 3D Printing Applications. Polymers 2023, 15, 325. [Google Scholar] [CrossRef]

- Bergamonti, L.; Bergonzi, C.; Graiff, C.; Lottici, P.P.; Bettini, R.; Elviri, L. 3D printed chitosan scaffolds: A new TiO2 support for the photocatalytic degradation of amoxicillin in water. Water Res. 2019, 163, 114841. [Google Scholar] [CrossRef] [PubMed]

- Bhardwaj, A.; Rahman, A.M.; Wei, X.; Pei, Z.; Truong, D.; Lucht, M.; Zou, N. 3D Printing of Biomass–Fungi Composite Material: Effects of Mixture Composition on Print Quality. J. Manuf. Mater. Process. 2021, 5, 112. [Google Scholar] [CrossRef]

- Romani, A.; Rognoli, V.; Levi, M. Design, Materials, and Extrusion-Based Additive Manufacturing in Circular Economy Contexts: From Waste to New Products. Sustainability 2021, 13, 7269. [Google Scholar] [CrossRef]

- Taieba Tuba, R.; Al Mazedur, R.; Zhijian, P.; Ketan, T.; Hongmin, Q.; Aleena, K. 3D printing of microalgae-enriched cookie dough: Determining feasible regions of process parameters for continuous extrusion. Green Manuf. Open 2023, 1, 11. [Google Scholar] [CrossRef]

- Roach, D.J.; Hamel, C.M.; Dunn, C.K.; Johnson, M.V.; Kuang, X.; Qi, H.J. The m4 3D printer: A multi-material multi-method additive manufacturing platform for future 3D printed structures. Addit. Manuf. 2019, 29, 100819. [Google Scholar] [CrossRef]

- Henke, K.; Talke, D.; Bunzel, F.; Buschmann, B.; Asshoff, C. Individual layer fabrication (ILF): A novel approach to additive manufacturing by the use of wood. Eur. J. Wood Wood Prod. 2021, 79, 745–748. [Google Scholar] [CrossRef]

- Kariz, M.; Sernek, M.; Obućina, M.; Kuzman, M.K. Effect of wood content in FDM filament on properties of 3D printed parts. Mater. Today Commun. 2018, 14, 135–140. [Google Scholar] [CrossRef]

- Sang, L.; Han, S.; Peng, X.; Jian, X.; Wang, J. Development of 3D-printed basalt fiber reinforced thermoplastic honeycombs with enhanced compressive mechanical properties. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105518. [Google Scholar] [CrossRef]

- Yavas, D.; Zhang, Z.; Liu, Q.; Wu, D. Interlaminar shear behavior of continuous and short carbon fiber reinforced polymer composites fabricated by additive manufacturing. Compos. Part B Eng. 2020, 204, 108460. [Google Scholar] [CrossRef]

- Heng, P.W.S.; Chan, L.W.; Chow, K.T. Development of Novel Nonaqueous Ethylcellulose Gel Matrices: Rheological and Mechanical Characterization. Pharm. Res. 2005, 22, 676–684. [Google Scholar] [CrossRef]

- Santamaría, A.; Lizaso, M.I.; Muñoz, M.E. Rheology of ethyl cellulose solutions. Macromol. Symp. 1997, 114, 109–119. [Google Scholar] [CrossRef]

- Bahcegul, E.; Toraman, H.E.; Erdemir, D.; Akinalan, B.; Ozkan, N.; Bakir, U. An unconventional approach for improving the integrity and mechanical properties of xylan type hemicellulose based films. RSC Adv. 2014, 4, 34117–34126. [Google Scholar] [CrossRef]

- Zilliox, C.; Debeire, P. Hydrolysis of wheat straw by a thermostable endoxylanase: Adsorption and kinetic studies. Enzym. Microb. Technol. 1998, 22, 58–63. [Google Scholar] [CrossRef]

- Liu, Z.; Bhandari, B.; Prakash, S.; Mantihal, S.; Zhang, M. Linking rheology and printability of a multicomponent gel system of carrageenan-xanthan-starch in extrusion based additive manufacturing. Food Hydrocoll. 2018, 87, 413–424. [Google Scholar] [CrossRef]

- M’barki, A.; Bocquet, L.; Stevenson, A. Linking Rheology and Printability for Dense and Strong Ceramics by Direct Ink Writing. Sci. Rep. 2017, 7, 6017. [Google Scholar] [CrossRef]

- Boddepalli, U.; Panda, B.; Gandhi, I.S.R. Rheology and printability of Portland cement based materials: A review. J. Sustain. Cem. Mater. 2022, 12, 789–807. [Google Scholar] [CrossRef]