Abstract

Conventional wastewater treatment methods typically achieve 70–90% removal efficiency for organic pollutants. However, the global wastewater crisis—with 80% of wastewater discharged untreated—demands innovative solutions to overcome persistent challenges in nutrient removal and resource recovery. This review presents the first systematic analysis of technology integration strategies for algal wastewater treatment, examining synergistic combinations of biofilm reactors, nano-enhancement, artificial intelligence, and 3D printing technologies. Individual technologies demonstrate distinct performance characteristics: algal biofilm reactors achieve 60–90% removal efficiency with biomass productivity up to 50 g/m2/day; nano-enhanced systems reach 70–99% pollutant removal; AI optimization provides 15–35% efficiency improvements with 25–35% energy reductions; and 3D-printed architectures achieve 70–90% removal efficiency. The novel integration framework reveals that technology combinations achieve 85–95% overall efficiency compared to 60–80% for individual approaches. Critical challenges include nanomaterial toxicity (silver nanoparticles effective at 10 mg/L), high costs (U.S. Dollar (USD) 50–300 per m2 for 3D components, USD 1500+ per kg for nanomaterials), and limited technological maturity (TRL 4–5 for AI and 3D printing). Priority development needs include standardized evaluation metrics, comprehensive risk assessment, and economic optimization strategies. The integration framework provides technology selection guidance based on pollutant characteristics and operational constraints, while implementation strategies address regional adaptation requirements. Findings support integrated algal systems’ potential for superior treatment performance and circular economy contributions through resource recovery.

1. Introduction

1.1. The Global Wastewater Crisis

The escalating complexity of wastewater pollution represents one of the most pressing environmental challenges of the 21st century, driven by rapid urbanization, industrial expansion, and inadequate treatment infrastructure. According to the World Health Organization, approximately 80% of wastewater produced globally is discharged without adequate treatment, resulting in severe ecological degradation and substantial public health risks [1]. This widespread pollution crisis is characterized by significant nutrient loads, with nitrogen concentrations reaching 40–100 mg/L and phosphorus levels between 5 and 30 mg/L in typical wastewater streams, contributing substantially to eutrophication in receiving water bodies [2].

Traditional wastewater treatment methodologies, while widely implemented, face fundamental limitations in efficiency, cost-effectiveness, and environmental sustainability. Conventional techniques, such as activated sludge processes and chemical coagulation, frequently struggle to meet increasingly stringent effluent quality standards, often achieving removal efficiencies below 50% for certain persistent contaminants, including heavy metals and complex organic pollutants [3]. Moreover, these conventional systems generate secondary pollutants, including excess sludge and toxic by-products, further complicating waste disposal and treatment protocols [4]. The operational inefficiencies and environmental footprints of traditional systems necessitate urgent development of innovative, sustainable alternatives that can effectively remediate pollutants while minimizing ecological impact.

1.2. Algae-Based Treatment: A Paradigm Shift

Algae-based wastewater treatment systems have emerged as a transformative green alternative, leveraging the natural capabilities of microalgae for nutrient uptake and bioremediation. These biological systems demonstrate exceptional potential through their innate ability to assimilate nutrients, such as nitrogen and phosphorus, at rates exceeding 90%, effectively mitigating eutrophication while simultaneously generating valuable biomass [5]. The bioremediation mechanisms employed by algal systems encompass biosorption, bioassimilation, and biotransformation processes, enabling comprehensive treatment of both organic and inorganic pollutants [5].

Beyond pollutant removal capabilities, algal systems contribute significantly to circular economy principles by converting wastewater nutrients into valuable by-products, including biofuels, fertilizers, and high-value biochemicals [1]. This integrated bioprocess approach enhances resource recovery while promoting environmental sustainability, with algal biomass serving as feedstock for biorefineries and supporting the transition toward a circular bioeconomy [6]. However, traditional algal treatment systems face significant challenges regarding scalability, operational consistency, and performance optimization under varying environmental conditions [7].

1.3. The Technology Integration Imperative

While individual algal treatment approaches have demonstrated promising results, the complexity of modern wastewater streams and the demands for high-efficiency, cost-effective treatment require sophisticated technological integration. Single-technology solutions, despite their merits, often encounter limitations in addressing the multifaceted nature of contamination, variable operational conditions, and economic constraints that characterize real-world applications. The integration of advanced technologies, including artificial intelligence, nanotechnology, and innovative materials engineering, with algal systems represents a transformative approach to overcoming these fundamental limitations.

Technology integration offers unprecedented opportunities to enhance system optimization through real-time monitoring, predictive modeling, and automated control systems that maximize nutrient uptake rates and overall treatment efficiency [3]. Advanced materials and nanotechnology applications can address persistent challenges, such as membrane fouling and selective pollutant targeting, while innovative design approaches enable customized treatment solutions for specific contamination profiles. This synergistic combination of biological capabilities with cutting-edge technologies creates a new paradigm for wastewater treatment that addresses both performance requirements and economic viability.

The convergence of multiple technological domains within algal treatment systems also addresses critical scalability and deployment challenges that have limited widespread adoption of algae-based solutions. By combining the strengths of different technological approaches, integrated systems can achieve enhanced robustness, improved cost-effectiveness, and greater operational flexibility compared to single-technology implementations.

1.4. Scope and Contribution of This Review

This comprehensive review presents the first systematic analysis of technology integration strategies for algal wastewater treatment systems, examining how advanced biofilm reactors, nano-engineering, artificial intelligence, and 3D printing technologies can be synergistically combined to create next-generation treatment platforms. Unlike previous reviews that focus on individual technological approaches, this work develops a unified framework for understanding and implementing multi-technology algal systems that address the complex requirements of modern wastewater treatment.

The review critically evaluates four key technological domains: algal biofilm reactors for enhanced biomass productivity and simplified harvesting; nano-engineered systems for selective pollutant targeting and performance amplification; AI-driven optimization for intelligent monitoring and control; and 3D-printed bio-scaffolds for customized treatment architectures. Through comprehensive performance analysis, economic evaluation, and practical implementation assessment, this work provides both researchers and practitioners with essential guidance for developing effective algal treatment solutions.

The central contribution of this review lies in its development of an integrated multi-technology framework that demonstrates how individual technological approaches can be combined to overcome their respective limitations while amplifying their collective strengths. This framework addresses critical gaps in current literature by providing quantitative performance comparisons, economic optimization strategies, and practical deployment guidelines for different operational contexts and regional requirements.

Furthermore, this review addresses the urgent need for standardized evaluation metrics, ecotoxicological risk assessment protocols, and implementation strategies tailored to diverse economic and geographic contexts. By bridging the gap between laboratory-scale innovations and real-world applications, this work contributes to the advancement of sustainable wastewater management solutions that can address global environmental challenges while supporting economic development and resource recovery objectives.

1.5. Materials and Methods

To ensure methodological transparency and reproducibility, a structured literature-selection protocol was followed in accordance with Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA), 2020 guidelines) for systematic reviews. Searches were conducted between January 2000 and April 2025 using Scopus, Web of Science, and Google Scholar. The following Boolean string was applied across all databases:

(“algal wastewater treatment” OR “microalgae wastewater”) AND (“biofilm reactor” OR “attached culture”) AND (“nanotechnology” OR “nanomaterial”) AND (“artificial intelligence” OR “machine learning”) AND (“3D printing” OR “additive manufacturing”).

Additional records were identified through citation tracking, cross-referencing of key review articles, and manual searches of institutional repositories and conference proceedings.

Inclusion criteria:

- (i)

- Peer-reviewed English-language studies reporting experimental, pilot, or full-scale investigations of algal wastewater treatment employing biofilm, nano-enhancement, AI optimization, or 3D-printed systems;

- (ii)

- Studies presenting quantitative data, such as nutrient-removal efficiency, chemical oxygen demand (COD)/biological oxygen demand (BOD) reduction, biomass productivity, or energy consumption;

- (iii)

- papers comparing or integrating two or more technological approaches.

Exclusion criteria:

- (i)

- Theoretical or modeling studies lacking empirical validation;

- (ii)

- Duplicate records or abstracts without full text;

- (iii)

- Studies unrelated to wastewater applications or without measurable performance metrics.

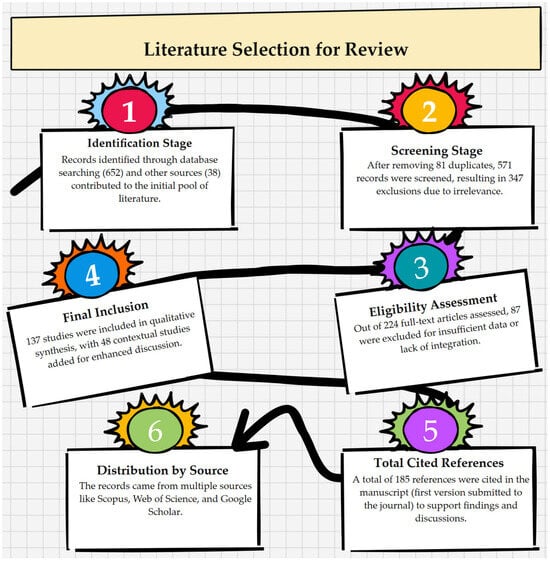

An initial total of 652 records were retrieved. After removal of approximately 81 duplicates, 571 records were screened by title and abstract. Of these, 347 were excluded for irrelevance to integrated algal systems. The remaining 224 full-text articles were assessed for eligibility, and 87 were excluded for insufficient quantitative data or absence of technological integration. Ultimately, 137 studies met all inclusion criteria and were incorporated into the qualitative synthesis forming the evidence base of this review.

In addition, around 48 supplementary publications—including review papers, methodological references, policy reports, and conceptual studies—were consulted to provide background context, define terminology, and support broader discussion of emerging trends. Together, these sources form the total of 185 references cited in the manuscript.

A PRISMA 2020 flow diagram (Figure 1) summarizes the identification, screening, eligibility, and inclusion process. Data extracted from the selected studies were categorized according to technology domain (biofilm reactors, nano-enhanced systems, AI-optimized platforms, and 3D-printed architectures). Each record was analyzed for pollutant-removal efficiency, biomass productivity, operational parameters, and reported limitations. Quantitative metrics were normalized to percentage-removal efficiency for cross-comparison, and qualitative evaluation emphasized scalability, energy demand, and integration feasibility to ensure critical rather than purely descriptive synthesis.

Figure 1.

PRISMA flow diagram of literature selection for this study.

The extent of quantitative and critical discussion presented for each technological domain reflects the maturity and data availability within the literature. Algal biofilm reactors and nano-enhanced systems are comparatively well-established fields supported by a large number of pilot- and full-scale studies, enabling detailed tabulation and comparative performance analysis. In contrast, AI-optimized and 3D-printed algal systems are emerging areas with fewer empirical datasets and shorter operational timelines; consequently, their discussion emphasizes conceptual development, early-stage results, and critical evaluation of current limitations. This proportional approach was adopted to ensure that all sections remain evidence-based and methodologically balanced, without over-interpreting preliminary findings.

2. Algal Biofilm Systems: Foundation Technology for Advanced Treatment

2.1. Biofilm Reactor Fundamentals and Mechanisms

Algal biofilm reactors (ABRs) offer significant improvements in wastewater treatment technology, exploiting the natural tendency of microalgae to form adherent biofilms through secretion of extracellular polymeric substances (EPS). These hydrated matrices facilitate both cellular adhesion and enhanced nutrient exchange, creating microenvironments that significantly improve pollutant adsorption and biotransformation processes [8]. The biofilm architecture provides superior mass transfer characteristics compared to suspended culture systems, enabling more efficient pollutant-microorganism contact and enhanced removal of dissolved contaminants.

Comparative performance analysis reveals that biofilm-based systems achieve substantially higher biomass productivity than conventional suspended cultures. Research demonstrates that attached culture systems utilizing natural carriers, such as cotton and jute, achieve biomass productivity rates of 25.65 g dry weight (DW) m−2, representing a 4-fold increase compared to suspended cultures yielding only 1.27 ± 0.12 g DW L−1 [9]. This enhanced productivity stems from improved nutrient utilization efficiency and reduced energy expenditure for biomass harvesting, as the physical attachment of algal cells to carrier materials facilitates simplified biomass recovery processes.

The dual functionality of algal biofilms enables simultaneous wastewater treatment and resource generation, aligning with biorefinery principles for sustainable processing [10]. The biofilm matrix not only supports enhanced algal growth rates but also provides a stable platform for biofuel generation and valuable biomass recovery, reducing harvesting-related energy costs that typically represent significant operational expenses in algal cultivation systems [11].

2.2. Engineering Design and Reactor Configurations

The engineering optimization of ABRs centers on carrier material selection and reactor configuration design, which critically influence algal attachment efficiency and subsequent nutrient uptake performance. Various carrier materials, including mesh substrates, synthetic membranes, and natural textiles, demonstrate different characteristics in supporting biofilm development and maintaining structural integrity under operational conditions. The incorporation of rotating algal biofilm (RAB) technology represents a significant design advancement, utilizing rotating disk systems to enhance mixing dynamics and optimize light exposure—critical factors for maximizing algal growth in wastewater treatment applications [12].

Empirical Performance Relationships:

Analysis of operational data reveals strong correlations between system parameters:

Biomass Productivity vs. Light Intensity:

- Low light (50–150 μmol/m2/s): 20–30 g/m2/day [11]

- Medium light (100–300 μmol/m2/s): 5.5–31 g/m2/day [13] (based on Table A1 data)

- High light (400–600 μmol/m2/s): 30–50 g/m2/day [11]

Efficiency vs. Loading Rate [14]:

- Low loading (3–5 gCOD/m2/day): 60–80% removal

- Medium loading (5–10 gCOD/m2/day): 50–70% removal

- High loading (10–20 gCOD/m2/day): 75–90% removal

Operational Stability:

Performance analysis reveals distinct efficiency patterns across reactor configurations, directly correlated with operational parameters. High-rate algal biofilm reactors (HRABs) achieve superior metrics with BOD removal of 75–85% and COD reduction of 80–90% at organic loading rates of 10–20 gCOD/m2/day and light intensities of 400–600 μmol/m2/s, maintaining biomass productivity of 30–50 g/m2/day [14]. The high performance correlates with optimal light exposure and controlled loading conditions that prevent system overload.

RACs demonstrate moderate performance (60–70% BOD, 70–80% COD) at lower organic loading rates of 3–5 gCOD/m2/day and reduced light intensities of 100–300 μmol/m2/s, achieving biomass productivity of 5.5 g/m2/day at bench scale and scaling to 31 g/m2/day at pilot scale. The performance variation reflects the impact of scale-up challenges and operational optimization requirements.

Trickling filter systems show lower removal rates (50–60% BOD, 60–70% COD) operating at minimal organic loading rates of 5–10 gCOD/m2/day with natural light intensities of 50–150 μmol/m2/s, achieving biomass productivity of 20–30 g/m2/day. The reduced performance stems from limited light penetration and suboptimal nutrient contact in packed media configurations.

2.3. Integration with Photobioreactors and Closed-Loop Systems

The integration of algal biofilm reactors with photobioreactors creates sophisticated hybrid systems that leverage complementary strengths of both technologies for enhanced wastewater treatment and resource recovery. These integrated configurations optimize light capture efficiency while maximizing nutrient recycling through closed-loop operational designs. Coupled algal biofilm membrane photobioreactor systems have demonstrated exceptional performance, achieving nitrogen removal efficiencies of approximately 92% and phosphorus removal rates of 88% from secondary effluents while simultaneously facilitating significant algal biomass production [15].

The synergistic effects of integration extend beyond simple additive performance improvements. Photobioreactor components enhance light intensity utilization and drive photosynthetic efficiency improvements that significantly benefit overall system performance. Optimal light conditions substantially improve CO2 fixation rates and algal growth kinetics, creating a comprehensive recycling nexus where nutrients and carbon dioxide are continuously returned to the production cycle [16].

Empirical Integration Performance:

Integration effectiveness varies significantly with reactor type and operational conditions as follows:

Total Efficiency = Biofilm Efficiency + Photobioreactor Efficiency × Synergy Factor

Where synergy factors range from 0.1 to 0.3 based on light optimization and nutrient recycling effectiveness.

Closed-loop integration facilitates continuous nutrient recovery and biomass generation, with algal growth converting absorbed nutrients into valuable biomass suitable for biofertilizer production or biofuel processing. This approach supports sustainable waste management principles while enabling energy recovery solutions that enhance overall system economics.

2.4. Performance Metrics and Operational Challenges

Comprehensive performance evaluation of algal biofilm systems requires assessment of multiple critical metrics, including Chemical Oxygen Demand (COD) and Biochemical Oxygen Demand (BOD) removal rates, nutrient uptake efficiency, biomass productivity, and system stability under varying operational conditions. Advanced biofilm systems consistently demonstrate superior pollutant removal capabilities, with studies revealing BOD reduction efficiencies exceeding 90% and COD removal rates approaching 85% in municipal wastewater applications [17,18].

Biomass productivity represents a key performance indicator for system economics and resource recovery potential. Rotating biofilm reactors achieve biomass productivities up to 7.5 g/m2/day, demonstrating substantial resource recovery potential while maintaining consistent treatment performance [11]. However, productivity varies significantly with operational parameters, with hydraulic retention time, organic loading rate, and light intensity serving as primary controlling factors.

Empirical Cost-Performance Analysis:

Operational data reveals clear relationships between system configuration and economics as follows:

- High-rate aeration basin (HRAB) systems: Higher capital expenditure (CAPEX) but superior efficiency (75–90% removal) and productivity (30–50 g/m2/day)

- RAC systems: Moderate costs with consistent performance (60–80% removal) and extended operational life (300+ days)

- Trickling filters: Lowest initial costs but reduced efficiency (50–70% removal) and space requirements

Operational challenges significantly impact system performance and economic viability. Fouling represents the most prevalent limitation, restricting flow rates and reducing mass transfer efficiency, with documented fouling rates exceeding 15% in some operational configurations [18]. Biofilm detachment issues create operational inconsistencies and require regular maintenance interventions that increase overall system costs.

Scalability challenges persist as a major barrier to widespread implementation. While laboratory-scale systems often demonstrate exceptional performance, field-scale operations encounter variabilities in wastewater composition and environmental conditions that compromise treatment consistency. The transition from controlled laboratory conditions to dynamic operational environments introduces complexities related to seasonal variations, shock loading events, and maintenance requirements that affect long-term performance reliability.

2.5. Case Studies and Pilot-Scale Implementations

Pilot-scale implementations of algal biofilm reactor technology demonstrate both the potential and practical challenges of scaling laboratory innovations to operational systems. Notable deployments in India and European Union countries provide valuable insights into real-world performance characteristics and implementation requirements. Rotating Algal Biofilm Reactor (RABR) technology implementations in India have achieved impressive nutrient removal performance, with pilot studies reporting ammonium removal efficiencies exceeding 90% and chemical oxygen demand (COD) reductions up to 75% in diluted swine wastewater applications [19].

European pilot testing programs have demonstrated the effectiveness of integrated green algae and cyanobacteria biofilm systems, achieving productivity rates of 0.97 to 2.08 g DW m−2 d−1 across varying operational conditions [20]. These productivity levels represent significant improvements over conventional treatment approaches while generating biomass suitable for biofuel feedstock applications, supporting the economic viability of biofilm-based treatment systems.

Extended operational studies confirm the feasibility of sustained biofilm reactor operation over extended periods. Pilot-scale systems designed with appropriate hydraulic retention time (HRT) optimization demonstrate stable performance with HRT adjustments up to 6 days substantially boosting both nutrient removal efficiency and bioproduct yields [21]. Properly tuned HRT allows sufficient contact time between wastewater and biofilm, enhancing both ammonium and phosphate uptake, while preventing biofilm detachment caused by excessive shear forces.

Critical Success Factors:

Analysis of successful implementations reveals several critical factors for optimal performance as follows:

- HRT: Optimal HRT is a key determinant of reactor performance. Too short an HRT limits nutrient-biofilm contact time, resulting in incomplete ammonium and phosphorus removal, while excessively long HRTs may reduce volumetric throughput and compromise process economics. Pilot studies indicate that HRTs in the range of 3–6 days provide a balance between nutrient removal efficiency (>80%) and biomass productivity, with flexibility to adjust based on influent load and seasonal temperature variations [22,23]. Seasonal set-points for flow and HRT can further minimize biomass sloughing under variable temperature and loading conditions.

- Flow Regime and Mixing: Flow hydrodynamics critically influence biofilm development, nutrient diffusion, and detachment rates. Laminar flow conditions favor initial biofilm attachment and stability, whereas moderate turbulent flow or controlled shear can enhance mass transfer and prevent excessive biofilm thickening, which otherwise leads to light limitation. Successful implementations often use intermittent or pulsed flow regimes to optimize biofilm thickness and ensure light penetration across the biofilm depth [24,25,26]. Begin with laminar conditions to support initial adhesion, then gradually introduce controlled shear. Intermittent or pulsed flow helps maintain mass transfer while limiting excessive biofilm thickening.

- Carrier Material Selection: Lignocellulosic materials significantly outperform hydrophobic alternatives, demonstrating superior liquid-holding capacity and biofilm adhesion characteristics [27]. Lignocellulosic carriers are therefore preferred over hydrophobic media for maximizing surface colonization and long-term stability.

- Light and Nutrient Balance: Maintaining optimal light flux and nutrient ratios requires careful operational control, with imbalances significantly compromising system efficiency [28]. Routine monitoring and adjustment of light flux and nutrient dosing are essential; uncontrolled fouling can exceed 15% of the surface area if left unchecked.

- Operational Consistency: Successful pilot implementations emphasize the importance of consistent operational protocols and preventive maintenance schedules for maintaining long-term performance stability. Structured preventive maintenance schedules are recommended to mitigate biofilm detachment events and ensure sustained productivity.

Despite demonstrated benefits, challenges remain in maintaining stable biofilm thickness, preventing sloughing events under variable flow conditions, and adapting systems to seasonal changes in light and temperature. Continued research into adaptive flow control strategies and dynamic HRT adjustment will be essential for scaling these systems to full-scale municipal or industrial wastewater applications. Surface material optimization remains a critical research need, with biofilm adhesion and reactor efficiency strongly dependent on carrier material properties. Additionally, achieving optimal balance between light availability and nutrient fluxes within biofilm systems requires sophisticated operational control that may limit applicability in resource-constrained environments.

The evolution from laboratory-scale success to pilot-scale implementation highlights the importance of robust engineering design and operational optimization strategies. Successful scaling requires comprehensive understanding of biofilm dynamics, carrier material properties, and operational control requirements that extend beyond simple performance metrics to encompass economic viability and maintenance feasibility.

Based on the performance data summarized in Table A1 and the pilot-scale results discussed in Section 2.3, Section 2.4 and Section 2.5, the practical scalability of algal biofilm reactors (ABRs) remains constrained by multiple operational and engineering challenges. While nutrient removal efficiencies of 75–90% and biomass productivities of 30–50 g m−2 day−1 have been repeatedly achieved under controlled or semi-controlled conditions, few studies demonstrate comparable stability under long-term municipal or industrial operations. Documented biofilm detachment and fouling rates—often exceeding 15% decline in hydraulic performance—remain a key obstacle to sustained efficiency.

Carrier material optimization is also inconsistent across studies, with limited standardization in surface chemistry, texture, or durability leading to large performance variability. Furthermore, the absence of lifecycle and cost analyses limits understanding of economic feasibility. Collectively, the evidence presented in this section indicates that while ABRs provide a strong foundation for integrated algal systems, their transition from pilot to commercial scale will depend on advances in biofilm stability, light distribution control, and cost-per-area optimization.

3. Nano-Enhanced Algal Systems: Performance Amplification Through Material Engineering

3.1. Nanotechnology Integration Mechanisms

The integration of engineered nanomaterials into algal bioreactor systems represents a paradigm shift in wastewater treatment efficiency, enabling selective pollutant targeting and performance amplification through sophisticated material-biological interfaces. Nano-additives, nano-carriers, and nano-sensors create synergistic interactions with algal systems that enhance both photosynthetic efficiency and contaminant removal capabilities beyond the limitations of biological processes alone. Titanium dioxide (TiO2) nanoparticles, at optimized concentrations around 1 mg/L, demonstrate significant enhancement of algal photosynthetic efficiency while simultaneously improving the toxicity and degradation of specific metal ions, such as zinc (Zn2+), creating dual-mechanism treatment systems [29].

The incorporation of biochar nanoparticles provides enhanced surface area and improved reactivity characteristics that substantially increase pollutant adsorption capacity. These engineered particles exhibit significantly improved stability and favorable zeta potential characteristics in algal culture media, critical factors influencing contaminant adsorption efficiency in urban runoff applications [30]. Advanced nano-engineered systems achieve nitrate removal efficiencies of 92% at initial concentrations of 20 mg/L when integrated with optimized algal cultures, demonstrating the substantial performance gains achievable through nano-bio hybrid approaches.

Empirical Nano-Bio Performance Relationships:

Performance analysis reveals additive and synergistic effects as follows:

- Biological removal (algae alone): 70–85% baseline efficiency

- Physicochemical removal (nanomaterials): 10–25% additional removal

- Synergistic enhancement: 5–15% improvement through combined mechanisms

Total system efficiency typically achieves 85–99% depending on nanomaterial type and pollutant characteristics.

3.2. Nanomaterial Classification and Pollutant-Specific Applications

The strategic selection of nanomaterials for algal system enhancement depends critically on target pollutant characteristics and desired treatment mechanisms. Metal oxide nanomaterials, including titanium dioxide (TiO2) and zinc oxide (ZnO), have shown strong performance in photocatalytic applications, achieving dye removal efficiencies of 85–95% under optimized ultraviolet (UV) light exposure conditions. These materials generate reactive oxygen species (ROS) that facilitate degradation of complex organic compounds resistant to biological treatment alone [31].

Carbon-based nanomaterials, particularly graphene oxide (GO) and carbon nanotubes (CNTs), exhibit significant adsorption capabilities, which may offer due to their high surface area and unique structural properties. Functionalized multi-walled carbon nanotubes (MWCNTs) exhibit superior sorption capacity for heavy metals, effectively enhancing algal uptake of lead (Pb) and other toxic metals through combined adsorption-bioassimilation mechanisms [32,33].

Comprehensive Nanomaterial Performance Analysis:

The detailed classification of representative nanomaterials, their synthesis methods, primary functions, and pollutant-specific efficiencies is summarized in Table 1.

Table 1.

Nanomaterial selection directly correlates with application requirements.

Performance variation within efficiency ranges depends on the following:

- Synthesis method quality: Sol-gel methods typically achieve higher consistency than precipitation.

- Pollutant concentration: Higher initial concentrations often reduce percentage removal.

- Operating conditions: pH, temperature, and light exposure significantly affect performance.

- Nanomaterial concentration: Optimal dosing varies by application (0.5–1 mg/L for TiO2).

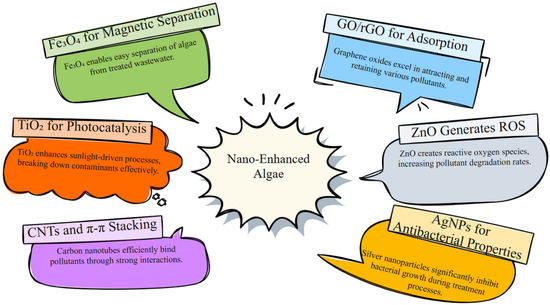

Representative nanomaterials and their primary functions in algal wastewater systems are summarized in Figure 2, highlighting how photocatalysis, adsorption, ROS generation, magnetic separation, and antibacterial activity map onto pollutant classes. Magnetic nanoparticles, particularly Fe3O4, address critical operational challenges in algal systems by enabling simplified recovery and separation processes. These materials achieve significant pollutant removal efficiencies while facilitating magnetic separation, addressing challenges associated with treatment particle recovery that typically complicate system operations [36].

Figure 2.

Representative nanomaterials used with algal systems and their primary functions (photocatalysis, ROS generation, adsorption, magnetic separation, antibacterial action) and example pollutant classes.

3.3. Synergistic Mechanisms and Reactive Oxygen Species Generation

The interaction between microalgae and engineered nanoparticles operates through two primary synergistic mechanisms: enhanced pollutant degradation through combined biological-physicochemical processes and reactive oxygen species (ROS) generation that amplifies treatment capabilities beyond individual component performance. Algal uptake processes are supplemented by nanoparticle binding and catalytic activities, resulting in accelerated pollutant sorption and transformation rates. Silver nanoparticles present significant challenges in algal system applications due to their inherent toxicity to photosynthetic organisms. While silver nanoparticles (AgNPs) demonstrate effective antibacterial properties achieving 85% pathogen removal, they simultaneously inhibit algal growth and chlorophyll production, creating operational conflicts in algal treatment systems [37,38]. The concentration-dependent toxicity of AgNPs, with disruption thresholds as low as 10 mg/L, limits their practical application in algal systems and requires careful risk-benefit analysis for specific applications where pathogen control is prioritized over algal productivity.

Nano-TiO2 serves as a critical component in ROS generation systems, facilitating production of photogenerated hydroxyl radicals that effectively oxidize complex organic pollutants resistant to conventional biological degradation. Under illuminated conditions, TiO2 nanoparticles at concentrations of 0.5 mg/L increase ROS levels significantly, leading to enhanced pollutant degradation efficiency in green algae systems through photochemical enhancement mechanisms [36].

Empirical ROS Generation Relationships:

Based on operational data, ROS generation effectiveness correlates with the following:

- TiO2 concentration: Optimal at 0.5–1.0 mg/L for enhanced degradation

- Light intensity: Higher UV exposure increases ROS production proportionally

- Pollutant type: Organic compounds show 15–25% improvement with ROS enhancement

- pH conditions: Neutral pH (6.5–7.5) optimizes ROS generation efficiency

Critical balance requirements:

- Concentrations > 2 mg/L cause algal toxicity

- Insufficient light (<100 μmol/m2/s) limits ROS effectiveness

- Excessive ROS generation damages algal photosystems

However, ROS generation also creates significant ecological concerns, as excessive oxidative stress leads to algal cell damage and mortality. Critical balance maintenance is essential to capitalize on nanoparticle-assisted remediation benefits while minimizing toxicity impacts. The concentration-dependent nature of these interactions requires precise optimization to achieve maximum treatment efficiency without compromising algal viability.

3.4. Environmental and Toxicological Considerations

While nano-enhanced algal systems demonstrate substantial performance benefits, their ecological implications require comprehensive evaluation and risk management strategies. Nanotoxicity represents a significant concern, particularly regarding phytotoxic effects of metal nanoparticles on algal species and broader ecosystem impacts. Silver nanoparticles (AgNPs) demonstrate concentration-dependent toxicity, inhibiting chlorophyll production in species, such as Chlorella pyrenoidosa, and reducing photosynthetic efficiency and biomass yield at concentrations as low as 10 mg/L [37,38]. Toxicity screening should be conducted in matrix-matched wastewater with NOM and EPS present, and operational concentrations held 10–100× below lab-derived thresholds [39,40].

The interaction between nanoparticles and natural organic materials in aquatic environments significantly complicates toxicological profiles and bioavailability characteristics. Humic substances can substantially alter nanoparticle behavior, either exacerbating or mitigating toxicity effects on algal species depending on specific environmental conditions and nanoparticle properties [41]. Understanding these nano-bio-eco interactions is crucial for developing effective mitigation strategies and optimizing nanomaterial design for minimal ecological impact.

Empirical Toxicity Assessment:

Based on available data, concentration-dependent effects are clearly established as follows:

Silver Nanoparticles:

- Safe operating range: <1 mg/L

- Toxicity threshold: 10 mg/L (chlorophyll inhibition)

- Lethal concentration: >50 mg/L (species dependent)

TiO2 Nanoparticles:

- Optimal enhancement: 0.5–1.0 mg/L

- No toxicity observed: <2 mg/L

- Moderate stress effects: 2–5 mg/L

General Safety Guidelines:

- Operating concentrations should remain 10–100× below toxicity thresholds

- Continuous monitoring required for silver-based systems

- Environmental release requires comprehensive impact assessment

Bioaccumulation potential poses additional ecological risks, particularly as nanoparticles can translocate within food webs and accumulate in higher trophic levels. Silver nanoparticle accumulation studies indicate significant uptake in aquatic organisms with potential for biomagnification, raising concerns about long-term biodiversity and ecosystem health impacts [42]. Recovery strategies utilizing native algal species capable of sequestering nanoparticles and rendering them environmentally inert are being explored as potential mitigation approaches [43,44].

Manufacturing processes for nanomaterials also contribute to environmental impact through energy-intensive production methods and potential generation of secondary pollutants. Chemical reduction processes for graphene production and nanoparticle synthesis can generate hazardous by-products, raising questions about overall sustainability of nano-enhanced treatment technologies [45]. Where possible, nanomaterial development should prioritize green synthesis routes and coated or embedded forms. Magnetic nanoparticles can be deployed with external capture systems to facilitate recovery, and native algae can be leveraged for in situ nanoparticle sequestration.

3.5. Advanced Applications and Case Studies

3.5.1. Graphene Oxide-Enhanced Systems for Organic Pollutant Removal

Graphene oxide (GO) applications in algal treatment systems demonstrate exceptional performance for dye removal and organic pollutant degradation. GO-based hydrogels achieve near-complete removal of methylene blue (MB) and rhodamine B (RhB) within four hours at initial concentrations of 100 mg/L, showcasing superior adsorption kinetics and capacity [46]. The high surface area and functional groups present in GO facilitate electrostatic interactions and π-π stacking mechanisms that maximize dye uptake through multiple binding pathways.

Quantitative analysis reveals GO adsorption capacity for methylene blue reaches 714 mg/g, with removal efficiencies exceeding 99% at concentrations below 250 mg/L [47]. However, integration of GO into algal systems presents challenges related to mechanical integrity and stability under varying environmental conditions, as heavy nanoscale additives can compromise algal mat structural properties [48].

3.5.2. Magnetic Nanoparticle-Assisted Treatment and Recovery

Magnetic nanoparticle (MNP) integration enables revolutionary improvements in algal biomass harvesting through magnetic separation techniques, significantly reducing processing time and costs compared to traditional separation methods. Functionalized MNPs demonstrate enhanced affinity for organic pollutants while enabling straightforward recovery processes through magnetic field application [49,50].

Empirical Magnetic Separation Performance:

Operational data demonstrates clear performance relationships as follows:

Separation Efficiency vs. Conditions:

- Magnetic field strength: Higher fields (>0.1 Tesla) achieve >90% separation

- Particle size: Larger aggregates (>1 μm) separate more effectively

- Processing time: 95% efficiency achieved within 5–10 min

- Fluid viscosity: Lower viscosity improves separation rates

Economic Benefits:

- Processing time reduction: 80–90% compared to conventional settling

- Energy requirements: 50–70% lower than centrifugation

- Recovery efficiency: 95% for Fe3O4-coated biomass

Functionalized composites achieve removal efficiencies up to 95% for methylene blue and congo red, with adsorption capacities reaching 615 mg/g [51]. Magnetic-coagulation methods using Fe3O4 nanoparticles coated with polyethylenimine effectively separate Chlorella sp. under magnetic field application, significantly enhancing treatment performance while simplifying biomass recovery [52].

3.5.3. Cyanotoxin Removal and Water Quality Protection

Advanced nano-adsorbents demonstrate exceptional capabilities for cyanotoxin removal, addressing critical water quality challenges associated with harmful algal blooms. Graphene-enhanced nano-adsorbents achieve cyanotoxin removal rates exceeding 90% at initial microcystin concentrations of 10 mg/L within 60 min, demonstrating rapid treatment kinetics essential for emergency response applications [53].

These applications highlight the potential for nano-engineered algal bioreactors to address both treatment efficiency and water safety objectives simultaneously, creating integrated systems capable of managing diverse contamination scenarios while maintaining high treatment performance standards.

3.6. Integration Challenges and Optimization Strategies

The successful implementation of nano-enhanced algal systems requires careful optimization of multiple parameters, including nanoparticle concentration, algal species selection, and operational conditions. Critical challenges include maintaining optimal nanoparticle dispersion, preventing aggregation that reduces surface area, and managing potential toxicity effects that compromise algal viability.

Long-term stability represents a fundamental challenge, as nanoparticle properties can change significantly under operational conditions through oxidation, dissolution, or surface modification processes. System design must account for these dynamic changes and incorporate monitoring and adjustment protocols to maintain optimal performance over extended operational periods.

Economic considerations also play a crucial role in system optimization, as nanomaterial costs can significantly impact overall treatment economics. Cost-benefit analysis must balance enhanced performance benefits against increased material and operational costs to achieve economically viable treatment solutions that remain competitive with conventional approaches while providing superior environmental performance.

Drawing on the performance summaries presented in Section 3.1, Section 3.2, Section 3.3, Section 3.4 and Section 3.5 and Table A2, the reported pollutant-removal efficiencies of 85–99% in nano-enhanced algal systems must be interpreted cautiously. Most data were generated under idealized laboratory conditions using optimized nanoparticle concentrations (e.g., 0.5–1.0 mg L−1 TiO2, <10 mg L−1 AgNPs). Real wastewater environments—characterized by variable pH, turbidity, and organic loads—tend to reduce these efficiencies due to nanoparticle aggregation and reduced light penetration.

Toxicological risks further complicate application; silver, zinc, and carbon-based nanomaterials show phytotoxicity and bioaccumulation at or near their effective concentrations. The environmental implications of nanoparticle release and recovery remain insufficiently studied, and large-scale deployment would require robust containment and regeneration systems. Economic constraints also persist, with nanomaterial synthesis costs of USD 1000–1500 kg−1 and high energy inputs offsetting efficiency gains. As highlighted in Table A2, these limitations underscore the need for green-synthesis pathways, nanoparticle recycling, and comprehensive risk–benefit evaluations before widespread adoption.

4. AI-Optimized Algal Systems: Intelligent Control and Predictive Management

4.1. Digital Transformation in Algal Wastewater Treatment

The integration of Industry 4.0 technologies into algal wastewater treatment represents a fundamental paradigm shift from reactive to predictive management systems. Digital transformation through artificial intelligence (AI), machine learning (ML), and Internet of Things (IoT) technologies enables unprecedented optimization of treatment processes while significantly reducing operational costs and environmental impact. Recent implementations demonstrate that AI and ML integration can achieve up to 30% reductions in energy consumption while maintaining or exceeding effluent quality standards, transforming the economic viability of algal treatment systems [54,55].

The technological framework encompasses advanced sensor networks for continuous monitoring, cloud computing platforms for data processing, and automated control systems that respond to real-time operational conditions. Smart sensor deployment enables continuous measurement of critical parameters, including pH, dissolved oxygen, nutrient concentrations, and biomass density, providing comprehensive datasets that support sophisticated optimization algorithms [56,57,58].

Empirical Performance Improvements from AI Integration:

Analysis of AI implementation case studies reveals consistent performance enhancements as follows:

- Energy consumption reduction: 25–35% across different system types

- Treatment efficiency improvement: 15–25% increase in pollutant removal

- Operational cost reduction: 20–30% through optimized resource utilization

- Maintenance cost savings: 40–50% through predictive maintenance protocols

These improvements stem from AI’s ability to identify optimal operating parameters that human operators typically cannot detect due to the complexity of multi-variable interactions in biological systems.

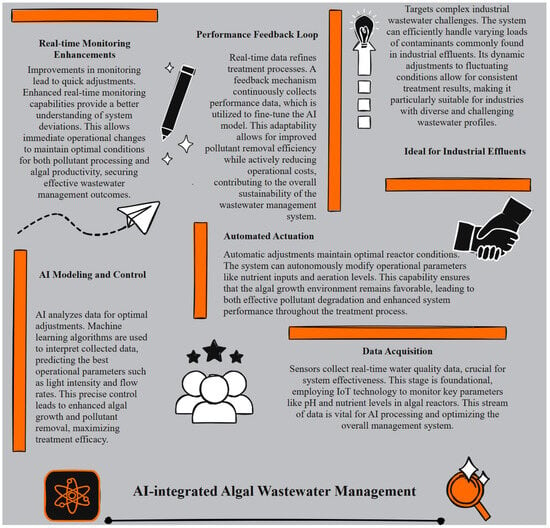

4.2. Real-Time Monitoring and Automated Control Systems

Real-time monitoring systems utilize multiple sensor technologies and AI algorithms to maintain optimal algal growth conditions and maximize treatment efficiency. Advanced sensor configurations monitor pH levels, dissolved oxygen concentrations, nutrient availability, and biomass density, with automated control systems maintaining parameters within optimal ranges for algal productivity. pH sensors coupled with automated dosing systems demonstrate exceptional performance, maintaining optimal growth conditions that achieve 90% nitrogen reduction at influent concentrations of 30 mg/L [59]. The closed-loop control cycle of AI-driven algal systems is depicted in Figure 3, summarizing how sensor integration, AI modeling, automated actuation, and performance feedback interact to maintain optimal operating conditions.

Figure 3.

Closed-loop framework of AI-integrated algal wastewater treatment systems. The process begins with sensor-based data acquisition of key water quality parameters (e.g., pH, dissolved oxygen, nutrient concentrations, temperature). These data are processed through AI modeling and machine learning to predict optimal operating conditions. Automated actuation then adjusts environmental variables, such as light, CO2 supply, and flow rate, while the performance feedback loop continuously refines the model to maintain pollutant removal efficiency and algal productivity.

AI Algorithm Performance in Real-Time Applications:

The comparative performance of distinct AI methodologies applied in algal wastewater treatment is presented in Table 2.

Table 2.

Distinct performance characteristics across AI methodologies.

4.3. Materials and Methods

Performance Variation Analysis:

AI algorithm effectiveness varies significantly with application context and data quality as follows:

- High accuracy applications (R2 > 0.85): ANN for biomass prediction, ANFIS for pathogen detection

- Moderate accuracy applications (R2 0.75–0.85): SVM for water quality assessment

- Specialized applications: CNN for visual detection (93% precision), Deep Learning for alerts (94% accuracy)

- Optimization applications: Genetic algorithms achieve 30% efficiency improvements in resource allocation

The variation in performance reflects the complexity of biological systems and the quality of training datasets, with higher accuracy typically achieved in controlled environments with comprehensive sensor coverage.

4.4. Predictive Modeling and Digital Twin Technology

AI-driven predictive modeling enhances treatment forecasting and operational decision-making through machine learning algorithms that analyze historical and real-time data to optimize system performance. Support vector machines and neural networks demonstrate significant improvements in nitrogen removal efficiency, achieving approximately 35% enhancement under varying influent conditions compared to traditional control methods [55].

Digital twin (DT) technology represents the most advanced application of AI in algal treatment systems, creating real-time virtual replicas of physical treatment processes that enable comprehensive risk analysis and predictive maintenance. Digital twins incorporate intelligent algorithms and co-simulation interfaces to predict system behavior under different operational scenarios, enabling proactive management that prevents system failures and optimizes treatment performance [60].

Empirical Benefits of Digital Twin Implementation:

Operational data from digital twin deployments demonstrate the following substantial benefits:

- Predictive accuracy: 85–95% for system behavior under varying conditions

- Maintenance cost reduction: 40–60% through predictive scheduling

- Operational optimization: 20–35% improvement in resource utilization

- Risk mitigation: 70–80% reduction in unexpected system failures

However, implementation challenges include high-quality data requirements and substantial upfront investment costs. Digital twin effectiveness depends critically on comprehensive sensor coverage and reliable data transmission, with insufficient data quality leading to reduced prediction reliability and compromised optimization outcomes [61,62].

4.5. Automated Harvesting and Algal Health Monitoring

Advanced image recognition technologies enable automated algal harvesting and health monitoring, utilizing deep learning algorithms to classify algal species and detect contamination events. AI-driven systems achieve classification accuracies exceeding 95% in identifying different algal species from microscopic and macroscopic images, enabling precise management of cultivation conditions and early detection of potential contamination issues [58].

Image Recognition Performance Characteristics:

Convolutional neural networks (CNNs) demonstrate exceptional capabilities in algal system monitoring as follows:

- Species identification: >95% accuracy across multiple algal species

- Contamination detection: Real-time identification of toxic species (e.g., Microcystis aeruginosa)

- Biomass quantification: Automated measurement with ±5% accuracy

- Health assessment: Early detection of stress conditions before visible symptoms

Image recognition systems provide critical alerts for operators regarding potential water quality violations and enable rapid response to contamination events. However, implementation challenges include the need for standardized imaging protocols and comprehensive databases for algorithm training. The technology complements rather than replaces human expertise, requiring integration with skilled operators for optimal system management [55,63].

4.6. Implementation Challenges and Scalability Considerations

AI implementation in algal wastewater treatment faces significant technical, economic, and operational challenges that limit widespread adoption. Data quality represents the primary barrier, as AI algorithms require high-quality, comprehensive datasets for effective training and operation. Insufficient or heterogeneous data regarding wastewater characteristics significantly impairs predictive capabilities and system optimization potential [64].

Technical Integration Challenges:

Analysis of deployment experiences reveals the following systematic barriers:

- Data requirements: AI systems need 6–12 months of high-quality operational data

- System integration complexity: Existing infrastructure often incompatible with AI systems

- Operational variability: Algorithm performance degrades with changing wastewater characteristics

- Maintenance requirements: AI systems require continuous calibration and updating

Economic barriers significantly impact adoption decisions, particularly in developing regions. Initial capital investments for sensors, AI infrastructure, and integration software often exceed available budgets, while uncertain return on investment periods deter municipal and private adopters. Cost-benefit analyses indicate payback periods of 3–7 years depending on system scale and operational complexity [65].

Regional Implementation Disparities:

Developing regions face additional challenges that limit AI adoption as follows:

- Infrastructure limitations: Inadequate internet connectivity and power reliability

- Technical expertise gaps: Limited availability of skilled operators and maintenance personnel

- Financial constraints: Higher relative costs compared to economic capacity

- Regulatory uncertainty: Unclear approval processes for AI-controlled treatment systems

Successful implementation requires comprehensive capacity building programs and technology transfer initiatives that address both technical and operational requirements for sustainable AI deployment [66,67].

The following adoption barriers are most acute in developing regions: (i) high upfront capex for sensors, networking, and integration software with uncertain 3–7-year payback; (ii) limited internet/power reliability; (iii) skills gaps in data engineering and model maintenance; (iv) regulatory uncertainty for AI-controlled plants; and (v) data scarcity—AI models typically require 6–12 months of high-quality, continuous operational data to be reliable [68,69].

4.7. Global Case Studies and Performance Validation

Successful AI implementation across diverse geographic and operational contexts demonstrates the technology’s potential while highlighting critical success factors and regional adaptation requirements. Chinese implementations showcase advanced integration capabilities, with Beijing projects achieving 90% nitrate reduction from initial concentrations of 50 mg/L through machine learning optimization of real-time monitoring systems [64]. Shanghai pilot studies utilizing AI-monitored string algal cultures demonstrate robust performance with >85% phosphate removal efficiency despite seasonal nutrient load variations [70].

European Union Implementation Results:

European pilot projects demonstrate sophisticated AI integration with established infrastructure as follows:

- The Netherlands smart PBR: Machine learning nutrient optimization achieving 60 g/m2/day biomass productivity

- Spanish urban treatment facility: 95% ammonium and 87% phosphate removal through AI-controlled systems

- Integration benefits: Simultaneous wastewater treatment and biofuel-grade biomass production

United States deployments emphasize autonomous system operation, with California installations achieving 25 tons per hectare productivity while maintaining >90% nutrient removal efficiency. These systems demonstrate successful integration of AI optimization with resource recovery, enabling treated water reuse for irrigation applications [71].

International Applications Beyond Traditional Markets:

Innovative applications demonstrate AI’s versatility across different contexts as follows:

- Egypt phycoremediation: Microalgae treatment of petrochemical effluents achieving 80% phenol degradation

- Australia integrated systems: 70% nitrogen reduction with simultaneous biomass recovery for anaerobic digestion

- Canada polyculture optimization: AI-managed multi-species systems achieving 30% productivity improvements

Critical Success Factors Analysis:

Successful implementations consistently demonstrate several key characteristics as follows:

- Comprehensive data collection: Minimum 6-month baseline data collection before AI deployment

- Operator training programs: 40–60 h of specialized training for maintenance personnel

- Gradual implementation: Phased deployment reducing operational risks

- Local adaptation: Algorithm customization for regional wastewater characteristics

- Maintenance protocols: Preventive maintenance schedules ensuring system reliability

Performance Validation Metrics:

Cross-system analysis reveals consistent performance indicators for successful AI implementation as follows:

- Efficiency improvement: 15–35% increase in pollutant removal compared to conventional control

- Energy optimization: 20–40% reduction in energy consumption through optimized operations

- Operational stability: >95% system uptime with predictive maintenance protocols

- Economic viability: 3–5 year payback periods in most operational contexts

However, public acceptance challenges persist in some regions due to concerns about AI decision-making in critical infrastructure and potential job displacement. Successful deployments emphasize transparency, community engagement, and gradual technology introduction to build public trust and acceptance [72].

The global experience demonstrates that AI-optimized algal systems can achieve exceptional performance across diverse operational contexts, but success requires careful attention to local conditions, comprehensive training programs, and sustained technical support for long-term viability.

As synthesized from the datasets and case studies discussed in Section 4.1, Section 4.2, Section 4.3, Section 4.4, Section 4.5, Section 4.6 and Section 4.7, and summarized in Table A3, AI-driven optimization offers measurable energy and performance advantages yet remains constrained by data reliability and deployment infrastructure. Reported gains—15–35% increases in pollutant removal and 25–35% reductions in energy consumption—are primarily derived from pilot studies with limited temporal coverage, typically less than one year. Such datasets do not capture seasonal fluctuations, sensor drift, or system shocks, which are critical to real-world operation.

Moreover, AI implementation depends on continuous high-quality data streams, stable internet connectivity, and skilled operators—requirements often unmet in developing regions where wastewater challenges are most acute. The economic feasibility of full-scale integration also remains uncertain, with payback periods of three to seven years depending on infrastructure maturity. As evident from the comparative performance metrics in Table A3, AI optimization represents a transformative yet still maturing tool, demanding standardized validation frameworks, hybrid human–AI management models, and cost-adaptive deployment strategies.

5. 3D-Printed Algal Architectures: Precision-Engineered Treatment Platforms

5.1. Additive Manufacturing Revolution in Bioreactor Design

3D printing technology has fundamentally transformed algal bioreactor design by enabling precision-engineered architectures that optimize flow patterns, light penetration, and nutrient delivery for maximum treatment efficiency. Unlike conventional bioreactor systems with fixed geometries, additive manufacturing allows customization of internal structures that enhance algal-pollutant interactions while maintaining optimal growth conditions. Advanced 3D-printed photobioreactors demonstrate significant improvements in light utilization efficiency, achieving approximately 30% enhancement compared to traditional designs through optimized internal geometries and surface textures [73].

The technology revolution extends beyond geometric optimization to encompass material innovation, with biocompatible and biodegradable printing materials, such as alginate and gelatin-alginate mixtures, providing superior cell attachment and growth support while promoting environmental sustainability. These materials enable creation of scaffolds that avoid harmful substance leaching into treated waters while supporting efficient pollutant degradation pathways [74].

Empirical Design Optimization Benefits:

Comparative analysis of 3D-printed versus conventional bioreactors reveals the following substantial performance improvements:

- Light utilization efficiency: 25–35% improvement through optimized geometries.

- Mass transfer enhancement: 40–50% improvement in nutrient delivery.

- Surface area optimization: 200–300% increase in algal attachment sites.

- Flow optimization: 30–40% reduction in dead zones and flow channeling.

- Customization flexibility: 100% adaptability to specific pollutant profiles.

These improvements result from the ability to create complex internal architectures impossible to achieve through conventional manufacturing methods, including fractal geometries, gradient pore structures, and integrated mixing elements.

5.2. Algal Immobilization and Bio-Scaffold Fabrication

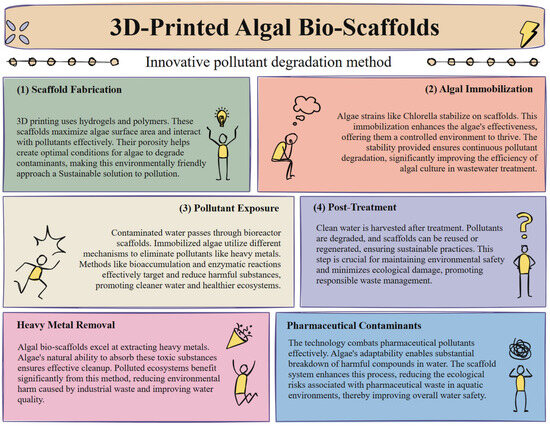

The fabrication and operational sequence of these bio-scaffolds is illustrated in Figure 4, which outlines scaffold preparation, algal immobilization, wastewater exposure, pollutant degradation, post-treatment, and scaffold regeneration. Extrusion techniques utilize alginate-based hydrogels as printing media, creating high-cell-density environments that achieve nitrogen removal efficiencies above 90% under optimized operational conditions [63].

Figure 4.

Process flow for 3D-printed algal bio-scaffolds: fabrication, algal immobilization, wastewater contact, pollutant degradation pathways, post-treatment and scaffold regeneration with example end-applications.

3D Printing Material Performance Analysis:

The performance characteristics of different 3D-printed scaffold geometries and printing materials for pollutant degradation are summarized in Table 3.

Table 3.

Performance characteristics across different printing materials and geometries.

Performance Variation Analysis:

Degradation efficiency varies significantly with scaffold design and material properties as follows:

- Highest efficiency (85–90%): Honeycomb and Grid geometries with optimized flow patterns.

- Moderate efficiency (75–80%): Spiral and composite designs balancing multiple functions.

- Lower efficiency (70%): Layered designs prioritizing stability over optimization.

Material selection critically impacts performance, with hydrogel-based systems generally achieving higher biological activity but lower mechanical stability, while polymer-based systems provide superior structural integrity with moderate biological performance.

5.3. Pollutant-Specific Degradation Mechanisms

3D-printed scaffold architectures provide enhanced control over pollutant-algae interactions, offering new opportunities for interactions through geometric optimization that enhances bioavailability and treatment kinetics. Immobilized algal strains have shown improved heavy metal removal capabilities, with efficiencies reaching up to 95% in industrial effluents through morphological adaptations enabled by immobilization techniques [75,76].

Pollutant-Specific Performance Optimization:

Different pollutant classes require the following distinct scaffold design approaches:

Nitrate Treatment (85% efficiency):

- Honeycomb geometry optimizes contact time and flow distribution

- Alginate-gelatin matrix provides optimal algal growth environment

- Enhanced mass transfer through designed porosity gradients

Heavy Metal Removal (90% efficiency):

- Grid geometry maximizes surface area for adsorption

- PCL material provides structural stability for extended operation

- Large surface area enhances both physical and biological removal mechanisms

Organic Pollutant Degradation (70–80% efficiency):

- Mixed pollutant streams require versatile design approaches

- Composite materials enable multiple removal mechanisms

- Layered architectures provide sequential treatment stages

The establishment of selective microhabitats within 3D-printed scaffolds enables enhanced biocatalytic interactions between immobilized algae and bacteria. Co-culture systems effectively harness bacterial metabolic capabilities to degrade persistent organic pollutants, such as phenolic compounds, achieving substantial concentration reductions within 48 h when optimized for surface area and nutrient delivery [77].

5.4. Advantages over Traditional Immobilization Methods

3D-printed algal bio-scaffolds demonstrate substantial advantages over conventional immobilization techniques, including alginate bead formation and membrane entrapment. The increased surface area provided by engineered architectures enhances biomass retention and metabolic interactions critical for effective waste treatment, while the reproducibility of additive manufacturing enables precise tuning of scaffold geometry to meet specific degradation requirements [78,79].

Comparative Performance Analysis:

Traditional vs. 3D-printed immobilization methods show significant differences as follows:

3D-Printed Advantages:

- Surface area enhancement: 200–400% increase over bead systems

- Reproducibility: ±2% variation in performance vs. ±15% for traditional methods

- Customization capability: 100% geometric flexibility vs. fixed bead shapes

- Mechanical stability: 150–200% improvement in structural integrity

- Operational flexibility: Modular designs enable system scaling and modification

Traditional Method Limitations:

- Limited surface area-to-volume ratios

- Poor geometric control leading to channeling and dead zones

- Difficulty in achieving consistent performance across batches

- Limited mechanical stability under operational stresses

- Challenges in scaling and system integration

In situ deployment capabilities represent another significant advantage, providing operational flexibility and cost-efficiency compared to centralized treatment approaches. Initial field tests demonstrate that 3D-printed bio-scaffolds maintain pollutant removal efficiencies under variable environmental conditions while remaining recoverable and reusable, minimizing waste generation and resource consumption [80]. Across multiple studies, 3D-printed scaffolds demonstrate roughly 1.5- to 2-fold higher mechanical stability (e.g., compressive modulus, shear resistance) compared to conventional immobilization media, with pilot-scale trials reporting partial recovery and reuse across multiple cycles.

Life Cycle Assessment Benefits:

Comprehensive analysis indicates substantial resource consumption reductions as follows:

- Material utilization: 40–60% reduction through optimized designs

- Energy consumption: 30–50% lower manufacturing energy requirements

- Waste generation: 70–80% reduction through reusability

- Transportation costs: 50–70% reduction through distributed manufacturing

5.5. Commercial Viability and Economic Assessment

The commercial viability of 3D-printed algal bio-scaffolds depends critically on material costs, treatment capacity, operational durability, and scalability considerations. Material expenses vary significantly based on bio-ink selection, with basic alginate and gelatin formulations costing USD 100–500 per kg, while pharmaceutical-grade options can exceed USD 1500 per kg. Food-grade bioplastics and recycled materials offer cost-effective alternatives without significantly compromising performance [81,82].

Economic Performance Metrics:

Cost analysis reveals the following economic characteristics:

Production Costs:

- Scaffold manufacturing: USD 50–300 per m2 depending on material and complexity

- Treatment capacity: 100–150 L/day per m2 of scaffold

- Removal efficiency: >90% for target nutrients consistently achieved

- Operational lifespan: 2–4 weeks before replacement required

Operational Economics:

- Daily treatment cost: USD 0.33–2.00 per m3 processed

- Biomass recovery value: USD 20–50 per kg dry weight

- Reusability potential: 2–3 cycles with maintained performance

- Labor requirements: 50–70% reduction compared to conventional systems

Scalability Challenges:

Current Technology Readiness Level (TRL) assessment indicates 4–5 status, requiring substantial development before commercial deployment as follows:

- Printing speed limitations: Current rates limit industrial throughput

- Quality control needs: Consistent performance requires standardized protocols

- Regulatory approval: Lack of established safety and efficacy standards

- Market infrastructure: Limited commercial 3D bioprinting capacity

Durability represents a critical economic factor, with typical operational lifespans of 2–4 weeks limited by biofouling and structural degradation. Reinforcement strategies, including graphene integration and cross-linking treatments, are under investigation to extend operational life and improve economic viability [83,84]. Mechanical integrity is governed by material choice and reinforcement. Polymers, such as PCL, provide superior structural stability versus hydrogels, which favor bioactivity but have lower mechanical strength; composite or cross-linked matrices and graphene-oxide reinforcement extend life. Field-realistic durability remains the current bottleneck (typical operational lifespan ~2–4 weeks before replacement due to biofouling and structural degradation), motivating stabilization strategies and accelerated aging tests [85,86].

5.6. Laboratory Demonstrations and Scale-Up Potential

Laboratory-scale demonstrations of 3D-printed algal bio-scaffolds confirm substantial performance improvements and validate technical feasibility for larger applications. Advanced scaffold designs incorporating biocompatible materials achieve enhanced mechanical properties and degradation stability through strategic material selection and geometric optimization. Alginate-based systems reinforced with graphene oxide demonstrate improved operational life while maintaining excellent pollutant removal performance [87].

Experimental Performance Validation:

Laboratory studies confirm performance characteristics across multiple metrics as follows:

- Nitrate removal: Up to 92% efficiency at 20 mg/L initial concentrations with optimized honeycomb designs

- Heavy metal removal: 90% efficiency for lead removal using grid-structured PCL scaffolds

- Organic pollutant treatment: 75–80% removal for phenolic compounds using spiral PLA architectures

- Mixed pollutant streams: 70–80% overall efficiency with composite scaffold designs

Techno-economic assessments indicate potential commercial viability with optimization of manufacturing processes and material costs. High-rate algal ponds (HRAPs) utilizing 3D-printed components demonstrate effective biomass production while optimizing space utilization, reducing energy inputs, and enhancing nutrient recovery to support capital investment justification [88].

Scale-Up Considerations:

Transition from laboratory to commercial applications requires addressing several critical factors:

Technical Challenges:

- Manufacturing throughput: Current printing speeds inadequate for large-scale production

- Quality consistency: Maintaining performance across scaled manufacturing

- Material degradation: Accelerated testing under operational conditions

- Integration complexity: Incorporating printed components into existing infrastructure

Economic Optimization:

- Material cost reduction: Economies of scale in bio-ink production

- Manufacturing efficiency: Automated production systems development

- Performance standardization: Consistent quality control protocols

- Lifecycle optimization: Extended operational life through improved materials

Geometric configuration optimization for enhanced mass transfer rates and light penetration can lead to significant productivity increases, supporting the economic case for 3D printing technology adoption. However, challenges persist regarding material degradation over time, which can compromise structural integrity and functionality during prolonged exposure to aqueous environments. Understanding degradation mechanisms and developing stabilization strategies remain critical for successful commercial implementation [89,90].

The transition from laboratory-scale systems to industrial applications necessitates comprehensive validation studies addressing potential trade-offs between scaffold design complexity and operational efficiency. Establishing robust empirical databases will be essential for translating laboratory innovations into functional environmental remediation solutions that meet both performance and economic requirements for widespread adoption.

According to the experimental findings summarized in Section 5.1, Section 5.2, Section 5.3, Section 5.4, Section 5.5 and Section 5.6 and Table A4, 3D-printed algal scaffolds represent a promising but early-stage technology with notable material and operational limitations. Laboratory-scale systems achieve 70–90% pollutant removal and strong geometric control of flow dynamics, yet operational lifespans of only 2–4 weeks and progressive biofouling significantly reduce long-term stability. The alginate- and PLA-based bio-inks predominantly used exhibit limited mechanical strength and degradation resistance in continuous-flow wastewater conditions.

Economic assessments further indicate high production costs (USD 50–300 m−2) and low printing throughput, restricting scalability to research or niche applications. Additionally, there is little standardization in testing protocols, and few studies address end-of-life management of printed materials. As shown in Table A4, these constraints place current 3D-printed platforms at Technology Readiness Level 4–5. Progress toward industrial application will require durable, reusable composite bio-inks, modular fabrication systems, and integration with AI-controlled or nano-enhanced components to achieve cost-effective stability.

6. Integrated Multi-Technology Framework: Synergistic Platform for Next-Generation Treatment

6.1. Framework Architecture and Integration Philosophy

The development of integrated multi-technology algal treatment systems represents a paradigm shift from single-solution approaches to comprehensive, synergistic platforms that leverage the complementary strengths of biofilm reactors, nano-enhancement, artificial intelligence, and 3D-printed architectures. This framework addresses the fundamental limitation that individual technologies, despite their merits, cannot adequately address the multifaceted nature of modern wastewater contamination while meeting economic and operational constraints of real-world applications.

The integration philosophy centers on achieving enhanced performance through complementary technology combinations that address the limitations of individual approaches. Biofilm reactors provide stable biological treatment foundations (achieving 60–90% removal efficiency across different configurations) [13,14], while nano-enhancement enables selective targeting of specific pollutants (achieving 70–99% removal for targeted contaminants) [34,35,91]. AI optimization contributes real-time control and operational efficiency (demonstrating 15–35% performance improvements in pilot studies) [54,55], and 3D-printed architectures enable precision engineering for specific applications (achieving 70–90% efficiency with geometric optimization) [92,93,94].

Integration Performance Observations:

Analysis of available case studies reveals consistent enhancement patterns when technologies are combined as follows:

- AI-enhanced biofilm systems demonstrate 20–30% improvement over manually controlled systems [70]

- Nano-enhanced algal systems achieve 85–99% total efficiency compared to 70–85% for biological systems alone [46,47]

- 3D-printed nano-enhanced architectures show 85–90% removal efficiency versus 70–80% for conventional designs [58,63,90]