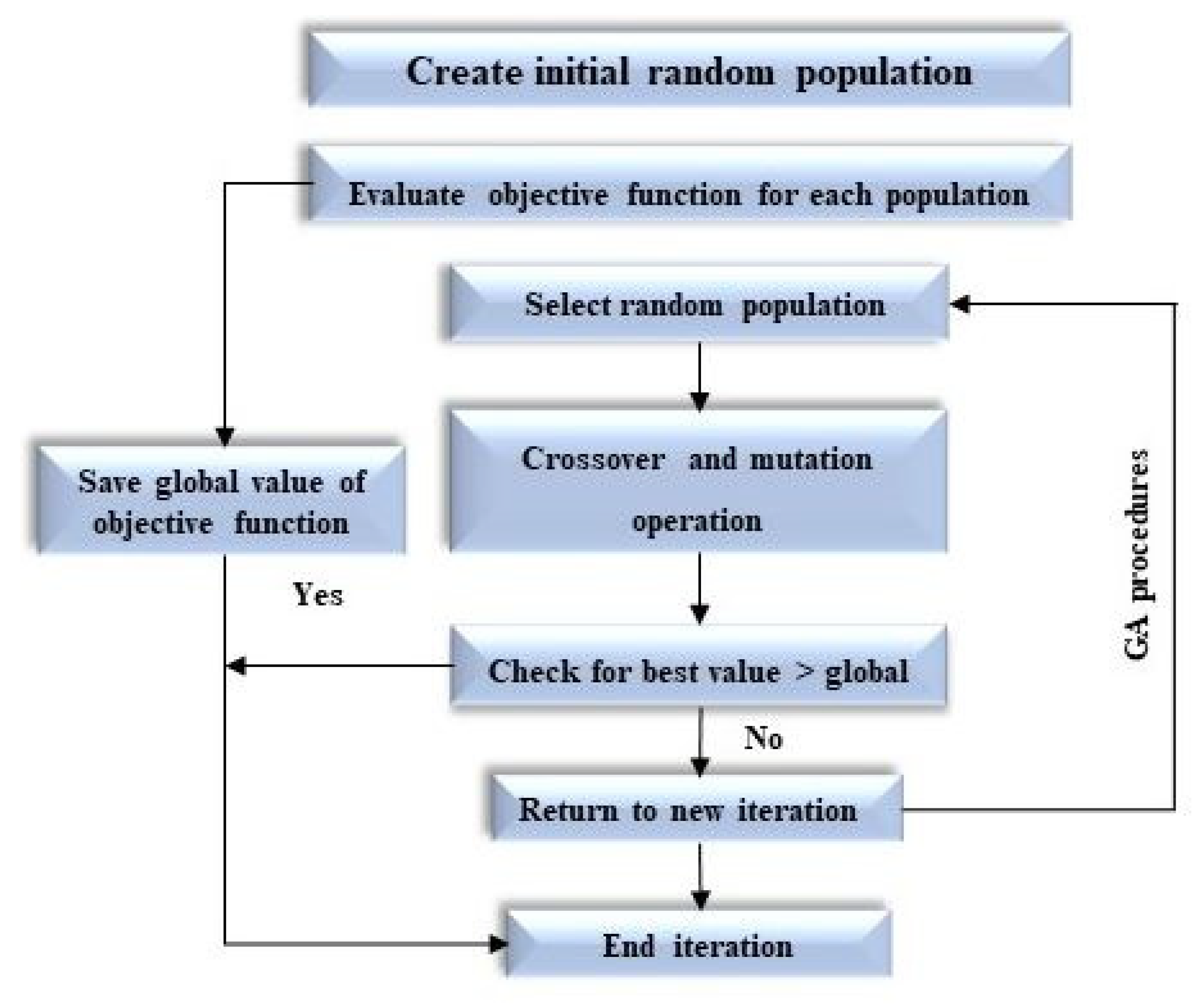

The optimization investigation focuses on using a GA to find the best operating parameters for the maximum gain output ratio and the minimum thermal energy ratio. MATLAB, which has been used in the present study, as is often the case, is an extremely potent tool for several engineering applications that involve numerous answers.

Application of GA in MSF-BR

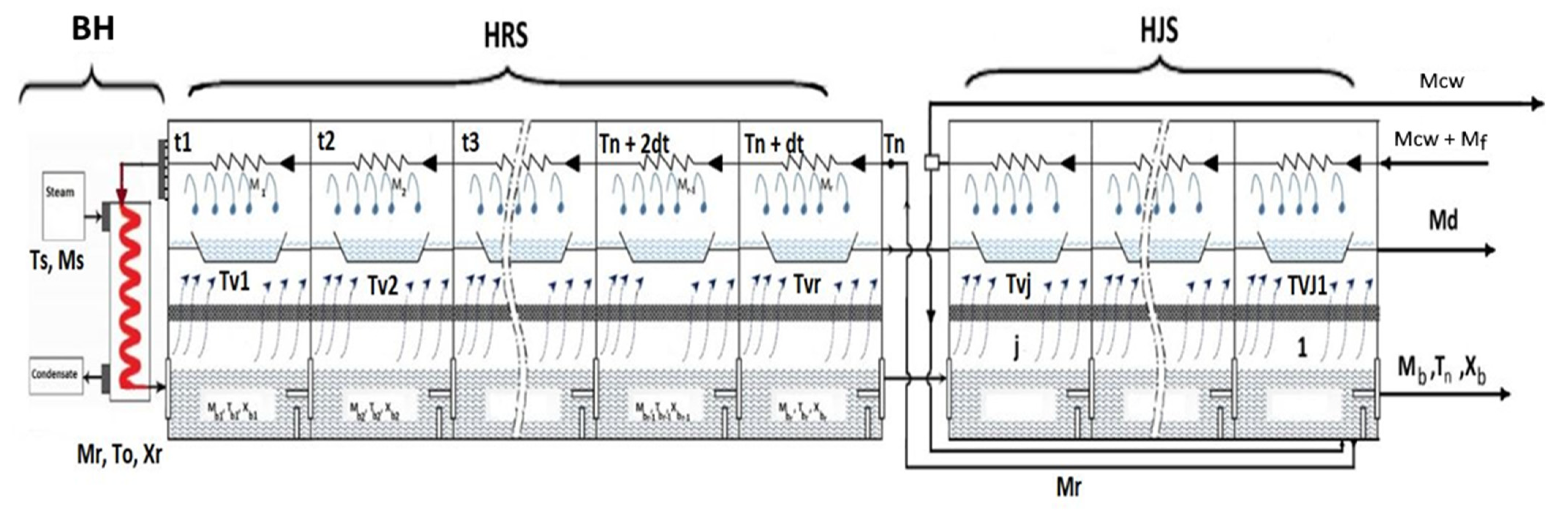

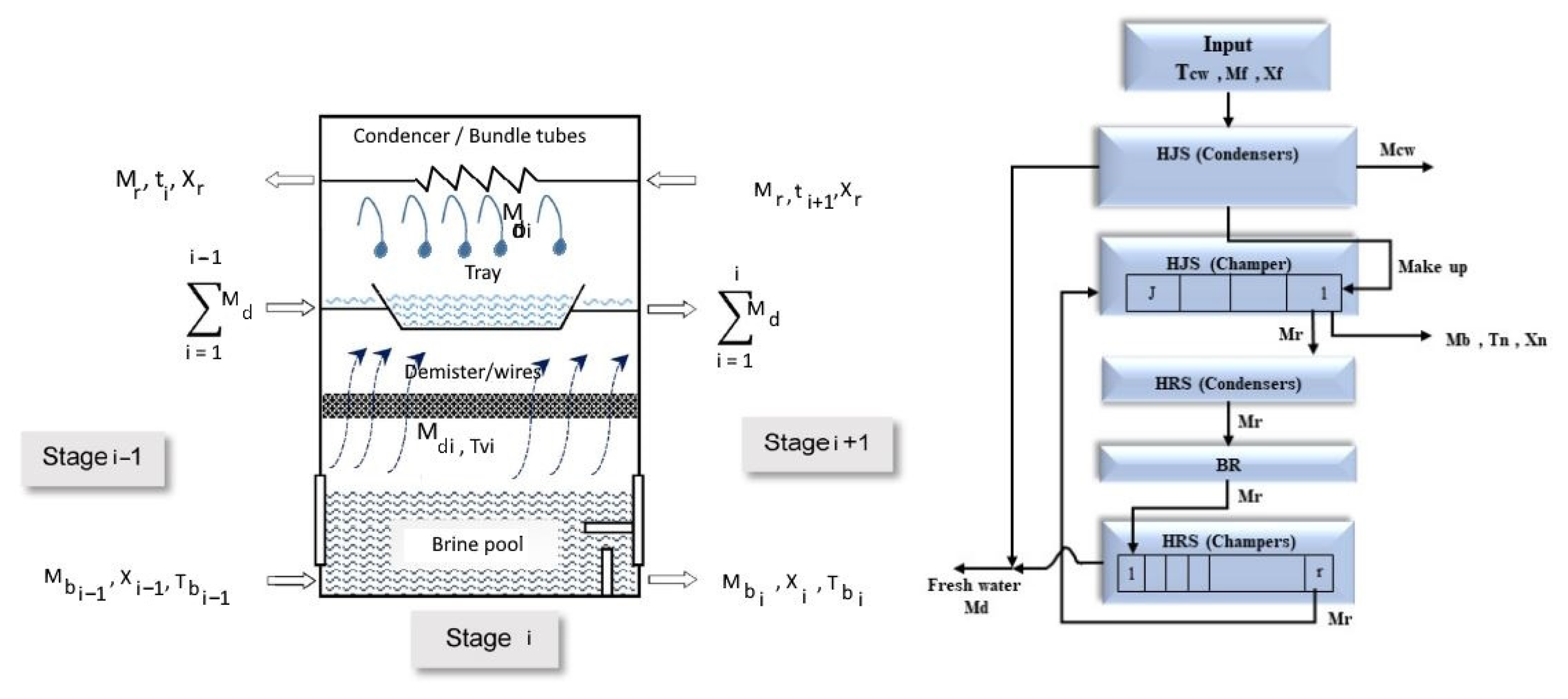

As shown in

Figure 3, the GA generates a set of solutions for random values of the MSF-BR operating variables. These random values generate a set of solutions to the objective function used in the problem. By comparing all the resulting solutions, the best solution will be selected from them. After finding the best solution, the GA will be used again via crossover and mutation operations to recalculate the objective function, compare it with the current solution, and extract the best solution among all the solutions.

After the components of the objective function are identified, they are optimized to allow adjustment of operating variables and ensure the optimal process gain output ratio. As mentioned previously, the optimization problem is to find the best combination of operating variables that maximizes the GOR and minimizes the RR, while satisfying the imposed constraints. The genetic algorithm was applied over a 12-month period (January to December) to provide seasonal operational recommendations.

Clarification is required regarding the fact that this study selected an MSF-BR plant that is scheduled to be maintained and cleaned during the month of December for all condenser tubes and stages. This study was conducted across all 12 months of the year to provide recommendations. This involves selecting December as the appropriate month for maintenance, ensuring that December is indeed the right choice. Based on Tf temperature, this determination was made from the perspective of improving plant gain output ratio and production ratio.

In order to be able to adapt our seasonal operation strategy to the entire year, the best seasonal operation strategy can be developed by solving the optimization problem. Consequently, solving the optimization problem can lead to a wide range of solutions for MSF-BR. In order to be able to adapt our seasonal operation strategy to the entire year, the best seasonal operation strategy can be developed by solving the optimization problem. Consequently, solving the optimization problem can lead to a wide range of solutions for MSF-BR. For example, as reported in

Table 5, if we investigate the operating minimum and maximum limitation (

Table 3) variables and their corresponding obj-f for March, the results reveal that the solutions did not incorporate the optimum GOR and obj-f. This is attributed to the restricted temperature (20.5 °C), indicating that the maximum

GOR and obj-f of 9.36 and 9.26, respectively, were achieved at T

s = 105.8 °C, n = 23, T

o = 96 °C, M

cw = 530.8 kg/s, and M

f = 2084.88 kg/s. It is also worth noting that the number of HJS remains constant for all the solutions. Also, the minimum GOR (1.08) and obj-f (0.19) resulted when the T

s, T

o, M

f, M

cw, and n, were 107.95 °C, 103.48 °C, 1723.83 kg/s, 1468.33 kg/s, and 15, respectively. Also, it must be noted that when M

f and M

cw were reduced by 35% and 51%, respectively, the obj-f increased 28% when the operating parameters were held constant (T

s = 113.8 °C, T0 = 89.7 °C, n = 19).

Figure 4 shows a graphical representation of the results for all months. The values of the operating state associated with optimum condition that were obtained by the GA technique do not guarantee a global optimal solution [

47]. Furthermore, the optimization results indicate that the thermal energy ratio decreases as the gain output ratio increases. The results illustrated in

Figure 4 show that the rising and falling obj-f behavior is consistent across all months. Examining the months from December to May reveals that the highest obj-f values for all were above 8, with the maximum obj-f achieved in February. In the months from June to November, the obj-f values followed a similar trend in that they all surpassed, with the highest obj-f occurring in September (RR < 0.2 and GOR > 9.5). Furthermore, the values obtained in September were less dense (points) compared to the other months, meaning that the number of obtained solutions was less than that obtained in other months. The results obtained revealed that the T

s was in the range of 98.21 °C (January) to 115.45 °C (June), T

o was in the range of 90.1 °C (January) to 107.71 °C (August), the Tn was in the range of 32.24 °C (January) to 40.13 °C (June), J was in the range of 1–2 for all months except May, and n was in the range of 19 (January) to 25 (August). These values were reflected in the obj-f and GOR values.

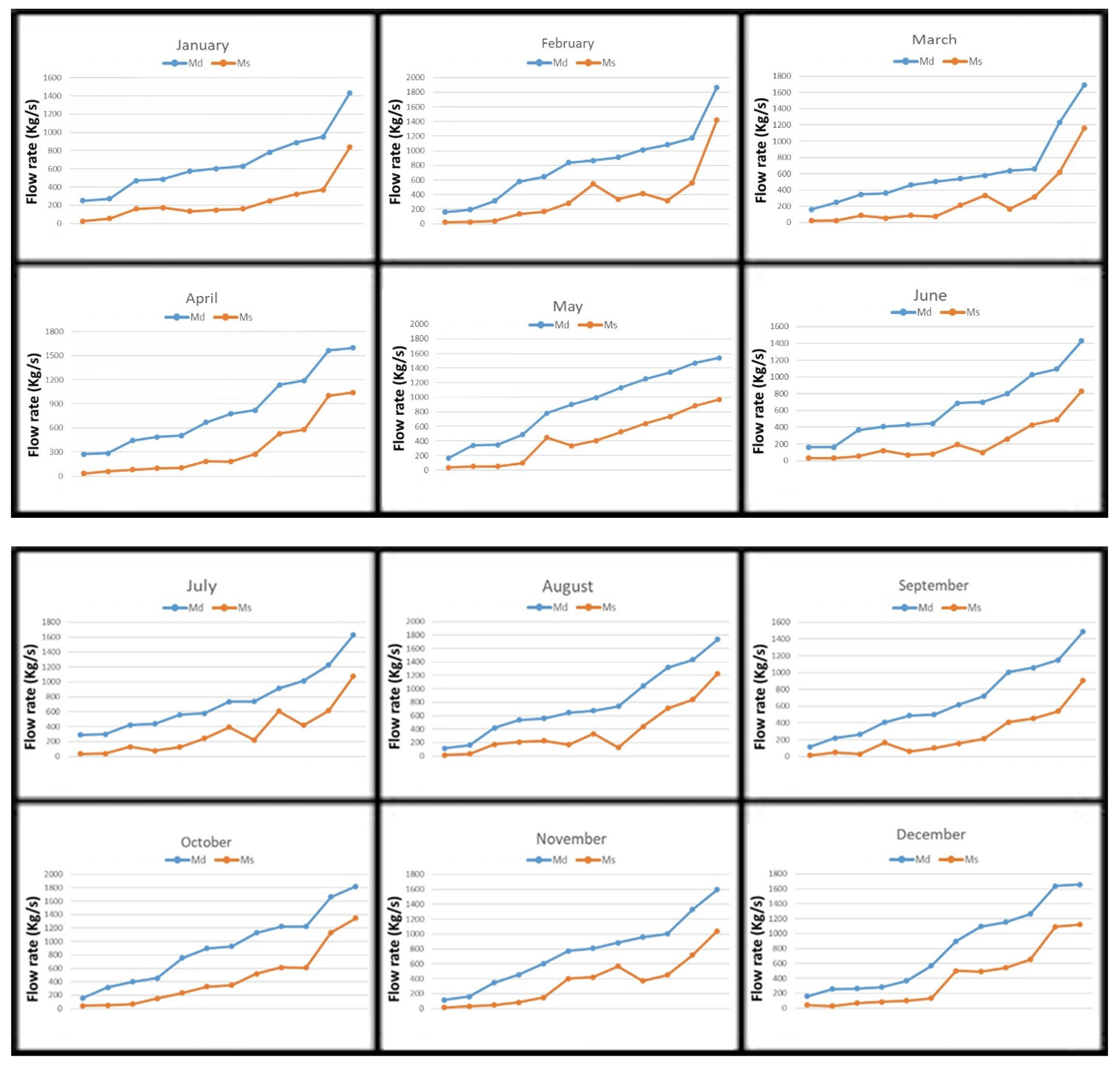

The rate of steam increases the rate of distillation production, according to a comparative study of the optimization findings.

Figure 5 illustrates the variety in production capacity over all months regarding the steam flow rate. The results revealed that an increase in the steam flow rate difference by a factor of 26.47 achieved a difference by a factor of 7.91 increase in the production rate (160.38 to 1428.49 kg/s) in June, while in October, when the steam flow differed by a factor of by 85.37, only a difference by a factor of 15.14 increase was observed in the distilled production rate. It is necessary to indicate that the results outlined in

Figure 5, and supported by

Table 5 and

Figure 4, demonstrate that the increase in production capacity is correlated with the increase in drive steam flow rate in the heater, which drives the desalination process across all stages of MSF-BR. The maximum increase in production capacity does not necessarily imply the optimal solution or the highest gain output ratio for the plant. It is crucial to establish connections between various operation factors and link different solutions for the optimal gain output ratio and obj-f.

The results have revealed the obj-f for all months of the year (

Table 5 and

Figure 4 and

Figure 5) and the results of optimal solutions during station operation. It has been determined that December is not the most suitable period for maintenance. Instead, the optimal choice is to schedule maintenance in January, as it proves to be the least favorable month in terms of GOR improvement. The increase in the steam flow rate difference by a factor of 27.13 (41.31 to 1120.65 kg/s) achieved a difference by a factor of 10.41 increase in the production rate (159.19 to 1120.65 kg/s) in December (

Figure 5), while an increase in steam flow difference by a factor of 33.29 led to an increase difference of by a factor of only 5.72, Also, the GORs were 9.14 and 8.87, and the obj-fs were 1.15 and 8.79, respectively, in December and January.

Summative assessments of the results obtained for 12 months (January to December) are displayed in

Table 6 and are as follows: the values of the current operating parameters, the values of their equivalent obj-f, and the difference between the obj-f values at specific Tf and the optimum value of the obj-f obtained by the GA. The optimum obj-f obtained by the GA (9.26) was achieved by the optimum solutions for the T

s, T

o, n, J, M

f, M

cw, and T

f of 98.68 °C, 95.62 °C, 21, 2, 1571.18 kg/s, 1624.24 kg/s, and 33.39 °C. The maximum difference between the obj-f and optimum obj-f (0.101) was achieved in January with GORs of 8.87 and 8.79 for obj-f, while the minimum difference was achieved in June with GORs of 9.73 and 9.64 for obj-f. Also, as reported in

Table 5, the best GOR and obj-f among all months were in June, with 9.64 and 9.59 for the

GOR and obj-f, respectively. The closest month to the optimum solution with respect to T

f = 33.39 °C was August at T

f = 33.8 °C, which achieved 9.59 and 9.4 for the GOR and obj-f, respectively.

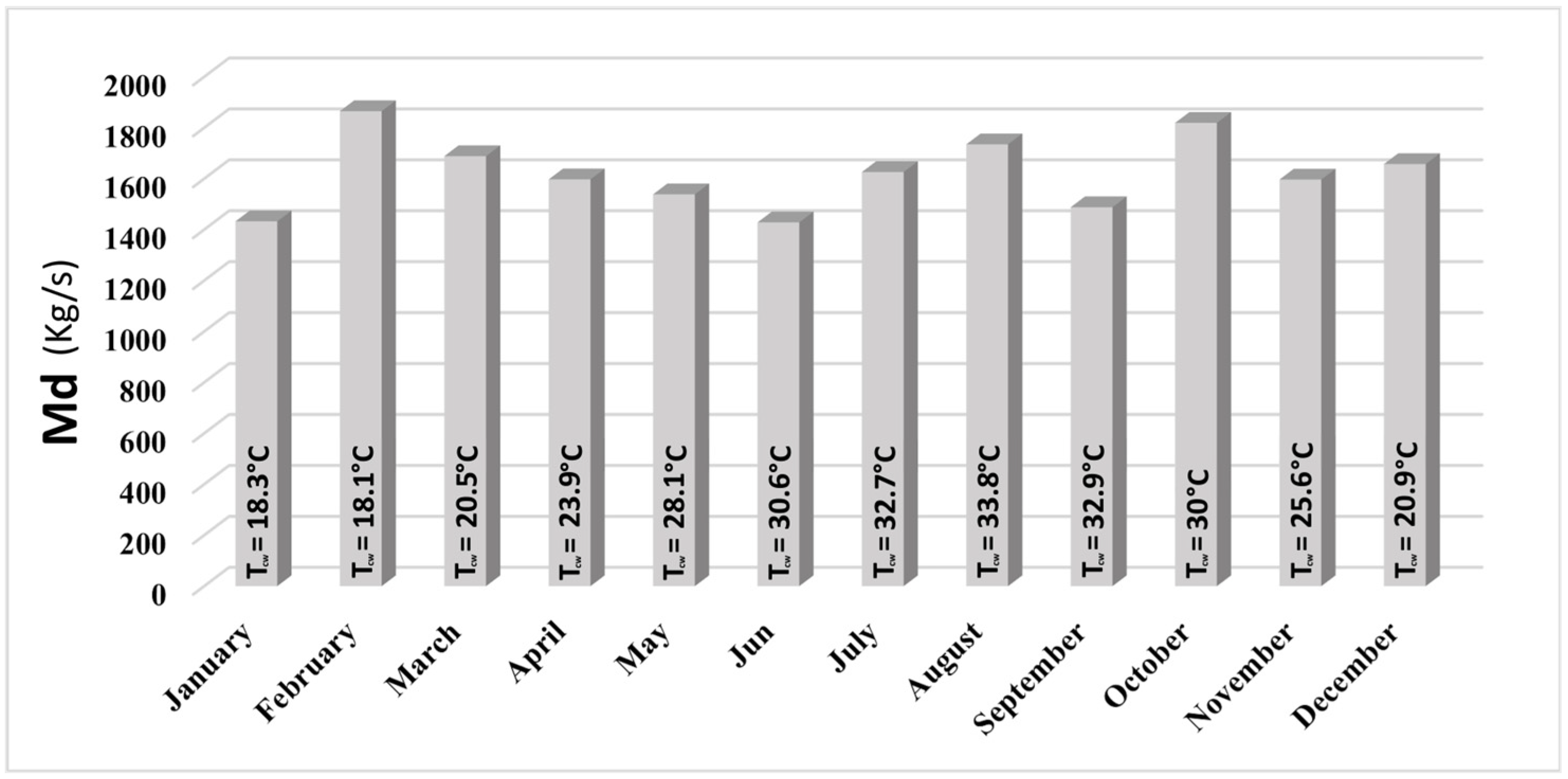

Based on values in

Table 3,

Figure 6 shows all the operation variables fixed at their minimum limitation values. Only n and J varied between the minimum and maximum limitations, taking the highest production capacity of the plant for each month. This condition was reflected in the GOR value. In addition, the maximum production capacity M

d was achieved in February (T

f = 18.1 °C) at the minimum limitation of operation variable values, while the minimum resulted in Jun (1428.487 kg/s) and January (1432.647 kg/s).

As reported in

Table 7, the results obtained in this investigation revealed that the GOR achieved an increment of 42.87% in comparison with the GOR of the current operation of the MSF-BR plant [

37] and by 29.39% in comparison with the investigation study implemented by Ben Ali and Kairouani [

30]. The obtained difference might be attributed to the fact that the MSF-BR operation is run under operating conditions that deviate from the optimum operating conditions proposed by the GA technique. Furthermore, the current values of the operating state are associated with an optimum condition that was not obtained by the GA resolution. However, a minimum deviation of only 2% was recorded in July, which emphasizes the fact that the real operating conditions are almost at the optimal level. However, a maximum deviation of 10% was noted in January.