Volatile Fatty Acids from Household Food Waste: Production and Kinetics

Abstract

1. Introduction

2. Materials and Methods

2.1. Food Waste and Inoculum

2.2. Experimental Setup

2.3. Analytical Methods

Propionic acid concentration · (COD of propionic acid/COD of acetic acid) =

Propionic acid concentration · (1.512/1.066) = Propionic acid concentration · 1.418

Butyric acid concentration · (COD of butyric acid/COD of acetic acid) =

Butyric acid concentration · (1.816/1.066) = Butyric acid concentration · 1.704

Valeric acid concentration · (COD of valeric acid/COD of acetic acid) =

Valeric acid concentration · (2.037/1.066) = Valeric acid concentration · 1.911

3. Results and Discussion

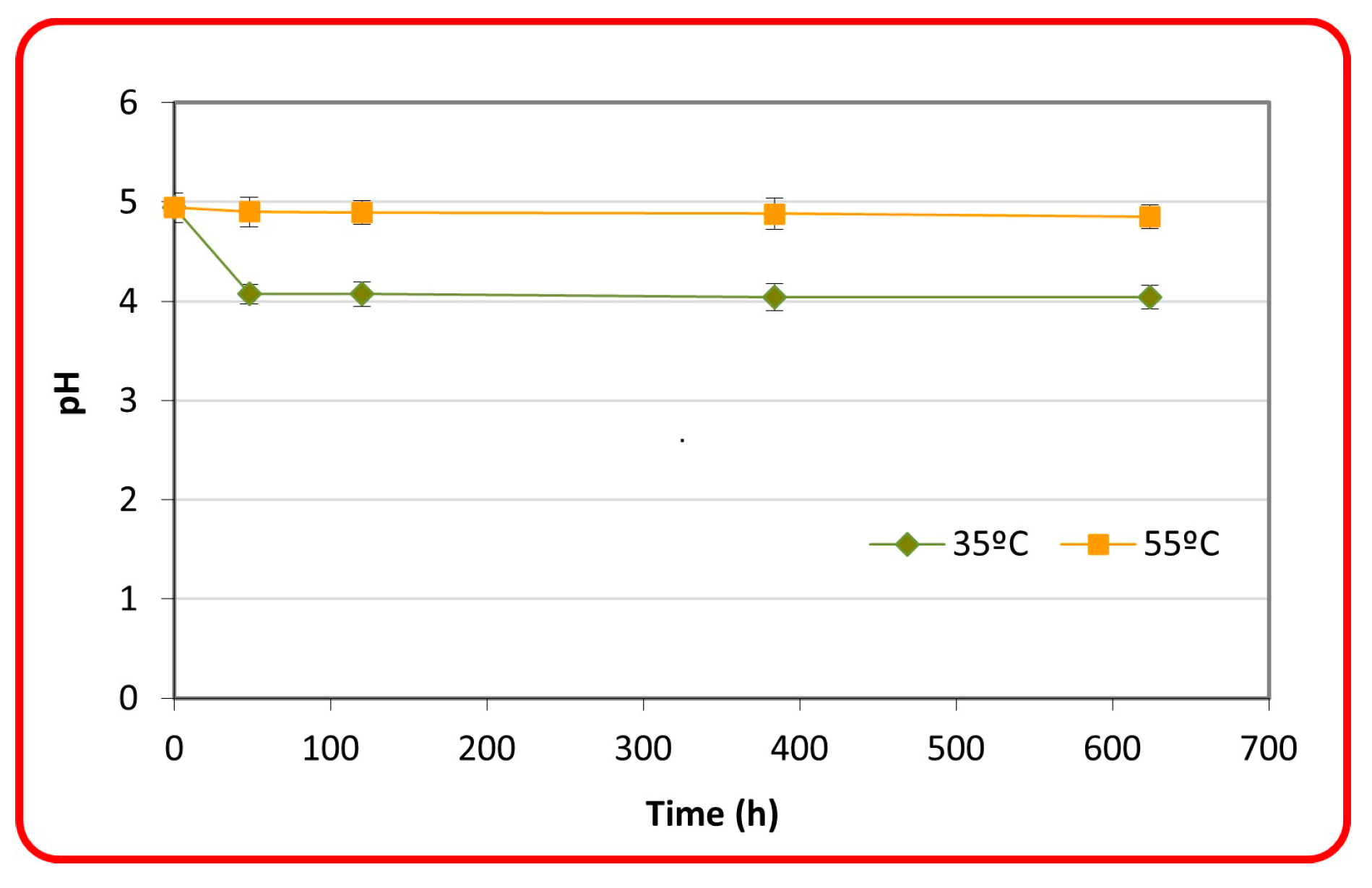

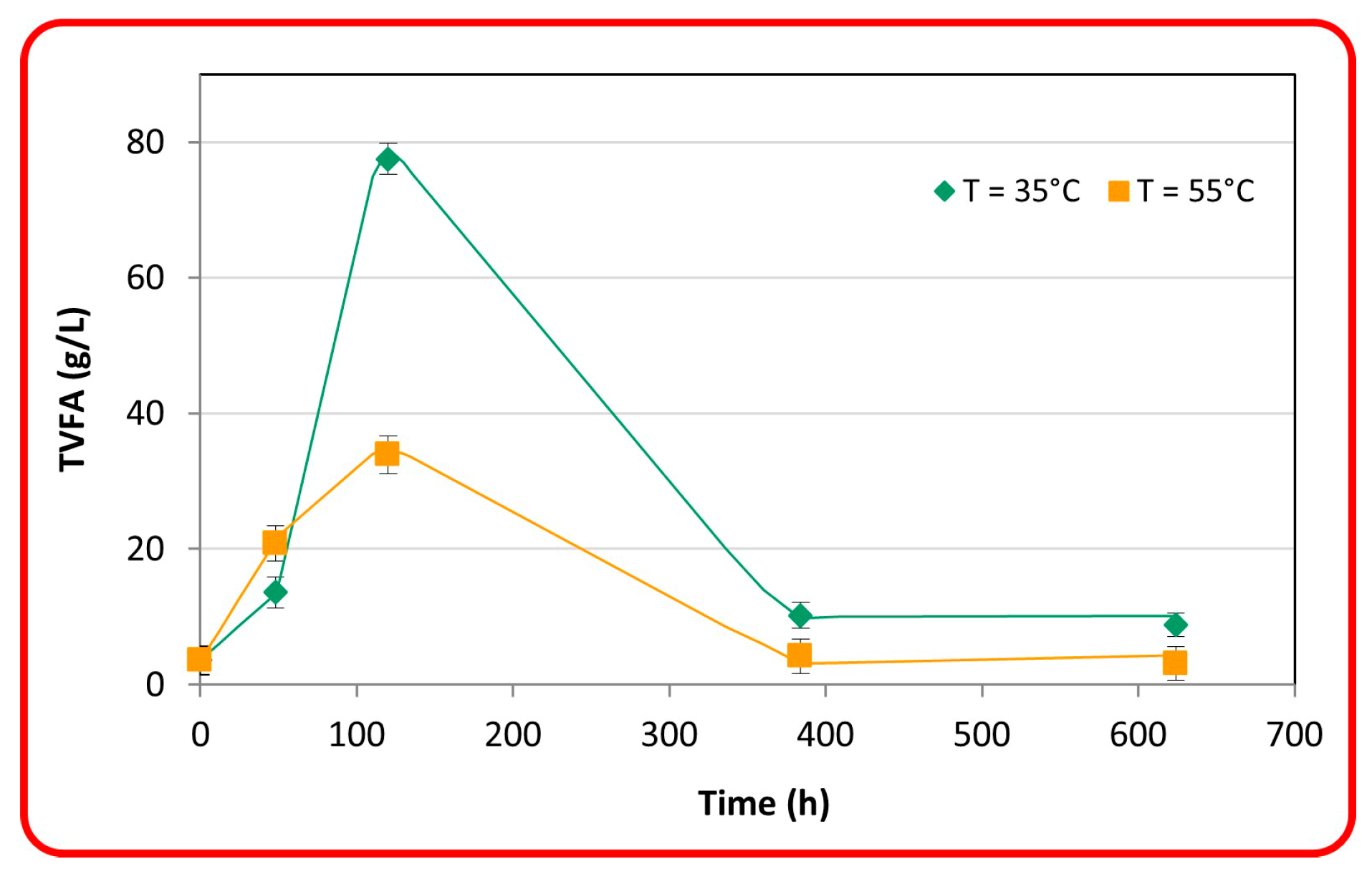

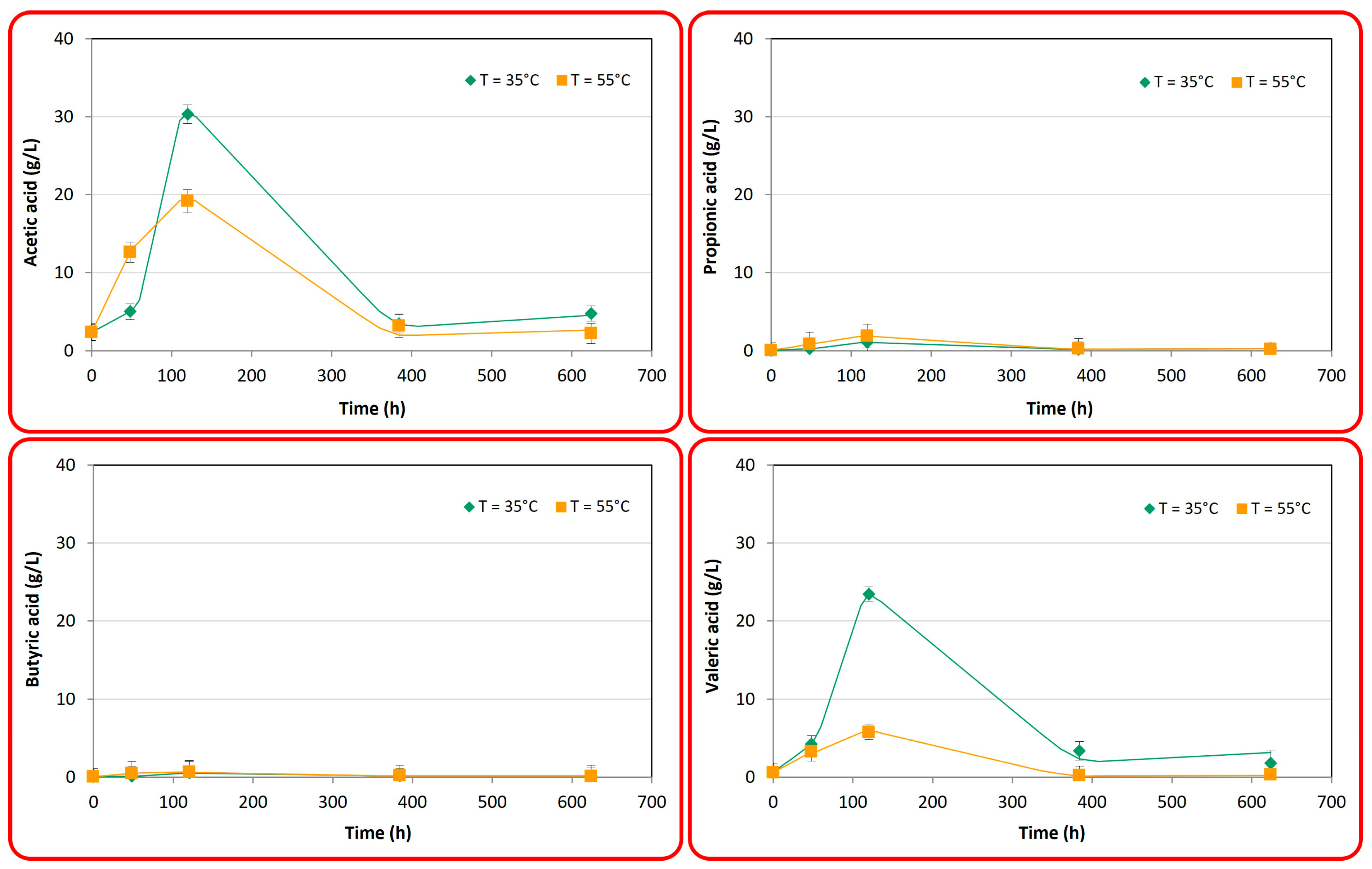

3.1. Volatile Fatty Acid (VFA) Production

3.2. Kinetic Model for Batch Anaerobic Digestion of Food Waste

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Worldometer. Población Mundial. Available online: https://www.worldometers.info/es/poblacion-mundial/ (accessed on 5 August 2024).

- Eurostat. Food Waste and Food Waste Prevention. Available online: https://ec.europa.eu/eurostat/databrowser/view/env_wasfw/default/table?lang=en (accessed on 5 August 2024).

- Vidal, C. Food Waste and Waste Activated Sludge Conversion into Volatile Fatty Acids to Produce Bioplastics. Ph.D. Thesis, Barcelona University, Barcelona, Spain, 2022. [Google Scholar]

- Fernández, D. Assessing Volatile Fatty Acids Production from Food Waste at MBT Plants: Focusing on Temperature Influence. Master’s Thesis, Barcelona University, Barcelona, Spain, 2019. [Google Scholar]

- Spekreijse, J.; Lammens, T.; Parisi, C.; Ronzon, T.; Vis, M. Insights into the European Market of Bio-Based Chemicals. Analysis Based on Ten Key Product Categories; JRC Science for Policy Report; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar]

- Fortuna Business Insight. Bio-Based Chemical Market Size, Share and Industry Analysis. Available online: https://www.fortunebusinessinsights.com/bio-based-chemicals-market-106586 (accessed on 5 August 2024).

- Jodhani, S.; Sebastian, J.; Lee, J.; Venkiteshwaran, K.; Lee, H.-S.; Singh, V.; Ormeci, B.; Hussain, A. Acidogenic Fermentation of Food Waste for the Production of Short-Chain Fatty Acids: The Impact of Inoculum Type and Inoculum Heat Pretreatment. Fermentation 2024, 10, 162. [Google Scholar] [CrossRef]

- Sotiropoulos, A.; Malamis, D.; Michailidis, P.; Krokida, M.; Loizidou, M. Research on the drying kinetics of household food waste for the development and optimization of domestic waste drying technique. Environ. Technol. 2015, 37, 929–939. [Google Scholar] [CrossRef] [PubMed]

- Selvam, A.; Ilamathi, P.M.K.; Udayakumar, M.; Murugesan, K.; Banu, J.R.; Khanna, Y.; Wong, J. Food Waste Properties. In Current Developments in Biotechnology and Bioengineering Sustainable Food Waste Management: Resource Recovery and Treatment; Wong, J., Kaur, G., Taherzadeh, M., Pandey, A., Lasaridi, K., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 11–41. [Google Scholar]

- Arras, W.; Hussain, A.; Hausler, R.; Guiot, S.R. Mesophilic, thermophilic and hyperthermophilic acidogenic fermentation of food waste in batch: Effect of inoculum source. Waste Manag. 2019, 87, 279–287. [Google Scholar] [CrossRef]

- Zacharof, M.-P.; Lovitt, R.W. Complex Effluent Streams as a Potential Source of Volatile Fatty Acids. Waste Biomass Valorization 2013, 4, 557–581. [Google Scholar] [CrossRef]

- Khatami, K.; Perez-Zabaleta, M.; Owusu-Agyeman, I.; Cetecioglu, Z. Waste to bioplastics: How close are we to sustainable polyhydroxyalkanoates production? Waste Manag. 2021, 119, 374–388. [Google Scholar] [CrossRef]

- Magama, P.; Chiyanzu, I.; Mulopo, J. A systematic review of sustainable fruit and vegetable waste recycling alternatives and possibilities for anaerobic biorefinery. Bioresour. Technol. Rep. 2022, 18, 101031. [Google Scholar] [CrossRef]

- Atasoy, M.; Owusu-Agyeman, I.; Plaza, E.; Cetecioglu, Z. Bio-based volatile fatty acid production and recovery from waste streams: Current status and future challenges. Bioresour. Technol. 2018, 268, 773–786. [Google Scholar] [CrossRef]

- Ramos-Suárez, M.; Zhang, Y.; Outram, V. Current perspectives on acidogenic fermentation to produce volatile fatty acids from waste. Rev. Environ. Sci. Biotechnol. 2021, 20, 439–478. [Google Scholar] [CrossRef]

- Zhou, M.; Yan, B.; Wong, J.W.C.; Zhang, Y. Enhanced volatile fatty acids production from anaerobic fermentation of food waste: A mini-review focusing on acidogenic metabolic pathways. Bioresour. Technol. 2018, 248, 68–78. [Google Scholar] [CrossRef]

- Polaris Market Research. Acetic Acid Market Share, Size, Trends, Industry Analysis Report. Available online: https://www.polarismarketresearch.com/industry-analysis/acetic-acid-market (accessed on 5 August 2024).

- Imarc Impactful Insights. Propionic Acid Market Report. Available online: https://www.imarcgroup.com/propionic-acid-market#:~:text=Market%20Overview%202024%2D2032%3A&text=Looking%20forward%2C%20IMARC%20Group%20expects,2.7%25%20during%202024%2D2032.&text=Propionic%20acid%20(PA)%20refers%20to,colorless%20and%20corrosive%20carboxylic%20acid (accessed on 5 August 2024).

- Imarc Impactful Insights. Butyric Acid Market Report. Available online: https://www.imarcgroup.com/butyric-acid-market (accessed on 5 August 2024).

- Research Nester. Valeric Acid Market Size and Share. Available online: https://www.researchnester.com/reports/valeric-acid-market/5809 (accessed on 5 August 2024).

- EMR Claight. Global Valeric Acid Market Analysis, Forecast, Outlook. Available online: https://www.expertmarketresearch.com/reports/valeric-acid-market (accessed on 5 August 2024).

- Bruni, C.; Foglia, A.; Eusebi, A.L.; Frison, N.; Akyol, Ç.; Fatone, F. Targeted biobased volatile fatty acid production from waste streams through anaerobic fermentation: Link between process parameters and operating scale. ACS Sustain. Chem. Eng. 2021, 9, 9970–9987. [Google Scholar] [CrossRef]

- Taricska, J.R.; Taricska, J.M.; Hung, Y.-T.; Wang, L.K. Restaurant Waste Treatment and Management. In Waste Treatment in the Service and Utility Industries, 1st ed.; Hung, Y.-T., Wang, L.K., Wang, M.-H.S., Shammas, N.K., Chen, J.P., Eds.; CRC Press: Boca Raton, FL, USA, 2017; pp. 183–206. [Google Scholar]

- Lopatkin, A.J.; Collins, J.J. Predictive biology: Modelling, understanding and harnessing microbial complexity. Nat. Rev. Microbiol. 2020, 18, 507–520. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, M.; Raajaraam, L.; Raman, K. Modelling microbial communities: Harnessing consortia for biotechnological applications. Comput. Struct. Biotechnol. J. 2021, 19, 3892–3907. [Google Scholar] [CrossRef]

- Pramanik, S.K.; Suja, F.B.; Porhemmat, M.; Pramanik, B.K. Performance and Kinetic Model of a Single-Stage Anaerobic Digestion System Operated at Different Successive Operating Stages for the Treatment of Food Waste. Processes 2019, 7, 600. [Google Scholar] [CrossRef]

- Sabiani, N.H.; Tajarudin, H.A.; Ghani, W.A.; Idris, A.; Baharuddin, A.S. Kinetic evaluation of sonicated food waste in continuously stirred tank reactor. Water Sci. Technol. 2022, 86, 395–409. [Google Scholar] [CrossRef] [PubMed]

- Parra-Orobio, B.A.; Donoso-Bravo, A.; Torres-Lozada, P. Anaerobic digestion of food waste. Predicting of methane production by comparing kinetic models. Ing. Comp. 2017, 19, 210–218. [Google Scholar]

- Mir, M.A.; Hussain, A.; Verma, C. Design considerations and operational performance of anaerobic digester: A review. Cogent Eng. 2016, 3, 1181696. [Google Scholar] [CrossRef]

- Gu, S.; Xing, H.; Zhang, L.; Wang, R.; Kuang, R.; Li, Y. Effects of food wastes based on different components on digestibility and energy recovery in hydrogen and methane co-production. Heliyon 2024, 10, e25421. [Google Scholar] [CrossRef]

- Burton, G.A.; Pitt, R.E. Stormwater Effects Handbook; Lewis Publishers: Boca Raton, FL, USA, 2002; p. 394. [Google Scholar]

- European Union. Commission Implementing Regulation (EU) 2024/771 of 29 February 2024 Amending Regulation (EC) No 152/2009 Laying Down the Methods of Sampling and Analysis for the Official Control of Feed. In Official Journal of the European Union; European Union: Luxembourg, 2024. [Google Scholar]

- American Public Health Association; American Water Works Association; Water Environment Federation. Standard Methods for the Examination of Water and Wastewater, 23rd ed.; American Public Health Association: Washington, DC, USA, 2017. [Google Scholar]

- Zahrim, A.Y.; Darwis, M.; Samantha, D.; Siti Hasanah, A.S.Z.; Aqeela, S.A.N.; Junidah, L.; Sariah, S.; Mariani, R. Composting of food waste in passive aerated bioreactor with turning mode. IOP Conf. Ser. Mat. Sci. Eng. 2021, 1195, 012001. [Google Scholar] [CrossRef]

- Koch, K.; Lübken, M.; Gehring, T.; Wichern, M.; Horn, H. Biogas from grass silage—Measurements and modeling with ADM1. Bioresour. Technol. 2010, 101, 8158–8165. [Google Scholar] [CrossRef] [PubMed]

- Mancipe, D. Estudio de la Depuración de un Agua Residual con Elevado Contenido Orgánico en un Reactor Anaerobio de Mezcla Completa—Influencia de la Concentración de Fósforo en el Influente. Bachelor’s Thesis, University of Salamanca, Salamanca, Spain, 2006. [Google Scholar]

- Parawira, W.; Murto, M.; Read, J.S.; Mattiasson, B. Volatile fatty acid production during anaerobic mesophilic digestion of solid potato waste. J. Chem. Technol. Biotechnol. 2004, 79, 673–677. [Google Scholar] [CrossRef]

- Sarkar, O.; Rova, U.; Christakopoulos, P.; Matsakas, L. Influence of initial uncontrolled pH on acidogenic fermentation of brewery spent grains to biohydrogen and volatile fatty acids production: Optimization and scale-up. Bioresour. Technol. 2021, 319, 124233. [Google Scholar] [CrossRef] [PubMed]

- Drennan, M. A Study of High Solids Anaerobic Digestion of Bucknell University Food Waste Followed by Aerobic Curing. Master’s Thesis, Bucknell University, Lewisburg, PA, USA, 2011. [Google Scholar]

- Law, C.K.Y.; De Henau, R.; De Vrieze, J. Feedstock thermal pretreatment selectively steers process stability during the anaerobic digestion of waste activated sludge. Appl. Microbiol. Biotechnol. 2020, 104, 3675–3686. [Google Scholar] [CrossRef] [PubMed]

- Veselovsky, V.A.; Dyachkova, M.S.; Bespiatykh, D.A.; Yunes, R.A.; Shitikov, E.A.; Polyaeva, P.S.; Danilenko, V.N.; Olekhnovich, E.I.; Klimina, K.M. The Gene Expression Profile Differs in Growth Phases of the Bifidobacterium Longum Culture. Microorganisms 2022, 10, 1683. [Google Scholar] [CrossRef] [PubMed]

- Cheah, Y.-K.; Vidal-Antich, C.; Dosta, J.; Mata-Álvarez, J. Volatile fatty acid production from mesophilic acidogenic fermentation of organic fraction of municipal solid waste and food waste under acidic and alkaline pH. Environ. Sci. Pollut. Res. 2019, 26, 35509–35522. [Google Scholar] [CrossRef] [PubMed]

- Liu, N.; Jiang, J.; Yan, F.; Xu, Y.; Yang, M.; Gao, Y.; Aihemaiti, A.; Zou, Q. Optimization of simultaneous production of volatile fatty acids and bio-hydrogen from food waste using response surface methodology. RSC Adv. 2018, 8, 10457–10464. [Google Scholar] [CrossRef]

- Moretto, G.; Valentino, F.; Pavan, P.; Majone, M.; Bolzonella, D. Optimization of urban waste fermentation for volatile fatty acids production. Waste Manag. 2019, 92, 21–29. [Google Scholar] [CrossRef]

- Jiang, Y.; Dennehy, C.; Lawlor, P.G.; Hu, Z.; McCabe, M.; Cormican, P.; Zhan, X.; Gardiner, G.E. Inhibition of volatile fatty acids on methane production kinetics during dry co-digestion of food waste and pig manure. Waste Manag. 2018, 79, 302–311. [Google Scholar] [CrossRef]

- Ding, H.; Barlaz, M.A.; de los Reyes, F.L.; Call, D.F. Influence of Inoculum Type on Volatile Fatty Acid and Methane Production in Short-Term Anaerobic Food Waste Digestion Tests. ACS Sustain. Chem. Eng. 2022, 10, 17071–17080. [Google Scholar] [CrossRef]

- García, A.; Ruíz, C.; Hermosilla, D.; Muñoz, R.; de Godos, I. Simultaneous production of biogas and volatile fatty acids through anaerobic digestion using cereal straw as substrate. Environ. Technol. Innov. 2023, 31, 103215. [Google Scholar]

- Pereira, M.A.; Sousa, D.Z.; Mota, M.; Alves, M.M. Mineralization of LCFA associated with anaerobic sludge: Kinetics, enhancement of methanogenic activity, and effect of VFA. Biotechnol. Bioeng. 2004, 88, 502–511. [Google Scholar] [CrossRef]

- Stams, A.J.M. Metabolic interactions between anaerobic bacteria in methanogenic environments. Anton. Leeuw. 1994, 66, 271–294. [Google Scholar] [CrossRef] [PubMed]

- Jiang, J.; Zhang, Y.; Li, K.; Wang, Q.; Gong, C.; Li, M. Volatile fatty acids production from food waste: Effects of pH, temperature, and organic loading rate. Bioresour. Technol. 2013, 143, 525–530. [Google Scholar] [CrossRef]

- Huang, X.; Shen, C.; Lui, J.; Lu, L. Improved volatile fatty acid production during waste activated sludge anaerobic fermentation by different bio-surfactants. Chem. Eng. J. 2015, 264, 280–290. [Google Scholar] [CrossRef]

- Sukphun, P.; Sittijunda, S.; Reungsang, A. Volatile Fatty Acid Production from Organic Waste with the Emphasis on Membrane-Based Recovery. Fermentation 2021, 7, 159. [Google Scholar] [CrossRef]

- Dearman, B.; Bentham, R.H. Anaerobic digestion of food waste: Comparing leachate exchange rates in sequential batch systems digesting food waste and biosolids. Waste Manag. 2007, 27, 1792–1799. [Google Scholar] [CrossRef] [PubMed]

- Bevilacqua, R.; Regueira, A.; Mauricio-Iglesias, M.; Lema, J.M.; Carballa, M. Steering the conversion of protein residues to volatile fatty acids by adjusting pH. Bioresour. Technol. 2021, 320, 124315. [Google Scholar] [CrossRef]

- Castro-Fernández, A.; Taboada-Santos, A.; Balboa, S.; Lema, J.M. Thermal hydrolysis pre-treatment has no positive influence on volatile fatty acids production from sewage sludge. Bioresour. Technol. 2023, 376, 128839. [Google Scholar] [CrossRef]

- Hoyles, L.; Swann, J. Influence of the Human Gut Microbiome on the Metabolic Phenotype. In The Handbook of Metabolic Phenotyping; Lindon, J.C., Nicholson, J.K., Holmes, E., Eds.; Elsevier Inc.: Oxford, UK, 2019; pp. 535–560. [Google Scholar]

- Owusu-Agyeman, I.; Plaza, E.; Cetecioglu, Z. Production of volatile fatty acids through co-digestion of sewage sludge and external organic waste: Effect of substrate proportions and longterm operation. Waste Manag. 2020, 112, 30–39. [Google Scholar] [CrossRef]

- Lukitawesa, R.J.P.; Millati, R.; Sárvári-Horváth, I.; Taherzadeh, M.J. Factors influencing volatile fatty acids production from food wastes via anaerobic digestion. Bioengineered 2020, 11, 39–52. [Google Scholar] [CrossRef]

- Nie, E.; He, P.; Zhang, H.; Hao, L.; Shao, L.; Lü, F. How does temperature regulate anaerobic digestion? Renew. Sustain. Energy Rev. 2021, 150, 111453. [Google Scholar] [CrossRef]

- Moza, A.; Ram, N.R.; Srivastava, N.K.; Nikhil, G.N. Bioprocessing of low-value food waste to high value volatile fatty acids for applications in energy and materials: A review on process-flow. Bioresour. Technol. Rep. 2022, 19, 101123. [Google Scholar] [CrossRef]

- Wainaina, S.; Lukitawesa, L.; Awasthi, M.K.; Taherzadeh, M.J. Bioengineering of anaerobic digestion for volatile fatty acids, hydrogen or methane production: A critical review. Bioengineered 2019, 10, 437–458. [Google Scholar] [CrossRef]

- Kim, M.; Speece, R.E. Reactor configuration-Part II. Comparative process stability and efficiency of thermophilic anaerobic digestion. Environ. Technol. 2002, 23, 643–654. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.; Gomec, C.Y.; Ahn, Y.; Speece, R.E. Hydrolysis and acidogenesis of particulate organic material in mesophilic and thermophilic anaerobic digestion. Environ. Technol. 2003, 24, 1183–1190. [Google Scholar] [CrossRef]

- Komemoto, K.; Lim, Y.G.; Nagao, N.; Onoue, Y.; Niwa, C.; Toda, T. Effect of temperature on VFA’s and biogas production in anaerobic solubilization of food waste. Waste Manag. 2009, 29, 2950–2955. [Google Scholar] [CrossRef] [PubMed]

- Mata-Álvarez, J.; Dosta, J.; Macé, J.; Astals, S. Codigestion of solid wastes: A review of its uses and perspectives including modeling. Crit. Rev. Biotechnol. 2011, 31, 99–111. [Google Scholar] [CrossRef]

- He, M.; Sun, Y.; Zou, D.; Yuan, H.; Zhu, B.; Li, X.; Pang, P. Influence of temperature on hydrolysis acidification of food waste. Procedia Environ. Sci. 2012, 16, 85–94. [Google Scholar] [CrossRef]

- Khosroshahi, S.R.M. Production of Volatile Fatty Acids from Anaerobic Digestion Using Food Waste and Sludge. Bachelor’s Thesis, Borås University, Borås, Sweden, 2019. [Google Scholar]

- Strazzera, G.; Battista, F.; Andreolli, M.; Menini, M.; Bolzonella, D.; Lampis, S. Influence of different household Food Wastes Fractions on Volatile Fatty Acids production by anaerobic fermentation. Bioresour. Technol. 2021, 335, 125289. [Google Scholar] [CrossRef]

- Jankowska, E.; Chwialkowska, J.; Stodolny, M.; Oleskowicz-Popiel, P. Volatile fatty acids production during mixed culture fermentation—The impact of substrate complexity and pH. Chem. Eng. J. 2017, 326, 901–910. [Google Scholar] [CrossRef]

- Faucher, M. Investigating the Hydrolysis Step of Staged Anaerobic Digestion and the Possibility of Using Rumen Microorganisms to Improve Hydrolysis. Master’s Thesis, IHE Delft Institute for Water Education, Delft, The Netherlands, 2020. [Google Scholar]

- da Fonseca, Y.A.; de Camargos, A.B.; Gomes, G.S.M.; Fregulia, P.; Silva, S.Q.; Gurgel, L.V.A.; Baêta, B.E.L. Enhancing Biobased Volatile Fatty Acids Production from Olive Mill Solid Waste by Optimization of pH and Substrate to Inoculum Ratio. Processes 2023, 11, 338. [Google Scholar] [CrossRef]

- Regueira, A.; Bevilacqua, R.; Rodicio, J.M.L.; Iglesias, M.M.; Arcos, M.C. Modelling VFA Production Kinetics from Protein-Rich Industrial Wastes. 2019. Available online: http://hdl.handle.net/10347/20434 (accessed on 5 August 2024).

- Regueira, A.; Turunen, R.; Vuoristo, K.S.; Carballa, M.; Lema, J.M.; Uusitalo, J.; Mauricio-Iglesias, M. Model-aided targeted volatile fatty acid production from food waste using a defined co-culture microbial community. Sci. Total Environ. 2023, 857, 159521. [Google Scholar] [CrossRef]

- Paulo, P.L.; Villa, G.; van Lier, J.B.; Letinga, G. The anaerobic conversion of metanol under thermophilic conditions: pH and bicarbonate dependence. J. Biosci. Bioeng. 2003, 96, 213–218. [Google Scholar] [CrossRef]

- Hall, H.K.; Karem, K.L.; Foster, J.W. Molecular responses of microbes to environmental pH stress. Adv. Microb. Physiol. 1995, 37, 229–272. [Google Scholar] [PubMed]

- Weijma, J. Methanol as electron donor for thermopillic biological sulfate and sulfite reduction. Ph.D. Thesis, Wageningen University, Wageningen, The Netherlands, 2000. [Google Scholar]

- Dilworth, M.J.; Glenn, A.R. Problems of adverse pH and bacterial strategies to combat it. In Bacterial Responses to pH; Chadwick, D.J., Cardew, G., Eds.; John Wiley & Sons: Chichester, UK, 1999; pp. 4–18. [Google Scholar]

- Nasir, I.M.; Mohd Ghazi, T.I.; Omar, R.; Idris, A. Anaerobic Digestion of Cattle Manure: Influence of Inoculum Concentration. Int. J. Eng. Technol. 2013, 10, 22–26. [Google Scholar]

- Silva, C.E.F.; Abud, A.K.S. Anaerobic biodigestion of sugarcane vinasse under mesophilic conditions using manure as inoculum. Rev. Ambiente Agua 2016, 11, 763–777. [Google Scholar] [CrossRef]

- de Sousa, A.; Tavares, T.J.; Sales, N.W.; Lopes, E.; Bezerra, A. S/X Ratio Impacts the Profile and Kinetics of Carboxylic Acids Production from the Acidogenic Fermentation of Dairy Wastewater. Environ. Pollut. 2021, 287, 117605. [Google Scholar] [CrossRef]

- Kumar, D.R.; Chanakya, H.N.; Bhatia, S.; Dasappa, S. Effect of Inoculum Concentration and Particle Size of the Substrate on Anaerobic Digestion of Yard Waste. In Biomethane through Resource Circularity, 1st ed.; Ghosh, S.K., Nelles, M., Chanakya, H.N., Baruah, D.C., Eds.; CRC Press: Boca Raton, FL, USA, 2022; pp. 119–124. [Google Scholar]

- Esteban, M.B.; García, A.J.; Ramos, P.; Márquez, M.C. Kinetics of amino acid production from hog hair by hydrolysis in sub-critical water. J. Supercrit. Fluids 2008, 46, 137–141. [Google Scholar] [CrossRef]

| Acid | Market in 2023 (USD million) | CAGR 2024–2032 (%) | Reference |

|---|---|---|---|

| Acetic | 22,220 | 4.4 | [17] |

| Propionic | 1800 | 2.7 | [18] |

| Butyric | 235 | 12.3 | [19] |

| Valeric | 17,000 | 5.3 | [20,21] |

| Parameter | Food Waste | Inoculum |

|---|---|---|

| Moisture (g/g fresh matter) | 0.80 ± 0.014 | 0.97 ± 0.012 |

| pH | 4.94 ± 0.10 | 7.01 ± 0.10 |

| Density (g/mL) | 1.04 ± 0.04 | 1.00 ± 0.01 |

| Total Solids (g/g fresh matter) | 0.20 ± 0.006 | 0.033 ± 0.0007 |

| Volatile Solids (g/g fresh matter) | 0.18 ± 0.006 | 0.031 ± 0.0006 |

| Total Organic Carbon (g/g dry matter) | 0.57 ± 0.017 | 0.58 ± 0.021 |

| Total Kjeldahl Nitrogen (g/g dry matter) | 0.020 ± 0.0005 | 0.023 ± 0.0006 |

| Parameter | Value |

|---|---|

| Moisture (g/g fresh matter) | 0.84 ± 0.015 |

| pH | 4.94 ± 0.10 |

| Density (g/mL) | 1.03 ± 0.04 |

| Total Solids (g/g fresh matter) | 0.16 ± 0.004 |

| Volatile Solids (g/g fresh matter) | 0.14 ± 0.004 |

| Total Organic Carbon (g/g dry matter) | 0.57 ± 0.017 |

| Total Kjeldahl Nitrogen (g/g dry matter) | 0.021 ± 0.0005 |

| Volatile fatty acids: | |

| Acetic acid (g/L) | 2.36 ± 0.16 |

| Propionic acid (g/L) | 0.019 ± 0.0012 |

| Butyric acid (g/L) | 0.65 ± 0.0042 |

| Valeric acid (g/L) | 0.56 ± 0.036 |

| Total (g/L) | 5.83 ± 0.41 1 |

| Acid | Chemical Reaction | COD Calculation |

|---|---|---|

| Acetic | ||

| Propionic | ||

| Butyric | ||

| Valeric |

| VFA | Temperature | |||||||

|---|---|---|---|---|---|---|---|---|

| 35 °C | 55 °C | |||||||

| kA (g·L−1·h−1) | kB (h−1) | kC (h−1) | R2 | kA (g·L−1·h−1) | kB (h−1) | kC (h−1) | R2 | |

| Total VFA | 8.05 × 101 | 1.71 × 10−2 | 2.15 × 10−2 | 1.0 | 2.66 × 102 | 1.17 × 10−2 | 3.81 × 10−2 | 0.99 |

| Acetic acid | 5.52 × 101 | 1.30 × 10−2 | 3.15 × 10−2 | 1.0 | 2.14 × 102 | 1.22 × 10−2 | 4.88 × 10−2 | 0.99 |

| Propionic acid | 4.67 × 100 | 9.00 × 10−3 | 6.70 × 10−1 | 0.99 | 1.72 × 101 | 1.20 × 10−2 | 4.10 × 10−1 | 1.0 |

| Butyric acid | 8.15 × 10−1 | 7.13 × 10−3 | 1.24 × 100 | 1.0 | 8.95 × 100 | 8.20 × 10−3 | 1.09 × 100 | 0.98 |

| Valeric acid | 7.63 × 101 | 1.28 × 10−2 | 4.08 × 10−2 | 0.99 | 5.56 × 101 | 2.07 × 10−2 | 1.42 × 10−1 | 1.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramos, R.E.; Márquez, M.C. Volatile Fatty Acids from Household Food Waste: Production and Kinetics. ChemEngineering 2024, 8, 84. https://doi.org/10.3390/chemengineering8050084

Ramos RE, Márquez MC. Volatile Fatty Acids from Household Food Waste: Production and Kinetics. ChemEngineering. 2024; 8(5):84. https://doi.org/10.3390/chemengineering8050084

Chicago/Turabian StyleRamos, Rosa E., and Mª Carmen Márquez. 2024. "Volatile Fatty Acids from Household Food Waste: Production and Kinetics" ChemEngineering 8, no. 5: 84. https://doi.org/10.3390/chemengineering8050084

APA StyleRamos, R. E., & Márquez, M. C. (2024). Volatile Fatty Acids from Household Food Waste: Production and Kinetics. ChemEngineering, 8(5), 84. https://doi.org/10.3390/chemengineering8050084