Modeling and Adoption of Technological Solutions in Order to Enhance the Effectiveness of Measures to Limit Water Inflows into Oil Wells under Conditions of Uncertainty

Abstract

:1. Introduction

1.1. Statement of the Research Problem

1.2. Literature Review

2. Materials and Methods

- Dependences of the values of the efficiency indicator and geological and technological factors were built according to their actual values. For this, the logarithms of the input and output variables were found, and utilizing the linear regression program, linear multiple equations of type (1) were constructed in the form of the following polynomials (polynomials) [17,18,19,20,21].

- 2.

- By carrying out the operations of potentiation of Expressions (2)–(5), the required dependences were obtained in a multiplicative form with the subsequent refinement of the parameters: For the duration of the effect, the following dependence was obtained:

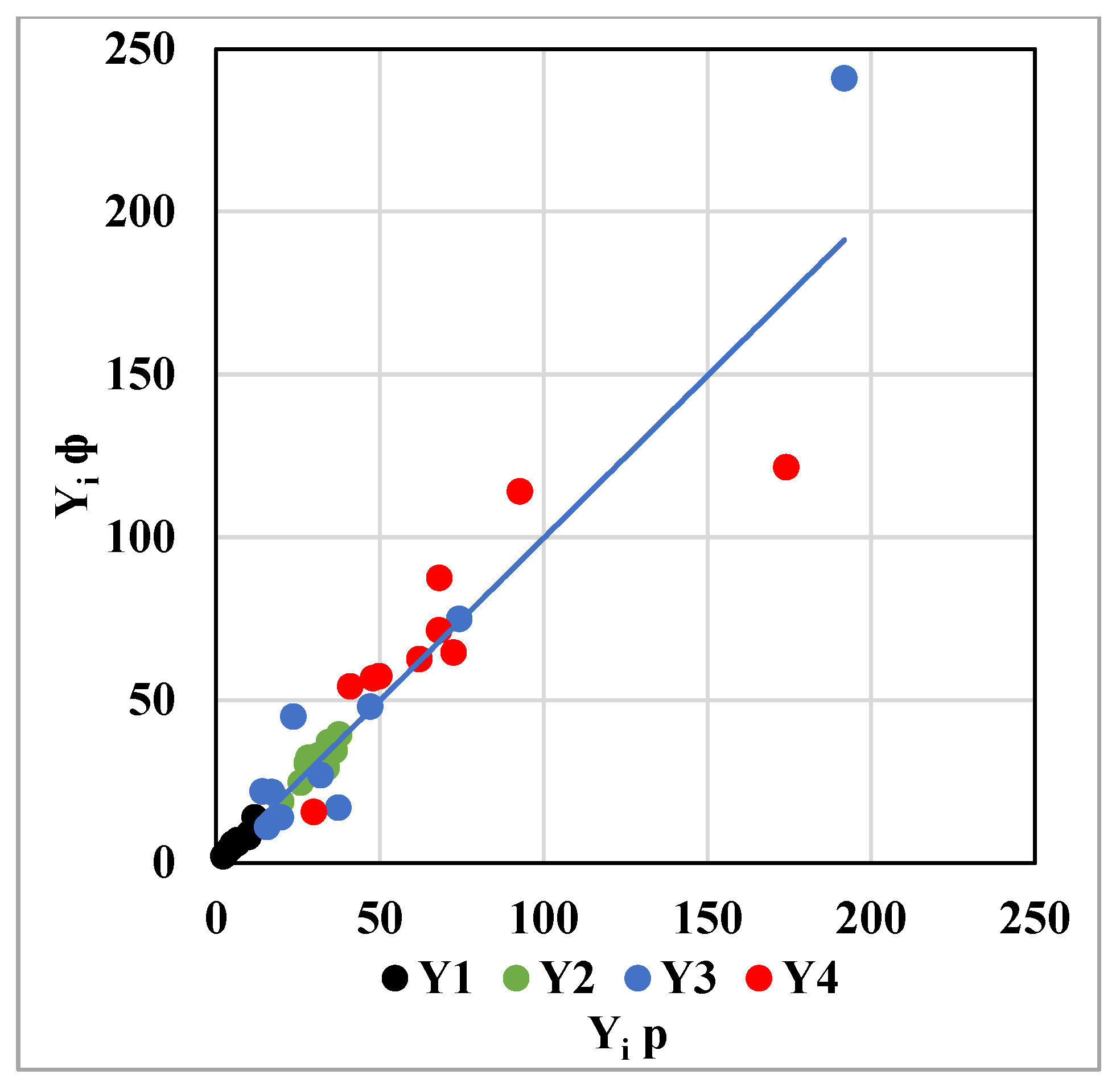

3. Results and Discussions

3.1. Analysis of the Factors Influencing the Efficiency of Isolation of Water Inflows in Production Wells by Sediment-Gelling Compositions

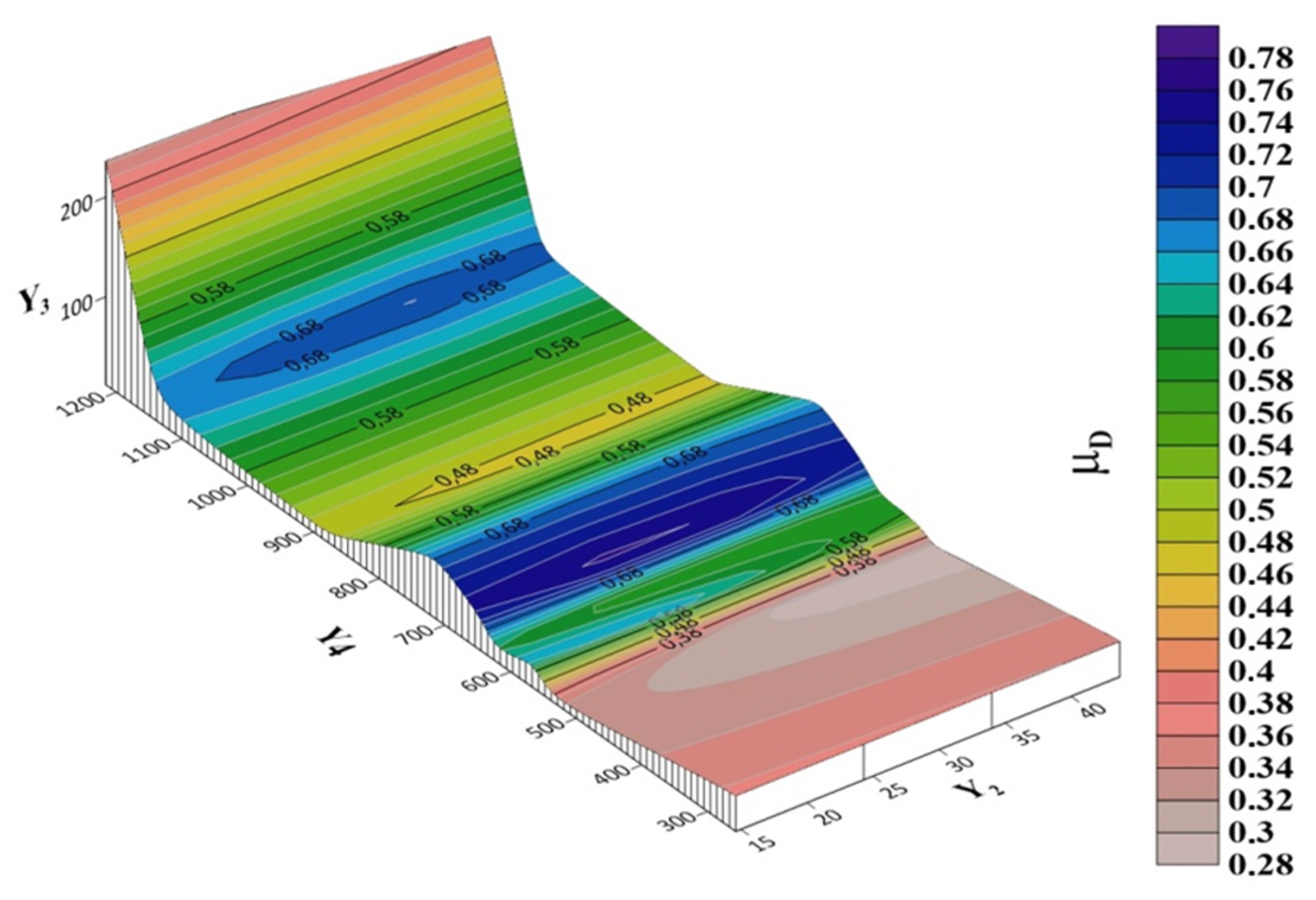

3.2. Making Decisions on the Choice of Technology for Waterproofing Works

4. Conclusions

- The performed analysis showed that with a change in one group of geological-physical, technical, and technological factors that characterize the bottomhole zone, the well, and the treatment technology, the values of the indicators selected as criteria for the effectiveness of isolation of water inflows by polymer solutions, increase, the other—decrease, and the third—the increase or decrease in values is selective. For example, an increase in the permeability and compartmentalization of the reservoir, reservoir pressure, oil viscosity in reservoir conditions, the current oil recovery factor, and coverage of the CCD with a polymer solution leads to an increase and an increase in bottomhole pressure, well flow rates for oil and water, water cut, filter length and amount of polymer per 1 m of filter leads to a decrease in the duration of the water inflow isolation effect.

- With an increase in reservoir compartmentalization, reservoir pressure, oil viscosity in reservoir conditions, well water flow rate and coverage of the CCD with a polymer solution, it leads to an increase, and an increase in reservoir permeability, bottom hole pressure, current oil recovery factor, well oil production rate, water cut, filter length and polymer amount per 1 m of filter—to a decrease in additional oil production. In the same way, it is possible to evaluate the influence of factors on other indicators of the effectiveness of waterproofing works.

- As a result of the performed analysis of changes in the efficiency indicators of the water inflow limitation technology, estimates were given for the parameters of the studied dependencies—the duration of the effect, additional oil production, volume of limited water, well profits taking into account the cost of the polymer by considering them as functions of geological and physical conditions and technological measures. Dependences of the noted indicators on the characteristics of geological and physical conditions and technological measures are constructed.

- A methodology has been developed in which, using the methods of mathematical statistics and fuzzy logic, an algorithm for evaluating optimal technological solutions according to four criteria is implemented based on information about the geological and physical conditions of the field and the experience of implementing geological and technical measures to limit water inflows, including the analysis of factors, their weighted contribution, building models, statistical evaluation of reliability indicators, decision-making taking into account uncertainty.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Taha, A.; Amani, M. Overview of Water Shutoff Operations in Oil and Gas Wells; Chemical and Mechanical Solutions. Chemengineering 2019, 3, 51. [Google Scholar] [CrossRef]

- González-Delgado, Á.D.; Aguilar-Vásquez, E.; Ramos-Olmos, M. Chemical and Process Inherent Safety Analysis of Large-Scale Suspension Poly(Vinyl Chloride) Production. Chemengineering 2023, 7, 76. [Google Scholar] [CrossRef]

- Ahmad, N.; Al-Shabibi, H.; Zeybek, M.; Malik, S. Comprehensive Diagnostic and Water Shut-off in Open and Cased Hole Carbonate Horizontal Wells. In Proceedings of the Abu Dhabi International Petroleum Conference and Exhibition, Abu Dhabi, United Arab Emirates, 15–18 November 2012. [Google Scholar] [CrossRef]

- Permana, D.; Ferdian, G.; Aji, M.; Siswati, E. Extracting Lessons Learned of 35 Water Shut-off Jobs in Mature Fields to Improve Success Ration of Water Shut-off Job. In Proceedings of the SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, Bali, Indonesia, 20–22 October 2015. [Google Scholar]

- Sydansk, D.; Romero-Zeron, L. Reservoir Conformance Improvement, 1st ed.; Society of Petroleum Engineers: Richardson, TX, USA, 2011. [Google Scholar]

- Guo, B.; Lyons, W.C.; Ghalambor, A. Petroleum Production Engineering a Computer-Assisted Approach; Gulf Professional Publishing: Houston, TX, USA, 2007. [Google Scholar]

- Fakher, S.; Elgahawy, Y.; Abdelaal, H.; El Tonbary, A.; Imqam, A. Reducing Excessive Water Production Associated with Gas Hydrate Reservoirs Using a Thermal In-Situ Heating-Inhibitor Method. In Proceedings of the SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, Dammam, Saudi Arabia, 23–26 April 2018. [Google Scholar] [CrossRef]

- Mishra, S.; Bera, A.; Mandal, A. Effect of Polymer Adsorption on Permeability Reduction in Enhanced Oil Recovery. J. Pet. Eng. 2014, 2014, 395857. [Google Scholar] [CrossRef]

- Fayzullin, M.; Tippel, P.; Gonzalez, J.; Egger, S. Understanding Excessive Water Production in Highly Faulted Mature Gas Condensate Field: From Well Operations to Revival of Integrated History Matching. In Proceedings of the IADC/SPE Asia Pacific Drilling Technology Conference, Bangkok, Thailand, 25–27 August 2014. [Google Scholar] [CrossRef]

- Xue, L.; Liu, P.; Zhang, Y. Status and Prospect of Improved Oil Recovery Technology of High Water Cut Reservoirs. Water 2023, 15, 1342. [Google Scholar] [CrossRef]

- Li, D. Main technical measures and enlightenment of foreign high water cut oilfields. Pet. Petrochem. Today 2013, 21, 13–15. [Google Scholar]

- Li, X.; Zhang, F.; Liu, G. Review on polymer flooding technology. IOP Conf. Ser. Earth Environ. Sci. 2021, 675, 012199. [Google Scholar] [CrossRef]

- Zeinijahromi, A.; Bedrikovetski, P. Controlling Excessive Water Production Using Induced Formation Damage. In Proceedings of the SPE European Formation Damage Conference and Exhibition, Budapest, Hungary, 3–5 June 2015. [Google Scholar]

- Thomas, F.B.; Bennion, D.B.; Anderson, G.E.; Meldrum, B.T.; Heaven, W.J. Water Shut-off Treatments-Reduce Water and Accelerate Oil Production. J. Can. Pet. Technol. 2000, 39, 25–29. [Google Scholar] [CrossRef]

- Surguchev, L.M. Water Shut-Off: Simulation and Laboratory Evaluation. In Proceedings of the European Petroleum Conference, The Hague, The Netherlands, 20–22 October 1998. [Google Scholar]

- Sun, Y.; Fang, Y.; Chen, A.; You, Q.; Dai, C.; Cheng, R.; Liu, Y. Gelation Behavior Study of a Resorcinol–Hexamethyleneteramine Crosslinked Polymer Gel for Water Shut-Off Treatment in Low Temperature and High Salinity Reservoirs. Energies 2017, 10, 913. [Google Scholar] [CrossRef]

- Gharbi, R.; Alajmi, A.; Algharaib, M. The Potential of a Surfactant/Polymer Flood in a Middle Eastern Reservoir. Energies 2012, 5, 58–70. [Google Scholar] [CrossRef]

- El-Karsani, K.S.M.; Al-Muntasheri, G.A.; Hussein, I.A. Polymer Systems for Water Shutoff and Profile Modification: A Review Over the Last Decade. SPE J. 2014, 19, 135–149. [Google Scholar] [CrossRef]

- Offenbacher, M.; Gadiyar, B.; Messler, D.; Krishnamoorthy, S.-R.; Abasher, D. Swellable Packer Fluids Designed for Zonal Isolation in Openhole Completions. In Proceedings of the SPE European Formation Damage Conference and Exhibition, Budapest, Hungary, 3–5 June 2015. [Google Scholar] [CrossRef]

- Epov, I.N.; Zotova, O.P. Flow diverting technologies as a method of increasing oil recovery in Russia and abroad. Fundam. Res. 2016, 12, 806–810. Available online: http://www.fundamentalresearch.ru/ru/article/view?id=41173 (accessed on 10 January 2016). (In Russian).

- Moiseev, N.A. Calculation of the true level of significance of predictors during the specification of the regression equation. Stat. Econ. 2017, 3, 10–20. [Google Scholar] [CrossRef]

- Noskov, S.I. Comparative assessment of the significance of predictors when using various methods for identifying the parameters of the regression model. Izvestiya TuzGU Tech. Sci. 2021, 9, 228–230. [Google Scholar]

- Strekov, A.S.; Mamedov, P.Z.; Koyshina, A.I. Decisions-making on the choice of geological and technical measures under uncertainty. In Proceedings of the Seventh International Conference on Soft Computing, Computing with Words and Perceptions in System Analysis, Decision and Control, Izmir, Turkey, 2–3 September 2013; pp. 381–384. [Google Scholar]

| No. | Permeability, µm2 | Compartmentalization | Reservoir Pressure, MPa | Bottomhole Pressure, MPa | Oil viscosity in Reservoir Conditions, mPa × s | Current Oil Recovery Factor | Well Flow Rate before Treatment | Water Cut, % | Filter Length, m | 1 m Thick Filter, kg | % CCD Polymer Flooding | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Oil, t/day | Water, m3/day | |||||||||||

| x1 | x2 | x3 | x4 | x5 | x6 | x7 | x8 | x9 | x10 | x11 | x12 | |

| 1 | 0.728 | 5.8 | 36 | 38 | 0.997 | 31.4 | 1.3 | 24.9 | 94.99 | 8 | 4.4 | 19.2 |

| 2 | 1.34 | 5.8 | 19.6 | 22.1 | 0.997 | 31.4 | 6.1 | 129.1 | 95.47 | 19.5 | 3.8 | 16.5 |

| 3 | 15.6 | 5.8 | 26.8 | 28.8 | 0.997 | 31.4 | 3.4 | 140.6 | 97.61 | 26 | 7.8 | 34.2 |

| 4 | 5.67 | 5.8 | 25.7 | 29.2 | 1.22 | 31.4 | 3.6 | 116.2 | 96.97 | 14 | 14 | 61.4 |

| 5 | 2.98 | 2.2 | 22.6 | 24.6 | 0.97 | 31.4 | 5.4 | 183.7 | 97.14 | 18 | 16.6 | 72.6 |

| 6 | 14.4 | 2.2 | 20.4 | 22.4 | 0.997 | 31.4 | 6.7 | 232.6 | 97.19 | 16 | 11.3 | 49.5 |

| 7 | 4.6 | 2.2 | 28 | 30 | 0.8 | 31.4 | 4.1 | 53.6 | 92.87 | 31 | 2.7 | 11.7 |

| 8 | 3.91 | 5.8 | 27.4 | 29.4 | 0.997 | 31.4 | 3 | 139 | 97.86 | 15 | 20.5 | 90 |

| 9 | 9.35 | 5.8 | 27.4 | 29.4 | 0.997 | 31.4 | 7.7 | 279.9 | 97.33 | 19 | 10.3 | 45.2 |

| 10 | 45.6 | 2.5 | 21.3 | 23.3 | 1.02 | 31.4 | 3.4 | 46.7 | 93.16 | 13 | 3.1 | 13.7 |

| No. | Y1 | Y2 | Y3 | Y4 |

|---|---|---|---|---|

| Effect Duration, Months | Average Values of Additional Oil Produced and Water Restrictions during the Effect Time | Profit from the Well, Taking into Account the Cost of the Polymer, Thousand Tenge | ||

| Oil, t | Water, m3 | |||

| 1. | 8 | 37.1 | 48 | 257.1 |

| 2. | 4 | 32.3 | 75 | 714.9 |

| 3. | 6 | 30.6 | 27 | 1141.2 |

| 4. | 9 | 34.5 | 11 | 542.2 |

| 5. | 7 | 29.2 | 45 | 646.3 |

| 6. | 6 | 28.3 | 21.8 | 626.3 |

| 7. | 2 | 18.8 | 241 | 1216.1 |

| 8. | 14 | 39.5 | 22 | 574.2 |

| 9. | 7 | 33.1 | 18 | 875.2 |

| 10. | 5 | 24.7 | 35 | 568 |

| Model | Weight Contribution | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| α⚜ | α⚜ | α⚜ | α⚜ | α⚜ | α⚜ | α⚜ | α⚜ | α⚜ | α⚜⚜ | α⚜⚜ | α⚜⚜ | |

| 1 | 3.7 | 21.9 | 21.6 | 2.1 | 5.3 | 2.1 | 0.3 | 21.5 | 10.4 | 0.3 | 9.8 | |

| 2 | 0.6 | 11.4 | 15.3 | 5.2 | 0.8 | 4.6 | 6.8 | 41 | 6.6 | 1 | 4.9 | |

| 7 | 1.9 | 18.6 | 21 | 6.5 | 3.8 | 3.9 | 9.8 | 5.5 | 12.9 | 0.52 | 8.6 | |

| 0.2 | 2.79 | 22.64 | 31.89 | 8.32 | 0.93 | 0.2 | 0.41 | 17.58 | 11.87 | 1.70 | 1.41 | |

| Factors | Regression Equation Coefficients | The Contribution of Each Factor to the Corresponding Isolation Effect Criterion, % | Overall Assessment of Each Factor Contribution to the Isolation Effect, % | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Y1 | Y2 | Y3 | Y4 | α1 | α2 | α3 | α4 | α | |

| a0 | 2.088 | 4.011 | 2.673 | 2.673 | - | - | - | - | - |

| X1 | 0.0279 | −0.0329 | −0.2207 | 0.0078 | 1 | 2 | 7 | 0.2 | 1.294 |

| X2 | 0.2117 | 0.0199 | −0.1253 | −0.2062 | 3.7 | 0.6 | 1.9 | 2.79 | 1.852 |

| X3 | 0.8552 | 0.2676 | −0.8418 | −1.1539 | 21.9 | 11.4 | 18.6 | 22.64 | 18.007 |

| X4 | −0.8354 | −0.3559 | 0.9415 | 1.6104 | 21.6 | 15.3 | 21 | 31.89 | 21.69 |

| X5 | 0.1911 | 0.2869 | −0.6897 | −0.9984 | 2.1 | 5.2 | 6.5 | 8.32 | 4.93 |

| X6 | 0.2134 | −0.0187 | −0.1753 | 0.0487 | 5.3 | 0.8 | 3.8 | 0.93 | 1.967 |

| X7 | −0.1116 | −0.1458 | 0.2407 | 0.017 | 2.1 | 4.6 | 3.9 | 0.2 | 1.657 |

| X8 | −0.0122 | 0.1664 | −0.4635 | 0.0217 | 0.3 | 6.8 | 9.8 | 0.41 | 1.692 |

| X9 | −1.0794 | −1.2373 | +0.3228 | 1.1505 | 21.5 | 41 | 5.5 | 17.58 | 17.086 |

| X10 | −0.6955 | −0.2664 | 1.0051 | 1.0366 | 10.4 | 6.6 | 12.9 | 11.87 | 10.125 |

| X11 | −0.0266 | −0.0446 | −0.0456 | −0.1685 | 0.3 | 1 | 0.52 | 1.70 | 0.718 |

| X12 | 0.5022 | 0.15 | −0.5124 | 0.0943 | 9.8 | 4.9 | 8.6 | 1.41 | 4.912 |

| Degree of identity | 0.881895 | 0.761143 | 0.884733 | 0.779909 | - | - | - | - | |

| N | Y1 | Y2 | Y3 | Y4 | |||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 8 | 37.1 | 48 | 257.1 | 0.975722 | 0.899162 | 0.963551 | 0.361174 | 0.361 |

| 2 | 4 | 32.3 | 75 | 714.9 | 0.678784 | 0.834876 | 0.998261 | 0.911067 | 0.679 |

| 3 | 6 | 30.6 | 27 | 1141.2 | 0.902111 | 0.805284 | 0.706975 | 0.993467 | 0.707 |

| 4 | 9 | 34.5 | 11 | 542.2 | 0.988225 | 0.867683 | 0.280246 | 0.774495 | 0.28 |

| 5 | 7 | 29.2 | 45 | 646.3 | 0.950605 | 0.778022 | 0.94944 | 0.869054 | 0.778 |

| 6 | 6 | 28.3 | 21,8 | 626.3 | 0.902111 | 0.759108 | 0.571493 | 0.853967 | 0.571 |

| 7 | 2 | 18.8 | 241 | 1216.1 | 0.326399 | 0.506227 | 1 | 0.995923 | 0.326 |

| 8 | 14 | 39.5 | 22 | 574.2 | 0.9997 | 0.922128 | 0.577067 | 0.807891 | 0.577 |

| 9 | 7 | 33.1 | 18 | 875.2 | 0.950605 | 0.847503 | 0.463752 | 0.965813 | 0.464 |

| 10 | 5 | 24.7 | 35 | 568 | 0.815258 | 0.673109 | 0.857261 | 0.801728 | 0.673 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moldabayeva, G.Z.; Efendiyev, G.M.; Kozlovskiy, A.L.; Buktukov, N.S.; Abbasova, S.V. Modeling and Adoption of Technological Solutions in Order to Enhance the Effectiveness of Measures to Limit Water Inflows into Oil Wells under Conditions of Uncertainty. ChemEngineering 2023, 7, 89. https://doi.org/10.3390/chemengineering7050089

Moldabayeva GZ, Efendiyev GM, Kozlovskiy AL, Buktukov NS, Abbasova SV. Modeling and Adoption of Technological Solutions in Order to Enhance the Effectiveness of Measures to Limit Water Inflows into Oil Wells under Conditions of Uncertainty. ChemEngineering. 2023; 7(5):89. https://doi.org/10.3390/chemengineering7050089

Chicago/Turabian StyleMoldabayeva, G. Zh., G. M. Efendiyev, A. L. Kozlovskiy, N. S. Buktukov, and S. V. Abbasova. 2023. "Modeling and Adoption of Technological Solutions in Order to Enhance the Effectiveness of Measures to Limit Water Inflows into Oil Wells under Conditions of Uncertainty" ChemEngineering 7, no. 5: 89. https://doi.org/10.3390/chemengineering7050089

APA StyleMoldabayeva, G. Z., Efendiyev, G. M., Kozlovskiy, A. L., Buktukov, N. S., & Abbasova, S. V. (2023). Modeling and Adoption of Technological Solutions in Order to Enhance the Effectiveness of Measures to Limit Water Inflows into Oil Wells under Conditions of Uncertainty. ChemEngineering, 7(5), 89. https://doi.org/10.3390/chemengineering7050089