Agricultural Biomass Waste to Biochar: A Review on Biochar Applications Using Machine Learning Approach and Circular Economy

Highlights

- Pyrolysis has been extensively used in the production of biochar in many publications over the last decade. This review article will summarize agricultural-biomass-waste-derived bio-char and its potential to reduce greenhouse gas emissions.

- The optimization and customization of biochar yield with microwave-assisted pyrolysis is summarized in this article.

- Pyrolysis has been extensively used in the production of biochar in many publications over the last decade. This review article will summarize agricultural-biomass-waste-derived bio-char and its potential to reduce greenhouse gas emissions.

- The optimization and customization of biochar yield with microwave-assisted pyrolysis is summarized in this article.

Abstract

1. Introduction

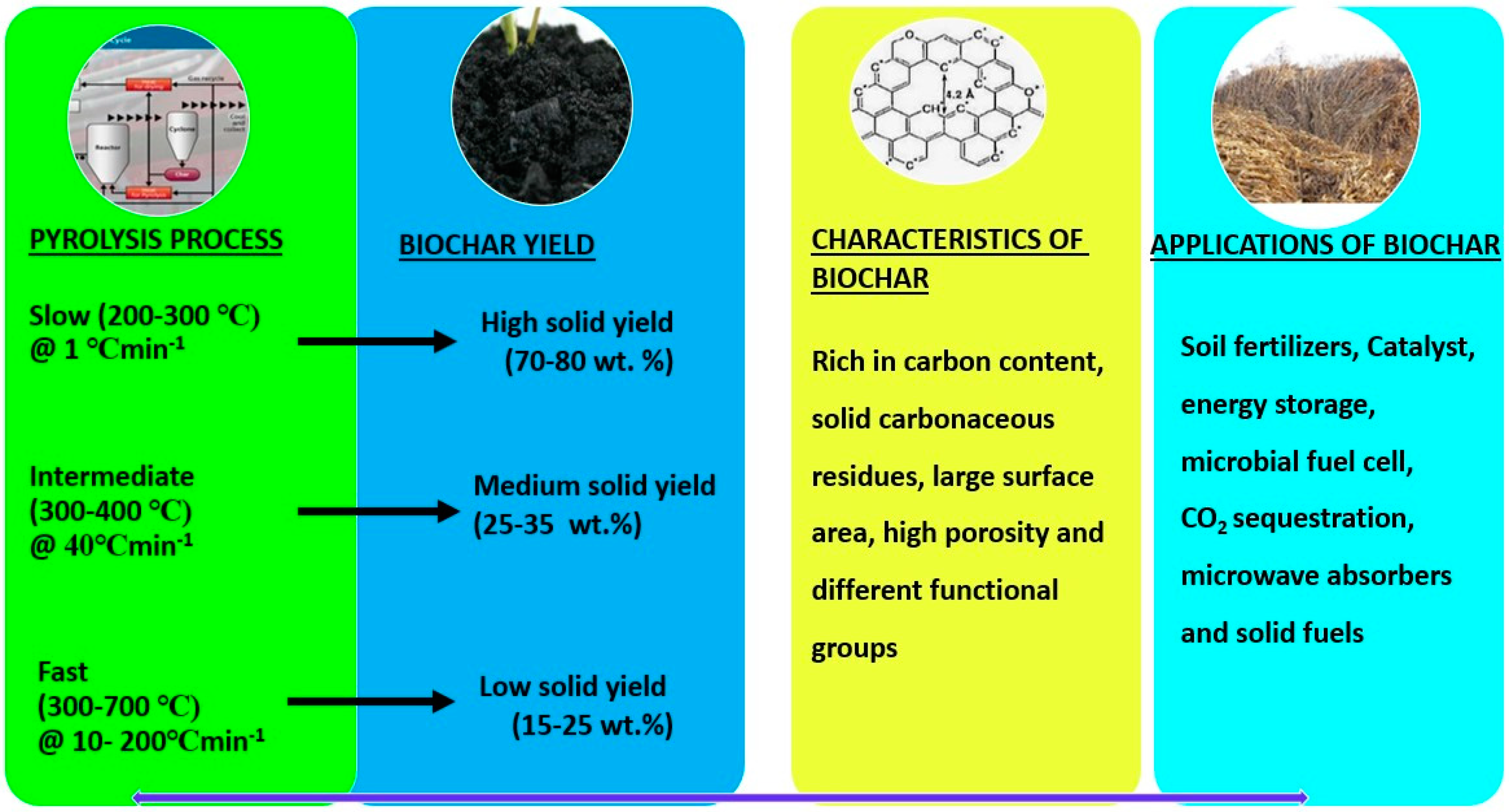

2. Production of Biochar

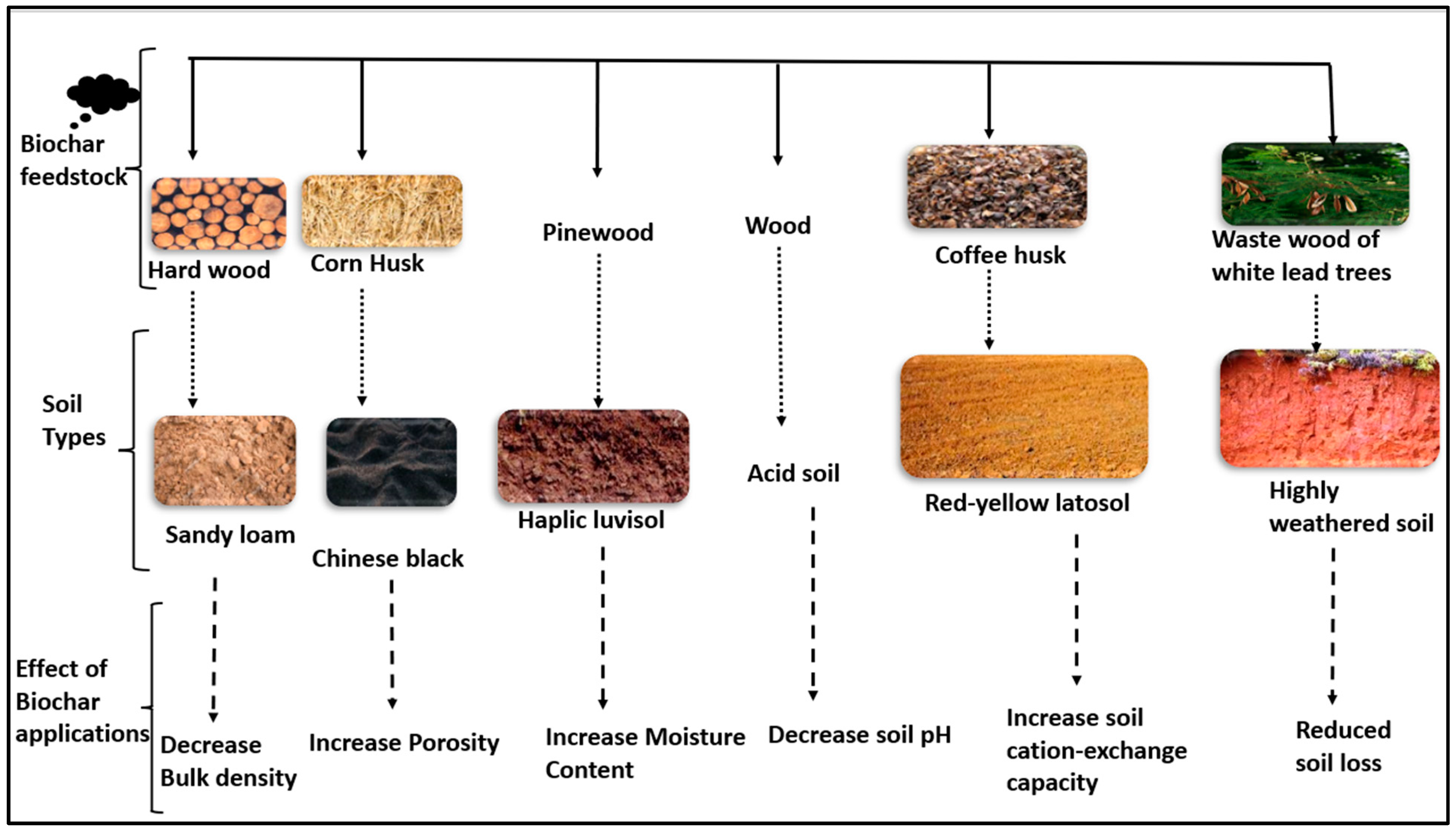

3. Agricultural Uses of Biochar

- Climatic conditions

- Characteristics of soil

- Environmental parameters

- Topography

- Frequency of application

4. Microwave Reactors

- Mode of operation

- Type of reactor

- Magnetron location (side, bottom, top)

- Frequency of microwaves

- Quartz or ceramic materials

- Microwave cavity

- Size of the reactor

5. Use of Catalysts in MAP

6. Machine Learning in Prediction of Biochar

| Type of Yield Prediction | Model | Input Variables | Output Variables | Neurons | MSE | R2 | Reference |

|---|---|---|---|---|---|---|---|

| Gaseous products | ANN | • Size of biomass • Air flow velocity • Reaction temperature | • H2 • CO • CH4 • CO2 | 7 | 0.01 | - | [80] |

| Refuse derived fuels (RDF) | ANN | • Heating rate • Pyrolysis temperature | • Biomass weight loss | 7 | 0.16 | 0.99 | [81] |

| Gas species | ANN | • Moisture content • Ash • Carbon • Hydrogen • Oxygen • Reduction temperature | • H2 • CO • CH4 • CO2 | 5 | 0.0873 | 0.99 | [82] |

| Biomass gasification in FBR | ANN | • Ash • Moisture • Carbon • Hydrogen • Oxygen • Reduction temperature | • CO | 2 | 0.79 | 0.99 | [83] |

| • CO2 | 0.41 | 0.98 | |||||

| • H2 | 0.62 | 0.99 | |||||

| • CH4 | 0.15 | 0.99 | |||||

| • Producer gas | 0.07 | 0.99 | |||||

| Kinetic parameters | ANN | • Percentage of carbon • Ratio of air/biomass • Volatile substance • Ash | • Pre-exponential factor (A) • Activation Energy (Ea) • Reaction order (n) | 9 | 0.1 | 0.93 | [84] |

| 10 | 0.01 | 0.94 | |||||

| 23 | 0.004 | 0.90 | |||||

| Kinetic parameters of biomass, pure and mixed components | ANN | • Biomass mass percentage composition of cellulose, hemicellulose, and lignin. | • Pre-exponential factor (ko) | 20 | <0.001 | >0.90 | [85] |

| • Activation Energy (Ea) | 17 | ||||||

| • Reaction order (n) | 30 | ||||||

| Optimization of Cerbera Manghas biodiesel production | ANN integrate with ACO | • H2SO4 catalyst concentration • Methanol to oil molar ratio • Reaction temperature • Reaction time | • Acid value | 10 | 0.03 | 0.99 | [86] |

| Highest heating value of biomass | SVM integrate with PSO | • Fixed carbon • Volatile matter • Reaction temperature • Residence time • Atomic oxygen/carbon ratio • Atomic hydrogen/carbon ratio | • Higher heating value (cubic-SVM) | 0.39 | [87] |

7. Circular Bioeconomy on Biochar Production

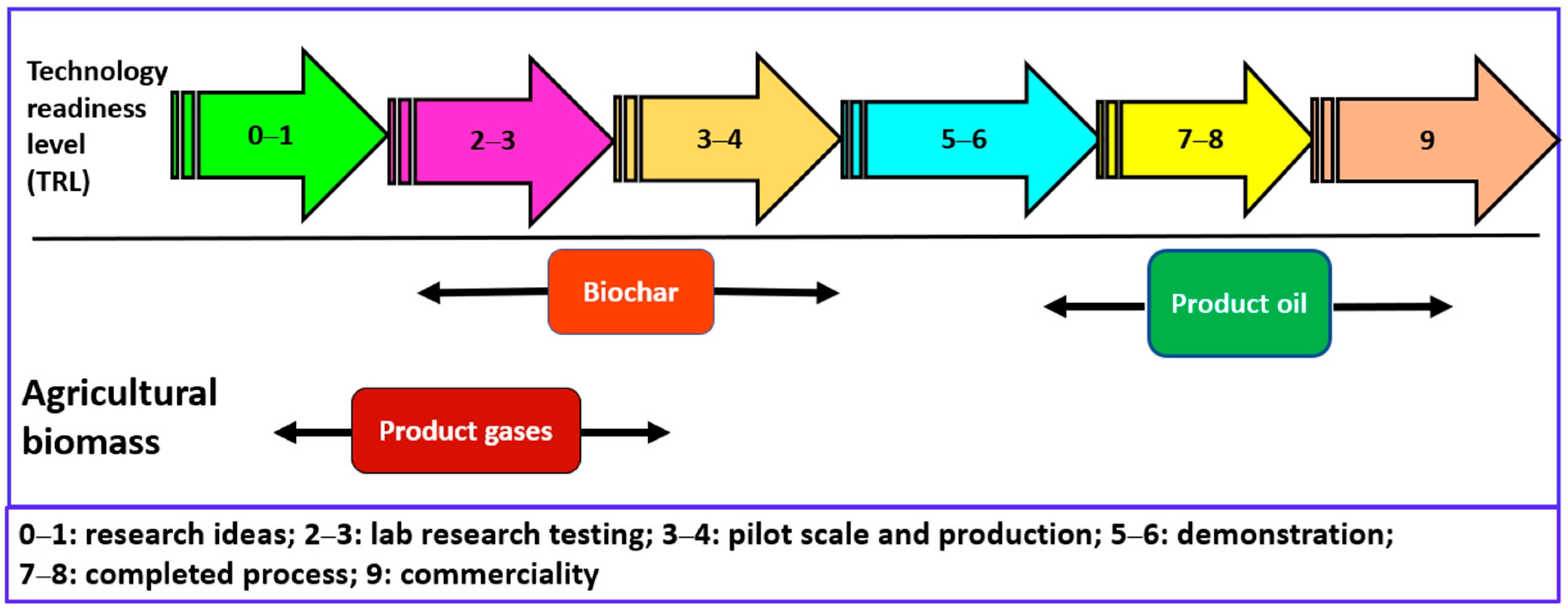

8. Technology Readiness Level

- Lab

- Pilot

- Commercial

9. Economic Viability of Biochar

- Adsorbents

- Soil enhancements

- Fertilizers

- Energy production

- Fixation of CO2

- Energy production

- Industrial value-added products

10. Technoeconomic Analysis

- Data collection

- Mass and Energy balance

- Cost estimation

- Economic assessment

- Risk analysis

- Sensitivity analysis

11. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| ANN | Artificial Neural Network |

| ML | Machine Learning |

| SVM | Support Vector Machine |

| RF | Random Forest |

| XGB | Extreme Gradient Boosting |

| PSO | Particle Swarm Optimization |

| ACO | Ant Colony Optimization |

| ABW | Agricultural Biomass Wastes |

| MAP | Microwave-assisted Pyrolysis |

| RSM | Response Surface Methodology |

| MLR | Multi Linear Regression |

| ANFIS | Adaptive Neuro Fuzzy Inference Systems |

| FCC | Federal Communication Commission |

| MSE | Mean Square Error |

| R2 | Regression Coefficient |

| DOE | Design of Experiments |

| A | Pre-exponential Factor |

| Ea | Activation Energy |

| n | Reaction order |

| TRL | Technology Readiness Level |

| CPERI | Chemical Process Energy Research Institute |

| ECN | Energy research Center of Netherlands |

| CNG | Compressed Natural Gas |

| MMT | Million Metric Tons |

| MLP | Multi-Layer Perception |

| TEA | Technoeconomic Analysis |

| NPV | Net Present Value |

| DPP | Discounted Payback Period |

| MSP | Minimum Selling Price |

| GDP | Gross Domestic Product |

References

- Shahbaz, M.; AlNouss, A.; Parthasarathy, P.; Abdelaal, A.H.; Mackey, H.; McKay, G.; Al-Ansari, T. Investigation of Biomass Components on the Slow Pyrolysis Products Yield Using Aspen Plus for Techno-Economic Analysis. Biomass Convers. Biorefinery 2022, 12, 669–681. [Google Scholar] [CrossRef]

- Aditya, L.; Mahlia, T.M.I.; Rismanchi, B.; Ng, H.M.; Hasan, M.H.; Metselaar, H.S.C.; Muraza, O.; Aditiya, H.B. A Review on Insulation Materials for Energy Conservation in Buildings. Renew. Sustain. Energy Rev. 2017, 73, 1352–1365. [Google Scholar] [CrossRef]

- Ge, S.; Yek, P.N.Y.; Cheng, Y.W.; Xia, C.; Wan Mahari, W.A.; Liew, R.K.; Peng, W.; Yuan, T.Q.; Tabatabaei, M.; Aghbashlo, M.; et al. Progress in Microwave Pyrolysis Conversion of Agricultural Waste to Value-Added Biofuels: A Batch to Continuous Approach. Renew. Sustain. Energy Rev. 2021, 135, 110148. [Google Scholar] [CrossRef]

- Rex, P.; Ganesan, V.; Sivashankar, V.; Tajudeen, S. Prospective Review for Development of Sustainable Catalyst and Absorbents from Biomass and Application on Plastic Waste Pyrolysis. Int. J. Environ. Sci. Technol. 2022, 19, 1–16. [Google Scholar] [CrossRef]

- Hasan, R.; Chong, C.C.; Bukhari, S.N.; Jusoh, R.; Setiabudi, H.D. Effective Removal of Pb(II) by Low-Cost Fibrous Silica KCC-1 Synthesized from Silica-Rich Rice Husk Ash. J. Ind. Eng. Chem. 2019, 75, 262–270. [Google Scholar] [CrossRef]

- Wang, Q.; Gao, C.; Zhang, W.; Luo, S. Electrochimica Acta Biomorphic Carbon Derived from Corn Husk as a Promising Anode Materials for Potassium Ion Battery. Electrochim. Acta 2019, 324, 134902. [Google Scholar] [CrossRef]

- Cheng, Y.W.; Lee, Z.S.; Chong, C.C.; Khan, M.R.; Cheng, C.K.; Ng, K.H.; Hossain, S.S. Hydrogen-Rich Syngas Production via Steam Reforming of Palm Oil Mill Effluent (POME)—A Thermodynamics Analysis. Int. J. Hydrogen Energy 2019, 44, 20711–20724. [Google Scholar] [CrossRef]

- Rex, P.; Masilamani, I.P.; Miranda, L.R. Microwave Pyrolysis of Polystyrene and Polypropylene Mixtures Using Different Activated Carbon from Biomass. J. Energy Inst. 2020, 93, 1819–1832. [Google Scholar] [CrossRef]

- Velmurugan, G.; Shankar, V.S.; Rahiman, M.K.; Prathiba, R.; Dhilipnithish, L.R.; Khan, F.A. Materials Today: Proceedings Effectiveness of Silica Addition on the Mechanical Properties of Jute/Polyester Based Natural Composite. Mater. Today Proc. 2022, 72, 2075–2081. [Google Scholar] [CrossRef]

- Premalatha, N.; Prathiba, R.; Angelo, M.; Lima, M.; Miranda, R. Pyrolysis of Polypropylene Waste Using Sulfonated Carbon Catalyst Synthesized from Sugarcane Bagasse. J. Mater. Cycles Waste Manag. 2021, 23, 1002–1014. [Google Scholar] [CrossRef]

- Prathiba, R.; Shruthi, M.; Miranda, L.R. Pyrolysis of Polystyrene Waste in the Presence of Activated Carbon in Conventional and Microwave Heating Using Modified Thermocouple. Waste Manag. 2018, 76, 528–536. [Google Scholar] [CrossRef] [PubMed]

- Sanjeevi, S.; Shanmugam, V.; Kumar, S.; Ganesan, V.; Sas, G.; Johnson, D.J.; Shanmugam, M.; Ayyanar, A.; Naresh, K.; Neisiany, R.E.; et al. Effects of Water Absorption on the Mechanical Properties of Hybrid Natural Fibre/Phenol Formaldehyde Composites. Sci. Rep. 2021, 11, 13385. [Google Scholar] [CrossRef] [PubMed]

- Shankar, V.S.; Velmurugan, G.; Prathiba, R.; Poornima, D.S.; Suvetha, M.; Keerthiga, V. Materials Today: Proceedings Effect of on-Farm Storage Structure on Physical and Bio-Chemical Changes in Aggregatum Onion. Mater. Today Proc. 2022, 72, 2417–2422. [Google Scholar] [CrossRef]

- Tomczyk, A.; Sokołowska, Z.; Boguta, P. Biochar Physicochemical Properties: Pyrolysis Temperature and Feedstock Kind Effects. Rev. Environ. Sci. Biotechnol. 2020, 19, 191–215. [Google Scholar] [CrossRef]

- Bridgwater, A.V. The Production of Biofuels and Renewable Chemicals by Fast Pyrolysis of Biomass. Int. J. Glob. Energy Issues 2007, 27, 160–203. [Google Scholar] [CrossRef]

- DeSisto, W.J.; Hill, N.; Beis, S.H.; Mukkamala, S.; Joseph, J.; Baker, C.; Ong, T.H.; Stemmler, E.A.; Wheeler, M.C.; Frederick, B.G.; et al. Fast Pyrolysis of Pine Sawdust in a Fluidized-Bed Reactor. Energy Fuels 2010, 24, 2642–2651. [Google Scholar] [CrossRef]

- Polygeneration, I.; Plant, P.; Firing, B.S.S.; Alghassab, M.; Samuel, O.D.; Khan, Z.A.; Imran, M.; Farooq, M. Exergoeconomic and Environmental Modeling Of. Energies 2020, 13, 6018. [Google Scholar]

- Pei-dong, Z.; Guomei, J.; Gang, W. Contribution to Emission Reduction of CO2 and SO2 by Household Biogas Construction in Rural China. Renew. Sustain. Energy Rev. 2007, 11, 1903–1912. [Google Scholar] [CrossRef]

- Thornley, P.; Upham, P.; Huang, Y.; Rezvani, S.; Brammer, J.; Rogers, J. Integrated Assessment of Bioelectricity Technology Options. Energy Policy 2009, 37, 890–903. [Google Scholar] [CrossRef]

- Aboulkas, A.; El Harfi, K.; El Bouadili, A. Non-Isothermal Kinetic Studies on Co-Processing of Olive Residue and Polypropylene. Energy Convers. Manag. 2008, 49, 3666–3671. [Google Scholar] [CrossRef]

- Abnisa, F.; Wan Daud, W.M.A.; Sahu, J.N. Optimization and Characterization Studies on Bio-Oil Production from Palm Shell by Pyrolysis Using Response Surface Methodology. Biomass Bioenergy 2011, 35, 3604–3616. [Google Scholar] [CrossRef]

- Allohverdi, T.; Mohanty, A.K.; Roy, P.; Misra, M. A Review on Current Status of Biochar Uses in Agriculture. Molecules 2021, 26, 5584. [Google Scholar] [CrossRef] [PubMed]

- Ayaz, M.; Feizienė, D.; Tilvikienė, V.; Akhtar, K.; Stulpinaitė, U.; Iqbal, R. Biochar Role in the Sustainability of Agriculture and Environment. Sustainability 2021, 13, 1330. [Google Scholar] [CrossRef]

- Rex, P.; Miranda, L.R. Catalytic Activity of Acid-Treated Biomass for the Degradation of Expanded Polystyrene Waste. Environ. Sci. Pollut. Res. 2020, 27, 438–455. [Google Scholar] [CrossRef]

- Al-Rumaihi, A.; Shahbaz, M.; Mckay, G.; Mackey, H.; Al-Ansari, T. A Review of Pyrolysis Technologies and Feedstock: A Blending Approach for Plastic and Biomass towards Optimum Biochar Yield. Renew. Sustain. Energy Rev. 2022, 167, 112715. [Google Scholar] [CrossRef]

- Osman, A.I.; Fawzy, S.; Farghali, M.; El-Azazy, M.; Elgarahy, A.M.; Fahim, R.A.; Maksoud, M.I.A.A.; Ajlan, A.A.; Yousry, M.; Saleem, Y.; et al. Biochar for Agronomy, Animal Farming, Anaerobic Digestion, Composting, Water Treatment, Soil Remediation, Construction, Energy Storage, and Carbon Sequestration: A Review; Springer International Publishing: Cham, Switzerland, 2022; Volume 20, ISBN 0123456789. [Google Scholar]

- Gonzaga, M.I.S.; Mackowiak, C.; de Almeida, A.Q.; de Carvalho Junior, J.I.T.; Andrade, K.R. Positive and Negative Effects of Biochar from Coconut Husks, Orange Bagasse and Pine Wood Chips on Maize (Zea mays L.) Growth and Nutrition. Catena 2018, 162, 414–420. [Google Scholar] [CrossRef]

- Puga, A.P.; Grutzmacher, P.; Cerri, C.E.P.; Ribeirinho, V.S.; Andrade, C.A. de Biochar-Based Nitrogen Fertilizers: Greenhouse Gas Emissions, Use Efficiency, and Maize Yield in Tropical Soils. Sci. Total Environ. 2020, 704, 135375. [Google Scholar] [CrossRef] [PubMed]

- Apelgren, P.; Amoroso, M.; Säljö, K.; Montelius, M.; Lindahl, A.; Stridh Orrhult, L.; Gatenholm, P.; Kölby, L.; Arulkumar, S.; Parthiban, S.; et al. Biochar Boosts Tropical but Not Temperate Crop Yields. Mater. Today Proc. 2019, 27, 053001. [Google Scholar]

- Chrysargris, A.; Prasad, M.; Kavanagh, A.; Tzortzakis, N. Biochar Type, Ratio, and Nutrient Levels in Growing Media A Ff Ects Seedling Production And. Agronomy 2020, 10, 1421. [Google Scholar] [CrossRef]

- Grutzmacher, P.; Puga, A.P.; Bibar, M.P.S.; Coscione, A.R.; Packer, A.P.; de Andrade, C.A. Carbon Stability and Mitigation of Fertilizer Induced N2O Emissions in Soil Amended with Biochar. Sci. Total Environ. 2018, 625, 1459–1466. [Google Scholar] [CrossRef]

- Axelsson, L.; Franzén, M.; Ostwald, M.; Berndes, G.; Lakshmi, G.; Ravindranath, N.H. Perspective: Jatropha Cultivation in Southern India: Assessing Farmers’ Experiences. Biofuels Bioprod. Biorefining 2012, 6, 246–256. [Google Scholar] [CrossRef]

- Karlen, D.L.; Lal, R.; Follett, R.F.; Kimble, J.M.; Hatfield, J.L.; Miranowski, J.M.; Cambardella, C.A.; Manale, A.; Anex, R.P.; Rice, C.W. Crop Residues: The Rest of the Story. Environ. Sci. Technol. 2009, 43, 8011–8015. [Google Scholar] [CrossRef]

- Goyal, H.B.; Seal, D.; Saxena, R.C. Bio-Fuels from Thermochemical Conversion of Renewable Resources: A Review. Renew. Sustain. Energy Rev. 2008, 12, 504–517. [Google Scholar] [CrossRef]

- Bertero, M.; Sedran, U. Coprocessing of Bio-Oil in Fluid Catalytic Cracking; Elsevier B.V.: Amsterdam, The Netherlands, 2015; ISBN 9780444632906. [Google Scholar]

- Strahan, G.D.; Mullen, C.A.; Boateng, A.A. Characterizing Biomass Fast Pyrolysis Oils by 13C NMR and Chemometric Analysis. Energy Fuels 2011, 25, 5452–5461. [Google Scholar] [CrossRef]

- Amenaghawon, A.N.; Anyalewechi, C.L.; Okieimen, C.O.; Kusuma, H.S. Biomass Pyrolysis Technologies for Value-Added Products: A State-of-the-Art Review; Springer: Dordrecht, The Netherlands, 2021; Volume 23, ISBN 1066802101276. [Google Scholar]

- Kan, T.; Strezov, V.; Evans, T.; He, J.; Kumar, R.; Lu, Q. Catalytic Pyrolysis of Lignocellulosic Biomass: A Review of Variations in Process Factors and System Structure. Renew. Sustain. Energy Rev. 2020, 134, 110305. [Google Scholar] [CrossRef]

- Samolada, M.C.; Papafotica, A.; Vasalos, I.A. Catalyst Evaluation for Catalytic Biomass Pyrolysis. Energy Fuels 2000, 14, 1161–1167. [Google Scholar] [CrossRef]

- Naqvi, S.R.; Uemura, Y.; Yusup, S.; Sugiura, Y.; Nishiyama, N. In Situ Catalytic Fast Pyrolysis of Paddy Husk Pyrolysis Vapors over MCM-22 and ITQ-2 Zeolites. J. Anal. Appl. Pyrolysis 2015, 114, 32–39. [Google Scholar] [CrossRef]

- Cai, J.; Xu, D.; Dong, Z.; Yu, X.; Yang, Y.; Banks, S.W.; Bridgwater, A.V. Processing Thermogravimetric Analysis Data for Isoconversional Kinetic Analysis of Lignocellulosic Biomass Pyrolysis: Case Study of Corn Stalk. Renew. Sustain. Energy Rev. 2018, 82, 2705–2715. [Google Scholar] [CrossRef]

- Chen, W.H.; Kuo, P.C. A Study on Torrefaction of Various Biomass Materials and Its Impact on Lignocellulosic Structure Simulated by a Thermogravimetry. Energy 2010, 35, 2580–2586. [Google Scholar] [CrossRef]

- Martín, M.T.; Sanz, A.B.; Nozal, L.; Castro, F.; Alonso, R.; Aguirre, J.L.; González, S.D.; Matía, M.P.; Novella, J.L.; Peinado, M.; et al. Microwave-Assisted Pyrolysis of Mediterranean Forest Biomass Waste: Bioproduct Characterization. J. Anal. Appl. Pyrolysis 2017, 127, 278–285. [Google Scholar] [CrossRef]

- Mohammed, I.Y.; Abakr, Y.A.; Kazi, F.K.; Yusuf, S.; Alshareef, I.; Chin, S.A. Pyrolysis of Napier Grass in a Fixed Bed Reactor: Effect of Operating Conditions on Product Yields and Characteristics. BioResources 2015, 10, 6457–6478. [Google Scholar] [CrossRef]

- Navarro, M.V.; López, J.M.; Veses, A.; Callén, M.S.; García, T. Kinetic Study for the Co-Pyrolysis of Lignocellulosic Biomass and Plastics Using the Distributed Activation Energy Model. Energy 2018, 165, 731–742. [Google Scholar] [CrossRef]

- Garcia-Nunez, J.A.; Pelaez-Samaniego, M.R.; Garcia-Perez, M.E.; Fonts, I.; Abrego, J.; Westerhof, R.J.M.; Garcia-Perez, M. Historical Developments of Pyrolysis Reactors: A Review; ACS Publications: Washington, DC, USA, 2017; Volume 31, ISBN 5093357758. [Google Scholar]

- Estel, L.; Poux, M.; Benamara, N.; Polaert, I. Continuous Flow-Microwave Reactor: Where Are We? Chem. Eng. Process. Process Intensif. 2017, 113, 56–64. [Google Scholar] [CrossRef]

- Lo, S.L.; Huang, Y.F.; Chiueh, P.T.; Kuan, W.H. Microwave Pyrolysis of Lignocellulosic Biomass. Energy Procedia 2017, 105, 41–46. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, M.; Liu, H.; Li, L.; Ma, C.; Song, Z. A Microwave Reactor for Characterization of Pyrolyzed Biomass. Bioresour. Technol. 2012, 104, 673–678. [Google Scholar] [CrossRef]

- Wang, X.; Chen, H.; Luo, K.; Shao, J.; Yang, H. The Influence of Microwave Drying on Biomass Pyrolysis. Energy Fuels 2008, 22, 67–74. [Google Scholar] [CrossRef]

- Zhou, J.; Liu, S.; Zhou, N.; Fan, L.; Zhang, Y.; Peng, P.; Anderson, E.; Ding, K.; Wang, Y.; Liu, Y.; et al. Development and Application of a Continuous Fast Microwave Pyrolysis System for Sewage Sludge Utilization. Bioresour. Technol. 2018, 256, 295–301. [Google Scholar] [CrossRef]

- Zhu, H.; Ye, J.; Gulati, T.; Yang, Y.; Liao, Y.; Yang, Y.; Huang, K. Dynamic Analysis of Continuous-Flow Microwave Reactor with a Screw Propeller. Appl. Therm. Eng. 2017, 123, 1456–1461. [Google Scholar] [CrossRef]

- Miura, M.; Kaga, H.; Sakurai, A.; Kakuchi, T.; Takahashi, K. Rapid Pyrolysis of Wood Block by Microwave Heating. J. Anal. Appl. Pyrolysis 2004, 71, 187–199. [Google Scholar] [CrossRef]

- Park, S.H.; Kim, H.S.; You, B.S. Improving the Tensile Strength of Mg-7Sn-1Al-1Zn Alloy through Artificial Cooling during Extrusion. Mater. Sci. Eng. A 2015, 625, 369–373. [Google Scholar] [CrossRef]

- Guo, X.; Wang, S.; Wang, Q.; Guo, Z.; Luo, Z. Properties of Bio-Oil from Fast Pyrolysis of Rice Husk. Chin. J. Chem. Eng. 2011, 19, 116–121. [Google Scholar] [CrossRef]

- Santos, T.; Costa, L.C.; Hennetier, L.; Valente, M.A.; Monteiro, J.; Sousa, J. Microwave Processing of Porcelain Tableware Using a Multiple Generator Configuration. Appl. Therm. Eng. 2013, 50, 677–682. [Google Scholar] [CrossRef]

- Ertaş, M.; Hakki Alma, M. Pyrolysis of Laurel (Laurus nobilis L.) Extraction Residues in a Fixed-Bed Reactor: Characterization of Bio-Oil and Bio-Char. J. Anal. Appl. Pyrolysis 2010, 88, 22–29. [Google Scholar] [CrossRef]

- Nizami, A.S.; Shahzad, K.; Rehan, M.; Ouda, O.K.M.; Khan, M.Z.; Ismail, I.M.I.; Almeelbi, T.; Basahi, J.M.; Demirbas, A. Developing Waste Biorefinery in Makkah: A Way Forward to Convert Urban Waste into Renewable Energy. Appl. Energy 2017, 186, 189–196. [Google Scholar] [CrossRef]

- Ao, W.; Fu, J.; Mao, X.; Kang, Q.; Ran, C.; Liu, Y.; Zhang, H. Microwave Assisted Preparation of Activated Carbon from Biomass: A Review. Renew. Sustain. Energy Rev. 2018, 92, 958–979. [Google Scholar] [CrossRef]

- Chen, W.H.; Lin, B.J.; Huang, M.Y.; Chang, J.S. Thermochemical Conversion of Microalgal Biomass into Biofuels: A Review. Bioresour. Technol. 2015, 184, 314–327. [Google Scholar] [CrossRef] [PubMed]

- Akpanudoh, N.S.; Gobin, K.; Manos, G. Catalytic Degradation of Plastic Waste to Liquid Fuel over Commercial Cracking Catalysts: Effect of Polymer to Catalyst Ratio/Acidity Content. J. Mol. Catal. A Chem. 2005, 235, 67–73. [Google Scholar] [CrossRef]

- Salema, A.A.; Afzal, M.T. Numerical Simulation of Heating Behaviour in Biomass Bed and Pellets under Multimode Microwave System. Int. J. Therm. Sci. 2015, 91, 12–24. [Google Scholar] [CrossRef]

- Lam, S.S.; Wan Mahari, W.A.; Ok, Y.S.; Peng, W.; Chong, C.T.; Ma, N.L.; Chase, H.A.; Liew, Z.; Yusup, S.; Kwon, E.E.; et al. Microwave Vacuum Pyrolysis of Waste Plastic and Used Cooking Oil for Simultaneous Waste Reduction and Sustainable Energy Conversion: Recovery of Cleaner Liquid Fuel and Techno-Economic Analysis. Renew. Sustain. Energy Rev. 2019, 115, 109359. [Google Scholar] [CrossRef]

- Liew, R.K.; Chai, C.; Yek, P.N.Y.; Phang, X.Y.; Chong, M.Y.; Nam, W.L.; Su, M.H.; Lam, W.H.; Ma, N.L.; Lam, S.S. Innovative Production of Highly Porous Carbon for Industrial Effluent Remediation via Microwave Vacuum Pyrolysis plus Sodium-Potassium Hydroxide Mixture Activation. J. Clean. Prod. 2019, 208, 1436–1445. [Google Scholar] [CrossRef]

- Wan Mahari, W.A.; Chong, C.T.; Lam, W.H.; Anuar, T.N.S.T.; Ma, N.L.; Ibrahim, M.D.; Lam, S.S. Microwave Co-Pyrolysis of Waste Polyolefins and Waste Cooking Oil: Influence of N2 Atmosphere versus Vacuum Environment. Energy Convers. Manag. 2018, 171, 1292–1301. [Google Scholar] [CrossRef]

- Wang, Y.; Zeng, Z.; Tian, X.; Dai, L.; Jiang, L.; Zhang, S.; Wu, Q.; Wen, P.; Fu, G.; Liu, Y.; et al. Production of Bio-Oil from Agricultural Waste by Using a Continuous Fast Microwave Pyrolysis System. Bioresour. Technol. 2018, 269, 162–168. [Google Scholar] [CrossRef]

- Salema, A.A.; Ani, F.N. Bioresource Technology Microwave Induced Pyrolysis of Oil Palm Biomass. Bioresour. Technol. 2011, 102, 3388–3395. [Google Scholar] [CrossRef] [PubMed]

- Xie, Q.; Addy, M.; Liu, S.; Zhang, B.; Cheng, Y.; Wan, Y.; Li, Y.; Liu, Y.; Lin, X.; Chen, P.; et al. Fast Microwave-Assisted Catalytic Co-Pyrolysis of Microalgae and Scum for Bio-Oil Production. Fuel 2015, 160, 577–582. [Google Scholar] [CrossRef]

- Anwar, Z.; Gulfraz, M.; Irshad, M. ScienceDirect Agro-Industrial Lignocellulosic Biomass a Key to Unlock the Future Bio-Energy: A Brief Review. J. Radiat. Res. Appl. Sci. 2014, 7, 163–173. [Google Scholar] [CrossRef]

- Kaczor, Z.; Buliński, Z.; Werle, S. Modelling Approaches to Waste Biomass Pyrolysis: A Review. Renew. Energy 2020, 159, 427–443. [Google Scholar] [CrossRef]

- Zhu, X.; Li, Y.; Wang, X. Machine Learning Prediction of Biochar Yield and Carbon Contents in Biochar Based on Biomass Characteristics and Pyrolysis Conditions. Bioresour. Technol. 2019, 288, 121527. [Google Scholar] [CrossRef]

- Pathy, A.; Meher, S.; Balasubramanian, P. Predicting Algal Biochar Yield Using EXtreme Gradient Boosting (XGB) Algorithm of Machine Learning Methods. Algal Res. 2020, 50, 102006. [Google Scholar] [CrossRef]

- Khan, M.; Ullah, Z.; Nouman, M.; Khan, A. Artificial Neural Networks for the Prediction of Biochar Yield: A Comparative Study of Metaheuristic Algorithms. Bioresour. Technol. 2022, 355, 127215. [Google Scholar] [CrossRef]

- Li, Y.; Gupta, R.; Zhang, Q.; You, S. Review of Biochar Production via Crop Residue Pyrolysis: Development and Perspectives. Bioresour. Technol. 2023, 369, 128423. [Google Scholar] [CrossRef]

- Hai, A.; Bharath, G.; Patah, M.F.A.; Daud, W.M.A.W.; Rambabu, K.; Show, P.L.; Banat, F. Machine Learning Models for the Prediction of Total Yield and Specific Surface Area of Biochar Derived from Agricultural Biomass by Pyrolysis. Environ. Technol. Innov. 2023, 30, 103071. [Google Scholar] [CrossRef]

- Venkata Ratnam, M.; Karthikeyan, C.; Nagamalleswara Rao, K.; Meena, V. Magnesium Oxide Nanoparticles for Effective Photocatalytic Degradation of Methyl Red Dye in Aqueous Solutions: Optimization Studies Using Response Surface Methodology. Mater. Today Proc. 2019, 26, 2308–2313. [Google Scholar] [CrossRef]

- Tripathi, M.; Bhatnagar, A.; Mubarak, N.M.; Sahu, J.N.; Ganesan, P. RSM Optimization of Microwave Pyrolysis Parameters to Produce OPS Char with High Yield and Large BET Surface Area. Fuel 2020, 277, 118184. [Google Scholar] [CrossRef]

- Asgari, S.; Moazamigoodarzi, H.; Tsai, P.J.; Pal, S.; Zheng, R.; Badawy, G.; Puri, I.K. Hybrid Surrogate Model for Online Temperature and Pressure Predictions in Data Centers. Futur. Gener. Comput. Syst. 2021, 114, 531–547. [Google Scholar] [CrossRef]

- El Aziz, M.A.; Hemdan, A.M.; Ewees, A.A.; Elhoseny, M.; Shehab, A.; Hassanien, A.E.; Xiong, S. Prediction of Biochar Yield Using Adaptive Neuro-Fuzzy Inference System with Particle Swarm Optimization. In Proceedings of the 2017 IEEE PES-IAS Power Africa Conference, Harnessing Energy, Information and Communications Technology (ICT) for Affordable Electrification of Africa, Accra, Ghana, 27–30 June 2017; pp. 115–120. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, L.; Wang, Q.; Yang, X.; Tu, X. Pyrolysis Products from Industrial Waste Biomass Based on a Neural Network Model. J. Anal. Appl. Pyrolysis 2016, 120, 94–102. [Google Scholar] [CrossRef]

- Çepelioğullar, Ö.; Mutlu, İ.; Yaman, S.; Haykiri-Acma, H. A Study to Predict Pyrolytic Behaviors of Refuse-Derived Fuel (RDF): Artificial Neural Network Application. J. Anal. Appl. Pyrolysis 2016, 122, 84–94. [Google Scholar] [CrossRef]

- Baruah, D.; Baruah, D.C.; Hazarika, M.K. Artificial Neural Network Based Modeling of Biomass Gasification in Fixed Bed Downdraft Gasifiers. Biomass Bioenergy 2017, 98, 264–271. [Google Scholar] [CrossRef]

- Puig-Arnavat, M.; Hernández, J.A.; Bruno, J.C.; Coronas, A. Artificial Neural Network Models for Biomass Gasification in Fluidized Bed Gasifiers. Biomass Bioenergy 2013, 49, 279–289. [Google Scholar] [CrossRef]

- Sunphorka, S.; Chalermsinsuwan, B.; Piumsomboon, P. Application of Artificial Neural Network for Kinetic Parameters Prediction of Biomass Oxidation from Biomass Properties. J. Energy Inst. 2017, 90, 51–61. [Google Scholar] [CrossRef]

- Sunphorka, S.; Chalermsinsuwan, B.; Piumsomboon, P. Artificial Neural Network Model for the Prediction of Kinetic Parameters of Biomass Pyrolysis from Its Constituents. Fuel 2017, 193, 142–158. [Google Scholar] [CrossRef]

- Silitonga, A.S.; Mahlia, T.M.I.; Shamsuddin, A.H.; Ong, H.C.; Milano, J.; Kusumo, F.; Sebayang, A.H.; Dharma, S.; Ibrahim, H.; Husin, H.; et al. Optimization of Cerbera Manghas Biodiesel Production Using Artificial Neural Networks Integrated with Ant Colony Optimization. Energies 2019, 12, 3811. [Google Scholar] [CrossRef]

- García Nieto, P.J.; García-Gonzalo, E.; Paredes-Sánchez, J.P.; Bernardo Sánchez, A.; Menéndez Fernández, M. Predictive Modelling of the Higher Heating Value in Biomass Torrefaction for the Energy Treatment Process Using Machine-Learning Techniques. Neural Comput. Appl. 2019, 31, 8823–8836. [Google Scholar] [CrossRef]

- Nematian, M.; Keske, C.; Ng’ombe, J.N. A Techno-Economic Analysis of Biochar Production and the Bioeconomy for Orchard Biomass. Waste Manag. 2021, 135, 467–477. [Google Scholar] [CrossRef] [PubMed]

- Bowyer, C.; Allen, B.; Nanni, S. Promoting a Circular, Sustainable Bioeconomy—Delivering the Bioeconomy Society Needs. Available online: https://ieep.eu/news/promoting-a-circular-sustainable-bioeconomy-delivering-the-bioeconomy-society-needs/ (accessed on 5 September 2022).

- Act Agricultural Act of 2014. Available online: https://www.congress.gov/bill/113th-congress/house-bill/2642 (accessed on 7 February 2022).

- Bill, F. Food, Conservation, and Energy Act of 2008. Available online: https://www.congress.gov/bill/110th-congress/house-bill/6124 (accessed on 18 June 2022).

- Service, N.R.C. Interim Conservation Practice Standard Soil Carbon Amendment. Available online: https://static1.squarespace.com/static/5b9362d89d5abb8c51d474f8/t/5e429f851f12287bd48c8e1a/1581424518098/CPS_808_SoilCarbonAmendment_Interim.pdf (accessed on 15 December 2021).

- Secretariat Indian Biochar and Bioresources Network. Available online: https://ibbn.org.in/ (accessed on 16 January 2023).

- Chen, W.; Farooq, W.; Shahbaz, M.; Raza, S.; Ali, I.; Al-ansari, T.; Aishah, N.; Amin, S. Current Status of Biohydrogen Production from Lignocellulosic Biomass, Technical Challenges and Commercial Potential through Pyrolysis Process. Energy 2021, 226, 120433. [Google Scholar] [CrossRef]

- Bridgwater, A.V. Review of Fast Pyrolysis of Biomass and Product Upgrading. Biomass Bioenergy 2011, 38, 68–94. [Google Scholar] [CrossRef]

- Shyam, S.; Arun, J.; Panchamoorthy, K.; Ribhu, G.; Ashish, M.; Ajay, S. Chemosphere Biomass as Source for Hydrochar and Biochar Production to Recover Phosphates from Wastewater: A Review on Challenges, Commercialization, and Future Perspectives. Chemosphere 2022, 286, 131490. [Google Scholar] [CrossRef]

- Draft, P.R. Survey and Analysis of the US Biochar Industry; Dovetail partners report; Dovetail Partners: Washington, DC, USA, 2018; pp. 1–9. [Google Scholar]

- Fernandez-akarregi, A.R.; Makibar, J.; Lopez, G.; Amutio, M.; Olazar, M. Design and Operation of a Conical Spouted Bed Reactor Pilot Plant (25 Kg/h) for Biomass Fast Pyrolysis. Fuel Process. Technol. 2013, 112, 48–56. [Google Scholar] [CrossRef]

- Raza, S.; Tariq, R.; Shahbaz, M.; Naqvi, M.; Aslam, M.; Khan, Z.; Mackey, H.; Mckay, G.; Al-ansari, T. Recent Developments on Sewage Sludge Pyrolysis and Its Kinetics: Resources Recovery, Thermogravimetric Platforms, and Innovative Prospects. Comput. Chem. Eng. 2021, 150, 107325. [Google Scholar] [CrossRef]

- Matovic, D. Biochar as a Viable Carbon Sequestration Option: Global and Canadian Perspective. Energy 2016, 36, 2011–2016. [Google Scholar] [CrossRef]

- Ahmad, J.; Patuzzi, F.; Rashid, U.; Shahabz, M.; Ngamcharussrivichai, C.; Baratieri, M. Exploring untapped effect of process conditions on biochar characteristics and applications. Environ. Technol. Innov. 2020, 21, 101310. [Google Scholar] [CrossRef]

- Fytili, D.; Zabaniotou, A. Circular Economy Synergistic Opportunities of Decentralized Thermochemical Systems for Bioenergy and Biochar Production Fueled with Agro-Industrial Wastes with Environmental Sustainability and Social Acceptance: A Review. Curr. Sustain. Energy Rep. 2018, 5, 150–155. [Google Scholar] [CrossRef]

- Haeldermans, T.; Campion, L.; Kuppens, T.; Vanreppelen, K.; Cuypers, A.; Schreurs, S. A Comparative Techno-Economic Assessment of Biochar Production from Different Residue Streams Using Conventional and Microwave Pyrolysis. Bioresour. Technol. 2020, 318, 124083. [Google Scholar] [CrossRef] [PubMed]

| Countries | Major Crops | Agricultural Biomass Waste Generated |

|---|---|---|

| Asian countries | Rice | Husk, straw, hull |

| India, China, Pakistan, and Thailand | Sugarcane | Bagasses |

| Indonesia, Malaysia, Thailand, and Nigeria | Palm | Kernel shells, palm fibres |

| Thailand, Indonesia, and Malaysia | Rubber | Roots, barks, leaves, unproductive rubber trees |

| Biochar Feedstock | Temperature °C | Components (wt.%) | Reference | ||||||

|---|---|---|---|---|---|---|---|---|---|

| C | N | O | H | K | S | P | |||

| Rice straw | 800 | 36.2 | 39.8 | - | - | - | - | [22] | |

| Corn cob | 600 | 79.1 | 4.25 | - | - | 10.1 | - | - | [23] |

| Corn stover | 600 | 69.8 | 1.01 | - | - | 9.95 | 0.181 | 2.461 | |

| Peanut hull | 600 | 65.5 | 2.0 | - | - | 10.0 | 0.0016 | 0.0015 | |

| Corn stover | 400 | 59.5 | 1.16 | - | - | 7.33 | 0.137 | 1.705 | |

| Corn stover and cob | 300 | 57.51 | 1.62 | 35.12 | - | 0.28 | - | - | |

| Rice husk and high-density polyethylene | 500 | 46.8 | 0.67 | - | 0.036 | - | - | - | [24] |

| Sugarcane bagasse and PP | 600 | 76.5 | 3.03 | 19.8 | 2.93 | - | - | - | [10] |

| Wheat straw and PS | 600 | 62.9 | - | - | - | - | - | - | [24] |

| Walnut shell | 900 | 55.3 | 0.47 | 1.6 | 0.89 | - | - | - | [25] |

| Pros | Cons |

|---|---|

| Very selective and volumetric heating of microwave absorbers | Consumption of energy is greater in poor microwave absorbers |

| Cost effective with reduced reaction temperature and time | Generation of plasma and hotspots |

| Control of reaction temperature by ON/OFF system | Thermal disturbances and disproportionate heating |

| Indigenous temperature measurement by thermocouple and infrared thermometer | Microwave arcing |

| Process | Microwave Absorber | Feed | Time (min) | Bio-Oil | Gas | Biochar | Reference |

|---|---|---|---|---|---|---|---|

| Domestic modified 1 kW microwave reactor | Char | Palm kernel shell | 25 | 20 | 30 | 50 | [67] |

| Oil palm fiber | 25 | 7 | 23 | 70 | |||

| Microwave pyrolysis reactor | Silicon carbide | Wheat straw | 10 | 32 | 22 | 46 | [49] |

| Lab scale multimode mode microwave reactor with 4 magnetrons | Char | Rice husk | 20 | 23 | 34 | 43 | [68] |

| Single mode microwave pyrolysis reactor with 1 magnetron | N/A | Bamboo leaves | 30 | 44 | 34 | 22 | [69] |

| Corn stover | 30 | 40 | 30 | 20 | |||

| Domestic lab scale single mode microwave reactor | Activated carbon | Coconut sheath | 15 | 46 | 32 | 22 | [8] |

| Single mode microwave reactor with 1 magnetron | N/A | Waste coffee grounds | 30 | 43 | 35 | 21 | [69] |

| Single mode microwave reactor with 1 magnetron | N/A | Sugarcane peel | 30 | 43 | 37 | 20 | [69] |

| Pilot scale 2 magnetron multimode microwave reactor | Silicon carbide | Large wood block | 15 | 18 | 61 | 21 | [48] |

| Policy | Support | Reference |

|---|---|---|

| Biorefinery, renewable chemical and biobased product manufacturing assistance | 80% project cost | [90] |

| Biomass crop assistance program (BCAP) | Sustainable development of crops | [91] |

| Natural resources conservation services (NRCS) | Biochar—soil amendment | [92] |

| India Biochar and Bioresources Network | Biochar—soil amendment | [93] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rex, P.; Mohammed Ismail, K.R.; Meenakshisundaram, N.; Barmavatu, P.; Sai Bharadwaj, A.V.S.L. Agricultural Biomass Waste to Biochar: A Review on Biochar Applications Using Machine Learning Approach and Circular Economy. ChemEngineering 2023, 7, 50. https://doi.org/10.3390/chemengineering7030050

Rex P, Mohammed Ismail KR, Meenakshisundaram N, Barmavatu P, Sai Bharadwaj AVSL. Agricultural Biomass Waste to Biochar: A Review on Biochar Applications Using Machine Learning Approach and Circular Economy. ChemEngineering. 2023; 7(3):50. https://doi.org/10.3390/chemengineering7030050

Chicago/Turabian StyleRex, Prathiba, Kalil Rahiman Mohammed Ismail, Nagaraj Meenakshisundaram, Praveen Barmavatu, and A V S L Sai Bharadwaj. 2023. "Agricultural Biomass Waste to Biochar: A Review on Biochar Applications Using Machine Learning Approach and Circular Economy" ChemEngineering 7, no. 3: 50. https://doi.org/10.3390/chemengineering7030050

APA StyleRex, P., Mohammed Ismail, K. R., Meenakshisundaram, N., Barmavatu, P., & Sai Bharadwaj, A. V. S. L. (2023). Agricultural Biomass Waste to Biochar: A Review on Biochar Applications Using Machine Learning Approach and Circular Economy. ChemEngineering, 7(3), 50. https://doi.org/10.3390/chemengineering7030050