Abstract

The aim of the work was to assess the possibility of utilizing the waste generated in the injection molding process for the production of new products based on polyamide 6 reinforced with glass fiber. The manufactured samples were prepared with the addition of 5, 10, 15, and 100 wt.% regrind from the runner system. The impact strength, tensile strength, and hardness of injection products were obtained directly and were assessed after conditioning in distilled water for 24 h. Moreover, the structure of the tested materials was assessed using the FTIR method and their thermal properties using the DSC method. The results of the tests confirm that the addition of regrind up to 15 wt.% to virgin polyamide does not adversely affect its impact strength, tensile strength, and hardness. The water-conditioned materials showed higher values of impact strength but lower values of tensile strength and Young’s modulus at a higher elongation at break. The obtained results are important due to the assumptions of the circular economy and the minimization of the amount of waste and material losses during the injection process.

1. Introduction

Polymer materials have played an essential role in the development of modern society. Due to the favorable material properties and affordable price, they have found applications in many different sectors, from packaging and construction to electronics and agriculture [1]. Approximately 99% of the plastics produced today come from crude oil, and the packaging industry alone uses over 38% of these plastics [2]. Unfortunately, it is estimated that approximately 80% of the total plastic produced, i.e., 6.3 trillion tons of plastic, has been thrown away [3]. These figures confirm the mismanagement of waste, the loss of resources, and the growing ecological disaster. In order to prevent the loss of material resources and environmental pollution, plastics management should be implemented in accordance with the assumptions of the circular economy. The transition to a circular economy (CE) should be implemented throughout the polymer materials processing chain to ensure circular design, production, use, and disposal of waste [4]. Reducing the amount of polymer plastic waste using recycled materials and reducing the carbon footprint using raw materials from renewable sources are key activities in line with the circular economy. The concept of sustainable development was enshrined in the Brundtland Report of the World Commission on Environment and Development of 1987. Sustainable development is defined there as development that meets the needs of the present without compromising the ability of future generations to meet their own needs [5]. Basic recycling methods include material, chemical, physical, biological, organic, and energy recovery [6]. However, reducing the carbon footprint of the products can be achieved by increasing the durability of the materials and using them in different product layouts by recycling the material flow in an open loop. One solution is to use recycled materials, such as mechanically recycled regrind, instead of virgin materials [7].

Depending on the application, different grades of polyamide are available, for example, PA6 and PA66, which account for around 90% of the world’s consumption of polyamide, and PA11 and PA12 [8,9]. Polyamide 6 is most commonly used in automotive, electrical/electronics, packaging, textiles, and consumer applications. The low heat deflection temperature, high water absorption, and dimensional instability of pure PA6 limit its use in elements requiring high thermal resistance. Therefore, it is used with various types of fillers, such as stabilizers [10], long or short glass fibers [11], or flame retardants [12]. Polyamide reinforced with short fiber, due to its properties such as high strength, stiffness, toughness, good resilience, dimensional stability, low tendency to creep, and chemical resistance, is used in the automotive industry, construction, and for the production of structural elements [13]. Among a wide variety of methods of thermoplastic processing, injection molding is one of the most utilized. In essence, plastic pellets are plasticized by the reciprocating screw in the barrel, and then, the melt is injected into the mold via cold or hot runner systems ending with a gate-entrance to the cavity. Since it is not always possible to use a hot runner system to minimize the waste, melted plastic is delivered to the mold cavity by the sprue and cold runners, which often doubles the weight of the final product.

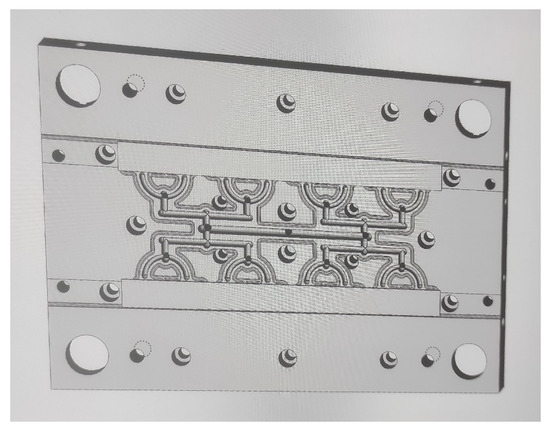

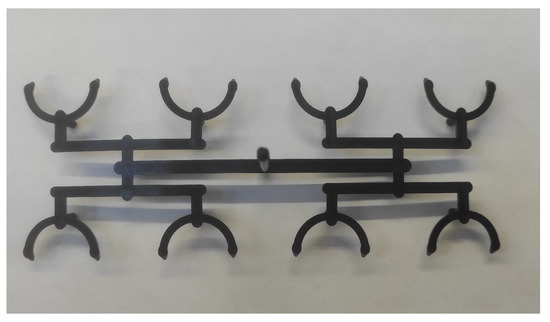

In Europe, the amount of plastic waste that was reprocessed in 2020 was only about 13% [14]. The polymer material obtained as a result of mechanical recycling can be classified as regrind (raw material produced as a result of waste milling), regranulate (raw material produced during extrusion without changing the chemical composition), and recompound or regenerate (chemically modified raw material) [6]. Since resin prices can be as high as 3.30 euro/kg for PA6 [15], it is economically viable to reuse sprues in the form of regrind without losing the mechanical strength or quality of the parts. An example of a cold runner in the injection mold type is shown in Figure 1. The function of the cold runner is to deliver the plasticized material to the cavities to produce the finished product [16]. Short-fiber-reinforced thermoplastic polymers are often used in industry due to their variety, recyclability, and low cost and cycle times associated with the injection molding process [17]. The characteristic waste of a runner in a cold runner system is shown in Figure 2. Therefore, this work aimed to investigate the possibility of using regrind for the production of new products with stable properties. The impact strength, tensile strength, and hardness were assessed for the manufactured materials made of polyamide with glass fiber and different regrind proportions. Moreover, the structure of the tested materials was assessed using the FTIR method and their thermal properties using the DSC method. The obtained results are important in promoting the assumptions of the circular economy and encouraging manufacturers to use production residues during injection molding.

Figure 1.

Cold runner injection mold type.

Figure 2.

The characteristic waste of a runner in a cold runner system.

2. Materials and Methods

2.1. Materials and Sample Preparation

Polyamide 6 (PA6) injection molding grade with 50% glass fiber and heat stabilized under the trade name Promyde B300 P2 G50 (Nurel S.A, Zaragoza, Spain) was used in the study. Promyde B300 P2 G50 has good flow properties combined with excellent mechanical and thermal properties and can be used in automotive and electrical applications, especially in long flow paths and thin-walled components.

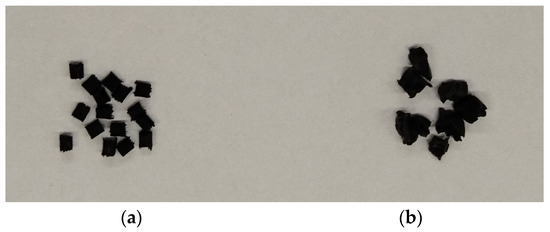

The waste of cold runner systems remaining after the industrial injection process was crushed with a low-speed granulator, and the regrind obtained during the process was used to make a new series of products (Figure 3). The samples were produced using an Engel Victory 50 injection molding machine. The injection molding temperature was 260 °C, mold temperature = 40 °C, injection pressure = 675 bar, holding pressure = 420 bar, and holding/cooling time = 6/15 s.

Figure 3.

Virgin polyamide granules (a) regrind from runner systems waste (b).

Samples containing 0, 5, 10, 15, and 100% regrind, respectively, were produced and described as 0PA, 5PA, 10PA, 15PA, and rPA. The second series of samples were conditioned for 24 h in distilled water and described as 0PAc; 5PAc; 10PAc; 15PAc; rPAc.

2.2. Methods

Fourier transform infrared (FT-IR) spectroscopy measurements were performed with a Jasco FT/IR-4600 spectrometer (Tokyo, Japan) at room temperature (23 °C) in attenuated total reflection mode (ATR-FT-IR) with 64 scans at a resolution of 4 cm−1.

Differential scanning calorimetry (DSC) analysis was conducted using a Netzsch DSC 204F1 Phoenix (Selb, Germany). Polyamide samples weighing 10.0 ± 0.15 mg were placed in aluminum crucibles with pierced lids, heated, and cooled in the range of 25–250 °C at a rate of 10 °C/min under an inert nitrogen atmosphere with two heating/cooling cycles. The crystallinity level of the materials was calculated based on the following equation:

where: ∆Hm is the measured melting enthalpy, ∆HPA is the theoretical melting enthalpy of 100% crystalline PA6 (190 J/g) [18], and expresses the weight percentage of used filler.

The impact strength of the rectangular unnotched samples of 80 × 10 × 4 mm was assessed by the Charpy method (ISO 179) at room temperature with a span of 62 mm. In addition, during the test, the peak load was measured as the maximum force (Fmax). A Zwick/Roell (Ulm, Germany) HIT 25P impact strength apparatus with a 5J hammer was used.

In order to determine the values of tensile strength Rm [MPa], Young’s modulus E [MPa], and elongation at breakage ε [%], a static tensile test was carried out in accordance with DIN EN ISO 527-1. A Zwick Z020NT universal testing machine was used with a tensile speed of 50 mm/min.

Rockwell hardness tests of samples were carried out using a Prüftechnik KB 150R apparatus with 358 N. Shore D hardness was measured with a Sauter HBD 100-0 (Germany) hardness tester in accordance with the PN-EN ISO 868 standard.

3. Results

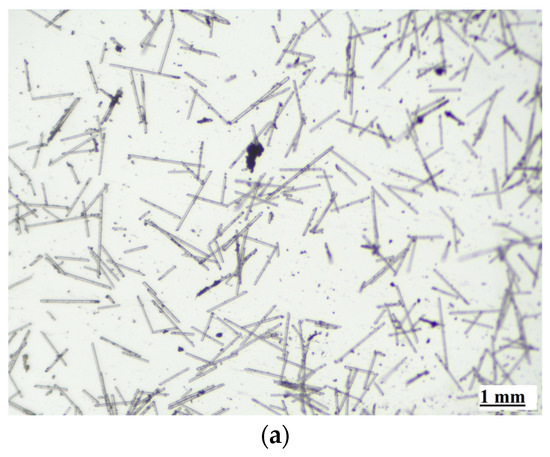

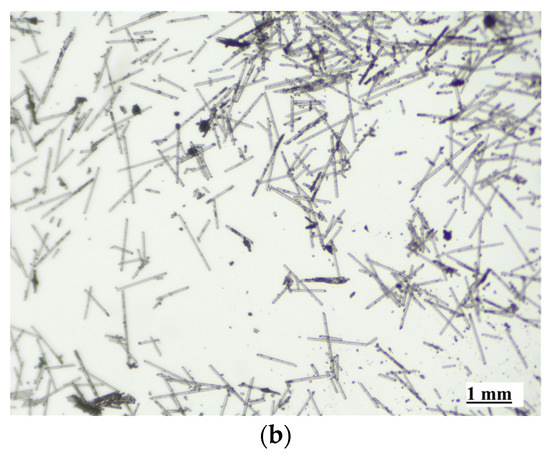

Short-glass-fiber-reinforced polyamide 6 materials are widely used in the automotive and construction industry where lightweight, creep resistance, stiffness, and durability are required [19]. During the mechanical recycling of fiber-reinforced polymers, the matrix material and fiber chains break, which can change the physical thermo-mechanical properties or appearance of the finished product [20]. The length of the fibers may be shortened during mechanical processing related to the grinding of residues. Therefore, the original granulate and regranulate were burned in a muffle furnace at 600 °C to separate the inorganic phase in the form of glass fibers. Figure 4 shows the structure of the glass fibers in the pure granulate and in the granulate from the milled runner waste. It should be emphasized that no significant shortening of the fibers in the regranulate was observed. This allows the waste to be classified as raw material and the use of material recycling in the production process. The average glass fiber length measured by optical microscopy was 1.6 mm for virgin PA6 and 1.4 mm for regranulate PA6, respectively.

Figure 4.

Glass fibers recovered from virgin PA6 (a) and regrind PA6 (b).

3.1. Fourier Transform Infrared Spectroscopy

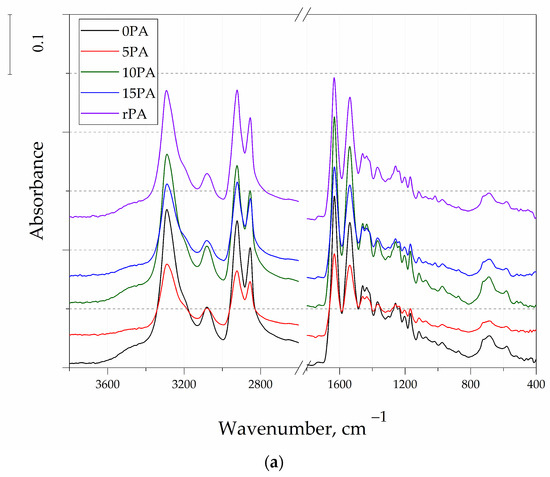

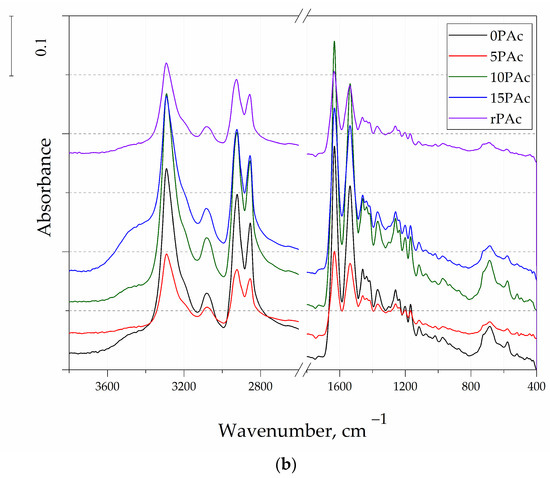

Polyamide is a polymer with a chain structure in which individual hydrocarbon segments are connected by amide bonds –CO–NH–. The abbreviation PA6 means a material obtained from a lactam with 6 carbon atoms (caprolactam). Figure 5a,b show the absorption spectra of the tested polyamides before and after conditioning. The most important changes in the spectra in the range from 400 to 1800 cm−1 and from 2600 to 4000 cm−1 were compared. All characteristic peaks for PA6 can be observed. The peak at 3300 cm−1 corresponds to the N–H (hydrogen bond) stretch, and the peak at 3080 cm−1 corresponds to the N–H stretch bond [21]. The peaks at 2920 cm−1 are ascribed to the CH2 asymmetric stretching (at 2930 cm−1), and 2848 cm−1 is ascribed to the CH2 symmetric stretching (reported at 2850 cm−1). The peaks between 2380 and 2310 cm−1 are from the CO2 group [22].

Figure 5.

FTIR spectra of tested materials (a) unconditioned PA (b) conditioned PA.

The peak at 1640 cm−1 is assigned to the amide I band, and the peak at 1550 cm−1 is assigned to the amide II band. The peak at 1460 cm−1 describes CH2 scissoring vibration, and the peak at 1365 cm−1 corresponds to CH2 twisting bond. The moves of amide I peak (1640 cm−1) and N–H stretching (3300 cm−1) to a lower and higher wavenumber after conditioning is caused by the enhancement of hydrogen bonding to the carbonyl group and the weakening of average hydrogen bond strength to the N–H group, correspondingly.

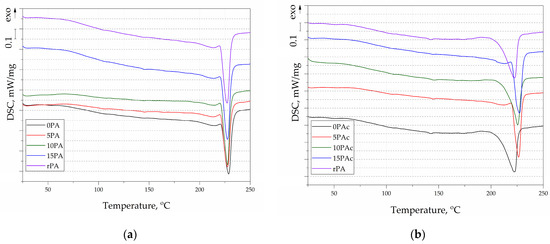

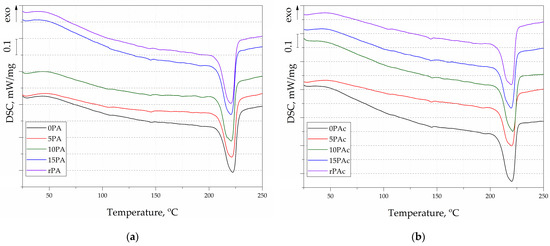

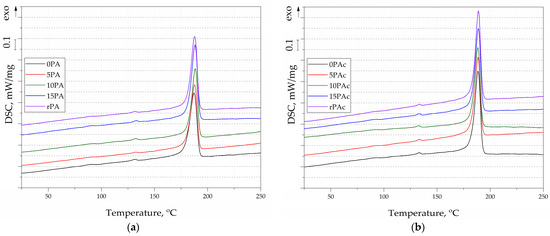

3.2. Differential Scanning Calorimetry

The determination of the degree of crystallinity of crystalline polymers after thermomechanical treatment is essential to understand its properties [23,24]. DSC analysis was performed for virgin material and samples containing regrind. The thermograms recorded during the first and second heating and the first cooling in the DSC test are shown in Figure 6, Figure 7 and Figure 8. The melting temperatures from the first and second heating (TmI and TmII) and temperature crystallization Tc from the first cooling cycle, as well as the melting enthalpy (ΔHmI and ΔHmII) and the degree of crystallinity (XcI and XcII), are summarized in Table 1. The main endothermic peak related to the melting of the polymer material as a result of the first heating cycle was observed at a temperature of approx. 227 °C. A slight decrease in the melting point can be observed for conditioned samples, especially for samples with a high content of regrind and regrind only (rPAc). A single peak at the melting point (TmII) of approximately 220 °C for all samples tested was observed in the second heating cycle. The melting temperature variations were very small, confirming that post-processing material can be recycled at constant process parameters like raw polyamide. Furthermore, the crystallization temperature in all cases was similar and averaged 188 °C. A slight increase in the degree of crystallinity can be observed for the conditioned materials both in the first and in the second heating cycle. The average XcI value for the unconditioned polyamide was 35% and, for the conditioned, 37%. However, the value of XcII for the PA series was, on average, 25% and for PAc series 26%. No significant influence of the regrind addition on the thermal properties of the tested materials was observed. This proves that secondary material from post-production waste can be successfully used to produce new products with stable thermal properties.

Figure 6.

DSC thermographs of the samples after first heating cycle: (a) polyamide samples before conditioning (b) polyamide after conditioning.

Figure 7.

DSC thermograms of the samples after second heating cycle: (a) polyamide samples before conditioning (b) polyamide after conditioning.

Figure 8.

DSC thermograms of the samples after first cooling cycle: (a) polyamide samples before conditioning (b) polyamide after conditioning.

Table 1.

Melting TmI and TmII and crystallization temperatures Tc, melting enthalpy, and crystallization degree values of the investigated materials.

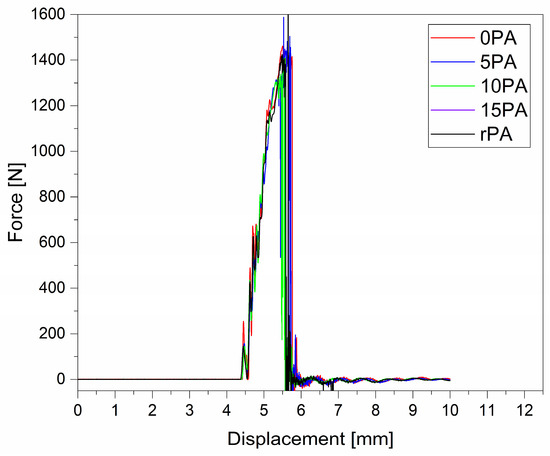

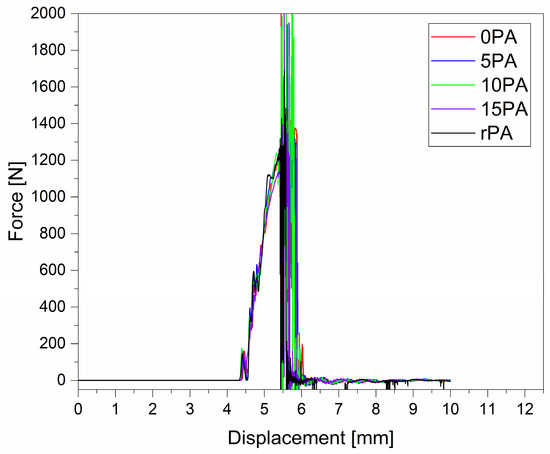

3.3. Impact Strength

The impact strength of polymeric materials is important due to the area of their application. Polyamide reinforced with glass fiber is characterized by high rigidity and dimensional stability, which allows it to be used in the production of responsible structural elements. Moisture or water can affect the mechanical, physicochemical properties, and dimensional stability of polyamide products [25]. Polyamide, in its structure, has polar amide groups that can form hydrogen bonds with water molecules; therefore, conditioning products in water after production significantly impact their properties [26]. The presence of water between the polymer chains increases the mobility of the chain, causing the effect of polyamide plasticization [27]. Therefore, stiffness and hardness after conditioning are reduced [28]. Samples conditioned in water were characterized by higher impact strength than unconditioned samples (Table 2). The average value of impact strength for conditioned samples with regranulate and virgin samples was 66 kJ/m2, while for not conditioned, 62 kJ/m2. Figure 9 and Figure 10 show the characteristic curves of maximum force versus displacement recorded during the unnotched Charpy impact test for the verified materials. All tested polyamide samples were broken with a hammer blow in accordance with the given measurement parameters. For the tested materials, a significant increase in the maximum force that was needed to destroy the samples subjected to conditioning can be observed. The occurrence of damage in a thermoplastic material containing short fibers is most often caused by two factors: fiber matrix deboning and microcracks in the matrix [29,30].

Table 2.

Impact strength values of the tested materials.

Figure 9.

The load-displacement curves of the investigated materials.

Figure 10.

The load–displacement curves of the investigated materials after condition.

Thomason also reports that conditioning the polyamide in hot water improves its impact strength [31]. However, for samples produced 100% from the regranulate, a decrease in impact value for both conditioned and not conditioned samples was observed. The reason for the decrease in the impact strength of materials made of regranulate or regrind may be degradation processes occurring during mechanical recycling and problems with miscibility in the polymer blend [6]. The absorbed water in the amorphous phase of the PA6 matrix can act as a plasticizer, leading to a reduction in the strength of the Van der Waals interactions. Therefore, as a result of conditioning, PA6 shows a loss of strength and stiffness but gains an increase in macro strength [32]. The obtained results confirm that materials containing up to 15% by mass of regranulate can be successfully compared with products made of virgin materials because they do not show a drastic decrease in impact properties. In addition, a beneficial effect of improving the impact strength by conditioning the samples in water was observed.

3.4. Tensile Strength

The results of the tensile test of the tested samples are presented in Table 3. All samples broke brittlely during testing. The presence of glass fibers in the tested polyamide affects its stiffness and brittle fracture. For materials with regrind content up to 15 wt.%, a slight decrease in tensile strength was observed. However, the Young’s modulus values were similar except for in the 15PA and rPA samples. The materials conditioned in water showed lower values of tensile strength and Young’s modulus but higher elongation at break [33]. Water can cause the polymer to swell and change its dimensional stability, stiffness, and permeability. The moisture acts as a plasticizer that reduces entanglement and bonding between molecular chains, thus, increasing their volume and mobility [31]. Therefore, absorbed water also lowers the tensile modulus but increases the elongation at break [34]. Although a decrease in strength properties was observed, water conditioning reduced the differences in the properties of the tested materials. Table 2 shows that the tensile strength value for all tested samples after conditioning was similar and amounted to 177 MPa, except for the rPA sample. Therefore, it is important to condition polyamide products in water before using them. This allows them to obtain products with stable mechanical properties and protects them against an uncontrolled decrease in properties that may occur due to their use in conditions of increased humidity.

Table 3.

Tensile test results of the investigated materials.

3.5. Hardness

The hardness values of the tested samples are presented in Table 4 and Table 5. The Rockwell hardness test is usually applied to measure hard polymeric materials such as polyamide, polycarbonate, polystyrene, or polyoxymethylene. In this case, hardness is described as the resistance to being permanently indented by a ball-loaded indenter. The Shore D hardness tester has a sharp indenter tip and a spring with high stiffness; therefore, it can also be used for hard polymers. The presence of filler particles such as glass fiber or mineral fillers in the polymer matrix improves their hardness [35]. Therefore, commercially available varieties of polyamide with glass fibers are characterized by a high hardness value. Glass-fiber-reinforced polyamides may be used for housings, supports, industrial articles, and electrical insulating parts. Polyamides exhibit high stiffness due to the presence of hydrogen bonds formed between the amide and carbonyl groups, which, after conditioning in water, are partially destroyed, resulting in a decrease in stiffness [36]. Therefore, a slight decrease in the hardness of the tested materials was observed as a result of conditioning. The average Shore-D hardness for virgin polyamide and polyamide samples with regrind content was 63 and 60 after conditioning. In turn, the Rockwell hardness was at the level of 165 for unconditioned samples and 161 for conditioned samples. For samples made of 100% regrind, a decrease in Rockwell hardness was observed compared to the other tested materials.

Table 4.

Rockwell hardness values.

Table 5.

Shore-D hardness values.

4. Discussion

According to [37], the global injection molded plastics market is estimated to grow from 357.34 billion $ in 2021 to 476.46 billion $ in 2028 at a CAGR of 4.2% in the period 2021–2028. First, choosing the right parameters for the injection molding process, such as melting point, mold temperature, injection pressure, pressurization, injection speed, holding time, and cooling time, allows large-scale production of products with favorable properties and minimal waste of resources [38]. Once the appropriate processing conditions are established, and the energy losses during processing are limited, the next important step is to reduce material losses [39]. Mechanical or secondary recycling involves the reprocessing of plastic waste by physical methods. Most often, plastic waste is shredded, washed, disinfected, and sorted mechanically according to the type of plastic. The main disadvantage of this method is the deterioration of the product properties, mainly related to the decrease in the molecular weight of the polymer after each cycle as a result of chain scission [40]. Therefore, these studies were carried out to assess whether the introduction of a small amount of regrind up to 15 wt.% adversely affects the mechanical properties of the product. Only in the case of samples made of 100% regrind was a slight deterioration of mechanical properties observed [41]. To sum up, the use of post-injection waste from cold-runner systems and their return to the process allows for reducing production costs, consumption of polymeric materials of petrochemical origin, and introduction of a circular production system in the company.

5. Conclusions

The life of polymeric materials can be extended by recycling and reusing them. The efficient use of plastic waste not only allows us to reduce the pollution of our planet but can also bring benefits in the form of energy recovery. In this work, it was shown that the introduction of regrind from cold runner system waste in the amount of up to 15% for virgin polyamide does not affect the deterioration of mechanical properties such as impact strength, hardness, and mechanical strength of the finished product manufactured in injection technology. In addition, it was proven that conditioning polyamide products in water has a beneficial effect on improving their impact strength and stabilizing tensile strength values. There was no significant effect of the regrind addition on the thermal properties determined by differential scanning calorimetry analysis of the tested materials. This confirms that secondary material from post-production waste can be successfully used to produce new products with stable thermal properties. It should be emphasized that these studies are of great practical and economic importance for promoting the manufacture of products with the use of post-production regrind. This allows producers to reduce the costs incurred for purchasing raw materials and energy related to the production of petrochemical polymers.

Author Contributions

Conceptualization, D.M. and T.O.; methodology, D.M. and T.O; validation, D.M., T.O. and J.A.; formal analysis, D.M.; investigation, D.M. and T.O.; resources, J.A.; data curation, D.M.; writing—original draft preparation, D.M. and T.O; writing—review and editing, D.M.; visualization, J.A.; supervision, D.M.; project administration, D.M.; funding acquisition, D.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Ministry of Science and Higher Education in Poland, Grant No. 0613/SBAD/4820.

Data Availability Statement

Data sharing not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Payne, J.; McKeown, P.; Jones, M.D. A circular economy approach to plastic waste. Polym. Degrad. Stab. 2019, 165, 170–181. [Google Scholar] [CrossRef]

- Rabnawaz, M.; Wyman, I.; Auras, R.; Cheng, S. A roadmap towards green packaging: The current status and future outlook for polyesters in the packaging industry. Green Chem. 2017, 19, 4737–4753. [Google Scholar] [CrossRef]

- Bucknall, D.G. Plastics as a materials system in a circular economy. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2020, 378, 20190268. [Google Scholar] [CrossRef] [PubMed]

- Tseng, M.-L.; Chiu, A.S.F.; Liu, G.; Jantaralolica, T. Circular economy enables sustainable consumption and production in multi-level supply chain system. Resour. Conserv. Recycl. 2020, 154, 104601. [Google Scholar] [CrossRef]

- Banerjee, R.; Ray, S.S. Sustainability and Life Cycle Assessment of Thermoplastic Polymers for Packaging: A Review on Fundamental Principles and Applications. Macromol. Mater. Eng. 2022, 307, 2100794. [Google Scholar] [CrossRef]

- Shamsuyeva, M.; Endres, H.-J. Plastics in the context of the circular economy and sustainable plastics recycling: Comprehensive review on research development, standardization and market. Compos. Part C Open Access 2021, 6, 100168. [Google Scholar] [CrossRef]

- Tinz, J.; de Ancos, T.; Rohn, H. Carbon Footprint of Mechanical Recycling of Post-Industrial Plastic Waste: Study of ABS, PA66GF30, PC and POM Regrinds. Waste 2022, 1, 127–139. [Google Scholar] [CrossRef]

- Harrass, K.; Mauer, S.; Tsekov, R. Resistance of glass fibre reinforced polyamide 6.6 materials to automotive cooling fluids: An analytical method for lifetime prediction. Polym. Int. 2022, 71, 724–733. [Google Scholar] [CrossRef]

- Bahrami, M.; Abenojar, J.; Martínez, M.A. Comparative Characterization of Hot-Pressed Polyamide 11 and 12: Mechanical, Thermal and Durability Properties. Polymers 2021, 13, 3553. [Google Scholar] [CrossRef]

- Bradler, P.R.; Fischer, J.; Pohn, B.; Wallner, G.M.; Lang, R.W. Effect of stabilizers on the failure behavior of glass fiber reinforced polyamides for mounting and framing of solar energy applications. Energy Procedia 2017, 119, 828–834. [Google Scholar] [CrossRef]

- Frihi, D.; Layachi, A.; Gherib, S.; Stoclet, G.; Masenelli-Varlot, K.; Satha, H.; Seguela, R. Crystallization of glass-fiber-reinforced polyamide 66 composites: Influence of glass-fiber content and cooling rate. Compos. Sci. Technol. 2016, 130, 70–77. [Google Scholar] [CrossRef]

- Gao, J.; Huang, W.; He, W.; Long, L.; Qin, S. Superior flame retardancy of glass fiber-reinforced polyamide 6T composites by synergism between DOPO-based derivative and carbon nanotube. J. Therm. Anal. Calorim. 2022, 147, 1265–1274. [Google Scholar] [CrossRef]

- Rudzinski, S.; Häussler, L.; Harnisch, C.; Mäder, E.; Heinrich, G. Glass fibre reinforced polyamide composites: Thermal behaviour of sizings. Compos. Part A Appl. Sci. Manuf. 2011, 42, 157–164. [Google Scholar] [CrossRef]

- Hinczica, J.; Messiha, M.; Koch, T.; Frank, A.; Pinter, G. Influence of Recyclates on Mechanical Properties and Lifetime Performance of Polypropylene Materials. Procedia Struct. Integr. 2022, 42, 139–146. [Google Scholar] [CrossRef]

- Ceny Tworzyw Sztucznych. Available online: https://www.plastech.pl/ceny-tworzyw (accessed on 20 February 2023).

- Mathur, S.; Kumar, R.; Mathur, V. Mathematical Modeling and Fuzzy Analysis of Hot Runner in Comparison to Cold Runner in Injection Moulding. J. Adv. Manuf. Syst. 2019, 18, 657–676. [Google Scholar] [CrossRef]

- Lee, J.; Lee, H.; Kim, N. Fiber Orientation and Strain Rate-Dependent Tensile and Compressive Behavior of Injection Molded Polyamide-6 Reinforced with 20% Short Carbon Fiber. Polymers 2023, 15, 738. [Google Scholar] [CrossRef]

- Krištofič, M.; Marcinčin, A.; Ujhelyiová, A. DSC study of PA 6, polyamides and copolyamides. J. Therm. Anal. Calorim. 2000, 60, 357–369. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, Y.; Mallick, P.K. Effects of temperature and strain rate on the tensile behavior of short fiber reinforced polyamide-6. Polym. Compos. 2002, 23, 858–871. [Google Scholar] [CrossRef]

- Evens, T.; Bex, G.-J.; Yigit, M.; De Keyzer, J.; Desplentere, F.; Van Bael, A. The Influence of Mechanical Recycling on Properties in Injection Molding of Fiber-Reinforced Polypropylene. Int. Polym. Process. 2019, 34, 398–407. [Google Scholar] [CrossRef]

- Dooher, T.; Archer, E.; Walls, T.; McIlhagger, A.; Dixon, D. Ageing of laser sintered glass-filled Polyamide 12 (PA12) parts at elevated temperature and humidity. Polym. Polym. Compos. 2021, 29, S1294–S1304. [Google Scholar] [CrossRef]

- Rhee, S.; White, J.L. Crystal structure and morphology of biaxially oriented polyamide 12 films. J. Polym. Sci. Part B Polym. Phys. 2002, 40, 1189–1200. [Google Scholar] [CrossRef]

- Barczewski, M.; Mysiukiewicz, O.; Kloziński, A. Complex modification effect of linseed cake as an agricultural waste filler used in high density polyethylene composites. Iran. Polym. J. 2018, 27, 677–688. [Google Scholar] [CrossRef]

- Millot, C.; Fillot, L.-A.; Lame, O.; Sotta, P.; Seguela, R. Assessment of polyamide-6 crystallinity by DSC. J. Therm. Anal. Calorim. 2015, 122, 307–314. [Google Scholar] [CrossRef]

- Nguyen, P.H.; Spoljaric, S.; Seppälä, J. Redefining polyamide property profiles via renewable long-chain aliphatic segments: Towards impact resistance and low water absorption. Eur. Polym. J. 2018, 109, 16–25. [Google Scholar] [CrossRef]

- Acierno, S.; Van Puyvelde, P. Rheological behavior of polyamide 11 with varying initial moisture content. J. Appl. Polym. Sci. 2005, 97, 666–670. [Google Scholar] [CrossRef]

- Meyer, A.; Jones, N.; Lin, Y.; Kranbuehl, D. Characterizing and Modeling the Hydrolysis of Polyamide-11 in a pH 7 Water Environment. Macromolecules 2002, 35, 2784–2798. [Google Scholar] [CrossRef]

- Paolucci, F.; Peters, G.W.M.; Govaert, L.E. Plasticity-controlled failure of sintered and molded polyamide 12: Influence of temperature and water absorption. J. Appl. Polym. Sci. 2020, 137, 48525. [Google Scholar] [CrossRef]

- Sato, N.; Kurauchi, T.; Sato, S.; Kamigaito, O. Microfailure behaviour of randomly dispersed short fibre reinforced thermoplastic composites obtained by direct SEM observation. J. Mater. Sci. 1991, 26, 3891–3898. [Google Scholar] [CrossRef]

- Günzel, S.; Hickmann, S.; Wittemeyer, C.; Trappe, V. Effects of Fiber Orientation and Moisture on the Crack Growth in Short Glass Fiber Reinforced Polyamide. Adv. Eng. Mater. 2012, 14, 867–872. [Google Scholar] [CrossRef]

- Thomason, J.L. The influence of fibre length, diameter and concentration on the impact performance of long glass-fibre reinforced polyamide 6,6. Compos. Part A Appl. Sci. Manuf. 2009, 40, 114–124. [Google Scholar] [CrossRef]

- Lei, Y.; Zhang, T.; Zhang, J.; Zhang, B. Dimensional stability and mechanical performance evolution of continuous carbon fiber reinforced polyamide 6 composites under hygrothermal environment. J. Mater. Res. Technol. 2021, 13, 2126–2137. [Google Scholar] [CrossRef]

- Hassan, A.; Rahman, N.A.; Yahya, R. Moisture absorption effect on thermal, dynamic mechanical and mechanical properties of injection-molded short glass-fiber/polyamide 6,6 composites. Fibers Polym. 2012, 13, 899–906. [Google Scholar] [CrossRef]

- Mohd Ishak, Z.; Ariffin, A.; Senawi, R. Effects of hygrothermal aging and a silane coupling agent on the tensile properties of injection molded short glass fiber reinforced poly(butylene terephthalate) composites. Eur. Polym. J. 2001, 37, 1635–1647. [Google Scholar] [CrossRef]

- Kiran, M.D.; Govindaraju, H.K.; Jayaraju, T.; Kumar, N. Review-Effect of Fillers on Mechanical Properties of Polymer Matrix Composites. Mater. Today Proc. 2018, 5, 22421–22424. [Google Scholar] [CrossRef]

- Taktak, R.; Guermazi, N.; Derbeli, J.; Haddar, N. Effect of hygrothermal aging on the mechanical properties and ductile fracture of polyamide 6: Experimental and numerical approaches. Eng. Fract. Mech. 2015, 148, 122–133. [Google Scholar] [CrossRef]

- Injection Molded Plastics Market Size. Available online: https://www.fortunebusinessinsights.com/injection-molded-plastics-market-101970 (accessed on 20 February 2023).

- Kuram, E.; Tasci, E.; Altan, A.I.; Medar, M.M.; Yilmaz, F.; Ozcelik, B. Investigating the effects of recycling number and injection parameters on the mechanical properties of glass-fibre reinforced nylon 6 using Taguchi method. Mater. Des. 2013, 49, 139–150. [Google Scholar] [CrossRef]

- Ľudmila, D.; František, G. Influence of Regrind on Properties of Plastics Produced By Injection Moulding. Mater. Eng. 2011, 18, 44–48. [Google Scholar]

- Okan, M.; Aydin, H.M.; Barsbay, M. Current approaches to waste polymer utilization and minimization: A review. J. Chem. Technol. Biotechnol. 2019, 94, 8–21. [Google Scholar] [CrossRef]

- Eriksson, P.A.; Albertsson, A.C.; Boydell, P.; Prautzsch, G.; Månson, J.A. Prediction of Mechanical Properties of Recycled Fiberglass Reinforced Polyamide 66. Polym. Compos. 1996, 17, 830–839. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).