1. Introduction

Drying is a frequently used process for treating many different types of materials before their further use or final consumption. In energy applications, drying is an essential process for preparing the optimal conditions for fuel utilization. Energy processing numerous kinds of biomass is often complicated by inhomogeneity and variety of quality. Non-uniform granulometry and high water content is affected by the origin and storage of the material [

1]. The water content of residual and waste wood reaches up to 50 wt % according to weight. Even the water content of bio-waste from the food industry (e.g., breweries, distilleries) ranges from 70 to 95 wt% [

2]. Drying biomass increases the fuel heating value, improves the combustion efficiency and boiler operation, and often reduces emissions [

3,

4].

In industrial drying, we differentiate two main types of dryers according to the heat applied to the dried material [

5]. The first are direct dryers, where heat is transferred mainly by convection and the material to be dried is in direct contact with the heating medium. It is often hot air, flue gas, or steam [

6]. The second is indirect or contact dryers, where heat is transferred mainly by conduction and the material to be dried and the heating medium are separate. The heat is supplied to the dried material through a heat-transfer surface, which defines the volume of the dryer. Steam or hot water is often used as a heating medium [

4,

5].

Drying is an energy-intensive process, so the energy demands to be taken into account include the choice of a suitable dryer type in regard to the dried material properties. The typical energy consumption of direct dryers ranges between 4.0 and 6.0 MJ per kg of evaporated water, whereas the typical energy consumption of indirect dryers ranges between 2.8 and 3.6 MJ per kg of evaporated water due to there being no heat loss in the outgoing drying medium of the dryer [

5]. Moreover, there is the possibility of heat recovery from the latent heat of the evaporated water vapor, which is not polluted by the drying medium and possesses a temperature close in the vicinity of 100 °C in atmospheric conditions [

7,

8]. This heat may be utilized for a further increase in the total efficiency of the system of integrated indirect drying or utilized for external consumption [

8].

The theoretical basics of an indirect drying process are described in the literature [

5,

9,

10,

11,

12]. However, for the reliable design of industrial dryers, it is necessary to experimentally determine and evaluate the drying rates and drying times for each material so as to predict the drying processes in a wider range of design and operating parameters.

Before the design of an industrial dryer for a specific material, it is important to experimentally prove the process and to determine the drying characteristics of the material. This paper focuses on the comparison of operating characteristics of indirect dryers in two configurations: a laboratory-scale drum dryer and a pilot rotary dryer.

2. Dryer Design

For setting the dimension sizes of a new dryer and optimizing its operation, it is important to predict the heat-transfer conditions. Schlünder et al. [

9,

10,

11,

12] investigated the theoretical basis of heat transfer in an indirect drying process which describes the principles of heat transfer from a heated surface to the wet material dried by contact with this heated surface. They introduced a heat-transfer model of a heated surface and the bed of a particulate material which is free flowing or mechanically agitated. In both cases, the so-called penetration model was applied to describe mechanical mixing [

5].

There is a steep temperature drop in the immediate vicinity of the wall

, followed by a further decrease toward the interior of the bed (average caloric bed temperature),

. These temperature differences are assigned to contact heat resistance,

, and to penetration resistance,

, respectively. Therefore, it is

The overall heat transfer coefficient (HTC)

is

and

For a mechanically agitated bed, it is at first assumed that there exists a certain time period

during which the bed is considered dense. After the time period

, a perfect mixing of the bed is achieved with more intensive heat transfer depending on the method and frequency of mixing. In [

9], the penetration model has been extended to contact drying, where it is assumed that a steep drying front propagates into the bed during the time period

. Not only the temperature, but also the moisture profile is changed at the end of each period. The contact HTC

does not change in principle [

10]. On the contrary, the consumption of heat by evaporation in the interior of the bed (the latent heat sink) has a significant influence on the penetration coefficient.

The biomass properties such as water content, bulk density, and particle size distribution influence the operation of the dryer including the final water content of the dried material and the energy demand [

13]. Satisfactory material mixing in the dryers is important for an intensive and stable drying process. For nonhomogeneous materials with variable particle size such as numerous kinds of waste biomass, rotary drum dryers prove a suitable option to utilize [

5,

14].

The design of industrial dryers is based on the experimentally determined drying characteristics of the specific dryer type as well as the material to be dried, which is transferable under various operating conditions [

5]. The evaporation capacity is used as the key parameter for setting the dimensions of the dryer [

5]. This parameter defines the amount of evaporated water emitted from the dried material as relative to the area or volume of the dryer.

The use of the square or volumetric evaporation capacity is related to the dryer type and method of heat supply during the drying process. The evaporation capacities and energy consumptions of common industrial dryers are shown in

Table 1. These values are approximate and are derived from current practice.

Indirect rotary dryers are most frequently used for materials with small particle sizes corresponding with many types of biomass used for energy utilization [

5]. For a direct rotary dryer, volumetric evaporation capacity is used. For an indirect dryer, where the heat is transferred from the dryer walls to the wet feed, the utilization of square evaporation capacity is more suitable. The square evaporation capacity

EC defines the amount of evaporated water

emitted from the dried material per drying time

t as relative to the dryer heated area

:

The evaporation capacity is influenced by these operating parameters [

7,

8]:

temperature of the heating medium

material filling ratio in the dryer

water content in the material

dryer revolution rate and inclination

The dryer revolutions and inclination are defined by the design of the dryer. For conventional direct rotary dryers, the recommended filling ratio of the dryer volume by material to be dried ranges from 10% to 15% of its volume [

5].

The contact HTC

depends on the geometry characteristics of the material and the properties of drying ambience [

10,

11]. The material bed

depends on materal thermal properties and the time period

[

6,

10]. Therefore, the heat overall transfer coefficient

is not directly affected by the filling ratio.

3. The Laboratory Drum Dryer

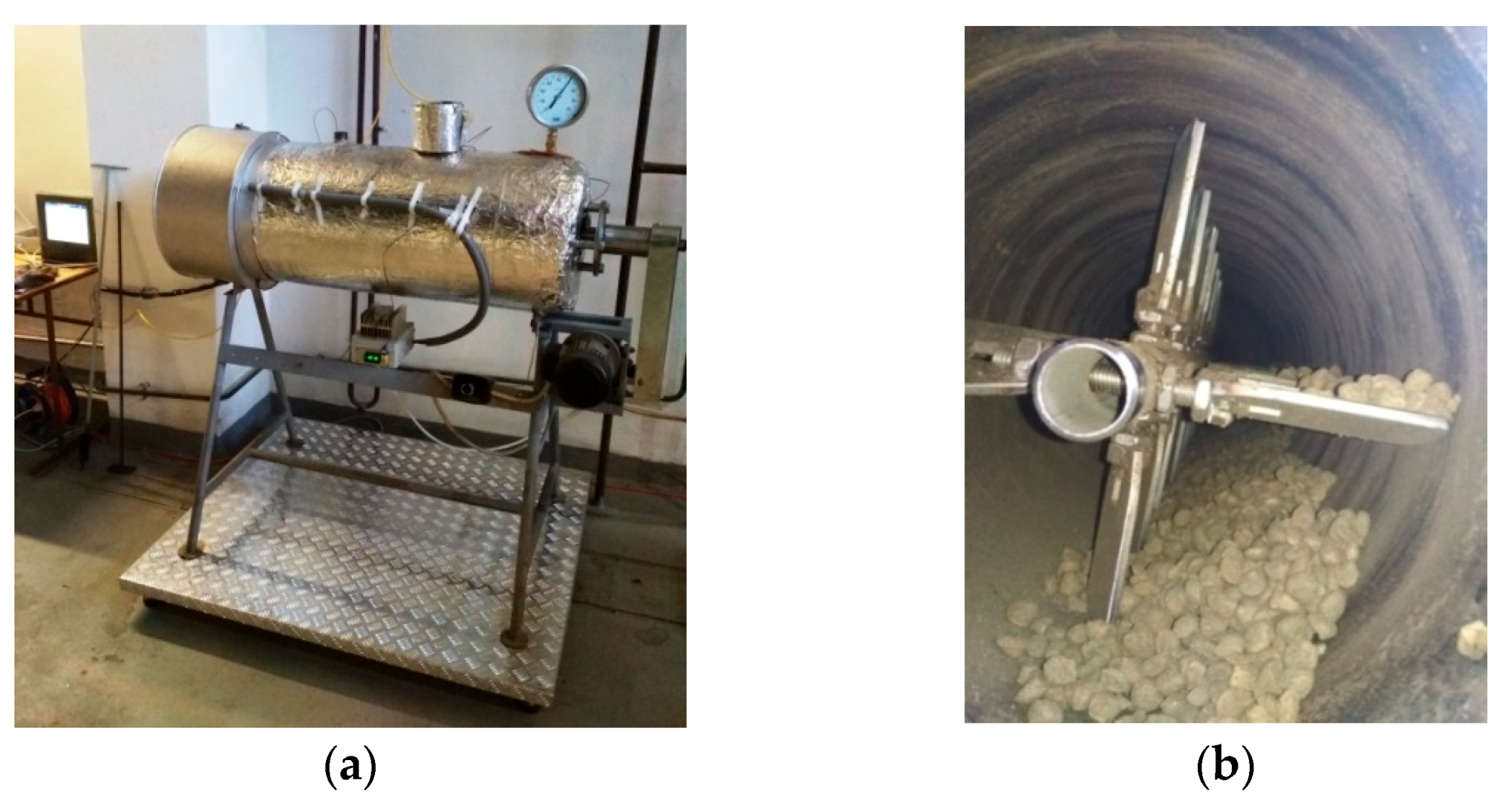

The indirect drum dryer in the laboratory scale (see

Figure 1) was designed and built for a better understanding of the indirect drying process and for testing the drying of various materials under differing conditions. The dryer is electrically heated. The drum has an inner diameter of 0.256 m and a length of 1 m. It works in a batch mode. The dryer is equipped with a paddle-wheel agitator for material mixing to intensify the heat transfer process. The rotation velocity is 18 rpm. The inner lateral surface area of the drying drum is 0.81 m

2 and the drum volume is 0.051 m

3. In the course of the experiments, the dryer is closed and sealed to prevent air penetration with the aim of reducing the energy consumption of the drying process.

The dryer is located on a tensometric scale, which monitors the change in weight of the dried material during the measurement. The heating surface of the dryer is equipped with 5 thermocouples measuring the temperature in the heater (2 at the top and 3 at the bottom). Thermocouples also provide an input for the control of the electric heater to maintain the desired temperature, which can be set in wide ranges to simulate heating by various mediums, e.g., hot water or low-potential steam. Additional thermocouples are used to measure the inside of the dryer and the temperature of the exhaust steam at the dryer outlet, which is emitted into the atmosphere by pipes in the upper part of the dryer due to small overpressure formed in the dryer as a result of developing steam during drying. Evaporated steam continuously leaves the drying drum at close to atmospheric pressure.

Drying Characteristics

Green wood chips and wet bark stored outdoors in an open area (see

Figure 2) with a water content of 50 to 65 wt % were used for the drying tests. The particle size of both materials differed greatly, varying from one millimeter to a few centimeters.

At the beginning of each measurement, the water content of the material is determined. Based on weight loss due to evaporated water, the change in the water content of the material at the time of drying is monitored. The drying process is usually illustrated by a drying curve defining the dependence of actual water content in the material on the drying time. From the amount of evaporated water, it is possible to determine the actual or average values of the evaporation capacity. Energy consumption is given by the electricity supply. Before the experiments, the heat loss of the dryer was measured at 120 W during operation without a material charge.

To obtain a description of dryer operation in various conditions, the effects of different dryer filling ratios and heating temperatures on the drying characteristics were tested. The range of the investigated process parameters is shown in

Table 2.

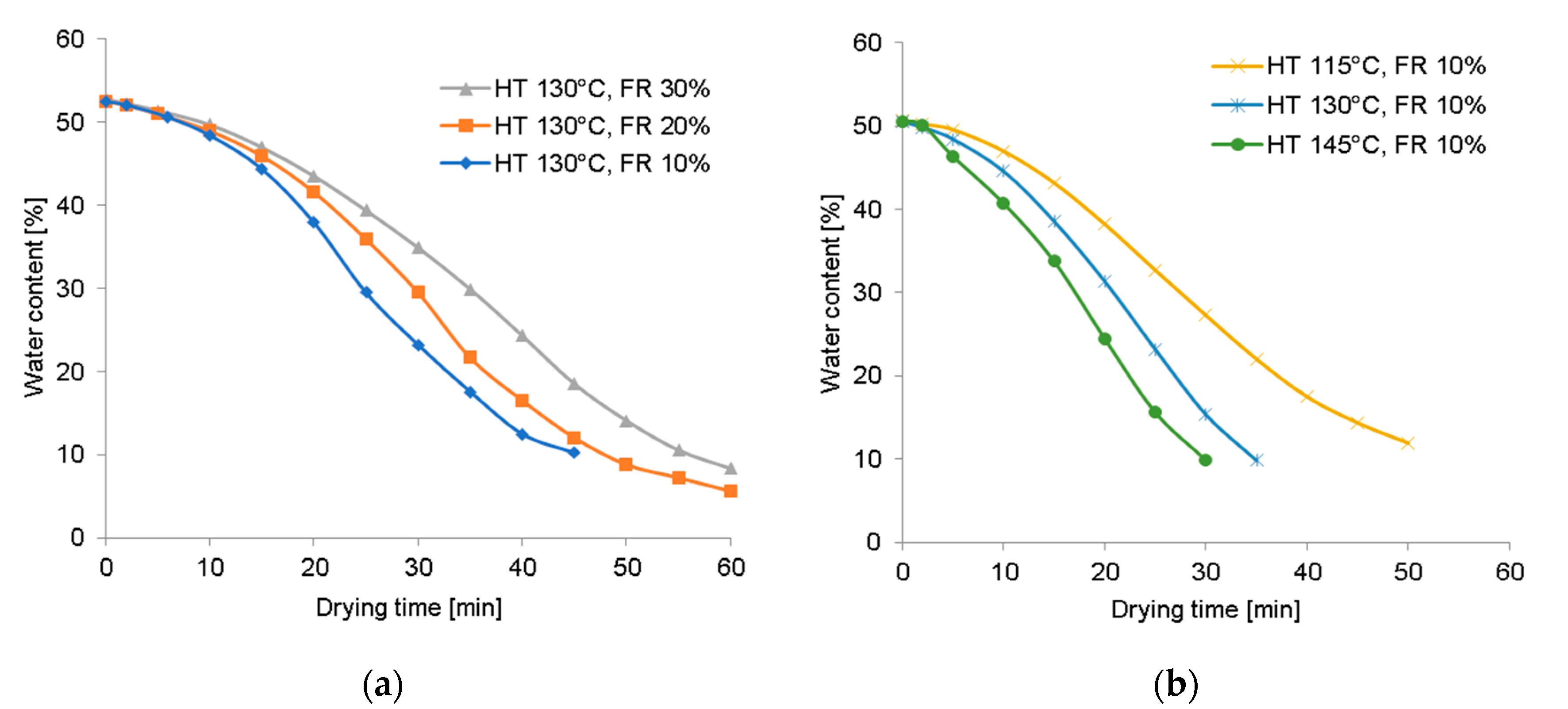

Drying curves for the various parameters shown in

Figure 3 illustrate the effects of the dryer filling ratio (FR) and heating temperature (HT) on the drying process of wet bark.

If the dryer filling ratio is larger, it is necessary to evaporate more water from the material, and therefore a longer drying time is required. Since the drying time varies with different filling ratios, it is preferable to characterize the drying process with a specific evaporation capacity per hour and unit of surface. At the same time, the total amount of evaporated water is larger due to the larger contact area of the heating surface with a larger volume of dried material.

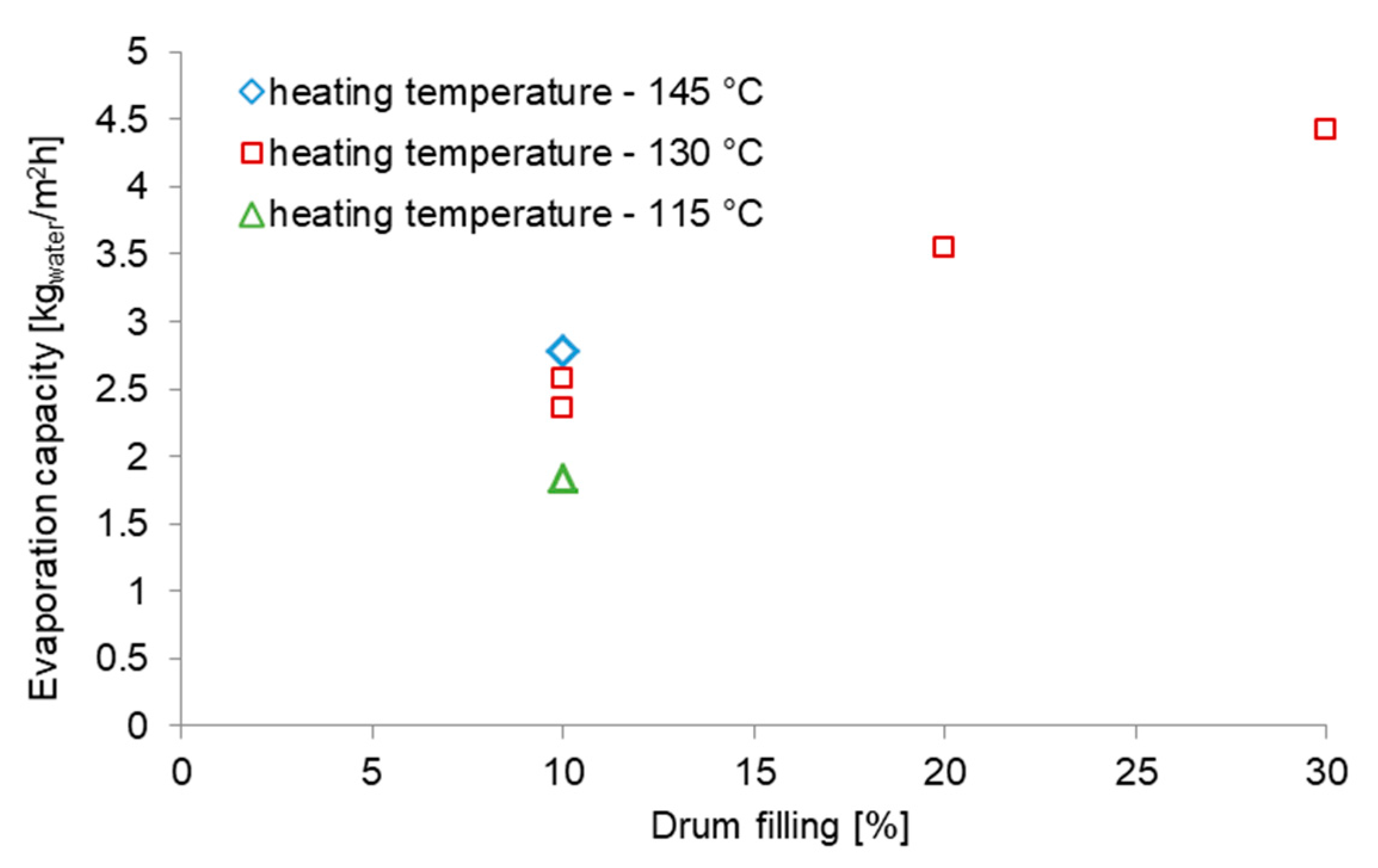

Figure 4 compares the evaporation capacities for a stable state of the drying process (between 30% and 50% water content; see

Figure 4). The dryer filling ratio has a significant influence on the value of the evaporation capacity, while the effect of heating temperature is slightly lower.

The evaporation capacities non-linearly rise with an increasing filling ratio and the heating temperature. The dryer filling ratio has a significant influence on the value of the evaporation capacity, while the effect of heating temperature is slightly lower.

An increase in the filling ratio affects the movements of solids in the dryer [

15]. Material mixing depends on the dryer geometry and the rotation speed of the dryer [

10,

15]. When the mixing in the dryer is applied, it is assumed that the material movement is sufficient and the significant thermal resistance for heat transfer is in the bed of dried material [

5,

10]. So, the change in mixing regime is negligible for the process balance [

5]. However, the amount of material in the dryer is given by filling ratio and affects the total energy balance.

4. Rotary Steam Dryer—Scale Up

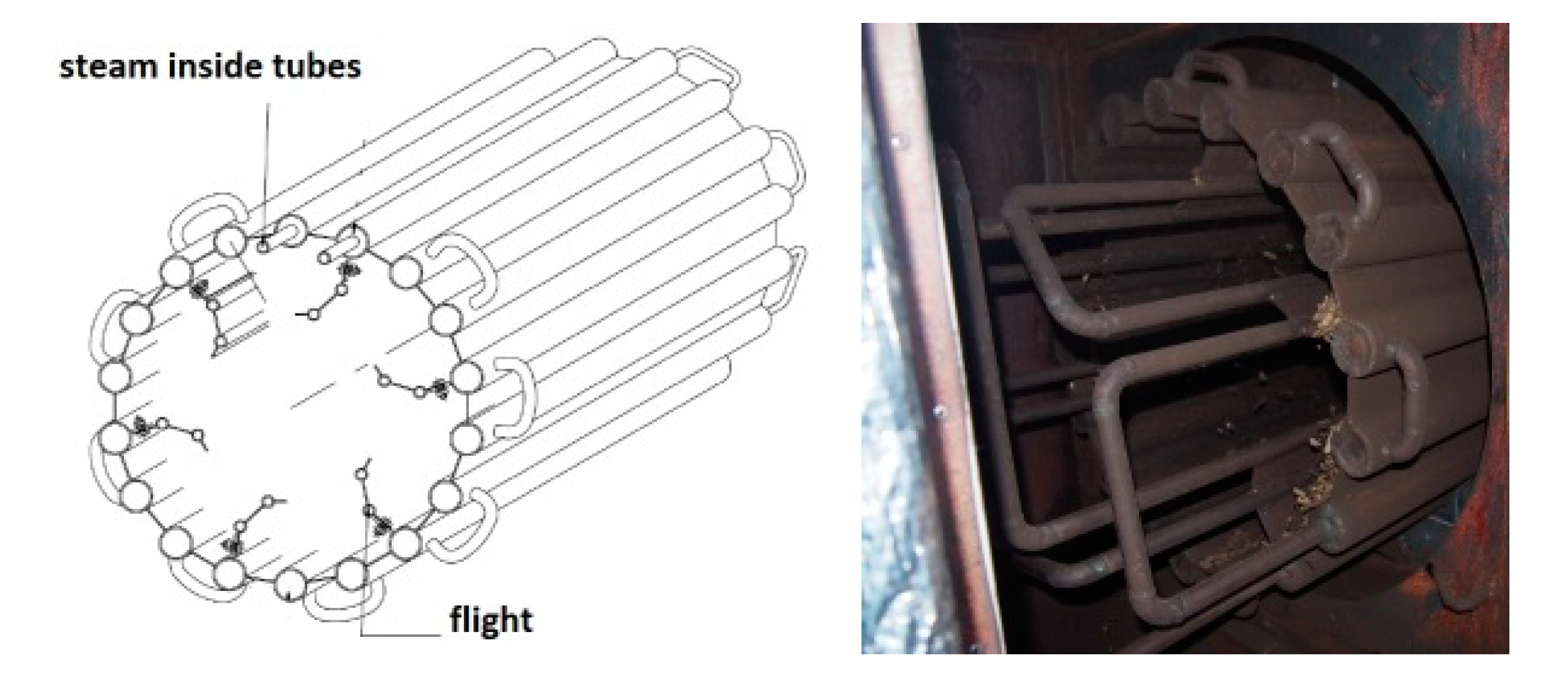

Based on experimentally determined drying characteristics and operational experience learned on the smaller scale, a prototype of a steam-heated rotary dryer (see

Figure 5) was designed and manufactured. The configuration of the rotating drum is chosen due to the use of steam as a heating medium and for an improved distribution of heat from the heating surface of the material where the heat transfer takes place in the lower part of the drum where the dried material lies. The rotating drum consists of a series of tubes with condensing steam inside. The drying chamber has an inner diameter of 0.6 m and a length of 2 m. The drum has an adjustable revolution speed. On the inner side (the drying material side), heated flights (see

Figure 6) are used to maintain a longer contact time with the heating surface and to increase the surface area of the dryer while maintaining its volume. The inner lateral surface area of the dryer is 6.42 m

2 and the dryer volume is 0.59 m

3. This drum also has an adjustable revolution speed. The dryer is heated by saturated steam from a steam network with regulated pressure rising up to 6 bars. The drying capacity is about 20 kg of evaporated water per hour. On the exterior, the drum is insulated with fiber insulation. Evaporated water is carried away out of the dryer by a header in the upper part of the dryer due to small overpressure in order of tens of Pa formed in the dryer as a result of developing steam during drying.

The drum configuration is shown in

Figure 6. The drum is heated by steam, which condenses inside the tube system. Internal fittings and flights promote agitation of the material and effectively double the total heat transfer surface compared to the surface of a bare drum.

After a single pass through the dryer, the material is reinserted into the inlet screw feeder and goes through the dryer repeatedly. This procedure simulates a longer drum dimension, thus providing the necessary drying time. It enables the collection of samples of the material for analysis of the actual water content during the drying process and adjusting the necessary drying time to achieve the final drying of the material.

Drying Characteristics

A set of measurements (see

Table 3) was carried out on a rotary steam dryer with the green wood chips and wet bark described above (see

Figure 2). For all the experiments, the dryer was heated by saturated steam with a pressure of 3.2 bar (corresponding to a saturated temperature of 136 °C). The value of the overpressure measured inside the dryer ranged from 10 to 20 Pa. The obtained results were compared with the previous experiments of wet bark drying under the similar operating conditions described in [

7].

At the beginning of each measurement, the water content of the material is determined by the laboratory. For reinserted material, after a single pass through the dryer, the weight loss of the control volume due to evaporated water was monitored at the time of drying. From the amount of evaporated water, it is possible to determine the change in the water content of the material and the values of the evaporation capacity. The energy consumption is given by the amount of heated steam condensate. The value without heat loss was calculated from the measured value, during operation without a material charge, and the heat loss of the dryer was measured as 3 kg of condensate per hour.

The value of the evaporation capacity increases with a higher filling of the dryer volume. A comparison of the drying curves of green wood chips for various dryer filling ratios is shown in

Figure 7. The two dashes lines determine the interval of a stable state of the drying process with a stable value of the evaporation capacity.

If the dryer filling ratio is larger, it is necessary to evaporate more water from the material. So, there is the requirement for the higher amount of supplied heat. The heat transfer coefficient is not dependent on the filling ratio [

6,

10,

11]; it is only dependent on the superficial area of the solids in relation to the volume of the dryer, which is given by the material filling ratio in the dryer [

15]. Therefore, a longer drying time is required but concurrently, the evaporative performance of the dryer is higher [

5]. Energy consumption for the indirect rotary dryer was found to be between 3.2 and 3.6 MJ per 1 kg of evaporated water for biomass in the form of wood chips or bark. The pilot dryer has a relatively high heat loss to the surroundings due to thin insulation; the energy consumption after the reduction of heat loss could be about 2.8 MJ/kg. This value is on a level corresponding to the material being heated and the specific vapor heat of the water.

5. Comparison of Operating Characteristics

The thermal resistance between the heating medium and the conducting wall and the thermal resistance across the conducting wall are negligible compared to the resistance between the wall and the surface of the bed of the drying material and the resistance across the bed of the drying material [

5,

15]. Therefore, it can be said that the heat transfer in the drying process is not dependent on the way the heat is supplied [

15]. Assuming sufficient material mixing in both dryer types, it is not necessary to take into account different concepts of indirect drying.

The heating temperature, water content in the material, the paddle or dryer revolutions, and the inclination are usually given by the design of the dryer or by the operating conditions. The dryer filling ratio is the parameter that is possible to change in the operation of the dryer and that which the most influences obtained operating characteristics. By optimizing the dryer filling, the maximum production of dried material can be achieved. So, a set of experiments with various filling ratios were performed to compare the operating characteristics of both dryers.

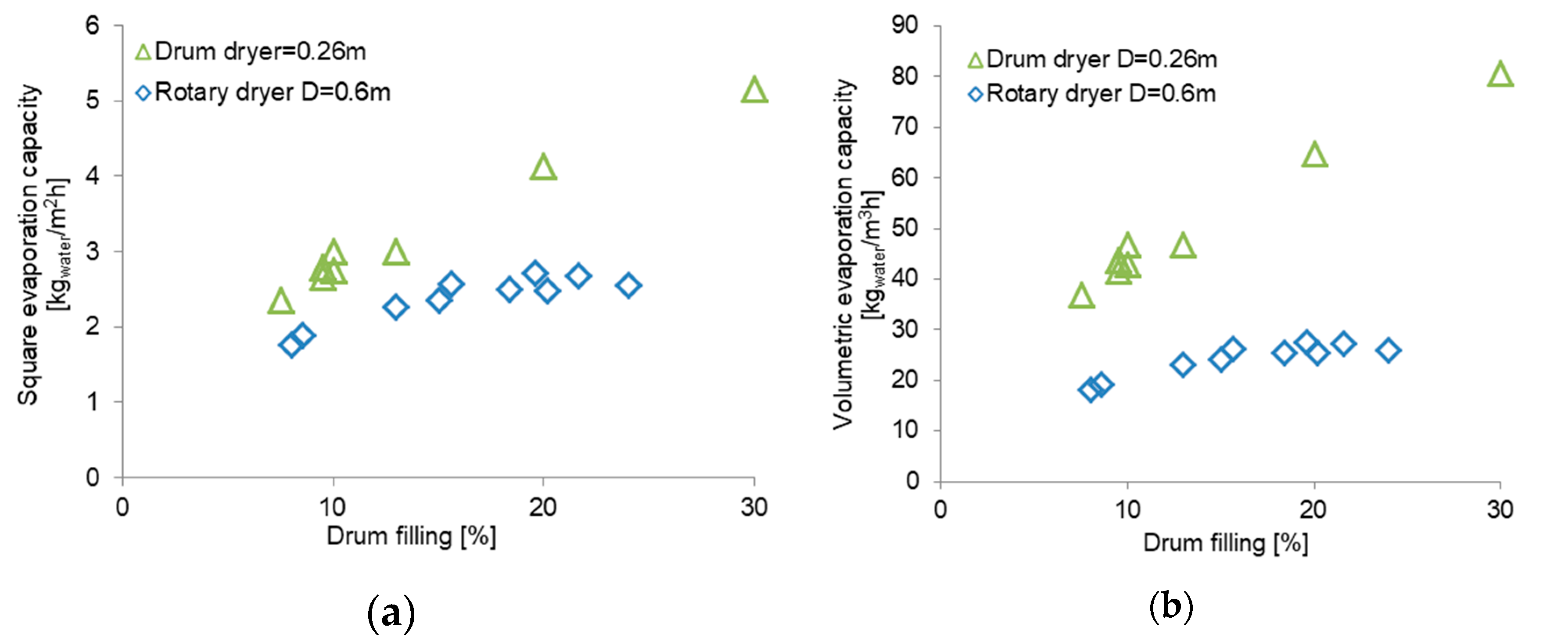

The evaporation capacities for both tested dryers evaluated from experiments with various dryer filling ratios are shown in

Figure 8. Since the evaporation capacity is dependent on the actual water content, all the values are evaluated for drying between 30% and 50% of the material water content as the mean value for this interval, which is in respect to a stable state of the drying process (see

Figure 7). The effect of the dryer filling ratio is shown for a heating temperature of approximately 135 °C.

The results show that the evaporation capacities increase with a higher dryer filling ratio. If the dryer filling ratio is higher, it is necessary to evaporate more water from the material in relation to the surface of the dryer; therefore, a longer drying time is required (see

Figure 3 and

Figure 7). In addition, the relative size of dryer surface to the volume of the dried material reduces with the increasing diameter of the drum at the same relative filling ratio; see

Figure 9.

This can explain the difference in the values of the square evaporation capacity of the smaller experimental dryer and larger pilot dryer in

Figure 8a. For comparing the evaporation capacities

EC of two dryers with various dimensions, a geometric correction was proposed (Equation (6)). It is possible to use the parameter x as a geometric scaling factor for sizing a dryer based on experimental results in another dryer with a different size. Correction

x is calculated according to the relative size of the dryer surface to the volume of the dried material

where

is dryer heated surface and

is the volume of the dried material for dryer 1 and the dryer 2, respectively.

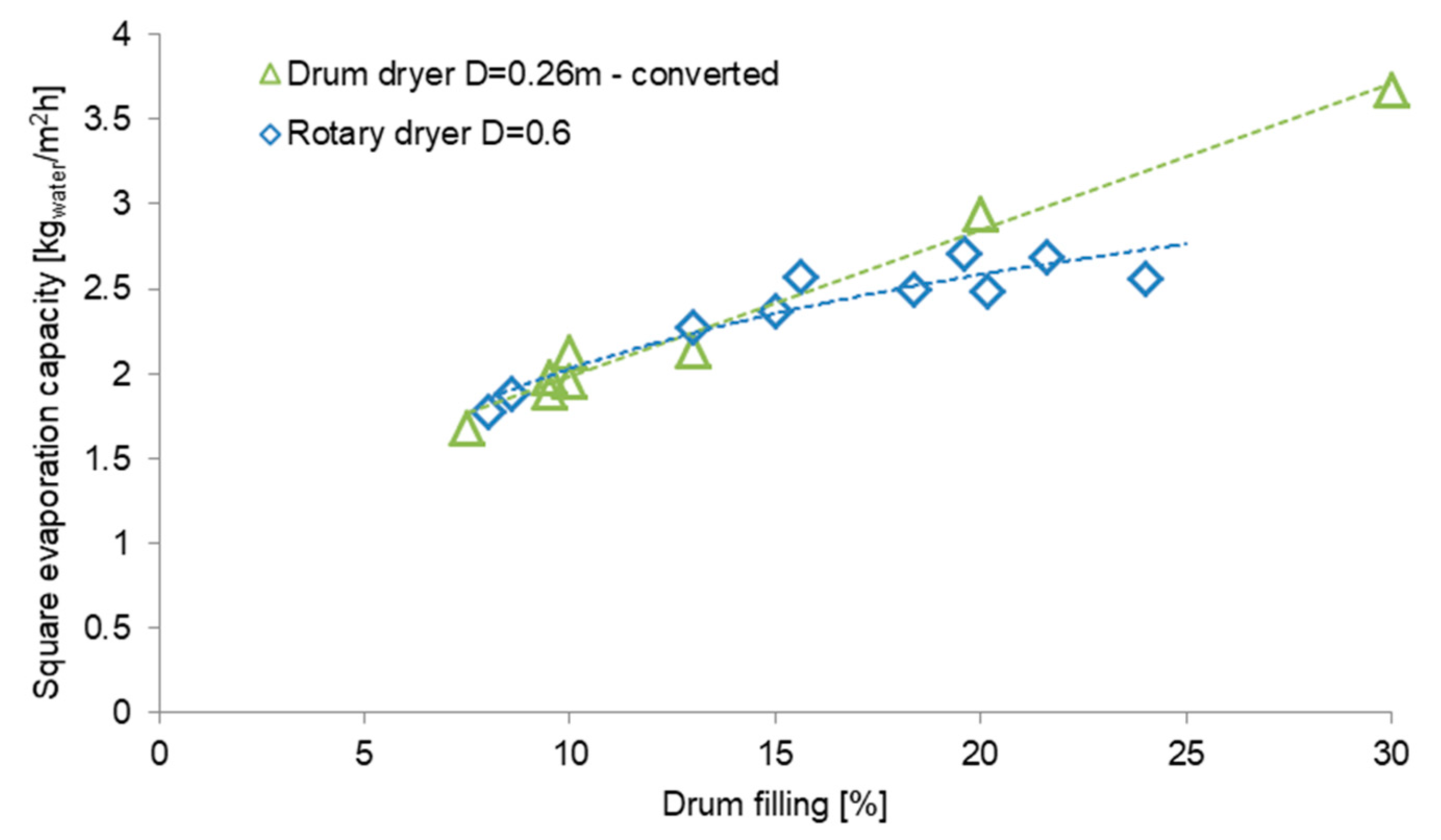

The values of the experimentally determined square evaporation capacities better correspond after correction by the surface-to-volume ratio for both dryers (see

Figure 10). For the volumetric evaporation capacity in

Figure 8b, the difference in the experimentally determined values remains without change. This result confirms the general recommendation to use square evaporation capacity for the design of indirect dryers [

5]. However, according to our results, it is necessary to do its conversion according to the change in the surface-to-volume ratio when scaling the size of devices. This conversion is particularly important when transferring values of the square evaporation capacity determined for a small experimental dryer to significantly larger industrial units.

Based on the results in

Figure 10, it can be stated that it is possible to use the parameter

x as a geometric scaling factor (see Equation (8)) for sizing a dryer with an estimated evaporation capacity

based on the experimentally determined evaporation capacity for another dryer with different size

The energy consumption for both solutions of indirect dryers was found to be between 3.2 and 3.6 MJ per 1 kg of evaporated water for biomass in the form of wood chips or bark, when the energy consumption without experimentally evaluated heat loss was approximately 2.6 to 2.9 MJ per 1 kg of evaporated water. This value is in a good agreement with the value introduced in [

5].

For the drum dryer, the evaporation capacity linearly increases; thus, the influence of the filling ratio on the HTC is not noticeable. For the rotary dryer, there is an evident decrease in the trend of the evaporation capacity with respect to the HTC with the increasing filling ratio, which can be explained by a worse mixing of the material.

6. Conclusions

The laboratory-scale indirect drum dryer was designed and built for the testing of the drying method and to better comprehend the indirect drying process. Based on experimentally determined drying characteristics and operational experience gained on the smaller scale, a prototype of a steam-heated rotary dryer was designed and manufactured. The critical drying parameters for the design of the dryers were experimentally determined. It can be stated that for both cases, the evaporation capacities significantly rise with an increased dryer filling ratio.

The transferability of the experimentally obtained values of the evaporation capacity from a small indirect drum dryer to a larger unit has been investigated. This confirmed that it is preferable to use a square evaporation capacity for the design of indirect dryers, as the volume evaporation capacity better describes the operation of direct dryers. For the transferability of the experimentally determined square evaporation capacity from a smaller to larger unit, it is necessary to do its conversion according to the surface-to-volume ratio of the dryers so as to maintain the similarity of their operation. It was identified that this geometric criterion has a much stronger effect on the resulting square evaporation capacity than, for example, the method of material mixing or the structural design of the dryer. The material in the experimental drum dryer was agitated with a stirrer and the rotary dryer had flights; however, after the conversion, the evaporation capacity values of both cases were very similar.

From this finding, it can be concluded that the value of the square evaporation capacity decreases with the increasing dryer diameter. Therefore, it would be preferable to design indirect dryers with a smaller diameter and thus with a slimmer and longer shape.

For biomass drying, the indirect dryers are energy efficient in comparison with commonly used industrial direct dryers. The values of the energy consumption without heat loss are similar for all dried materials and were found to be between 2.6 and 2.9 MJ per 1 kg of evaporated water.