Extraction Centrifuges—Intensified Equipment Facilitating Modular and Flexible Plant Concepts

Abstract

1. Introduction

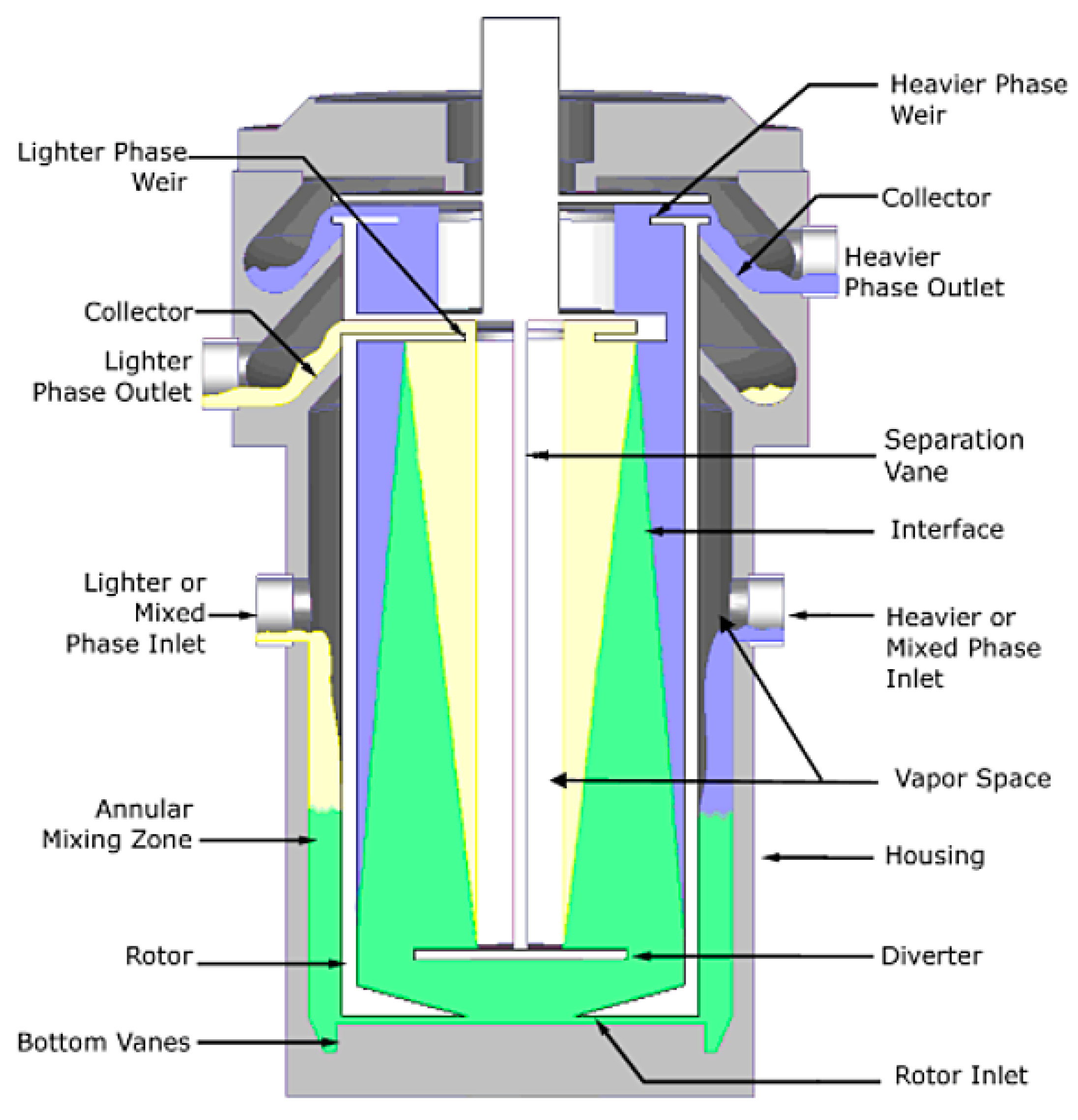

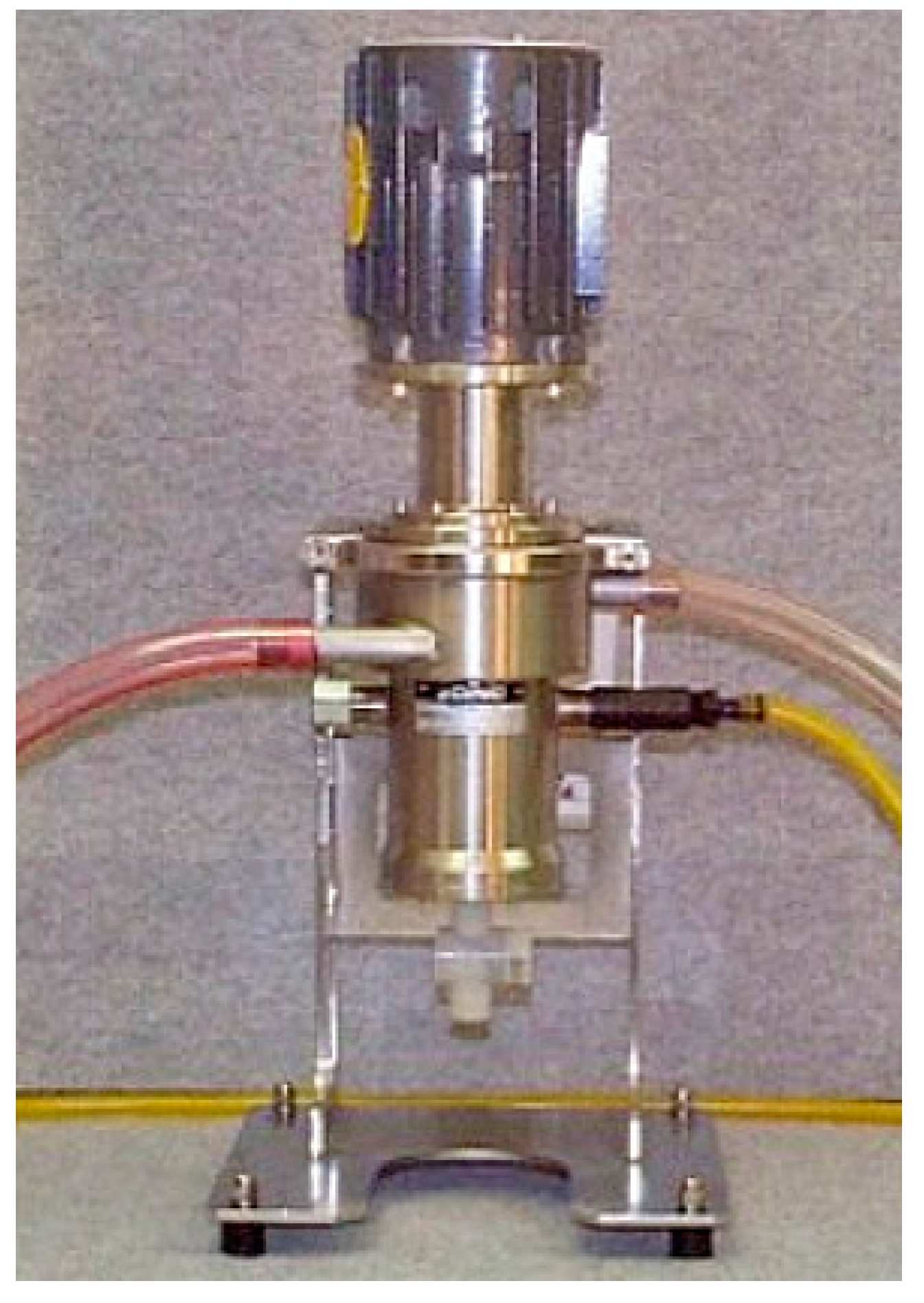

2. Extraction Centrifuges

2.1. Theory of Operation

2.2. Fields of Application

3. Smart Multi-Purpose Production Facilities

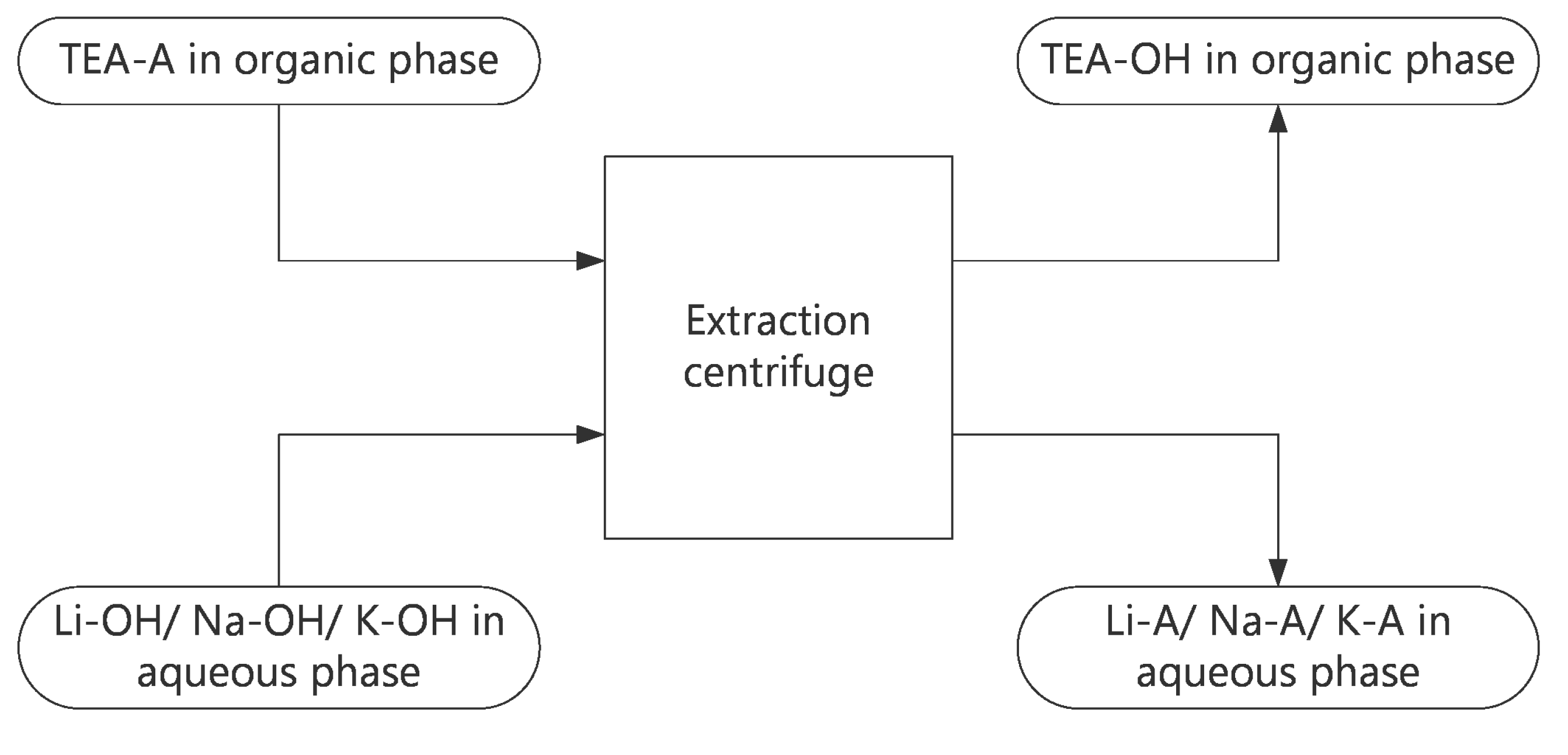

4. Extractive Centrifuges at Lonza

4.1. Feasibility Studies and Scale-Up

- Poor Phase separation

- Tendency to form emulsions

- High-energy input necessary

- Low number of theoretical stages necessary (<5) and low construction height obligatory

4.2. Application in Production Facilities

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kiss, A.A. Distillation technology—Still young and full of breakthrough opportunities. J. Chem. Technol. Biotechnol. 2014, 89, 479–498. [Google Scholar] [CrossRef]

- Asprion, N.; Kaibel, G. Dividing wall columns: Fundamentals and recent advances. Chem. Eng. Process. 2010, 49, 139–146. [Google Scholar] [CrossRef]

- Staak, D.; Grützner, T.; Schwegler, B.; Roederer, D. Dividing wall column for industrial multipurpose use. Chem. Eng. Process. 2014, 75, 48–57. [Google Scholar] [CrossRef]

- Staak, D.; Grützner, T. Process integration by application of an extractive dividing-wall-column: An industrial case study. Chem. Eng. Res. Des. 2017, 123, 120–129. [Google Scholar] [CrossRef]

- Brodhagen, A.; Grünewald, M.; Kleiner, M.; Lier, S. Erhöhung der Wirtschaftlichkeit durch beschleunigte Produkt- und Prozessentwicklung mit Hilfe modularer und skalierbarer Apparate. Chem. Ing. Tech. 2012, 84, 624–632. [Google Scholar] [CrossRef]

- Lier, S.; Wörsdörfer, D.; Grünewald, M. Transformable Production Concepts: Flexible, Mobile, Decentralized, Modular, Fast. ChemBioEng Rev. 2016, 3, 16–25. [Google Scholar] [CrossRef]

- Hohmann, L.; Kössel, K.; Kockmann, N.; Schembecker, G.; Bramsiepe, C. Modules in process industry—A life cycle definition. Chem. Eng. Process. Process Intensif. 2017, 111, 115–126. [Google Scholar] [CrossRef]

- Lang, J.; Stenger, F.; Schütte, R. Chemieanlage der Zukunft—Unikate und/oder Module. Chem. Ing. Tech. 2012, 84, 883–884. [Google Scholar]

- Bieringer, T.; Buchholz, S.; Kockmann, N. Future Production Concepts in the Chemical Industry: Modular—Small-Scale—Continuous. Chem. Eng. Technol. 2013, 36, 900–910. [Google Scholar] [CrossRef]

- Roberge, D.; Zimmermann, B.; Rainone, F.; Gottsponer, M.; Eyholzer, M.; Kockmann, N. Microreactor Technology and Continuous Processes in the Fine Chemical and Pharmaceutical Industry: Is the Revolution Underway? Org. Process Res. Dev. 2008, 12, 905–910. [Google Scholar] [CrossRef]

- Grützner, T.; Seyfang, B.; Zollinger, D.; Kuenzle, N. Reducing time-to-market by innovative development and production strategies. Chem. Eng. Technol. 2016, 39, 1835–1844. [Google Scholar] [CrossRef]

- Fletcher, P.; Haswell, S.; Pompo-Villar, E.; Warrington, B.; Watts, P.; Wong, S.; Zhang, X. Micro reactors: Principles and applications in organic synthesis. Tetrahedron 2002, 38, 4735–4757. [Google Scholar] [CrossRef]

- Sundberg, A. Micro-Scale Distillation and Microplants in Process Development. Doctoral Dissertation, Aalto University, Helsinki, Finland, 2014. [Google Scholar]

- Wellsandt, T.; Stanisch, B.; Strube, J. Development of Micro Separation Technology Modules. Part 1: Liquid-Liquid Extraction. Chem. Ing. Tech. 2015, 87, 1198–1206. [Google Scholar] [CrossRef]

- Stanisch, B.; Wellsandt, T.; Strube, J. Development of Micro Separation Technology Modules. Part 2: Distillation. Chem. Ing. Tech. 2015, 87, 1207–1214. [Google Scholar] [CrossRef]

- Lier, S.; Paul, S.; Ferdinand, D.; Grünewald, M. Modulare Verfahrenstechnik: Apparateentwicklung für wandlungsfähige Produktionssysteme. Chem. Ing. Tech. 2016, 88, 1444–1454. [Google Scholar] [CrossRef]

- Sirkar, K.K. Membranes, Phase Interfaces, and Separations: Novel Techniques and Membranes—An Overview. Ind. Eng. Chem. Res. 2008, 47, 5250–5266. [Google Scholar] [CrossRef]

- Li, X.; Liu, Y.; Li, Z.; Wang, X. Continuous distillation experiment with rotating packed bed. Chin. J. Chem. Eng. 2008, 16, 656–662. [Google Scholar] [CrossRef]

- Sudhoff, D.; Leimbrink, M.; Schleinitz, M.; Górak, A.; Lutze, P. Modelling, design and flexibility analysis of rotating packed beds for distillation. Chem. Eng. Res. Des. 2015, 94, 72–89. [Google Scholar] [CrossRef]

- Schuur, B.; Jansma, W.; Winkelman, J.; Heeres, H. Determination of the interfacial area of a continuous integrated mixer/separator (CINC) using a chemical reaction method. Chem. Eng. Process. 2008, 47, 1484–1491. [Google Scholar] [CrossRef]

- Schuur, B.; Kraai, G.; Winkelman, J.; Heeres, H. Hydrodynamic features of centrifugal contactor separators: Experimental studies on liquid hold-up, residence time distribution, phase behavior and drop size distributions. Chem. Eng. Process. 2012, 55, 8–19. [Google Scholar] [CrossRef]

- Technical Data. Available online: www.cinc.de (accessed on 25 September 2018).

- Monostage Liquid/Liquid Centrifugal Contactors (Model BXP). Rousselet Robatel Company Presentation 2017. Available online: http://www.rousselet-robatel.com/brochures/Monostage_centrifugal_contactors_BXP_Eng.pdf (accessed on 25 September 2018).

- Birdwell, J.; McFarlane, J.; Hunt, R.; Luo, H.; DePaoli, D. Separation of Ionic Liquid Dispersions in Centrifugal Solvent Extraction Contactors. Sep. Sci. Technol. 2005, 41, 2205–2223. [Google Scholar] [CrossRef]

- Goedecke, R. Fluidverfahrenstechnik, Grundlagen, Methodik, Technik, Praxis; Wiley-VCH: Weinheim, Germany, 2006; ISBN 978-3-527-31198-9. [Google Scholar]

- Kraai, G.; van Zwol, F.; Schuur, B.; Heeres, H.; de Vries, J. Two-phase (bio) catalytic reactions in a table-top centrifugal contact separator. Angew. Chem. Int. Ed. 2008, 47, 3905–3908. [Google Scholar] [CrossRef] [PubMed]

- Allemann, C.; Marti, R.; Vorlet, O.; Martin, O.; Riedlberger, P.; Leonhardt, T.; Gössi, A.; Riedl, W.; Segura, J.-M.; Zinn, M.; et al. Continuous Processes and Flow Chemistry at the Universities of Applied Sciences in Switzerland. Chimia 2017, 71, 525–527. [Google Scholar] [CrossRef] [PubMed]

- Heckmann, G.; Previdoli, F.; Riedel, T.; Ruppen, D.; Veghini, D.; Zacher, U. Process development and production concepts for the manufacturing of organic fine chemicals at LONZA. Chimia 2006, 60, 530–533. [Google Scholar] [CrossRef]

- Rauch, J. Mehrproduktanlagen; Wiley-VCH: Weinheim, Germany, 1998. [Google Scholar]

- Brandt, H.; Reissinger, K.-H.; Schröter, J. Moderne Flüssig-flüssig-Extraktoren—Übersicht und Auswahlkriterien. Chem. Ing. Tech. 1978, 50, 345–354. [Google Scholar] [CrossRef]

| Parameter | V02/CS50 | V10/CS 250 | CS 330 | V16 | V20/CS 500 |

|---|---|---|---|---|---|

| Flow rate (l/min) | 0.01–1 | 1.0–100 | 1.0–160 | 1.0–300 | 1.0–750 |

| L × W × H (cm) | 30 × 30 × 60 | 70 × 70 × 170 | 105 × 105 × 214 | 112 × 112 × 230 | 120 × 120 × 260 |

| Mass (kg) | 30 | 400 | 900 | 1400 | 2000 |

| Rotor rpm | 0–6000 | 0–3000 | 0–3000 | 0–2400 | 0–2100 |

| g-force | 0–1000 | 0–1250 | 0–1600 | 0–1250 | 0–1250 |

| Parameter | BXP012 | BXP025 | BXP040 | BXP080 | BXP190 | BXP320 | BXP360 | BXP520 |

|---|---|---|---|---|---|---|---|---|

| Flow rate (l/min) | 0–0.03 | 0–0.2 | 0.01–1 | 1.0–11 | 1.0–60 | 1.0–230 | 1.0–460 | 1.0–1000 |

| L × W × H (cm) | 10 × 10 × 29 | 17 × 17 × 48 | 18 × 18 × 49 | 38 × 38 × 57 | 55 × 55 × 130 | 94 × 94 × 155 | 104 × 104 × 185 | 133 × 133 × 230 |

| Mass (kg) | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. |

| Rotor rpm | 0–10,000 | 0–4000 | 0–3600 | 0–3600 | 0–3500 | 0–3500 | 0–3500 | 0–1750 |

| g-force | 671 | 224 | 290 | 580 | 1377 | 2318 | 2608 | 890 |

| Density Difference | Small Δρ ≤ 50 kg/m3 | Medium 50 kg/m3 ≤ Δρ ≤ 250 kg/m3 | Large Δρ ≥ 250 kg/m3 |

|---|---|---|---|

| Viscosity | Similar to water η ≤ 3 mPas | Increased 3 mPas ≤ η ≤ 10 mPas | high η ≥ 10 mPas |

| Interfacial tension | Small σ ≤ 5 mN/m | Medium 5 mN/m ≤ σ ≤ 15 mN/m | Large σ ≥ 15 mN/m |

| Settling time | Well coalescing tE ≤ 60 s | Inhibited coalescence 60 s ≤ tE ≤ 300 s | Bad coalescence tE ≥ 300 s |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seyfang, B.C.; Klein, A.; Grützner, T. Extraction Centrifuges—Intensified Equipment Facilitating Modular and Flexible Plant Concepts. ChemEngineering 2019, 3, 17. https://doi.org/10.3390/chemengineering3010017

Seyfang BC, Klein A, Grützner T. Extraction Centrifuges—Intensified Equipment Facilitating Modular and Flexible Plant Concepts. ChemEngineering. 2019; 3(1):17. https://doi.org/10.3390/chemengineering3010017

Chicago/Turabian StyleSeyfang, Bernhard C., Andreas Klein, and Thomas Grützner. 2019. "Extraction Centrifuges—Intensified Equipment Facilitating Modular and Flexible Plant Concepts" ChemEngineering 3, no. 1: 17. https://doi.org/10.3390/chemengineering3010017

APA StyleSeyfang, B. C., Klein, A., & Grützner, T. (2019). Extraction Centrifuges—Intensified Equipment Facilitating Modular and Flexible Plant Concepts. ChemEngineering, 3(1), 17. https://doi.org/10.3390/chemengineering3010017