Smart Kitchens of the Future: Technology’s Role in Food Safety, Hygiene, and Culinary Innovation

Abstract

1. Introduction

1.1. Overview of Microbial Safety Challenges in Professional Kitchens

1.2. Importance of Monitoring Microbial Safety for Public Health and Culinary Excellence

1.3. The Role of Technology in Enhancing Food Safety

2. The Evolution of Food Safety in Kitchens

2.1. Historical Practices in Microbial Safety and Food Hygiene

2.2. Key Regulations and Standards (e.g., HACCP, FSMA)

3. Technological Innovations in Microbial Monitoring

3.1. Smart Sensors and IoT Devices

Application of IoT in Ensuring Food Safety

3.2. Rapid Microbial Detection Tools

3.2.1. Advanced Biosensors and Microbial Testing Kits for Rapid Results

3.2.2. Use of Adenosine Triphosphate (ATP) Testing for Surface Cleanliness

3.3. Artificial Intelligence (AI) and Machine Learning (ML)

3.3.1. Predictive Analytics for Identifying Microbial Risks

3.3.2. Automated Data Analysis for Compliance Monitoring

3.4. Blockchain Technology

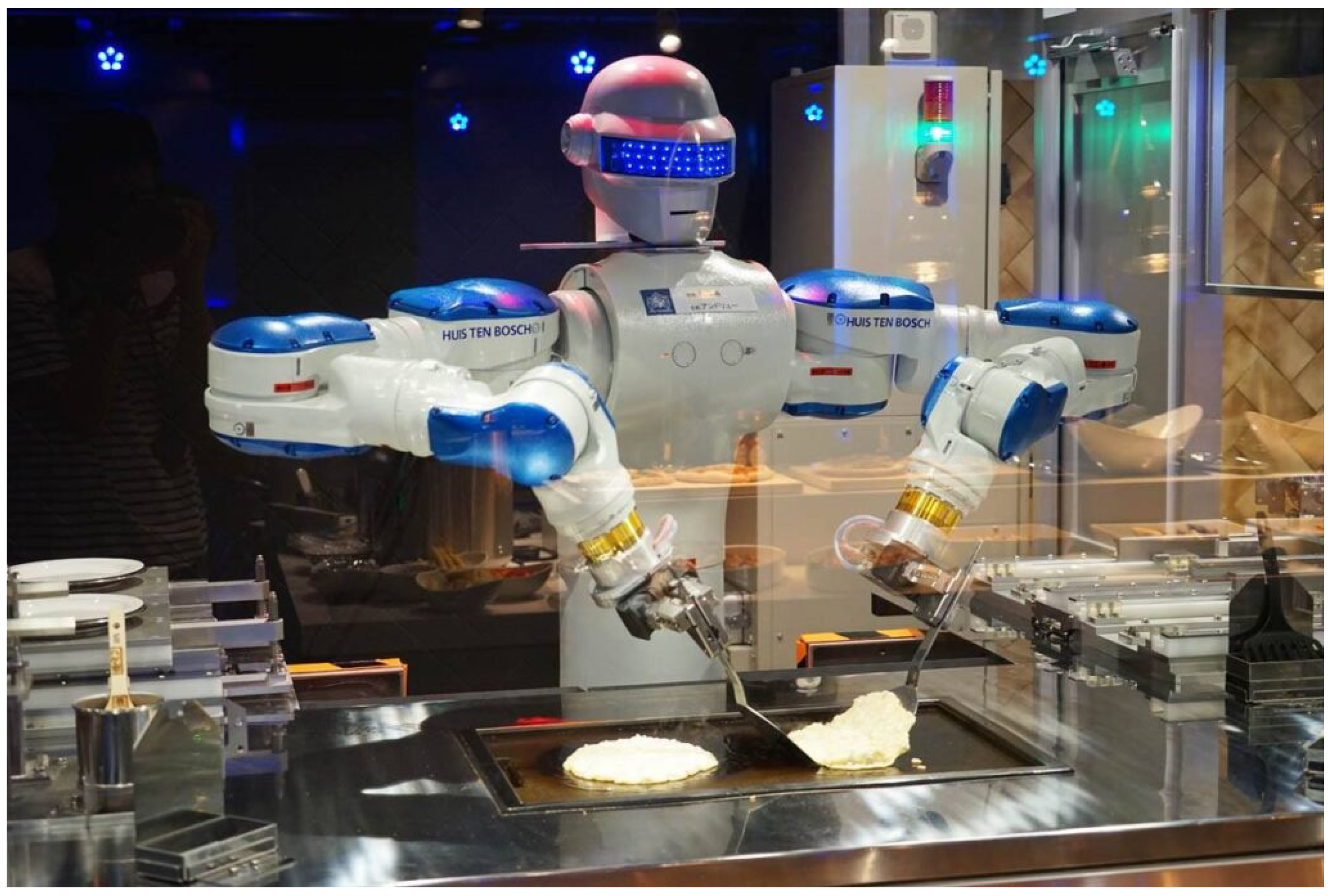

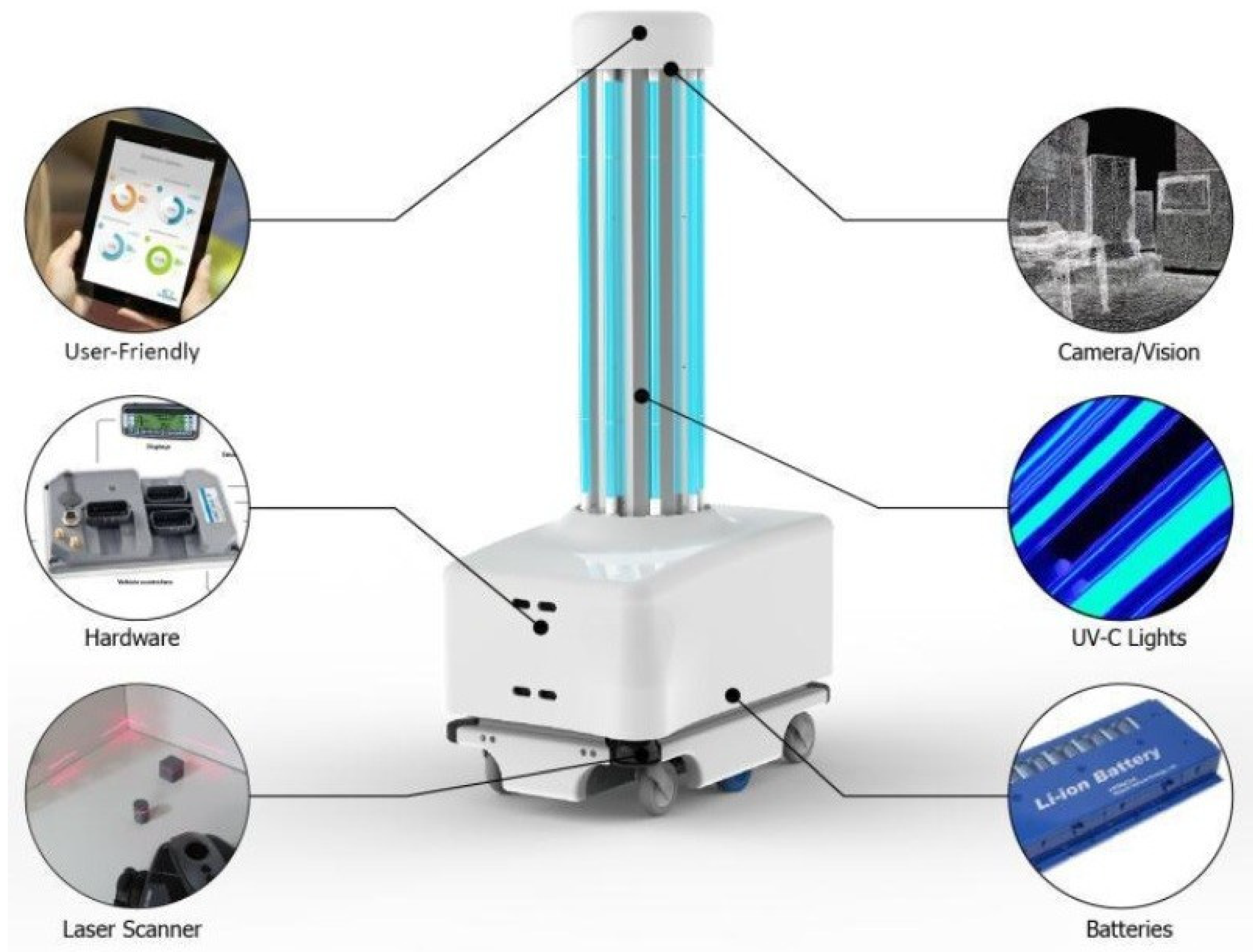

3.5. Robotics and Automation

Robots in Food Preparation and Cleaning to Minimize Human Contamination

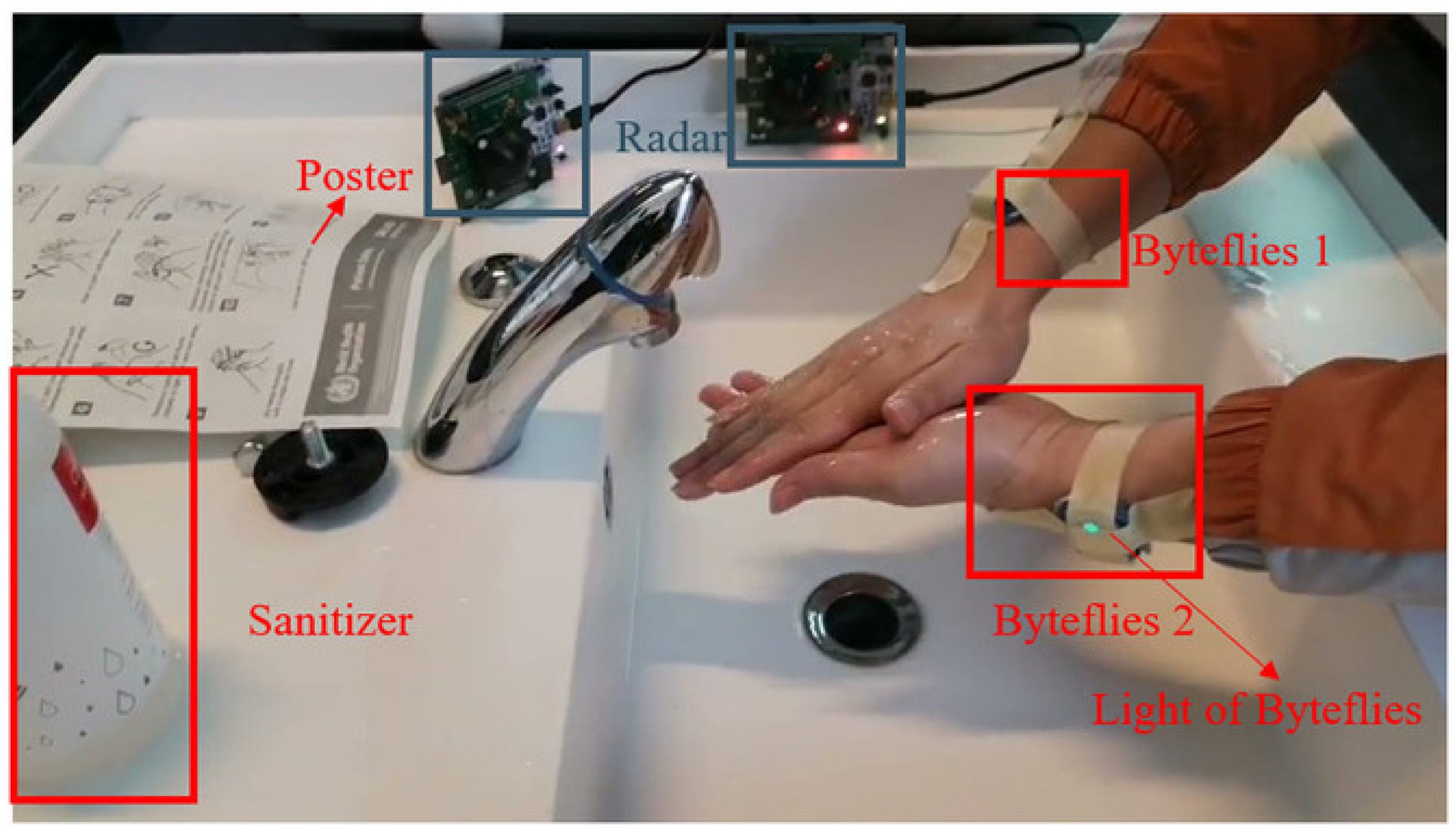

3.6. Wearable Technology (Devices for Kitchen Staff to Ensure Personal Hygiene Standards)

4. Multidimensional Impacts of Advanced Technologies on Professional Kitchens

4.1. Operational Efficiency and Microbial Safety

4.2. Economic Considerations and Cost–Benefit Analysis

4.3. Staff Training and Adaptation to New Technologies

4.4. Consumer Confidence, Transparency, and Traceability

5. Impact on Gastronomy and Culinary Innovation

5.1. Preservation of Culinary Creativity

5.2. Adoption of Molecular Gastronomy

5.3. Food Sustainability and Waste Reduction

5.4. Enhanced Dining Experiences

6. Challenges and Limitations

6.1. Financial Constraints

6.2. Technical Limitations and Reliability Issues

6.3. Workforce and Operational Disruptions

6.4. Regulatory and Compliance Challenges

6.5. Ethical and Social Implications

6.6. Emerging Microbial Threats

7. Future Trends

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Mac Con Iomaire, M.; Afifi, M.F.; Healy, J. Chefs’ perspectives of failures in foodservice kitchens, part 1: A phenomenological exploration of the concepts, types, and causes of food production failure. J. Foodserv. Bus. Res. 2021, 24, 177–214. [Google Scholar] [CrossRef]

- Scallan, E.; Hoekstra, R.M.; Angulo, F.J.; Tauxe, R.V.; Widdowson, M.A.; Roy, S.L.; Jones, J.L.; Griffin, P.M. Foodborne illness acquired in the United States—Major pathogens. Emerg. Infect. Dis. 2011, 17, 7. [Google Scholar] [CrossRef] [PubMed]

- Batz, M.B.; Richardson, L.C.; Bazaco, M.C.; Parker, C.C.; Chirtel, S.J.; Cole, D.; Golden, N.J.; Griffin, P.M.; Gu, W.; Schmitt, S.K.; et al. Recency-weighted statistical modeling approach to attribute illnesses caused by 4 pathogens to food sources using outbreak data, United States. Emerg. Infect. Dis. 2021, 27, 214. [Google Scholar] [CrossRef] [PubMed]

- Taché, J.; Carpentier, B. Hygiene in the home kitchen: Changes in behaviour and impact of key microbiological hazard control measures. Food Control 2014, 35, 392–400. [Google Scholar] [CrossRef]

- Ifedinezi, O.V.; Nnaji, N.D.; Anumudu, C.K.; Ekwueme, C.T.; Uhegwu, C.C.; Ihenetu, F.C.; Obioha, P.; Simon, B.O.; Ezechukwu, P.S.; Onyeaka, H. Environmental antimicrobial resistance: Implications for food safety and public health. Antibiotics 2024, 13, 1087. [Google Scholar] [CrossRef]

- Samtiya, M.; Matthews, K.R.; Dhewa, T.; Puniya, A.K. Antimicrobial resistance in the food chain: Trends, mechanisms, pathways, and possible regulation strategies. Foods 2022, 11, 2966. [Google Scholar] [CrossRef]

- Awuchi, C.G. HACCP, quality, and food safety management in food and agricultural systems. Cogent Food Agric. 2023, 9, 2176280. [Google Scholar] [CrossRef]

- WHO. Food Safety; WHO: Geneva, Switzerland, 2024. [Google Scholar]

- Frank, C.; Werber, D.; Cramer, J.P.; Askar, M.; Faber, M.; an der Heiden, M.; Bernard, H.; Fruth, A.; Prager, R.; Spode, A. Epidemic profile of Shiga-toxin–producing Escherichia coli O104: H4 outbreak in Germany. N. Engl. J. Med. 2011, 365, 1771–1780. [Google Scholar] [CrossRef]

- Malik, S.; Krishnaswamy, K.; Mustapha, A. Hazard analysis and risk-based preventive controls (HARPC): Current food safety and quality standards for complementary foods. Foods 2021, 10, 2199. [Google Scholar] [CrossRef]

- Brack, W.; Dulio, V.; Ågerstrand, M.; Allan, I.; Altenburger, R.; Brinkmann, M.; Bunke, D.; Burgess, R.M.; Cousins, I.; Escher, B.I. Towards the review of the European Union Water Framework management of chemical contamination in European surface water resources. Sci. Total Environ. 2017, 576, 720–737. [Google Scholar] [CrossRef]

- Self, D.; Rothstein, H. Institutional constraints on ‘nudge-style’risk rating systems: Explaining why food hygiene barometers were rolled-out in the UK but abandoned in Germany. J. Risk Res. 2021, 24, 1465–1481. [Google Scholar] [CrossRef]

- CFIA. Food Safety Standards and Guidelines; CFIA: Ottawa, ON, Canada, 2020. [Google Scholar]

- Thanh, N.; Anne, W.; May, A. Food safety and quality systems in Canada. An exploratory study. Int. J. Qual. Reliab. Manag. 2004, 21, 655–671. [Google Scholar]

- Akegbe, H.; Onyeaka, H.; Omotosho, A.D.; Ochulor, C.E.; Njoagwuani, E.I.; Mazi, I.M.; Oladunjoye, I.O.; Nwaiwu, O.; Odeyemi, O.A.; Tamasiga, P. The Need for Nigeria to Embrace the Hygiene Rating Scheme. Hygiene 2023, 3, 221–235. [Google Scholar] [CrossRef]

- Yang, L.; Li, Z.; Xie, T.; Feng, J.; Xu, X.; Zhao, Y.; Gao, X. Effects of Sous-Vide on Quality, Structure and Flavor Characteristics of Tilapia Fillets. Molecules 2023, 28, 8075. [Google Scholar] [CrossRef]

- Anyogu, A.; Olukorede, A.; Anumudu, C.; Onyeaka, H.; Areo, E.; Adewale, O.; Odimba, J.N.; Nwaiwu, O. Microorganisms and food safety risks associated with indigenous fermented foods from Africa. Food Control 2021, 129, 108227. [Google Scholar] [CrossRef]

- Coşansu, S.; Mol, S.; Haskaraca, G. Sous-vide cooking: Effects on seafood quality and combination with other hurdles. Int. J. Gastron. Food Sci. 2022, 29, 100586. [Google Scholar] [CrossRef]

- Choi, J.R.; Yong, K.W.; Choi, J.Y.; Cowie, A.C. Emerging point-of-care technologies for food safety analysis. Sensors 2019, 19, 817. [Google Scholar] [CrossRef]

- Mu, W.; Kleter, G.A.; Bouzembrak, Y.; Dupouy, E.; Frewer, L.J.; Radwan Al Natour, F.N.; Marvin, H. Making food systems more resilient to food safety risks by including artificial intelligence, big data, and internet of things into food safety early warning and emerging risk identification tools. Compr. Rev. Food Sci. Food Saf. 2024, 23, e13296. [Google Scholar] [CrossRef]

- Eyvazi, S.; Baradaran, B.; Mokhtarzadeh, A.; de la Guardia, M. Recent advances on development of portable biosensors for monitoring of biological contaminants in foods. Trends Food Sci. Technol. 2021, 114, 712–721. [Google Scholar] [CrossRef]

- Luo, Y.; Alocilja, E.C. Portable nuclear magnetic resonance biosensor and assay for a highly sensitive and rapid detection of foodborne bacteria in complex matrices. J. Biol. Eng. 2017, 11, 14. [Google Scholar] [CrossRef]

- Kumar, K.; Verma, A.; Verma, P. IoT-HGDS: Internet of Things integrated machine learning based hazardous gases detection system for smart kitchen. Internet Things 2024, 28, 101396. [Google Scholar] [CrossRef]

- Saxena, V.; Gautam, A. Machine learning and artificial intelligence in food industry. Int. Res. J. Mod. Eng. Technol. Sci. 2021, 3, 585–603. [Google Scholar]

- Telenor-IoT. IoT Enabled Refrigerators: A Case Study with ISA. 2019. Available online: https://iot.telenor.com/iot-case/isa-smart-refrigeration-with-iot/ (accessed on 5 May 2025).

- Amit, S.K.; Uddin, M.M.; Rahman, R.; Islam, S.R.; Khan, M.S. A review on mechanisms and commercial aspects of food preservation and processing. Agric. Food Secur. 2017, 6, 1–22. [Google Scholar] [CrossRef]

- Zaccheo, A.; Palmaccio, E.; Venable, M.; Locarnini-Sciaroni, I.; Parisi, S.; Zaccheo, A.; Palmaccio, E.; Venable, M.; Locarnini-Sciaroni, I.; Parisi, S. A brief history of food, food safety, and hygiene. In Food Hygiene and Applied Food Microbiology in an Anthropological Cross Cultural Perspective; Springer Nature: Dordrecht, The Netherlands, 2017; pp. 7–15. [Google Scholar]

- Ikram, S. Choice Cuts: Meat Production in Ancient Egypt; Peeters: Leuven, Belgium, 1995; Volume 69. [Google Scholar]

- Maestro, D.; Šegalo, S.; Pašalić, A.; Maestro, N.; Čaušević, A. Food safety–From pioneering steps to the modern scientific discipline. J. Health Sci. 2022, 12, 178–183. [Google Scholar] [CrossRef]

- Jay, J.M.; Loessner, M.J.; Golden, D.A. Modern Food Microbiology; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Rankin, S.; Bradley, R.; Miller, G.; Mildenhall, K. A 100-Year Review: A century of dairy processing advancements—Pasteurization, cleaning and sanitation, and sanitary equipment design. J. Dairy Sci. 2017, 100, 9903–9915. [Google Scholar] [CrossRef]

- Sperber, W.H. Introduction to the microbiological spoilage of foods and beverages. In Compendium of the Microbiological Spoilage of Foods and Beverages; Springer: New York, NY, USA, 2009; pp. 1–40. [Google Scholar]

- Hoffmann, S.; Ashton, L.; Ahn, J.W. Food safety: A policy history and introduction to avenues for economic research. Appl. Econ. Perspect. Policy 2021, 43, 680–700. [Google Scholar] [CrossRef]

- Hulebak, K.L.; Schlosser, W. Hazard analysis and critical control point (HACCP) history and conceptual overview. Risk Anal. 2002, 22, 547–552. [Google Scholar] [CrossRef]

- Deluyker, H.; Silano, V. The first ten years of activity of EFSA: A success story. EFSA J. 2012, 10, se101. [Google Scholar] [CrossRef]

- FAO. Assuring Food Safety and Quality: Guidelines for Strengthening National Food Control Systems; FAO: Rome, Italy, 2003. [Google Scholar]

- Ribera, L.A.; Knutson, R.D. The FDA’s food safety modernization act and its economic implications. Choices 2011, 26, 1. [Google Scholar]

- Camino Feltes, M.M.; Arisseto-Bragotto, A.P.; Block, J.M. Food quality, food-borne diseases, and food safety in the Brazilian food industry. Food Qual. Saf. 2017, 1, 13–27. [Google Scholar] [CrossRef]

- Chen, K. Food safety regulatory systems in Europe and China: A study of how co-regulation can improve regulatory effectiveness. J. Integr. Agric. 2015, 14, 2203–2217. [Google Scholar] [CrossRef]

- Bai, L.; Ma, C.-L.; Yang, Y.-S.; Zhao, S.-K.; Gong, S.-L. Implementation of HACCP system in China: A survey of food enterprises involved. Food Control 2007, 18, 1108–1112. [Google Scholar] [CrossRef]

- Zhao, X.; Li, M.; Liu, Y. Microfluidic-based approaches for foodborne pathogen detection. Microorganisms 2019, 7, 381. [Google Scholar] [CrossRef] [PubMed]

- Salihah, N.T.; Hossain, M.M.; Lubis, H.; Ahmed, M.U. Trends and advances in food analysis by real-time polymerase chain reaction. J. Food Sci. Technol. 2016, 53, 2196–2209. [Google Scholar] [CrossRef] [PubMed]

- Solieri, L.; Dakal, T.C.; Giudici, P. Next-generation sequencing and its potential impact on food microbial genomics. Ann. Microbiol. 2013, 63, 21–37. [Google Scholar] [CrossRef]

- Ali, A.A.; Altemimi, A.B.; Alhelfi, N.; Ibrahim, S.A. Application of biosensors for detection of pathogenic food bacteria: A review. Biosensors 2020, 10, 58. [Google Scholar] [CrossRef]

- Law, J.W.-F.; Ab Mutalib, N.-S.; Chan, K.-G.; Lee, L.-H. Rapid methods for the detection of foodborne bacterial pathogens: Principles, applications, advantages and limitations. Front. Microbiol. 2015, 5, 770. [Google Scholar] [CrossRef]

- Wu, W.; Zhao, S.; Mao, Y.; Fang, Z.; Lu, X.; Zeng, L. A sensitive lateral flow biosensor for Escherichia coli O157: H7 detection based on aptamer mediated strand displacement amplification. Anal. Chim. Acta 2015, 861, 62–68. [Google Scholar] [CrossRef]

- Palanisamy, Y.; Kadirvel, V.; Ganesan, N.D. Recent technological advances in food packaging: Sensors, automation, and application. Sustain. Food Technol. 2025, 3, 161–180. [Google Scholar] [CrossRef]

- Castillo-Henríquez, L.; Brenes-Acuña, M.; Castro-Rojas, A.; Cordero-Salmerón, R.; Lopretti-Correa, M.; Vega-Baudrit, J.R. Biosensors for the detection of bacterial and viral clinical pathogens. Sensors 2020, 20, 6926. [Google Scholar] [CrossRef]

- Lane, K.; McLandsborough, L.A.; Autio, W.R.; Kinchla, A.J. Efficacy of ATP monitoring for measuring organic matter on postharvest food contact surfaces. J. Food Prot. 2020, 83, 1829–1837. [Google Scholar] [CrossRef]

- Göransson, M.; Nilsson, F.; Jevinger, Å. Temperature performance and food shelf-life accuracy in cold food supply chains–Insights from multiple field studies. Food Control 2018, 86, 332–341. [Google Scholar] [CrossRef]

- Ramanathan, U.; Ramanathan, R.; Adefisan, A.; Da Costa, T.; Cama-Moncunill, X.; Samriya, G. Adapting digital technologies to reduce food waste and improve operational efficiency of a frozen food company—The case of Yumchop Foods in the UK. Sustainability 2022, 14, 16614. [Google Scholar] [CrossRef]

- Shih, C.-W.; Wang, C.-H. Integrating wireless sensor networks with statistical quality control to develop a cold chain system in food industries. Comput. Stand. Interfaces 2016, 45, 62–78. [Google Scholar] [CrossRef]

- Dhal, S.B.; Kar, D. Leveraging artificial intelligence and advanced food processing techniques for enhanced food safety, quality, and security: A comprehensive review. Discov. Appl. Sci. 2025, 7, 75. [Google Scholar] [CrossRef]

- Hassan, C.A.U.; Iqbal, J.; Khan, M.S.; Hussain, S.; Akhunzada, A.; Ali, M.; Gani, A.; Uddin, M.; Ullah, S.S. Design and Implementation of Real-Time Kitchen Monitoring and Automation System Based on Internet of Things. Energies 2022, 15, 6778. [Google Scholar] [CrossRef]

- Abass, T.; Eruaga, M.A.; Itua, E.O.; Bature, J.T. Advancing food safety through iot: Real-time monitoring and control systems. Int. Med. Sci. Res. J. 2024, 4, 276–283. [Google Scholar] [CrossRef]

- Adeleke, I.; Nwulu, N.; Adebo, O.A. Internet of Things (IoT) in the food fermentation process: A bibliometric review. J. Food Process Eng. 2023, 46, e14321. [Google Scholar] [CrossRef]

- Iftekhar, A.; Cui, X. Blockchain-based traceability system that ensures food safety measures to protect consumer safety and COVID-19 free supply chains. Foods 2021, 10, 1289. [Google Scholar] [CrossRef]

- Luo, Z.; Zhu, J.; Sun, T.; Liu, Y.; Ren, S.; Tong, H.; Yu, L.; Fei, X.; Yin, K. Application of the IoT in the food supply chain─ from the perspective of carbon mitigation. Environ. Sci. Technol. 2022, 56, 10567–10576. [Google Scholar] [CrossRef]

- Heyder, M.; Theuvsen, L.; Hollmann-Hespos, T. Investments in tracking and tracing systems in the food industry: A PLS analysis. Food Policy 2012, 37, 102–113. [Google Scholar] [CrossRef]

- Li, Z.; Liu, G.; Liu, L.; Lai, X.; Xu, G. IoT-based tracking and tracing platform for prepackaged food supply chain. Ind. Manag. Data Syst. 2017, 117, 1906–1916. [Google Scholar] [CrossRef]

- Liu, Y.; Han, W.; Zhang, Y.; Li, L.; Wang, J.; Zheng, L. An Internet-of-Things solution for food safety and quality control: A pilot project in China. J. Ind. Inf. Integr. 2016, 3, 1–7. [Google Scholar] [CrossRef]

- Ferone, M.; Gowen, A.; Fanning, S.; Scannell, A.G. Microbial detection and identification methods: Bench top assays to omics approaches. Compr. Rev. Food Sci. Food Saf. 2020, 19, 3106–3129. [Google Scholar] [CrossRef]

- Nnachi, R.C.; Sui, N.; Ke, B.; Luo, Z.; Bhalla, N.; He, D.; Yang, Z. Biosensors for rapid detection of bacterial pathogens in water, food and environment. Environ. Int. 2022, 166, 107357. [Google Scholar] [CrossRef]

- Castle, L.M.; Schuh, D.A.; Reynolds, E.E.; Furst, A.L. Electrochemical sensors to detect bacterial foodborne pathogens. ACS Sens. 2021, 6, 1717–1730. [Google Scholar] [CrossRef] [PubMed]

- Cimafonte, M.; Fulgione, A.; Gaglione, R.; Papaianni, M.; Capparelli, R.; Arciello, A.; Bolletti Censi, S.; Borriello, G.; Velotta, R.; Della Ventura, B. Screen printed based impedimetric immunosensor for rapid detection of Escherichia coli in drinking water. Sensors 2020, 20, 274. [Google Scholar] [CrossRef] [PubMed]

- Trinh, K.T.L.; Chae, W.R.; Lee, N.Y. Recent advances in the fabrication strategies of paper-based microfluidic devices for rapid detection of bacteria and viruses. Microchem. J. 2022, 180, 107548. [Google Scholar] [CrossRef]

- Boehle, K.E.; Gilliand, J.; Wheeldon, C.R.; Holder, A.; Adkins, J.A.; Geiss, B.J.; Ryan, E.P.; Henry, C.S. Utilizing paper-based devices for antimicrobial-resistant bacteria detection. Angew. Chem. Int. Ed. 2017, 56, 6886–6890. [Google Scholar] [CrossRef]

- Bisha, B.; Adkins, J.A.; Jokerst, J.C.; Chandler, J.C.; Pérez-Méndez, A.; Coleman, S.M.; Sbodio, A.O.; Suslow, T.V.; Danyluk, M.D.; Henry, C.S. Colorimetric paper-based detection of Escherichia coli, Salmonella spp., and Listeria monocytogenes from large volumes of agricultural water. JoVE (J. Vis. Exp.) 2014, 88, e51414. [Google Scholar]

- Bedford, B.; Liggans, G.; Williams, L.; Jackson, L. Allergen removal and transfer with wiping and cleaning methods used in retail and food service establishments. J. Food Prot. 2020, 83, 1248–1260. [Google Scholar] [CrossRef] [PubMed]

- Bakke, M. A comprehensive analysis of ATP tests: Practical use and recent progress in the total adenylate test for the effective monitoring of hygiene. J. Food Prot. 2022, 85, 1079–1095. [Google Scholar] [CrossRef]

- Cannon, J.L.; Park, G.W.; Anderson, B.; Leone, C.; Chao, M.; Vinjé, J.; Fraser, A.M. Hygienic monitoring in long-term care facilities using ATP, crAssphage, and human noroviruses to direct environmental surface cleaning. Am. J. Infect. Control. 2022, 50, 289–294. [Google Scholar] [CrossRef]

- Aoyama, T.; Kudo, T. Comparison of the disinfecting effect of sodium hypochlorite aqueous solution and surfactant on hospital kitchen hygiene using adenosine triphosphate swab testing. PLoS ONE 2021, 16, e0249796. [Google Scholar] [CrossRef] [PubMed]

- Irie, Y.; Ono, M.; Aritsune, M.; Imamura, Y.; Nishioka, S.; Akiyama, K.; Enokidani, M.; Horikita, T. Cleaning procedures and cleanliness assessments of bucket milkers and suckling buckets on Japanese dairy farms. J. Vet. Med. Sci. 2021, 83, 863–868. [Google Scholar] [CrossRef] [PubMed]

- Kumar, V.; Ahire, J.J.; Taneja, N.K. Advancing microbial food safety and hazard analysis through predictive mathematical modeling. Microbe 2024, 2, 100049. [Google Scholar] [CrossRef]

- Ding, H.; Tian, J.; Yu, W.; Wilson, D.I.; Young, B.R.; Cui, X.; Xin, X.; Wang, Z.; Li, W. The application of artificial intelligence and big data in the food industry. Foods 2023, 12, 4511. [Google Scholar] [CrossRef]

- Lopatkin, A.J.; Collins, J.J. Predictive biology: Modelling, understanding and harnessing microbial complexity. Nat. Rev. Microbiol. 2020, 18, 507–520. [Google Scholar] [CrossRef]

- Taiwo, O.R.; Onyeaka, H.; Oladipo, E.K.; Oloke, J.K.; Chukwugozie, D.C. Advancements in Predictive Microbiology: Integrating new technologies for efficient food safety models. International journal of microbiology. 2024, 1, 6612162. [Google Scholar] [CrossRef]

- Tarlak, F. The Use of Predictive Microbiology for the Prediction of the Shelf Life of Food Products. Foods 2023, 12, 4461. [Google Scholar] [CrossRef]

- Song, H.-S.; Cannon, W.R.; Beliaev, A.S.; Konopka, A. Mathematical modeling of microbial community dynamics: A methodological review. Processes 2014, 2, 711–752. [Google Scholar] [CrossRef]

- Sachani, D.K.; Dhameliya, N.; Mullangi, K.; Anumandla, S.K.R.; Vennapusa, S.C.R. Enhancing food service sales through AI and automation in convenience store kitchens. Glob. Discl. Econ. Bus. 2021, 10, 105–116. [Google Scholar] [CrossRef]

- Eze, J.; Duan, Y.; Eze, E.; Ramanathan, R.; Ajmal, T. Machine learning-based optimal temperature management model for safety and quality control of perishable food supply chain. Sci. Rep. 2024, 14, 27228. [Google Scholar] [CrossRef] [PubMed]

- Cassin, M.H.; Lammerding, A.M.; Todd, E.C.; Ross, W.; McColl, R.S. Quantitative risk assessment for Escherichia coli O157: H7 in ground beef hamburgers. Int. J. Food Microbiol. 1998, 41, 21–44. [Google Scholar] [CrossRef] [PubMed]

- Ma, J.; Du, K.; Zheng, F.; Zhang, L.; Gong, Z.; Sun, Z. A recognition method for cucumber diseases using leaf symptom images based on deep convolutional neural network. Comput. Electron. Agric. 2018, 154, 18–24. [Google Scholar] [CrossRef]

- Gougouli, M.; Kalantzi, K.; Beletsiotis, E.; Koutsoumanis, K.P. Development and application of predictive models for fungal growth as tools to improve quality control in yogurt production. Food Microbiol. 2011, 28, 1453–1462. [Google Scholar] [CrossRef]

- Liu, N.; Bouzembrak, Y.; Van den Bulk, L.M.; Gavai, A.; van den Heuvel, L.J.; Marvin, H.J. Automated food safety early warning system in the dairy supply chain using machine learning. Food Control 2022, 136, 108872. [Google Scholar] [CrossRef]

- Qin, J.; Hong, J.; Cho, H.; Van Kessel, J.A.S.; Baek, I.; Chao, K.; Kim, M.S. A multimodal optical sensing system for automated and intelligent food safety inspection. J. Asabe 2023, 66, 839–849. [Google Scholar] [CrossRef]

- Iuhasz, G.; Fortiş, T.-F.; Panica, S. Exploring machine learning methods for the identification of production cycles and anomaly detection. Internet Things 2025, 30, 101508. [Google Scholar] [CrossRef]

- Xu, J.; Guo, S.; Xie, D.; Yan, Y. Blockchain: A new safeguard for agri-foods. Artif. Intell. Agric. 2020, 4, 153–161. [Google Scholar] [CrossRef]

- Rejeb, A.; Keogh, J.G.; Zailani, S.; Treiblmaier, H.; Rejeb, K. Blockchain technology in the food industry: A review of potentials, challenges and future research directions. Logistics 2020, 4, 27. [Google Scholar] [CrossRef]

- Jang, H.; Lee, D.; Yoon, B. Development of a Blockchain-Based Food Safety System for Shared Kitchens. Systems 2024, 12, 509. [Google Scholar] [CrossRef]

- Yépez, J.; Ko, S.-B. IoT-based intelligent residential kitchen fire prevention system. J. Electr. Eng. Technol. 2020, 15, 2823–2832. [Google Scholar] [CrossRef]

- Kamath, R. Food traceability on blockchain: Walmart’s pork and mango pilots with IBM. J. Br. Blockchain Assoc. 2018, 1, 1–12. [Google Scholar] [CrossRef]

- Wass, S. Food Companies Unite to Advance Blockchain for Supply Chain Traceability; Global Trade Review. 2017. Available online: https://www.gtreview.com/news/digital-trade/food-companies-unite-to-advance-blockchain-for-supply-chain-traceability/ (accessed on 3 May 2025).

- Tian, F. A supply chain traceability system for food safety based on HACCP, blockchain & Internet of things. In Proceedings of the 2017 International Conference on Service Systems and Service Management, Dalian, China, 16–18 June 2017; pp. 1–6. [Google Scholar]

- Kamilaris, A.; Fonts, A.; Prenafeta-Boldύ, F.X. The rise of blockchain technology in agriculture and food supply chains. Trends Food Sci. Technol. 2019, 91, 640–652. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Sharma, R. Modeling the blockchain enabled traceability in agriculture supply chain. Int. J. Inf. Manag. 2020, 52, 101967. [Google Scholar] [CrossRef]

- Grobbelaar, W.; Verma, A.; Shukla, V.K. Analyzing human robotic interaction in the food industry. J. Phys. Conf. Ser. 2021, 1714, 012032. [Google Scholar] [CrossRef]

- Sansebastiano, G.; Zoni, R.; Bigliardi, L. Cleaning and disinfection procedures in the food industry general aspects and practical applications. In Food Safety: A Practical and Case Study Approach; Springer: Boston, MA, USA, 2007; pp. 253–280. [Google Scholar]

- Derossi, A.; Di Palma, E.; Moses, J.; Santhoshkumar, P.; Caporizzi, R.; Severini, C. Avenues for non-conventional robotics technology applications in the food industry. Food Res. Int. 2023, 113265. [Google Scholar] [CrossRef]

- Nayik, G.A.; Muzaffar, K.; Gull, A. Robotics and food technology: A mini review. J. Nutr. Food Sci 2015, 5, 1–11. [Google Scholar]

- Kim, J.; Kwon, Y.-K.; Kim, H.-W.; Seol, K.-H.; Cho, B.-K. Robot technology for pork and beef meat slaughtering process: A review. Animals 2023, 13, 651. [Google Scholar] [CrossRef]

- DMRI. Automatic Handling of the Bung; DMRI: Roskilde, Denmark, 2017. [Google Scholar]

- Karin, K. Robot Chef. 2016. Available online: https://madeinjapan.com.br/2016/12/15/chef-robo/ (accessed on 7 April 2025).

- Khanna, S.; Srivastava, S. The Emergence of AI based Autonomous UV Disinfection Robots in Pandemic Response and Hygiene Maintenance. Int. J. Appl. Health Care Anal. 2022, 7, 1–19. [Google Scholar]

- Singh, J.P. From Algorithmic Arbiters to Stochastic Stewards: Deconstructing the Mechanisms of Ethical Reasoning Implementation in Contemporary AI Applications. Int. J. Responsible Artif. Intell. 2020, 10, 20–33. [Google Scholar]

- Robotic_Magazine. UV Disinfection Robot. 2016. Available online: https://www.roboticmagazine.com/popular/uv-disinfection-robot (accessed on 10 May 2025).

- Burton, M.; Cobb, E.; Donachie, P.; Judah, G.; Curtis, V.; Schmidt, W.-P. The effect of handwashing with water or soap on bacterial contamination of hands. Int. J. Environ. Res. Public Health 2011, 8, 97–104. [Google Scholar] [CrossRef]

- Alzyood, M.; Jackson, D.; Aveyard, H.; Brooke, J. COVID-19 reinforces the importance of handwashing. J. Clin. Nurs. 2020, 29, 2760. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Xue, T.; Liu, Z.; Chen, W.; Vanrumste, B. Detecting hand washing activity among activities of daily living and classification of WHO hand washing techniques using wearable devices and machine learning algorithms. Healthc. Technol. Lett. 2021, 8, 148–158. [Google Scholar] [CrossRef]

- Bal, M.; Abrishambaf, R. A system for monitoring hand hygiene compliance based-on Internet-of-Things. In Proceedings of the 2017 IEEE International Conference on Industrial Technology (ICIT), Toronto, ON, Canada, 22–25 March 2017; pp. 1348–1353. [Google Scholar]

- Mondol, M.A.S.; Stankovic, J.A. Harmony: A hand wash monitoring and reminder system using smart watches. EAI Endorsed Trans. Ambient Syst. 2015, 2, 11–20. [Google Scholar]

- ŞENEL, P.; ÖNÇEL, S. Hand Hygiene Experiences of Gastronomy and Culinary Arts Students: The Case of Anadolu University. J. Tour. Gastron. Stud. 2019, 7, 637–646. [Google Scholar] [CrossRef]

- Clark, J.; Crandall, P.; Shabatura, J. Wearable technology effects on training outcomes of restaurant food handlers. J. Food Prot. 2018, 81, 1220–1226. [Google Scholar] [CrossRef]

- Liu, P.; Lee, Y.M. An investigation of consumers’ perception of food safety in the restaurants. Int. J. Hosp. Manag. 2018, 73, 29–35. [Google Scholar] [CrossRef]

- Singh, V.; Archana, T.; Singh, A.; Tyagi, P.K. Utilizing Technology for Food Waste Management in the Hospitality Industry Hotels and Restaurants. In Sustainable Disposal Methods of Food Wastes in Hospitality Operations; IGI Global: Hershey, PA, USA, 2024; pp. 287–295. [Google Scholar]

- Griffith, C. Surface sampling and the detection of contamination. In Handbook of Hygiene Control in the Food Industry; Elsevier: Amsterdam, The Netherlands, 2016; pp. 673–696. [Google Scholar]

- Caporaso, N. The impact of molecular gastronomy within the food science community. In Gastronomy and Food Science; Elsevier: Amsterdam, The Netherlands, 2021; pp. 1–18. [Google Scholar]

- Gössling, S.; Hall, C.M. The Sustainable Chef: The Environment in Culinary Arts, Restaurants, and Hospitality; Routledge: London, UK, 2021. [Google Scholar]

- Božić, A.; Milošević, S. Contemporary trends in the restaurant industry and gastronomy. J. Hosp. Tour. Res. 2021, 45, 905–907. [Google Scholar] [CrossRef]

- Rodgers, S. Technological innovation supporting different food production philosophies in the food service sectors. Int. J. Contemp. Hosp. Manag. 2008, 20, 19–34. [Google Scholar] [CrossRef]

- Holliday, L.S. Kitchen Technologies: Promises and Alibis, 1944-1966. Camera Obscura 2001, 16, 1–131. [Google Scholar] [CrossRef]

- Detwiler, D. Implementing future food safety technologies. Build. Future Food Saf. Technol. 2020, 231. [Google Scholar] [CrossRef]

- Mohammad, Z.H.; Arias-Rios, E.V.; Ahmad, F.; Juneja, V.K. Microbial Contamination in the Food Processing Environment. In Microbial Biotechnology in the Food Industry: Advances, Challenges, and Potential Solutions; Springer: Berlin/Heidelberg, Germany, 2024; pp. 15–43. [Google Scholar]

- Hao, F.; Guo, Y.; Zhang, C.; Chon, K. Revolutionizing the restaurant industry: Exploring the implementation and impact of blockchain technology on the dining experience. Asia Pac. J. Tour. Res. 2024, 1–14. [Google Scholar] [CrossRef]

- Kergourlay, G.; Taminiau, B.; Daube, G.; Vergès, M.-C.C. Metagenomic insights into the dynamics of microbial communities in food. Int. J. Food Microbiol. 2015, 213, 31–39. [Google Scholar] [CrossRef]

- Adedeji, A.A.; Priyesh, P.V.; Odugbemi, A.A. The Magnitude and Impact of Food Allergens and the Potential of AI-Based Non-Destructive Testing Methods in Their Detection and Quantification. Foods 2024, 13, 994. [Google Scholar] [CrossRef]

- Sosa-Holwerda, A.; Park, O.-H.; Albracht-Schulte, K.; Niraula, S.; Thompson, L.; Oldewage-Theron, W. The role of artificial intelligence in nutrition research: A scoping review. Nutrients 2024, 16, 2066. [Google Scholar] [CrossRef]

- Seyitoğlu, F.; Fusté-Forné, F.; Yiğit, S.; Engin, S. The role of technology in the skills and creativity of chefs. Eur. J. Tour. Res. 2025, 39, 3912. [Google Scholar] [CrossRef]

- BioCote. Antimicrobial Technology for Commercial Kitchens: The Role of Antimicrobial Paints and Coatings. 2024. Available online: https://www.biocote.com/antimicrobial-technology-for-commercial-kitchens-the-role-of-antimicrobial-paints-and-coatings/ (accessed on 23 January 2025).

- Typsy. How Molecular Gastronomy Revolutionized the Dining Experience. 2025. Available online: https://blog.typsy.com/how-molecular-gastronomy-changed-the-dining-experience (accessed on 23 January 2025).

- Science_Meets_Food. When Food Science Meets Culinary Innovation: An Overview of Molecular Gastronomy. 2014. Available online: https://sciencemeetsfood.org/food-science-meets-culinary-innovation-overview-molecular-gastronomy/ (accessed on 23 January 2025).

- García-Segovia, P.; Garrido, M.D.; Vercet, A.; Arboleya, J.C.; Fiszman, S.; Martínez-Monzó, J.; Laguarda, S.; Palacios, V.; Ruiz, J. Molecular gastronomy in Spain. J. Culin. Sci. Technol. 2014, 12, 279–293. [Google Scholar] [CrossRef]

- Barham, P.; Skibsted, L.H.; Bredie, W.L.; Bom Frøst, M.; Møller, P.; Risbo, J.; Snitkjær, P.; Mortensen, L.M. Molecular gastronomy: A new emerging scientific discipline. Chem. Rev. 2010, 110, 2313–2365. [Google Scholar] [CrossRef]

- Food_Safety_Tech. Five Ways Restaurants Can Use Technology to Improve Food Safety. 2022. Available online: https://foodsafetytech.com/column/five-ways-restaurants-can-use-technology-to-improve-food-safety/ (accessed on 23 January 2025).

- McGee, H. On Food and Cooking: The Science and Lore of the Kitchen; Scribner Book Company: New York, NY, USA, 1984. [Google Scholar]

- Çekiç, İ.; Oğan, Y. Global Concepts in Gastronomy; Eğitim Yayinevi: Konya, Türkiye, 2023. [Google Scholar]

- This, H. Molecular Gastronomy: Exploring the Science of Flavor; Columbia University Press: New York, NY, USA, 2006. [Google Scholar]

- Sen, D.J. Cross linking of calcium ion in alginate produce spherification in molecular gastronomy by pseudoplastic flow. World J. Pharm. Sci. 2017, 5, 1–80. [Google Scholar]

- Barham, P. The Science of Cooking; Springer: Berlin/Heidelberg, Germany, 2001. [Google Scholar]

- Myhrvold, N. Modernist Cuisine: The Art and Science of Cooking; The Cooking Lab: Port Washington, NY, USA, 2011; Volume 1. [Google Scholar]

- Caporaso, N.; Formisano, D. Developments, applications, and trends of molecular gastronomy among food scientists and innovative chefs. Food Rev. Int. 2016, 32, 417–435. [Google Scholar] [CrossRef]

- Onyeaka, H.; Akinsemolu, A.; Miri, T.; Nnaji, N.D.; Duan, K.; Pang, G.; Tamasiga, P.; Khalid, S.; Al-Sharify, Z.T.; Chineye, U. Artificial Intelligence in Food System: Innovative Approach to Minimizing Food Spoilage and Food Waste. J. Agric. Food Res. 2025, 101895. [Google Scholar] [CrossRef]

- Anumudu, C.K.; Miri, T.; Onyeaka, H. Multifunctional Applications of Lactic Acid Bacteria: Enhancing Safety, Quality, and Nutritional Value in Foods and Fermented Beverages. Foods 2024, 13, 3714. [Google Scholar] [CrossRef]

- Bidyalakshmi, T.; Jyoti, B.; Mansuri, S.M.; Srivastava, A.; Mohapatra, D.; Kalnar, Y.B.; Narsaiah, K.; Indore, N. Application of artificial intelligence in food processing: Current status and future prospects. Food Eng. Rev. 2025, 17, 27–54. [Google Scholar] [CrossRef]

- Uehara, Y.; Ohtake, S.; Fukura, T. A mash temperature monitoring system for sake brewing. In Proceedings of the 2018 IEEE International Conference on Consumer Electronics-Taiwan (ICCE-TW), Taichung, Taiwan, 19–21 May 2018; pp. 1–2. [Google Scholar]

- Tomtsis, D.; Kontogiannis, S.; Kokkonis, G.; Zinas, N. IoT architecture for monitoring wine fermentation process of debina variety semi-sparkling wine. In Proceedings of the SouthEast European Design Automation, Computer Engineering, Computer Networks and Social Media Conference, Kastoria, Greece, 25–27 September 2016; pp. 42–47. [Google Scholar]

- Vošahlík, J.; Hart, J. Measurability of quality in fermentation process of rice wine by IoT in the field of industry 4.0. Agron. Res. 2021, 19 (Suppl. S3), 1318–1324. [Google Scholar] [CrossRef]

- Zhang, L.; Li, J.; Yue, S.; He, H.; Ouyang, J. Biocompatible blends of an intrinsically conducting polymer as stretchable strain sensors for real-time monitoring of starch-based food processing. Adv. Funct. Mater. 2021, 31, 2102745. [Google Scholar] [CrossRef]

- Recuero-Virto, N.; Valilla-Arróspide, C. Forecasting the next revolution: Food technology’s impact on consumers’ acceptance and satisfaction. Br. Food J. 2022, 124, 4339–4353. [Google Scholar] [CrossRef]

- Singh, V.; Karthik, K. Optimizing Food Quality and Customer Service in Restaurants Through AI-Powered Monitoring Systems. In Technological Innovations in the Food Service Industry; IGI Global Scientific Publishing: Hershey, PA, USA, 2025; pp. 49–68. [Google Scholar]

- Tuncer, I. Customer experience in the restaurant industry: Use of smart technologies. In Handbook of Research on Smart Technology Applications in the Tourism Industry; IGI Global: Hershey, PA, USA, 2020; pp. 254–272. [Google Scholar]

- Milton, T. Artificial Intelligence Transforming Hotel Gastronomy: An In-depth Review of AI-driven Innovations in Menu Design, Food Preparation, and Customer Interaction, with a Focus on Sustainability and Future Trends in the Hospitality Industry. Int. J. Multidimens. Res. Perspect. 2024, 2, 47–61. [Google Scholar] [CrossRef]

- Bole, D.K. Food Safety Challenges in Foodservice Environments. 2021. Available online: https://www.food-safety.com/articles/7163-food-safety-challenges-in-foodservice-environments (accessed on 23 January 2025).

- Loman.AI. AI Analytics for Restaurant Food Safety Compliance. 2024. Available online: https://loman.ai/blog/ai-analytics-for-restaurant-food-safety-compliance (accessed on 8 April 2025).

- Mohseni, P.; Ghorbani, A. Exploring the Synergy of Artificial Intelligence in Microbiology: Advancements, Challenges, and Future Prospects. Comput. Struct. Biotechnol. Rep. 2024, 1, 100005. [Google Scholar] [CrossRef]

- Lelieveld, H.L.M. Hurdling New Technology Challenges: Making the Business Case for New Technologies. Available online: https://www.food-safety.com/articles/4638-hurdling-new-technology-challenges-making-the-business-case-for-new-technologies (accessed on 8 April 2025).

- Valero, A.; Rodríguez, M.-Y.; Posada-Izquierdo, G.D.; Pérez-Rodríguez, F.; Carrasco, E.; García-Gimeno, R.M. Risk factors influencing microbial contamination in food service centers. In Significance, Prevention and Control of Food Related Diseases; Makun, H., Ed.; IntechOpen: London, UK, 2016; Volume 27, Chapter 2; ISBN 978-953-51-2277-7. [Google Scholar]

- Valdramidis, V.P.; Koutsoumanis, K.P. Challenges and perspectives of advanced technologies in processing, distribution and storage for improving food safety. Curr. Opin. Food Sci. 2016, 12, 63–69. [Google Scholar] [CrossRef]

- Azmat, H. Cybersecurity in Supply Chains: Protecting Against Risks and Addressing Vulnerabilities. Int. J. Digit. Innov. 2025, 6, 1–8. [Google Scholar]

- Martin, K.D.; Borah, A.; Palmatier, R.W. Data privacy: Effects on customer and firm performance. J. Mark. 2017, 81, 36–58. [Google Scholar] [CrossRef]

- Jasmontaite, L.; Kamara, I.; Zanfir-Fortuna, G.; Leucci, S. Data protection by design and by default: Framing guiding principles into legal obligations in the GDPR. Eur. Data Prot. L. Rev. 2018, 4, 168. [Google Scholar] [CrossRef]

- Kalyanam, A.K. The Future of Commercial Kitchens Embracing Automation and IoT (Transforming Efficiency and Innovation in the Culinary World). Int. J. Innov. Res. Creat. Technol. 2022, 8, 1–11. [Google Scholar]

- SMRTR. How does Food Safety Technology Impact Consumer Confidence? 2024. Available online: https://smrtrsolutions.com/2024/02/15/how-does-food-safety-technology-impact-consumer-confidence/ (accessed on 23 January 2025).

- Pancer, E.; Noseworthy, T.J.; McShane, L.; Taylor, N.; Philp, M. Robots in the kitchen: The automation of food preparation in restaurants and the compounding effects of perceived love and disgust on consumer evaluations. Appetite 2025, 204, 107723. [Google Scholar] [CrossRef]

- Osmólska, E.; Stoma, M.; Starek-Wójcicka, A. Application of biosensors, sensors, and tags in intelligent packaging used for food products—A review. Sensors 2022, 22, 9956. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, Y.; Zhang, Y.; Wang, X.; Zhang, C.; Cheng, N. Intelligent Biosensors Promise Smarter Solutions in Food Safety 4.0. Foods 2024, 13, 235. [Google Scholar] [CrossRef]

- Onyeaka, H.; Ukwuru, M.; Anumudu, C.; Anyogu, A. Food fraud in insecure times: Challenges and opportunities for reducing food fraud in Africa. Trends Food Sci. Technol. 2022, 125, 26–32. [Google Scholar] [CrossRef]

- Nnaji, N.D.; Onyeaka, H.; Ughamba, K.T.; Ononugbo, C.M.; Olovo, C.V.; Mazi, I.M. Chemical Toxicants Used for Food Preservation in Africa. Is it a Case of Ignorance or Food Fraud? A Review. Health Sci. Rep. 2025, 8, e70333. [Google Scholar] [CrossRef]

- Çöl, B.G.; İmre, M.; Yıkmış, S. Virtual reality and augmented reality technologies in gastronomy: A review. Efood 2023, 4, e84. [Google Scholar] [CrossRef]

| Function/Technology | Application | AI/Robotics Contribution | Impact | References |

|---|---|---|---|---|

| Automated Technology | Predicting contamination risk and outbreaks | AI-driven prediction models for microbial risks | Proactive microbial management and risk prevention | [77,79] |

| AI in Sampling | Automating microbial sample collection | Automated data analysis for the detection of the presence of microorganisms | Enhanced data accuracy and efficiency | [85] |

| Metagenomics Incorporation | Analyzing microbial communities in food | AI-based analysis for microbial and genetic data | Early detection of pathogens and spoilage organisms | [125] |

| IoT Sensors | Environmental and microbial monitoring | Real-time predictive analytics | Proactive food safety measures | [55,61] |

| Robotic Sanitation | Cleaning and disinfecting food areas | Automation of sanitization routines | Reduced risk of cross-contamination | [100,104] |

| Allergen Detection | Monitoring recipes and raw ingredients | AI detection of potential allergens. Robots can scan raw ingredients for contamination | Improved allergen safety | [126] |

| Quality Control | Monitoring the quality of food | AI predicts and prevents contamination during food storage and preparation | Improved food quality | [77] |

| Nutritional Customization | Personalized meal preparation | AI adjusts meals to meet dietary and caloric needs | Optimized health outcomes | [127] |

| Molecular Gastronomy Techniques | Description | Culinary Application | References |

|---|---|---|---|

| Emulsification | Combining two immiscible liquids, such as oil and water, using emulsifiers such as lecithin. | Results in foams or creamy textures that are light and airy, often used in sauces or garnishes to add an airy feel without heavy creams, e.g., foamed oils or liquid-based sauces. | [135,136] |

| Spherification | A process where liquids are transformed into flavorful spheres that burst in the mouth using sodium alginate. | Creates caviar-like spheres, widely used in avant-garde dishes to add a unique texture and a burst of liquid flavor, e.g., balsamic vinegar pearls or fruit caviars. | [137,138] |

| Gelification | The use of gelling agents like agar-agar or gelatin to create firm textures from liquids. | Allows chefs to produce gels from almost any liquid, providing a wide variety of textures for both savory and dessert dishes, e.g., gelled olive oil or fruit-based gels. | [136,139] |

| Flash Freezing (Cryogenic Cooking) | Rapid freezing of ingredients using liquid nitrogen to create crisp texture and unique presentation methods. | Enhances texture by flash freezing liquids or solids, resulting in novel textures in food, e.g., frozen fruit powders or shattering frozen elements in desserts. | [140,141] |

| Foaming and Aeration | Using chemical agents like soy lecithin to create stable foams. | Adds visual appeal and unique textures to dishes, often used to top desserts, soups, or beverages, e.g., coffee or fruit foams that add flavor without heaviness. | [133] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anumudu, C.K.; Augustine, J.A.; Uhegwu, C.C.; Uche, J.N.; Ugwoegbu, M.O.; Shodeko, O.R.; Onyeaka, H. Smart Kitchens of the Future: Technology’s Role in Food Safety, Hygiene, and Culinary Innovation. Standards 2025, 5, 21. https://doi.org/10.3390/standards5030021

Anumudu CK, Augustine JA, Uhegwu CC, Uche JN, Ugwoegbu MO, Shodeko OR, Onyeaka H. Smart Kitchens of the Future: Technology’s Role in Food Safety, Hygiene, and Culinary Innovation. Standards. 2025; 5(3):21. https://doi.org/10.3390/standards5030021

Chicago/Turabian StyleAnumudu, Christian Kosisochukwu, Jennifer Ada Augustine, Chijioke Christopher Uhegwu, Joy Nzube Uche, Moses Odinaka Ugwoegbu, Omowunmi Rachael Shodeko, and Helen Onyeaka. 2025. "Smart Kitchens of the Future: Technology’s Role in Food Safety, Hygiene, and Culinary Innovation" Standards 5, no. 3: 21. https://doi.org/10.3390/standards5030021

APA StyleAnumudu, C. K., Augustine, J. A., Uhegwu, C. C., Uche, J. N., Ugwoegbu, M. O., Shodeko, O. R., & Onyeaka, H. (2025). Smart Kitchens of the Future: Technology’s Role in Food Safety, Hygiene, and Culinary Innovation. Standards, 5(3), 21. https://doi.org/10.3390/standards5030021