Two Obstacle Factors for Technological Standardization: The Viewpoint of Technological Frame

Abstract

:1. New Modes of Innovation and Standardization Research

2. The Lack of Shared Frames for Architectural Design

2.1. City OS and Standards as a Platform

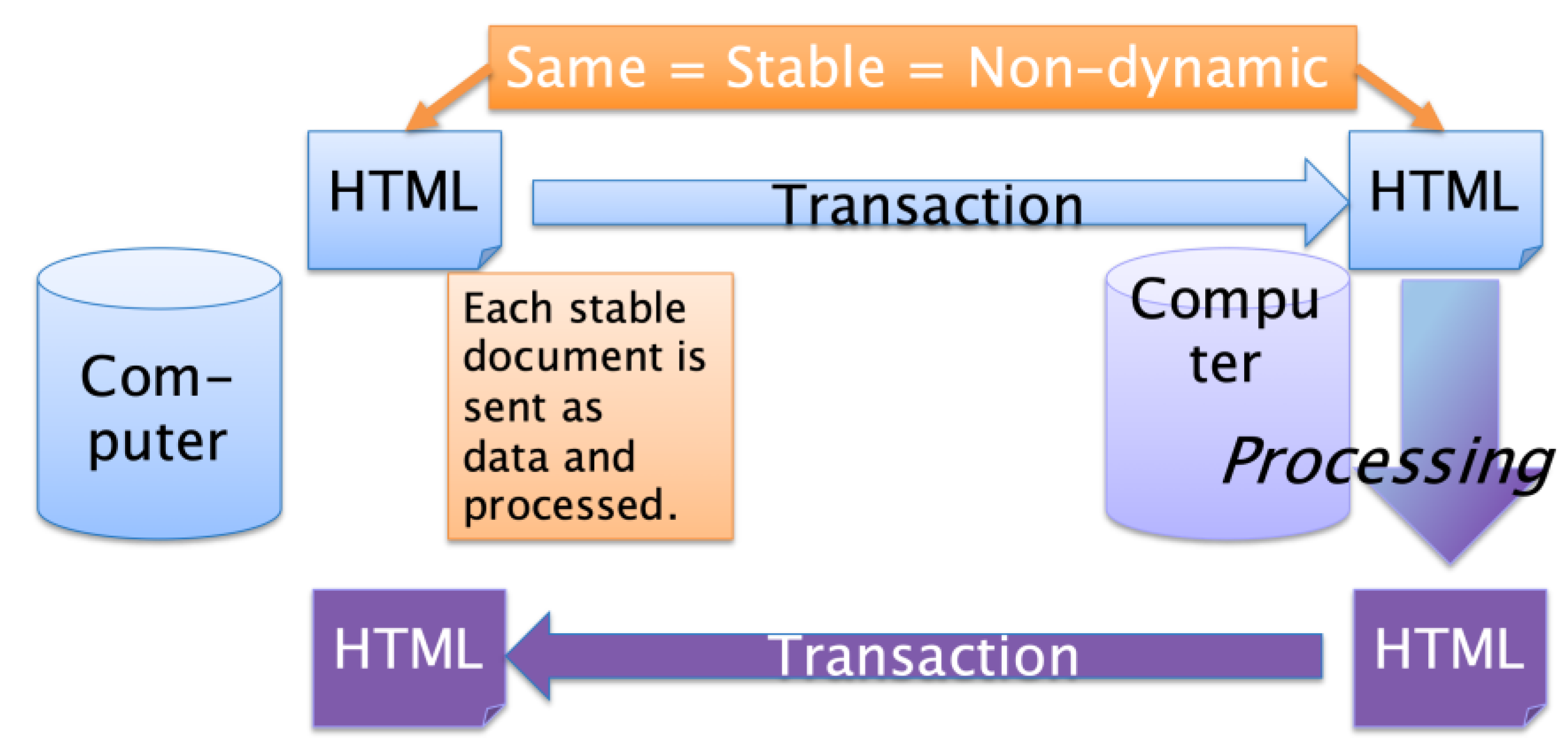

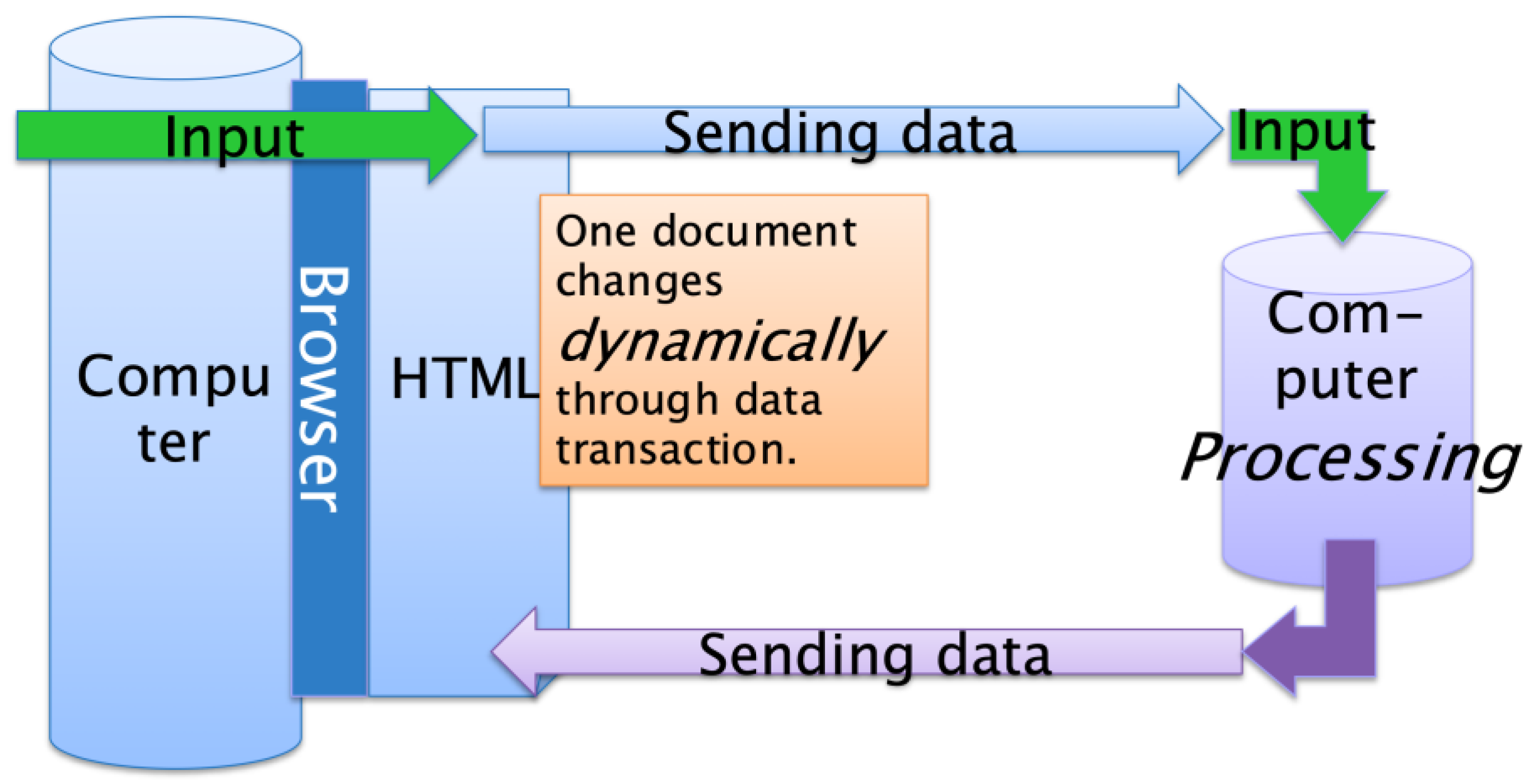

2.2. HTML Update as a Framing Contest

2.3. Competition and Cooperation for Standard Setting

3. Trade-Offs between Scalability and Diversity

3.1. Standardization in the Industrial Internet and Social Change

3.2. Craftspersonship, Innovation, and Standardization

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hermann, M.; Pentek, T.; Otto, B.; Pentek, T. Design Principles for Industrie 4.0 Scenarios. In Proceedings of the 49th Hawaii International Conference on System Sciences, Koloa, HI, USA, 5–8 January 2016; p. 16. [Google Scholar] [CrossRef]

- Narvaez Rojas, C.; Alomia Peñafiel, G.A.; Loaiza Buitrago, D.F.; Tavera Romero, C.A. Society 5.0: A Japanese Concept for a Superintelligent Society. Sustainability 2021, 13, 6567. [Google Scholar] [CrossRef]

- Ministry of Economy, Trade and Industry of Japan. "Connected Industries" Tokyo Initiative; Ministry of Economy, Trade and Industry of Japan: Tokyo, Japan, 2017. Available online: https://www.meti.go.jp/english/press/2017/pdf/1002_004b.pdf (accessed on 15 August 2021).

- ISO/IWA 39. The Gap Analysis for Standardization on Sustainable and Human-Centered Societies Enabled with Cyber Physical Systems; ISO: Geneva, Switzerland, 2020. [Google Scholar]

- Nambisan, S.; Lyytinen, K.; Majchrzak, A.; Song, M. Digital Innovation Management: Reinventing Innovation Management Research in a Digital World. MIS Q. 2017, 41, 223–238. [Google Scholar] [CrossRef]

- Evans, P.C.; Basole, R.C. Economic and Business Dimensions: Revealing the API Ecosystem and Enterprise Strategy via Visual Analytics. Commun. ACM 2016, 59, 26–28. [Google Scholar] [CrossRef]

- Zachariadis, M.; Ozcan, P. The API Economy and Digital Transformation in Financial Services: The Case of Open Banking; Elsevier BV: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Tan, W.; Fan, Y.; Ghoneim, A.; Hossain, M.A.; Dustdar, S. From the Service-Oriented Architecture to the Web API Economy. IEEE Internet Comput. 2016, 20, 64–68. [Google Scholar] [CrossRef]

- Immonen, A.; Palviainen, M.; Ovaska, E. Requirements of an Open Data Based Business Ecosystem. IEEE Access 2014, 2, 88–103. [Google Scholar] [CrossRef]

- Janssen, M.; Zuiderwijk, A. Infomediary Business Models for Connecting Open Data Providers and Users. Soc. Sci. Comput. Rev. 2014, 32, 694–711. [Google Scholar] [CrossRef]

- Granstrand, O.; Holgersson, M. Innovation Ecosystems: A Conceptual Review and a New Definition. Technovation 2020, 90–91, 102098. [Google Scholar] [CrossRef]

- IEEE Standard Association. IEEE Standards Activities in the Internet of Things (IoT); IEEE Standard Association: Piscataway, NJ, USA. Available online: https://standards.ieee.org/content/dam/ieee-standards/standards/web/documents/other/iot.pdf (accessed on 15 August 2021).

- Baldwin, C.; von Hippel, E. Modeling a Paradigm Shift: From Producer Innovation to User and Open Collaborative Innovation. Organ. Sci. 2011, 22, 1399–1417. [Google Scholar] [CrossRef] [Green Version]

- Farrell, J.; Saloner, G. Standardization and Variety. Econ. Lett. 1986, 20, 71–74. [Google Scholar] [CrossRef]

- Farrell, J.; Saloner, G. Standardization, Compatibility, and Innovation. RAND J. Econ. 1985, 16, 70–83. [Google Scholar] [CrossRef]

- Fuenfschilling, L.; Truffer, B. The Interplay of Institutions, Actors and Technologies in Socio-Technical Systems—An Analysis of Transformations in the Australian Urban Water Sector. Technol. Forecast. Soc. Chang. 2016, 103, 298–312. [Google Scholar] [CrossRef]

- Cusumano, M. The Evolution of Platform Thinking. Commun. ACM 2010, 53, 32. [Google Scholar] [CrossRef]

- Baldwin, C.Y.; Woodard, C.J. The Architecture of Platforms: A Unified View. In Platforms, Markets and Innovation; Gawer, A., Ed.; Edward Elgar Publishing: Cheltenham, UK, 2009; ISBN 9781848440708. [Google Scholar]

- Meyer, M.; Utterback, J. The Product Family and the Dynamics of Core Capability. Sloan Manag. Rev. 1993, 34, 29–47. [Google Scholar]

- Ghazawneh, A.; Henfridsson, O. Balancing Platform Control and External Contribution in Third-Party Development: The Boundary Resources Model. Inf. Syst. J. 2013, 23, 173–192. [Google Scholar] [CrossRef]

- Iansiti, M. How the Incumbent Can Win: Managing Technological Transitions in the Semiconductor Industry. Manag. Sci. 2000, 46, 169–185. [Google Scholar] [CrossRef]

- Magistretti, S.; Dell’Era, C.; Verganti, R. Searching for the Right Application: A Technology Development Review and Research Agenda. Technol. Forecast. Soc. Chang. 2020, 151, 119879. [Google Scholar] [CrossRef]

- Bunduchi, R.; Tursunbayeva, A.; Pagliari, C. Coping with Institutional Complexity: Intersecting Logics and Dissonant Visions in a Nation-Wide Healthcare IT Implementation Project. Inf. Technol. People 2020, 33, 311–339. [Google Scholar] [CrossRef]

- Verganti, R. Design Driven Innovation: Changing the Rules of Competition by Radically Innovating What Things Mean; Harvard Business Press: Boston, MA, USA, 2009; ISBN 1422136574. [Google Scholar]

- Orlikowski, W.J.; Gash, D.C. Technological Frames: Making Sense of Information Technology in Organizations. ACM Trans. Inf. Syst. 1994, 12, 174–207. [Google Scholar] [CrossRef] [Green Version]

- Acha, V. Technology Frames: The Art of Perspective and Interpretation in Strategy. SPRU Work. Pap. Ser. 2004, 44, 23. [Google Scholar]

- Iansiti, M.; Levien, R. The Keystone Advantage; Harvard Business School Press: Boston, MA, USA, 2004. [Google Scholar]

- Gawer, A.; Cusumano, M.A. Platform Leadership: How Intel, Microsoft, and Cisco Drive Industry Innovation; Harvard Business School Press: Boston, MA, USA, 2002; ISBN 1578515149. [Google Scholar]

- Benford, R.D.; Snow, D.A. Framing Processes and Social Movements. An Overview and Assessment. Am. J. Sociol. 2000, 26, 611–639. [Google Scholar] [CrossRef] [Green Version]

- Haas, P.M. Do Regimes Matter? Epistemic Communities and Mediterranean Pollution Control. Int. Organ. 1989, 43, 377–403. [Google Scholar] [CrossRef] [Green Version]

- Braithwaite, J.; Drahos, P. Global Business Regulation; Cambridge University Press: Cambridge, UK, 2000. [Google Scholar]

- Weick, K.E. Sensemaking in Organizations; Sage Publications: Thousand Oaks, CA, USA, 1995. [Google Scholar]

- Hargrave, T.; Van De Ven, A. A Collective Action Model of Innovation Institutional. Acad. Manag. Rev. 2006, 31, 864–888. [Google Scholar] [CrossRef] [Green Version]

- Kaplan, S. Framing Contests: Strategy Making Under Uncertainty. Organ. Sci. 2008, 19, 729–752. [Google Scholar] [CrossRef] [Green Version]

- Garud, R.; Rappa, M.A. A Socio-Cognitive Model of Technology Evolution: The Case of Cochlear Implants. Organ. Sci. 1994, 5, 344–362. [Google Scholar] [CrossRef] [Green Version]

- Gilbert, C.G. Change in the Presence of Residual Fit: Can Competing Frames Coexist? Organ. Sci. 2006, 17, 150–167. [Google Scholar] [CrossRef]

- Tripsas, M.; Gavetti, G. Capabilities, Cognition, and Inertia: Evidence from Digital Imaging. Strateg. Manag. J. 2000, 21, 1147–1161. [Google Scholar] [CrossRef]

- Pinch, T.J.; Bijker, W.E. The Social Construction of Facts and Artifacts: Or How the Sociology of Science and the Sociology of Technology Might Benefit Each Other. In The Social Construction of Technological Systems; MIT Press: Cambridge, MA, USA, 1987; pp. 17–50. [Google Scholar]

- Fukami, Y.; Shimizu, T. Innovating through Standardization: How Google Leverages the Value of Open Digital Platforms. In Proceedings of the Twenty-Second Pacific Asia Conference on Information Systems, Yokohama, Japan, 26–30 June 2018; pp. 2273–2285. [Google Scholar]

- Rochet, J.-C.; Tirole, J. Platform Competition in Two-Sided Markets. J. Eur. Econ. Assoc. 2003, 1, 990–1029. [Google Scholar] [CrossRef] [Green Version]

- Parker, G.G.; Alstyne, M.W. Van Two-Sided Network Effects: A Theory of Information Product Design. Management 2005, 51, 1494–1504. [Google Scholar] [CrossRef]

- Eisenmann, T.R.; Parker, G.; Van Alstyne, M.W. Strategies for Two-Sided Markets. Harv. Bus. Rev. 2006, 84, 92. [Google Scholar]

- Bales, G.L.; Das, J.; Tsugawa, J.; Linke, B.; Kong, Z. Digitalization of Human Operations in the Age of Cyber Manufacturing: Sensorimotor Analysis of Manual Grinding Performance. J. Manuf. Sci. Eng. 2017, 139. [Google Scholar] [CrossRef] [Green Version]

- Wartena, F.; Muskens, J.; Schmitt, L. Continua: The Impact of a Personal Telehealth Ecosystem. In Proceedings of the International Conference on eHealth, Telemedicine, and Social Medicine, eTELEMED 2009, Cancun, Mexico, 1–7 February 2009; pp. 13–18. [Google Scholar]

- Carroll, R.; Cnossen, R.; Schnell, M.; Simons, D. Continua: An Interoperable Personal Healthcare Ecosystem. IEEE Pervasive Comput. 2007, 6, 90–94. [Google Scholar] [CrossRef]

- Aragüés, A.; Escayola, J.; Martínez, I.; Del Valle, P.; Muñoz, P.; Trigo, J.D.; García, J. Trends and Challenges of the Emerging Technologies toward Interoperability and Standardization in E-Health Communications. IEEE Commun. Mag. 2011, 49, 182–188. [Google Scholar] [CrossRef]

- Funk, J.L.; Methe, D.T. Market- and Committee-Based Mechanisms in the Creation and Diffusion of Global Industry Standards: The Case of Mobile Communication. Res. Policy 2001, 30, 589–610. [Google Scholar] [CrossRef]

- Simcoe, T. Delay and de jure standardization: Exploring the slowdown in Internet standards development. In Standards and Public Policy; Greenstein, S.M., Stango, V., Eds.; Cambridge University Press: New York, NY, USA, 2006; pp. 260–295. ISBN 9780511493249. [Google Scholar]

- Farrell, J.; Simcoe, T. Choosing the Rules for Formal Standardization. RAND J. Econ. 2012, 43, 235–252. [Google Scholar] [CrossRef] [Green Version]

- MacKenzie, D.; Wajcman, J. The Social Shaping of Technology, 2nd ed.; Open University Press: Buckingham, UK, 1999; ISBN 9781316691489. [Google Scholar]

- Büth, L.; Blume, S.; Posselt, G.; Herrmann, C. Training Concept for and with Digitalization in Learning Factories: An Energy Efficiency Training Case. Procedia Manuf. 2018, 23, 171–176. [Google Scholar] [CrossRef]

- Bücking, M.; Steinhart, H. Headspace GC and Sensory Analysis Characterization of the Influence of Different Milk Additives on the Flavor Release of Coffee Beverages. J. Agric. Food Chem. 2002, 50, 1529–1534. [Google Scholar] [CrossRef] [PubMed]

- Buffo, R.A.; Cardelli-Freire, C. Coffee Flavour: An Overview. Flavour Fragr. J. 2004, 19, 99–104. [Google Scholar] [CrossRef]

- Sunarharum, W.B.; Williams, D.J.; Smyth, H.E. Complexity of Coffee Flavor: A Compositional and Sensory Perspective. Food Res. Int. 2014, 62, 315–325. [Google Scholar] [CrossRef]

- Caprioli, G.; Cortese, M.; Sagratini, G.; Vittori, S. The Influence of Different Types of Preparation (Espresso and Brew) on Coffee Aroma and Main Bioactive Constituents. Int. J. Food Sci. Nutr. 2015, 66, 505–513. [Google Scholar] [CrossRef]

- Bhumiratana, N.; Adhikari, K.; Chambers, E. Evolution of Sensory Aroma Attributes from Coffee Beans to Brewed Coffee. LWT-Food Sci. Technol. 2011, 44, 2185–2192. [Google Scholar] [CrossRef] [Green Version]

- Czerny, M.; Mayer, F.; Grosch, W. Sensory Study on the Character Impact Odorants of Roasted Arabica Coffee. J. Agric. Food Chem. 1999, 47, 695–699. [Google Scholar] [CrossRef] [PubMed]

- Czerny, M.; Grosch, W. Potent Odorants of Raw Arabica Coffee. Their Changes during Roasting. J. Agric. Food Chem. 2000, 48, 868–872. [Google Scholar] [CrossRef] [PubMed]

- Scheidig, C.; Czerny, M.; Schieberle, P. Changes in Key Odorants of Raw Coffee Beans during Storage under Defined Conditions. J. Agric. Food Chem. 2007, 55, 5768–5775. [Google Scholar] [CrossRef]

- Farah, A.; De Paulis, T.; Trugo, L.C.; Martin, P.R. Effect of Roasting on the Formation of Chlorogenic Acid Lactones in Coffee. J. Agric. Food Chem. 2005, 53, 1505–1513. [Google Scholar] [CrossRef]

- Nebesny, E.; Budryn, G. Evaluation of Sensory Attributes of Coffee Brews from Robusta Coffee Roasted under Different Conditions. Eur. Food Res. Technol. 2006, 224, 159–165. [Google Scholar] [CrossRef]

- Baggenstoss, J.; Poisson, L.; Kaegi, R.; Perren, R.; Escher, F. Coffee Roasting and Aroma Formation: Application of Different Time-Temperature Conditions. J. Agric. Food Chem. 2008, 56, 5836–5846. [Google Scholar] [CrossRef] [PubMed]

- Yang, N.; Liu, C.; Liu, X.; Degn, T.K.; Munchow, M.; Fisk, I. Determination of Volatile Marker Compounds of Common Coffee Roast Defects. Food Chem. 2016, 211, 206–214. [Google Scholar] [CrossRef]

- Dong, W.; Hu, R.; Long, Y.; Li, H.; Zhang, Y.; Zhu, K.; Chu, Z. Comparative Evaluation of the Volatile Profiles and Taste Properties of Roasted Coffee Beans as Affected by Drying Method and Detected by Electronic Nose, Electronic Tongue, and HS-SPME-GC-MS. Food Chem. 2019, 272, 723–731. [Google Scholar] [CrossRef] [PubMed]

- Bicho, N.C.; Leitão, A.E.; Ramalho, J.C.; de Alvarenga, N.B.; Lidon, F.C. Impact of Roasting Time on the Sensory Profile of Arabica and Robusta Coffee. Ecol. Food Nutr. 2013, 52, 163–177. [Google Scholar] [CrossRef]

- Borém, F.M.; Ribeiro, F.C.; Figueiredo, L.P.; Giomo, G.S.; Fortunato, V.A.; Isquierdo, E.P. Evaluation of the Sensory and Color Quality of Coffee Beans Stored in Hermetic Packaging. J. Stored Prod. Res. 2013, 52, 1–6. [Google Scholar] [CrossRef]

- Di Donfrancesco, B.; Gutierrez Guzman, N.; Chambers IV, E. Comparison of Results from Cupping and Descriptive Sensory Analysis of Colombian Brewed Coffee. J. Sens. Stud. 2014, 29, 301–311. [Google Scholar] [CrossRef] [Green Version]

- Chambers, E.; Sanchez, K.; Phan, U.X.T.; Miller, R.; Civille, G.V.; Di Donfrancesco, B. Development of a “Living” Lexicon for Descriptive Sensory Analysis of Brewed Coffee. J. Sens. Stud. 2016, 31, 465–480. [Google Scholar] [CrossRef]

- Ogawa, S. Does Sticky Information Affect the Locus of Innovation? Evidence from the Japanese Convenience-Store Industry. Res. Policy 1998, 26, 777–790. [Google Scholar] [CrossRef] [Green Version]

- Hippel, E. Explorations of the Impact of „Sticky“ Local Information on the Locus of Innovation. In Innovationsforschung und Technologiemanagement; Springer: Berlin/Heidelberg, Germany, 1998; pp. 275–284. [Google Scholar] [CrossRef]

- Marti, A.; De La Peña, E. When “Old Is New Again” Artisan Baking Grows. Cereal Foods World 2018, 63, 51. [Google Scholar]

- DeVore, P.W. Technology and science. In Essential Topics for Technology Educators; CTTE Yearbook Planning Committee, Ed.; McGraw-Hill: Glencoe, UK, 2009; pp. 2–20. [Google Scholar]

- Skolimowski, H. The Structure of Thinking in Technology. Technol. Cult. 1966, 7, 371. [Google Scholar] [CrossRef]

- Adolphs, P.; Bedenbender, H.; Dirzus, D.; Ehlich, M.; Epple, U.; Hankel, M. Reference Architecture Model Industrie 4.0 (RAMI4.0); Verein Deutscher Innenieure: Dusseldorf, Germany; Zentralverband Elektrotechnik und Elektronikindustrie: Frankfurt, Germany, 2015; Available online: https://www.zvei.org/fileadmin/user_upload/Presse_und_Medien/Publikationen/2016/januar/GMA_Status_Report__Reference_Archtitecture_Model_Industrie_4.0__RAMI_4.0_/GMA-Status-Report-RAMI-40-July-2015.pdf (accessed on 15 August 2021).

- Ministry of Internal Affiars and Communications. Smart City Security Guideline (Ver 1.0). Tokyo, Japan. 2020. Available online: https://www.soumu.go.jp/main_sosiki/joho_tsusin/eng/presentation/pdf/Smart_City_Security_Guideline_ver1.0.pdf (accessed on 15 August 2021).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fukami, Y. Two Obstacle Factors for Technological Standardization: The Viewpoint of Technological Frame. Standards 2022, 2, 1-13. https://doi.org/10.3390/standards2010001

Fukami Y. Two Obstacle Factors for Technological Standardization: The Viewpoint of Technological Frame. Standards. 2022; 2(1):1-13. https://doi.org/10.3390/standards2010001

Chicago/Turabian StyleFukami, Yoshiaki. 2022. "Two Obstacle Factors for Technological Standardization: The Viewpoint of Technological Frame" Standards 2, no. 1: 1-13. https://doi.org/10.3390/standards2010001