3.1. Volatile Content and Compliance Assessment

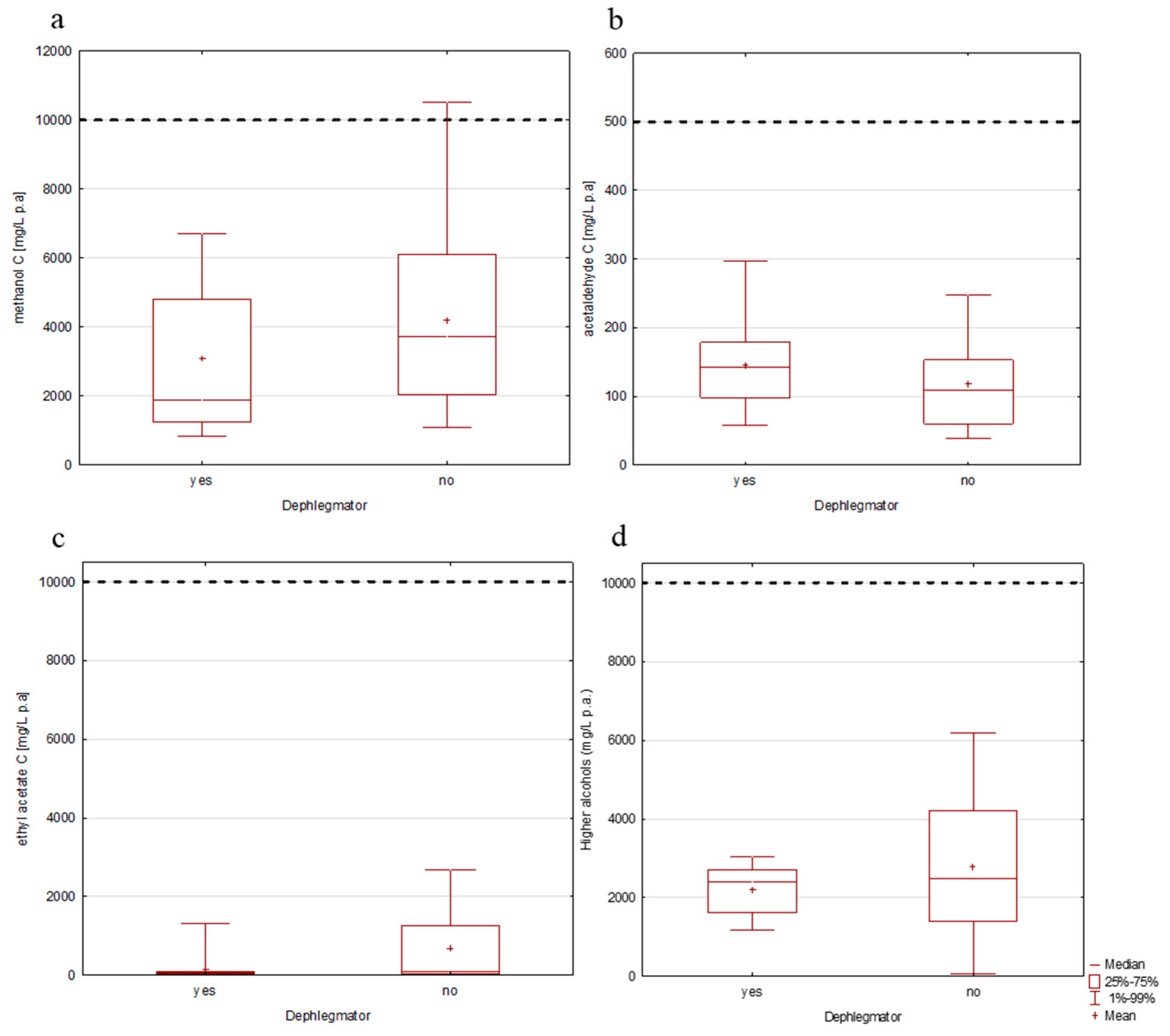

The dephlegmator-distilled spirits had a median methanol content of 1878 mg/L p.a. versus 3722 mg/L p.a. in the spirits distilled without it (

Figure 1a).

Although the Mann–Whitney test did not reveal a statistically significant difference between the two groups (U = 112,

p = 0.19), the methanol content in the non-dephlegmator group was almost double. Notably, one sample exceeded the legal limit of 10,000 mg/L p.a. for methanol, reaching 10,506 mg/L p.a., which triggers a safety alarm. This was the plum spirit sample, which corroborates previous findings that stone fruit spirits (plum and apricot) have the highest level of methanol, followed by pome fruits (apple, pear, and quince) (due to the high pectin content in both types of fruits [

22]), and far behind grape rakija; no significant difference was observed for ethyl acetate and higher alcohols [

3]. Therefore, it is noteworthy that the number of rakija samples distilled with and without a dephlegmator was balanced, considering fruit classes.

Furthermore, this is in line with the observations from Spaho [

12], who reported that column stills with reflux can lower methanol levels by 10% in plum rakija compared to traditional pot stills, primarily due to more effective separation of volatile compounds through controlled reflux and tray design. Similarly, García-Llobodanin et al., 2011 [

15], reduced methanol concentrations by roughly the same value in column-distilled pear spirits using optimized distillation parameters, particularly the reflux rate and head-cut point. Methanol is particularly difficult to remove due to its low boiling point and high water solubility, thus behaving differently than many other alcohol congeners during distillation. In pot stills, it tends to concentrate in the tail fraction as the ethanol content decreases; in column stills, it is more likely to emerge early in the distillate, where it can be effectively separated [

12,

22]. Despite these minor reductions, more extreme actions are required to ensure safety. As explained by Lučić [

23], enzymatic treatment of the mash, acidification to inhibit pectin methylesterase activity, and premature heating of the fermented material can all minimize methanol formation during fermentation. The use of demethanolization columns during distillation was promising, with the potential to decrease methanol content by as much as 75% [

24]. In addition, careful choice of yeast strains with lower methanol-forming abilities and rigorous maintenance of fermentation conditions also contribute to safer end products. It can be concluded that a dephlegmator reduces the methanol content, but it should be considered a part of a more comprehensive strategy. A combination of optimized fermentation techniques, targeted enzymatic and heat treatments, and better distillation technologies, such as demethanolization, is required to meet safety standards and reduce consumer exposure to methanol, particularly in unrecorded fruit spirits [

22,

25].

All spirit samples were within the EU regulatory limits and AMPHORA recommendations concerning acetaldehyde content (

Figure 1b). Although the median acetaldehyde content was slightly lower in the group without a dephlegmator (109 mg/L p.a.) than in the group with it (141 mg/L p.a.), there was no statistical significance between the groups (U = 111,

p = 0.18). Spaho [

12] compared single- and double-stage pot still distillation of plum brandy and found that single-pot distillation yielded more than double the acetaldehyde content (448 mg/L p.a.) compared to double distillation (209 mg/L p.a.), underscoring the efficacy of a second run in removing volatile aldehydes. Meanwhile, García-Llobodanin et al., 2011 [

15] demonstrated that, in pear spirit production, under optimized reflux and precise head-cut control, column distillation could reduce acetaldehyde by 40% relative to single-pot still distillation. These findings indicate that distillation configuration alone (pot still vs. column) does not deterministically set final acetaldehyde levels. Instead, the number of distillation stages, reflux control, vapor residence time, and the objectivity of fraction cuts are critical. A double-pot still run effectively halves acetaldehyde relative to a single run [

12]. A well-controlled column can achieve similar or better reductions, albeit only if the reflux ratio and cut points are tightly regulated. Moreover, fermentation practices (yeast strain selection and anaerobic handling) and minimizing the delay between fermentation and distillation further suppress unwanted acetaldehyde formation. For small-scale producers, the practical takeaway is to combine at least two distillation passes in pot stills or employ a carefully managed column reflux using simple sensors (e.g., temperature or refractive index probes) to standardize head cuts and distill promptly after fermentation to ensure both traditional character and consumer safety [

12,

15,

26].

When comparing the ethyl acetate concentrations (

Figure 1c), no statistically significant difference between the two groups (U = 113,

p = 0.2) was found. The median concentration for the dephlegmator group was 53 mg/L p.a. and slightly higher in the group produced without it (75 mg/L p.a.). All the values were below the regulatory limits, in line with the previously published research [

3], where neither recorded nor unrecorded Serbian rakija exceeded the regulatory limit; that is, they both did not raise health concerns. Despite its comparatively low health hazard, ethyl acetate is still a key contributor to the fruit spirits’ sensory profile due to its fruit-like, sweet smell. Therefore, its presence, in acceptable amounts, is crucial to guarantee the desirable flavor qualities [

8].

When the sum of higher alcohols (the total concentration of isoamyl alcohol,

n-propanol, isobutanol, and

n-butanol) was considered (

Figure 1d), the difference between “rakija” produced with and without a dephlegmator was not statistically significant (U = 132,

p = 0.52). The dephlegmator group ranged from 1182 to 3044 mg/L p.a., with a median concentration of 2394 mg/L p.a., while the non-dephlegmator group had a similar median of 2472 mg/L p.a. but a wider range, from 62 to 6182 mg/L p.a. The wide range in the non-dephlegmator group emphasizes the need for reflux control towards the stability of product composition. Although median content was not significantly different, the broader range and presence of outlier values in spirits produced without a dephlegmator suggest a lack of control in distillation, resulting in less uniform quality of products. Despite variations, none of the rakija samples, regardless of the production method, exceeded the AMPHORA guideline limit of 10,000 mg/L p.a. for the sum of higher alcohols. Nevertheless, from the toxicological aspect, it is important to highlight that the analysis focused only on isoamyl alcohol,

n-propanol, isobutanol, and

n-butanol; other fusel alcohols, which could contribute to the content of higher alcohols, such as 2-methyl-1-butanol (amyl alcohol), 1-hexanol, 2-phenylethanol, and others commonly found in fruit spirits, were not included in the quantification [

27]. However, it is essential to note that even in permissible amounts, higher alcohols can still affect spirit sensory quality, especially when present in mutually disproportionate concentrations. Unpleasant sensory effects such as pungency and burning mouthfeel were previously shown for spirits from home distilleries with elevated levels of fusel alcohols. Thus, while the dephlegmator may not significantly reduce the absolute levels of higher alcohols, its use promotes product compositional consistency and flavor compound composition. In small-scale or traditional distillation practices, this can improve both the sensory quality and consumer safety at once [

28,

29].

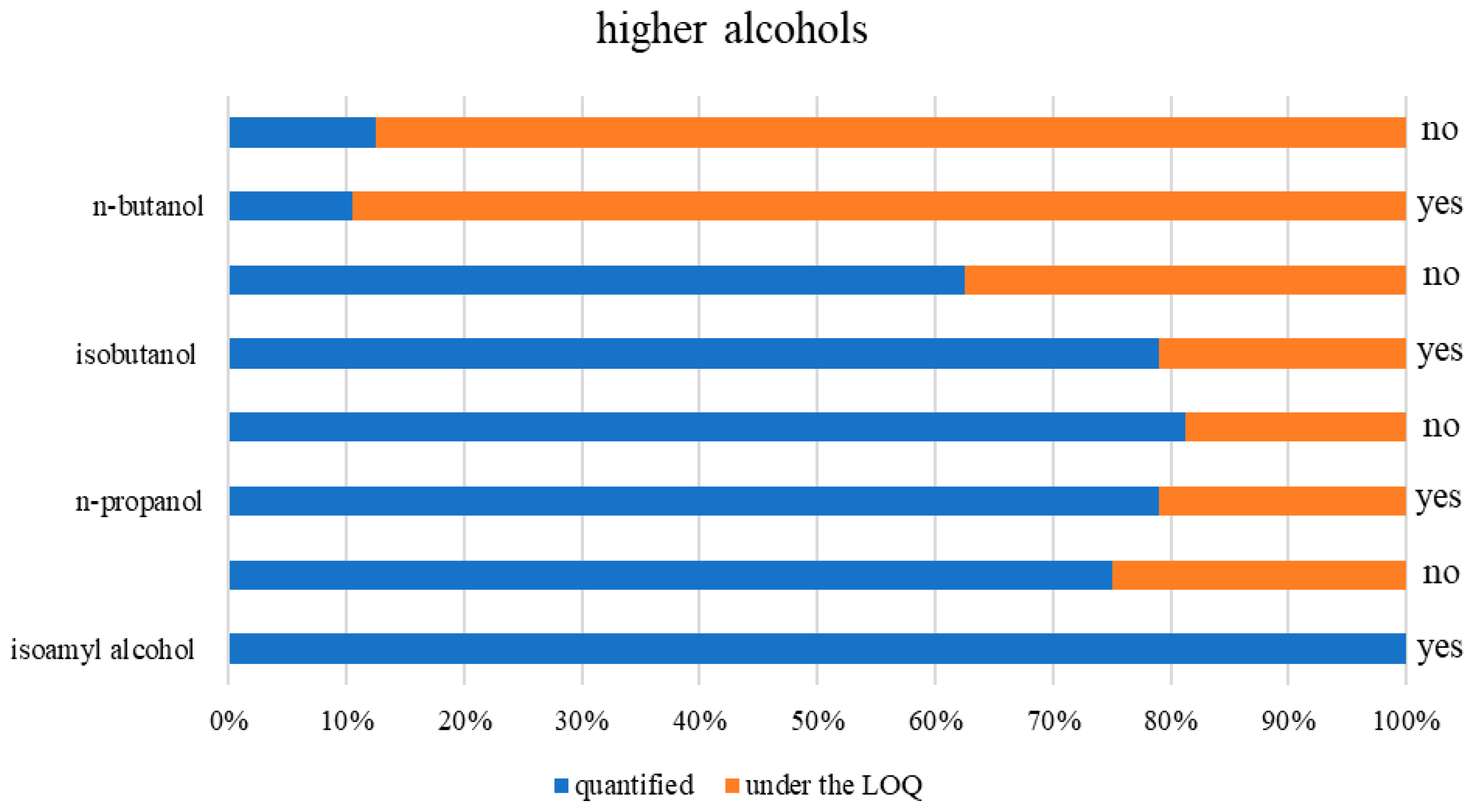

Among the higher alcohols detected, isoamyl alcohol was the most abundant across all analyzed spirit samples (

Figure 2), as it was quantified in 89% of the samples. Isoamyl alcohol was previously identified as the dominant fusel alcohol in fruit spirits, deriving from the amino acid leucine via the Ehrlich pathway [

29]. In samples produced using a dephlegmator, isoamyl alcohol ranged from 808 to 2960 mg/L p.a., while the non-dephlegmator group showed a broader range, from 1339 to 5124 mg/L p.a., suggesting less consistent separation of volatile compounds. However, the median contents were similar at 1904 mg/L and 2082 mg/L p.a. (U = 128,

p = 0.44). The observed difference in concentration spans aligns with prior studies showing that column stills with dephlegmators provide more controlled separation of volatiles via rectification and reflux, while pot stills (often used without dephlegmators) may retain more fusel alcohols due to less precise cut points [

12].

n-Propanol, which was quantified in 80% of all analyzed spirits (

Figure 2), was ranked second when considering the abundance of higher alcohols. In the dephlegmator group, its concentration ranged from 8 to 694 mg/L p.a. (median: 304 mg/L p.a.), while in the group without it, the range was from 24 to 1230.48 mg/L p.a. (median: 279.33 mg/L p.a.). Again, no significant difference between medians was observed (U = 131,

p = 0.5), although the variability was much greater in the absence of a dephlegmator, a pattern also noted in previous chemometric assessments of fruit spirits [

3].

Isobutanol, which was present in 71% of all samples (

Figure 2), had a median of 43 mg/L p.a. (range: 27–413 mg/L p.a.) in the dephlegmator group and 33 mg/L p.a. (range: 25–427.78 mg/L p.a.) in the non-dephlegmator group (U = 126,

p = 0.39, non-significant). On the other hand,

n-butanol was the least frequently detected higher alcohol, appearing in only four samples: the dephlegmator group yielded values of 111 and 166 mg/L p.a.; the non-dephlegmator group had 96 and 588 mg/L p.a. Due to the limited number of samples, no statistical comparison was conducted, but the isolated high reading in the non-dephlegmator group confirms product compositional variability.

The maximum allowable concentrations of individual long-chain alcohols in alcoholic beverages are not regulated, although they may contain significant amounts, depending on the distillation method/type of beverage. Although the safety of chronic exposure is not fully established for any of them, it is known that the acute toxicity of straight-chain monohydroxy alcohols is directly proportional to the carbon chain length (Richardson’s law). Their presence is only indirectly monitored by distillers or official laboratories, in line with the provision for the sum of higher alcohols, as they are meant to maintain the sensory quality of the final product. Mukerjee and Siciliano proposed that concentrations of alcohols in commercial beverages without labeling should be limited to a maximum of 86 mM multiplied by 0.344 for each additional carbon compared to ethanol. For

n-propanol, that would be 1774 mg/L p.a., and for

n-butanol, that would be 754 mg/L p.a. The content of straight-chain monohydroxy alcohols in all investigated samples was below or, in sporadic cases, near the proposed limit [

30].

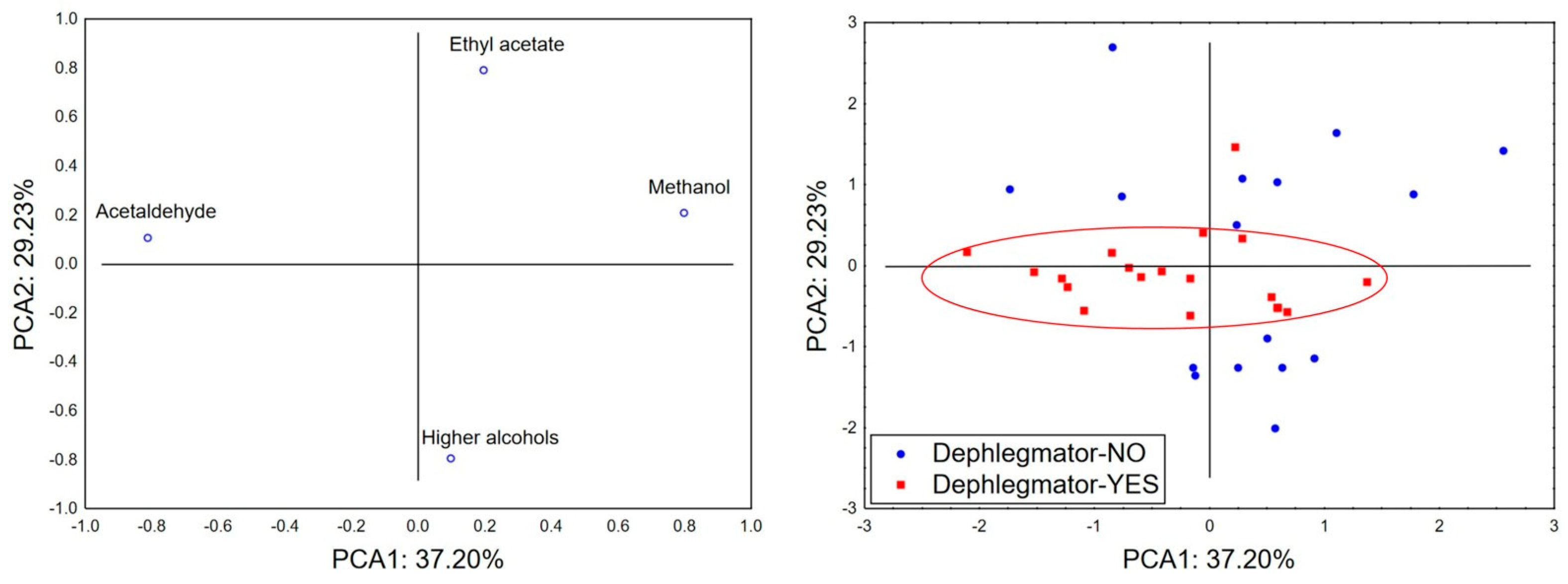

The application of principal component analysis (PCA) on data reporting the concentrations of methanol, acetaldehyde, ethyl acetate, and the sum of higher alcohols in the analyzed samples suggests that the first two principal components (PCA1 and PCA2) are of statistical significance for defining a simplified model of the original dataset (determined according to the criteria of the scree plot and eigenvalues (Ev; Ev > 1)—Ev (PCA1) = 1.49 and Ev (PCA2) = 1.17)). Namely, PCA1 and PCA2 were found to describe around 66% of the original dataset’s variability (

Figure 3), whereas the size of the samples’ variability (in terms of PCA1) mostly correlates with the concentrations of acetaldehyde and methanol. The position of the analyzed samples in the space defined by the first two principal components indicates a trend of lower methanol concentrations in samples produced via dephlegmator application. On the other hand, no specific patterns of samples’ separative grouping could be noticed in terms of PCA2, which correlates with the levels of ethyl acetate and the sum of higher alcohols. However, a more “compact” grouping of samples (

Figure 3, red circle) produced by the application of a dephlegmator in terms of PCA2 suggests the lower variability of ethyl acetate and higher alcohol concentrations in these samples.

To conclude, although a dephlegmator did not significantly reduce the absolute concentration of individual higher alcohols or ethyl acetate, it appeared to contribute to a more uniform product composition with fewer extremes. In small-scale settings, where quality consistency is a challenge, even modest improvements in fractionation control could enhance the safety and organoleptic quality of the final spirit.

3.2. Risk Assessment

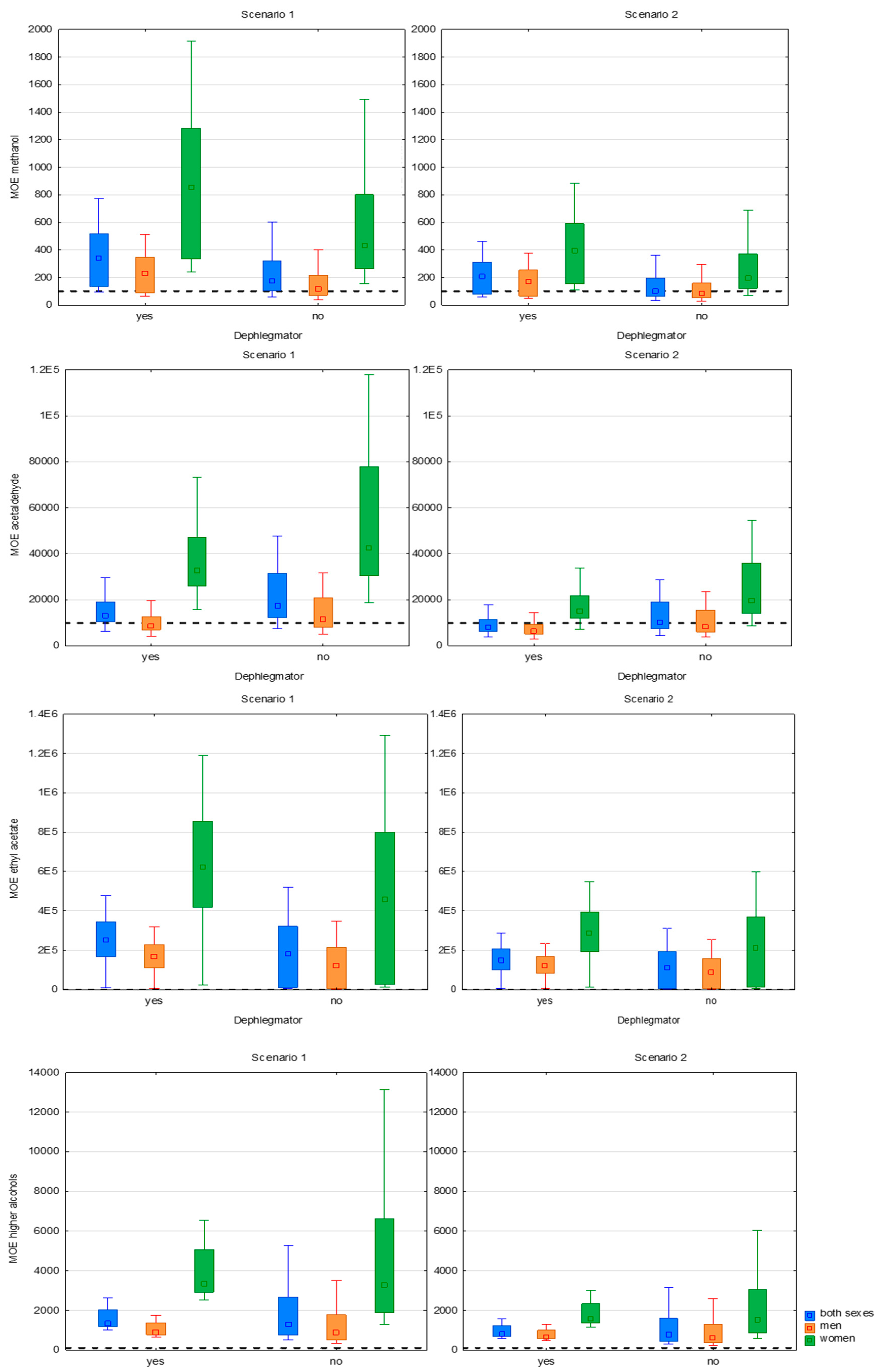

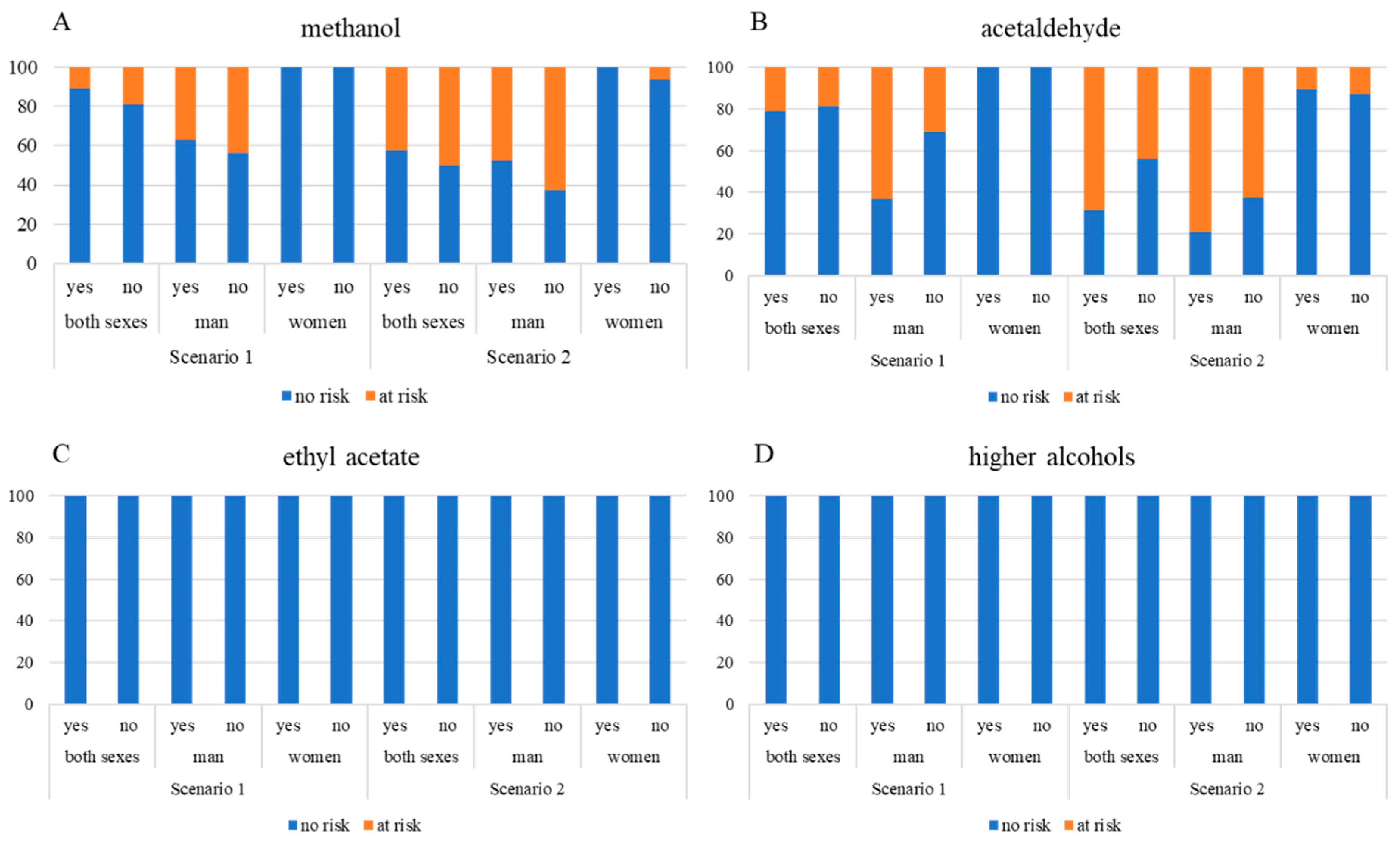

To assess the influence of the distillation technique on consumer safety, the MOE approach was applied to evaluate the methanol-related risk in unrecorded fruit spirits (

Figure 4). In Scenario 1, where exposure levels are equated to general population averages, a higher share of samples distilled with a dephlegmator was in the “no risk” category than in the case of spirits distilled without it. Among male consumers, 63% of dephlegmator-distilled spirits did not pose a risk (MOE > 100), compared to 56% in the non-dephlegmator group; among females, no samples at all posed risk concerns due to lower ethanol consumption volumes (

Figure 4 and

Figure 5).

In Scenario 2, where exposure estimates reflect habitual or high-end consumption, the distinction between the two distillation methods was more pronounced in favor of spirits distilled with the dephlegmator, especially in the case of male consumers: 53% vs. 37% fell into the no-risk category (

Figure 5); for females, the proportion was 100:93% (

Figure 5). These findings lead to the conclusion that a dephlegmator may reduce the health risk associated with methanol, particularly among regular male drinkers. The lower incidence of concerning MOE values in the dephlegmator group aligns with prior chemical analyses showing lower methanol concentrations, albeit without statistical significance between the medians of the two groups.

Moreover, previous risk assessments in unrecorded spirits from Serbia by Srdjenović-Čonić, Kladar, Božin, and Torović [

11] highlighted methanol as one of the main risks to consumer health, with MOE values often falling below the safety margin. The current data confirm this pattern but also show that improvements in distillation technology, such as dephlegmator incorporation, can help shift a larger share of products above the minimum acceptable MOE value, especially in populations with elevated alcohol consumption. Altogether, these results demonstrate that while methanol remains a key toxicological concern in unrecorded spirits, its impact on consumer safety can be mitigated through technical upgrades in production, particularly those enhancing reflux control and volatile separation [

11,

12,

15]

When considering the influence of a dephlegmator on the health risk associated with acetaldehyde, the results of the MOE-based assessment revealed that this distillation feature did not offer a clear protective effect. In Scenario 1 (

Figure 4 and

Figure 5), more than two-thirds (68%) of the spirits distilled without a dephlegmator fell into the “no risk” group for male consumers, in contrast to one-third (36%) of those from the dephlegmator group; there were no risky samples in the case of females. The difference remained at approximately the same level under Scenario 2, 37% vs. 21% for males; for females, there was no practical difference (almost 90% of the samples from each group). This finding indicates that dephlegmator usage could not remove the acetaldehyde effectively and might even hinder its removal in some cases. The explanation can be found in the physicochemical properties of acetaldehyde, since it has a low boiling point and consequently concentrates in the head fraction. If head–heart separation is not optimally controlled, acetaldehyde can pass into the heart cut even when modern equipment is employed. Some studies have shown that column distillation without well-defined fractionation settings results in higher levels of acetaldehyde, while more traditional pot stills based on slower, sensory-guided cuts can allow for greater separation. Thus, even equipment with greater technical potential may not guarantee a safer product without adequate operational expertise [

11,

12,

15,

31].

The risk assessment for ethyl acetate and higher alcohols indicates that neither analyte posed a health risk to consumers, regardless of the distillation method or the consumption scenario. Across all categories, both sexes, men and women, in both scenarios (1—average consumption, 2—regular drinkers), 100% of spirits were placed in the “no risk” category (

Figure 4 and

Figure 5). This finding is consistent with previous studies on fruit spirits, which have shown that although higher alcohols and ethyl acetate contribute significantly to the aroma and flavor profile of the beverage, they are generally not considered critical toxicological hazards at levels typically found in traditional distillates [

3,

11]. Regardless of the rigidness of production condition control, these compounds are typically in the safe zone, especially when compared to substances like methanol or acetaldehyde, which are commonly identified as major hazards. However, their role in the sensory perception and acceptability of the final product remains important and warrants attention in quality evaluations [

29].

Finally, some study limitations need to be noted. The findings rely on a rather small collection of rakija samples, lacking information about yeast strains and the length of fermentation or the distillation temperature applied in the production process, which could also affect the volatile profile of the spirits. However, since the study has a comparative approach, it is a reasonable assumption that the balancing of the samples in terms of their botanical origin and producers versus two technologically distinctive production processes compensates the effect of the mentioned factors to an extent, ensuring that observed variability is under the dominant influence of dephlegmator employment in the distillation process.

This pilot research, together with several previous ones, indicates the importance of a deeper understanding of the distillation process and thus warrants further research in this area.