Integrated Investigation Approach for Solid Waste Landfill Hazards—A Case Study of Two Decommissioned Industrial Sites

Abstract

1. Introduction

2. Materials and Methods

3. Methodology

3.1. Geophysical Detection

3.1.1. Transient Electromagnetic Method

3.1.2. High-Density Electrical Resistivity Method

3.1.3. Ground-Penetrating Radar Method

3.1.4. Survey Line Layout

3.1.5. Data Processing

3.1.6. Data Quality Assessment

3.2. Borehole Layout

3.3. Mutual Verification of Geophysical and Drilling Detection Results

3.4. Earth Volumetric Studio (EVS)

4. Results

4.1. Analysis of Geophysical Data

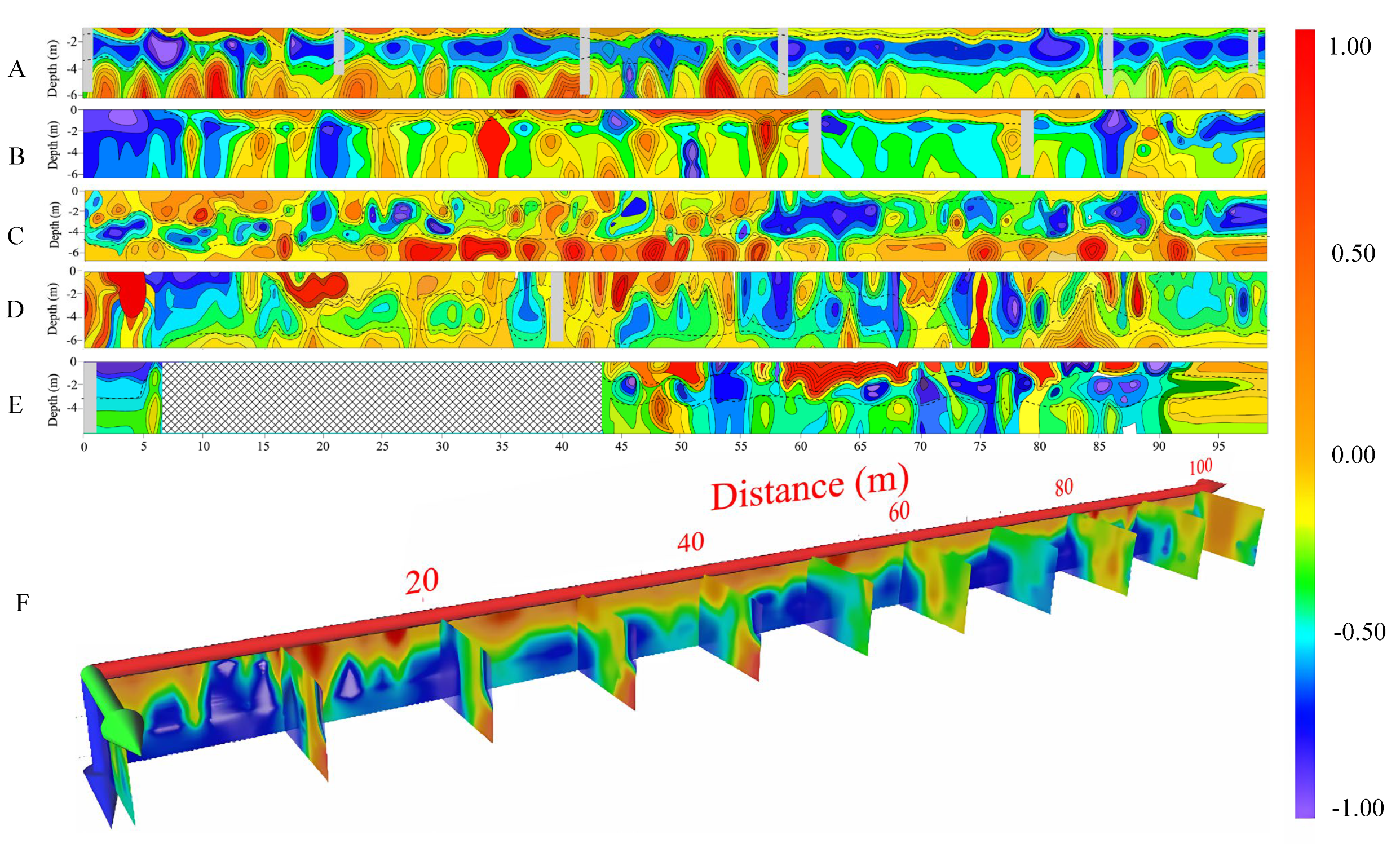

4.1.1. Analysis of Transient Electromagnetic Detection Results

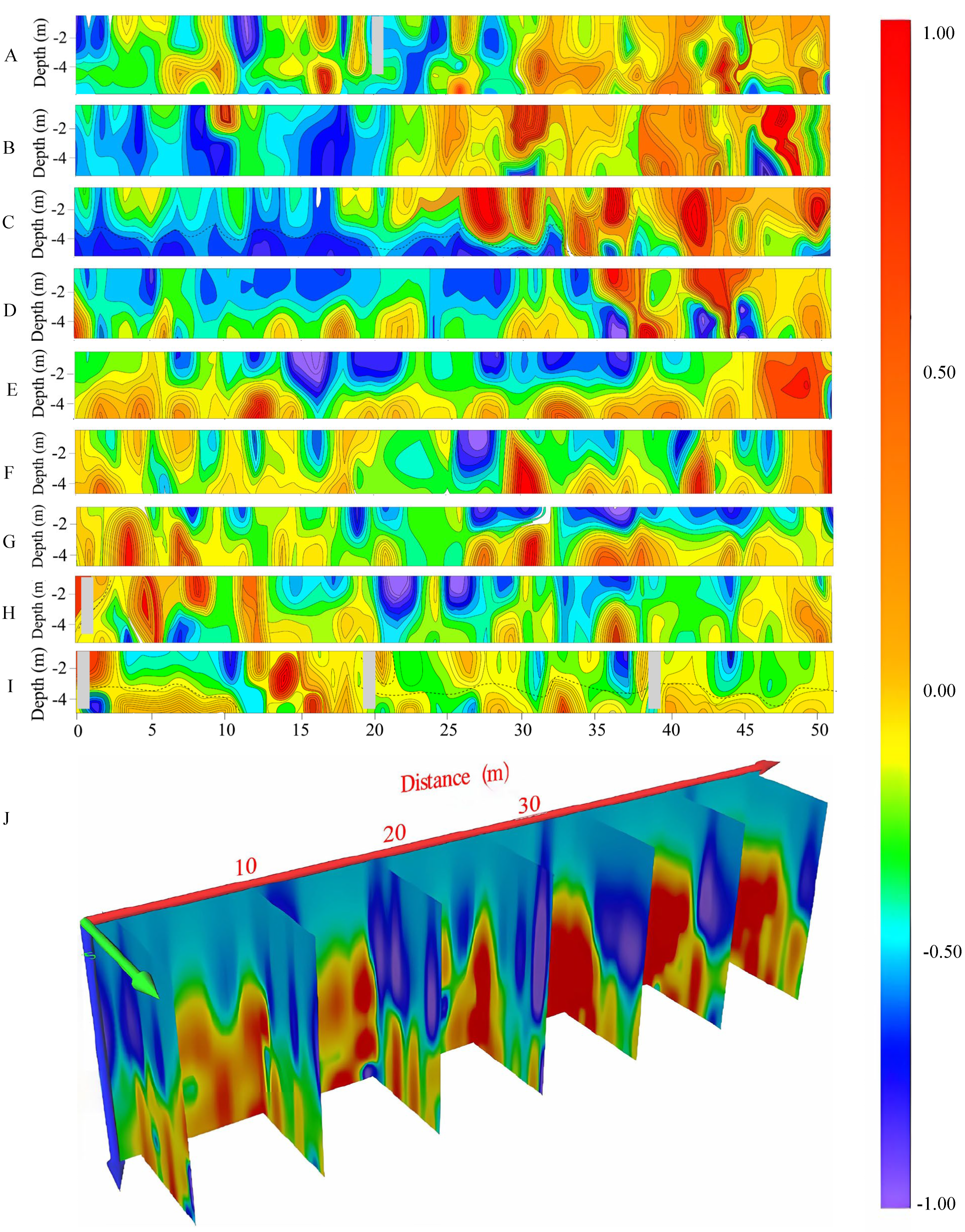

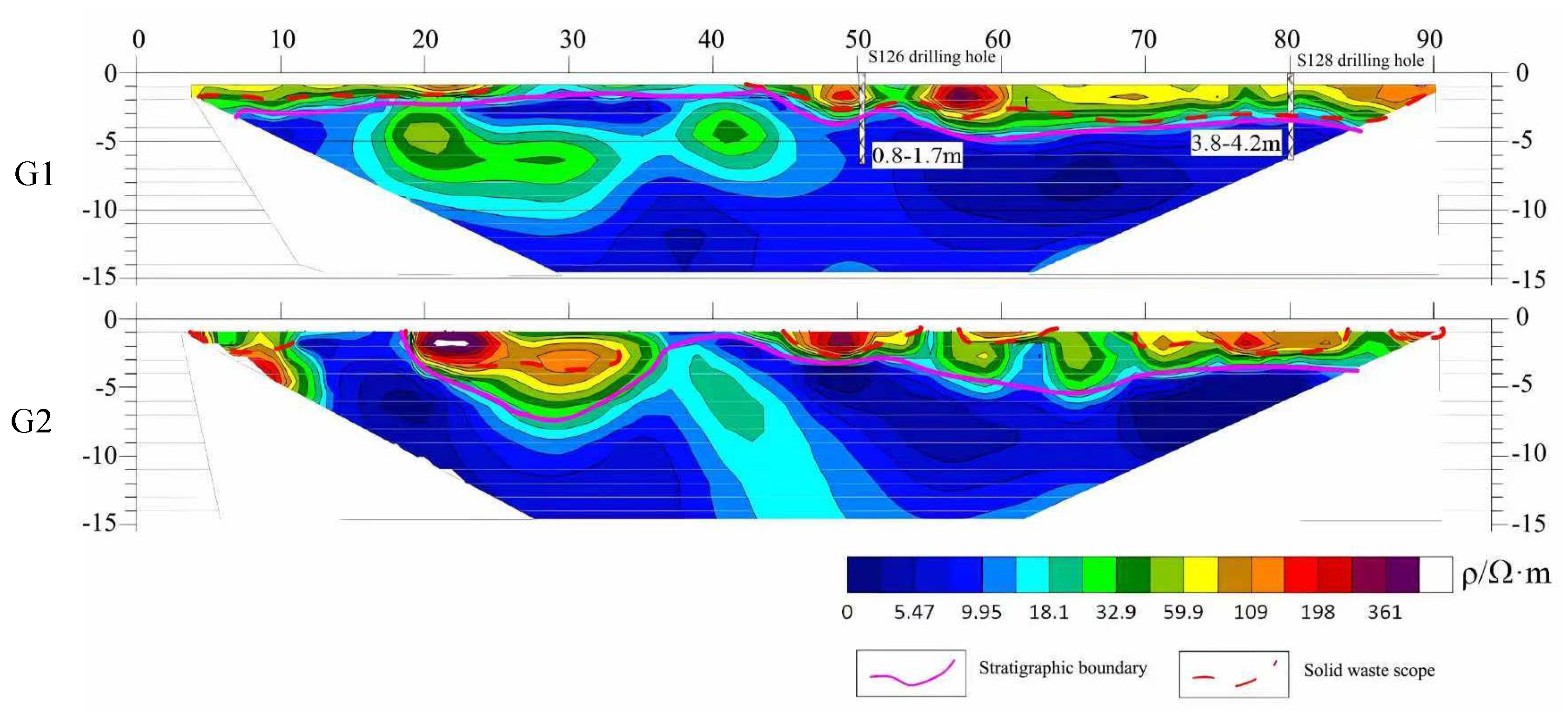

4.1.2. Analysis of High-Density Electrical Resistivity Detection Results

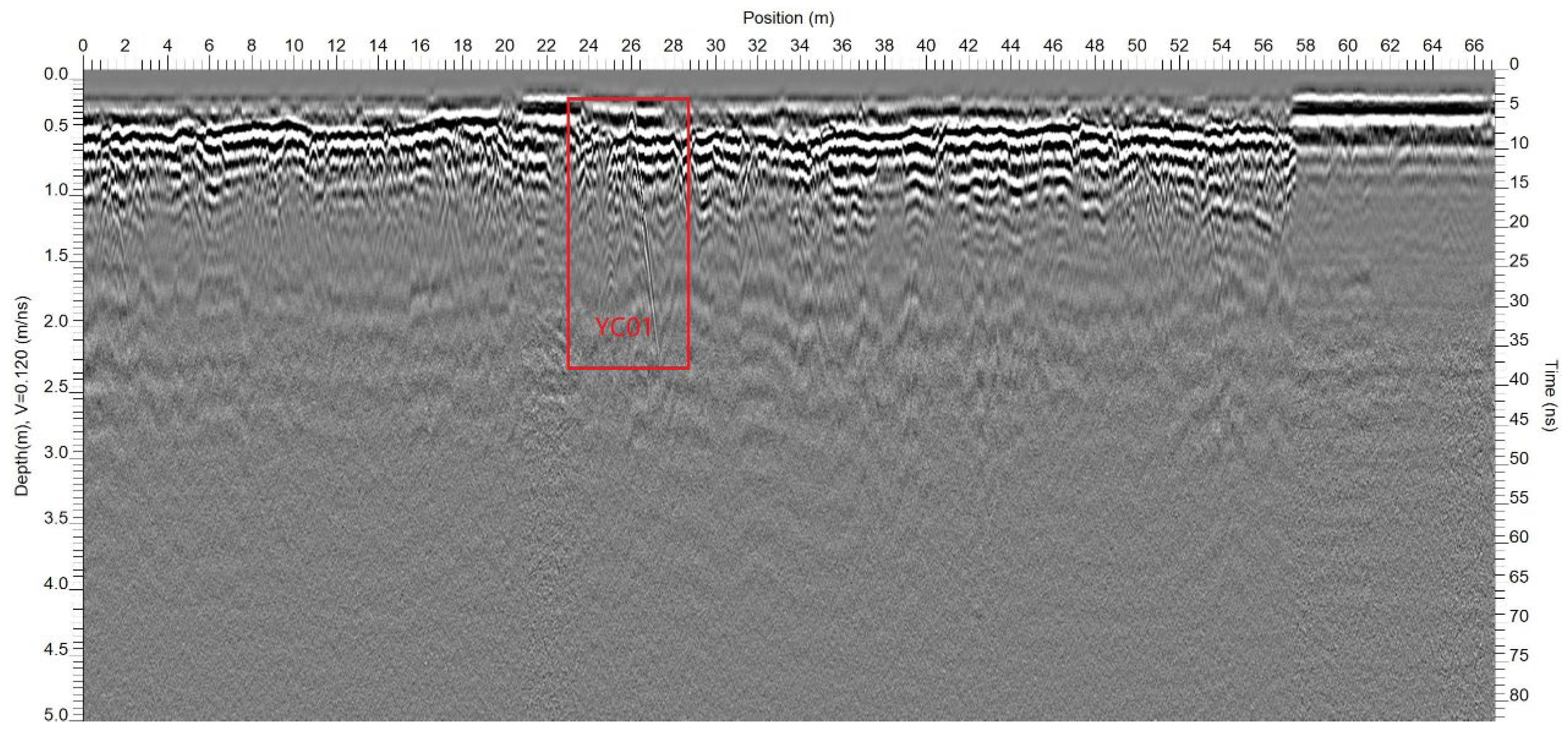

4.1.3. Analysis of Ground-Penetrating Radar Detection Results

4.2. Analysis of Drilling Results

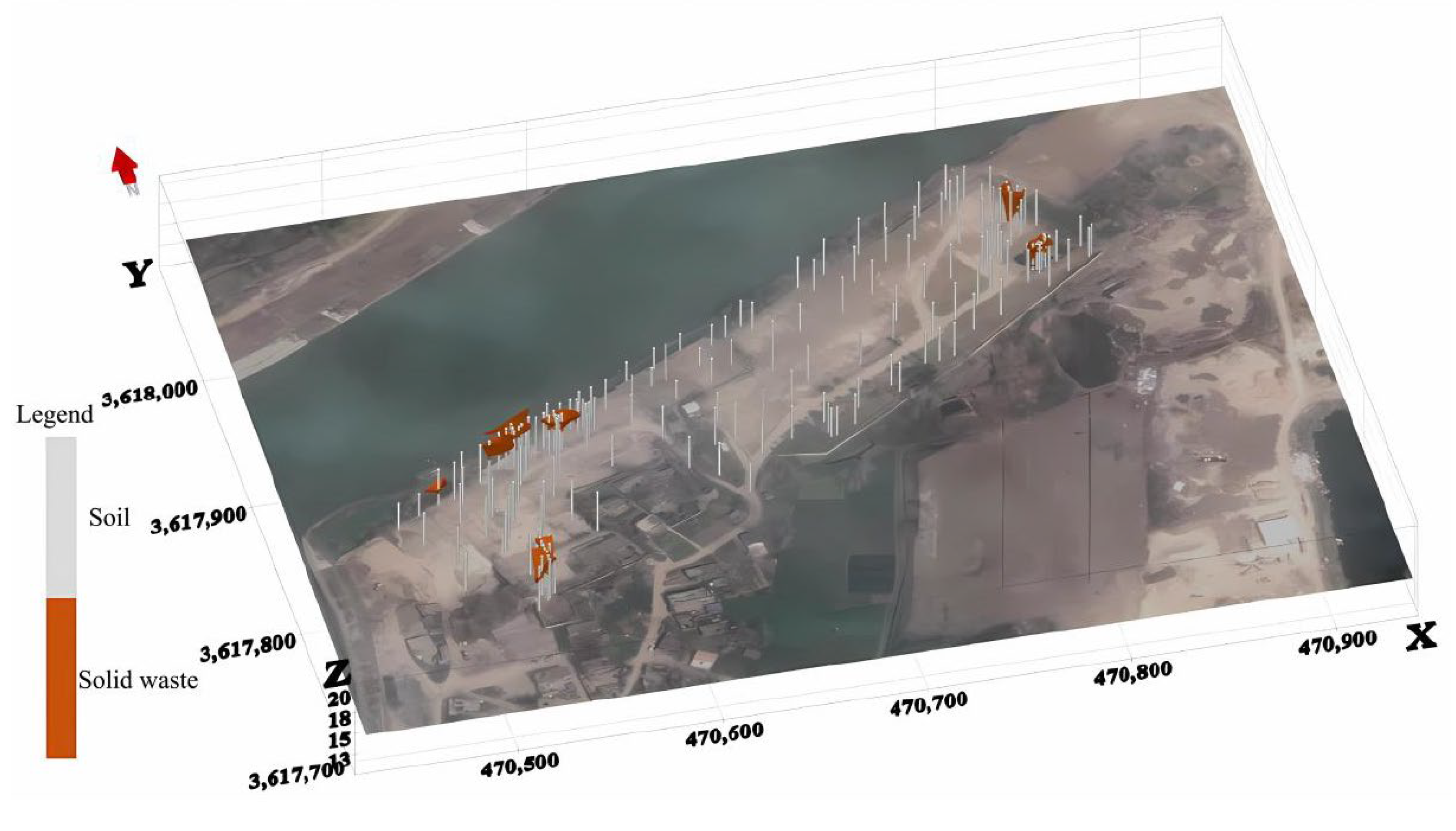

4.3. Interpolation Simulation of the Three-Dimensional Spatial Distribution of Landfilled Waste

5. Discussion

6. Conclusions

- (1)

- The geophysical data highlight two main characteristics of the anomaly distribution: first, anomalies exhibit a “sparse distribution with multiple points”; second, there is a variety of anomalies, including solid waste anomalies, remnants of the original factory building foundations, contaminated soil, voids, cracks, and household waste. These types were differentiated by synthesizing multiple data types, including geophysical responses and historical records (personnel interviews), and by conducting drilling verification. The anomalous areas are mainly distributed in the A2, A4, and A6 investigation areas, with solid waste primarily located in A2, featuring “multiple points, small quantity”. A4 may contain a small amount of suspected landfilled solid waste, while the anomalies in A6 are mainly caused by the contaminated soil layers, which are interspersed with landfilled garbage according to personnel interviews and drilling data.

- (2)

- A total of 136 drilling locations were investigated within the site, identifying nine drilling locations with solid waste landfill that are concentrated in three specific areas. The characteristics of the solid waste vary, and their vertical distribution is irregular. The landfill thickness ranges from 0.2 to 1.3 m. This suggests that incomplete clearance could be the reason for the persistence of residual solid waste and their irregular distribution and sporadic patterns.

- (3)

- Based on the drilling data (location distribution, landfill thickness, etc.), EVS was utilized to conduct a spatial distribution simulation of the landfilled waste using the Kriging interpolation method. The simulation estimated that the total volume of solid waste landfilled within the site is 266.9 m3.

- (4)

- Integrating targeted drilling with geophysics resolved the accuracy limitations, providing high-resolution spatial waste distribution data. This strategy reduces investigation costs by >30% and establishes a replicable framework for landfill characterization.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ustra, A.; Slater, L.; Ntarlagiannis, D.; Elis, V. Spectral induced polarization (SIP) signatures of clayey soils containing toluene. Near Surf. Geophys. 2012, 10, 503–515. [Google Scholar] [CrossRef]

- Godio, A.; Chiampo, F. Geophysical monitoring of leachate injection in pretreated waste landfill. Appl. Sci. 2023, 13, 5661. [Google Scholar] [CrossRef]

- Karslı, H.; Babacan, A.E.; Sayıl, N.; Çoban, K.H.; Akın, Ö. An assessment of seismicity and near surface geophysical characteristics of potential solid waste landfill sites in the Eastern Black Sea Region of Türkiye. Environ. Sci. Pollut. Res. 2024, 31, 14156–14177. [Google Scholar] [CrossRef] [PubMed]

- Bichet, V.; Grisey, E.; Aleya, L. Spatial characterization of leachate plume using electrical resistivity tomography in a landfill composed of old and new cells (Belfort, France). Eng. Geol. 2016, 211, 61–73. [Google Scholar] [CrossRef]

- Piegari, E.; De Donno, G.; Melegari, D.; Paoletti, V. A machine learning-based approach for mapping leachate contamination using geoelectrical methods. Waste Manag. 2023, 157, 121–129. [Google Scholar] [CrossRef] [PubMed]

- Gazoty, A.; Fiandaca, G.; Pedersen, J.; Auken, E.; Christiansen, A.V.; Pedersen, J.K. Mapping leachate plumes at a legacy landfill site using time-domain spectral induced polarization. Waste Manag. 2021, 119, 91–102. [Google Scholar] [CrossRef]

- Soupios, P.; Ntarlagiannis, D. Characterization and monitoring of solid waste disposal sites using geophysical methods: Current applications and novel trends. In Modelling Trends in Solid and Hazardous Waste Management; Springer: Singapore, 2017; pp. 75–103. [Google Scholar] [CrossRef]

- Zhang, T.; Zhang, D.; Zheng, D.; Guo, X.; Zhao, W. Construction waste landfill volume estimation using ground penetrating radar. Waste Manag. Res. 2022, 40, 1167–1175. [Google Scholar] [CrossRef]

- Chao, C.; Ma, X.; Liu, S.; Zheng, C.; Mao, D. Characterization of solid waste deposit using electrical resistivity tomography and time domain induced polarization. J. Environ. Manag. 2024, 366, 121854. [Google Scholar] [CrossRef]

- Colombo, D.; Turkoglu, E.; Li, W.; Sandoval-Curiel, E.; Rovetta, D. Physics-driven deep-learning inversion with application to transient electromagnetics. Geophysics 2021, 86, 209–224. [Google Scholar] [CrossRef]

- Pavoni, M.; Boaga, J.; Peruzzo, L.; Barone, I.; Mary, B.; Cassiani, G. Characterization of a contaminated site using hydro-geophysical methods: From large-scale ERT surface investigations to detailed ERT and GPR cross-hole monitoring. Water 2024, 16, 1280. [Google Scholar] [CrossRef]

- Ibraheem, I.M.; Yogeshwar, P.; Bergers, R.; Tezkan, B. Joint interpretation of magnetic, transient electromagnetic, and electric resistivity tomography data for landfill characterization and contamination detection. Sci. Rep. 2024, 14, 30616. [Google Scholar] [CrossRef]

- Orlando, O. GPR to constrain ERT data inversion in cavity searching: Theoretical and practical applications in archeology. J. Appl. Geophys. 2013, 89, 35–47. [Google Scholar] [CrossRef]

- Di Maio, R.; Fais, S.; Ligas, P.; Piegari, E.; Raga, R.; Cossu, R. 3D geophysical imaging for site-specific characterization plan of an old landfill. Waste Manag. 2018, 76, 629–642. [Google Scholar] [CrossRef]

- Shao, S.; Guo, X.; Gao, C.; Liu, H. Quantitative relationship between the resistivity distribution of the by-product plume and the hydrocarbon degradation in an aged hydrocarbon contaminated site. J. Hydrol. 2021, 596, 126122. [Google Scholar] [CrossRef]

- De Donno, G.; Melegari, D.; Paoletti, V.; Piegari, E. An integrated study of hard and soft cluster analyses for detecting leachate in a MSW landfill site using geoelectrical data. Waste Manag. 2025, 195, 22–31. [Google Scholar] [CrossRef] [PubMed]

- Alabi, A.; Olurin, O.; Adetoyinbo, A.; Ogungbe, A.; Coker, J.; Adewale, A.; Aladegboye, A.; Kadiri, S. Site Characterization of an Abandoned Dumpsite for Engineering Purposes Using Integrated Techniques. J. Solid Waste Technol. Manag. 2022, 48, 124–136. [Google Scholar] [CrossRef] [PubMed]

- Ramalho, E.-C.; Dill, A.-C.; Rocha, R. Assessment of the leachate movement in a sealed landfill using geophysical methods. Environ. Earth Sci. 2013, 68, 343–354. [Google Scholar] [CrossRef]

- Isobe, Y.; Ishimori, H. Continuous Electrical Resistivity Tomography Monitoring in Waste Landfill Sites with Different Properties and Visualization of Water Channels. Appl. Sci. 2025, 15, 6920. [Google Scholar] [CrossRef]

- Helene, L.-P.-I.; Moreira, C.-A.; Bovi, R.-C. Identification of leachate infiltration and its flow pathway in landfill by means of electrical resistivity tomography (ERT). Environ. Monit. Assess. 2020, 192, 249. [Google Scholar] [CrossRef]

- Hermans, T.; Nguyen, F.; Robert, T.; Revil, A. Geophysical methods for monitoring temperature changes in shallow low enthalpy geothermal systems. Energies 2014, 7, 5083–5118. [Google Scholar] [CrossRef]

- Martorana, R.; Lombardo, L.; Messina, N.; Luzio, D. Integrated geophysical survey for 3d modelling of a coastal aquifer polluted by seawater. Near Surf. Geophys. 2014, 12, 45–59. [Google Scholar] [CrossRef]

- GB 36600-2018; Soil Environmental Quality-Risk Control Standard for Soil Contamination of Development Land. China Environmental Science Press: Beijing, China, 2018.

- Angelis, D.; Tsourlos, P.; Tsokas, G.; Vargemezis, G.; Zacharopoulou, G.; Power, C. Combined application of GPR and ERT for the assessment of a wall structure at the heptapyrgion fortress (Thessaloniki, Greece). J. Appl. Geophys. 2018, 152, 208–220. [Google Scholar] [CrossRef]

- Di Fiore, V.; Cavuoto, G.; Punzo, M.; Tarallo, D.; Casazza, M.; Guarriello, S.M.; Lega, M. Integrated hierarchical geo-environmental survey strategy applied to the detection and investigation of an illegal landfill: A case study in the Campania Region (Southern Italy). Forensic Sci. Int. 2017, 279, 96–105. [Google Scholar] [CrossRef] [PubMed]

- Whiteley, R.-J. Geophysics at Australian Landfills: Case Studies. ASEG Ext. Abstr. 2010, 2010, 1–4. [Google Scholar] [CrossRef]

- Guinea, A.; Bicknell, J.; Cox, N.; Swan, H.; Simmons, N. Characterization of legacy landfills with electrical resistivity tomography; a comparative study. J. Appl. Geophys. 2022, 203, 104716. [Google Scholar] [CrossRef]

- Power, C.; Tsourlos, P.; Ramasamy, M.; Nivorlis, A.; Mkandawire, M. Combined DC resistivity and induced polarization (DC-IP) for mapping the internal composition of a mine waste rock pile in Nova Scotia, Canada. J. Appl. Geophys. 2018, 150, 40–51. [Google Scholar] [CrossRef]

- Jegede, S.I.; Ujuanbi, O.; Abdullahi, N.K.; Iserhien-Emekeme, R.E. Mapping and monitoring of leachate plume migration at an open waste disposal site using non-invasive methods. Res. J. Environ. Earth Sci. 2012, 4, 26–33. [Google Scholar]

- Lago, A.L.; Elis, V.R.; Borges, W.R.; Penner, G.C. Geophysical investigation using resistivity and GPR methods: A case study of a lubricant oil waste disposal area in the city of Ribeirão Preto, São Paulo, Brazil. Environ. Geol. 2009, 58, 407–417. [Google Scholar] [CrossRef]

- Saksa, P.; Vepsäläinen, M. Electromagnetic survey of old landfill boundaries—A case study. Near Surf. Geophys. 2025, 23, 153–172. [Google Scholar] [CrossRef]

- Lau, A.M.P.; Ferreira, F.J.F.; Stevanato, R.; Filho, E.F.d.R. Geophysical and physicochemical investigations of an area contaminated by tannery waste: A case study from southern Brazil. Environ. Earth Sci. 2019, 78, 517. [Google Scholar] [CrossRef]

| Line No. | Anomaly No. | Anomaly Position (Horizontal) | Affected Depth | Inference and Interpretation |

|---|---|---|---|---|

| A2-1 | YC01 | 22.8~28.8 m | 0.3~2.4 m | Solid waste |

| A3-1 | YC02 | 17.6~23 m | 0.6~1.8 m | Isolated stone |

| YC03 | 32.5~37.2 m | 0.6~1.8 m | Non-compactness | |

| YC04 | 39~43.2 m | 0.5~1.2 m | Isolated stone | |

| A3-2 | YC05 | 15.4~16.8 m | 0.5~2.2 m | Localized void |

| YC06 | 18.5~20.8 m | 0.75~1.9 m | Localized void | |

| YC07 | 41.5~44 m | 0.75~1.2 m | Localized void | |

| A3-3 | YC08 | 16.5~19.5 m | 0.4~1.4 m | Localized void |

| A3-4 | YC09 | 13~16 m | 0.4~0.8 m | Non-compactness |

| A3-5 | YC10 | 4.2~7.4 m | 0.3~1.1 m | Cavity |

| A5-2 | YC11 | 30.5~33.6 m | 0.8~1.7 m | Construction debris |

| A5-6 | YC12 | 39~44 m | 1.7~2.4 m | Non-compactness |

| A5-7 | YC13 | 39~43.8 m | 1.7~2.5 m | Non-compactness |

| A6-1 | YC14 | 10.8~13.6 m | 0.6~1.4 m | Localized void |

| YC15 | 17.8~21.8 m | 1~1.9 m | Localized void | |

| A6-2 | YC16 | 8.5~11.8 m | 0.6~2 m | Non-compactness |

| YC17 | 14.3~17 m | 0.5~2.3 m | Non-compactness |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Yin, A.; Lu, Y.; Hu, Z.; Sun, L.; Ji, W.; Li, Q.; Zhao, C.; Feng, Y.; Kong, L.; et al. Integrated Investigation Approach for Solid Waste Landfill Hazards—A Case Study of Two Decommissioned Industrial Sites. Toxics 2025, 13, 807. https://doi.org/10.3390/toxics13100807

Zhang X, Yin A, Lu Y, Hu Z, Sun L, Ji W, Li Q, Zhao C, Feng Y, Kong L, et al. Integrated Investigation Approach for Solid Waste Landfill Hazards—A Case Study of Two Decommissioned Industrial Sites. Toxics. 2025; 13(10):807. https://doi.org/10.3390/toxics13100807

Chicago/Turabian StyleZhang, Xiaoyu, Aijing Yin, Yuanyuan Lu, Zhewei Hu, Li Sun, Wenbing Ji, Qi Li, Caiyi Zhao, Yanhong Feng, Lingya Kong, and et al. 2025. "Integrated Investigation Approach for Solid Waste Landfill Hazards—A Case Study of Two Decommissioned Industrial Sites" Toxics 13, no. 10: 807. https://doi.org/10.3390/toxics13100807

APA StyleZhang, X., Yin, A., Lu, Y., Hu, Z., Sun, L., Ji, W., Li, Q., Zhao, C., Feng, Y., Kong, L., & Ying, R. (2025). Integrated Investigation Approach for Solid Waste Landfill Hazards—A Case Study of Two Decommissioned Industrial Sites. Toxics, 13(10), 807. https://doi.org/10.3390/toxics13100807