Blockchain Technology and Sustainability in Supply Chains and a Closer Look at Different Industries: A Mixed Method Approach

Abstract

1. Introduction

- What is the distribution of publications over the years?

- What are the top research components (sources, authors, affiliations, countries, keywords) in terms of production and how they are interrelated?

- Does the research collection confirm the bibliometric laws (Bradford’s Law and Lotka’s Law) based on source and author productivity?

- What are the topmost cited publications?

- What themes have been discovered in the literature thus far and how have they changed over the years?

- 6.

- What are the benefits, challenges, and uses of BT in different industries?

- 7.

- What methods and theories are used in the studies?

- 8.

- What are the open research questions for different industries?

2. Background

3. Methodology

3.1. Analysis and Tool

- Unlike other methods (e.g., content analysis), bibliometric analysis is more reliable and scalable.

- Bibliometric methods can offer valuable and detailed information by providing an in-depth and thorough analysis of the numerous relationships (such as citations, keywords, and co-citations) associated with the publications under review.

- Using bibliometric approaches, researchers may easily and intuitively visualize key research areas.

3.2. Search Protocol

3.2.1. Databases

3.2.2. Search Criteria

3.2.3. Search Strings

- Sustainability in supply chain: (“supply chain” OR “supply chains” OR scm OR “supply chain management”) AND (sustainable OR sustainability) [64].

3.2.4. Combining Databases and Search Results

4. Findings

4.1. Bibliometric Analysis

4.1.1. Overview

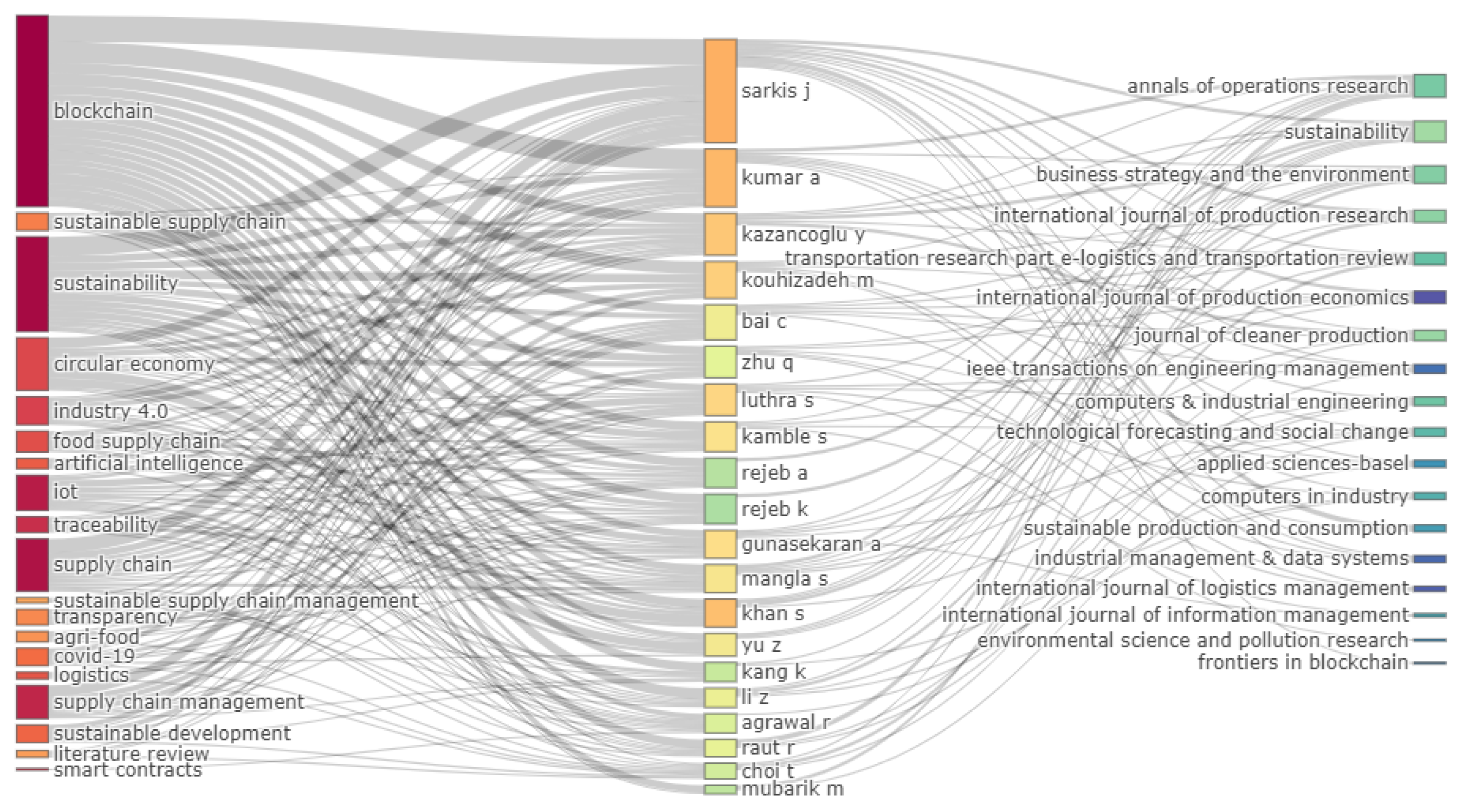

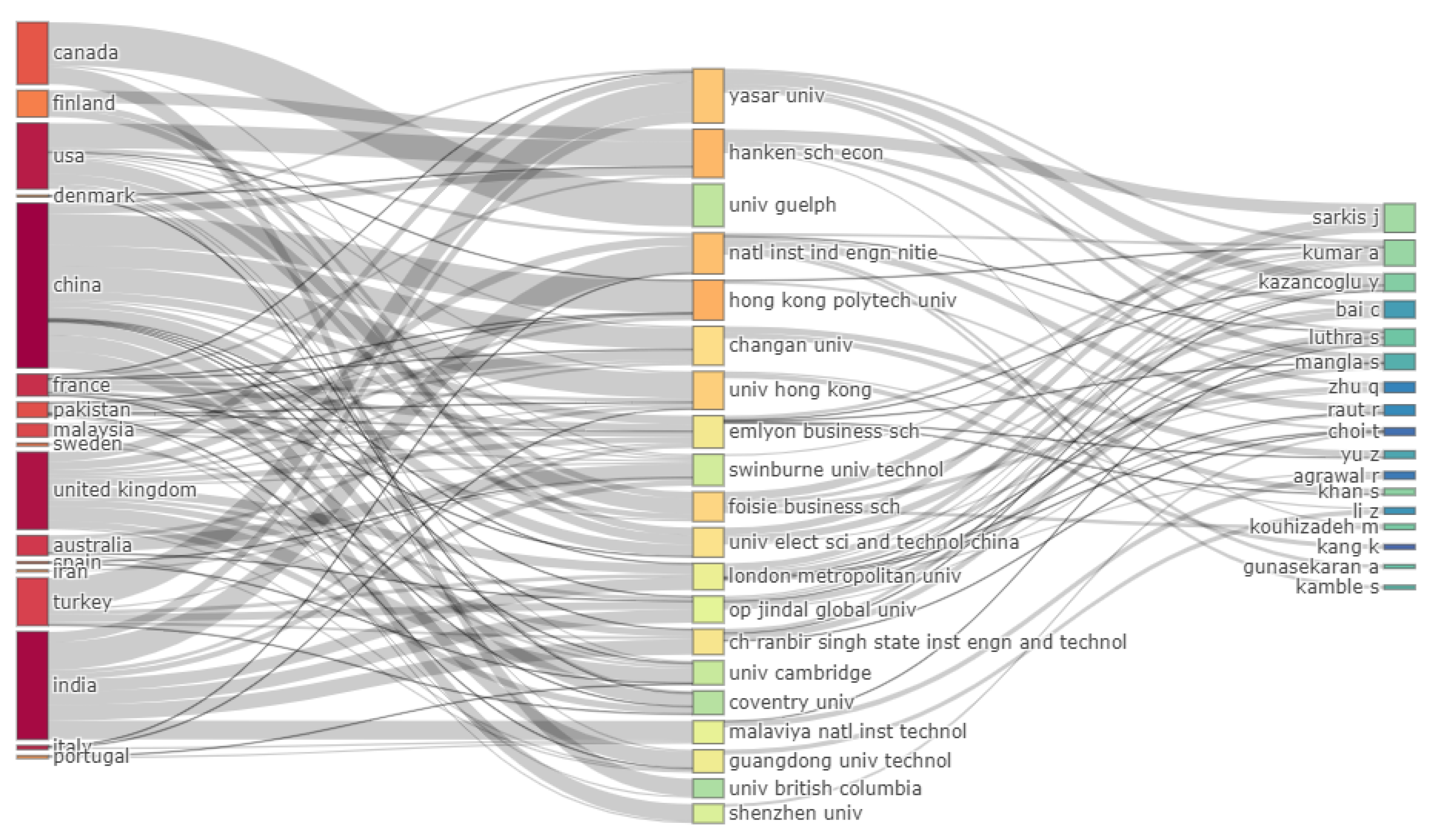

4.1.2. Three-Field Analysis

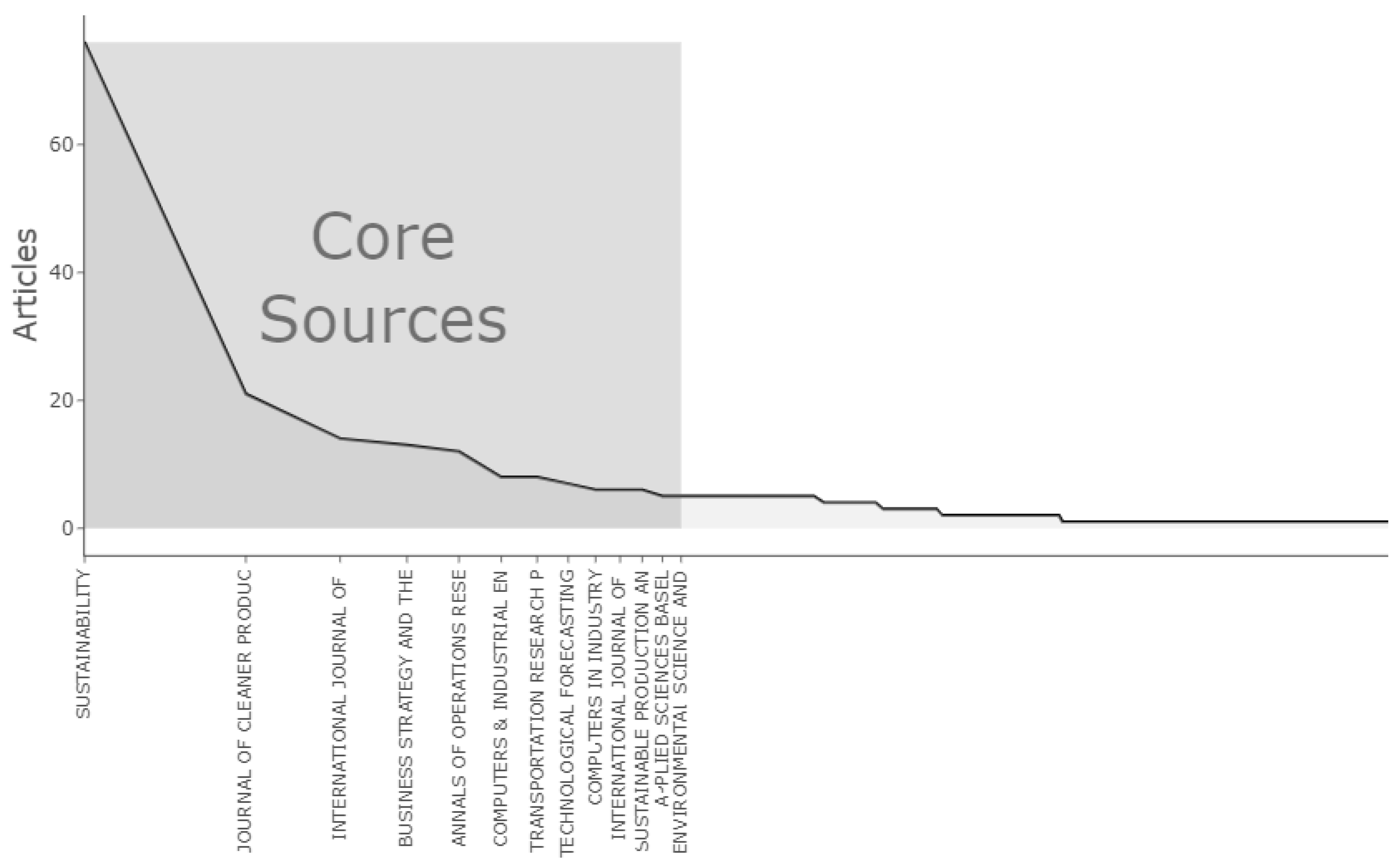

4.1.3. Bradford’s Law

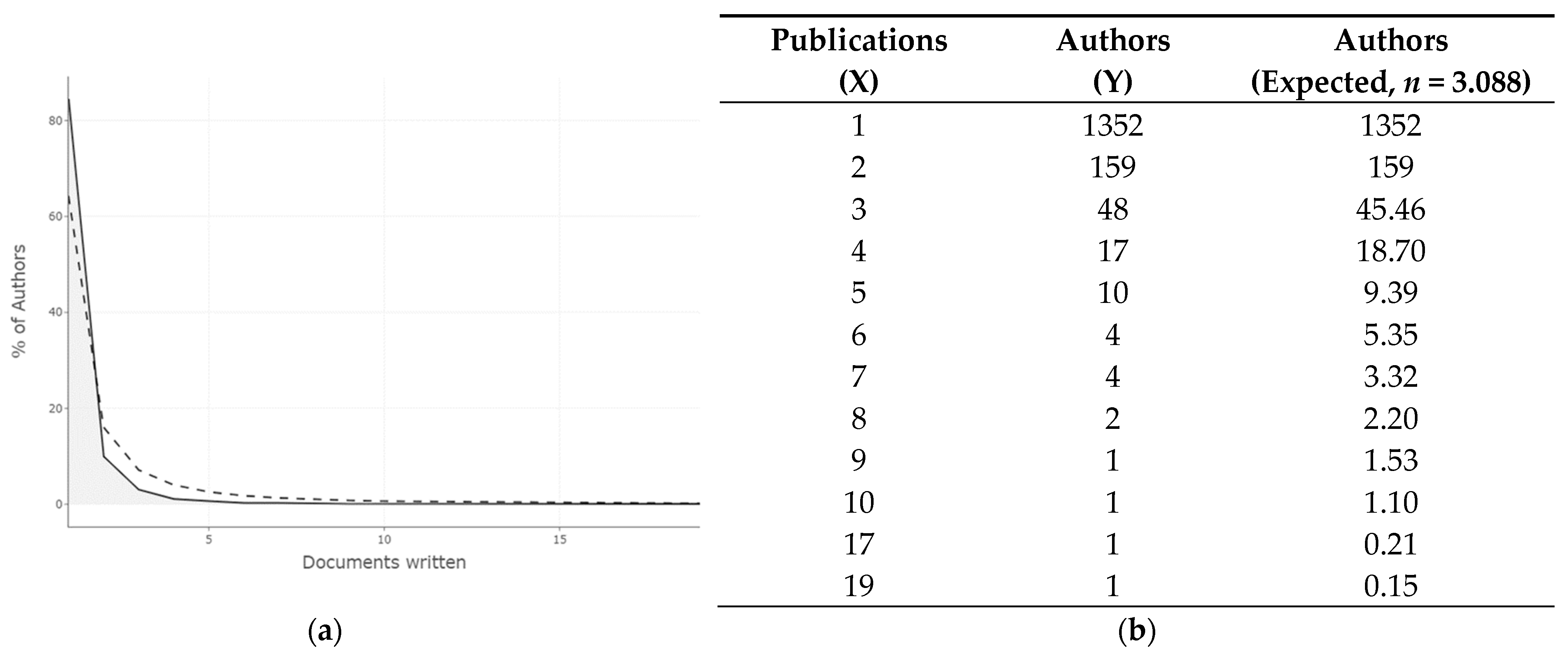

4.1.4. Lotka’s Law

4.1.5. Most Impactful Publications

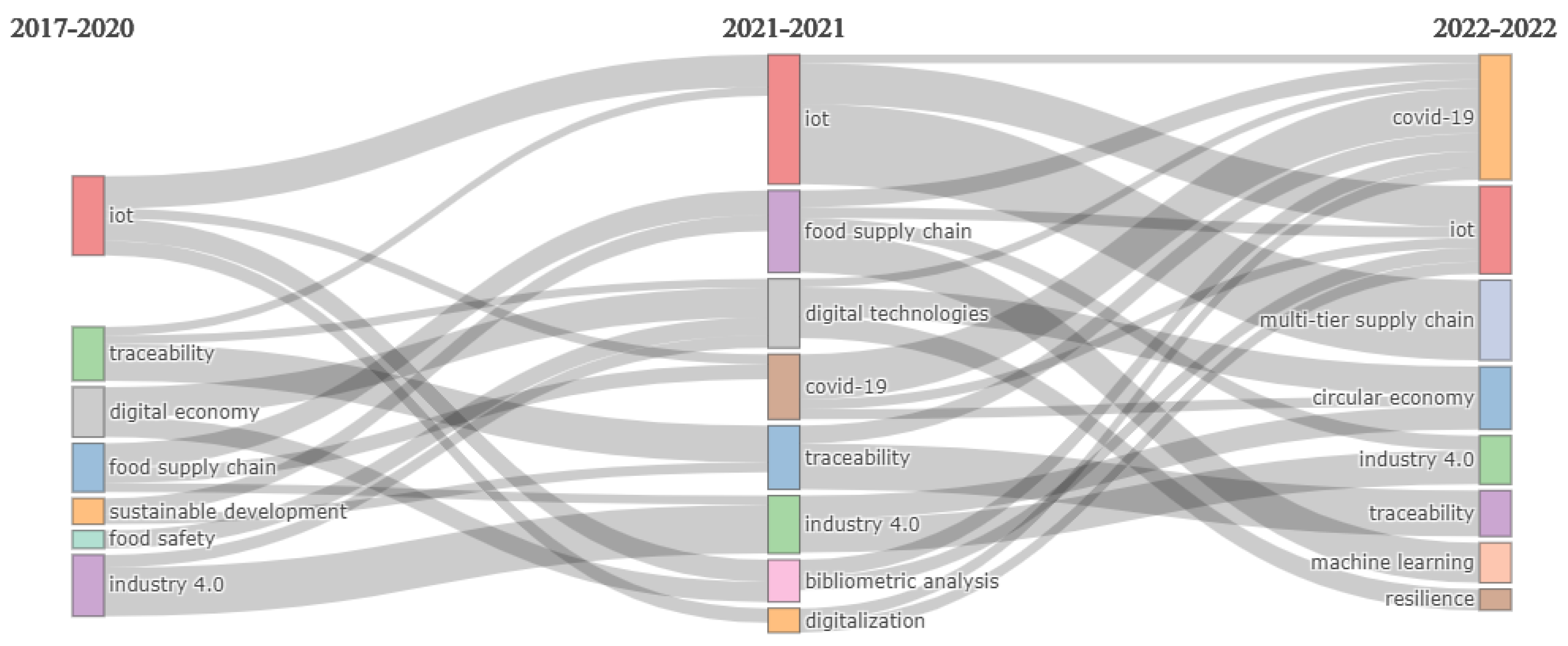

4.1.6. Thematic Evolution

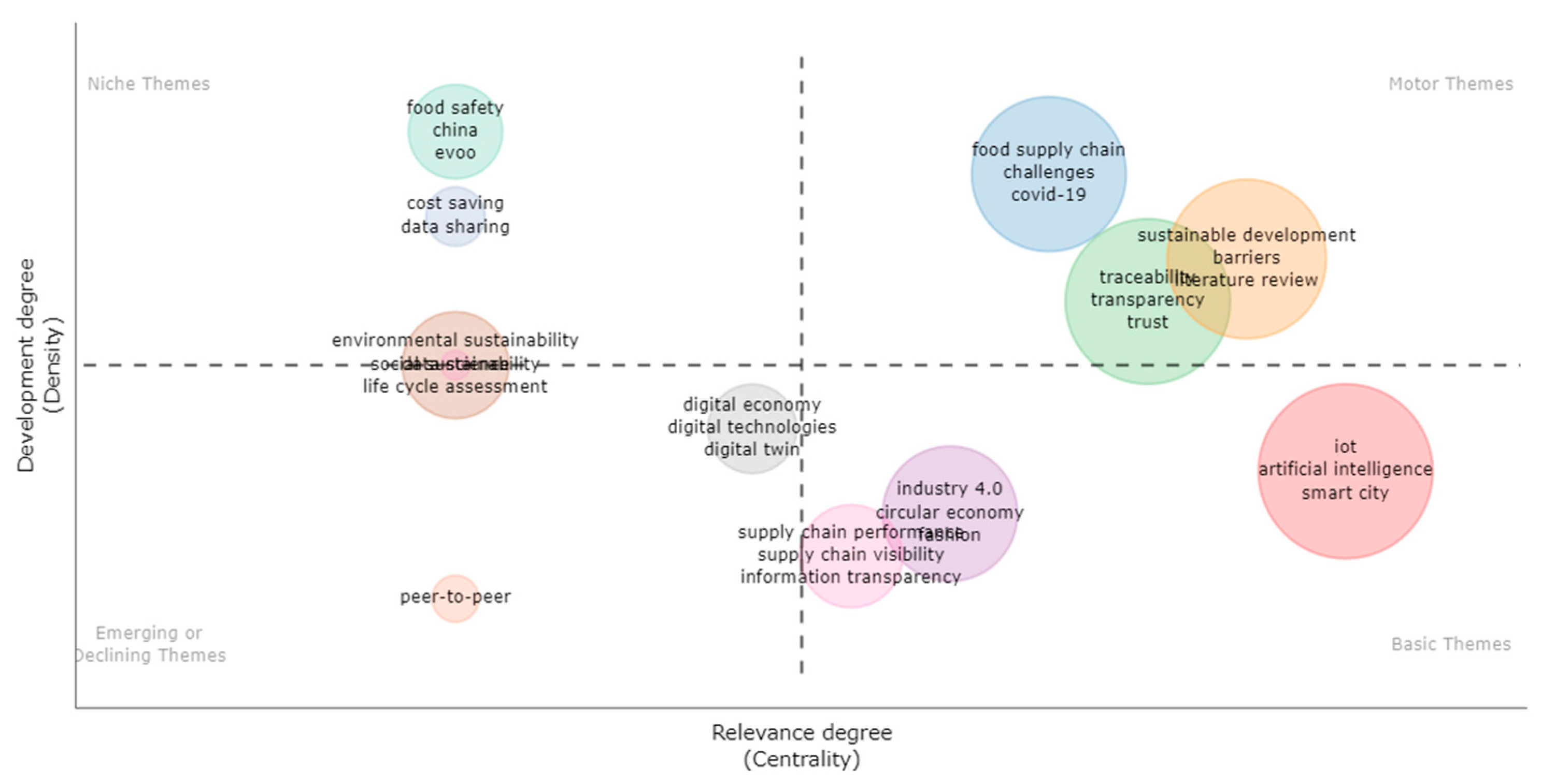

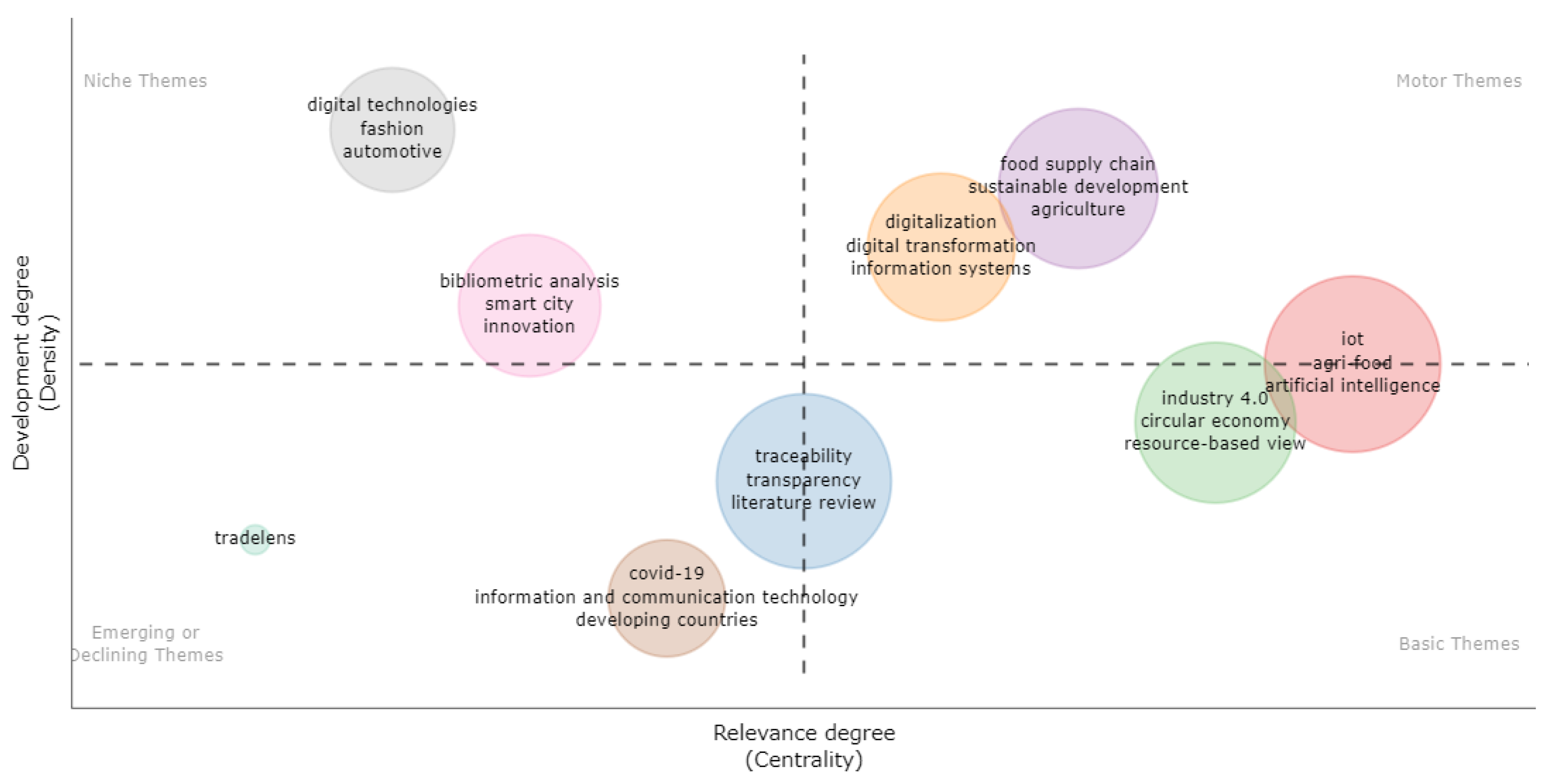

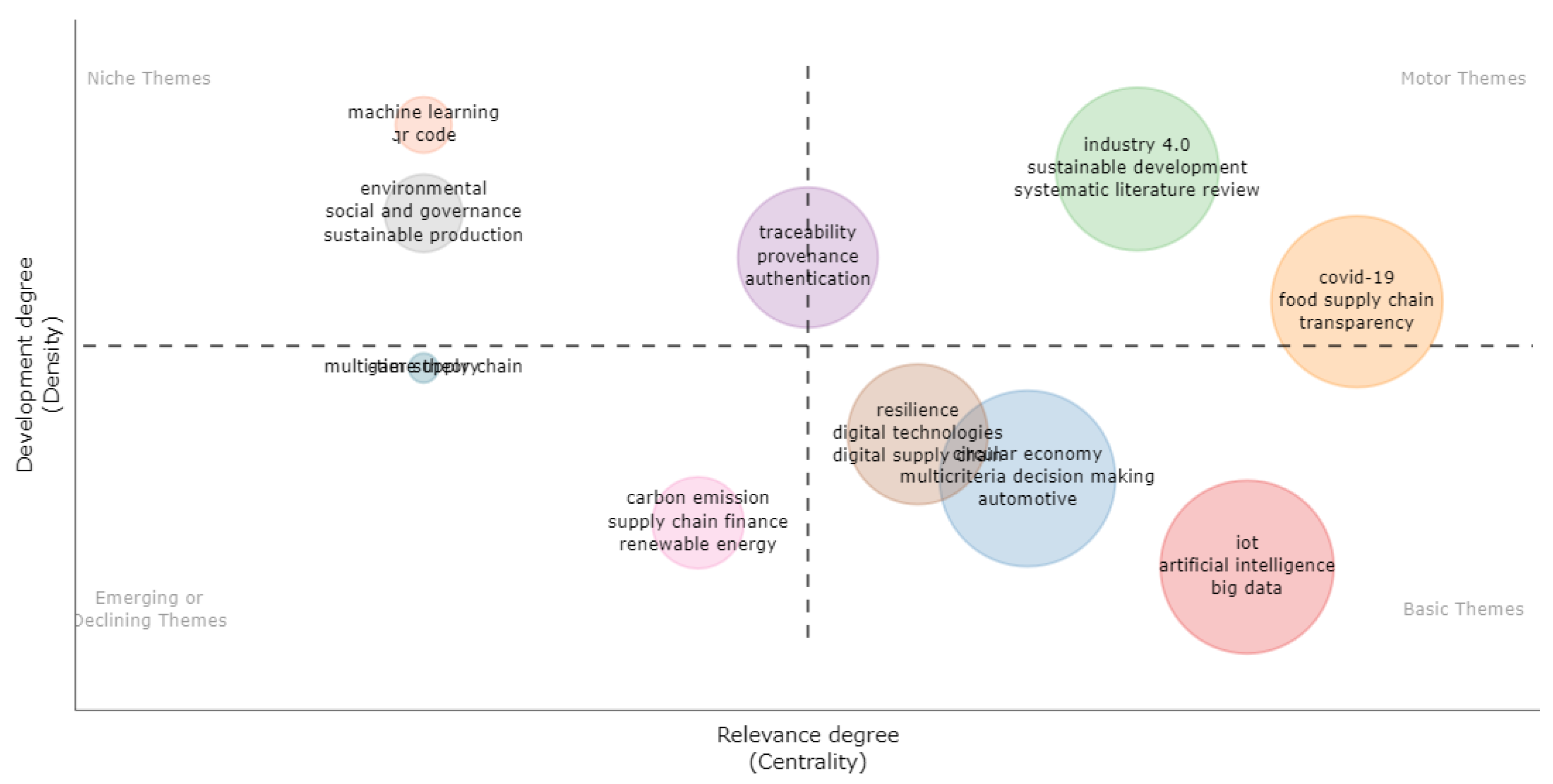

- Niche themes (upper-left quadrant; high density and low centrality): They are often referred to as “highly developed and isolated themes”. The connections between themes are strong internally but weak outside. They are just marginally relevant to the field.

- Motor themes (upper-right quadrant; high density and high centrality): This quadrant addresses well-developed themes crucial to the structure of a research area.

- Emerging or declining themes (lower-left quadrant; low density and low centrality): This quadrant demonstrates weakly developed and peripheral themes.

- Basic themes (lower-right quadrant; low density and high centrality): Although they are poorly developed, the themes in the lower-right quadrant are crucial for a research topic. Therefore, this quadrant gathers “general, basic, and transversal” themes.

4.2. Content Analysis

4.2.1. The Uses, Benefits and Challenges of Blockchain Technology

Food and Agriculture Industries

Fashion, Textile and Apparel Industries

Manufacturing Industry

Maritime and Shipping Industries

- It is possible for smart contracts to be misunderstood, and smart contracts frequently need to be updated to account for shifting circumstances in the real world. As a result, there may be discrepancies between what is expected of them and what really happens.

- There can be cyberattacks against elements of the blockchain, such as ledger and blockchain maintenance nodes.

- Failures of the hardware or infrastructure upon which the blockchain system is based can happen.

- There may be unintentional exposure or leakage of private company information.

- This technology may result in infrastructure failures, smart contract hazards, delays in payment processing, and bottlenecks throughout the supply chain.

Automotive Industry

Healthcare and Pharmaceutical Industries

Mining and Mineral Industries

Energy Industry

4.2.2. The Methodology-Based Evaluations

4.2.3. Future Directions

- Food and Agriculture Industries: Despite its many benefits, the real implementation of blockchain in the agricultural food supply chain is still in its infancy [79,153,180,264]. Much research should be done to use it to create reliable and secure decentralized apps [172]. Unvalidated sustainable e-agriculture implementation and non-informalized sustainable analysis are still understudied as developing themes [106]. The biggest issue with this is that there are not many incidents of it happening, and the direct and indirect social and environmental benefits of the technologies have not been properly tracked down or measured yet. Longitudinal studies could be very helpful to detect the direct and indirect social and environmental benefits of the technologies in the long run [153,268]. It would also be helpful to compare the effects on different supply chains, including long and short FSCs [153].

- Fashion, Textile and Apparel Industries: Since the implementation of BT is complicated, future research can focus more on to examine the challenges related to implementation in these industries [197], and the interaction and integration of diverse blockchain systems [206]. Considering the methodological point of view, case studies are based on a small sample in the reviewed studies, as very few brands and suppliers in the fashion, textile, and apparel industries are starting to adopt the use of blockchain. Therefore, future studies may include more brands and suppliers [203]. Additionally, other than qualitative case studies, it is advised to use quantitative techniques to create robust inferences in cases [205,210].

- Manufacturing Industry: Future research is suggested to focus on the creation of an integrated technological application framework to combine blockchain and artificial intelligence in the manufacturing sector [213]. In addition, the multi-cloud seamless method for collaborative enterprise management, wherein corporate information systems based on various clouds are capable of handling synchronous workloads, can be the focus of future research [214]. Future research should involve more companies and larger sample of areas or countries [218]. For instance, the reviewed studies focused on Malaysian [218], Danish [215], and Chinese [220] manufacturing companies. More research is also needed to compare BT uses in both traditional manufacturing and remanufacturing [215]. It is advised that the government enact necessary regulations to encourage the use of BT throughout the nation or industry (manufacturing) [273]. Although the concept of combining BT with additive manufacturing is recommended, in practice it is considerably more complicated, and more research should be conducted [222]. A blockchain-based additive manufacturing system will need to work in harmony with a variety of stakeholders [222].

- Maritime and Shipping Industries: On various maritime information infrastructures, cross-sectional and longitudinal case studies can be carried out [225] as more case studies needed to generalize the findings [227]. Regarding the many aspects, including environmental, business internal, and technological, a study on the collaboration between shipping companies and shippers is suggested [226]. By creating an end-to-end blockchain network combining smart contracts with machine learning features for the global process of exporting and importing, future research can further utilize the shipping sector [229]. In addition to a risk-focused strategy, examining the difficulties and suggested adaptive techniques in implementing a blockchain integrated system may provide a more thorough understanding of blockchain’s potential in the maritime shipping industry [233]. Moreover, future studies can concentrate on examining the unique characteristics of maritime industry in comparison to other industries in terms of blockchain acceptability, as well as the role of government authorities in terms of the adoption and usage of the technology [231].

- Automotive Industry: Since research generally is based on the data taken from the automobile industry of a particular country (for example, India), it would not be correct to generalize the results of the studies in this sector to the whole world. The results will likely be different for less developed countries with limited organizational skills and access to information resources [236]. Future researchers can extend the models used by using complex mathematical modeling and simulations to reveal the underlying phenomena between variables [237].

- Healthcare and Pharmaceutical Industries: The examined publications’ recommendations for future research emphasized the need for governments to assist the use of BT by enterprises for innovative solutions [247]. It is also crucial to consider other aspects of the healthcare industry and the various types of equipment that are used [244]. In addition, many methods can be used, including real case studies and additional mathematical and empirical modeling tools for these industries BT applications [245].

- Mining and Mineral Industries: Like other industries, more case studies and quantitative analysis are required for mining and mineral industries in future studies [256]. Future studies might compare blockchain versus non-blockchain solutions more thoroughly in terms of costs and other factors, and look at the relationship between consumers’ traits and how they respond to BT-based items [252]. It is also important to carefully consider how mandatory and optional frameworks of blockchain implementations differ from one another [253].

- Energy Industry: Blockchain adoption in energy research is still in its early stages [257,260,262]. Future research needs to obtain empirical data from pilot studies [262]. The findings in [260] stressed the significance of incentives for the energy industry. The establishment of research platforms and the study of BT should be supported by several institutions, such as companies, institutions, and universities. In addition, governments should streamline management processes and increase management levels and efficiency to safeguard energy blockchain innovation. In future studies, a blockchain-based energy transaction platform can be implemented in a smart home environment. In addition, long-term comparisons can be made by calculating the energy costs between a normal home and a smart home using the recommended platform [261].

5. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kouhizadeh, M.; Saberi, S.; Sarkis, J. Blockchain Technology and the Sustainable Supply Chain: Theoretically Exploring Adoption Barriers. Int. J. Prod. Econ. 2021, 231, 107831. [Google Scholar] [CrossRef]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J. Blockchains and the Supply Chain: Findings from a Broad Study of Practitioners. IEEE Eng. Manag. Rev. 2019, 47, 95–103. [Google Scholar] [CrossRef]

- Lim, M.K.; Li, Y.; Wang, C.; Tseng, M.-L. A Literature Review of Blockchain Technology Applications in Supply Chains: A Comprehensive Analysis of Themes, Methodologies and Industries. Comput. Ind. Eng. 2021, 154, 107133. [Google Scholar] [CrossRef]

- Gad, A.G.; Mosa, D.T.; Abualigah, L.; Abohany, A.A. Emerging Trends in Blockchain Technology and Applications: A Review and Outlook. J. King Saud Univ.-Comput. Inf. Sci. 2022, 34, 6719–6742. [Google Scholar] [CrossRef]

- Beamon, B.M. Supply Chain Design and Analysis: Models and Methods. Int. J. Prod. Econ. 1998, 55, 281–294. [Google Scholar] [CrossRef]

- Breese, J.L.; Park, S.-J.; Vaidyanathan, G. Blockchain Technology Adoption in Supply Change Management: Two Theoretical Perspectives. Issues Inf. Syst. 2019, 20, 140–150. [Google Scholar] [CrossRef]

- Munir, M.A.; Habib, M.S.; Hussain, A.; Shahbaz, M.A.; Qamar, A.; Masood, T.; Sultan, M.; Mujtaba, M.A.; Imran, S.; Hasan, M.; et al. Blockchain Adoption for Sustainable Supply Chain Management: Economic, Environmental, and Social Perspectives. Front. Energy Res. 2022, 10, 899632. [Google Scholar] [CrossRef]

- Khan, S.A.; Mubarik, M.S.; Kusi-Sarpong, S.; Gupta, H.; Zaman, S.I.; Mubarik, M. Blockchain Technologies as Enablers of Supply Chain Mapping for Sustainable Supply Chains. Bus. Strategy Environ. 2022, 31, 3742–3756. [Google Scholar] [CrossRef]

- Rejeb, A.; Rejeb, K. Blockchain and supply chain sustainability. Logforum 2020, 16, 363–372. [Google Scholar] [CrossRef]

- Pagell, M.; Shevchenko, A. Why Research in Sustainable Supply Chain Management Should Have No Future. J. Supply Chain Manag. 2014, 50, 44–55. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a Literature Review to a Conceptual Framework for Sustainable Supply Chain Management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Rajeev, A.; Pati, R.K.; Padhi, S.S.; Govindan, K. Evolution of Sustainability in Supply Chain Management: A Literature Review. J. Clean. Prod. 2017, 162, 299–314. [Google Scholar] [CrossRef]

- Saeed, M.A.; Kersten, W. Drivers of Sustainable Supply Chain Management: Identification and Classification. Sustainability 2019, 11, 1137. [Google Scholar] [CrossRef]

- Nitsche, B.; Straube, F. Defining the “New Normal” in International Logistics Networks: Lessons Learned and Implications of the COVID-19 Pandemic. WiSt—Wirtsch Stud. 2021, 50, 16–25. [Google Scholar] [CrossRef]

- Pritchard, A. Statistical Bibliography or Bibliometrics. J. Doc. 1969, 25, 348. [Google Scholar]

- Noyons, E.C.; Moed, H.F.; Luwel, M. Combining Mapping and Citation Analysis for Evaluative Bibliometric Purposes: A Bibliometric Study. J. Am. Soc. Inf. Sci. 1999, 50, 115–131. [Google Scholar] [CrossRef]

- Noyons, E.; Moed, H.; Van Raan, A. Integrating Research Performance Analysis and Science Mapping. Scientometrics 1999, 46, 591–604. [Google Scholar] [CrossRef]

- Donthu, N.; Kumar, S.; Mukherjee, D.; Pandey, N.; Lim, W.M. How to Conduct a Bibliometric Analysis: An Overview and Guidelines. J. Bus. Res. 2021, 133, 285–296. [Google Scholar] [CrossRef]

- Gaur, A.; Kumar, M. A Systematic Approach to Conducting Review Studies: An Assessment of Content Analysis in 25 Years of IB Research. J. World Bus. 2018, 53, 280–289. [Google Scholar] [CrossRef]

- Seuring, S.; Gold, S. Conducting Content-Analysis Based Literature Reviews in Supply Chain Management. Supply Chain Manag. Int. J. 2012, 17, 544–555. [Google Scholar] [CrossRef]

- Drisko, J.W.; Maschi, T. Content Analysis. In Pocket Guide to Social Work Re; Oxford University Press: Oxford, UK, 2016. [Google Scholar]

- Krippendorff, K. Content Analysis. In An Introduction to Its Methodology; Sage Publications: Thousand Oaks, CA, USA, 2018. [Google Scholar]

- Morris, R. Computerized Content Analysis in Management Research: A Demonstration of Advantages&Limitations. J. Manag. 1994, 20, 903–931. [Google Scholar]

- Mody, M.A.; Hanks, L.; Cheng, M. Sharing Economy Research in Hospitality and Tourism: A Critical Review Using Bibliometric Analysis, Content Analysis and a Quantitative Systematic Literature Review. Int. J. Contemp. Hosp. Manag. 2021, 33, 1711–1745. [Google Scholar] [CrossRef]

- Nagariya, R.; Kumar, D.; Kumar, I. Service Supply Chain: From Bibliometric Analysis to Content Analysis, Current Research Trends and Future Research Directions. Benchmarking Int. J. 2020, 28, 333–369. [Google Scholar] [CrossRef]

- Fallahpour, A.; Wong, K.Y.; Rajoo, S.; Fathollahi-Fard, A.M.; Antucheviciene, J.; Nayeri, S. An Integrated Approach for a Sustainable Supplier Selection Based on Industry 4.0 Concept. Environ. Sci. Pollut. Res. 2021, 1–19. [Google Scholar] [CrossRef] [PubMed]

- Sahoo, S.; Kumar, S.; Sivarajah, U.; Lim, W.M.; Westland, J.C.; Kumar, A. Blockchain for Sustainable Supply Chain Management: Trends and Ways Forward. Electron. Commer. Res. 2022, 1–56. [Google Scholar] [CrossRef]

- Crosby, M.; Pattanayak, P.; Verma, S.; Kalyanaraman, V. Blockchain Technology: Beyond Bitcoin. Appl. Innov. 2016, 2, 71. [Google Scholar]

- Yuan, Y.; Wang, F.-Y. Towards Blockchain-Based Intelligent Transportation Systems. In Proceedings of the 2016 IEEE 19th International Conference on Intelligent Transportation Systems (ITSC), Rio de Janeiro, Brazil, 1–4 November 2016; pp. 2663–2668. [Google Scholar] [CrossRef]

- Treiblmaier, H. The Impact of the Blockchain on the Supply Chain: A Theory-Based Research Framework and a Call for Action. Supply Chain Manag. Int. J. 2018, 23, 545–559. [Google Scholar] [CrossRef]

- Zkik, K.; Belhadi, A.; Khan, S.A.R.; Kamble, S.S.; Oudani, M.; Touriki, F.E. Exploration of Barriers and Enablers of Blockchain Adoption for Sustainable Performance: Implications for e-Enabled Agriculture Supply Chains. Int. J. Logist. Res. Appl. 2022, 1–38. [Google Scholar] [CrossRef]

- Zhao, J.L.; Fan, S.; Yan, J. Overview of Business Innovations and Research Opportunities in Blockchain and Introduction to the Special Issue. Financ. Innov. 2016, 2, 28. [Google Scholar] [CrossRef]

- Kshetri, N. Can Blockchain Strengthen the Internet of Things? IT Prof. 2017, 19, 68–72. [Google Scholar] [CrossRef]

- Hackius, N.; Petersen, M. Blockchain in Logistics and Supply Chain: Trick or Treat? In Digitalization in Supply Chain Management and Logistics: Smart and Digital Solutions for an Industry 4.0 Environment, Proceedings of the Hamburg International Conference of Logistics (HICL), Hamburg, Germany, 12–14 October 2017; Epubli GmbH: Berlin, Germany, 2017; Volume 23, pp. 3–18. [Google Scholar] [CrossRef]

- Schlegel, M.; Zavolokina, L.; Schwabe, G. Blockchain Technologies from the Consumers’ Perspective: What Is There and Why Should Who Care? In Proceedings of the Proceedings of the 51st Hawaii International Conference on System Sciences, Hilton Waikoloa Village, Hawaii, USA, 3–6 January 2018.

- Coita, D.C.; Abrudan, M.M.; Matei, M.C. Effects of the Blockchain Technology on Human Resources and Marketing: An Exploratory Study. In Strategic Innovative Marketing and Tourism; Springer: Berlin/Heidelberg, Germany, 2019; pp. 683–691. [Google Scholar]

- Waters, D. Logistics. In Supply Chain Management. M.: UNITI-DANA.; Kogan Page: London, UK, 2003. [Google Scholar]

- Min, H.; Zhou, G. Supply Chain Modeling: Past, Present and Future. Comput. Ind. Eng. 2002, 43, 231–249. [Google Scholar] [CrossRef]

- Vonderembse, M.A.; Uppal, M.; Huang, S.H.; Dismukes, J.P. Designing Supply Chains: Towards Theory Development. Int. J. Prod. Econ. 2006, 100, 223–238. [Google Scholar] [CrossRef]

- Hervani, A.A.; Helms, M.M.; Sarkis, J. Performance Measurement for Green Supply Chain Management. Benchmarking Int. J. 2005, 12, 330–353. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Ngai, E.W. Information Systems in Supply Chain Integration and Management. Eur. J. Oper. Res. 2004, 159, 269–295. [Google Scholar] [CrossRef]

- Park, A.; Li, H. The Effect of Blockchain Technology on Supply Chain Sustainability Performances. Sustainability 2021, 13, 1726. [Google Scholar] [CrossRef]

- Mukherjee, A.A.; Singh, R.K.; Mishra, R.; Bag, S. Application of Blockchain Technology for Sustainability Development in Agricultural Supply Chain: Justification Framework. Oper. Manag. Res. 2021, 15, 46–61. [Google Scholar] [CrossRef]

- Carter, C.R.; Rogers, D.S. A Framework of Sustainable Supply Chain Management: Moving toward New Theory. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 360–387. [Google Scholar] [CrossRef]

- Rejeb, A.; Rejeb, K.; Simske, S.; Treiblmaier, H. Blockchain Technologies in Logistics and Supply Chain Management: A Bibliometric Review. Logist.-Basel 2021, 5, 72. [Google Scholar] [CrossRef]

- Esen, M.; Bellibas, M.S.; Gumus, S. The Evolution of Leadership Research in Higher Education for Two Decades (1995–2014): A Bibliometric and Content Analysis. Int. J. Leadersh. Educ. 2020, 23, 259–273. [Google Scholar] [CrossRef]

- Calabuig-Moreno, F.; Gonzalez-Serrano, M.H.; Alonso-Dos-Santos, M.; Gómez-Tafalla, A. Entrepreneurial Ecosystems, Knowledge Spillovers, and Their Embeddedness in the Sport Field: A Bibliometric and Content Analysis. Knowl. Manag. Res. Pract. 2021, 19, 65–83. [Google Scholar] [CrossRef]

- Bretas, V.P.; Alon, I. Franchising Research on Emerging Markets: Bibliometric and Content Analyses. J. Bus. Res. 2021, 133, 51–65. [Google Scholar] [CrossRef]

- Aria, M.; Cuccurullo, C. Bibliometrix: An R-Tool for Comprehensive Science Mapping Analysis. J. Informetr. 2017, 11, 959–975. [Google Scholar] [CrossRef]

- Nafade, V.; Nash, M.; Huddart, S.; Pande, T.; Gebreselassie, N.; Lienhardt, C.; Pai, M. A Bibliometric Analysis of Tuberculosis Research, 2007–2016. PLoS ONE 2018, 13, e0199706. [Google Scholar] [CrossRef]

- Derviş, H. Bibliometric Analysis Using Bibliometrix an R Package. J. Scientometr. Res. 2019, 8, 156–160. [Google Scholar] [CrossRef]

- Firdaus, A.; Razak, M.F.A.; Feizollah, A.; Hashem, I.A.T.; Hazim, M.; Anuar, N.B. The Rise of “Blockchain”: Bibliometric Analysis of Blockchain Study. Scientometrics 2019, 120, 1289–1331. [Google Scholar] [CrossRef]

- Munim, Z.H.; Dushenko, M.; Jimenez, V.J.; Shakil, M.H.; Imset, M. Big Data and Artificial Intelligence in the Maritime Industry: A Bibliometric Review and Future Research Directions. Marit. Policy Manag. 2020, 47, 577–597. [Google Scholar] [CrossRef]

- Rodríguez-Soler, R.; Uribe-Toril, J.; Valenciano, J.D.P. Worldwide Trends in the Scientific Production on Rural Depopulation, a Bibliometric Analysis Using Bibliometrix R-Tool. Land Use Policy 2020, 97, 104787. [Google Scholar] [CrossRef]

- Moral-Muñoz, J.A.; Herrera-Viedma, E.; Santisteban-Espejo, A.; Cobo, M.J. Software Tools for Conducting Bibliometric Analysis in Science: An up-to-Date Review. Prof. Inf. 2020, 29, e290103. [Google Scholar] [CrossRef]

- Zhu, J.; Liu, W. A Tale of Two Databases: The Use of Web of Science and Scopus in Academic Papers. Scientometrics 2020, 123, 321–335. [Google Scholar] [CrossRef]

- Caputo, A.; Kargina, M. A User-Friendly Method to Merge Scopus and Web of Science Data during Bibliometric Analysis. J. Mark. Anal. 2022, 10, 82–88. [Google Scholar] [CrossRef]

- Echchakoui, S. Why and How to Merge Scopus and Web of Science during Bibliometric Analysis: The Case of Sales Force Literature from 1912 to 2019. J. Mark. Anal. 2020, 8, 165–184. [Google Scholar] [CrossRef]

- Dabbagh, M.; Sookhak, M.; Safa, N.S. The Evolution of Blockchain: A Bibliometric Study. IEEE Access 2019, 7, 19212–19221. [Google Scholar] [CrossRef]

- Tandon, A.; Kaur, P.; Mäntymäki, M.; Dhir, A. Blockchain Applications in Management: A Bibliometric Analysis and Literature Review. Technol. Forecast. Soc. Chang. 2021, 166, 120649. [Google Scholar] [CrossRef]

- Ejsmont, K.; Gladysz, B.; Kluczek, A. Impact of Industry 4.0 on Sustainability—Bibliometric Literature Review. Sustainability 2020, 12, 5650. [Google Scholar] [CrossRef]

- Furstenau, L.B.; Sott, M.K.; Kipper, L.M.; Machado, E.L.; Lopez-Robles, J.R.; Dohan, M.S.; Cobo, M.J.; Zahid, A.; Abbasi, Q.H.; Imran, M.A. Link between Sustainability and Industry 4.0: Trends, Challenges and New Perspectives. IEEE Access 2020, 8, 140079–140096. [Google Scholar] [CrossRef]

- Muessigmann, B.; von der Gracht, H.; Hartmann, E. Blockchain Technology in Logistics and Supply Chain Management—A Bibliometric Literature Review from 2016 to January 2020. IEEE Trans. Eng. Manag. 2020, 67, 988–1007. [Google Scholar] [CrossRef]

- Muñoz-Villamizar, A.; Solano, E.; Quintero-Araujo, C.; Santos, J. Sustainability and Digitalization in Supply Chains: A Bibliometric Analysis. Uncertain Supply Chain Manag. 2019, 7, 703–712. [Google Scholar] [CrossRef]

- Aria, M.; Cuccurullo, C. Package ‘Bibliometrix’. J. Informetr. 2020, 11, 959–975. [Google Scholar] [CrossRef]

- Janik, A.; Ryszko, A.; Szafraniec, M. Scientific Landscape of Smart and Sustainable Cities Literature: A Bibliometric Analysis. Sustainability 2020, 12, 779. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, S.; Sidhu, A.S.; Pruncu, C.I. Bibliometric Analysis of Specific Energy Consumption (SEC) in Machining Operations: A Sustainable Response. Sustainability 2021, 13, 5617. [Google Scholar] [CrossRef]

- Mühl, D.D.; de Oliveira, L. A Bibliometric and Thematic Approach to Agriculture 4.0. Heliyon 2022, 8, e09369. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Li, X.; Wang, P.; Liu, Q. Bibliometric Analysis of Digital Twin Literature: A Review of Influencing Factors and Conceptual Structure. Technol. Anal. Strateg. Manag. 2022, 1–15. [Google Scholar] [CrossRef]

- Riehmann, P.; Hanfler, M.; Froehlich, B. Interactive Sankey Diagrams. In Proceedings of the IEEE Symposium on Information Visualization, 2005. INFOVIS 200; IEEE: Piscataway, NJ, USA, 2005; pp. 233–240. [Google Scholar]

- Bradford, S.C. Sources of Information on Specific Subjects. Engineering 1934, 137, 85–86. [Google Scholar]

- Kumar, A.; Mohindra, R. Bibliometric Analysis on Knowledge Management Research. Int. J. Inf. Dissem. Technol. 2015, 5, 106. [Google Scholar]

- Tsay, M.; Li, C. Bibliometric Analysis of the Journal Literature on Women’s Studies. Scientometrics 2017, 113, 705–734. [Google Scholar] [CrossRef]

- Su, Y.-S.; Lin, C.-L.; Chen, S.-Y.; Lai, C.-F. Bibliometric Study of Social Network Analysis Literature. Libr. Hi Technol. 2020, 38, 420–433. [Google Scholar] [CrossRef]

- Lotka, A.J. The Frequency Distribution of Scientific Productivity. J. Wash. Acad. Sci. 1926, 16, 317–323. [Google Scholar]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain Technology and Its Relationships to Sustainable Supply Chain Management. Int. J. Prod. Res. 2019, 57, 2117–2135. [Google Scholar] [CrossRef]

- Kshetri, N. 1 Blockchain’s Roles in Meeting Key Supply Chain Management Objectives. Int. J. Inf. Manag. 2018, 39, 80–89. [Google Scholar] [CrossRef]

- Hughes, L.; Dwivedi, Y.K.; Misra, S.K.; Rana, N.P.; Raghavan, V.; Akella, V. Blockchain Research, Practice and Policy: Applications, Benefits, Limitations, Emerging Research Themes and Research Agenda. Int. J. Inf. Manag. 2019, 49, 114–129. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Sharma, R. Modeling the Blockchain Enabled Traceability in Agriculture Supply Chain. Int. J. Inf. Manag. 2020, 52, 101967. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Achieving Sustainable Performance in a Data-Driven Agriculture Supply Chain: A Review for Research and Applications. Int. J. Prod. Econ. 2020, 219, 179–194. [Google Scholar] [CrossRef]

- Cahlik, T. Search for Fundamental Articles in Economics. Scientometrics 2000, 49, 389–402. [Google Scholar] [CrossRef]

- Cobo, M.J.; López-Herrera, A.G.; Herrera-Viedma, E.; Herrera, F. An Approach for Detecting, Quantifying, and Visualizing the Evolution of a Research Field: A Practical Application to the Fuzzy Sets Theory Field. J. Informetr. 2011, 5, 146–166. [Google Scholar] [CrossRef]

- Aria, M.; Misuraca, M.; Spano, M. Mapping the Evolution of Social Research and Data Science on 30 Years of Social Indicators Research. Soc. Indic. Res. 2020, 149, 803–831. [Google Scholar] [CrossRef]

- Zhang, J.Z.; Srivastava, P.R.; Sharma, D.; Eachempati, P. Big Data Analytics and Machine Learning: A Retrospective Overview and Bibliometric Analysis. Expert Syst. Appl. 2021, 184, 115561. [Google Scholar] [CrossRef]

- Munim, Z.H.; Balasubramaniyan, S.; Kouhizadeh, M.; Hossain, N.U.I. Assessing Blockchain Technology Adoption in the Norwegian Oil and Gas Industry Using Bayesian Best Worst Method. J. Ind. Inf. Integr. 2022, 28, 100346. [Google Scholar] [CrossRef]

- Mandolla, C.; Petruzzelli, A.M.; Percoco, G.; Urbinati, A. Building a Digital Twin for Additive Manufacturing through the Exploitation of Blockchain: A Case Analysis of the Aircraft Industry. Comput. Ind. 2019, 109, 134–152. [Google Scholar] [CrossRef]

- Di Vaio, A.; Varriale, L. Blockchain Technology in Supply Chain Management for Sustainable Performance: Evidence from the Airport Industry. Int. J. Inf. Manag. 2020, 52, 102014. [Google Scholar] [CrossRef]

- Arunmozhi, M.; Venkatesh, V.G.; Arisian, S.; Shi, Y.; Sreedharan, V.R. Application of Blockchain and Smart Contracts in Autonomous Vehicle Supply Chains: An Experimental Design. Transp. Res. Part E Logist. Transp. Rev. 2022, 165, 102864. [Google Scholar] [CrossRef]

- Sudhan, A.; Nene, M.J. Employability of Blockchain Technology in Defence Applications. In Proceedings of the Proceedings of the International Conference on Intelligent Sustainable Systems (ICISS 2017), Palladam, India, 7–8 December 2017; IEEE: New York, NY, USA, 2017; pp. 630–637. [Google Scholar] [CrossRef]

- Tran-Dang, H.; Kim, D.-S. Physical Internet for Military Logistics: Perspectives. In Proceedings of the 2019 10th International Conference on Information and Communication Technology Convergence (ICTC), Jeju, Korea, 16–18 October 2019; Ict Convergence Leading the Autonomous Future; IEEE: New York, NY, USA, 2019; pp. 755–757. [Google Scholar] [CrossRef]

- Munoz, M.F.; Zhang, K.; Shahzad, A.; Ouhimmou, M. LogLog: A Blockchain Solution for Tracking and Certifying Wood Volumes. In Proceedings of the 2021 IEEE International Conference on Blockchain and Cryptocurrency (ICBC), Sydney, Australia, 3–6 May 2021; IEEE: New York, NY, USA, 2021. [Google Scholar] [CrossRef]

- Alacam, S.; Sencer, A. Using Blockchain Technology to Foster Collaboration among Shippers and Carriers in the Trucking Industry: A Design Science Research Approach. Logist.-Basel 2021, 5, 37. [Google Scholar] [CrossRef]

- Arbatskaya, E.; Khoreva, L. Blockchain as an Innovative Digitalization Achievement in Logistics of Eco-Tourism. In Proceedings of the E3S Web of Conferences, Chelyabinsk, Russia, 17–19 February 2021; Kankhva, V., Ed.; [Google Scholar] [CrossRef]

- Zhang, N.; Xu, Y. Environmental Study on Cooperation System of Cross-Border Tracking Economic Crimes Based on Block Chain-Take Telecommunication Fraud as an Example. Ekoloji 2019, 28, 4437–4446. [Google Scholar]

- Tsoukas, V.; Gkogkidis, A.; Kampa, A.; Spathoulas, G.; Kakarountas, A. Blockchain Technology in Food Supply Chain: A State of the Art. In Proceedings of the 2021 6th South-East Europe Design Automation, Computer Engineering, Computer Networks and Social Media Conference (SEEDA-CECNSM), Preveza, Greece, 24–26 September 2021; pp. 1–8. [Google Scholar] [CrossRef]

- Bhat, S.A.; Huang, N.-F.; Sofi, I.B.; Sultan, M. Agriculture-Food Supply Chain Management Based on Blockchain and IoT: A Narrative on Enterprise Blockchain Interoperability. Agric.-Basel 2021, 12, 40. [Google Scholar] [CrossRef]

- Agnusdei, G.P.; Coluccia, B. Sustainable Agrifood Supply Chains: Bibliometric, Network and Content Analyses. Sci. Total Environ. 2022, 824, 153704. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Ma, X.; Shu, L.; Hancke, G.P.; Abu-Mahfouz, A.M. From Industry 4.0 to Agriculture 4.0: Current Status, Enabling Technologies, and Research Challenges. IEEE Trans. Ind. Inform. 2020, 17, 4322–4334. [Google Scholar] [CrossRef]

- Hassoun, A.; Ait-Kaddour, A.; Abu-Mahfouz, A.M.; Rathod, N.B.; Bader, F.; Barba, F.J.; Biancolillo, A.; Cropotova, J.; Galanakis, C.M.; Jambrak, A.R.; et al. The Fourth Industrial Revolution in the Food Industry-Part I: Industry 4.0 Technologies. Crit. Rev. Food Sci. Nutr. 2022, 1–17. [Google Scholar] [CrossRef]

- Cao, Y.; Yi, C.; Wan, G.; Hu, H.; Li, Q.; Wang, S. An Analysis on the Role of Blockchain-Based Platforms in Agricultural Supply Chains. Transp. Res. Part E-Logist. Transp. Rev. 2022, 163, 102731. [Google Scholar] [CrossRef]

- Tseng, C.-T.; Shang, S.S.C. Exploring the Sustainability of the Intermediary Role in Blockchain. Sustain. Switz. 2021, 13, 1936. [Google Scholar] [CrossRef]

- Khanna, A.; Jain, S.; Burgio, A.; Bolshev, V.; Panchenko, V. Blockchain-Enabled Supply Chain Platform for Indian Dairy Industry: Safety and Traceability. Foods 2022, 11, 2716. [Google Scholar] [CrossRef]

- Varriale, V.; Cammarano, A.; Michelino, F.; Caputo, M. Sustainable Supply Chains with Blockchain, IoT and RFID: A Simulation on Order Management. Sustain. Switz. 2021, 13, 6372. [Google Scholar] [CrossRef]

- Lezoche, M.; Hernandez, J.E.; Díaz, M.D.M.E.A.; Panetto, H.; Kacprzyk, J. Agri-Food 4.0: A Survey of the Supply Chains and Technologies for the Future Agriculture. Comput. Ind. 2020, 117, 103187. [Google Scholar] [CrossRef]

- Dadi, V.; Nikla, S.R.; Moe, R.S.; Agarwal, T.; Arora, S. Agri-Food 4.0 and Innovations: Revamping the Supply Chain Operations. Prod. Eng. Arch. 2021, 27, 75–89. [Google Scholar] [CrossRef]

- Song, L.; Wang, X.; Merveille, N. Research on Blockchain for Sustainable E-Agriculture. In Proceedings of the 2020 IEEE Technology and Engineering Management Conference, TEMSCON 2020, Novi, MI, USA, 3–6 June 2020. [Google Scholar] [CrossRef]

- Kumar, S.; Raut, R.D.; Nayal, K.; Kraus, S.; Yadav, V.S.; Narkhede, B.E. To Identify Industry 4.0 and Circular Economy Adoption Barriers in the Agriculture Supply Chain by Using ISM-ANP. J. Clean. Prod. 2021, 293, 126023. [Google Scholar] [CrossRef]

- Sodamin, D.; Vaněk, J.; Ulman, M.; Šimek, P. Fair Label versus Blockchain Technology from the Consumer Perspective: Towards a Comprehensive Research Agenda. AGRIS -Line Pap. Econ. Inform. 2022, 14, 111–119. [Google Scholar] [CrossRef]

- Scuderi, A.; La Via, G.; Timpanaro, G.; Sturiale, L. The Digital Applications of “Agriculture 4.0”: Strategic Opportunity for the Development of the Italian Citrus Chain. Agric.-Basel 2022, 12, 400. [Google Scholar] [CrossRef]

- Singh, V.; Sharma, S.K. Application of Blockchain Technology in Shaping the Future of Food Industry Based on Transparency and Consumer Trust. J. Food Sci. Technol. 2022, 246, 6–17. [Google Scholar] [CrossRef]

- Tsolakis, N.; Schumacher, R.; Dora, M.; Kumar, M. Artificial Intelligence and Blockchain Implementation in Supply Chains: A Pathway to Sustainability and Data Monetisation? Ann. Oper. Res. 2022, 1–54. [Google Scholar] [CrossRef]

- Dey, S.; Saha, S.; Singh, A.K.; McDonald-Maier, K. SmartNoshWaste: Using Blockchain, Machine Learning, Cloud Computing and QR Code to Reduce Food Waste in Decentralized Web 3.0 Enabled Smart Cities. Smart Cities 2022, 5, 162–176. [Google Scholar] [CrossRef]

- Dong, S.; Yang, L.; Shao, X.; Zhong, Y.; Li, Y.; Qiao, P. How Can Channel Information Strategy Promote Sales by Combining ICT and Blockchain? Evidence from the Agricultural Sector. J. Clean. Prod. 2021, 299, 126857. [Google Scholar] [CrossRef]

- Alkahtani, M.; Khalid, Q.S.; Jalees, M.; Omair, M.; Hussain, G.; Pruncu, C.I. E-Agricultural Supply Chain Management Coupled with Blockchain Effect and Cooperative Strategies. Sustainability 2021, 13, 816. [Google Scholar] [CrossRef]

- Vodenicharova, M.S. Supply Chain Study in Food Industry in Bulgaria. Int. J. Retail Distrib. Manag. 2020, 48, 921–938. [Google Scholar] [CrossRef]

- Nurgazina, J.; Pakdeetrakulwong, U.; Moser, T.; Reiner, G. Distributed Ledger Technology Applications in Food Supply Chains: A Review of Challenges and Future Research Directions. Sustainability 2021, 13, 4206. [Google Scholar] [CrossRef]

- Rahman, L.F.; Alam, L.; Marufuzzaman, M.; Sumaila, U.R. Traceability of Sustainability and Safety in Fishery Supply Chain Management Systems Using Radio Frequency Identification Technology. Foods 2021, 10, 2265. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Mangla, S.K.; Kumar, P. Barriers for Adoption of Industry 4.0 in Sustainable Food Supply Chain: A Circular Economy Perspective. Int. J. Product. Perform. Manag. 2022. [Google Scholar] [CrossRef]

- Adams, D.; Donovan, J.; Topple, C. Achieving Sustainability in Food Manufacturing Operations and Their Supply Chains: Key Insights from a Systematic Literature Review. Sustain. Prod. Consum. 2021, 28, 1491–1499. [Google Scholar] [CrossRef]

- Haji, M.; Kerbache, L.; Muhammad, M.; Al-Ansari, T. Roles of Technology in Improving Perishable Food Supply Chains. Logist.-Basel 2020, 4, 33. [Google Scholar] [CrossRef]

- Qian, J.; Ruiz-Garcia, L.; Fan, B.; Villalba, J.I.R.; McCarthy, U.; Zhang, B.; Yu, Q.; Wu, W. Food Traceability System from Governmental, Corporate, and Consumer Perspectives in the European Union and China: A Comparative Review. Trends Food Sci. Technol. 2020, 99, 402–412. [Google Scholar] [CrossRef]

- Oruma, S.O.; Misra, S.; Fernandez-Sanz, L. Agriculture 4.0: An Implementation Framework for Food Security Attainment in Nigeria’s Post-Covid-19 Era. IEEE Access 2021, 9, 83592–83627. [Google Scholar] [CrossRef]

- Kazancoglu, Y.; Ozbiltekin-Pala, M.; Sezer, M.D.; Luthra, S.; Kumar, A. Resilient Reverse Logistics with Blockchain Technology in Sustainable Food Supply Chain Management during COVID-19. Bus. Strategy Environ. 2022. [Google Scholar] [CrossRef]

- Barbosa, M.W. Uncovering Research Streams on Agri-Food Supply Chain Management: A Bibliometric Study. Glob. Food Secur. 2021, 28, 100517. [Google Scholar] [CrossRef]

- Mendi, A.F. Blockchain for Food Tracking. Electronics 2022, 11, 2491. [Google Scholar] [CrossRef]

- Wünsche, J.F.; Fernqvist, F. The Potential of Blockchain Technology in the Transition Towards Sustainable Food Systems. Sustain. Switz. 2022, 14, 7739. [Google Scholar] [CrossRef]

- Dayioglu, M.A.; Turker, U. Digital Transformation for Sustainable Future—Agriculture 4.0: A Review. J. Agric. Sci.-Tarim Bilim. Derg. 2021, 27, 373–399. [Google Scholar] [CrossRef]

- Lin, S.-Y.; Zhang, L.; Li, J.; Ji, L.; Sun, Y. A Survey of Application Research Based on Blockchain Smart Contract. Wirel. Netw. 2022, 28, 635–690. [Google Scholar] [CrossRef]

- Rejeb, A.; Keogh, J.G.; Zailani, S.; Treiblmaier, H.; Rejeb, K. Blockchain Technology in the Food Industry: A Review of Potentials, Challenges and Future Research Directions. Logistics 2020, 4, 27. [Google Scholar] [CrossRef]

- Ekawati, R.; Arkeman, Y.; Suprihatin; Sunarti, T.C. Proposed Design of White Sugar Industrial Supply Chain System Based on Blockchain Technology. Int. J. Adv. Comput. Sci. Appl. 2021, 12, 459–465. [Google Scholar] [CrossRef]

- Ali, M.H.; Chung, L.; Kumar, A.; Zailani, S.; Tan, K.H. A Sustainable Blockchain Framework for the Halal Food Supply Chain: Lessons from Malaysia. Technol. Forecast. Soc. Chang. 2021, 170, 120870. [Google Scholar] [CrossRef]

- Bechtsis, D.; Tsolakis, N.; Iakovou, E.; Vlachos, D. Data-Driven Secure, Resilient and Sustainable Supply Chains: Gaps, Opportunities, and a New Generalised Data Sharing and Data Monetisation Framework. Int. J. Prod. Res. 2022, 60, 4397–4417. [Google Scholar] [CrossRef]

- Kayikci, Y.; Usar, D.D.; Aylak, B.L. Using Blockchain Technology to Drive Operational Excellence in Perishable Food Supply Chains during Outbreaks. Int. J. Logist. Manag. 2022, 33, 836–876. [Google Scholar] [CrossRef]

- Rana, R.L.; Tricase, C.; De Cesare, L. Blockchain Technology for a Sustainable Agri-Food Supply Chain. Br. Food J. 2021, 123, 3471–3485. [Google Scholar] [CrossRef]

- Kumar, A.; Srivastava, S.K.; Singh, S. How Blockchain Technology Can Be a Sustainable Infrastructure for the Agrifood Supply Chain in Developing Countries. J. Glob. Oper. Strateg. Sourc. 2022, 15, 380–405. [Google Scholar] [CrossRef]

- Joo, J.; Han, Y. An Evidence of Distributed Trust in Blockchain-Based Sustainable Food Supply Chain. Sustainability 2021, 13, 10980. [Google Scholar] [CrossRef]

- Tsolakis, N.; Niedenzu, D.; Simonetto, M.; Dora, M.; Kumar, M. Supply Network Design to Address United Nations Sustainable Development Goals: A Case Study of Blockchain Implementation in Thai Fish Industry. J. Bus. Res. 2021, 131, 495–519. [Google Scholar] [CrossRef]

- Kramer, M.P.; Bitsch, L.; Hanf, J. Blockchain and Its Impacts on Agri-Food Supply Chain Network Management. Sustainability 2021, 13, 2168. [Google Scholar] [CrossRef]

- Phua, C.; Andradi-Brown, D.A.; Mangubhai, S.; Ahmadia, G.N.; Mahajan, S.L.; Larsen, K.; Friel, S.; Reichelt, R.; Hockings, M.; Gill, D. Marine Protected and Conserved Areas in the Time of COVID. Parks 2021, 27, 85–102. [Google Scholar] [CrossRef]

- Amentae, T.K.; Gebresenbet, G. Digitalization and Future Agro-Food Supply Chain Management: A Literature-Based Implications. Sustain. Switz. 2021, 13, 12181. [Google Scholar] [CrossRef]

- Mercuri, F.; della Corte, G.; Ricci, F. Blockchain Technology and Sustainable Business Models: A Case Study of Devoleum. Sustain. Switz. 2021, 13, 5619. [Google Scholar] [CrossRef]

- Jo, J.; Yi, S.; Lee, E. Including the Reefer Chain into Genuine Beef Cold Chain Architecture Based on Blockchain Technology. J. Clean. Prod. 2022, 363, 132646. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Z.; Liang, Y. Research on the Three-in-One Model of Agricultural Products E-Commerce Logistics under the Combination of Resource Saving and Blockchain Technology. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 677, p. 032111. [Google Scholar] [CrossRef]

- Bager, S.L.; Singh, C.; Persson, U.M. Blockchain is not a silver bullet for agro-food supply chain sustainability: Insights from a coffee case study. Curr. Res. Environ. Sustain. 2022, 4, 100163. [Google Scholar] [CrossRef]

- Griffin, T.W.; Harris, K.D.; Ward, J.K.; Goeringer, P.; Richard, J.A. Three Digital Agriculture Problems in Cotton Solved by Distributed Ledger Technology. Appl. Econ. Perspect. Policy 2022, 44, 237–252. [Google Scholar] [CrossRef]

- Fakkhong, K.; Rangsaritvorakarn, N.; Tantitecha, C. Using Blockchain Technology for a Sustainable Agri-Food Supply Chain in Thailand. In Proceedings of the 2022 International Conference on Decision Aid Sciences and Applications, DASA 2022, Chiangrai, Thailand, 23–25 March 2022; pp. 1783–1786. [Google Scholar] [CrossRef]

- Vlachopoulou, M.; Ziakis, C.; Vergidis, K.; Madas, M. Analyzing AgriFood-Tech e-Business Models. Sustainability 2021, 13, 5516. [Google Scholar] [CrossRef]

- Friedman, N.; Ormiston, J. Blockchain as a Sustainability-Oriented Innovation?: Opportunities for and Resistance to Blockchain Technology as a Driver of Sustainability in Global Food Supply Chains. Technol. Forecast. Soc. Chang. 2021, 175, 121403. [Google Scholar] [CrossRef]

- Mangla, S.K.; Kazançoğlu, Y.; Yıldızbaşı, A.; Öztürk, C.; Çalık, A. A Conceptual Framework for Blockchain-Based Sustainable Supply Chain and Evaluating Implementation Barriers: A Case of the Tea Supply Chain. Bus. Strategy Environ. 2022, 31, 3693–3716. [Google Scholar] [CrossRef]

- Han, J.-W.; Zuo, M.; Zhu, W.-Y.; Zuo, J.-H.; Lu, E.-L.; Yang, X.-T. A Comprehensive Review of Cold Chain Logistics for Fresh Agricultural Products: Current Status, Challenges, and Future Trends. Trends Food Sci. Technol. 2021, 109, 536–551. [Google Scholar] [CrossRef]

- Samoggia, A.; Beyhan, Z. Fairness-Enabling Practices in Agro-Food Chain. Sustainability 2022, 14, 6391. [Google Scholar] [CrossRef]

- Motta, G.A.; Tekinerdogan, B.; Athanasiadis, I.N. Blockchain Applications in the Agri-Food Domain: The First Wave. Front. Blockchain 2020, 3, 6. [Google Scholar] [CrossRef]

- Kohler, S.; Pizzol, M. Technology Assessment of Blockchain-Based Technologies in the Food Supply Chain. J. Clean. Prod. 2020, 269, 122193. [Google Scholar] [CrossRef]

- Varavallo, G.; Caragnano, G.; Bertone, F.; Vernetti-Prot, L.; Terzo, O. Traceability Platform Based on Green Blockchain: An Application Case Study in Dairy Supply Chain. Sustainability 2022, 14, 3321. [Google Scholar] [CrossRef]

- Mirabelli, G.; Solina, V. Blockchain-Based Solutions for Agri-Food Supply Chains: A Survey. Int. J. Simul. Process Model. 2021, 17, 1–15. [Google Scholar] [CrossRef]

- Bager, S.L.; Dudder, B.; Henglein, F.; Hebert, J.M.; Wu, H. Event-Based Supply Chain Network Modeling: Blockchain for Good Coffee. Front. Blockchain 2022, 5, 846783. [Google Scholar] [CrossRef]

- Durrant, A.; Markovic, M.; Matthews, D.; May, D.; Leontidis, G.; Enright, J. How Might Technology Rise to the Challenge of Data Sharing in Agri-Food? Glob. Food Secur. 2021, 28, 100493. [Google Scholar] [CrossRef]

- Rünzel, M.A.; Hassler, E.E.; Rogers, R.E.; Formato, G.; Cazier, J.A. Designing a Smart Honey Supply Chain for Sustainable Development. IEEE Consum. Electron. Mag. 2021, 10, 69–78. [Google Scholar] [CrossRef]

- Dos Santos, R.B.; Torrisi, N.M.; Pantoni, R.P. Third Party Certification of Agri-Food Supply Chain Using Smart Contracts and Blockchain Tokens. Sensors 2021, 21, 5307. [Google Scholar] [CrossRef]

- Kaur, H. Modelling Internet of Things Driven Sustainable Food Security System. Benchmarking- Int. J. 2021, 28, 1740–1760. [Google Scholar] [CrossRef]

- Niu, B.; Shen, Z.; Xie, F. The Value of Blockchain and Agricultural Supply Chain Parties’ Participation Confronting Random Bacteria Pollution. J. Clean. Prod. 2021, 319, 128579. [Google Scholar] [CrossRef]

- Qian, J.; Wu, W.; Yu, Q.; Ruiz-Garcia, L.; Xiang, Y.; Jiang, L.; Shi, Y.; Duan, Y.; Yang, P. Filling the Trust Gap of Food Safety in Food Trade between the EU and China: An Interconnected Conceptual Traceability Framework Based on Blockchain. Food Energy Secur. 2020, 9, e249. [Google Scholar] [CrossRef]

- Astill, J.; Dara, R.A.; Campbell, M.; Farber, J.M.; Fraser, E.D.G.; Sharif, S.; Yada, R.Y. Transparency in Food Supply Chains: A Review of Enabling Technology Solutions. Trends Food Sci. Technol. 2019, 91, 240–247. [Google Scholar] [CrossRef]

- Galanakis, C.M.; Rizou, M.; Aldawoud, T.M.S.; Ucak, I.; Rowan, N.J. Innovations and Technology Disruptions in the Food Sector within the COVID-19 Pandemic and Post-Lockdown Era. Trends Food Sci. Technol. 2021, 110, 193–200. [Google Scholar] [CrossRef]

- Anastasiadis, F.; Manikas, I.; Apostolidou, I.; Wahbeh, S. The Role of Traceability in End-to-End Circular Agri-Food Supply Chains. Ind. Mark. Manag. 2022, 104, 196–211. [Google Scholar] [CrossRef]

- Lin, K.; Chavalarias, D.; Panahi, M.; Yeh, T.; Takimoto, K.; Mizoguchi, M. Mobile-Based Traceability System for Sustainable Food Supply Networks. Nat. Food 2020, 1, 673–679. [Google Scholar] [CrossRef]

- Liu, W.; Shao, X.-F.; Wu, C.-H.; Qiao, P. A Systematic Literature Review on Applications of Information and Communication Technologies and Blockchain Technologies for Precision Agriculture Development. J. Clean. Prod. 2021, 298, 126763. [Google Scholar] [CrossRef]

- Ada, N.; Kazancoglu, Y.; Sezer, M.D.; Ede-Senturk, C.; Ozer, I.; Ram, M. Analyzing Barriers of Circular Food Supply Chains and Proposing Industry 4.0 Solutions. Sustainability 2021, 13, 6812. [Google Scholar] [CrossRef]

- Smetana, S.; Aganovic, K.; Heinz, V. Food Supply Chains as Cyber-Physical Systems: A Path for More Sustainable Personalized Nutrition. Food Eng. Rev. 2021, 13, 92–103. [Google Scholar] [CrossRef]

- Duan, J.; Zhang, C.; Gong, Y.; Brown, S.; Li, Z. A Content-Analysis Based Literature Review in Blockchain Adoption within Food Supply Chain. Int. J. Environ. Res. Public. Health 2020, 17, 1784. [Google Scholar] [CrossRef]

- della Corte, G.; Ricci, F.; Modaffari, G.; Scafarto, V. Blockchain as a Strategic Enabler of Agri-Food Sustainability. In Proceedings of the 2021 IEEE International Conference on Technology Management, Operations and Decisions (ICTMOD), Marrakech, Morocco, 24–26 November 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Bansal, L.; Chaurasia, S.; Sabharwal, M.; Vij, M. Blockchain Integration with End-to-End Traceability in the Food Supply Chain. In Proceedings of the 2022 2nd International Conference on Advance Computing and Innovative Technologies in Engineering, ICACITE 2022, Greater Noida, India, 28–29 April 2022; pp. 1152–1156. [Google Scholar] [CrossRef]

- Kraft, S.K.; Kellner, F. Can Blockchain Be a Basis to Ensure Transparency in an Agricultural Supply Chain? Sustain. Switz. 2022, 14, 8044. [Google Scholar] [CrossRef]

- Leduc, G.; Kubler, S.; Georges, J.-P. Innovative Blockchain-Based Farming Marketplace and Smart Contract Performance Evaluation. J. Clean. Prod. 2021, 306, 127055. [Google Scholar] [CrossRef]

- Song, L.; Luo, Y.; Chang, Z.; Jin, C.; Nicolas, M. Blockchain Adoption in Agricultural Supply Chain for Better Sustainability: A Game Theory Perspective. Sustainability 2022, 14, 1470. [Google Scholar] [CrossRef]

- Nayal, K.; Raut, R.D.; Narkhede, B.E.; Priyadarshinee, P.; Panchal, G.B.; Gedam, V.V. Antecedents for Blockchain Technology-Enabled Sustainable Agriculture Supply Chain. Ann. Oper. Res. 2021, 1–45. [Google Scholar] [CrossRef]

- Remondino, M.; Zanin, A. Logistics and Agri-Food: Digitization to Increase Competitive Advantage and Sustainability. Literature Review and the Case of Italy. Sustain. Switz. 2022, 14, 787. [Google Scholar] [CrossRef]

- Morales, M.L.V.; Elkader, M.A.A. Logistics 4.0 Technologies in Agriculture Systems: Potential Impacts in the Sdg. In Proceedings of the Towards the Digital World and Industry X.0—Proceedings of the 29th International Conference of the International Association for Management of Technology, IAMOT 2020; Pretorius, L.P.M.W., Ed.; University of Pretoria: Pretoria, South Africa, 2020; pp. 976–989. [Google Scholar]

- Sharma, R.; Samad, T.A.; Jabbour, C.J.C.; de Queiroz, M.J. Leveraging Blockchain Technology for Circularity in Agricultural Supply Chains: Evidence from a Fast-Growing Economy. J. Enterp. Inf. Manag. 2021. [Google Scholar] [CrossRef]

- Bai, C.; Quayson, M.; Sarkis, J. Analysis of Blockchain’s Enablers for Improving Sustainable Supply Chain Transparency in Africa Cocoa Industry. J. Clean. Prod. 2022, 358, 131896. [Google Scholar] [CrossRef]

- Luzzani, G.; Grandis, E.; Frey, M.; Capri, E. Blockchain Technology in Wine Chain for Collecting and Addressing Sustainable Performance: An Exploratory Study. Sustain. Switz. 2021, 13, 12898. [Google Scholar] [CrossRef]

- Richter, B.; Hanf, J.H. Cooperatives in the Wine Industry: Sustainable Management Practices and Digitalisation. Sustainability 2021, 13, 5543. [Google Scholar] [CrossRef]

- Paul, T.; Mondal, S.; Islam, N.; Rakshit, S. The Impact of Blockchain Technology on the Tea Supply Chain and Its Sustainable Performance. Technol. Forecast. Soc. Chang. 2021, 173, 121163. [Google Scholar] [CrossRef]

- Mangla, S.K.; Kazancoglu, Y.; Ekinci, E.; Liu, M.; Ozbiltekin, M.; Sezer, M.D. Using System Dynamics to Analyze the Societal Impacts of Blockchain Technology in Milk Supply Chainsrefer. Transp. Res. Part E-Logist. Transp. Rev. 2021, 149, 102289. [Google Scholar] [CrossRef]

- Howson, P. Building Trust and Equity in Marine Conservation and Fisheries Supply Chain Management with Blockchain. Mar. Policy 2020, 115, 103873. [Google Scholar] [CrossRef]

- Rowan, N.J. The Role of Digital Technologies in Supporting and Improving Fishery and Aquaculture across the Supply Chain–Quo Vadis? Aquac. Fish. 2022, in press. [Google Scholar] [CrossRef]

- Arena, A.; Bianchini, A.; Perazzo, P.; Vallati, C.; Dini, G. BRUSCHETTA: An IoT Blockchain-Based Framework for Certifying Extra Virgin Olive Oil Supply Chain. In Proceedings of the 2019 IEEE International Conference on Smart Computing (Smartcomp 2019), Washington, DC, USA, 12–15 June 2019; pp. 173–179. [Google Scholar] [CrossRef]

- Violino, S.; Pallottino, F.; Sperandio, G.; Figorilli, S.; Antonucci, F.; Ioannoni, V.; Fappiano, D.; Costa, C. Are the Innovative Electronic Labels for Extra Virgin Olive Oil Sustainable, Traceable, and Accepted by Consumers? Foods 2019, 8, 529. [Google Scholar] [CrossRef]

- Vo, K.T.; Nguyen-Thi, A.-T.; Nguyen-Hoang, T.-A. Building Sustainable Food Supply Chain Management System Based On Hyperledger Fabric Blockchain. In Proceedings of the 2021 15th International Conference on Advanced Computing and Applications (Acomp 2021), Ho Chi Minh City, Vietnam, 24–26 November 2021; Le, L.S., Nguyen, H., Phan, T.A., Clavel, M., Dang, T.K., Eds.; pp. 9–16. [Google Scholar] [CrossRef]

- Feng, H.; Wang, X.; Duan, Y.; Zhang, J.; Zhang, X. Applying Blockchain Technology to Improve Agri-Food Traceability: A Review of Development Methods, Benefits and Challenges. J. Clean. Prod. 2020, 260, 121031. [Google Scholar] [CrossRef]

- Saurabh, S.; Dey, K. Blockchain Technology Adoption, Architecture, and Sustainable Agri-Food Supply Chains. J. Clean. Prod. 2020, 284, 124731. [Google Scholar] [CrossRef]

- Kittipanya-ngam, P.; Tan, K.H. A Framework for Food Supply Chain Digitalization: Lessons from Thailand. Prod. Plan. Control 2020, 31, 158–172. [Google Scholar] [CrossRef]

- Awan, S.; Ahmed, S.; Ullah, F.; Nawaz, A.; Khan, A.; Uddin, M.I.; Alharbi, A.; Alosaimi, W.; Alyami, H. IoT with BlockChain: A Futuristic Approach in Agriculture and Food Supply Chain. Wirel. Commun. Mob. Comput. 2021, 2021, 5580179. [Google Scholar] [CrossRef]

- Yadav, S.; Luthra, S.; Garg, D. Modelling Internet of Things (IoT)-Driven Global Sustainability in Multi-Tier Agri-Food Supply Chain under Natural Epidemic Outbreaks. Environ. Sci. Pollut. Res. 2021, 28, 16633–16654. [Google Scholar] [CrossRef] [PubMed]

- Rainero, C.; Modarelli, G. Food Tracking and Blockchain-Induced Knowledge: A Corporate Social Responsibility Tool for Sustainable Decision-Making. Br. Food J. 2021, 123, 4284–4308. [Google Scholar] [CrossRef]

- Benyam, A.; Soma, T.; Fraser, E. Digital Agricultural Technologies for Food Loss and Waste Prevention and Reduction: Global Trends, Adoption Opportunities and Barriers. J. Clean. Prod. 2021, 323, 129099. [Google Scholar] [CrossRef]

- Wang, B.; Luo, W.; Zhang, A.; Tian, Z.; Li, Z. Blockchain-Enabled Circular Supply Chain Management: A System Architecture for Fast Fashion. Comput. Ind. 2020, 123, 103324. [Google Scholar] [CrossRef]

- Tam, F.Y.; Lung, J.W. Impact of COVID-19 and Innovative Ideas for a Sustainable Fashion Supply Chain in the Future. Foresight, 2022; ahead-of-print. [Google Scholar] [CrossRef]

- Akram, S.V.; Malik, P.K.; Singh, R.; Gehlot, A.; Juyal, A.; Ghafoor, K.Z.; Shrestha, S. Implementation of Digitalized Technologies for Fashion Industry 4.0: Opportunities and Challenges. Sci. Program. 2022, 2022, 7523246. [Google Scholar] [CrossRef]

- Ahmed, W.A.H.; MacCarthy, B.L. Blockchain-Enabled Supply Chain Traceability in the Textile and Apparel Supply Chain: A Case Study of the Fiber Producer, Lenzing. Sustainability 2021, 13, 10496. [Google Scholar] [CrossRef]

- Abreu, A.; Afonso, A.P.; Freitas, J. Blockchain Towards Supply Chain Management. In Proceedings of the International Conference on Tourism, Technology and Systems, Cartagena, Colombia, 29–31 October 2020; pp. 396–407. [Google Scholar]

- Noonan, J.; Doran, P. Blockchain’s Impact on Consumer’s Perspective in the Luxury Fashion Industry: A Position Paper. Lect. Notes Comput. Sci. Subser. Lect. Notes Artif. Intell. Lect. Notes Bioinforma. 2021, 12896, 596–606. [Google Scholar] [CrossRef]

- Benstead, A.V.; Mwesiumo, D.; Moradlou, H.; Boffelli, A. Entering the World behind the Clothes That We Wear: Practical Applications of Blockchain Technology. Prod. Plan. Control 2022, 1–18. [Google Scholar] [CrossRef]

- Ribeiro, F.A.; Brito, M.A. Blockchain Technology Applications: Enhancing Fashion Supply Chain Sustainability. In Proceedings of the 2022 17th Iberian Conference on Information Systems and Technologies (CISTI), Madrid, Spain, 22–25 June 2022; pp. 1–4. [Google Scholar] [CrossRef]

- Caldarelli, G.; Zardini, A.; Rossignoli, C. Blockchain Adoption in the Fashion Sustainable Supply Chain: Pragmatically Addressing Barriers. J. Organ. Chang. Manag. 2021, 34, 507–524. [Google Scholar] [CrossRef]

- Agrawal, T.K.; Kumar, V.; Pal, R.; Wang, L.; Chen, Y. Blockchain-Based Framework for Supply Chain Traceability: A Case Example of Textile and Clothing Industry. Comput. Ind. Eng. 2021, 154, 107130. [Google Scholar] [CrossRef]

- Huynh, P.H. Enabling Circular Business Models in the Fashion Industry: The Role of Digital Innovation. Int. J. Product. Perform. Manag. 2021, 71, 870–895. [Google Scholar] [CrossRef]

- Guo, S.; Sun, X.; Lam, H.K.S. Applications of Blockchain Technology in Sustainable Fashion Supply Chains: Operational Transparency and Environmental Efforts. IEEE Trans. Eng. Manag. 2020, 1–17. [Google Scholar] [CrossRef]

- Oguntegbe, K.F.; Di Paola, N.; Vona, R. Communicating Responsible Management and the Role of Blockchain Technology: Social Media Analytics for the Luxury Fashion Supply Chain. TQM J. 2022. [Google Scholar] [CrossRef]

- Oguntegbe, K.F.; Di Paola, N.; Vona, R. Blockchain Technology, Social Capital and Sustainable Supply Chain Management. Sinergie 2021, 39, 163–188. [Google Scholar] [CrossRef]

- Nath, S.D.; Khayer, A.; Majumder, J.; Barua, S. Factors Affecting Blockchain Adoption in Apparel Supply Chains: Does Sustainability-Oriented Supplier Development Play a Moderating Role? Ind. Manag. Data Syst. 2022, 122, 1183–1214. [Google Scholar] [CrossRef]

- Choi, T.-M.; Luo, S. Data Quality Challenges for Sustainable Fashion Supply Chain Operations in Emerging Markets: Roles of Blockchain, Government Sponsors and Environment Taxes. Transp. Res. Part E-Logist. Transp. Rev. 2019, 131, 139–152. [Google Scholar] [CrossRef]

- Zhang, H. Blockchain Facilitates a Resilient Supply Chain in Steel Manufacturing under COVID-19. In Proceedings of the Proceedings of the 22nd European Conference on Knowledge Management (ECKM 2021); GarciaPerez, A., Simkin, L., Eds.; Acad Conferences Ltd.: Nr Reading, UK, 2021; pp. 964–972. [Google Scholar]

- Matenga, A.E.; Mpofu, K. Blockchain-Based Cloud Manufacturing SCM System for Collaborative Enterprise Manufacturing: A Case Study of Transport Manufacturing. Appl. Sci.-Basel 2022, 12, 8664. [Google Scholar] [CrossRef]

- Govindan, K. Tunneling the Barriers of Blockchain Technology in Remanufacturing for Achieving Sustainable Development Goals: A Circular Manufacturing Perspective. Bus. Strategy Environ. 2022, 31, 3769–3785. [Google Scholar] [CrossRef]

- Ko, T.; Lee, J.; Ryu, D. Blockchain Technology and Manufacturing Industry: Real-Time Transparency and Cost Savings. Sustainability 2018, 10, 4274. [Google Scholar] [CrossRef]

- Mubarik, M.; Rasi, R.Z.R.M.; Mubarak, M.F.; Ashraf, R. Impact of Blockchain Technology on Green Supply Chain Practices: Evidence from Emerging Economy. Manag. Environ. Qual. 2021, 32, 1023–1039. [Google Scholar] [CrossRef]

- Tan, C.L.; Tei, Z.; Yeo, S.F.; Lai, K.-H.; Kumar, A.; Chung, L. Nexus among Blockchain Visibility, Supply Chain Integration and Supply Chain Performance in the Digital Transformation Era. Ind. Manag. Data Syst. 2022; in press. [Google Scholar] [CrossRef]

- Fernando, Y.; Rozuar, N.H.M.; Mergeresa, F. The Blockchain-Enabled Technology and Carbon Performance: Insights from Early Adopters. Technol. Soc. 2021, 64, 101507. [Google Scholar] [CrossRef]

- Sun, Y.; Shahzad, M.; Razzaq, A. Sustainable Organizational Performance through Blockchain Technology Adoption and Knowledge Management in China. J. Innov. Knowl. 2022, 7, 100247. [Google Scholar] [CrossRef]

- Chidepatil, A.; Bindra, P.; Kulkarni, D.; Qazi, M.; Kshirsagar, M.; Sankaran, K. From Trash to Cash: How Blockchain and Multi-Sensor-Driven Artificial Intelligence Can Transform Circular Economy of Plastic Waste? Adm. Sci. 2020, 10, 23. [Google Scholar] [CrossRef]

- Ghimire, T.; Joshi, A.; Sen, S.; Kapruan, C.; Chadha, U.; Selvaraj, S.K. Blockchain in Additive Manufacturing Processes: Recent Trends&Its Future Possibilities. In Proceedings of the Materials Today-Proceedings; Elsevier: Amsterdam, The Netherlands, 2021; Volume 50, pp. 2170–2180. [Google Scholar]

- Han, X.; Rani, P. Evaluate the Barriers of Blockchain Technology Adoption in Sustainable Supply Chain Management in the Manufacturing Sector Using a Novel Pythagorean Fuzzy-CRITIC-CoCoSo Approach. Oper. Manag. Res. 2022, 15, 725–742. [Google Scholar] [CrossRef]

- Zhang, F.; Gu, Y. Approach to an Equivalent Freight-Based Sustainable Joint-Quotation Strategy for Shipping Blockchain Alliance. Sustainability 2022, 14, 10441. [Google Scholar] [CrossRef]

- Henriquez, R.; Martinez De Oses, R.X.; Martinez Marin, J.E. Dlt-Based Sustainable Business Models for The Shipping Industry. Int. J. Transp. Econ. 2021, 48, 433–454. [Google Scholar] [CrossRef]

- Bae, H. The Interaction Effect of Information Systems of Shipping and Logistics Firms and Managers’ Support for Blockchain Technology on Cooperation with Shippers for Sustainable Value Creation. Sustainability 2021, 13, 4493. [Google Scholar] [CrossRef]

- Wong, S.; Yeung, J.-K.-W.; Lau, Y.-Y.; So, J. Technical Sustainability of Cloud-Based Blockchain Integrated with Machine Learning for Supply Chain Management. Sustainability 2021, 13, 8270. [Google Scholar] [CrossRef]

- Philipp, R.; Prause, G.; Gerlitz, L. Blockchain and Smart Contracts for Entrepreneurial Collaboration in Maritime Supply Chains. Transp. Telecommun. 2019, 20, 365–378. [Google Scholar] [CrossRef]

- Tan, W.K.A.; Sundarakani, B. Assessing Blockchain Technology Application for Freight Booking Business: A Case Study from Technology Acceptance Model Perspective. J. Glob. Oper. Strateg. Sourc. 2020, 14, 202–223. [Google Scholar] [CrossRef]

- Vujicic, S.; Hasanspahic, N.; Car, M.; Campara, L. Distributed Ledger Technology as a Tool for Environmental Sustainability in the Shipping Industry. J. Mar. Sci. Eng. 2020, 8, 366. [Google Scholar] [CrossRef]

- Jovic, M.; Tijan, E.; Zgaljic, D.; Aksentijevic, S. Improving Maritime Transport Sustainability Using Blockchain-Based Information Exchange. Sustainability 2020, 12, 8866. [Google Scholar] [CrossRef]

- Gong, Y.; Wang, Y.; Frei, R.; Wang, B.; Zhao, C. Blockchain Application in Circular Marine Plastic Debris Management. Ind. Mark. Manag. 2022, 102, 164–176. [Google Scholar] [CrossRef]

- Nguyen, S.; Chen, P.S.-L.; Du, Y. Risk Assessment of Maritime Container Shipping Blockchain-Integrated Systems: An Analysis of Multi-Event Scenarios. Transp. Res. Part E-Logist. Transp. Rev. 2022, 163, 102764. [Google Scholar] [CrossRef]

- Kazancoglu, I.; Ozbiltekin-Pala, M.; Mangla, S.K.; Kumar, A.; Kazancoglu, Y. Using Emerging Technologies to Improve the Sustainability and Resilience of Supply Chains in a Fuzzy Environment in the Context of COVID-19. Ann. Oper. Res. 2022, 1–24. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Tatge, L.; Xu, X.; Liu, Y. Blockchain Applications in the Supply Chain Management in German Automotive Industry. Prod. Plan. Control 2022, 1–15. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Subramanian, N.; Ghadge, A.; Belhadi, A.; Venkatesh, M. Blockchain Technology’s Impact on Supply Chain Integration and Sustainable Supply Chain Performance: Evidence from the Automotive Industry. Ann. Oper. Res. 2021, 1–26. [Google Scholar] [CrossRef]

- Yu, Z.; Umar, M.; Rehman, S.A. Adoption of Technological Innovation and Recycling Practices in Automobile Sector: Under the COVID-19 Pandemic. Oper. Manag. Res. 2022, 15, 298–306. [Google Scholar] [CrossRef]

- Rizvi, S.W.H.; Agrawal, S.; Murtaza, Q. Circularity Issues and Blockchain Technology in the Auto Industry. Energy Sources Part -Recovery Util. Environ. Eff. 2022, 44, 7132–7144. [Google Scholar] [CrossRef]

- Zhang, H.; Li, S.; Yan, W.; Jiang, Z.; Wei, W. A Knowledge Sharing Framework for Green Supply Chain Management Based on Blockchain and Edge Computing. Smart Innov. Syst. Technol. 2019, 155, 413–420. [Google Scholar] [CrossRef]

- Ghadge, A.; Mogale, D.G.; Bourlakis, M.; Maiyar, L.M.; Moradlou, H. Link between Industry 4.0 and Green Supply Chain Management: Evidence from the Automotive Industry. Comput. Ind. Eng. 2022, 169, 108303. [Google Scholar] [CrossRef]

- Ada, N.; Ethirajan, M.; Kumar, A.; Vimal, K.E.K.; Nadeem, S.P.; Kazancoglu, Y.; Kandasamy, J. Blockchain Technology for Enhancing Traceability and Efficiency in Automobile Supply Chain—A Case Study. Sustain. Switz. 2021, 13, 13667. [Google Scholar] [CrossRef]

- Alptekin, B.; Tunaboylu, B.; Zaim, S.; Perlo, P. Smart Manufacturing of Electric Vehicles. Lect. Notes Mech. Eng. 2020, 767–773. [Google Scholar] [CrossRef]

- Vishwakarma, A.; Dangayach, G.S.; Meena, M.L.; Gupta, S.; Luthra, S. Adoption of Blockchain Technology Enabled Healthcare Sustainable Supply Chain to Improve Healthcare Supply Chain Performance. Manag. Environ. Qual. Int. J. 2022; ahead-of-print. [Google Scholar] [CrossRef]

- Wang, B.; Lin, Z.; Wang, M.; Wang, F.; Xiangli, P.; Li, Z. Applying Blockchain Technology to Ensure Compliance with Sustainability Standards in the PPE Multi-Tier Supply Chain. Int. J. Prod. Res. 2022, 1–17. [Google Scholar] [CrossRef]

- Bhaskar, S.; Tan, J.; Bogers, M.L.A.M.; Minssen, T.; Badaruddin, H.; Israeli-Korn, S.; Chesbrough, H. At the Epicenter of COVID-19-the Tragic Failure of the Global Supply Chain for Medical Supplies. Front. Public Health 2020, 8, 562882. [Google Scholar] [CrossRef]

- Rahman, T.; Moktadir, M.A.; Paul, S.K. Key Performance Indicators for a Sustainable Recovery Strategy in Health-Care Supply Chains: COVID-19 Pandemic Perspective. J. Asia Bus. Stud. 2021, 16, 472–494. [Google Scholar] [CrossRef]

- Kuberkar, S.; Singhal, T.K. Factors Influencing the Adoption Intention of Blockchain and Internet-of-Things Technologies for Sustainable Blood Bank Management. Int. J. Healthc. Inf. Syst. Inform. 2021, 16, 1–21. [Google Scholar] [CrossRef]

- Alharthi, S.; Cerotti, P.; Far, S.M. The Impact of Blockchain Implementation on Pharmaceutical Supply Chain Sustainability: A Conceptual Study. In Proceedings of the Education Excellence and Innovation Management: A 2025 Vision to Sustain Economic Development During Global Challenges; Soliman, K.S., Ed.; Int Business Information Management Assoc-Ibima: Norristown, PA, USA, 2020; pp. 9231–9252. [Google Scholar]

- Hastig, G.M.; Sodhi, M.S. Blockchain for Supply Chain Traceability: Business Requirements and Critical Success Factors. Prod. Oper. Manag. 2020, 29, 935–954. [Google Scholar] [CrossRef]

- Sylim, P.; Liu, F.; Marcelo, A.; Fontelo, P. Blockchain Technology for Detecting Falsified and Substandard Drugs in Distribution: Pharmaceutical Supply Chain Intervention. Jmir Res. Protoc. 2018, 7, e10163. [Google Scholar] [CrossRef]

- Mugurusi, G.; Ahishakiye, E. Blockchain Technology Needs for Sustainable Mineral Supply Chains: A Framework for Responsible Sourcing of Cobalt. In Proceedings of the Procedia Computer Science; Longo, F., Affenzeller, M.P.A., Eds.; Elsevier B.V.: Amsterdam, The Netherlands, 2022; Volume 200, pp. 638–647. [Google Scholar]

- Kshetri, N. Blockchain Systems and Ethical Sourcing in the Mineral and Metal Industry: A Multiple Case Study. Int. J. Logist. Manag. 2022, 33, 1–27. [Google Scholar] [CrossRef]

- Deberdt, R.; Le Billon, P. Conflict Minerals and Battery Materials Supply Chains: A Mapping Review of Responsible Sourcing Initiatives. Extr. Ind. Soc.-Int. J. 2021, 8, 100935. [Google Scholar] [CrossRef]

- Calvao, F.; Archer, M. Digital Extraction: Blockchain Traceability in Mineral Supply Chains. Polit. Geogr. 2021, 87, 102381. [Google Scholar] [CrossRef]

- Liu, J.; Li, J.; Wang, J.; Uddin, M.M.; Zhang, B. Research on the Application of Blockchain Technology in Coal Supply Chain Finance. Sustainability 2022, 14, 10099. [Google Scholar] [CrossRef]

- Batwa, A.; Norrman, A.; Arvidsson, A. How Blockchain Interrelates with Trust in the Supply Chain Context: Insights from Tracing Sustainability in the Metal Industry. In Proceedings of the Proceedings of the Hamburg International Conference of Logistics; Kersten, W., Ringle, C.M.B.T., Eds.; Institute of Business Logistics and General Management, Hamburg University of Technology: Hamburg, Germany, 2021; Volume 31, pp. 329–351. [Google Scholar]

- Wu, Y.; Wu, Y.; Cimen, H.; Vasquez, J.C.; Guerrero, J.M. Towards Collective Energy Community: Potential Roles of Microgrid and Blockchain to Go beyond P2P Energy Trading. Appl. Energy 2022, 314, 119003. [Google Scholar] [CrossRef]

- Mangina, E.; Narasimhan, P.K.; Saffari, M.; Vlachos, I. Data Analytics for Sustainable Global Supply Chains. J. Clean. Prod. 2020, 255, 120300. [Google Scholar] [CrossRef]

- Almutairi, K.; Hosseini Dehshiri, S.J.; Hosseini Dehshiri, S.S.; Hoa, A.X.; Arockia Dhanraj, J.; Mostafaeipour, A.; Issakhov, A.; Techato, K. Blockchain Technology Application Challenges in Renewable Energy Supply Chain Management. Environ. Sci. Pollut. Res. 2022, 1–18. [Google Scholar] [CrossRef] [PubMed]

- Zhu, S.; Song, M.; Lim, M.K.; Wang, J.; Zhao, J. The Development of Energy Blockchain and Its Implications for China’s Energy Sector. Resour. Policy 2020, 66, 101595. [Google Scholar] [CrossRef]

- Park, L.W.; Lee, S.; Chang, H. A Sustainable Home Energy Prosumer-Chain Methodology with Energy Tags over the Blockchain. Sustainability 2018, 10, 658. [Google Scholar] [CrossRef]

- Schletz, M.; Cardoso, A.; Prata Dias, G.; Salomo, S. How Can Blockchain Technology Accelerate Energy Efficiency Interventions? A Use Case Comparison. Energies 2020, 13, 5869. [Google Scholar] [CrossRef]

- Tayal, A.; Solanki, A.; Kondal, R.; Nayyar, A.; Tanwar, S.; Kumar, N. Blockchain-Based Efficient Communication for Food Supply Chain Industry: Transparency and Traceability Analysis for Sustainable Business. Int. J. Commun. Syst. 2021, 34, e4696. [Google Scholar] [CrossRef]

- Ma, X.; Zhang, Q. Tracing Information for Agricultural Product and Identifying Key Regulatory Decisions towards Eco-Economics Sustainability. Math. Probl. Eng. 2022, 2022, 8142802. [Google Scholar] [CrossRef]

- Sharma, M.; Joshi, S.; Luthra, S.; Kumar, A. Managing Disruptions and Risks amidst COVID-19 Outbreaks: Role of Blockchain Technology in Developing Resilient Food Supply Chains. Oper. Manag. Res. 2022, 15, 268–281. [Google Scholar] [CrossRef]

- Yadav, S.; Singh, S.P. An Integrated Fuzzy-ANP and Fuzzy-ISM Approach Using Blockchain for Sustainable Supply Chain. J. Enterp. Inf. Manag. 2021, 34, 54–78. [Google Scholar] [CrossRef]

- Botelho, A.; Silva, I.R.; Ribeiro, L.; Lopes, M.S.; Au-Yong-Oliveira, M. Improving Food Transparency through Innovation and Blockchain Technology. In Proceedings of the European Conference on Innovation and Entrepreneurship, ECIE; De Nisco, A., Ed.; Academic Conferences and Publishing International Limited: Reading, UK, 2020; pp. 128–136. [Google Scholar]

- Rogerson, M.; Parry, G.C. Blockchain: Case Studies in Food Supply Chain Visibility. Supply Chain Manag.-Int. J. 2020, 25, 601–614. [Google Scholar] [CrossRef]

- Violino, S.; Pallottino, F.; Sperandio, G.; Figorilli, S.; Ortenzi, L.; Tocci, F.; Vasta, S.; Imperi, G.; Costa, C. A Full Technological Traceability System for Extra Virgin Olive Oil. Foods 2020, 9, 624. [Google Scholar] [CrossRef]

- Yadav, V.S.; Singh, A.R.; Raut, R.D.; Mangla, S.K.; Luthra, S.; Kumar, A. Exploring the Application of Industry 4.0 Technologies in the Agricultural Food Supply Chain: A Systematic Literature Review. Comput. Ind. Eng. 2022, 169, 108304. [Google Scholar] [CrossRef]

- Alves, L.; Ferreira Cruz, E.; Lopes, S.I.; Faria, P.M.; Rosado da Cruz, A.M. Towards Circular Economy in the Textiles and Clothing Value Chain through Blockchain Technology and IoT: A Review. Waste Manag. Res. 2022, 40, 3–23. [Google Scholar] [CrossRef]

- Carrieres, V.; Lemieux, A.-A.; Pellerin, R. Opportunities of Blockchain Traceability Data for Environmental Impact Assessment in a Context of Sustainable Production. In Advances in Production Management Systems: Artificial Intelligence for Sustainable and Resilient Production Systems, Apms 2021, Pt I.; Dolgui, A., Bernard, A., Lemoine, D., VonCieminski, G., Romero, D., Eds.; Springer International Publishing Ag: Cham, Switzerland, 2021; Volume 630, pp. 124–133. ISBN 978-3-030-85874-2. [Google Scholar]

- Mubarik, M.; Mubarak, M.F. Fostering Supply Chain Integration through Blockchain Technology: A Study of Malaysian Manufacturing Sector. Int. J. Manag. Sustain. 2020, 9, 135–147. [Google Scholar] [CrossRef]

| Description | Results |

|---|---|

| Period | 2017–September 2022 |

| Publications | 552 |

| Sources | 272 |

| Annual growth rate % | 152.19 |

| Average citations per publication | 19 |

| Authors | 1600 |

| Authors of single-authored publication | 40 |

| Document types: | |

| article | 316 |

| article; early access | 47 |

| article; proceedings paper | 3 |

| conference paper | 62 |

| proceedings paper | 40 |

| review | 72 |

| review; early access | 12 |

| Year | Publications |

|---|---|

| 2017 | 2 |

| 2018 | 8 |

| 2019 | 50 |

| 2020 | 109 |

| 2021 | 179 |

| 2022 | 204 |

| Author | Title | Total Citations |

|---|---|---|

| Saberi et al. [76] | Blockchain technology and its relationships to sustainable supply chain management | 988 (Scopus) 829 (WoS) |

| Kshetri [77] | Blockchain’s roles in meeting key supply chain management objectives | 732 (Scopus) |

| Hughes et al. [78] | Blockchain research, practice and policy: Applications, benefits, limitations, emerging research themes and research agenda | 287 (Scopus) |

| Kamble et al. [79] | Modeling the blockchain enabled traceability in agriculture supply chain | 270 (Scopus) |

| Kamble et al. [80] | Achieving sustainable performance in a data-driven agriculture supply chain: A review for research and applications | 255 (Scopus) |

| Industry | Number of Publications |

|---|---|

| Food and Agriculture | 115 |

| Fashion, Textile, and Apparel | 18 |

| Manufacturing | 12 |

| Maritime and Shipping | 10 |

| Automotive | 9 |

| Healthcare and Pharmaceutical | 8 |

| Mining and Mineral | 7 |

| Energy | 6 |

| Total | 185 |

| Industry | Categories | F | Publications |

|---|---|---|---|

| Food and Agriculture | Methods | ||

| Quantitative | 31 | [31,43,79,97,109,114,118,123,125,129,136,142,151,160,161,165,167,175,176,179,180,181,183,188,191,194,263,264,265,266] | |

| Qualitative | 8 | [109,121,129,148,182,195,267,268] | |

| Proposal (model, architecture, etc.) | 24 | [79,100,102,103,112,125,128,130,135,146,147,158,159,162,166,172,173,174,187,189,190,191,193,269] | |

| Case Study | 28 | [42,77,101,110,111,115,126,131,132,133,137,138,139,141,144,146,149,152,153,154,156,177,181,184,185,187,192,267] | |

| Literature Review | 47 | [42,43,79,95,96,98,99,104,105,106,107,108,110,113,115,116,117,119,120,122,127,129,132,133,134,137,138,140,143,145,146,150,155,157,163,164,168,169,170,171,177,178,186,190,196,267,270] | |

| Theories | |||

| Critical Success Factors Theory | 1 | [263] | |

| Cumulative Prospect Theory | 1 | [31] | |

| Game Theory | 2 | [161,175] | |

| Technology, Organization, Environment Theory | 2 | [176,180] | |

| Unified Theory of Acceptance and Use of Technology | 1 | [176] | |

| E-CAOS Model | 1 | [141] | |

| System Theory and System Dynamics Modelling | 1 | [184] | |

| Innovation Resistance Theory | 1 | [148] | |

| Information Processing Theory | 1 | [194] | |

| Dynamic Capability Theory | 1 | [194] | |

| Fashion, Textile, and Apparel | Methods | ||

| Quantitative | 4 | [202,208,211,212] | |

| Qualitative | 1 | [209] | |

| Proposal (model, architecture, etc.) | 3 | [197,206,271] | |

| Case Study | 8 | [198,200,203,205,206,207,210,272] | |

| Literature Review | 4 | [198,201,204,271] | |

| Theories | |||

| Social Capital and Resource Based Theory | 1 | [210] | |

| Diffusion of Innovation Theory | 1 | [211] | |

| Manufacturing | Methods | ||

| Quantitative | 9 | [215,216,217,218,219,220,221,223,273] | |

| Qualitative | 1 | [273] | |

| Proposal (model, architecture, etc.) | 1 | [223] | |

| Case Study | 4 | [213,214,215,223] | |

| Literature Review | 2 | [213,222] | |

| Theories | |||

| Resource Based Theory and Network Theory | 1 | [218] | |

| Technology, Organization, Environment Theory | 1 | [219] | |

| Unified Theory of Acceptance and Use of Technology | 1 | [220] | |

| Maritime and

Shipping | Methods | ||

| Quantitative | 1 | [226,233] | |

| Qualitative | 1 | [228,233] | |

| Proposal (model, architecture, etc.) | 3 | [224,225,227] | |

| Case Study | 5 | [225,227,228,229,232] | |

| Literature Review | 3 | [227,230,231] | |

| Theories | |||

| Technology Acceptance Model Theory | 1 | [229] | |

| Automotive | Methods | ||

| Quantitative | 5 | [234,236,237,238,240] | |

| Proposal (model, architecture, etc.) | 3 | [239,241,242] | |

| Case Study | 2 | [234,235] | |

| Theories | |||

| Dynamic Capabilities Theory | 1 | [236] | |

| Technology, Organization, Environment Theory | 1 | [235] | |

| Healthcare and Pharmaceutical | Methods | ||

| Quantitative | 2 | [243,247] | |

| Qualitative | 1 | [249] | |

| Proposal (model, architecture, etc.) | 3 | [245,248,250] | |

| Case Study | 1 | [246] | |

| Literature Review | 1 | [244] | |

| Theories | |||

| Technology Adoption Models Theory and Task-Technology Fit | 1 | [247] | |

| Graph Theory and Matrix Approach Theory | 1 | [246] | |

| Unified Theory of Acceptance and Use of Technology | 1 | [250] | |

| Mining and Mineral | Methods | ||

| Qualitative | 3 | [249,254,256] | |

| Proposal (model, architecture, etc.) | 2 | [251,255] | |

| Case Study | 2 | [252,256] | |

| Literature Review | 2 | [251,253] | |

| Energy | Methods | ||

| Qualitative | 2 | [258,259] | |

| Proposal (model, architecture, etc.) | 1 | [261] | |

| Case Study | 3 | [259,260,262] | |

| Literature Review | 1 | [257] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ayan, B.; Güner, E.; Son-Turan, S. Blockchain Technology and Sustainability in Supply Chains and a Closer Look at Different Industries: A Mixed Method Approach. Logistics 2022, 6, 85. https://doi.org/10.3390/logistics6040085

Ayan B, Güner E, Son-Turan S. Blockchain Technology and Sustainability in Supply Chains and a Closer Look at Different Industries: A Mixed Method Approach. Logistics. 2022; 6(4):85. https://doi.org/10.3390/logistics6040085