The Complexity of the Meat Supply Chain in Cameroon: Multiplicity of Actors, Interactions and Challenges

Abstract

1. Motivation and Background of the Study

1.1. Motivation of the Study

1.2. Literature Review

1.2.1. The Supply Chain

1.2.2. Supply Chain Management

2. Characteristics and Functioning of the Meat Supply Chain

2.1. Cattle Breeding

2.2. The Livestock Trade

2.3. Slaughter and Transport of Carcasses: Two Antagonistic Logistics Coexist

2.3.1. Slaughter in Traditional Slaughterhouses

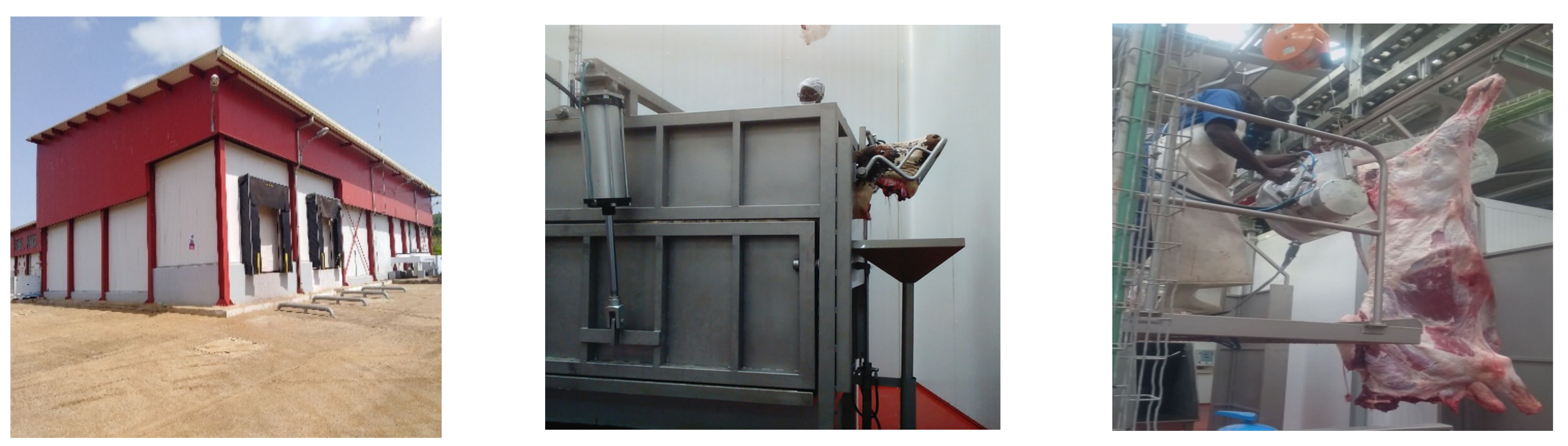

2.3.2. Slaughter at the Ngaoundéré Industrial Slaughterhouse

2.4. The Sale of Meat in Markets and Butcheries

3. Results from Difficulties Encountered by Actors of Meat Supply Chain

3.1. Methodological Approach

- With the breeders, we discussed the choice of breeds, the feeding of the animals, the safety and health monitoring of the animals, the handling of the animals at the livestock markets, the economic viability of the breeding activity and the difficulties encountered.

- Interviews with livestock market actors provided information on the origin of the livestock traded, the main market participants, the organization and functioning of the market, the transport of livestock after purchase and the main difficulties encountered.

- With the stakeholders of the traditional slaughterhouses, the discussions focused on the management and operation of the slaughterhouse, the origin of the animals slaughtered, the distribution of tasks between stakeholders, the economic viability of the slaughterhouse and the difficulties encountered.

- The director of the modern slaughterhouse of Ngaoundéré, after a guided tour of his structure, talked to us about the creation and mission of the slaughterhouse, the infrastructure and the main services offered, the economic viability of the slaughterhouse and the difficulties encountered.

- The interviews with the butchers gave us an insight into the butchering profession, the relationship between the butcher–retailers and the butcher–wholesalers, and the management of the interactions with the inspection services, trade agents and consumers.

| Person Interviewed | Profession | Seniority in the Profession |

|---|---|---|

| R1 | Breeder | More than 25 years |

| R2 | Breeder | about 15 years |

| R3 | Breeder | About 10 years |

| R4 | Livestock market actor | More than 10 years |

| R5 | Livestock market actor | About 5 years |

| R6 | Minepia Regional Delegate | 5 years at the duty station |

| R7 | Stakeholders of the traditional slaughterhouse | More than 10 years |

| R8 | Stakeholders of the traditional slaughterhouse | More than 20 years |

| R9 | Butcher–wholesaler | About 15 years |

| R10 | Modern slaughterhouse manager | 5 years at the duty station |

| R11 | Retail butcher | More than 15 years |

| R12 | Retail butcher | About 10 years |

| R13 | Retail butcher | About 10 years |

3.2. Characterization of the Difficulties Encountered by Each Link in the Meat Supply Chain

3.2.1. Technical Difficulties

3.2.2. Financial Difficulties

3.2.3. Cultural and Managerial Difficulties

3.3. Discussion of Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- INS (Institut National de la Statistique du Cameroun). Annuaire Statistique du Cameroun; INS: Yaoundé, Cameroun, 2019; pp. 210–219. [Google Scholar]

- Ministère de l’Élevage, des Pêches et des Industries Animales (MINEPIA). Document de Stratégie du Sous-Secteur de L’élevage, des Pêches et des Industries Animales; Ministère de l’Élevage, des Pêches et des Industries Animales (MINEPIA): Yaoundé, Cameroun, 2011.

- Mravili, A.; Abdelfetah, E.; Abdourahamane, H. Étude sur les Abattoirs d’Animaux de Boucherie en Afrique Centrale (Cameroun—Congo—Gabon—Tchad); Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2013. [Google Scholar]

- Ministère de l’Élevage, des Pêches et des Industries Animales (MINEPIA). Cadre de Gestion Environnementale et Sociale (CGES) du Projet de Développement de L’élevage (PRODEL); Ministère de l’Élevage, des Pêches et des Industries Animales (MINEPIA): Yaoundé, Cameroun, 2016; p. 161.

- Labonne, M.; Magrong, P.; Oustalet, Y. Le Secteur de l’Élevage au Cameroun et dans les Provinces du Grand Nord: Situation Actuelle, Contraintes, Enjeux et Défis. 2007. Available online: https://hal.archives-ouvertes.fr/hal-001139191 (accessed on 31 August 2021).

- Investir au Cameroun. Viande de Bœuf: Le Cameroun devrait entamer ses Stocks de Securité pour satisfaire la Demande au Deuxième Trimestre. 2022. Available online: https://www.investiraucameroun.com/economie/2604-17826 (accessed on 17 August 2022).

- Mouafo, H.T.; Baomog, M.B.; Adjele, J.J.B.; Sokamte, A.T.; Mbawala, A.; Ndjouenkeu, R. Microbial Profile of Fresh Beef Sold in the Markets of Ngaoundéré, Cameroon, and Antiadhesive Activity of a Biosurfactant against Selected Bacterial Pathogens. J. Food Qual. 2020, 2020, 5989428. [Google Scholar] [CrossRef]

- Investir au Cameroun. Les Produits Alimentaires ont dopé l’Inflation au Cameroun, au Cours des Neuf Premiers Mois de l’Année 2020 (INS). 2020. Available online: https://www.investiraucameroun.com/gestion-publique/1712-15742 (accessed on 26 August 2021).

- Institut National de la Statistique du Cameroun (INS). Note sur l’Évolution des Prix à la Consommation Finale des Ménages à Douala en Septembre 2020; INS-Cameroun: Yaoundé, Cameroun, 2020; Available online: https://ww.ins-cameroun.cm (accessed on 26 August 2021).

- WFP (United Nations World Food Program); Minader (Ministère de l’Agriculture et du Développement Rural). Evaluation de L’impact de la Hausse des Prix des Denrées Alimentaires sur la Sécurité Alimentaire des Ménages dans Les Villes de Bamenda, Douala, Maroua et Yaoundé au Cameroun; WFP (United Nations World Food Program): Rome, Italy; Minader (Ministère de l’Agriculture et du Développement Rural): Rome, Italy, 2009; Available online: https//reliefwebintt/sites/reliefwebint/files/resources/679D6038819B5D2E052575D100781540-Rapport-complet.pdf (accessed on 26 August 2021).

- INS—ECAM IV. Quatrième Enquête Camerounaise auprès des Ménages; INS-Cameroun, Archive Nationale des Données du Cameroun (ANADOC): Yaoundé, Cameroun, 2017. [Google Scholar]

- Lee, H.L.; Billington, C. Material management in decentralized supply chains. Oper. Res. 1993, 41, 5. [Google Scholar] [CrossRef]

- Rota-Frantz, K.; Bel, G.; Thierry, C. Gestion des Flux Dans les Chaînes Logistiques. In Performance Industrielle et Gestion des Flux; Hermes Science: Paris, France, 2001; pp. 153–187. [Google Scholar]

- La Londe, B.J.; Masters, J.M. Emerging Logistics Strategies: Blueprints for the next century. Int. J. Phys. Distrib. Logist. Manag. 1994, 24, 35–47. [Google Scholar] [CrossRef]

- Tayur, S.; Ganeshan, R.; Magazine, M. Quantitative Models for Supply Chain Management; Kluwer Academic Publishers: Norwell, MA, USA, 1999. [Google Scholar]

- Mentzer, J.T.; Dewitt, W.; Keebler, J.S.; Min, S.; Nix, N.W.; Smith, C.D.; Zacharia, Z.G. Defining supply chain management. J. Bus. Logist. 2001, 22, 1–25. [Google Scholar] [CrossRef]

- Stadtler, H.; Kilger, C. Supply Chain Management and Advanced Planning; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Belin-Munier, C. Logistique, chaîne logistique et SCM dans les revues francophones de gestion: Quelle dimension stratégique? In Proceedings of the XXIIIème Conférence de L’association Internationale de Management Stratégique (AIMS), Rennes, France, 26–27 May 2014. [Google Scholar]

- Belin-Munier, C. Etat de la recherche sur le supply chain management et sa performance: Une revue de la littérature récente. Logistique Manag. 2008, 162, 17–29. [Google Scholar] [CrossRef]

- Dominguez, H.; Lashkari, R.S. Model for integrating the supply chain of an appliance company: A value of information approach. Int. J. Prod. Res. 2004, 42, 2113–2140. [Google Scholar] [CrossRef]

- Simchi-Levi, D.; Kamnisky, P.; Simchi-Levi, E. Designing and Managing the Supply Chain: Concepts, Strategies, and Case Studies; McGraw-Hill/Irwin: New York, NY, USA, 2003. [Google Scholar]

- Geunes, J.; Chang, B. Operations research models for supply chain management and design. In Encyclopaedia of Optimization; Floudas, C.A., Ed.; Springer: Berlin/Heidelberg, Germany, 2008; pp. 2704–2715. [Google Scholar]

- Fabbe-Costes, N.; Meschi, P.-X. Situations-types et évolution de la logistique dans l’organisation. Logistique Manag. 2000, 8, 101–112. [Google Scholar] [CrossRef]

- FAO (Food and Agricultural Organization). Bonnes Pratiques pour l’industrie de la Viande; FAO: Rome, Italy, 2006. [Google Scholar]

- FAO/OMS Codex Alimentarius. Code d’Usages en Matière d’Hygiène pour la Viande (CXC 58-2005); FAO/OMS Codex Alimentarius: Rome, Italy, 2005. [Google Scholar]

- Mounir, Y.; Gouiferda, F. Pratiques de collaboration dans la chaîne logistique industrielle. Rev. Int. Des. Sci. Gest. 2020, 3, 410–424. [Google Scholar]

- Halley, A.; Beaulieu, M.; Roy, J. Quel niveau de connectivité pour votre chaîne logistique? Du temps réel aux besoins factuels. Rev. Gest. 2006, 31, 46–55. [Google Scholar]

- Talkhokhet, D.; Ouriachi, N.; Moutmih, M. Pratiques collaboratives entre acteurs de la chaîne logistique. Rev. Française d’Economie et de Gestion. 2021, 2, 116–130. [Google Scholar]

- Roy, J.; Landry, S.; Beaulieu, M. Collaborer dans la chaîne logistique: Où en sommes-nous? Gestion 2006, 31, 70–76. [Google Scholar] [CrossRef]

- El Bakkouri, A. Les déterminants de la collaboration verticale dans la chaîne logistique: Cas du secteur pharmaceutique de la région Souss Massa. Rev. Française D’economie Gest. 2021, 2, 205–223. [Google Scholar]

- Tsapi, V.; Assene, M.-N.; Hapsatou, H. Les mécanismes de gestion des flux d’information: Quelle incidence sur la performance logistique des entreprises au Cameroun? Rech. En Sci. Gest. 2021, 2, 205–229. [Google Scholar] [CrossRef]

- Assene, M.-N.; Djouhuo, E.L. Organisation du transport des marchandises et efficacité logistique en contexte camerounais. Manag. Avenir 2018, 105, 35–57. [Google Scholar] [CrossRef]

- Grawitz, M. Méthodes des Sciences Sociales; Dalloz: Paris, France, 1996. [Google Scholar]

- Girod-Séville, M.; Perret, V. Fondements épistémologiques de la recherche. In Méthodes de Recherche en Management; Dunod: Paris, France, 1999; pp. 13–33. [Google Scholar]

- Valet, A.M. Choix Méthodologiques: Pourquoi tant de Chiffres? Hall, Open Science. 2010. Available online: https://hal.archives-ouvertes.fr/hal-00479481 (accessed on 8 August 2022).

- Ministère de l’Economie, de la Planification et de l’Aménagement du Territoire (MINPAT); PNUD (Programme des Nations Unies pour le Développement). Projet PNUD-OPS CMR/98/005/01/99. Études Socio-Economiques Régionales au Cameroun: Eradication de la Pauvreté, Amélioration des Données Sociales; PNUD-OPS: Ngaoundéré, Yaoundé, 2000. [Google Scholar]

- Tsapi, V. La Vache, La Viande et le Lait Dans L’Adamaoua: Pour la Redynamisation d’une Industrie «négligée». In De l’Adamawa à l’Adamaoua: Histoire, Enjeux et Perspectives pour le Nord-Cameroun; Harmattan: Paris, France, 2014. [Google Scholar]

- Deffo, V.; Ottou, J.-F.; Messiné, O.; Achundoh, L.E.; Djoumessi, M. Facteurs socio-économiques affectant l’utilisation des sous-produits agro-industriels pour l’embouche bovine à contre-saison dans l’Adamaoua, Cameroun. Biotechnol. Agron. Soc. Environ. 2009, 13, 357–365. [Google Scholar]

- Dieng, T.O. Enjeux et défis du management de la recherché universitaire: Les spécificités de la recherche publique dans un pays en développement. Rech. En Sci. Gest. 2021, 143, 57–83. [Google Scholar] [CrossRef]

- Njonmeta, N.L.A.; Ejoh, R.A.; Djouldé, R.; Mbofung, C.M.; Etoa, X.F. Microbiological and safety evaluation of street vended meat and meat product in Ngaoundere metropolis (Cameroon). Micro. Hyg. Alim. 2004, 16, 43–48. [Google Scholar]

- IRZ/GTZ. Livestock Farming Systems in Adamawa; Research Report n1; IRZ: Wakwa, Cameroon, 1989. [Google Scholar]

- NEPAD-PDDAA; FAO. Profil de Projet d’Investissement Bancable: Appui au Développement de la Filière Viande Bovine, TCP/CMR/2906 (I) (NEPAD Ref. 04/05 F); Volume III et IV; NEPAD-PDDAA: Midrand, South Africa; FAO: Rome, Italy, 2004; Available online: https://www.fao.org/3/ae411f/ae411f00.htm (accessed on 26 August 2021).

- Samii, A.K. Stratégie Logistique; Dunod: Paris, France, 2004. [Google Scholar]

- Colin, J. De la maîtrise des opérations logistiques au supply chain management. Gestion 2000, 2002, 59–74. [Google Scholar]

- OCDE; FAO. Perspectives Agricoles de l’OCDE et de la FAO 2020–2029; OECD Publishing: Paris, France, 2020. [Google Scholar] [CrossRef]

| 2015 | 2016 | 2017 | 2018 | |

|---|---|---|---|---|

| National cattle herd (number of heads) | 6,859,359 | 7456,123 | 7,890,962 | 8,761,385 |

| National cattle slaughter volume (number of heads) | 548,749 | 756,205 | 799,668 | 882,503 |

| National beef production (in tons) | 112,909 | 122,306 | 133,625 | 144,818 |

| Authors | Definition of SCM |

|---|---|

| [13] | Doing SCM means that we seek to integrate all the internal and external means to meet customer demand, the objective being the search for simultaneous and non-sequential optimization of all logistics processes. |

| [17] | The purpose of supply chain management is to integrate all the organizational units involved in the management of physical, information and financial flows throughout the supply chain in order to ensure their coordination in such a way as to satisfy the customer. while improving the competitiveness of the chain. |

| [20] | The primary objective of SCM is to allocate production, distribution, transmission and information resources efficiently, in the presence of conflicting objectives, in order to achieve the level of service demanded by customers at a reasonable price. |

| [21] | Supply chain management is a set of approaches used to effectively integrate suppliers, producers and distributors so that the goods are produced and distributed in the right quantity, in the right place and at the right time with the aim of minimizing costs and ensuring the level of service required by the customer. |

| [22] | Supply chain management is the coordination and integration of supply chain activities with the goal of achieving viable competitive advantage. Supply chain management, therefore, includes a wide range of strategic, financial and operational issues. |

| [23] | The compartmentalized management of flows in the SC prevents any synergy in the management of activities, increases costs, stock shortages and waste and leads to poor quality of service. The SCM approach, on the other hand, aims to eliminate intra- and inter-organizational borders, by advocating the creation of common databases, dialogue, fluidity of information and concerted decision-making between all the actors involved. The objective is on the one hand to create value for the end customer, and on the other hand, to increase the overall performance and competitiveness of the entire SC. |

| Authors | Nature of the Problem Addressed | Methodological Approach | Conclusion of the Study |

|---|---|---|---|

| [26] | Analyze collaborative practices in the supply chains of companies in the industrial sector in the context of tight local markets. | Qualitative study with the managers of eight partners in the upstream supply chain belonging to the same industrial sector in Morocco. | The inter-organizations are not necessarily based, at the initial stage, on the dimensions relational, and the exchange of information is the only collaborative practice exercised despite the absence of inter-organizational information systems. |

| [27] | Analyze the degree of connectivity in the SC of Canadian manufacturing companies. | Descriptive study based on an analysis of existing literature and an empirical survey conducted among 509 Canadian manufacturing companies. | Downstream connectivity in the supply chain is generally associated with extensive practices of sharing operational, tactical and, to a lesser degree, strategic information. In contrast, upstream connectivity in the supply chain is typically associated with limited practices of sharing mostly operational information. |

| [28] | Characterize the collaborative relationships established between SC authors. | Theoretical approach essentially based on a critical analysis of the existing literature. | Successful supply chains are those that have succeeded in adopting innovative management solutions based on lasting relationships that are characterized by trust, the involvement of partners and the implementation of an evaluation system. |

| [29] | Make a comparative analysis of the forms of collaboration in the SC of Quebec companies and deduce the managerial implications | Qualitative approach based on exploitation of the existing literature and a comparative study of six (06) cases of Quebec companies. | Collaboration between SC partners can take many forms and have different levels, ranging from the exchange of information or knowledge sharing to forms of partnerships that engage the partners in the realization of joint projects or the creation of strategic alliances. |

| [30] | Identify the determinants of vertical collaboration in the global supply chain, in the pharmaceutical sector of the Souss–Massa region in Morocco. | Methodology based on a review of the existing literature and on an exploratory qualitative study broken down into semi-structured interviews with the various managers of the pharmaceutical sector of the Souss–Massa region. | Collaboration in the supply chain has real advantages in terms of reducing costs, risks, uncertainties, improving the quality of service and adding value to the customer. Vertical collaboration in SC is influenced in particular by information sharing, trust and commitment. |

| [31] | Identify the mechanisms deployed by SC actors to manage their information flows and analyze their impact on the overall logistics performance of the company. | Descriptive and explanatory study was conducted among 60 industrial, commercial and service companies in Cameroon. | In Cameroon, SC actors are mobilizing both personalized and digitized mechanisms for exchanging information and sharing knowledge. These mechanisms have a significant impact on their logistical performance. |

| [32] | Describe and explain strategic choices operated by companies in Cameroon in the transport of goods and assess their efficiency | Descriptive and explanatory approach through an empirical survey of a sample of 96 industrial and commercial companies. | The strategic choices made by companies for the transport of their goods are aimed at resolving the triptych of costs–deadlines–quality. However, in Cameroon, companies that opt for outsourcing to freight forwarders do better than those that transport on their own fleet. |

| Activities | Problems |

|---|---|

| Breeders |

|

| |

| |

| |

| |

| Cattle traders |

|

| |

| |

| Modern slaughterhouse |

|

| |

| |

| |

| |

| Traditional slaughterhouses |

|

| |

| |

| |

| Traditional butchers |

|

| |

| |

| |

|

| R1 | “To have a good carcass yield and provide quality meat, great attention must be paid to the feeding and well-being of the animals. However, we have enormous difficulties in accessing water and pasture. In the dry season, we are forced to drive our animals to very remote areas in search of water and pasture and this exposes the animals and the shepherds to many risks, including the risk of aggression and removal!” |

| R4 | “Livestock markets do not have enclosures to facilitate control of the entry and exit of animals. Some animals escape the control of veterinary inspectors and not all animal sales are recorded. We do not have a device to weigh the weight of the beast before negotiating its price. I have a meter to measure the size of the beast but for the weight, I estimate by eye and by experience.” |

| R7 | “We have problems accessing water and energy. Our current workspace is cramped. Sometimes, we are forced to slaughter the animals in the open air and on bare ground. In addition, the scale we used to weigh the carcasses is old and unreliable...sometimes we weigh it works and sometimes we weigh, the butcher complains that it doesn’t work!” |

| R11 | “We do not have a cold room or freezer to store meat. In case of unsold for 02 days, we proceed to the smoking.” |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsapi, V.; Assene, M.-N.; Haasis, H.-D. The Complexity of the Meat Supply Chain in Cameroon: Multiplicity of Actors, Interactions and Challenges. Logistics 2022, 6, 86. https://doi.org/10.3390/logistics6040086

Tsapi V, Assene M-N, Haasis H-D. The Complexity of the Meat Supply Chain in Cameroon: Multiplicity of Actors, Interactions and Challenges. Logistics. 2022; 6(4):86. https://doi.org/10.3390/logistics6040086

Chicago/Turabian StyleTsapi, Victor, Marie-Noël Assene, and Hans-Dietrich Haasis. 2022. "The Complexity of the Meat Supply Chain in Cameroon: Multiplicity of Actors, Interactions and Challenges" Logistics 6, no. 4: 86. https://doi.org/10.3390/logistics6040086

APA StyleTsapi, V., Assene, M.-N., & Haasis, H.-D. (2022). The Complexity of the Meat Supply Chain in Cameroon: Multiplicity of Actors, Interactions and Challenges. Logistics, 6(4), 86. https://doi.org/10.3390/logistics6040086