Investigating the Performance of the Order-Picking Process by Using Smart Glasses: A Laboratory Experimental Approach

Abstract

1. Introduction

2. Identification and Selection of Parameters

2.1. Subsection

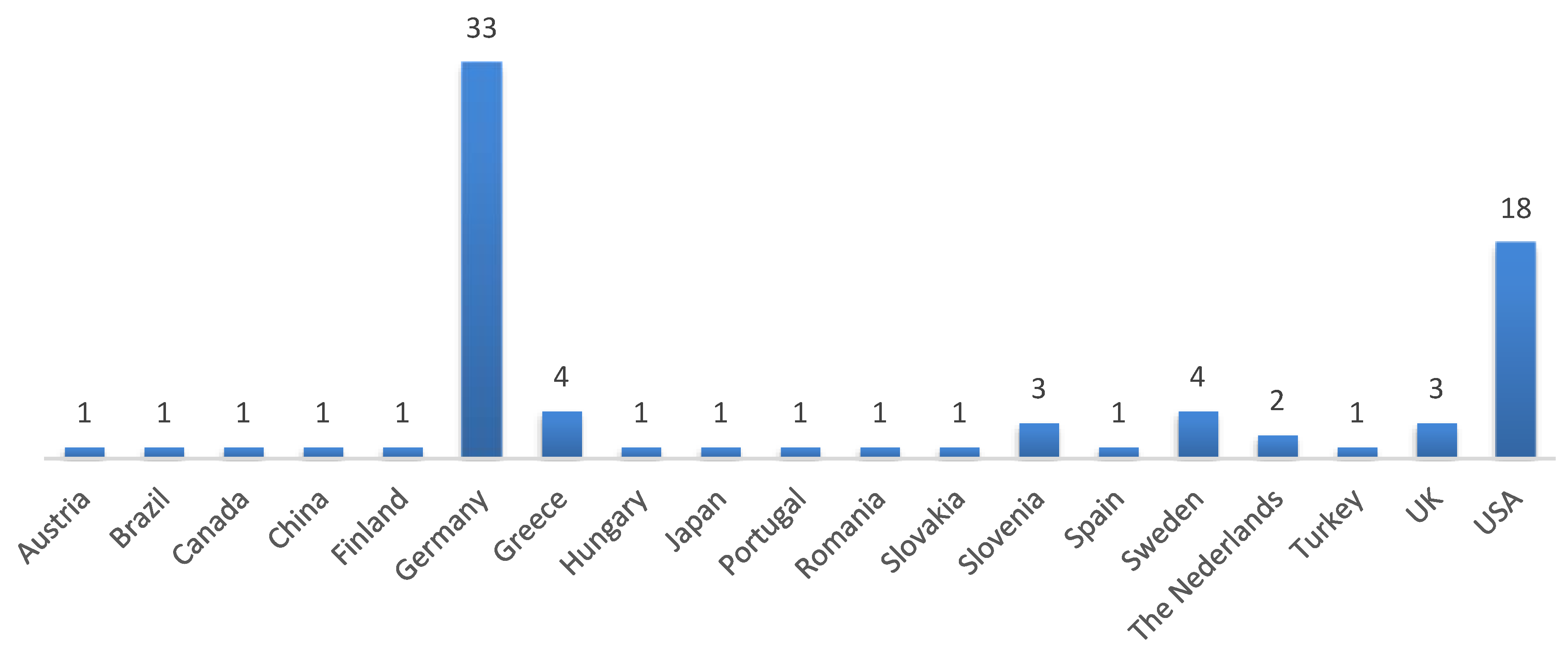

2.2. Descriptive Analysis of the Corpus

2.3. Identification of Parameters for the Design and Investigation of Pick-by-Vision Systems

2.4. Selection of Parameters for the Design and Investigation of Pick-by-Vision Systems

- Step 1: Presentation of the main aim and objective of this research.

- Step 2: Detailed description of reviewed parameters to the participants (experts).

- Step 3: Specific instructions given to participants on how to complete the questionnaire.

- Step 4: Rating of pick-by-vision system design parameters by experts (completed via questionnaire).

3. Design of Experiments

3.1. Experimental Design

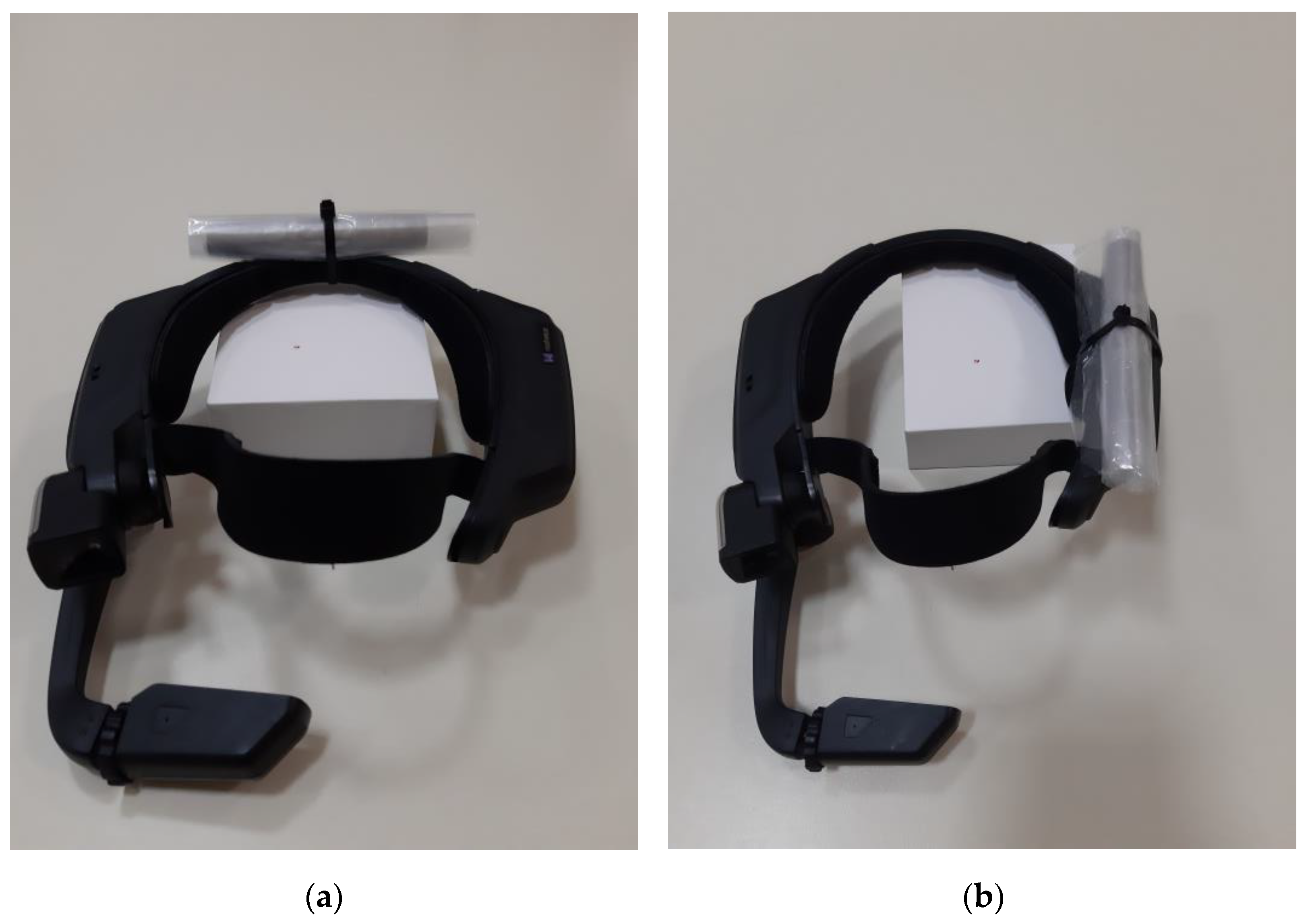

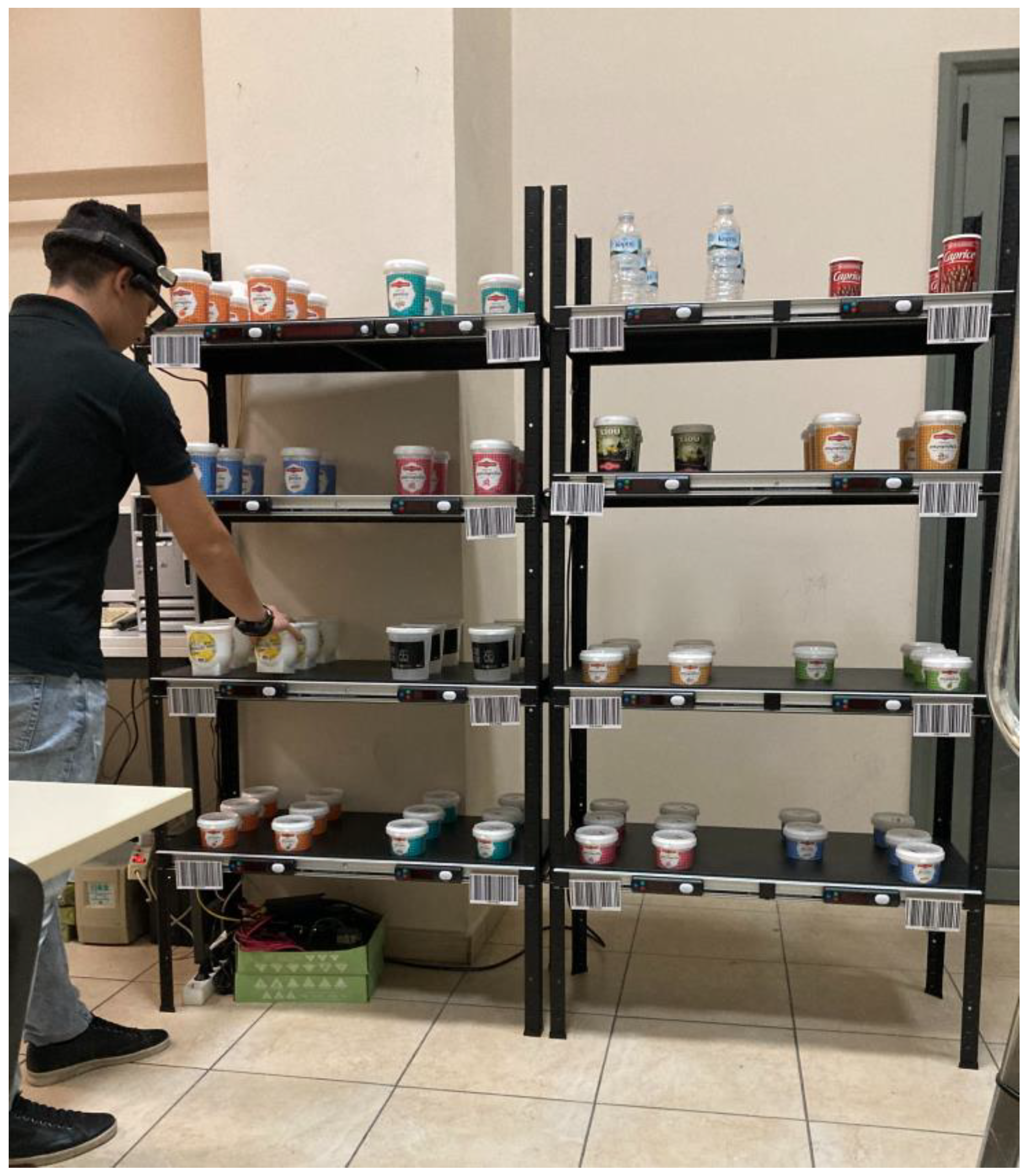

3.2. Subjects’ Features, and Experimental Equipment and Set-Up

3.3. Formulation of Research Hypothesis

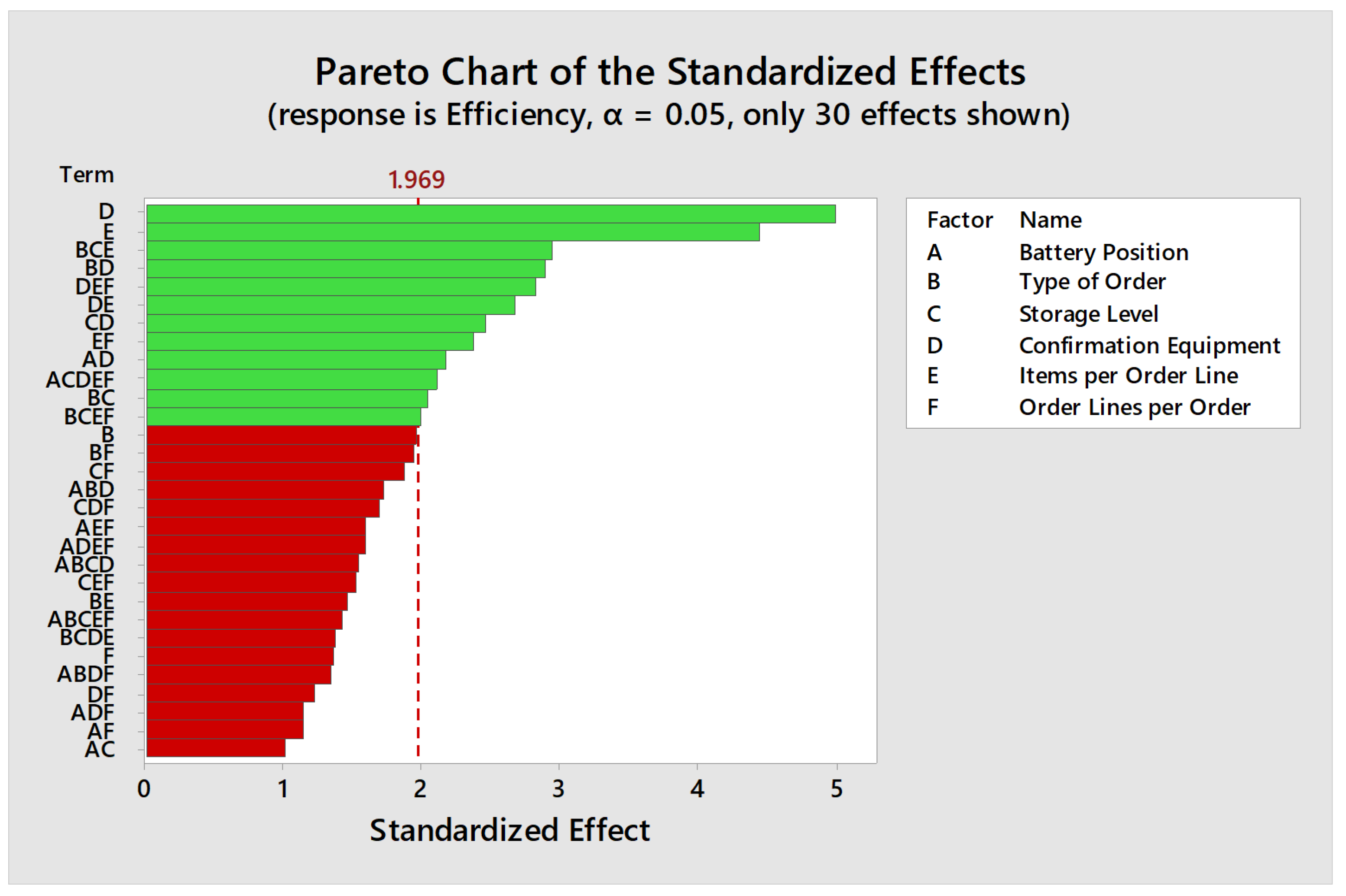

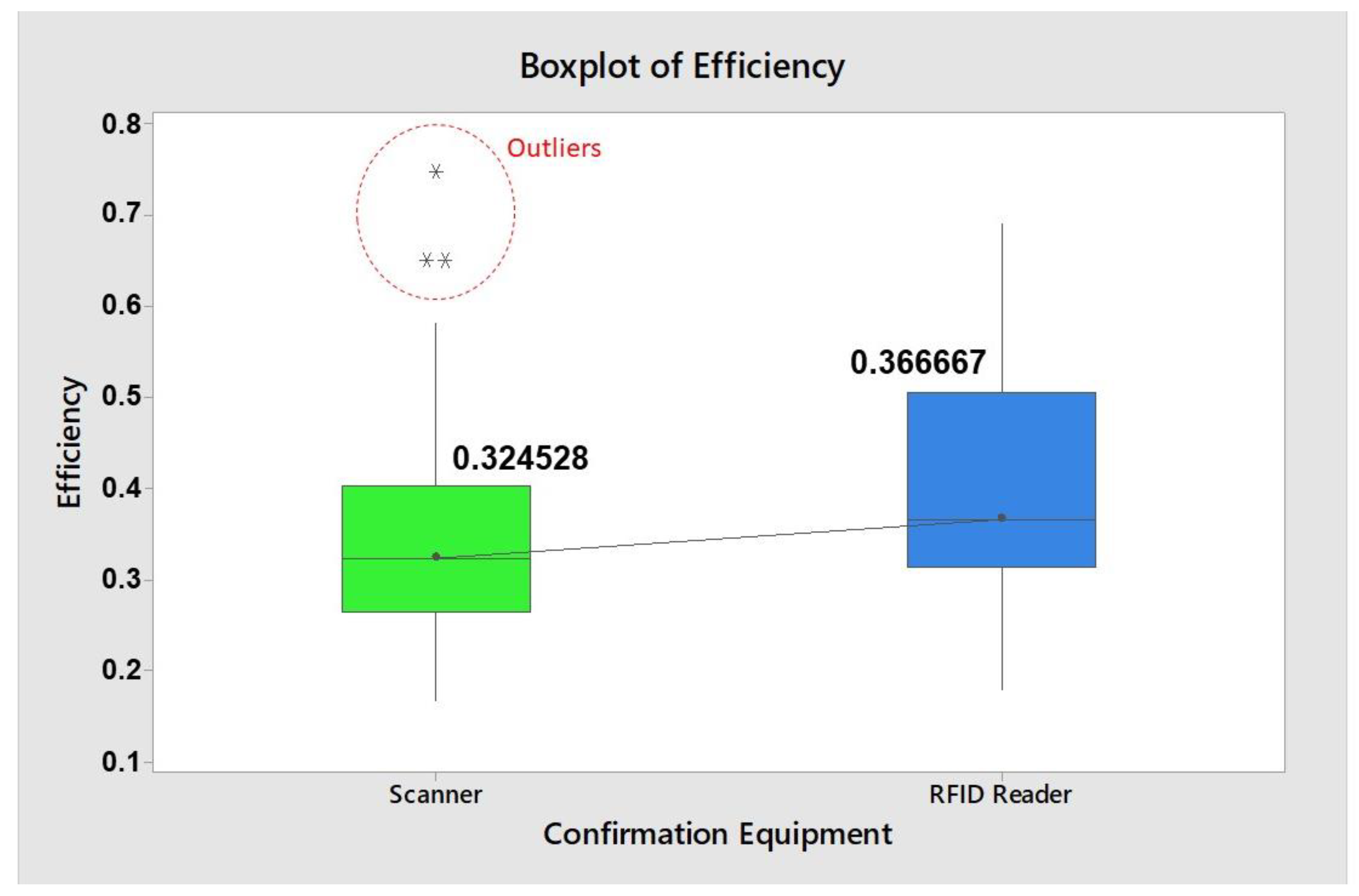

3.4. Results from the Statistical Analysis

4. Perceived Workload Evaluation

5. Discussion

5.1. Contribution to Theory

5.2. Practical Implications

- Organizational culture: an effective digital transformation from typical order-picking methods to the pick-by-vision system needs more than updating the current technology. Automation tools are likely to create dissatisfaction among the workforce if not managed properly. An organizational culture is needed, the lack of which can cause the investment to fail and reduced performance.

- Process re-engineering: apart from the need for organizational culture, malfunction may be caused by a lack of necessary process re-engineering. It is thus crucial for companies to identify their needs and adjust their order-picking processes in accordance with the adopted new technology.

- Staff resistance to change: staff tend to resist to technological change because they believe that their position is in danger. Typical examples of such situations are met in the logistics sector when new order-picking techniques/systems are introduced. In order to keep the workforce and management united, continuous staff training, user-friendly systems, and technologies facilitating worker’s lives are essential.

- Motivation for maintaining the new way of doing business: after a complete and multilevel installation of an order-picking system, it is important to maintain the new way of doing business. Continuous improvement is required in order to maintain the interest of the user, as are suggestions for improvements from people working with the new system.

5.3. Limitations and Future Research

- Human factor: the human factor plays a critical role when new technologies are adopted, especially for the pick-by-vision system, where training and familiarization are necessary for its use. Despite the fact that most people can work over long periods with pick-by-vision headbands or glasses without being strained, there are still some people who find reading continuously from a smart device difficult. Issues that should be further investigated include ergonomics, mental and physical demand on users, performance, and frustration level.

- Technical issues: Another critical issue for future investigation is the technical aspect of pick-by-vision, especially when it comes to the user interface (UI). Furthermore, attention should also be paid to issues from integrating the pick-by-vision system into other systems, especially in the closer integration of augmented reality (AR) and warehouse management systems (WMSs), the increasing comfort of hardware components, and the potential connection of picking systems with automatic identification systems, such as RFID tags. Other technical issues to be further investigated may include battery life and scanning distance.

- Comparative assessment with other picking technologies: Lately, a comparative assessment of pick-by-vision with alternative picking technologies, such as voice picking and pick to light, have come up, but still there are many research opportunities in this area. Indeed, experiments should be conducted in order to assess the accuracy and efficiency of different picking technologies. Last but not least, it is worth evaluating investment costs in order to compare not only the performance but also the cost of obtaining an order-picking system.

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Marchet, G.; Melacini, M.; Perotti, S. Investigating order picking system adoption: A case-study-based approach. Int. J. Logist. Res. Appl. 2015, 18, 82–98. [Google Scholar] [CrossRef]

- Lu, W.; McFarlane, D.; Giannikas, V.; Zhang, Q. An algorithm for dynamic order-picking in warehouse operations. Eur. J. Oper. Res. 2016, 248, 107–122. [Google Scholar] [CrossRef]

- Van Gils, T.; Ramaekers, K.; Caris, A.; de Koster, R.B.M. Designing efficient order picking systems by combining planning problems: State-of-the-art classification and review. Eur. J. Oper. Res. 2018, 267, 1–15. [Google Scholar] [CrossRef]

- Franzke, T.; Grosse, E.H.; Glock, C.H.; Elbert, R. An investigation of the effects of storage assignment and picker routing on the occurrence of picker blocking in manual picker-to-parts warehouses. Int. J. Logist. Manag. 2017, 28, 841–863. [Google Scholar] [CrossRef]

- Theys, C.; Bräysy, O.; Dullaert, W.; Raa, B. Using a TSP heuristic for routing order pickers in warehouses. Eur. J. Oper. Res. 2010, 200, 755–763. [Google Scholar] [CrossRef]

- Chen, F.; Wang, H.; Xie, Y.; Qi, C. An ACO-based online routing method for multiple order pickers with congestion consideration in warehouse. J. Intell. Manuf. 2016, 27, 389–408. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing Smart Factory of Industrie 4.0: An Outlook. Int. J. Distrib. Sens. Netw. 2016, 12, 3159805. [Google Scholar] [CrossRef]

- Hanson, R.; Falkenström, W.; Miettinen, M. Augmented reality as a means of conveying picking information in kit preparation for mixed-model assembly. Comput. Ind. Eng. 2017, 113, 570–575. [Google Scholar] [CrossRef]

- Stoltz, M.H.; Giannikas, V.; McFarlane, D.; Strachan, J.; Um, J.; Srinivasan, R. Augmented Reality in Warehouse Operations: Opportunities and Barriers. IFAC-PapersOnLine 2017, 50, 12979–12984. [Google Scholar] [CrossRef]

- Grosse, E.H.; Glock, C.H.; Neumann, W.P. Human Factors in Order Picking: A Content Analysis of the Literature. Int. J. Prod. Res. 2017, 55, 1260–1276. [Google Scholar] [CrossRef]

- Van Gils, T.; Ramaekers, K.; Braekers, K.; Depaire, B.; Caris, A. Increasing order picking efficiency by integrating storage, batching, zone picking, and routing policy decisions. Int. J. Prod. Econ. 2018, 197, 243–261. [Google Scholar] [CrossRef]

- Boysen, N.; de Koster, R.; Weidinger, F. Warehousing in the E-Commerce Era: A Survey. Eur. J. Oper. Res. 2019, 277, 396–411. [Google Scholar] [CrossRef]

- Masae, M.; Glock, C.H.; Grosse, E.H. Order picker routing in warehouses: A systematic literature review. Int. J. Prod. Econ. 2020, 224, 107564. [Google Scholar] [CrossRef]

- Gialos, A.; Zeimpekis, V. Defining and testing system parameters for enhancing vision picking technology in warehouse operations. In Supply Chain 4.0: Improving Supply Chains with Analytics and Industry 4.0 Technologies; Aktas, E., Bourlakis, M., Zeimpekis, V., Minis, I., Eds.; Kogan Page: London, UK, 2021; ISBN 978-1789660753. [Google Scholar]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a methodology for developing evidence-informed management knowledge by means of systematic review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Touboulic, A.; Walker, H. Theories in Sustainable Supply Chain Management: A Structured Literature Review. Int. J. Phys. Distrib. Logist. Manag. 2015, 45, 16–42. [Google Scholar] [CrossRef]

- Lagorio, A.; Pinto, R.; Golini, R. Research in Urban Logistics: A Systematic Literature Review. Int. J. Phys. Distrib. Logist. Manag. 2016, 46, 908–931. [Google Scholar] [CrossRef]

- Gialos, A.; Zeimpekis, V. Vision picking technology: Defining design parameters via a systematic literature review. Int. J. Logist. Syst. Manag. 2020, 37, 106–139. [Google Scholar] [CrossRef]

- Khan, M.; Parvaiz, G.S.; Ali, A.; Jehangir, M.; Hassan, N.; Bae, J. A model for understanding the mediating association of transparency between emerging technologies and humanitarian logistics sustainability. Sustainability 2022, 14, 16917. [Google Scholar] [CrossRef]

- Glock, C.H.; Grosse, E.H.; Neumann, W.P.; Feldman, A. Assistive devices for manual materials handling in warehouses: A systematic literature review. Int. J. Prod. Res. 2021, 59, 3446–3469. [Google Scholar] [CrossRef]

- Khan, M.; Parvaiz, G.S.; Tohirovich-Dedahanov, A.; Iqbal, M.; Junghan, B. Research trends in humanitarian logistics and sustainable development: A bibliometric analysis. Cogent Bus. Manag. 2022, 9, 2143071. [Google Scholar] [CrossRef]

- Schwerdtfeger, B.; Frimor, T.; Pustka, D.; Klinker, G. Mobile Information Presentation Schemes for Supra-adaptive Logistics Applications. In Lecture Notes in Computer Science (Including Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); Springer: Cham, Switzerland, 2006; pp. 998–1007. ISBN 3540497765. [Google Scholar]

- Baumann, H.; Starner, T.; Zschaler, P. Studying order picking in an operating automobile manufacturing plant. In Proceedings of the Proceedings—International Symposium on Wearable Computers, ISWC, Newcastle Upon Tyne, UK, 18–22 June 2012. [Google Scholar]

- Funk, M.; Shirazi, A.S.; Mayer, S.; Lischke, L.; Schmidt, A. Pick from Here-An interactive mobile cart using in-situ projection for order picking. In Proceedings of the UbiComp 2015—Proceedings of the 2015 ACM International Joint Conference on Pervasive and Ubiquitous Computing, Osaka, Japan, 7–11 September 2015. [Google Scholar]

- Kim, S.; Nussbaum, M.A.; Gabbard, J.L. Influences of augmented reality head-worn display type and user interface design on performance and usability in simulated warehouse order picking. Appl. Ergon. 2019, 74, 186–193. [Google Scholar] [CrossRef] [PubMed]

- Matsumoto, T.; Kosaka, T.; Sakurada, T.; Nakajima, Y.; Tano, S. Picking work using AR instructions in warehouses. In Proceedings of the 2019 IEEE 8th Global Conference on Consumer Electronics (GCCE), Osaka, Japan, 15–18 October 2019; pp. 31–34. [Google Scholar] [CrossRef]

- Smith, E.; Burch, V.R.F.; Strawderman, L.; Chander, H.; Smith, B.K. A comfort analysis of using smart glasses during “picking” and “putting” tasks. Int. J. Ind. Ergon. 2021, 83, 103133. [Google Scholar] [CrossRef]

- Krajcovic, M.; Gabajova, G.; Micieta, B. Order picking using augmented reality. Komunikacie 2014, 16, 106–111. [Google Scholar] [CrossRef]

- Diete, A.; Sztyler, T.; Weiland, L.; Stuckenschmidt, H. Exploring a multi-sensor picking process in the future warehouse. In Proceedings of the UbiComp ’16: Proceedings of the 2016 ACM International Joint Conference on Pervasive and Ubiquitous Computing: Adjunct, Heidelberg, Germany, 12–16 September 2016; pp. 1755–1758. [CrossRef]

- Renner, P.; Pfeiffer, T. Augmented Reality Assistance in the Central Field-of-View Outperforms Peripheral Displays for Order Picking: Results from a Virtual Reality Simulation Study. In Proceedings of the Adjunct Proceedings of the 2017 IEEE International Symposium on Mixed and Augmented Reality, ISMAR-Adjunct, Nantes, France, 9–13 October 2017. [Google Scholar]

- Elbert, R.; Knigge, J.K.; Sarnow, T. Transferability of order picking performance and training effects achieved in a virtual reality using head mounted devices. IFAC-Pap. 2018, 51, 686–691. [Google Scholar] [CrossRef]

- Reif, R.; Günthner, W.A. Pick-by-vision: Augmented reality supported order picking. Vis. Comput. 2009, 25, 461–467. [Google Scholar] [CrossRef]

- Baumann, H.; Starner, T.; Iben, H.; Lewandowski, A.; Zschaler, P. Evaluation of graphical user-interfaces for order picking using head-mounted displays. In Proceedings of the 13th International Conference on Multimodal Interfaces—ICMI’11, Alicante, Spain, 14–18 November 2011. [Google Scholar]

- Gialos, A.; Zeimpekis, V. Testing vision picking technology in warehouse operations: Evidence from laboratory experiments. Int. J. Ind. Eng. Manag. 2020, 11, 19–30. [Google Scholar] [CrossRef]

- Vidovič, E.; Gajšek, B. Analysing Picking Errors in Pick-by-vision Systems. Logist. Sustain. Transp. 2020, 11, 90–100. [Google Scholar] [CrossRef]

- Reif, R.; Günthner, W.A.; Schwerdtfeger, B.; Klinker, G. Pick-by-Vision Comes on Age: Evaluation of an Augmented Reality Supported Picking System in a Real Storage Environment. In Proceedings of the AFRIGRAPH ’09: 6th International Conference on Computer Graphics, Virtual Reality, Visualisation and Interaction in Africa, Pretoria, South Africa, 4–6 February 2009. [Google Scholar] [CrossRef]

- Guo, A.; Wu, X.; Shen, Z.; Starner, T.; Baumann, H.; Gilliland, S. Order Picking with Head-Up Displays. Computer 2015, 48, 16–24. [Google Scholar] [CrossRef]

- Syberfeldt, A.; Danielsson, O.; Gustavsson, P. Augmented Reality Smart Glasses in the Smart Factory: Product Evaluation Guidelines and Review of Available Products. IEEE Access 2017, 5, 9118–9130. [Google Scholar] [CrossRef]

- Schwerdtfeger, B.; Klinker, G. Supporting Order Picking with Augmented Reality. In Proceedings of the—7th IEEE International Symposium on Mixed and Augmented Reality 2008, ISMAR 2008, Washington, DC, USA, 15–18 September 2008. [Google Scholar]

- Schwerdtfeger, B.; Reif, R.; Günthner, W.A.; Klinker, G. Pick-by-Vision: There Is Something to Pick at the End of the Augmented Tunnel. Virtual Real. 2011, 15, 213–223. [Google Scholar] [CrossRef]

- Murauer, N.; Panz, N.; Von Hassel, C. Comparison of Scan Mechanisms in Augmented Reality Supported Order Picking Processes. Proc. CEUR Workshop Proc. 2018, 2082, 69–76. [Google Scholar]

- Gabbard, J.L.; Mehra, D.G.; Swan, J.E. Effects of Ar Display Context Switching and Focal Distance Switching on Human Performance. IEEE Trans. Vis. Comput. Graph. 2019, 25, 2228–2241. [Google Scholar] [CrossRef] [PubMed]

- Van Krevelen, D.; Poelman, R. A Survey of Augmented Reality Technologies, Applications and Limitations. Int. J. Virtual Real. 2010, 9, 1–20. [Google Scholar] [CrossRef]

- Rejeb, A.; Keogh, J.G.; Leong, G.K.; Treiblmaier, H. Potentials and Challenges of Augmented Reality Smart Glasses in Logistics and Supply Chain Management: A Systematic Literature Review. Int. J. Prod. Res. 2021, 59, 3747–3776. [Google Scholar] [CrossRef]

- Frimor, T. Display Technologies for Augmented Reality Support in Logistics. Master’s Thesis, Technical University of Munich, Munich, Germany, 2006. [Google Scholar]

- Josefsson, P.; Lingegard, S. Potential of Smart Glasses in a Spare Parts Distribution Center. Master’s Thesis, Chalmers University of Technology, Göteborg, Sweden, 2017. [Google Scholar]

- Iben, H.; Baumann, H.; Ruthenbeck, C.; Klug, T. Visual Based Picking Supported by Context Awareness. In Proceedings of the Eleventh International Conference on Multimodal Interfaces and the Sixth Workshop on Machine Learning for Multimodal Interaction, Boston, MA, USA, 2–6 November 2009. [Google Scholar]

- Fang, W.; An, Z. A Scalable Wearable AR System for Manual Order Picking Based on Warehouse Floor-Related Navigation. Int. J. Adv. Manuf. Technol. 2020, 109, 2023–2037. [Google Scholar] [CrossRef]

- Reif, R.; Günthner, W.A.; Schwerdtfeger, B.; Klinker, G. Evaluation of an Augmented Reality Supported Picking System under Practical Conditions. Comput. Graph. Forum 2010, 29, 2–12. [Google Scholar] [CrossRef]

- Biocca, F.; Tang, A.; Owen, C.; Xiao, F. Attention Funnel: Omnidirectional 3D Cursor for Mobile Augmented Reality Platforms. In Proceedings of the Conference on Human Factors in Computing Systems—Proceedings, Montreal, QC, Canada, 22–27 April 2006. [Google Scholar]

- Grubert, J.; Hamacher, D.; Mecke, R.; Böckelmann, I.; Schega, L.; Huckauf, A.; Urbina, M.; Schenk, M.; Doil, F.; Tümler, J. Extended Investigations of User-Related Issues in Mobile Industrial AR. In Proceedings of the 9th IEEE International Symposium on Mixed and Augmented Reality 2010: Science and Technology, ISMAR 2010—Proceedings, Seoul, Republic of Korea, 13–16 October 2010. [Google Scholar]

- Murauer, N. Design Thinking: Using Photo Prototyping for a User-Centered Interface Design for Pick-by-Vision Systems. In Proceedings of the ACM International Conference Proceeding Series, Tokyo, Japan, 25–28 November 2018. [Google Scholar]

- Bräuer, P.; Mazarakis, A. AR in Order-Picking—Experimental Evidence with Microsoft HoloLens. In Proceedings of the Mensch und Computer, Dresden, Germany, 2–5 September 2018. [Google Scholar]

- Williams, M.K. Augmented Reality Supported Batch Picking System. Bachelor’s Thesis, University of Twente, Enschede, The Netherlands, 2019. [Google Scholar]

- Gajsek, B.; Herzog, N.V. Smart Glasses in Sustainable Manual Order Picking Systems. DEStech Trans. Soc. Sci. Educ. Hum. Sci. 2020, 23. [Google Scholar] [CrossRef]

- Schwerdtfeger, B.; Reif, R.; Günthner, W.A.; Klinker, G.; Hamacher, D.; Schega, L.; Böckelmann, I.; Doil, F.; Tümler, J. Pick-by-Vision: A First Stress Test. In Proceedings of the Science and Technology Proceedings—IEEE 2009 International Symposium on Mixed and Augmented Reality, ISMAR 2009, Washington, DC, USA, 19–22 October 2009. [Google Scholar]

- Kim, S.; Nussbaum, M.A.; Gabbard, J.L. Augmented Reality “Smart Glasses” in the Workplace: Industry Perspectives and Challenges for Worker Safety and Health. IIE Trans. Occup. Ergon. Hum. Factors 2016, 4, 253–258. [Google Scholar] [CrossRef]

- Mocan, A.; Draghici, A. Reducing Ergonomic Strain in Warehouse Logistics Operations by Using Wearable Computers. Procedia-Soc. Behav. Sci. 2018, 238, 1–8. [Google Scholar] [CrossRef]

- Reif, R.; Walch, D. Augmented & Virtual Reality Applications in the Field of Logistics. Vis. Comput. 2008, 24, 987–994. [Google Scholar] [CrossRef]

- Glockner, H.; Jannek, K.; Mahn, J.; Theis, B. Augmented Reality in Logistics Changing the Way We See Logistics—A DHL Perspective. In DHL Customer Solutions & Innovation; DHL Innovation Center: Troisdorf, Germany, 2014. [Google Scholar]

- Fraga-Lamas, P.; Fernández-Caramés, T.M.; Blanco-Novoa, Ó.; Vilar-Montesinos, M.A. A Review on Industrial Augmented Reality Systems for the Industry 4.0 Shipyard. IEEE Access 2018, 6, 13358–13375. [Google Scholar] [CrossRef]

- Tumler, J.; Doil, F.; Mecke, R.; Paul, G.; Schenk, M.; Pfister, E.A.; Huckauf, A.; Böckelmann, I.; Roggentin, A. Mobile Augmented Reality in Industrial Applications: Approaches for Solution of User-Related Issues. In Proceedings of the 2008 7th IEEE/ACM International Symposium on Mixed and Augmented Reality, (ISMAR 2008), Cambridge, UK, 15–18 September 2008; pp. 87–90. [Google Scholar] [CrossRef]

- Guo, A.; Starner, T.; Raghu, S.; Xie, X.; Ismail, S.; Luo, X.; Simoneau, J.; Gilliland, S.; Baumann, H.; Southern, C. A Comparison of Order Picking Assisted by Head-up Display (HUD), Cart-Mounted Display (CMD), Light, and Paper Pick List. In Proceedings of the 2014 ACM International Symposium on Wearable Computers—ISWC ’14, Seattle, WA, USA, 13–17 September 2014. [Google Scholar]

- Lang, S.; Dastagir Kota, M.S.S.; Weigert, D.; Behrendt, F. Mixed Reality in Production and Logistics: Discussing the Application Potentials of Microsoft HoloLensTM. Procedia Comput. Sci. 2019, 149, 118–129. [Google Scholar] [CrossRef]

- Wu, X.; Haynes, M.; Zhang, Y.; Jiang, Z.; Shen, Z.; Guo, A.; Starner, T.; Gilliland, S. Comparing Order Picking Assisted by Head-up Display versus Pick-by-Light with Explicit Pick Confirmation. In Proceedings of the 2015 ACM International Symposium on Wearable Computers—ISWC’15, Osaka, Japan, 7–11 September 2015. [Google Scholar]

- Elbert, R.; Knigge, J.K.; Makhlouf, R.; Sarnow, T. Experimental Study on User Rating of Virtual Reality Applications in Manual Order Picking. IFAC-Pap. 2019, 52, 719–724. [Google Scholar] [CrossRef]

- Herter, J. Augmented Reality Supported Order Picking Using Projected User Interfaces. Bachelor’s Thesis, University of Stuttgart, Stuttgart, Germany, 2014. [Google Scholar]

- Pickl, S. Augmented Reality for Order Picking Using Wearable Computers with Head-Mounted Displays. Bachelor’s Thesis, University of Stuttgart, Stuttgart, Germany, 2014. [Google Scholar]

- Saaty, T.L. Decision Making with the Analytic Hierarchy Process. Int. J. Serv. Sci. 2008, 1, 83–98. [Google Scholar] [CrossRef]

- NIST/SEMATECH E-Handbook of Statistical Methods; NIST: Gaithersburg, MD, USA, 2012. [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments, 5th ed.; Wiley: Hoboken, NJ, USA, 2012. [Google Scholar]

- Eisenstein, D.D. Analysis and Optimal Design of Discrete Order Picking Technologies along a Line. Nav. Res. Logist. 2008, 55, 350–362. [Google Scholar] [CrossRef]

- De Koster, R.; Le-Duc, T.; Roodbergen, K.J. Design and Control of Warehouse Order Picking: A Literature Review. Eur. J. Oper. Res. 2007, 182, 481–501. [Google Scholar] [CrossRef]

- NASA. NASA Task Load Index—V 1.0; NASA Ames Research Center: Moffett Field, CA, USA, 1986. [Google Scholar]

- Zimmerman, M.E. Task Load. In Encyclopedia of Clinical Neuropsychology; Springer: Cham, Switzerland, 2018; pp. 3403–3404. [Google Scholar] [CrossRef]

- Farmer, E.; Brownson, A. Review of Workload Measurement, Analysis and Interpretation Methods. Eur. Organ. Saf. Air Navig. 2003, 47, 5427–5438. [Google Scholar] [CrossRef]

- Casner, S.M.; Gore, B.F. Measuring and Evaluating Workload: A Primer. NASA Tech. Memo. 2010, 35, 216395. [Google Scholar]

| No | Description of Research Question |

|---|---|

| RQ1 | Which are the main parameters that should be taken into consideration for a pick-by-vision device parameterization (system design)? |

| RQ2 | Which are the main parameters that should be taken into consideration for the evaluation and optimization of pick-by-vision systems in terms of operational performance? |

| RQ3 | Which are the main parameters that should be taken into consideration for the evaluation and comparative assessment of pick-by-vision technology in terms of order profile? |

| RQ4 | Which are the main performance measurement indices and side effects that should be taken into consideration for the evaluation pick-by-vision technology in terms of performance and ergonomics? |

| Inclusion Criteria | Description |

|---|---|

| Search terms/Keywords | Vision picking, pick-by-vision, wearable technology, wearable computers, order picking, augmented reality, head-mounted displays, smart glasses, user interface, logistics |

| Source types | (a) peer-reviewed journals, (b) international conferences, (c) reports, (d) dissertations |

| Language | English |

| Category | Subcategory | Parameter | References |

|---|---|---|---|

| A. Parameters for system design | Ergonomic aspects | Display Position | [22,23,24] |

| Display Type | [24,25,26,27] | ||

| Interaction Device | [24,25,28,29,30,31] | ||

| Battery Position | [27] | ||

| Display Holder | [22,30,32] | ||

| Scanner Position | [9,32,33,34,35] | ||

| Weight of Equipment | [27,34,36,37,38] | ||

| Visualization aspects | Field of View | [26,30,39,40,41] | |

| Focal Distance | [26,39,42] | ||

| Visualization Optics | [29,38,41,43,44] | ||

| Information Mode | [8,22,25,26,45,46] | ||

| Information Availability | [25,34] | ||

| Display View | [9,33,37,47,48] | ||

| Existence of AR | [45,46,49] | ||

| Direction Interface | [28,32,50,51,52] | ||

| Display Settings | [25,26,29] | ||

| Technical aspects | Barcode Type | [9,35,53,54,55] | |

| Scanning Distance | [8,44,56,57,58] | ||

| Battery Life | [27,38,59,60,61] | ||

| Existence of Tracking System | [32,40] | ||

| Confirmation Equipment | [28,34,36,41,62] | ||

| B. Parameters for system evaluation in terms of operation | Picking Strategy | [63,64] | |

| Handling Unit | [32,57] | ||

| Existence of Confirmation | [14,28,29,37,65] | ||

| C. Parameters for system evaluation in terms of order profile | Number of Orders | [33,36,37,47,49,56,59,66] | |

| Lines per Order | [14,24,33,37,47,56,64,66,67,68] | ||

| Items per Line | [14,32,33,37,47,49,56,64,66] | ||

| D. Performance measurement indices | Efficiency (Time) | [9,25,34,47,62,65] | |

| Accuracy | [23,25,34,39,47,65] | ||

| Workload | [30,33,34,37,41,42,68] | ||

| Dimension Description | Weight of Dimensions | Rank | Parameters Description | Local Weight of Parameters | Overall Weight of Parameters | Overall Ranking of Parameters |

|---|---|---|---|---|---|---|

| Ergonomic aspects(EAs) | 0.44 | 1st | Display Position | 0.023 | 0.023 | 17th |

| Display Type | 0.069 | 0.069 | 6th | |||

| Interaction Device | 0.032 | 0.032 | 11th | |||

| Display Holder | 0.024 | 0.024 | 16th | |||

| Weight of Equipment | 0.151 | 0.151 | 1st | |||

| Scanner Position | 0.076 | 0.076 | 4th | |||

| Battery Position | 0.030 | 0.030 | 12th | |||

| Storage level | 0.034 | 0.034 | 10th | |||

| Visualization aspects(VAs) | 0.16 | 3rd | Field of View | 0.060 | 0.060 | 7th |

| Focal Distance | 0.009 | 0.009 | 23rd | |||

| Visualization Optics | 0.006 | 0.006 | 24th | |||

| Information Mode | 0.035 | 0.035 | 9th | |||

| Information Availability | 0.025 | 0.025 | 14th | |||

| Display View | 0.013 | 0.013 | 22nd | |||

| Existence of AR | 0.004 | 0.004 | 26th | |||

| Direction Interface | 0.003 | 0.003 | 28th | |||

| Display Settings | 0.018 | 0.018 | 20th | |||

| Technical aspects(TAs) | 0.08 | 5th | Barcode Type | 0.029 | 0.029 | 13th |

| Scanning Distance | 0.006 | 0.006 | 25th | |||

| Battery Life | 0.043 | 0.043 | 8th | |||

| Ex. of Tracking System | 0.004 | 0.004 | 27th | |||

| Confirmation Equipment | 0.020 | 0.020 | 19th | |||

| Operation aspects(OAs) | 0.11 | 4th | Picking Strategy | 0.069 | 0.069 | 5th |

| Handling Unit | 0.025 | 0.025 | 15th | |||

| Existence of Confirmation | 0.013 | 0.013 | 21st | |||

| Order-profile aspects(OPAs) | 0.21 | 2nd | Number of Orders | 0.079 | 0.079 | 3rd |

| Lines per Order | 0.107 | 0.107 | 2nd | |||

| Items per Line | 0.021 | 0.021 | 18th |

| Run | Battery Position | Type of Order | Storage Level | Confirmation Equipment | Items per Order Line | Order Lines per Order |

|---|---|---|---|---|---|---|

| 1 | Weighted Side | Discrete | Low | Scanner | Few | Few |

| 2 | Weighted Side | Discrete | Low | Scanner | Few | Many |

| 3 | Weighted Side | Discrete | Low | Scanner | Many | Few |

| 4 | Weighted Side | Discrete | Low | Scanner | Many | Many |

| 5 | Weighted Side | Discrete | Low | RFID Reader | Few | Few |

| 6 | Weighted Side | Discrete | Low | RFID Reader | Few | Many |

| 7 | Weighted Side | Discrete | Low | RFID Reader | Many | Few |

| 8 | Weighted Side | Discrete | Low | RFID Reader | Many | Many |

| 9 | Weighted Side | Discrete | High | Scanner | Few | Few |

| 10 | Weighted Side | Discrete | High | Scanner | Few | Many |

| 11 | Weighted Side | Discrete | High | Scanner | Many | Few |

| 12 | Weighted Side | Discrete | High | Scanner | Many | Many |

| 13 | Weighted Side | Discrete | High | RFID Reader | Few | Few |

| 14 | Weighted Side | Discrete | High | RFID Reader | Few | Many |

| 15 | Weighted Side | Discrete | High | RFID Reader | Many | Few |

| 16 | Weighted Side | Discrete | High | RFID Reader | Many | Many |

| 17 | Weighted Side | Multiple | Low | Scanner | Few | Few |

| 18 | Weighted Side | Multiple | Low | Scanner | Few | Many |

| 19 | Weighted Side | Multiple | Low | Scanner | Many | Few |

| 20 | Weighted Side | Multiple | Low | Scanner | Many | Many |

| 21 | Weighted Side | Multiple | Low | RFID Reader | Few | Few |

| 22 | Weighted Side | Multiple | Low | RFID Reader | Few | Many |

| 23 | Weighted Side | Multiple | Low | RFID Reader | Many | Few |

| 24 | Weighted Side | Multiple | Low | RFID Reader | Many | Many |

| 25 | Weighted Side | Multiple | High | Scanner | Few | Few |

| 26 | Weighted Side | Multiple | High | Scanner | Few | Many |

| 27 | Weighted Side | Multiple | High | Scanner | Many | Few |

| 28 | Weighted Side | Multiple | High | Scanner | Many | Many |

| 29 | Weighted Side | Multiple | High | RFID Reader | Few | Few |

| 30 | Weighted Side | Multiple | High | RFID Reader | Few | Many |

| 31 | Weighted Side | Multiple | High | RFID Reader | Many | Few |

| 32 | Weighted Side | Multiple | High | RFID Reader | Many | Many |

| 33 | Weighted Back | Discrete | Low | Scanner | Few | Few |

| 34 | Weighted Back | Discrete | Low | Scanner | Few | Many |

| 35 | Weighted Back | Discrete | Low | Scanner | Many | Few |

| 36 | Weighted Back | Discrete | Low | Scanner | Many | Many |

| 37 | Weighted Back | Discrete | Low | RFID Reader | Few | Few |

| 38 | Weighted Back | Discrete | Low | RFID Reader | Few | Many |

| 39 | Weighted Back | Discrete | Low | RFID Reader | Many | Few |

| 40 | Weighted Back | Discrete | Low | RFID Reader | Many | Many |

| 41 | Weighted Back | Discrete | High | Scanner | Few | Few |

| 42 | Weighted Back | Discrete | High | Scanner | Few | Many |

| 43 | Weighted Back | Discrete | High | Scanner | Many | Few |

| 44 | Weighted Back | Discrete | High | Scanner | Many | Many |

| 45 | Weighted Back | Discrete | High | RFID Reader | Few | Few |

| 46 | Weighted Back | Discrete | High | RFID Reader | Few | Many |

| 47 | Weighted Back | Discrete | High | RFID Reader | Many | Few |

| 48 | Weighted Back | Discrete | High | RFID Reader | Many | Many |

| 49 | Weighted Back | Multiple | Low | Scanner | Few | Few |

| 50 | Weighted Back | Multiple | Low | Scanner | Few | Many |

| 51 | Weighted Back | Multiple | Low | Scanner | Many | Few |

| 52 | Weighted Back | Multiple | Low | Scanner | Many | Many |

| 53 | Weighted Back | Multiple | Low | RFID Reader | Few | Few |

| 54 | Weighted Back | Multiple | Low | RFID Reader | Few | Many |

| 55 | Weighted Back | Multiple | Low | RFID Reader | Many | Few |

| 56 | Weighted Back | Multiple | Low | RFID Reader | Many | Many |

| 57 | Weighted Back | Multiple | High | Scanner | Few | Few |

| 58 | Weighted Back | Multiple | High | Scanner | Few | Many |

| 59 | Weighted Back | Multiple | High | Scanner | Many | Few |

| 60 | Weighted Back | Multiple | High | Scanner | Many | Many |

| 61 | Weighted Back | Multiple | High | RFID Reader | Few | Few |

| 62 | Weighted Back | Multiple | High | RFID Reader | Few | Many |

| 63 | Weighted Back | Multiple | High | RFID Reader | Many | Few |

| 64 | Weighted Back | Multiple | High | RFID Reader | Many | Many |

| Source of Variation | Term | p-Value |

|---|---|---|

| Main Effects | Battery Position | 0.55 |

| Type of Order | 0.052 | |

| Storage Level | 0.732 | |

| Confirmation Equipment | 0 | |

| Items per Order Line | 0 | |

| Order Lines per Order | 0.173 | |

| 2-way interactions | Battery Position*Type of Order | 0.35 |

| Battery Position*Storage Level | 0.314 | |

| Battery Position*Confirmation Equipment | 0.031 | |

| Battery Position*Items per Order Line | 0.925 | |

| Battery Position*Order Lines per Order | 0.256 | |

| Type of Order*Storage Level | 0.042 | |

| Type of Order*Confirmation Equipment | 0.004 | |

| Type of Order*Items per Order Line | 0.145 | |

| Type of Order*Order Lines per Order | 0.053 | |

| Storage Level*Confirmation Equipment | 0.014 | |

| Storage Level*Items per Order Line | 0.621 | |

| Storage Level*Order Lines per Order | 0.062 | |

| Confirmation Equipment*Items per Order Line | 0.008 | |

| Confirmation Equipment*Order Lines per Order | 0.219 | |

| Items per Order Line*Order Lines per Order | 0.019 | |

| 3-way interactions | Battery Position*Type of Order*Storage Level | 0.513 |

| Battery Position*Type of Order*Confirmation Equipment | 0.085 | |

| Battery Position*Type of Order*Items per Order Line | 0.564 | |

| Battery Position*Type of Order*Order Lines per Order | 0.839 | |

| Battery Position*Storage Level*Confirmation Equipment | 0.411 | |

| Battery Position*Storage Level*Items per Order Line | 0.77 | |

| Battery Position*Storage Level*Order Lines per Order | 0.891 | |

| Battery Position*Confirmation Equipment*Items per Order Line | 0.374 | |

| Battery Position*Confirmation Equipment*Order Lines per Order | 0.251 | |

| Battery Position*Items per Order Line*Order Lines per Order | 0.111 | |

| Type of Order*Storage Level*Confirmation Equipment | 0.644 | |

| Type of Order*Storage Level*Items per Order Line | 0.003 | |

| Type of Order*Storage Level*Order Lines per Order | 0.932 | |

| Type of Order*Confirmation Equipment*Items per Order Line | 0.436 | |

| Type of Order*Confirmation Equipment*Order Lines per Order | 0.855 | |

| Type of Order*Items per Order Line*Order Lines per Order | 0.778 | |

| Storage Level*Confirmation Equipment*Items per Order Line | 0.386 | |

| Storage Level*Confirmation Equipment*Order Lines per Order | 0.092 | |

| Storage Level*Items per Order Line*Order Lines per Order | 0.128 | |

| Confirmation Equipment*Items per Order Line*Order Lines per Order | 0.005 | |

| 4-way interactions | Battery Position*Type of Order*Storage Level*Confirmation Equipment | 0.125 |

| Battery Position*Type of Order*Storage Level*Items per Order Line | 0.815 | |

| Battery Position*Type of Order*Storage Level*Order Lines per Order | 0.729 | |

| Battery Position*Type of Order*Confirmation Equipment*Items per Order Line | 0.572 | |

| Battery Position*Type of Order*Confirmation Equipment*Order Lines per Order | 0.181 | |

| Battery Position*Type of Order*Items per Order Line*Order Lines per Order | 0.603 | |

| Battery Position*Storage Level*Confirmation Equipment*Items per Order Line | 0.552 | |

| Battery Position*Storage Level*Confirmation Equipment*Order Lines per Order | 0.797 | |

| Battery Position*Storage Level*Items per Order Line*Order Lines per Order | 0.53 | |

| Battery Position*Confirmation Equipment*Items per Order Line*Order Lines per Order | 0.111 | |

| Type of Order*Storage Level*Confirmation Equipment*Items per Order Line | 0.171 | |

| Type of Order*Storage Level*Confirmation Equipment*Order Lines per Order | 0.963 | |

| Type of Order*Storage Level*Items per Order Line*Order Lines per Order | 0.048 | |

| Type of Order*Confirmation Equipment*Items per Order Line*Order Lines per Order | 0.422 | |

| Storage Level*Confirmation Equipment*Items per Order Line*Order Lines per Order | 0.43 | |

| 5-way interactions | Battery Position*Type of Order*Storage Level*Confirmation Equipment*Items per Order Line | 0.341 |

| Battery Position*Type of Order*Storage Level*Confirmation Equipment*Order Lines per Order | 0.608 | |

| Battery Position*Type of Order*Storage Level*Items per Order Line*Order Lines per Order | 0.156 | |

| Battery Position*Type of Order*Confirmation Equipment*Items per Order Line*Order Lines per Order | 0.34 | |

| Battery Position*Storage Level*Confirmation Equipment*Items per Order Line*Order Lines per Order | 0.035 | |

| Type of Order*Storage Level*Confirmation Equipment*Items per Order Line*Order Lines per Order | 0.942 | |

| Battery Position*Type of Order*Storage Level*Confirmation Equipment*Items per Order Line*Order Lines per Order | 0.371 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chondromatidis, N.; Gialos, A.; Zeimpekis, V. Investigating the Performance of the Order-Picking Process by Using Smart Glasses: A Laboratory Experimental Approach. Logistics 2022, 6, 84. https://doi.org/10.3390/logistics6040084

Chondromatidis N, Gialos A, Zeimpekis V. Investigating the Performance of the Order-Picking Process by Using Smart Glasses: A Laboratory Experimental Approach. Logistics. 2022; 6(4):84. https://doi.org/10.3390/logistics6040084

Chicago/Turabian StyleChondromatidis, Nikolaos, Anastasios Gialos, and Vasileios Zeimpekis. 2022. "Investigating the Performance of the Order-Picking Process by Using Smart Glasses: A Laboratory Experimental Approach" Logistics 6, no. 4: 84. https://doi.org/10.3390/logistics6040084

APA StyleChondromatidis, N., Gialos, A., & Zeimpekis, V. (2022). Investigating the Performance of the Order-Picking Process by Using Smart Glasses: A Laboratory Experimental Approach. Logistics, 6(4), 84. https://doi.org/10.3390/logistics6040084