Current Trend of Industry 4.0 in Logistics and Transformation of Logistics Processes Using Digital Technologies: An Empirical Study in the Slovak Republic

Abstract

1. Introduction

2. Literature Overview

2.1. Conceptual Framework for Industry 4.0

2.2. Role of Technologies in the Age of Industry 4.0

2.3. Digital Transformation of Logistics-Logistics 4.0

3. Research Methodology

- The comparative overview of views on a conceptual framework for Industry 4.0,

- The comparative analysis of views on the role of technology in the age of Industry 4.0,

- The comparative review of views on the digital transformation of logistics-Logistics 4.0,

- Descriptive analysis of the questionnaire survey,

- Inferential analysis of the questionnaire survey,

- Summarisation of the research issues.

3.1. Description of Collection Tool

3.2. Research Design

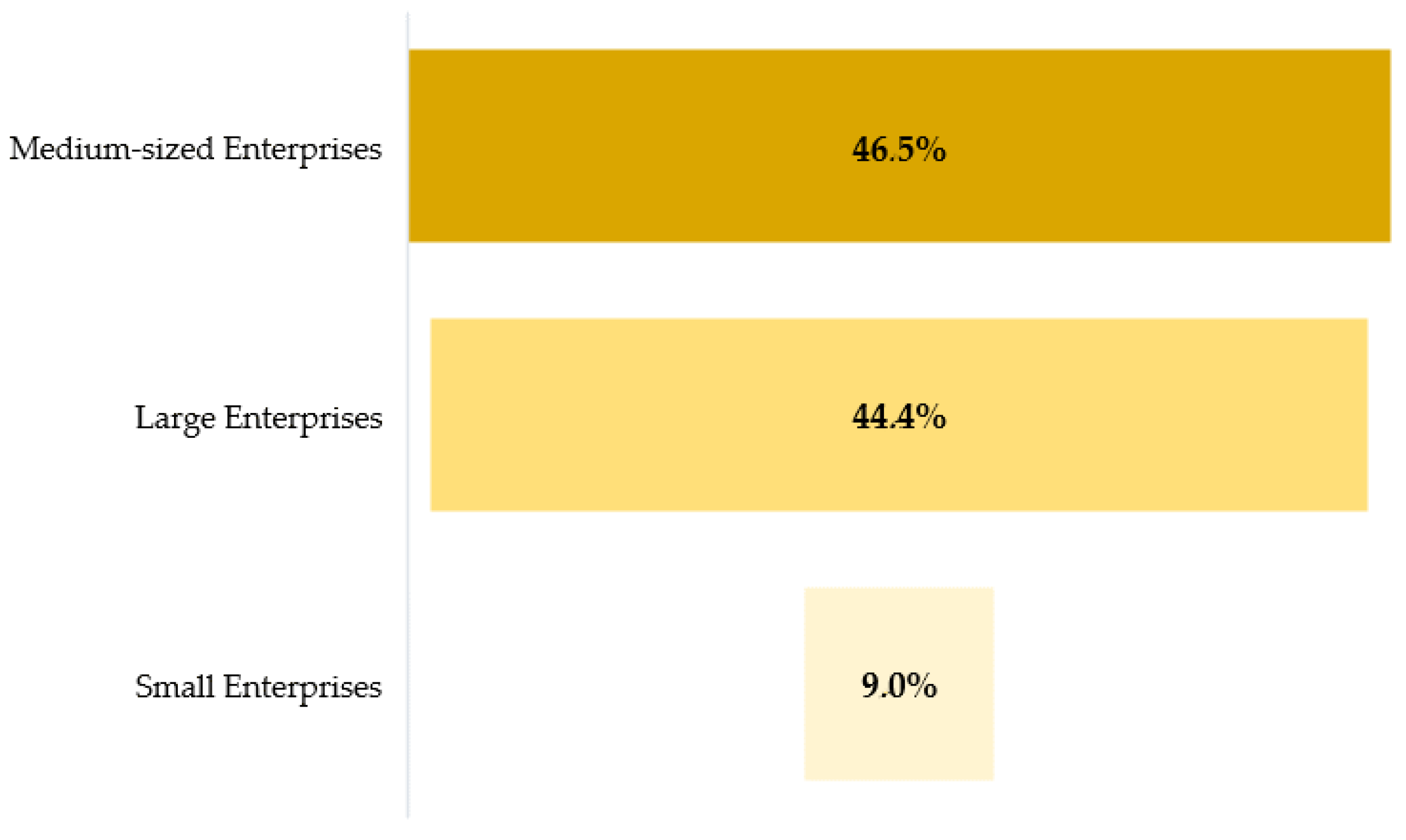

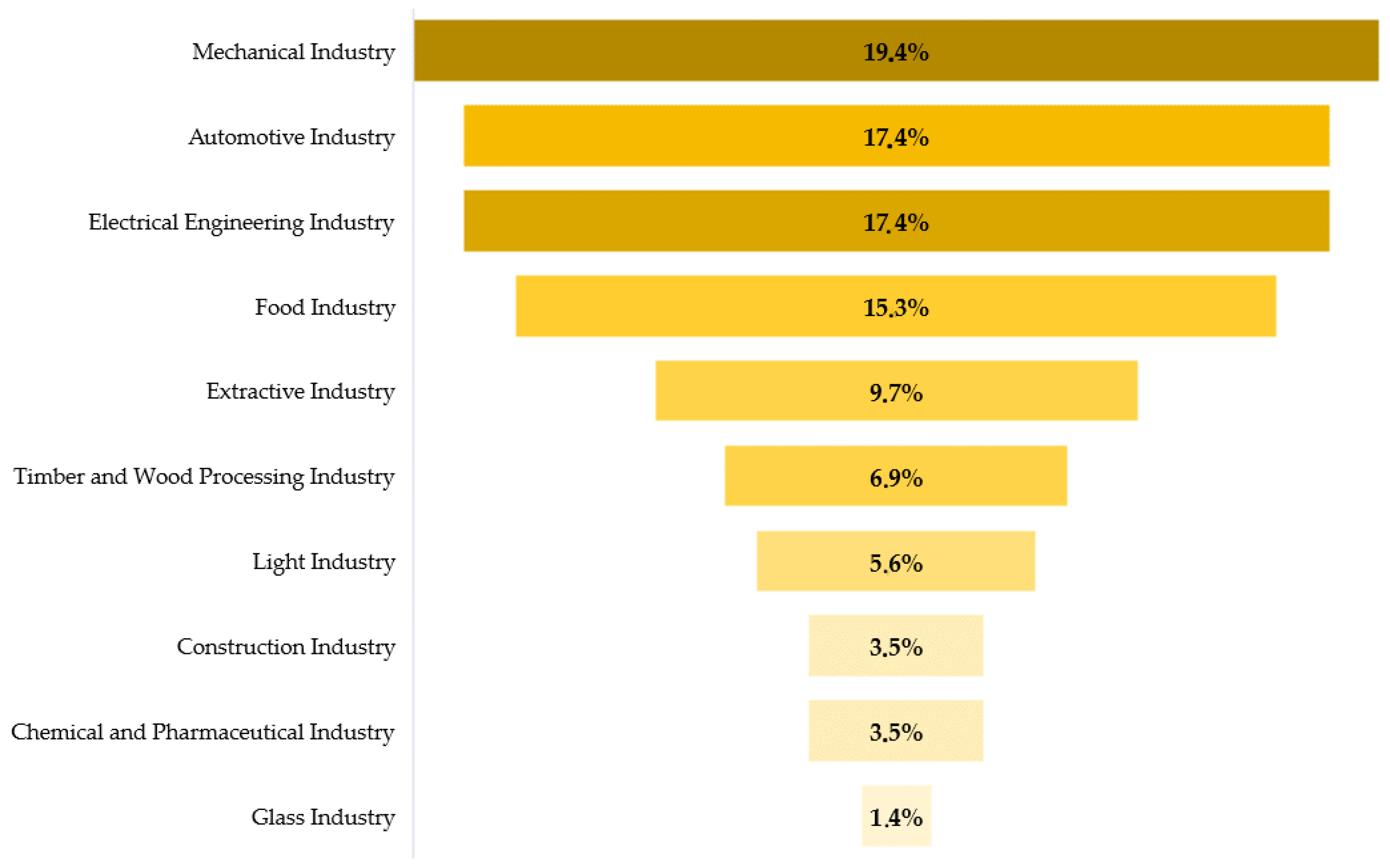

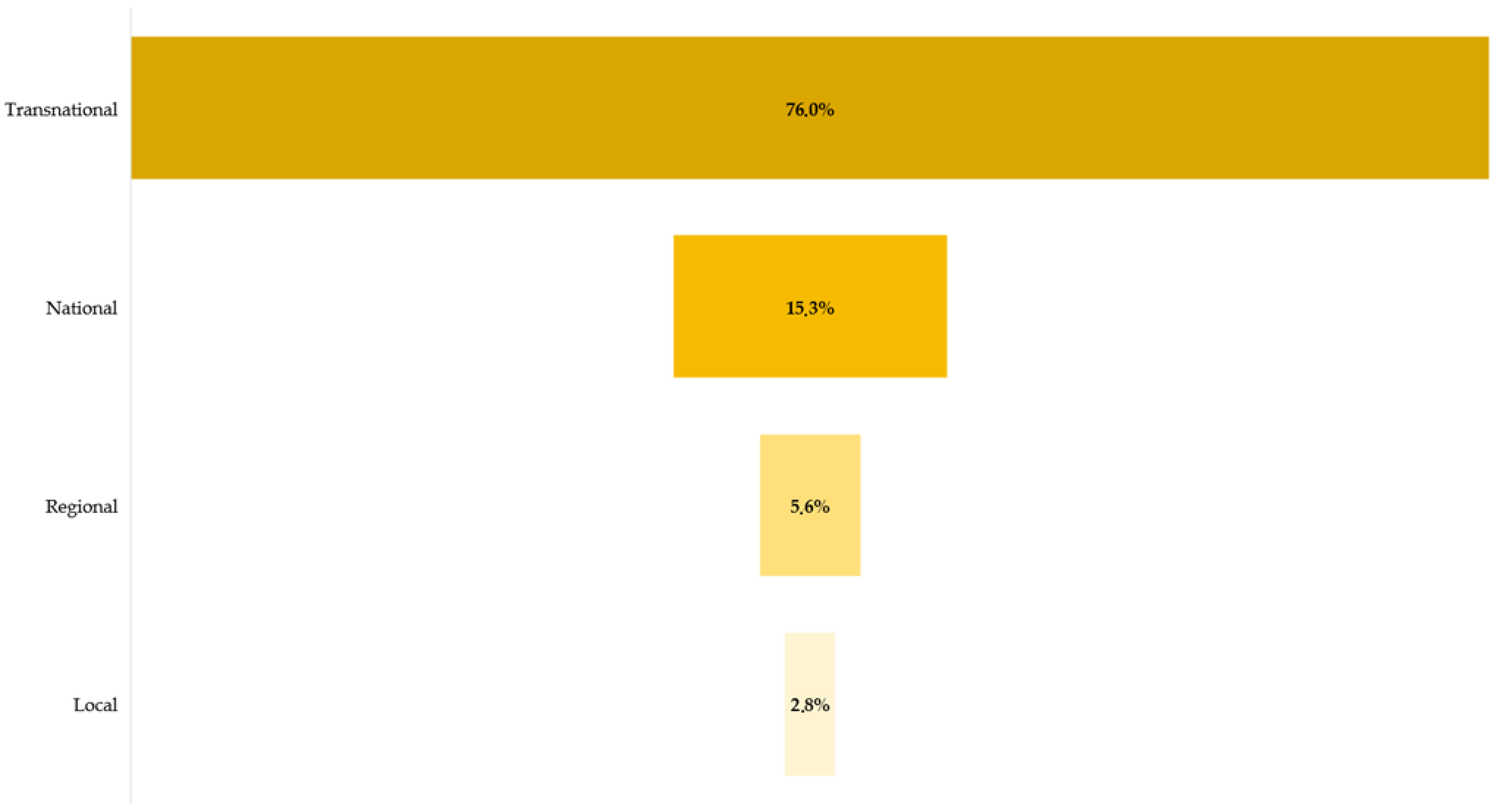

3.3. Descriptions of Research Participants

4. Results Analysis and Discussion

4.1. Evaluation of Descriptive Analysis

4.2. Evaluation of Inferential Analysis

Research Question (RQ): How Is Industry 4.0 Affecting Corporate Logistics?

5. Conclusions

5.1. Research Implications

5.2. Limitations

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bohsali, S.; Samad, R.A. Preparing for the Digital Era: The State of Digitalization in GCC Businesses. Available online: https://www.strategyand.pwc.com/reports/preparingdigital-era (accessed on 10 June 2022).

- Nwaiwu, F. Review and Comparison of Conceptual Frameworks on Digital Business Transformation. J. Compet. 2018, 10, 86–100. [Google Scholar] [CrossRef]

- Rymaszewska, A.; Helo, P.; Gunasekaran, A. IoT powered servitization of manufacturing—An exploratory case study. Int. J. Prod. Econ. 2017, 192, 92–105. [Google Scholar] [CrossRef]

- Brunswicker, S.; Bertino, E.; Matei, S. Big Data for Open Digital Innovation—A Research Roadmap. Big Data Res. 2015, 2, 53–58. [Google Scholar] [CrossRef]

- Mittal, S.; Khan, M.A.; Romero, D.; Wuest, T. Smart manufacturing: Characteristics, technologies and enabling factors. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2017, 233, 1342–1361. [Google Scholar] [CrossRef]

- Pfohl, H.-C.; Yahsi, B.; Kuznaz, T. The impact of Industry 4.0 on the Supply Chain. In Proceedings of the Hamburg International Conference of Logistic (HICL), Berlin, Germany, 20 August 2015; pp. 32–58. [Google Scholar]

- Barrett, M.; Davidson, E.; Prabhu, J.; Vargo, S.L. Service Innovation in the Digital Age: Key Contributions and Future Directions. MIS Q. 2015, 39, 135–154. [Google Scholar] [CrossRef]

- Cichosz, M.; Wallenburg, C.M.; Knemeyer, A.M. Digital transformation at logistics service providers: Barriers, success factors and leading practices. Int. J. Logist. Manag. 2020, 31, 209–238. [Google Scholar] [CrossRef]

- Fragapane, G.; Ivanov, D.; Peron, M.; Sgarbossa, F.; Strandhagen, J.O. Increasing flexibility and productivity in Industry 4.0 production networks with autonomous mobile robots and smart intralogistics. Ann. Oper. Res. 2020, 308, 125–143. [Google Scholar] [CrossRef]

- Schniederjans, D.G.; Curado, C.; Khalajhedayati, M. Supply chain digitisation trends: An integration of knowledge management. Int. J. Prod. Econ. 2019, 220, 107439. [Google Scholar] [CrossRef]

- Rotatori, D.; Lee, E.J.; Sleeva, S. The evolution of the workforce during the fourth industrial revolution. Hum. Resour. Dev. Int. 2020, 24, 92–103. [Google Scholar] [CrossRef]

- Ustundag, A.; Cevikcan, E. Industry 4.0: Managing the Digital Transformation; Springer International: Cham, Switzerland, 2018. [Google Scholar]

- Schäfer, M. The fourth industrial revolution: How the EU can lead it. Eur. View 2018, 17, 5–12. [Google Scholar] [CrossRef]

- Suleiman, Z.; Shaikholla, S.; Dikhanbayeva, D.; Shehab, E.; Turkyilmaz, A. Industry 4.0: Clustering of concepts and characteristics. Cogent Eng. 2022, 9, 2034264. [Google Scholar] [CrossRef]

- Nosalska, K.; Mazurek, G. Marketing principles for Industry 4.0—A conceptual framework. Eng. Manag. Prod. Serv. 2019, 11, 9–20. [Google Scholar] [CrossRef]

- Bláha, J.; Klimsza, L.; Lokaj, A.; Nierostek, L. Multidimensional Analysis of Ethical Leadership for Business Development. Eur. J. Sustain. Dev. 2021, 10, 290. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Industry 4.0, digitization, and opportunities for sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Bauer, W.; Schlund, S.; Hornung, T.; Schuler, S. Digitalization of Industrial Value Chains—A Review and Evaluation of Existing Use Cases of Industry 4.0 in Germany. Logforum 2018, 14, 331–340. [Google Scholar] [CrossRef]

- Bai, C.; Dallasega, P.; Orzes, G.; Sarkis, J. Industry 4.0 technologies assessment: A sustainability perspective. Int. J. Prod. Econ. 2020, 229, 107776. [Google Scholar] [CrossRef]

- Vaidya, S.; Ambad, P.; Bhosle, S. Industry 4.0—A Glimpse. Procedia Manuf. 2018, 20, 233–238. [Google Scholar] [CrossRef]

- Lennon Olsen, T.; Tomlin, B. Industry 4.0: Opportunities and Challenges for Operations Management. SSRN Electron. J. 2019, 22, 113–122. [Google Scholar] [CrossRef]

- Abdirad, M.; Krishnan, K. Industry 4.0 in Logistics and Supply Chain Management: A Systematic Literature Review. Eng. Manag. J. 2020, 33, 187–201. [Google Scholar] [CrossRef]

- Nierostek, L.; Horváthová, P. Importance of Intellectual Capital and Business Education as Global Topic in Development of Company International Business from the Perspective of Company Management. SHS Web Conf. 2021, 92, 1–9. [Google Scholar] [CrossRef]

- Porubčinová, M.; Fidlerová, H. Determinants of Industry 4.0 Technology Adaption and Human—Robot Collaboration. Res. Pap. Fac. Mater. Sci. Technol. Slovak Univ. Technol. 2020, 28, 10–21. [Google Scholar] [CrossRef]

- Mokrá, K.; Horváthová, P.; Kauerová, L. The level of health and safety promotion in workplaces of Czech family-owned manufacturing firms: A case study. J. Hum. Resour. Manag. Comenius Univ. Bratisl. Fac. Manag. 2021, 24, 12–27. [Google Scholar]

- Adamson, G.; Wang, L.; Moore, P. Feature-based control and information framework for adaptive and distributed manufacturing in cyber physical systems. J. Manuf. Syst. 2017, 43, 305–315. [Google Scholar] [CrossRef]

- Lopes de Sousa Jabbour, A.B.; Jabbour, C.J.C.; Godinho Filho, M.; Roubaud, D. Industry 4.0 and the circular economy: A proposed research agenda and original roadmap for sustainable operations. Ann. Oper. Res. 2018, 270, 273–286. [Google Scholar] [CrossRef]

- Grabowska, S. Smart Factories in the Age of Industry 4.0. Manag. Syst. Prod. Eng. 2020, 28, 90–96. [Google Scholar] [CrossRef]

- Fidlerová, H.; Stareček, A.; Vraňaková, N.; Bulut, C.; Keaney, M. Sustainable Entrepreneurship for Business Opportunity Recognition: Analysis of an Awareness Questionnaire among Organisations. Energies 2022, 15, 849. [Google Scholar] [CrossRef]

- Imran, M.; Hameed, W.U.; Haque, A.u. Influence of Industry 4.0 on the Production and Service Sectors in Pakistan: Evidence from Textile and Logistics Industries. Soc. Sci. 2018, 7, 246. [Google Scholar] [CrossRef]

- Kalsoom, T.; Ramzan, N.; Ahmed, S.; Ur-Rehman, M. Advances in Sensor Technologies in the Era of Smart Factory and Industry 4.0. Sensors 2020, 20, 6783. [Google Scholar] [CrossRef]

- Bigliardi, B.; Bottani, E.; Casella, G. Enabling technologies, application areas and impact of industry 4.0: A bibliographic analysis. Procedia Manuf. 2020, 42, 322–326. [Google Scholar] [CrossRef]

- Ibarra, D.; Ganzarain, J.; Igartua, J.I. Business model innovation through Industry 4.0: A review. Procedia Manuf. 2018, 22, 4–10. [Google Scholar] [CrossRef]

- De Giovanni, P.; Cariola, A. Process innovation through industry 4.0 technologies, lean practices and green supply chains. Res. Transp. Econ. 2020, 90, 100869. [Google Scholar] [CrossRef]

- Dilyard, J.; Zhao, S.; You, J.J. Digital innovation and Industry 4.0 for global value chain resilience: Lessons learned and ways forward. Thunderbird Int. Bus. Rev. 2021, 63, 577–584. [Google Scholar] [CrossRef]

- Alcácer, V.; Cruz-Machado, V. Scanning the Industry 4.0: A Literature Review on Technologies for Manufacturing Systems. Eng. Sci. Technol. Int. J. 2019, 22, 899–919. [Google Scholar] [CrossRef]

- Chiarini, A. Industry 4.0 technologies in the manufacturing sector: Are we sure they are all relevant for environmental performance? Bus. Strategy Environ. 2021, 30, 3194–3207. [Google Scholar] [CrossRef]

- Tutak, M.; Brodny, J. Business Digital Maturity in Europe and Its Implication for Open Innovation. J. Open Innov. Technol. Mark. Complex. 2022, 8, 27. [Google Scholar] [CrossRef]

- Pivoto, D.G.S.; de Almeida, L.F.F.; da Rosa Righi, R.; Rodrigues, J.J.P.C.; Lugli, A.B.; Alberti, A.M. Cyber-physical systems architectures for industrial internet of things applications in Industry 4.0: A literature review. J. Manuf. Syst. 2021, 58, 176–192. [Google Scholar] [CrossRef]

- Sony, M.; Naik, S. Key ingredients for evaluating Industry 4.0 readiness for organizations: A literature review. Benchmarking Int. J. 2019, 27, 2213–2232. [Google Scholar] [CrossRef]

- Rayna, T.; Striukova, L. 360° Business Model Innovation: Toward an Integrated View of Business Model Innovation. Res. Technol. Manag. 2016, 59, 21–28. [Google Scholar] [CrossRef][Green Version]

- Markov, K.; Vitliemov, P. Logistics 4.0 and supply chain 4.0 in the automotive industry. IOP Conf. Ser. Mater. Sci. Eng. 2020, 878, 012047. [Google Scholar] [CrossRef]

- Ghadge, A.; Er Kara, M.; Moradlou, H.; Goswami, M. The impact of Industry 4.0 implementation on supply chains. J. Manuf. Technol. Manag. 2020, 31, 669–686. [Google Scholar] [CrossRef]

- Bongomin, O.; Gilibrays Ocen, G.; Oyondi Nganyi, E.; Musinguzi, A.; Omara, T. Exponential Disruptive Technologies and the Required Skills of Industry 4.0. J. Eng. 2020, 2020, 1–17. [Google Scholar] [CrossRef]

- Kosacka-Olejnik, M.; Pitakaso, R. Industry 4.0: State of the art and research implications. Logforum 2019, 15, 478–485. [Google Scholar] [CrossRef]

- Ammar, M.; Haleem, A.; Javaid, M.; Walia, R.; Bahl, S. Improving material quality management and manufacturing organizations system through Industry 4.0 technologies. Mater. Today Proc. 2021, 45, 5089–5096. [Google Scholar] [CrossRef]

- Sahal, R.; Alsamhi, S.H.; Breslin, J.G.; Brown, K.N.; Ali, M.I. Digital Twins Collaboration for Automatic Erratic Operational Data Detection in Industry 4.0. Appl. Sci. 2021, 11, 3186. [Google Scholar] [CrossRef]

- Rosin, F.; Forget, P.; Lamouri, S.; Pellerin, R. Impacts of Industry 4.0 technologies on Lean principles. Int. J. Prod. Res. 2019, 58, 1644–1661. [Google Scholar] [CrossRef]

- Čemerková, Š.; Malátek, V. Human Resources Management in Multinational Companies in Response to Logistics Needs and Meeting Their Goals. In Proceedings of the 2nd International Conference on Decision Making for Small and Medium-Sized Enterprises; Conference Proceedings. Silesian University in Opava, School of Business Administration in Karviná: Karviná, Czech Republic, 2019; pp. 61–69. [Google Scholar]

- Nitsche, B.; Straube, F.; Wirth, M. Application areas and antecedents of automation in logistics and supply chain management: A conceptual framework. Supply Chain. Forum Int. J. 2021, 22, 223–239. [Google Scholar] [CrossRef]

- Nitsche, B.; Straube, F. Defining the “New Normal” in International Logistics Networks: Lessons Learned and Implications of the COVID-19 Pandemic. WiSt—Wirtsch. Stud. 2021, 50, 16–25. [Google Scholar] [CrossRef]

- Nitsche, B. Exploring the Potentials of Automation in Logistics and Supply Chain Management: Paving the Way for Autonomous Supply Chains. Logistics 2021, 5, 51. [Google Scholar] [CrossRef]

- Gerlach, B.; Zarnitz, S.; Nitsche, B.; Straube, F. Digital Supply Chain Twins—Conceptual Clarification, Use Cases and Benefits. Logistics 2021, 5, 86. [Google Scholar] [CrossRef]

- Winkelhaus, S.; Grosse, E.H. Logistics 4.0: A systematic review towards a new logistics system. Int. J. Prod. Res. 2019, 58, 18–43. [Google Scholar] [CrossRef]

- Dördüncü, H. Logistics, Supply Chains and Smart Factories. In Accounting, Finance, Sustainability, Governance & Fraud: Theory and Application; Springer: Singapore, 2021; pp. 137–152. [Google Scholar] [CrossRef]

- Barreto, L.; Amaral, A.; Pereira, T. Industry 4.0 implications in logistics: An overview. Procedia Manuf. 2017, 13, 1245–1252. [Google Scholar] [CrossRef]

- Nicoletti, B. The Future: Procurement 4.0. Agile Procurement; Palgrave Macmillan: Cham, Switzerland, 2017; pp. 189–230. [Google Scholar] [CrossRef]

- Kozma, D.; Varga, P.; Hegedüs, C. Supply Chain Management and Logistics 4.0—A Study on Arrowhead Framework Integration. In Proceedings of the 8th International Conference on Industrial Technology and Management (ICITM), Cambridge, UK, 2–4 March 2019. [Google Scholar] [CrossRef]

- Tutam, M. Warehousing 4.0. In Accounting, Finance, Sustainability, Governance & Fraud: Theory and Application; Springer: Singapore, 2021; pp. 95–118. [Google Scholar] [CrossRef]

- Brach, J. Formation of transport 4.0 and transport system 4.0 in the context of the impact of revolution 4.0 on modern road transport. Ekon. XXI Wieku 2019, 3, 87–101. [Google Scholar] [CrossRef]

- Jeschke, S. Logistics 4.0—Artificial Intelligence and Other Modern Trends in Transport and Logistics. In XIII Forum of Polish Logistics Managers POLISH LOGISTICS; Center for Innovation Management and Transfer of Technology in Warsaw; University of Technology: Warsaw, Poland, 2016. [Google Scholar]

- Amr, M.; Ezzat, M.; Kassem, S. Logistics 4.0: Definition and Historical Background. In Proceedings of the 2019 Novel Intelligent and Leading Emerging Sciences Conference (NILES), Giza, Egypt, 28–30 October 2019. [Google Scholar] [CrossRef]

- Glistau, E.; Coello Machado, N.I. Industry 4.0, Logistics 4.0 and Materials—Chances and Solutions. Mater. Sci. Forum 2018, 919, 307–314. [Google Scholar] [CrossRef]

- Kim, E.; Kim, Y.; Park, J. The Necessity of Introducing Autonomous Trucks in Logistics 4.0. Sustainability 2022, 14, 3978. [Google Scholar] [CrossRef]

- Strandhagen, J.O.; Vallandingham, L.R.; Fragapane, G.; Strandhagen, J.W.; Stangeland, A.B.H.; Sharma, N. Logistics 4.0 and emerging sustainable business models. Adv. Manuf. 2017, 5, 359–369. [Google Scholar] [CrossRef]

- Şekkeli, Z.H.; Bakan, İ. By the Effect of the Industry 4.0 on Logistics 4.0. J. Life Econ. 2018, 5, 17–36. [Google Scholar] [CrossRef]

- Timm, I.J.; Lorig, F. Logistics 4.0—A challenge for simulation. In Proceedings of the 2015 Winter Simulation Conference (WSC), Huntington Beach, CA, USA, 6–9 December 2015. [Google Scholar] [CrossRef]

- Prinz, C.; Morlock, F.; Freith, S.; Kreggenfeld, N.; Kreimeier, D.; Kuhlenkötter, B. Learning Factory Modules for Smart Factories in Industrie 4.0. Procedia CIRP 2016, 54, 113–118. [Google Scholar] [CrossRef]

- Gattullo, M.; Scurati, G.W.; Fiorentino, M.; Uva, A.E.; Ferrise, F.; Bordegoni, M. Towards augmented reality manuals for industry 4.0: A methodology. Robot. Comput. -Integr. Manuf. 2019, 56, 276–286. [Google Scholar] [CrossRef]

- Diniz, F.; Duarte, N.; Amaral, A.; Pereira, C. Industry 4.0: Individual Perceptions About Its Nine Technologies. In Lecture Notes in Information Systems and Organisation; Springer: Cham, Switzerland, 2022; pp. 257–267. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Sustainable Industry 4.0 framework: A systematic literature review identifying the current trends and future perspectives. Process Saf. Environ. Prot. 2018, 117, 408–425. [Google Scholar] [CrossRef]

- Klee, H.; Allen, R. Simulation of Dynamic Systems with MATLAB and Simulink, 3rd ed.; Taylor & Francis: Boca Raton, FL, USA, 2018. [Google Scholar]

- Sigov, A.; Ratkin, L.; Ivanov, L.A.; Xu, L.D. Emerging Enabling Technologies for Industry 4.0 and Beyond. Information Systems Front. A J. Res. Innov. 2022, 24, 1–11. [Google Scholar] [CrossRef]

- Kumar, A.; Nayyar, A. si3-Industry: A Sustainable, Intelligent, Innovative, Internet-of-Things Industry. In A Roadmap to Industry 4.0: Smart Production, Sharp Business and Sustainable Development; Springer: Cham, Switzerland, 2019; pp. 1–21. [Google Scholar] [CrossRef]

- Graetz, G.; Michaels, G. Robots at Work. Rev. Econ. Stat. 2018, 100, 753–768. [Google Scholar] [CrossRef]

- Perona, M.; Zheng, T.; Adrodegari, F.; Ardolino, M.; Bacchetti, A. An exploratory survey on the impacts of Logistics 4.0 on Italian manufacturing companies. Int. J. Logist. Syst. Manag. 2021, 1, 1. [Google Scholar] [CrossRef]

- Nobrega, J.H.C.; Rampasso, I.S.; Sanchez-Rodrigues, V.; Quelhas, O.L.G.; Leal Filho, W.; Serafim, M.P.; Anholon, R. Logistics 4.0 in Brazil: Critical Analysis and Relationships with SDG 9 Targets. Sustainability 2021, 13, 13012. [Google Scholar] [CrossRef]

- Batz, A.; Oleśków-Szłapka, J.; Stachowiak, A.; Pawłowski, G.; Maruszewska, K. Identification of Logistics 4.0 Maturity Levels in Polish Companies—Framework of the Model and Preliminary Research. In Sustainable Logistics and Production in Industry 4.0; Springer: Cham, Switzerland, 2019; pp. 161–175. [Google Scholar] [CrossRef]

- Group-IPS—Industrial Projects Services. New Survey Analyses the Degree of Spanish Supply Chain Digitalization. Group-IPS. Available online: https://www.group-ips.com/ips-news/detail/new-survey-analyses-the-degree-of-spanish-supply-chain-digitalization (accessed on 10 June 2022).

- Correa, J.S.; Sampaio, M.; Barros, R.D.C.; Hilsdorf, W.D.C. IoT and BDA in the Brazilian future logistics 4.0 scenario. Production 2020, 30, 1–14. [Google Scholar] [CrossRef]

- Alamsjah, F.; Yunus, E.N. Achieving Supply Chain 4.0 and the Importance of Agility, Ambidexterity, and Organizational Culture: A Case of Indonesia. J. Open Innov. Technol. Mark. Complex. 2022, 8, 83. [Google Scholar] [CrossRef]

- Dallasega, P.; Woschank, M.; Sarkis, J.; Tippayawong, K.Y. Logistics 4.0 measurement model: Empirical validation based on an international survey. Ind. Manag. Data Syst. 2022, 122, 1384–1409. [Google Scholar] [CrossRef]

- Woschank, M.; Dallasega, P. The Impact of Logistics 4.0 on Performance in Manufacturing Companies: A Pilot Study. Procedia Manuf. 2021, 55, 487–491. [Google Scholar] [CrossRef]

- Richnák, P. Key Challenges and Opportunities of Industry 4.0 in Metallurgical Industry in Slovakia. DANUBE 2022, 13, 137–154. [Google Scholar] [CrossRef]

- Richnák, P. Current Perspectives on Development of Industry 4.0 in Logistics of Machinery and Equipment Industry in Slovakia. LOGI—Sci. J. Transp. Logist. 2022, 13, 25–36. [Google Scholar] [CrossRef]

- Richnák, P. Intensity of Innovation Activity and its Progressivity in Enterprises in Slovakia in the Era of Industry 4.0. AD ALTA 2021, 11, 250–254. [Google Scholar] [CrossRef]

| Author | Logistics Process 4.0 | Definition of Logistics Process 4.0 |

|---|---|---|

| Nicoletti [57] | Procurement 4.0 | Procurement 4.0 uses technologies such as warehouse robots, self-driving vehicles to enable the introduction of processes that do not require operators and minimise human labour. The main intention is to integrate automation and information and communication solutions. |

| Kozma et al. [58] | Inventory management 4.0 | Inventory management 4.0 represents the processes of warehouse and stock management, which are becoming more transparent and predictable with the development of the Industrial Internet of Things. Inventory management 4.0 is subject to monitoring and controlling the use of space by means of information and communication devices, for example, actual pallet location data is transmitted via RFID technology. |

| Tutam [59] | Warehousing 4.0 | Warehousing 4.0 represents intelligent, automated and connected systems and represents a transformation to autonomy in industry by removing human participation. Autonomous systems, which require less space and operate 24/7, complement mechanical, electromechanical and automated systems by increasing productivity, efficiency, flexibility, modularity and agility, making warehouses more efficient. |

| Brach [60] | Transport 4.0 | Transport 4.0 involves more autonomous transport, the core of which is based on automation and autonomy. Transport 4.0 concentrates on reducing the negative impact on the environment, on the process of movement along with all transport activities that are dominant in the networked environment. |

| Author | Logistics 4.0 Technologies | Definition of Logistics 4.0 Technologies |

|---|---|---|

| Gattullo et al. [69] | Virtual Reality and Augmented Reality | Virtual Reality and Augmented Reality are complementary Industry 4.0 technologies. With the help of virtual reality, users are transported, via a headset, into a virtual world. But with augmented reality, applications present the illusion of multiple graphical layers of information layered on top of each other over a specific part of the user’s field of view. |

| Diniz et al. [70] | Big Data | The large amount of structured and unstructured data from different types of sources, which may come from interconnected objects, describes a large amount of data. A fundamental characteristic of Big Data is performing analysis on this data. |

| Kamble et al. [71] | Internet of Things | Internet of Things is creating an industrial system that enables a combination of intelligent machines, advanced predictive analytics, and machine-human collaboration to promote productivity, efficiency, and reliability. |

| Klee and Allen [72] | Advanced simulation | Simulation is a common method of analysing the behaviour of complex systems. Simulation is a classical technology whose foundations date back to the era of analog computers. |

| Sigov et al. [73] | Artificial intelligence | Artificial intelligence involves building intelligent machines capable of performing tasks that typically require human intelligence. The essence of artificial intelligence lies in reasoning, knowledge representation, planning, learning, processing machine learning approaches including artificial neural networks. |

| Kumar and Nayyar [74] | Smart sensors | Smart sensors act as manufacturing assets that collect large amounts of data about products and their environment. This is data for example to measure temperature, humidity and smoke in the air. Smart sensors can detect anomalous activities and can provide the ability to communicate wirelessly, making the data synthetic through a cloud interface as well. |

| Graetz and Michaels [75] | Autonomous robots | Autonomous robots perform autonomous manufacturing more precisely and can work alongside humans or even in places where humans are constrained. Autonomous robots have the ability to complete tasks on time and accurately, with a focus on flexibility, safety, versatility and collaboration. |

| Digital Transformation in Logistics | Small Enterprises | Medium-Sized Enterprises | Large Enterprises | |

|---|---|---|---|---|

| Yes | Absolute Frequency | 9 | 52 | 57 |

| Relative Frequency | 69.2% | 77.6% | 89.1% | |

| No | Absolute Frequency | 4 | 15 | 7 |

| Relative Frequency | 30.8% | 22.4% | 10.9% | |

| Total | Absolute Frequency | 13 | 67 | 64 |

| Relative Frequency | 100.0% | 100.0% | 100.0% | |

| Small Enterprises | Medium-Sized Enterprises | Large Enterprises | ||

|---|---|---|---|---|

| Strategy implemented | Absolute Frequency | 1 | 18 | 38 |

| Relative Frequency | 7.7% | 26.9% | 59.4% | |

| Strategy in implementation | Absolute Frequency | 10 | 32 | 17 |

| Relative Frequency | 76.9% | 47.8% | 26.6% | |

| Pilot initiatives launched | Absolute Frequency | 0 | 13 | 8 |

| Relative Frequency | 0.0% | 19.4% | 12.5% | |

| No strategy exists | Absolute Frequency | 2 | 4 | 1 |

| Relative Frequency | 15.4% | 6.0% | 1.6% | |

| Total | Absolute Frequency | 13 | 67 | 64 |

| Relative Frequency | 100.0% | 100.0% | 100.0% | |

| Small Enterprises | Medium-Sized Enterprises | Large Enterprises | ||

|---|---|---|---|---|

| Production Logistics | Absolute Frequency | 5 | 54 | 51 |

| Relative Frequency | 38.5% | 80.6% | 79.7% | |

| Procurement Logistics | Absolute Frequency | 4 | 4 | 4 |

| Relative Frequency | 30.8% | 6.0% | 6.2% | |

| Distribution Logistics | Absolute Frequency | 4 | 9 | 9 |

| Relative Frequency | 30.8% | 13.4% | 14.1% | |

| Total | Absolute Frequency | 13 | 67 | 64 |

| Relative Frequency | 100.0% | 100.0% | 100.0% | |

| Small Enterprises | Medium-Sized Enterprises | Large Enterprises | ||

|---|---|---|---|---|

| Investment costs | Absolute Frequency | 11 | 59 | 38 |

| Relative Frequency | 84.6% | 88.1% | 59.4% | |

| New supply chain setting | Absolute Frequency | 1 | 8 | 24 |

| Relative Frequency | 7.7% | 11.9% | 37.5% | |

| Concern about meeting objectives | Absolute Frequency | 1 | 0 | 1 |

| Relative Frequency | 7.7% | 0.0% | 1.6% | |

| Shortage of skilled labour | Absolute Frequency | 0 | 0 | 1 |

| Relative Frequency | 0.0% | 0.0% | 1.6% | |

| Total | Absolute Frequency | 13 | 67 | 64 |

| Relative Frequency | 100.0% | 100.0% | 100.0% | |

| ANOVA | Sum of Squares | df | Mean Square | F | Sig. | |

|---|---|---|---|---|---|---|

| Virtual reality and Augmented reality | Between Groups | 58.102 | 6 | 9.684 | 2.628 | 0.019 |

| Within Groups | 504.836 | 137 | 3.685 | |||

| Total | 562.937 | 143 | ||||

| Drones | Between Groups | 84.849 | 6 | 14.142 | 3.257 | 0.005 |

| Within Groups | 594.901 | 137 | 4.342 | |||

| Total | 679.750 | 143 | ||||

| Big Data | Between Groups | 63.194 | 6 | 10.532 | 2.498 | 0.025 |

| Within Groups | 577.632 | 137 | 4.216 | |||

| Total | 640.826 | 143 | ||||

| 5G network | Between Groups | 15.581 | 6 | 2.597 | 2.567 | 0.022 |

| Within Groups | 138.578 | 137 | 1.012 | |||

| Total | 154.160 | 143 | ||||

| Additive manufacturing | Between Groups | 135.580 | 6 | 22.597 | 5.053 | 0.000 |

| Within Groups | 612.643 | 137 | 4.472 | |||

| Total | 748.222 | 143 | ||||

| Internet of Things | Between Groups | 97.277 | 6 | 16.213 | 4.180 | 0.001 |

| Within Groups | 531.383 | 137 | 3.879 | |||

| Total | 628.660 | 143 | ||||

| Advanced simulation | Between Groups | 73.336 | 6 | 12.223 | 3.161 | 0.006 |

| Within Groups | 529.664 | 137 | 3.866 | |||

| Total | 603.000 | 143 | ||||

| Artificial intelligence | Between Groups | 69.328 | 6 | 11.555 | 2.818 | 0.013 |

| Within Groups | 561.831 | 137 | 4.101 | |||

| Total | 631.160 | 143 | ||||

| Smart sensors | Between Groups | 63.494 | 6 | 10.582 | 2.962 | 0.009 |

| Within Groups | 489.444 | 137 | 3.573 | |||

| Total | 552.938 | 143 | ||||

| Autonomous robots | Between Groups | 47.976 | 6 | 7.996 | 3.823 | 0.001 |

| Within Groups | 286.579 | 137 | 2.092 | |||

| Total | 334.556 | 143 | ||||

| Cloud computing | Between Groups | 62.366 | 6 | 10.394 | 3.477 | 0.003 |

| Within Groups | 409.523 | 137 | 2.989 | |||

| Total | 471.889 | 143 | ||||

| Cyber-physical systems | Between Groups | 52.693 | 6 | 8.782 | 2.690 | 0.017 |

| Within Groups | 447.196 | 137 | 3.264 | |||

| Total | 499.889 | 143 | ||||

| ANOVA | Sum of Squares | df | Mean Square | F | Sig. | |

|---|---|---|---|---|---|---|

| Virtual reality and Augmented reality | Between Groups | 24.550 | 6 | 4.092 | 0.726 | 0.630 |

| Within Groups | 772.450 | 137 | 5.638 | |||

| Total | 797.000 | 143 | ||||

| Drones | Between Groups | 36.567 | 6 | 6.095 | 1.190 | 0.315 |

| Within Groups | 701.655 | 137 | 5.122 | |||

| Total | 738.222 | 143 | ||||

| Big Data | Between Groups | 70.746 | 6 | 11.791 | 3.282 | 0.005 |

| Within Groups | 492.191 | 137 | 3.593 | |||

| Total | 562.938 | 143 | ||||

| 5G network | Between Groups | 91.178 | 6 | 15.196 | 3.537 | 0.003 |

| Within Groups | 588.572 | 137 | 4.296 | |||

| Total | 679.750 | 143 | ||||

| Additive manufacturing | Between Groups | 34.457 | 6 | 5.743 | 1.298 | 0.262 |

| Within Groups | 606.369 | 137 | 4.426 | |||

| Total | 640.826 | 143 | ||||

| Internet of Things | Between Groups | 126.091 | 6 | 21.015 | 6.247 | 0.000 |

| Within Groups | 460.847 | 137 | 3.364 | |||

| Total | 586.938 | 143 | ||||

| Advanced simulation | Between Groups | 57.713 | 6 | 9.619 | 2.661 | 0.018 |

| Within Groups | 495.224 | 137 | 3.615 | |||

| Total | 552.938 | 143 | ||||

| Artificial intelligence | Between Groups | 57.709 | 6 | 9.618 | 4.760 | 0.000 |

| Within Groups | 276.847 | 137 | 2.021 | |||

| Total | 334.556 | 143 | ||||

| Smart sensors | Between Groups | 75.379 | 6 | 12.563 | 4.341 | 0.000 |

| Within Groups | 396.510 | 137 | 2.894 | |||

| Total | 471.889 | 143 | ||||

| Autonomous robots | Between Groups | 12.272 | 6 | 2.045 | 1.975 | 0.073 |

| Within Groups | 141.888 | 137 | 1.036 | |||

| Total | 154.160 | 143 | ||||

| Cloud computing | Between Groups | 107.693 | 6 | 17.949 | 3.705 | 0.002 |

| Within Groups | 663.745 | 137 | 4.845 | |||

| Total | 771.438 | 143 | ||||

| Cyber-physical systems | Between Groups | 18.452 | 6 | 3.075 | 0.541 | 0.776 |

| Within Groups | 778.548 | 137 | 5.683 | |||

| Total | 797.000 | 143 | ||||

| ANOVA | Sum of Squares | df | Mean Square | F | Sig. | |

|---|---|---|---|---|---|---|

| Virtual reality and Augmented reality | Between Groups | 32.186 | 6 | 5.364 | 1.135 | 0.345 |

| Within Groups | 647.564 | 137 | 4.727 | |||

| Total | 679.750 | 143 | ||||

| Drones | Between Groups | 44.437 | 6 | 7.406 | 1.701 | 0.125 |

| Within Groups | 596.389 | 137 | 4.353 | |||

| Total | 640.826 | 143 | ||||

| Big Data | Between Groups | 68.096 | 6 | 11.349 | 2.774 | 0.014 |

| Within Groups | 560.564 | 137 | 4.092 | |||

| Total | 628.660 | 143 | ||||

| 5G network | Between Groups | 52.202 | 6 | 8.700 | 2.164 | 0.050 |

| Within Groups | 550.798 | 137 | 4.020 | |||

| Total | 603.000 | 143 | ||||

| Additive manufacturing | Between Groups | 47.271 | 6 | 7.878 | 1.490 | 0.186 |

| Within Groups | 724.167 | 137 | 5.286 | |||

| Total | 771.438 | 143 | ||||

| Internet of Things | Between Groups | 102.735 | 6 | 17.122 | 4.439 | 0.000 |

| Within Groups | 528.425 | 137 | 3.857 | |||

| Total | 631.160 | 143 | ||||

| Advanced simulation | Between Groups | 70.957 | 6 | 11.826 | 3.140 | 0.006 |

| Within Groups | 515.980 | 137 | 3.766 | |||

| Total | 586.938 | 143 | ||||

| Artificial intelligence | Between Groups | 49.953 | 6 | 8.325 | 2.703 | 0.016 |

| Within Groups | 421.936 | 137 | 3.080 | |||

| Total | 471.889 | 143 | ||||

| Smart sensors | Between Groups | 86.766 | 6 | 14.461 | 3.041 | 0.008 |

| Within Groups | 651.456 | 137 | 4.755 | |||

| Total | 738.222 | 143 | ||||

| Autonomous robots | Between Groups | 78.959 | 6 | 13.160 | 3.265 | 0.005 |

| Within Groups | 552.200 | 137 | 4.031 | |||

| Total | 631.160 | 143 | ||||

| Cloud computing | Between Groups | 43.875 | 6 | 7.313 | 2.197 | 0.047 |

| Within Groups | 456.013 | 137 | 3.329 | |||

| Total | 499.889 | 143 | ||||

| Cyber-physical systems | Between Groups | 4.661 | 6 | .777 | 0.712 | 0.641 |

| Within Groups | 149.498 | 137 | 1.091 | |||

| Total | 154.160 | 143 | ||||

| Pearson Correlation | Sig. (2-tailed) | N | |

|---|---|---|---|

| Customer service | 0.333 | 0.000 | 144 |

| Inventory Management | 0.328 | 0.000 | 144 |

| logistics Communication | 0.341 | 0.000 | 144 |

| Material handling | 0.197 | 0.018 | 144 |

| Order processing | 0.275 | 0.001 | 144 |

| Packaging | 0.168 | 0.044 | 144 |

| Procurement/Purchasing | 0.172 | 0.039 | 144 |

| Transport and Transportation | 0.266 | 0.001 | 144 |

| Warehousing | 0.353 | 0.000 | 144 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Richnák, P. Current Trend of Industry 4.0 in Logistics and Transformation of Logistics Processes Using Digital Technologies: An Empirical Study in the Slovak Republic. Logistics 2022, 6, 79. https://doi.org/10.3390/logistics6040079

Richnák P. Current Trend of Industry 4.0 in Logistics and Transformation of Logistics Processes Using Digital Technologies: An Empirical Study in the Slovak Republic. Logistics. 2022; 6(4):79. https://doi.org/10.3390/logistics6040079

Chicago/Turabian StyleRichnák, Patrik. 2022. "Current Trend of Industry 4.0 in Logistics and Transformation of Logistics Processes Using Digital Technologies: An Empirical Study in the Slovak Republic" Logistics 6, no. 4: 79. https://doi.org/10.3390/logistics6040079

APA StyleRichnák, P. (2022). Current Trend of Industry 4.0 in Logistics and Transformation of Logistics Processes Using Digital Technologies: An Empirical Study in the Slovak Republic. Logistics, 6(4), 79. https://doi.org/10.3390/logistics6040079