Abstract

Background: Companies partaking in modern supply chains face numerous intra- and interorganizational barriers when it comes to the adoption of blockchain technology. Empirical research is missing that explores how exactly these barriers can be overcome. In this paper we first explore barriers that organizations need to overcome to successfully deploy blockchain technology. In a second step, we investigate the agrifood industry and highlight differences in coping strategies between incumbents and start-ups. Methods: We conducted a quantitative survey with 190 supply chain experts to identify barriers and an in-depth qualitative study that included 10 expert interviews to better understand the current situation in agrifood organizations. Results: The findings from the quantitative study show that the most relevant organizational barrier to blockchain adoption is the widespread lack of understanding of the technology and its potential benefits. In the qualitative study we illustrate how various intra- and interorganizational barriers can be overcome and how the resources and capabilities differ between incumbents and start-ups. Conclusions: Our results provide academics with a better understanding of the relevant barriers and bridges of blockchain adoption. Practitioners benefit from learning about the resources and capabilities they need to deploy in order to benefit from blockchain technology.

1. Introduction

The effective and efficient management of supply chains is a complex task whose practical implications extend far beyond increasing companies’ operational performance or profits. Many of these problems are exacerbated in the supply chains of perishable goods. Opacity and inefficiencies in supply chains cause the perishing of agrifood products, which leads to substantial waste and even poisoning with potentially fatal consequences for human beings. Recent examples of the latter are listed on dedicated websites that showcase outbreaks of E.coli, salmonella, or campylobacter, all of which were caused by tainted food [1]. Additionally, the amount of global waste in this area is alarming. Thyberg et al. [2] estimate the aggregate disposal rate in the United States to be 0.28 kg per person per day, equating to 32.2 million tons of waste disposed of annually. Caldeira et al. [3] present a detailed analysis for the European Union and assess the yearly total amount of food waste to lie between 119 and 145 million tons. Not surprisingly, the highest proportions of waste were found among highly perishable food categories such as fruit (41%), vegetables (46%), and fish (51%).

Academia and industry generally agree that blockchain technologies are an appropriate means to tackle some of the most pressing problems in this sector. Rana et al. [4], for example, review existing academic literature and conclude that the application of blockchain can help to create sustainable agrifood supply chains. However, they also point out that new challenges related to scalability, privacy, cost, and connectivity might arise (see also Lacity [5], van Hoek et al. [6], Rejeb et al. [7], Treiblmaier [8]). In their systematic review, Rocha et al. [9] identify several supporting activities that blockchain can offer to agribusiness, including financial and environmental management. Rogerson and Parry [10] identify visibility as the main adoption driver in agrifood supply chains but also mention unsolved challenges such as lack of trust, human error, fraud, and governance issues. Based on a comprehensive literature review, Rejeb et al. [11] identify various technical, organizational, and regulatory challenges in blockchain adoption. Finally, Garaus and Treiblmaier [12] take a consumer perspective and illustrate that the traceability of agrifood products helps to strengthen consumers’ trust in retailers, which is especially pronounced for unfamiliar retailers.

Given the huge potential of the technology, it is not surprising that the industry has already launched several high-profile projects. The IBM Food Trust, for example, was established with the mission to improve transparency, standardization, and efficiency throughout the food supply chain [13,14]. Another example is OriginTrail, a supply chain ecosystem that fosters universal data exchange, connecting legacy IT systems and enabling data integrity. OriginTrail established several technology and research partnerships, with companies such as SAP, BSI, GS1, and Oracle, among others [15]. In addition to well-established players, numerous start-ups such as AgriChain, AgriDigital, Agrolot, Greenfence, Mixing Bowl, Ripe, and TE-FOOD harness blockchain technologies to improve communication between supply chain participants, enable the traceability of the produce, establish cryptomarkets of agricultural crops, and facilitate the trading of agrifood products [16,17].

As opposed to their incumbent counterparts, newly founded ventures usually do not face the same intra- and interorganizational barriers and also differ in their practices, methods, and knowledge management tools [18]. They cannot capitalize on their existing network of ecosystem partners such as incumbents do and often have limited access to resources [19]. Previous research has also postulated that a firm’s prior experience is a key driver for success and found, for example, that incumbents establish significantly more productive new plants than entrepreneurial entrants [20].

Given these differences between established and new enterprises, it makes sense for any study investigating the potentials of blockchain technology adoption to scrutinize the differing importance of intra- and interorganizational barriers depending on industry experience and the resources that companies have at their disposal to overcome such barriers. In the context of this study, a company’s resources include all assets, processes, capabilities, attributes, information, and knowledge that enable it to improve its effectiveness and efficiency [21,22].

Given the amount of literature that has recently been published on the potentials of blockchain in supply chain management [23,24], a solid understanding regarding the importance of adoption barriers exists. However, there still is a dearth of research that explores how to overcome those barriers. Additionally, prior research has not quantified the potential positive impact of blockchain, nor has research identified the resources companies could deploy to capitalize on the use of blockchain. To fill these research gaps, we therefore strive to answer the following four research questions:

Research Question 1 (RQ1a): Which intra- and interorganizational barriers to organizational blockchain adoption identified in prior literature are still rated most important by supply chain professionals?

(RQ1b): To what degree are organizations ready to adopt blockchain technologies?

Research Question 2 (RQ2): What resources can organizations in the agrifood industry use to overcome intra- and interorganizational barriers to blockchain adoption?

Research Question 3 (RQ3): What are the differences in coping strategies between incumbents and start-ups in the agrifood industry?

RQ1a and RQ1b are assessed using quantitative data from a survey with 190 respondents conducted at a major supply chain conference. RQ2 and RQ3 are answered with the help of case studies, including qualitative interviews, panel discussions, and the analysis of publicly available material from blockchain incumbents and start-ups.

This paper is organized as follows: We summarize the literature on barriers to effective blockchain adoption in SCM in the literature review section. We describe the quantitative and qualitative research approaches in the methodology section. We then discuss the results of our quantitative and qualitative analyses, and focus on identifying the key resources that can support organizational blockchain adoption. We end this paper with the discussion and conclusion sections, as well as an outlook on future research.

2. Literature Review: Barriers to Effective SCM and Blockchain Adoption

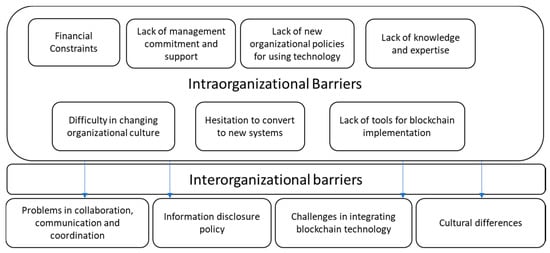

On a general level, numerous important barriers to strategic supply chain management (SCM) have been identified, the impact of which Fawcett, Magnan, and McCarter [25] label as “intimidating”. They analyzed organizational and individual implementation barriers to effective SCM. Their list includes lack of top management support, non-aligned strategic and operating philosophies, inability or unwillingness to share information, lack of trust among supply chain members, unwillingness to share risks and rewards, inflexible organizational systems and processes, cross-functional conflicts and “turf” protection, inconsistent/inadequate performance measures, resistance to change, and lack of training for new mindsets on skills. More specifically concerning blockchain in supply chains, Saberi et al. [26] identify and group the major barriers to blockchain into four categories, namely intra- and interorganizational barriers, systems-related barriers, and external barriers. In this study, we build on this existing framework and especially focus on the former two since those are the ones that organizations can influence themselves (see Figure 1). In the following sections, we provide an overview of how current literature perceives these barriers and which solutions have been suggested so far, with a special focus on the agrifood industry.

Figure 1.

Intra- and interorganizational barriers to blockchain adoption based on [26].

2.1. Intra-Organizational Barriers

2.1.1. Financial Constraints

Financial resources are typically considered to be critical for the ability of organizations to acquire blockchain technology [27,28]. The digitalization of agrifood supply chain processes using blockchain technology requires investment in hardware, software, and knowledge [29,30]. Even though this investment may not be as substantial as that required for other supply chain technologies [6], the exact nature of the investment and operating costs are currently not widely and well-understood by managers considering blockchain [31]. In this respect, Dutta et al. [28] point out that blockchain’s non-trivial operational and implementation costs must not be underestimated. Additionally, the maintenance costs of blockchain systems need to be adequately monitored [32] to gain a competitive advantage [33]. In the long run, blockchain-enabled agrifood traceability systems need to yield a positive return on investment to justify the deployed resources [34]. Similarly, the use of blockchain for agrifood traceability might be too costly for small organizations with insufficient resources since system operation and maintenance routinely require significant financial resources [35]. Therefore, in ensuring the smooth implementation of blockchain, sufficient financial resources are a key intraorganizational barrier to the innovation and adoption of the technology.

2.1.2. Management Commitment and Support

The potential value of blockchain adoption in the agrifood organization can be undermined by a lack of management commitment and support as well as a lack of management engagement in the technology across the organization [27,31]. As per Rogerson and Parry [10], the absence of management support can stifle new technology adoption. As such, when orientating their agrifood business processes toward blockchain integration, agrifood organizations need a clear strategic perspective that emphasizes top management involvement and organizational support to facilitate the implementation within their business operations [28]. With sufficient managerial support, blockchain adoption can be significantly enhanced since this ensures the mobilization of sufficient resources. Nevertheless, the immaturity of the technology is still an important concern for managers that negatively affects their commitment and support [27]. As a result, given that (mostly upper level) managers oversee critical activities and budgets, their support is an important prerequisite for providing crucial resources.

2.1.3. Organizational Policies

Adopting blockchain requires new organizational policies, mechanisms, and procedures to be implemented as part of an organization’s overarching corporate strategy. According to Kouhizadeh et al. [27], a lack of organizational policies represents a prominent barrier to blockchain adoption. The potentials of leveraging blockchain in agrifood operations can therefore only be fully realized if the enablers of its adoption are reinforced with favorable organizational strategies and policies [36]. For example, Chanson et al. [37] point out how organizational policies are necessary to define how the users of blockchain systems can prevent, identity, and overcome security incidents. Moreover, there is a need to employ changes in current organizational structures (e.g., changes in responsibilities, goals, routines, decision-making activities, systems) and policies so that blockchain can confer substantial benefits on the agrifood organization. Therefore, the compatibility of blockchain with an agrifood organization’s existing policies and practices is essential to its successful deployment [38,39,40]. In this respect, agrifood organizations need to support a wide range of activities (e.g., product control, monitoring, data capture and documentation, traceability) that should be governed by organizational policies and mechanisms to achieve more efficient processes operational excellence.

2.1.4. Knowledge and Expertise

Organizations perceive blockchain adoption as a demanding task requiring a sufficient understanding of the technology and its integration in the agrifood supply chain [41]. Klerkx and Rose [39] argue that digital technologies strongly impact supply chain operations and demand new knowledge, skills, and labor management across various actors. Given its immaturity, Zhao et al. [42] posit that a limited number of people possess in-depth knowledge and skills on how blockchain can be successfully adopted in the agrifood supply chain. Since the users’ level of knowledge and skills ultimately determines the effectiveness of system use in various contexts [43], a lack of knowledge and engagement with blockchain technology can significantly slow down its adoption in the agrifood industry [35]. Antonucci et al. [44] therefore suggest that agrifood organizations upgrade their base knowledge and technical assistance to support and help other stakeholders, and that governments assume an active role in supporting blockchain-enabled agrifood supply chains. However, Lin et al. [45] note that if the current organizational systems adequately satisfy their business needs, adopting blockchain is not likely to happen because successful implementation requires knowledge on both agriculture and blockchain and a certain amount of external pressure to do so.

2.1.5. Organizational Culture

Organizational culture plays an important role as an enabling factor when it comes to the adoption of blockchain within an agrifood organization. According to Kouhizadeh et al. [27], the integration of blockchain in the supply chain can be impeded by difficulties in changing organizational culture. In the context of the agrifood industry, Yadav et al. [46] state that stakeholders such as farmers and middlemen may resist blockchain adoption because this would require a substantial cultural change. The management culture induced by blockchain-enabled agrifood supply chains can significantly impact the quality of agrifood products and the vitality of the organizations involved [47]. Blockchain has the potential to alter the organizational culture of farming businesses, transforming it from a “hands-on” and experience-driven management style to a more data-driven approach and algorithmic rationality [39]. Although the technology can support a culture of trust through its tamper-proof recording capability [48], blockchain adoption faces several issues on a more human level. In this regard, Kurpjuweit et al. [49] argue that the successful implementation of blockchain is preceded by a supportive organizational culture that encourages employees and managers to take risks and deliberately push the implementation process.

2.1.6. Conversion to New Systems

A challenging issue facing agrifood organizations is the involvement of employees in new systems and organizational mechanisms that may include the use of new technology. As an emerging technology, blockchain integration in the organization may require modifying legacy systems [27]. In a recent study, Abreu and Coutinho [50] assert that numerous legacy systems lack direct interfaces to blockchains and require a substantial redesign when integrating data or blockchain-based functionalities with legacy systems. The immaturity of blockchain and its ongoing development raises further problems for system development and the integration of existing legacy systems [51,52]. For some early adopters of the technology, caution has been exercised to weigh the potential benefits of blockchain against the barriers to its implementation [53]. In addition, the intrinsic complexity of blockchain systems makes traditional ways for managing business processes inapplicable, thereby resulting in issues pertaining to ease of use, process delays, and resistance to adapt to the blockchain environment [35,46,48]. Therefore, managing the resistance to blockchain adoption within an organization is a complicated issue that needs to be tackled sensibly to motivate the active participation of employees, increase awareness, and avoid the failure of the adoption process.

2.1.7. Implementation Tools

Despite the predicted potential of blockchain, there also exists a substantial likelihood of failure. One of the explanations for this is the lack of tools necessary for the effective integration of the technology [27]. As such, blockchain is not a standalone technology, but rather depends on its integration into sensing technologies such as the Internet of Things (IoT) and Radio-Frequency Identification (RFID) [14,54,55]. Agrifood organizations are thus compelled to invest in these digital technologies, with a special focus on integrating real-time information and data processing tools to optimize production, facilitating traceability and increasing responsiveness to changing conditions in their supply chain [56,57,58]. Agrifood organizations also need accurate, robust, and efficient tools to ensure the transparent and efficient control of safety in raw materials in accordance with compliance standards [59]. Moreover, blockchain needs to be sustained by IoT capabilities to unleash its full potential and to provide process visibility, transparency, and data access [60]. However, Tsolakis et al. [48] believe that the supply, implementation, and maintenance of digital tools (e.g., IoT, sensors, RFID equipment) can be challenging due to infrastructural configuration requirements.

2.2. Interorganizational Barriers

2.2.1. Collaboration, Communication, and Coordination

Collaboration represents a vital prerequisite for improving supply chain effectiveness, particularly for farmers and their customers [61,62]. Collaboration, communication, and coordination are critical in reducing logistics costs and increasing partners’ involvement in identifying and reducing waste across the supply chain. A lack of coordinated approaches can impede blockchain adoption [27]. Conflicting objectives, priorities, and incentives among the various entities may lead to several consistency problems, inefficiencies, and increased costs (e.g., production costs, inventory costs, long lead times) [28,33,63]. Despite the manifold advantages, Yadav et al. [46] argue that organizations may be reluctant to actually collaborate and engage in consortia creation. Potential reasons for this behavior are the urge to obtain individual advantages from technology adoption and a reluctance to work with competitors. It is crucial to overcome these barriers since collaboration must no longer be seen as an option, but rather as a necessity [64] that enables organizations to intelligently exploit blockchain technology and leverage its collaborative capabilities in the industry.

2.2.2. Information Disclosure Policy

Information disclosure is beneficial to partners in agrifood supply chains as it helps to reduce potential hazards in critical processes and ensure agrifood safety [65]. Although information disclosure represents a key variable in developing and maintaining mutual relationships between the stakeholders, it is a risky practice that can result in the loss of control, power, tactical flexibility, and image [66]. In this regard, the adoption of blockchain in the agrifood supply chain can be hampered by the challenges associated with the information disclosure policy between partners [27]. For example, Lin et al. [32] highlight that sensitive information disclosure is a major issue slowing the use of blockchain for agrifood traceability. The loss of information, inaccurate information dissemination, and inadvertently allowing access to confidential information to unauthorized parties are additional information disclosure risks in the agrifood supply chain [27]. Distrust among agrifood organizations through the data captured and disclosed by blockchain constitutes another emerging threat in agrifood supply chains that can lead to adverse consequences for collaborative relationships. This can be attributed to a perception of insecurity regarding blockchain and general suspicion toward its capabilities [54].

2.2.3. Integrating Blockchain Technology

Achieving sustainable development in an agrifood supply chain requires organizations to focus on a clear strategy for delivering healthy and high-quality agrifood products, thereby ensuring better economic, environmental, and social performance [67]. A clear path toward fostering agrifood supply chain sustainability is to benefit from blockchain’s capabilities of reducing agrifood fraud, increasing product originality and quality, enforcing fair competition, and promoting sustainable practices among organizations [47]. Despite the fact that blockchain can be a potential contributor and a transition pathway toward sustainable agrifood supply chains, the integration of sustainable practices and blockchain is a complex task for many organizations and needs to be coordinated with numerous business partners. In this regard, Kouhizadeh et al. [27] state that some managers fail to establish long-term commitment and support for sustainability practices through supply chain processes, particularly after adopting new technology. Similarly, the transition toward sustainability is a challenging task that permeates an entire organization and necessitates that all industry stakeholders are committed to the realization of core sustainability objectives. This implies that a lack of reward systems to guarantee data integrity and incentivize sustainability initiatives by government and agrifood organizations can hinder the promotion of sustainable practices and blockchain technology within and across organizations [27]. Thus, agrifood organizations’ overall orientation toward the combination of sustainability and blockchain represents a multi-phase and dynamic process that occurs over a long time and requires strenuous efforts to ensure sustainability in their supply chains.

2.2.4. Cultural Differences

Previous research has established that cultural differences can cause increased transaction costs and reduced cooperation [68]. Cultural gaps have the potential to heavily influence the operations of agrifood organizations, which in turn impacts their decisions pertaining to production planning, demand forecasting, and quality management. In the context of blockchain adoption, Kouhizadeh et al. [27] find that the cultural differences of supply chain partners regarding technology and sustainability yield diverse mindsets that can hamper blockchain implementation and transparency in the supply chain. Hew et al. [40] illustrate the case of Malaysia as a country with a conservative culture that prohibits the adoption of emerging technologies such as blockchain. Qian et al. [69] emphasize the need to create a culture of collaboration to accelerate the transition from traditional to blockchain-based agrifood supply chains.

Table 1 summarizes the main problems that we identified in previous research building on the categories from Saberi [26]. Additionally, we include related literature that goes further into detail as well as the measures that we used for their operationalization. We discuss the measures in some detail in the following sections, and the exact wordings can be found in Appendix A (Table A1 and Table A2).

Table 1.

Previous research findings and operationalization.

3. Methodology

The initial exploration of barriers to and drivers for blockchain adoption in supply chain was enabled by the early work of Saberi et al. [26] and van Hoek [72]. The conceptual study of Saberi et al. [26] established the main categories of blockchain adoption barriers, and the study of van Hoek [72] built upon this by conducting an initial measurement of the applicability of those barriers in a focus group setting. In an earlier paper, we reported on focus group findings that helped to operationalize the categories of barriers and drivers from literature into concrete items [73]. To further our understanding at the start of this research project, we extended this effort by conducting a larger study with two audiences at a US-based conference and at a Polish supply chain conference. Across the estimated 400 total attendees during the two conference sessions, we captured 190 responses. While the dataset represents a convenience sample, it served to further the exploration of blockchain adoption barriers as perceived by supply chain experts. The aim was not to achieve statistical generalization, but rather to explore possible patterns in a larger dataset. This in turn was used to focus our qualitative research stage, which included the analysis of various artifacts and the conducting of 10 interviews with supply chain managers. In these interviews, we specifically focused on intra- and interorganizational barriers in the agrifood industry to eliminate the confounding influence of the type of industry. The questions for the interviews can be found in Appendix B.

4. Results

In the following sections, we first present the results from our quantitative survey among 190 supply chain experts to answer RQ1a and RQ1b regarding the nature of intra- and interorganizational barriers related to general blockchain adoption and organizational readiness. Next, we present the findings from a qualitative survey among agrifood industry professionals to identify the resources companies in the agrifood industry can use to overcome the respective barriers (RQ2). Finally, we differentiate between coping strategies between incumbents and start-ups in the agrifood industry (RQ3).

4.1. Quantitative Results

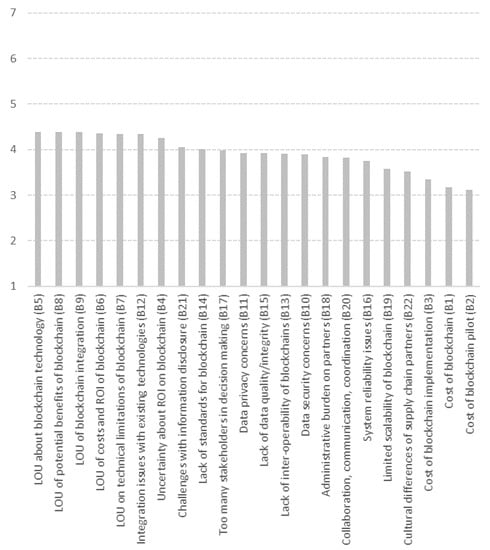

Figure 2 illustrates the respondents’ assessments of the respective organizational barriers as measured with several Likert-type items with a 7-point range, from 1 (“not at all”) to 7 (“to a very large degree”).

Figure 2.

Average assessment of organizational barriers to blockchain adoption (n = 190; 1 = “not at all”; 7 = “to a very large degree”; LOU: Lack of Understanding).

On average, the respondents’ assessment hovered between 3 (“to a small degree”) and 5 (“to a sizeable degree”), with many answers being close to 4, the midpoint of our scale (“to a modest degree”). It has to be noted, however, that there was substantial variation among the answers, and we received the full range of answers from 1–7 for each respective item. In a nutshell, items B1–B4 were related to the costs and uncertainties of blockchain implementation, B5–B9 measured the lack of understanding on the side of the companies, B10 and B11 were about data security and privacy concerns, and B12–B22 operationalized several technical, regulatory, collaborative, and cultural issues. Further details can be found in Table A1 in the Appendix A.

The most relevant organizational barriers to blockchain adoption turned out to be the widespread lack of understanding pertaining to the technology itself and its potential benefits. Furthermore, the experts also highlighted that it is uncertain how blockchain can be integrated with legacy systems, how high the resulting costs as opposed to the expected ROI will be, and what the current technical limitations of blockchain technology are. The three least relevant items turned out to be the actual implementation and deployment costs as well as the costs of having a blockchain pilot. Again, it has to be pointed out that the range of answers was relatively small, ranging from 4.39 (LOU about blockchain technology) to 3.11 (cost of blockchain pilot). This indicates that, on average, the experts agree that numerous relevant organizational barriers exist but none of them constitutes an insurmountable obstacle.

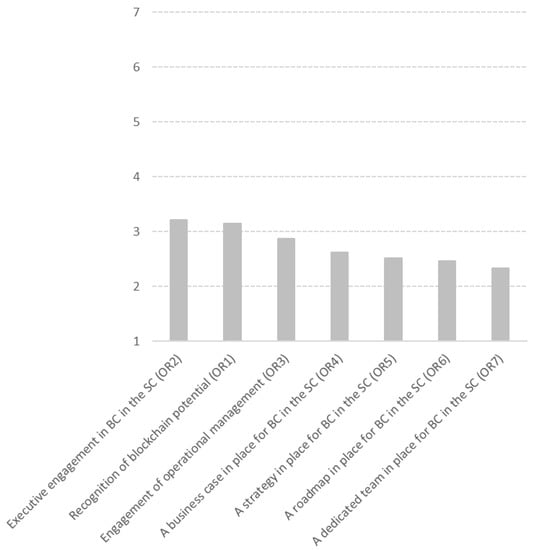

In spite of the average assessment pertaining to the importance of existing barriers to blockchain adoption, organizations do not consider themselves to be ready yet, as can be seen in Figure 3.

Figure 3.

Average assessment of organizational readiness to blockchain adoption (n = 190; 1 = “not at all”; 7 = “to a very large degree”).

The average assessment regarding the various readiness dimensions hovers around values between 2 (“to a very small degree”) and values slightly higher than 3 (“to a small degree”). It has to be noted, again, that the full range of answers showed a high level of dispersion, ranging from 1 to 7 for all questions. OR1–OR3 measure the internal recognition of the importance of blockchain as well as the management’s engagement. OR4–OR7 refer to an existing business case, strategy, roadmap, and dedicated team, respectively. Again, more descriptive statistics can be found in Appendix A.

When it comes to the respective criteria of organizational readiness, executive engagement and the general recognition of blockchain’s potential came first, followed by the engagement of operational management. Conversely, an existing roadmap and a dedicated team were the two drivers of organizational readiness that came in last. On average, the experts perceive a fairly low level of organizational readiness when adopting blockchain.

In a next step, we explored the underlying factor structure for our measurement items that were not based on previous research but rather gained from operationalizing the barriers suggested in the literature. Following the recommendation from Treiblmaier and Filzmoser [74], we conducted an exploratory factor analysis (EFA) using the scree plot and Eigenvalues > 1 as criteria for selecting the number of factors and an orthogonal Varimax rotation to facilitate the interpretation of the factors. Since the factor structure was not known ex-ante, our research aimed to investigate the preliminary construct validity. As can be seen in Table A3 in Appendix A, the four emerging factors mimic the aforementioned structure of (1) cost and uncertainty, (2) lack of understanding, (3) security and privacy, and (4) technical, regulatory, collaborative, and cultural issues, with only one single item (B4: Uncertainty about ROI on blockchain) exhibiting a cross-loading. In summary, these items can be used as a foundation for further scale development and future quantitative studies.

4.2. Qualitative Results

After confirming the importance of the respective barriers as well as assessing organizations’ insufficient level of preparedness to cope with them, we explored coping strategies and techniques, with a special focus on the agrifood industry. In order to do this, we used a number of evidentiary sources that include online material from companies (e.g., reports, video presentation), panel discussions, and in-depth qualitative interviews [75]. In total, 10 interviews were conducted with managers involved in blockchain-based IT projects from incumbents (6) and start-ups (4), respectively, until a level of theoretical saturation was reached, and no further resources and capabilities emerged. The companies operated in different agrifood supply chains, including meat, beverages, wool, and agrifood health products. We explicitly differentiated between incumbents and start-ups to consider the varying resources they possess and their respective level of specialization [18,19,20].

In Table 2, we summarize the main resources that companies in the agrifood supply chain use following the framework shown in Figure 1 and further illustrate whether there are any relevant differences in the coping strategies between incumbents and start-ups.

Table 2.

Bridging techniques and capabilities to overcome barriers to blockchain adoption in the agrifood industry.

In order to successfully cope with the first major intraorganizational barrier, namely financial constraints, dedicated budgets for blockchain adoption are needed. Given the novelty of the technology, the total costs of implementation and operation are hard to calculate. Incumbents and start-ups deal with financial bottlenecks in different ways. While the former mostly depend on internal funding (including financial support from parent organizations and global budgets), the latter frequently need to find external support, which might come in the form of equity or loans. Additionally, public funding provides an alternative strategy for start-ups.

Lack of management commitment may pose a major hurdle that incumbents try to overcome with an internal bottom-up informational strategy, external advice (e.g., from specialized consulting companies), and the creation of prototypes that should illustrate the viability of the technology. When it comes to missing organizational policies, incumbents need to change existing structures and processes and refer to internal restructuring and process redesign, whereas start-ups in the blockchain space usually design their business models from scratch to account for the idiosyncrasies of the technology. Occasionally, start-ups also refer to external support and mentoring, the latter of which is sometimes included in state-funded support campaigns. The current lack of knowledge and expertise is equally perceived by incumbents and start-ups, and the existing market supply is insufficient to fulfil the demand of the industry regarding developers in that area. Incumbents are regularly capable of paying higher wages and recruiting skills from existing labor markets, but they also foster in-house education. Start-ups also occasionally rely on external consultants, active networking (e.g., via social media), and existing communities. Most notably, several start-ups also indicated that they rely on external support for business matters, which is less frequently the case for incumbents. Cultural issues and the hesitation to convert to new systems only pose a problem for incumbents, which is not surprising since the start-ups were specifically founded for blockchain projects, and their internal procedures are aligned with the requirements of blockchain adoption. Consequently, several incumbents find it difficult to adapt their existing culture and processes to decentralized systems that often require a change in thinking, which is especially profound in cases where decentralization affects existing power structures [76]. In order to cope with this problem, they refer to internal change management but also frequently consult external advisors.

The final intraorganizational barrier pertains to a lack of tools, many of which are not fully developed and frequently require extended testing periods. Again, outsourcing and external consulting provide viable strategies for all companies, although this option is more frequently pursued by incumbents. As opposed to start-ups, incumbents also have to deal with the integration with legacy systems, which can be seen as another barrier but also as a resource, since they do not frequently need to develop a system completely from scratch but can rely on existing infrastructure.

As far as interorganizational barriers are concerned, collaboration, communication, and coordination along the whole supply chain turned out to be the most complex barrier to overcome for both incumbents and start-ups. They all stress the need to create common standards (which is frequently beyond the capability of a single company), but also to draw up contracts that are in line with the idiosyncrasies of blockchain (e.g., when it comes to the immutability of data) and actively communicate the value and benefits of blockchain-based platforms to their partners.

Quite obviously, established companies can rely on their existing networks and can include their business partners in the design and creation of blockchain-based networks. In contrast, start-ups first need to build their brand and create trust-based relationships with their business partners, which necessitates the alignment of numerous strategic and operational processes [77,78]. When it comes to the information disclosure policy, the interviewees highlighted the need to follow existing regulations and to communicate this within their respective business circles. Again, transparency in information use is a major resource and a prerequisite for sustainable supply chain relationships.

Concerning problems pertaining to the interorganizational integration of blockchain technology, both incumbents and start-ups either rely on their in-house competencies or interorganizational cooperation. Alternatively, both refer to external support, as was the case with the intraorganizational barrier labeled “lack of knowledge and expertise”. Finally, cultural differences pose a well-known barrier that is fairly pronounced in supply chain networks. Since the adoption of blockchain technologies regularly implies increased data sharing and transparency, close cooperation based on trust and clear procedures and responsibilities are seen as the main capabilities needed to overcome this barrier. In this regard, incumbents can rely on their established networks while start-ups still need to develop their brand and long-lasting relationships.

Generalizing our findings, Table 3 summarizes the major barriers and bridges of the 4 start-ups and 6 incumbents as well as differences and similarities when it comes to blockchain adoption.

Table 3.

Overview of differences in blockchain barriers and adoption between start-ups and incumbents.

5. Discussion and Implications

Previous research and evidence from the industry has indicated numerous potentials of blockchain technology for supply chain management [23,62]. However, the disruptive nature of the technology necessitates significant changes within and between organizations, which leads to the emergence of adoption barriers [79]. While these barriers have been identified and categorized in previous literature [31,72], a structured approach was missing to highlight the resources that companies can deploy to overcome them. In this paper, we close this research gap and build on a comprehensive literature review, a quantitative survey, and an in-depth qualitative study to identify and categorize the respective resources and capabilities. Furthermore, we exemplify our findings by focusing on the needs of the agrifood industry and differentiating between incumbents and start-ups. Specifically, we illustrate that different resources are needed for successful blockchain adoption depending on a company’s experience and relations in the market.

5.1. Theoretical Contributions

From an academic perspective, our exploratory study postulates that numerous strategic resources exist, which a firm can exploit to achieve sustainable competitive advantage. The identification of these resources, which we accomplished in this paper, will support future academic research that strives to dive deeper and investigates how a specific resource in one of the established categories can actually impact a company’s effectiveness or efficiency [80]. This research stream can build heavily on the resource-based view of the firm, with the goal of identifying those resources that can gain a competitive advantage for a company [23,55].

Our study extends previous conceptual and empirical research in the agrifood industry in that we highlight how substantial investments in hardware, software, and knowledge are needed if companies in the agrifood company want to adopt blockchain [29]. More specifically, we build on previous research and identify those operational barriers that specifically impede the adoption of blockchain technology [30]. Prior studies have also identified lack of government regulation and trust among stakeholders as major adoption barriers [46], which our study confirms and extends by highlighting additional and more refined impediments. We also detail specific measures related to some of the more generic challenges (e.g., organizational, social, technological) outlined in previous literature [56].

Previous research agrees on the importance of several key factors such as traceability in agrifood chains and the suitability of blockchain to foster transparency [57,58]. Our research contributes to this growing body of literature by pinpointing specific barriers and highlighting the differences between start-ups and incumbents, which has been largely ignored so far. We also contribute to existing literature, which stresses the importance of interorganizational cooperation as an antecedent of successful blockchain adoption and deployment [61,62]. The resources and capabilities that we identify in this paper provide some indications for tackling pending problems in interorganizational communication and collaboration.

This study therefore provides fertile ground for a plethora of novel research questions and allows for interesting comparisons between companies and industries when it comes to blockchain adoption [81]. Furthermore, measures need to be developed to operationalize the impact of specific resources [82], which can be achieved by building on the operationalizations that we introduce in this study (see Appendix A and Appendix B). All of these tasks are important prerequisites for further rigorous studies that help to build a theory-based academic research agenda [83].

5.2. Managerial Contributions

From an industry perspective, the presented resources and capabilities represent those pain points that companies need to tackle in order to successfully integrate blockchain technology into their agrifood supply chain. More specifically, the application of blockchain can help to streamline agrifood chains and tackle several important issues such as the need to reduce food waste [2,3], to increase food chain sustainability [4], and to ultimately improve the quality and healthiness of food products [67]. Furthermore, the bridging techniques and capabilities presented in this paper provide viable managerial policies and strategies which can help to realize the benefits of blockchain that previous research identified for the agroindustry [9]. Our results also provide some indications on how to overcome existing challenges pertaining to the lack of trust and governance, which is an important obstacle in the industry [10].

Further work in this area can include the development of checklists that help managers to better understand their current blockchain adoption status and which issues they need to tackle to overcome existing barriers. A systematic interorganizational analysis of blockchain adoption barriers and the resources needed to bridge them will also help industry associations and standardization bodies to detect problems that can only be solved from an overarching perspective.

6. Conclusions, Limitations, and Further Research

This study presents a snapshot of existing blockchain adoption barriers in supply chains and potential corresponding solutions, with a specific focus on the agrifood industry. The technology in this area is advancing fast, as is the surrounding environment, which includes legislation and regulation. Our findings are also limited by the size and the composition of the quantitative and qualitative samples that we used, and we recommend that replication studies be conducted, with a special focus on other sectors in the industry and different stakeholder groups. Several of the critical resources that we identify in this paper might be commonly available in the future and no longer be a pending issue, while new barriers that lead to the emergence of new critical resources might yet arise.

Furthermore, we have presented all intra- and interorganizational barriers as independent of each other, which might not be the case in the real world and yields numerous interesting research questions as to what extent these barriers can be addressed simultaneously. In summary, we believe that this paper provides the foundation for numerous research streams, be it the development of more refined frameworks, models, or theories in academia or the identification of important pain points in the industry as well as the resources and strategies that are necessary to overcome them.

Author Contributions

Data curation, H.T.; Formal analysis, H.T. and A.R.; Investigation, A.R., R.v.H. and M.L.; Methodology, H.T.; Project administration, H.T., R.v.H. and M.L.; Resources, H.T.; Writing—original draft, H.T., A.R., R.v.H. and M.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A. Quantitative Survey

Table A1.

Barriers. To what degree is your company experiencing the following barriers to blockchain in the supply chain?

Table A1.

Barriers. To what degree is your company experiencing the following barriers to blockchain in the supply chain?

| Mean | SD | Var | Min | Max | ||

|---|---|---|---|---|---|---|

| B1 | Cost of blockchain | 3.17 | 1.84 | 3.39 | 1 | 7 |

| B2 | Cost of blockchain pilot | 3.11 | 1.76 | 3.09 | 1 | 7 |

| B3 | Cost of blockchain implementation | 3.34 | 1.85 | 3.43 | 1 | 7 |

| B4 | Uncertainty about ROI on blockchain | 4.25 | 1.95 | 3.81 | 1 | 7 |

| B5 | Lack of understanding (LOU) about blockchain technology | 4.39 | 1.9 | 3.61 | 1 | 7 |

| B6 | LOU of costs and ROI of blockchain | 4.35 | 1.9 | 3.62 | 1 | 7 |

| B7 | LOU of technical limitations of blockchain | 4.34 | 1.87 | 3.52 | 1 | 7 |

| B8 | LOU of potential benefits of blockchain | 4.39 | 1.93 | 3.72 | 1 | 7 |

| B9 | LOU of how to integrate blockchain into existing supply chain processes | 4.39 | 1.97 | 3.87 | 1 | 7 |

| B10 | Data security concerns | 3.89 | 1.94 | 3.75 | 1 | 7 |

| B11 | Data privacy concerns | 3.93 | 1.97 | 3.87 | 1 | 7 |

| B12 | Integration issues with existing technologies | 4.34 | 1.91 | 3.64 | 1 | 7 |

| B13 | Lack of interoperability of blockchains | 3.91 | 1.87 | 3.51 | 1 | 7 |

| B14 | Lack of standards for blockchain | 4.01 | 1.84 | 3.39 | 1 | 7 |

| B15 | Lack of data quality/integrity | 3.92 | 1.86 | 3.46 | 1 | 7 |

| B16 | System reliability issues | 3.75 | 1.82 | 3.31 | 1 | 7 |

| B17 | Large number of stakeholders involved in decision making about blockchain | 3.98 | 1.95 | 3.8 | 1 | 7 |

| B18 | Administrative burden of blockchain on supply chain partners | 3.83 | 1.82 | 3.29 | 1 | 7 |

| B19 | Limited scalability of blockchain | 3.57 | 1.83 | 3.36 | 1 | 7 |

| B20 | Collaborating, communicating, and coordinating in the supply chain | 3.82 | 1.85 | 3.41 | 1 | 7 |

| B21 | Challenges in information disclosure policy between supply chain partners | 4.06 | 1.92 | 3.68 | 1 | 7 |

| B22 | Cultural differences of supply chain partners | 3.52 | 1.94 | 3.77 | 1 | 7 |

(1: not at all; 2: to a very small degree; 3: to a small degree; 4: to a modest degree; 5: to a sizeable degree; 6: to a large degree; 7: to a very large degree; n = 190).

Table A2.

Organizational readiness. To what degree does your company have….

Table A2.

Organizational readiness. To what degree does your company have….

| Var | Text | Mean | SD | Var | Min | Max |

|---|---|---|---|---|---|---|

| OR1 | Recognition throughout the company of the potential of blockchain in the supply chain (BC in the SC) | 3.15 | 1.71 | 2.91 | 1 | 7 |

| OR2 | Executive engagement in BC in the SC | 3.22 | 1.79 | 3.21 | 1 | 7 |

| OR3 | Engagement of operational management in BC in the SC | 2.87 | 1.7 | 2.89 | 1 | 7 |

| OR4 | A business case in place for BC in the SC | 2.62 | 1.69 | 2.86 | 1 | 7 |

| OR5 | A strategy in place for BC in the SC | 2.52 | 1.71 | 2.94 | 1 | 7 |

| OR6 | A roadmap in place for BC in the SC | 2.46 | 1.71 | 2.92 | 1 | 7 |

| OR7 | A dedicated team in place for BC in the SC | 2.33 | 1.71 | 2.92 | 1 | 7 |

(1: not at all … 7: to a very large degree; n = 190).

Table A3.

Factor analysis.

Table A3.

Factor analysis.

| Factor1 | Factor2 | Factor3 | Factor4 | |

|---|---|---|---|---|

| B1 | 0.885 | |||

| B2 | 0.899 | |||

| B3 | 0.866 | |||

| B4 | 0.625 | 0.409 | ||

| B5 | 0.839 | |||

| B6 | 0.848 | |||

| B7 | 0.821 | |||

| B8 | 0.697 | |||

| B9 | 0.741 | |||

| B10 | 0.807 | |||

| B11 | 0.845 | |||

| B12 | 0.657 | |||

| B13 | 0.671 | |||

| B14 | 0.661 | |||

| B15 | 0.653 | |||

| B16 | 0.718 | |||

| B17 | 0.690 | |||

| B18 | 0.819 | |||

| B19 | 0.751 | |||

| B20 | 0.720 | |||

| B21 | 0.673 | |||

| B22 | 0.612 | |||

| SS loadings | 6.197 | 4.400 | 3.076 | 2.053 |

| Proportion Var | 0.282 | 0.200 | 0.140 | 0.093 |

| Cumulative Var | 0.282 | 0.482 | 0.621 | 0.715 |

(Four-factor solution based on scree plot and Eigenvalue > 1; varimax rotation; items with loadings below 0.4 were suppressed).

Appendix B. Interview Guideline for the Qualitative Survey

- Intraorganizational barriers

- Does your company face the following intraorganizational barriers?

- If so, what kind of measures do you take or resources do you use to overcome them?

- Financial constraints;

- Lack of management commitment and support;

- Lack of new organizational policies for using blockchain technology;

- Lack of knowledge and expertise;

- Difficulties in changing organizational culture;

- Hesitation to convert to new systems;

- Lack of tools for blockchain technology implementation in sustainable supply chains.

- Interorganizational barriers

- Does your company face the following interorganizational barriers?

- If so, what kind of measures do you take, or resources do you use to overcome them?

- Problems in collaboration, communication, and coordination in the supply chain;

- Challenges of information disclosure policy between partners in the supply chain;

- Challenges in integrating sustainable practices and blockchain technology through SCM;

- Cultural differences of supply chain partners.

References

- Apnews Food Poisoning. Available online: https://apnews.com/hub/food-poisoning (accessed on 6 April 2021).

- Thyberg, K.L.; Tonjes, D.J.; Gurevitch, J. Quantification of Food Waste Disposal in the United States: A Meta-Analysis. Environ. Sci. Technol. 2015, 49, 13946–13953. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Caldeira, C.; De Laurentiis, V.; Corrado, S.; van Holsteijn, F.; Sala, S. Quantification of Food Waste per Product Group along the Food Supply Chain in the European Union: A Mass Flow Analysis. Resour. Conserv. Recycl. 2019, 149, 479–488. [Google Scholar] [CrossRef] [PubMed]

- Rana, R.L.; Tricase, C.; De Cesare, L. Blockchain Technology for a Sustainable Agri-Food Supply Chain. Br. Food J. 2021, 123, 3471–3485. [Google Scholar] [CrossRef]

- Lacity, M.C. Addressing Key Challenges to Making Enterprise Blockchain Applications a Reality. MIS Q. Exec. 2018, 17, 201–222. [Google Scholar]

- van Hoek, R.; Fugate, B.; Davletshin, M.; Waller, M.A. Integrating Blockchain into Supply Chain Management: A Toolkit for Practical Implementation, 1st ed.; Kogan Page: London, UK; New York, NY, USA, 2019; ISBN 978-0-7494-9826-9. [Google Scholar]

- Rejeb, A.; Keogh, J.G.; Treiblmaier, H. How Blockchain Technology Can Benefit Marketing: Six Pending Research Areas. Front. Blockchain 2020, 3, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Treiblmaier, H. Toward More Rigorous Blockchain Research: Recommendations for Writing Blockchain Case Studies. Front. Blockchain 2019, 2, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Rocha, G.S.R.; de Oliveira, L.; Talamini, E. Blockchain Applications in Agribusiness: A Systematic Review. Future Internet 2021, 13, 95. [Google Scholar] [CrossRef]

- Rogerson, M.; Parry, G.C. Blockchain: Case Studies in Food Supply Chain Visibility. Supply Chain. Manag. 2020, 25, 601–614. [Google Scholar] [CrossRef]

- Rejeb, A.; Keogh, J.G.; Zailani, S.; Treiblmaier, H.; Rejeb, K. Blockchain Technology in the Food Industry: A Review of Potentials, Challenges and Future Research Directions. Logistics 2020, 4, 27. [Google Scholar] [CrossRef]

- Garaus, M.; Treiblmaier, H. The Influence of Blockchain-Based Food Traceability on Retailer Choice: The Mediating Role of Trust. Food Control 2021, 129, 108082. [Google Scholar] [CrossRef]

- IBM. IBM Food Trust–Blockchain for the World’s Food Supply. Available online: https://www.ibm.com/blockchain/solutions/food-trust (accessed on 7 April 2021).

- Lacity, M.; van Hoek, R. What We’ve Learned So Far About Blockchain for Business. Available online: https://sloanreview.mit.edu/article/what-weve-learned-so-far-about-blockchain-for-business/ (accessed on 30 April 2021).

- OriginTrail. Making Supply Chains Work. Together. Available online: https://origintrail.io (accessed on 7 April 2021).

- AgroHub. Meet The Blockchain Startups Disrupting Agriculture Right Now. Available online: https://agrohub.bg/meet-the-blockchain-startups-disrupting-agriculture-right-now/ (accessed on 3 December 2021).

- Xu, J.; Guo, S.; Xie, D.; Yan, Y. Blockchain: A New Safeguard for Agri-Foods. Artif. Intell. Agric. 2020, 4, 153–161. [Google Scholar] [CrossRef]

- Oliva, F.L.; Kotabe, M. Barriers, Practices, Methods and Knowledge Management Tools in Startups. J. Knowl. Manag. 2019, 23, 1838–1856. [Google Scholar] [CrossRef]

- Polidoro, F.; Yang, W. Corporate Investment Relationships and the Search for Innovations: An Examination of Startups’ Search Shift Toward Incumbents. Organ. Sci. 2021, 32, 909–939. [Google Scholar] [CrossRef]

- Balasubramanian, N. New Plant Venture Performance Differences Among Incumbent, Diversifying, and Entrepreneurial Firms: The Impact of Industry Learning Intensity. Manag. Sci. 2011, 57, 549–565. [Google Scholar] [CrossRef]

- Barney, J. Firm Resources and Sustained Competitive Advantage. J. Manag. 1991, 17, 99–120. [Google Scholar] [CrossRef]

- Daft, R.L. Organization Theory and Design; West Pub. Co.: Saint Paul, MI, USA, 1983; ISBN 978-0-314-69645-8. [Google Scholar]

- Treiblmaier, H. The Impact of the Blockchain on the Supply Chain: A Theory-Based Research Framework and a Call for Action. Supply Chain. Manag. 2018, 23, 545–559. [Google Scholar] [CrossRef] [Green Version]

- Treiblmaier, H. Combining Blockchain Technology and the Physical Internet to Achieve Triple Bottom Line Sustainability: A Comprehensive Research Agenda for Modern Logistics and Supply Chain Management. Logistics 2019, 3, 10. [Google Scholar] [CrossRef] [Green Version]

- Fawcett, S.E.; Magnan, G.M.; McCarter, M.W. Benefits, Barriers, and Bridges to Effective Supply Chain Management. Supply Chain. Manag. Int. J. 2008, 13, 35–48. [Google Scholar] [CrossRef] [Green Version]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain Technology and Its Relationships to Sustainable Supply Chain Management. Int. J. Prod. Res. 2019, 57, 2117–2135. [Google Scholar] [CrossRef] [Green Version]

- Kouhizadeh, M.; Saberi, S.; Sarkis, J. Blockchain Technology and the Sustainable Supply Chain: Theoretically Exploring Adoption Barriers. Int. J. Prod. Econ. 2021, 231, 107831. [Google Scholar] [CrossRef]

- Dutta, P.; Choi, T.-M.; Somani, S.; Butala, R. Blockchain Technology in Supply Chain Operations: Applications, Challenges and Research Opportunities. Transp. Res. Part E Logist. Transp. Rev. 2020, 142, 102067. [Google Scholar] [CrossRef]

- Kittipanya-ngam, P.; Tan, K.H. A Framework for Food Supply Chain Digitalization: Lessons from Thailand. Prod. Plan. Control. 2020, 31, 158–172. [Google Scholar] [CrossRef]

- Vivaldini, M. Blockchain in Operations for Food Service Distribution: Steps before Implementation. Int. J. Logist. Manag. 2021, 32, 995–1029. [Google Scholar] [CrossRef]

- van Hoek, R. Developing a Framework for Considering Blockchain Pilots in the Supply Chain–Lessons from Early Industry Adopters. Supply Chain. Manag. Int. J. 2020, 25, 115–121. [Google Scholar] [CrossRef]

- Lin, Q.; Wang, H.; Pei, X.; Wang, J. Food Safety Traceability System Based on Blockchain and EPCIS. IEEE Access 2019, 7, 20698–20707. [Google Scholar] [CrossRef]

- Kumar, A.; Liu, R.; Shan, Z. Is Blockchain a Silver Bullet for Supply Chain Management? Technical Challenges and Research Opportunities. Decis. Sci. 2019, 51, 8–37. [Google Scholar] [CrossRef]

- Chen, S.; Liu, X.; Yan, J.; Hu, G.; Shi, Y. Processes, Benefits, and Challenges for Adoption of Blockchain Technologies in Food Supply Chains: A Thematic Analysis. Inf. Syst. e-Bus. Manag. 2020, 19, 909–935. [Google Scholar] [CrossRef]

- Kayikci, Y.; Subramanian, N.; Dora, M.; Bhatia, M.S. Food Supply Chain in the Era of Industry 4.0: Blockchain Technology Implementation Opportunities and Impediments from the Perspective of People, Process, Performance, and Technology. Prod. Plan. Control. 2020, 1–21. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Sharma, R. Modeling the Blockchain Enabled Traceability in Agriculture Supply Chain. Int. J. Inf. Manag. 2019, 52, 101967. [Google Scholar] [CrossRef]

- Chanson, M.; Bogner, A.; Bilgeri, D.; Fleisch, E.; Wortmann, F. Blockchain for the IoT: Privacy-Preserving Protection of Sensor Data. J. Assoc. Inf. Syst. 2019, 20, 1274–1309. [Google Scholar] [CrossRef] [Green Version]

- Perboli, G.; Musso, S.; Rosano, M. Blockchain in Logistics and Supply Chain: A Lean Approach for Designing Real-World Use Cases. IEEE Access 2018, 6, 62018–62028. [Google Scholar] [CrossRef]

- Klerkx, L.; Rose, D. Dealing with the Game-Changing Technologies of Agriculture 4.0: How Do We Manage Diversity and Responsibility in Food System Transition Pathways? Glob. Food Secur. 2020, 24, 100347. [Google Scholar] [CrossRef]

- Hew, J.-J.; Wong, L.-W.; Tan, G.W.-H.; Ooi, K.-B.; Lin, B. The Blockchain-Based Halal Traceability Systems: A Hype or Reality? Supply Chain. Manag. 2020, 25, 863–879. [Google Scholar] [CrossRef]

- Longo, F.; Nicoletti, L.; Padovano, A. Estimating the Impact of Blockchain Adoption in the Food Processing Industry and Supply Chain. Int. J. Food Eng. 2020, 16, 5–6. [Google Scholar] [CrossRef]

- Zhao, G.; Liu, S.; Lopez, C.; Lu, H.; Elgueta, S.; Chen, H.; Boshkoska, B.M. Blockchain Technology in Agri-Food Value Chain Management: A Synthesis of Applications, Challenges and Future Research Directions. Comput. Ind. 2019, 109, 83–99. [Google Scholar] [CrossRef]

- Jasperson, J.S.; Carter, P.E.; Zmud, R.W. A Comprehensive Conceptualization of Post-Adoptive Behaviors Associated with Information Technology Enabled Work Systems. MIS Q. 2005, 29, 525–557. [Google Scholar] [CrossRef]

- Antonucci, F.; Figorilli, S.; Costa, C.; Pallottino, F.; Raso, L.; Menesatti, P. A Review on Blockchain Applications in the Agri-Food Sector. J. Sci. Food Agric. 2019, 99, 6129–6138. [Google Scholar] [CrossRef]

- Lin, W.; Huang, X.; Fang, H.; Wang, V.; Hua, Y.; Wang, J.; Yin, H.; Yi, D.; Yau, L. Blockchain Technology in Current Agricultural Systems: From Techniques to Applications. IEEE Access 2020, 8, 143920–143937. [Google Scholar] [CrossRef]

- Yadav, V.S.; Singh, A.R.; Raut, R.D.; Govindarajan, U.H. Blockchain Technology Adoption Barriers in the Indian Agricultural Supply Chain: An Integrated Approach. Resour. Conserv. Recycl. 2020, 161, 104877. [Google Scholar] [CrossRef]

- Katsikouli, P.; Wilde, A.S.; Dragoni, N.; Høgh-Jensen, H. On the Benefits and Challenges of Blockchains for Managing Food Supply Chains. J. Sci. Food Agric. 2021, 101, 2175–2181. [Google Scholar] [CrossRef]

- Tsolakis, N.; Niedenzu, D.; Simonetto, M.; Dora, M.; Kumar, M. Supply Network Design to Address United Nations Sustainable Development Goals: A Case Study of Blockchain Implementation in Thai Fish Industry. J. Bus. Res. 2020, 131, 459–519. [Google Scholar] [CrossRef]

- Kurpjuweit, S.; Schmidt, C.G.; Klöckner, M.; Wagner, S.M. Blockchain in Additive Manufacturing and Its Impact on Supply Chains. J. Bus. Logist. 2021, 42, 46–70. [Google Scholar] [CrossRef]

- Abreu, A.W.; Coutinho, E.F. A Pattern Adherence Analysis to a Blockchain Web Application. In Proceedings of the 2020 IEEE International Conference on Software Architecture Companion, ICSA-C 2020, Salvador, Brazil, 16–20 March 2020; pp. 103–109. [Google Scholar]

- Tönnissen, S.; Teuteberg, F. Analysing the Impact of Blockchain-Technology for Operations and Supply Chain Management: An Explanatory Model Drawn from Multiple Case Studies. Int. J. Inf. Manag. 2020, 52, 101953. [Google Scholar] [CrossRef]

- Sillaber, C.; Waltl, B.; Treiblmaier, H.; Gallersdörfer, U.; Felderer, M. Laying the Foundation for Smart Contract Development: An Integrated Engineering Process Model. Inf. Syst. e-Bus. Manag. 2020, 19, 863–882. [Google Scholar] [CrossRef] [Green Version]

- Bai, C.; Sarkis, J. A Supply Chain Transparency and Sustainability Technology Appraisal Model for Blockchain Technology. Int. J. Prod. Res. 2020, 58, 2142–2162. [Google Scholar] [CrossRef]

- Kamble, S.; Gunasekaran, A.; Arha, H. Understanding the Blockchain Technology Adoption in Supply Chains-Indian Context. Int. J. Prod. Res. 2019, 57, 2009–2033. [Google Scholar] [CrossRef]

- Karamchandani, A.; Srivastava, S.K.; Kumar, S.; Srivastava, A. Analysing Perceived Role of Blockchain Technology in SCM Context for the Manufacturing Industry. Int. J. Prod. Res. 2021, 59, 3398–3429. [Google Scholar] [CrossRef]

- Lezoche, M.; Panetto, H.; Kacprzyk, J.; Hernandez, J.E.; Alemany Díaz, M.M.E. Agri-Food 4.0: A Survey of the Supply Chains and Technologies for the Future Agriculture. Comput. Ind. 2020, 117, 103187. [Google Scholar] [CrossRef]

- Feng, H.; Wang, X.; Duan, Y.; Zhang, J.; Zhang, X. Applying Blockchain Technology to Improve Agri-Food Traceability: A Review of Development Methods, Benefits and Challenges. J. Clean. Prod. 2020, 260, 121031. [Google Scholar] [CrossRef]

- Patelli, N.; Mandrioli, M. Blockchain Technology and Traceability in the Agrifood Industry. J. Food Sci. 2020, 85, 3670–3678. [Google Scholar] [CrossRef]

- Galvez, J.F.; Mejuto, J.C.; Simal-Gandara, J. Future Challenges on the Use of Blockchain for Food Traceability Analysis. Trends Anal. Chem. 2018, 107, 222–232. [Google Scholar] [CrossRef]

- Tan, A.; Gligor, D.; Ngah, A. Applying Blockchain for Halal Food Traceability. Int. J. Logist. Res. Appl. 2020, 1–18. [Google Scholar] [CrossRef]

- Dania, W.A.P.; Xing, K.; Amer, Y. Collaboration Behavioural Factors for Sustainable Agri-Food Supply Chains: A Systematic Review. J. Clean. Prod. 2018, 186, 851–864. [Google Scholar] [CrossRef]

- Rejeb, A.; Keogh, J.G.; Simske, S.J.; Stafford, T.; Treiblmaier, H. Potentials of Blockchain Technologies for Supply Chain Collaboration: A Conceptual Framework. Int. J. Logist. Manag. 2021, 32, 973–994. [Google Scholar] [CrossRef]

- Barbosa, M.W. Uncovering Research Streams on Agri-Food Supply Chain Management: A Bibliometric Study. Glob. Food Secur. 2021, 28, 100517. [Google Scholar] [CrossRef]

- Vodenicharova, M.S. Supply Chain Study in Food Industry in Bulgaria. Int. J. Retail. Distrib. Manag. 2020, 48, 921–938. [Google Scholar] [CrossRef]

- Zhang, A.; Zhong, R.Y.; Farooque, M.; Kang, K.; Venkatesh, V.G. Blockchain-Based Life Cycle Assessment: An Implementation Framework and System Architecture. Resour. Conserv. Recycl. 2020, 152, 104512. [Google Scholar] [CrossRef]

- Ramsay, J. Serendipity and the Realpolitik of Negotiations in Supply Chains. Supply Chain. Manag. Int. J. 2004, 9, 219–229. [Google Scholar] [CrossRef]

- León-Bravo, V.; Moretto, A.; Cagliano, R.; Caniato, F. Innovation for Sustainable Development in the Food Industry: Retro and Forward-Looking Innovation Approaches to Improve Quality and Healthiness. Corp. Soc. Responsib. Environ. Manag. 2019, 26, 1049–1062. [Google Scholar] [CrossRef]

- Beugré, C.D.; Acar, W. Offshoring and Cross-Border Interorganizational Relationships: A Justice Model. Decis. Sci. 2008, 39, 445–468. [Google Scholar] [CrossRef]

- Qian, J.; Wu, W.; Yu, Q.; Ruiz-Garcia, L.; Xiang, Y.; Jiang, L.; Shi, Y.; Duan, Y.; Yang, P. Filling the Trust Gap of Food Safety in Food Trade between the EU and China: An Interconnected Conceptual Traceability Framework Based on Blockchain. Food Energy Secur. 2020, 9, e249. [Google Scholar] [CrossRef]

- Galanakis, C.M.; Rizou, M.; Aldawoud, T.M.S.; Ucak, I.; Rowan, N.J. Innovations and Technology Disruptions in the Food Sector within the COVID-19 Pandemic and Post-Lockdown Era. Trends Food Sci. Technol. 2021, 110, 193–200. [Google Scholar] [CrossRef]

- Tiscini, R.; Testarmata, S.; Ciaburri, M.; Ferrari, E. The Blockchain as a Sustainable Business Model Innovation. Manag. Decis. 2020, 58, 1621–1642. [Google Scholar] [CrossRef]

- van Hoek, R. Exploring Blockchain Implementation in the Supply Chain: Learning from Pioneers and RFID Research. Int. J. Oper. Prod. Manag. 2019, 39, 829–859. [Google Scholar] [CrossRef]

- van Hoek, R. Unblocking the Chain–Findings from an Executive Workshop on Blockchain in the Supply Chain. Supply Chain. Manag. Int. J. 2020, 25, 255–261. [Google Scholar] [CrossRef]

- Treiblmaier, H.; Filzmoser, P. Exploratory Factor Analysis Revisited: How Robust Methods Support the Detection of Hidden Multivariate Data Structures in IS Research. Inf. Manag. 2010, 47, 197–207. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research, 5th ed.; Sage Publications: Los Angeles, CA, USA, 2013; ISBN 978-1-4522-4256-9. [Google Scholar]

- Treiblmaier, H. Optimal Levels of (de)Centralization for Resilient Supply Chains. Int. J. Logist. Manag. 2018, 29, 435–455. [Google Scholar] [CrossRef]

- Strebinger, A.; Treiblmaier, H. E-Adequate Branding: Building Offline and Online Brand Structure within a Polygon of Interdependent Forces. Electron. Mark. 2004, 14, 153–164. [Google Scholar] [CrossRef]

- Treiblmaier, H.; Strebinger, A. The Effect of E-Commerce on the Integration of IT Structure and Brand Architecture. Inf. Syst. J. 2008, 18, 479–498. [Google Scholar] [CrossRef]

- Clohessy, T.; Treiblmaier, H.; Acton, T.; Rogers, N. Antecedents of Blockchain Adoption: An Integrative Framework. Strateg. Chang. 2020, 29, 501–515. [Google Scholar] [CrossRef]

- Nandi, M.L.; Nandi, S.; Moya, H.; Kaynak, H. Blockchain Technology-Enabled Supply Chain Systems and Supply Chain Performance: A Resource-Based View. Supply Chain. Manag. 2020, 25, 841–862. [Google Scholar] [CrossRef]

- Liang, T.-P.; Kohli, R.; Huang, H.-C.; Li, Z.-L. What Drives the Adoption of the Blockchain Technology? A Fit-Viability Perspective. J. Manag. Inf. Syst. 2021, 38, 314–337. [Google Scholar] [CrossRef]

- Dotan, M.; Pignolet, Y.-A.; Schmid, S.; Tochner, S.; Zohar, A. Survey on Blockchain Networking: Context, State-of-the-Art, Challenges. ACM Comput. Surv. 2021, 54, 1–34. [Google Scholar] [CrossRef]

- Wang, Y.; Han, J.H.; Beynon-Davies, P. Understanding Blockchain Technology for Future Supply Chains: A Systematic Literature Review and Research Agenda. Supply Chain. Manag. Int. J. 2019, 24, 62–84. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).