Abstract

Background: Digital supply chain twins (DSCT) are gaining increased attention in academia and practice as they emerge as one of the most important trends in logistics and supply chain management (LSCM). Still, there seems to be no common understanding of the term in scientific literature. Moreover, the broad field of LSCM allows for a multitude of feasible application areas and use cases, yet there exists no conclusive list of them as to date. Methods: This study builds upon a systematic literature review of 66 DSCT articles to identify application areas of DSCT in LSCM as well as specific use cases and their respective intended benefits. Results: To start with, the study derives a unified definition of DSCTs, including possible scopes of applications. Afterwards, five application areas of DSCT in LSCM are synthesized as well as 14 individual use cases and their respective intended benefits. Conclusions: The study leads towards a conceptual clarification of DSCT that is of importance for research and practice alike. For managers it additionally provides up-to-date use cases to guide DSCT applications in practice.

1. Introduction

The increasing complexity of supply chains creates significant challenges for companies nowadays. The ongoing digital transformation of various traditional business processes goes along with these challenges, but can also be the source of future competitive advantages. As an interdisciplinary and cross-sectional function, LSCM can fulfill a key role in this digital transformation [1].

Demand for efficiency and flexibility is at an all-time high [2] while transparency in value systems is gaining increased attention in the light of the COVID-19 pandemic [3]. Meanwhile, the DSCT is discussed as a promising solution for developing an agile logistic network. At the latest, after entering Gartner’s hype cycle in 2017 as one of the most disruptive technologies, the DSCT is gaining more and more attention. In 2019 [4] and 2020 [5], Gartner placed digital supply chain twins (DSCTs) in the top eight technology trends in the supply chain, but other studies also stress the future importance of the DSCT concept in LSCM [6]. The DSCT is recognized as an innovation that not only leads to local optimizations and improvements within a logistics system, but rather ensures a holistic approach for optimally planning and controlling an entire system [7,8,9]. The DSCT creates collaborative environments for stakeholders in LSCM while also providing the basis for data-based decision-making [10]. By simulating possible real-world scenarios in a digital world, the DSCT is able to predict the best achievable outcome for the present and the future for the whole business ecosystem [11].

The enablers and at the same time the drivers for DSCT solutions are technological advancements that have been made in recent years in many relevant fields. For example, better and more cost-efficient sensor technology, widespread applications of the “Internet of Things” (IoT) and advanced data analytics, just to name a few. These technological advancements are being used to realize digital twins (DTs) on a commercial scale and justify the rapid growth of interest in the concept [8,12,13]. Gartner expects that by 2022, around two thirds of all large companies that have implemented IoT technology will operate at least one DT concept [14].

In the current academic debate, DT and DSCT do not have a consistent definition [15,16]. The concept is sometimes used in a misleading way [11]. Furthermore, current literature about DT primarily discusses concepts that are asset-focused and associated with digital images of single machines. However, asset-focused twins do not adequately reflect the diverse application fields and implementation possibilities of the whole DSCT concept [17]. Especially in the context of LSCM, with all its complex challenges such as increasing customer requirements in terms of speed and flexibility [18] or responding efficiently to volatile markets [19], the DSCT has to be considered in a very differentiated context as opposed to “classical” research on DT.

As LSCM is a very broad field of study, many possible use cases of DSCT are feasible. In an extensive trend study from 2019, DHL opened up the field of possible application areas for digital twins in the context of DSCT. The scope ranges from containers to warehouses to value networks [6]. However, this list has not been revised by scientific literature. Researchers, on the other hand, have described several use cases in academia. Some of the more prominent examples being risk management [20] and production planning [21]. These researchers have also described individual benefits, even though they have mostly not been quantified [22]. Although these use cases and benefits have been described singularly, there is currently no broad overview of the field of DSCTs in respect to use cases and benefits.

Considering those developments and recent shortcomings of current literature in this field, this study seeks to contribute to a much-needed conceptual clarification and systematization of DSCT and their applications. More specifically, this study aims at the following research objectives (RO):

- RO1:

- Describe the distinct characteristics and scopes of DSCT in LSCM literature and derive a unified definition of DSCT.

- RO2:

- Synthesize the application areas of DSCT in LSCM.

- RO3:

- Consolidate specific DSCT use cases and their intended individual benefits.

In order to contribute to RO1, the following section provides a conceptual clarification of DSCT literature to provide a baseline for future scientific research. More specifically, it outlines current developments in DT and DSCT literature, summarizes existing DSCT definitions and understanding, highlights their core characteristics and derives a common definition from them. Moreover, the scopes of DSCTs in current literature are discussed. Afterwards, to contribute to RO2 and RO3, a systematic literature review (SLR) was executed to give an overview about the current state of scientific literature concerning DSCTs. Special attention was given to the identification of application areas in the field of LSCM, as well as use cases and their respective benefits. The analysis highlights five application areas as well as 14 individual use cases with specific characteristics and thereby demonstrates the current scope, potential shortcomings and future research directions of DSCTs in LSCM.

2. Conceptual Clarification of Digital Supply Chain Twins

To first give a brief history of the origin and development of the DT concept, an overview in accordance with Tao et al. (2019) is given. The concept of a DT was originally introduced in the field of product lifecycle management (PLM). Professor Michael Grieves was the first to mention the DT concept in a presentation at the University of Michigan in 2003 as a way of synchronizing physical products with a virtual counterpart. Lacking relevant studies or applications at that time, National Aeronautics and Space Administration (NASA) and the U.S. Air Force applied DTs to predict the remaining useful life of aerospace vehicles. In 2012, Glaessgen and Stargel wrote a landmark article about this paradigm. Since then, the DT concept has been applied to various other fields such as product design, production line design or production process optimization [8]. While at the beginning DTs were merely focused on single products or machines, with time the DT concept has been applied to more complex systems.

In recent years researchers and practitioners have looked into the application of the DT concept in the field of LSCM, where the twin can depict as much as a whole multi-site, multi-stakeholder value system. This concept is commonly referred to as a “digital supply chain twin”. In accordance with RO1, a unified definition of the term DSCT is synthesized from literature in the following section. Furthermore, possible scopes of a DSCT are examined.

2.1. Development of a Definition of DSCT

In order to define a digital supply chain twin (or digital logistics twin), we will first look at what a digital twin is. Currently there is no uniform understanding of the term [23]. The lowest common denominator of many definitions is that a DT is a virtual representation of a physical product. Some definitions emphasize the connection between the two parts, while others include possible applications of DTs, for example simulation [24]. To provide a broader understanding, some selected DT definitions are shown below.

Grieves und Vickers (2017) [25]:

“The Digital Twin is a set of virtual information constructs that fully describes a potential or actual physical manufactured product from the micro atomic level to the macro geometrical level. At its optimum, any information that could be obtained from inspecting a physical manufactured product can be obtained from its Digital Twin.”

Glaessgen and Stargel (2012) [26]:

“A Digital Twin is an integrated multiphysics, multiscale, probabilistic simulation of an […] system that uses the best available physical models, sensor updates, […], to mirror the life of its corresponding […] twin. The Digital Twin is ultra-realistic and may consider one or more important and interdependent […] systems […]. The Digital Twin integrates sensor data from the […] system, […] and all available historical […] data obtained using data mining and text mining.”

Miller et al. (2020) [27]:

“A Digital Twin is a digital representation of a physical thing’s data, state, relationships and behavior.”

In addition, Miller et al. define six characteristics of a DT:

- Physical and virtual: A DT considers both the physical system and the virtual system.

- Bidirectional data: A DT supports bidirectional data exchange between the physical and virtual system.

- Timely updates: A DT provides timely updates, depending on the requirements of the use case.

- Maintain state: A DT is able to store the last state of the physical system in order to deal with disconnections.

- Modeling and analytics: A DT provides modeling and analytics capabilities.

- Reporting: A DT passes results to people and/or machines.

This selection of definitions shows both differences and similarities. The basic idea of the DT remains the same: one observes the DT (a digital image) to draw conclusions about a real-world system. In addition, the high level of detail of the digital image is always emphasized, which allows high-quality inferences to be made about the real system. However, the nature of the digital image is perceived differently. For example, the descriptions “set of virtual information constructs”, “probabilistic simulation” and “digital representation” each allow different interpretations and degrees of freedom. Furthermore, sensor technology is sometimes mentioned as a necessary technology.

The application of the DT concept to the field of LSCM has been more frequently known as a digital supply chain twin. Several approaches can be found in scientific literature for defining the DSCT. The various definitions and understanding differ in some details from source to source, as the following Table 1 shows. Even if the term DSCT is not mentioned specifically, the selected sources always refer to a DT concept in an LSCM environment.

Table 1.

Definitions and Understanding of DSCT.

Again, many similarities, but also many differences can be found between the existing definitions and understanding. One objective of this work is to synthesize a general definition for DSCT from this collection. The claim for this definition is to assign a specific meaning to the DSCT term. In doing so, the commonalities will be addressed, on which the literature is largely in agreement. Points of disagreement are to be discussed and substantiated or deliberately left open. For this purpose, some guidelines will be defined:

- The term DSCT is derived from the term DT, which was originally developed for product development. The basic idea of a DT is therefore to be retained in the definition of the DSCT.

- Although DTs have been discussed a lot in literature and are already used extensively in practice [33], the DSCT has only been mentioned in Gartner’s top “supply chain technology trends” since 2019 [4,5]. This suggests that a DSCT does not merely describe a new application field of classic DT, but represents a new, innovative technology concept. The definition of DSCT should therefore be clearly distinguished from that of DT to do justice to the special application field of LSCM [34].

- In DT literature, the automated exchange of data on both sides between the physical and digital system is often emphasized as a characteristic of DT. This is achieved on one side by the use of sensors, and on the other side by the use of actuators and other control elements. In relation to logistics systems, however, this characteristic is questionable, since humans still play a major role in most logistics systems [35]. Data transfer from the logistics system to the DSCT can certainly be implemented with the help of sensors and IoT technology, but automated control of the logistics system by control elements is unrealistic for most use cases. The exchange of data from the DSCT to the logistics system can therefore also take place by a knowledge gain which the actors involved achieve through analyzing the DSCT.

- Many definitions describe the DSCT as a model or simulation model. However, digital simulation models of logistics systems have been used for decision-making in LSCM for years, and are therefore not to be seen as a new, innovative technology concept [36]. The DSCT definition should therefore be clearly distinguished from simple digital models and their use for simulation purposes [37].

- Depending on the literature, different purposes and methods are assigned to DSCT. In this respect there is no consensus among authors. A general definition of DSCT should therefore be independent of the specific purpose.

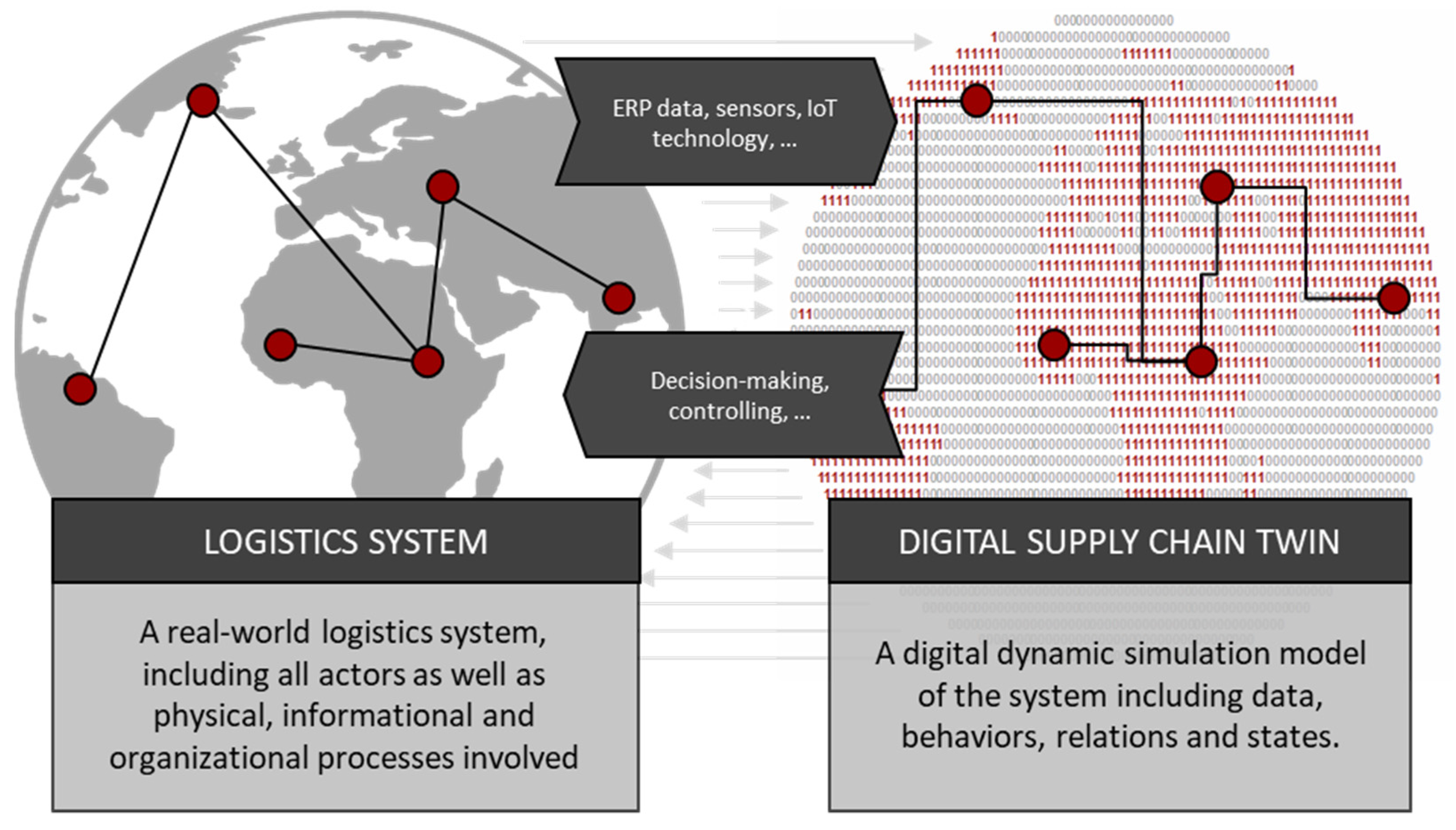

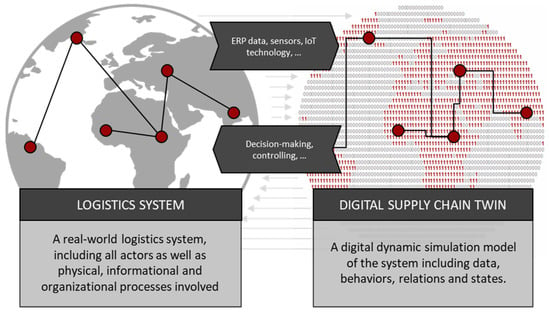

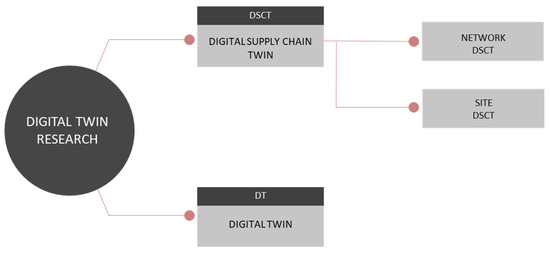

Based on these guidelines, a conceptual clarification for the DSCT is proposed (see Figure 1):

Figure 1.

Digital supply chain twin.

A digital logistics twin or digital supply chain twin (DSCT) is a digital dynamic simulation model of a real-world logistics system, which features a long-term, bidirectional and timely data-link to that system. The logistics system in question may take the form of a whole value network or a subsystem thereof.

Through observing the digital model, it is possible to acquire information about the real logistics system to draw conclusions, make decisions and carry out actions in the real world. The DSCT enables the use of diagnostic, predictive and prescriptive methods with the ultimate goal of holistically improving the logistics performance along the whole customer order process.

The DSCT maps data, state, relations and behavior of the logistics system, including physical, informational and organizational processes. It mimics the system’s behavior using dynamic simulation capabilities. Therefore, any relevant information that can be obtained by observing the real-world logistics system can optimally also be obtained by observing the digital model. A DSCT acts as a tool for decision-makers in logistics and supply chain management to holistically improve logistics performance along the whole customer order process through data-driven decision-making.

The data exchange between the logistics system and its DSCT can be characterized by three attributes:

- Bidirectional: Data are exchanged in both directions. Changes in the state of the logistics system therefore lead to changes in the state of the digital model. Similarly, knowledge gained from the digital model leads to actions or decision-making in the logistics system. A certain degree of automation regarding the data exchange is explicitly not a prerequisite for a DSCT.

- Timely: Data exchange takes place in a timely manner. The specific frequency is determined by the use case. Continuous updates in real-time are explicitly not a prerequisite for a DSCT, unless the use case requires this.

- Long-term: The data exchange and thus the lifetime of the DSCT are designed for continuous, long-term use. Digital simulation models created as part of project activities or for one-time use are thus explicitly not to be considered DSCTs.

A dynamic simulation model is a model that enables dynamic experimentation, i.e., a model on the basis of which time-sensitive simulation experiments can be performed [36]. This distinguishes the DSCT from other static digital models. Still, it does not exclusively generate benefit by running simulation experiments. The range of value-adding methods used in a DSCT can range from simple means of business intelligence like reporting and monitoring to more advanced analytics tools like network optimization algorithms or scenario analyses though simulation experiments. Likewise, several benefits might arise from DSCT applications, such as agility, robustness, sustainability and efficiency improvements. This definition is deliberately kept general, since a specific definition can only be derived from a specific use case.

2.2. Scopes of DSCT

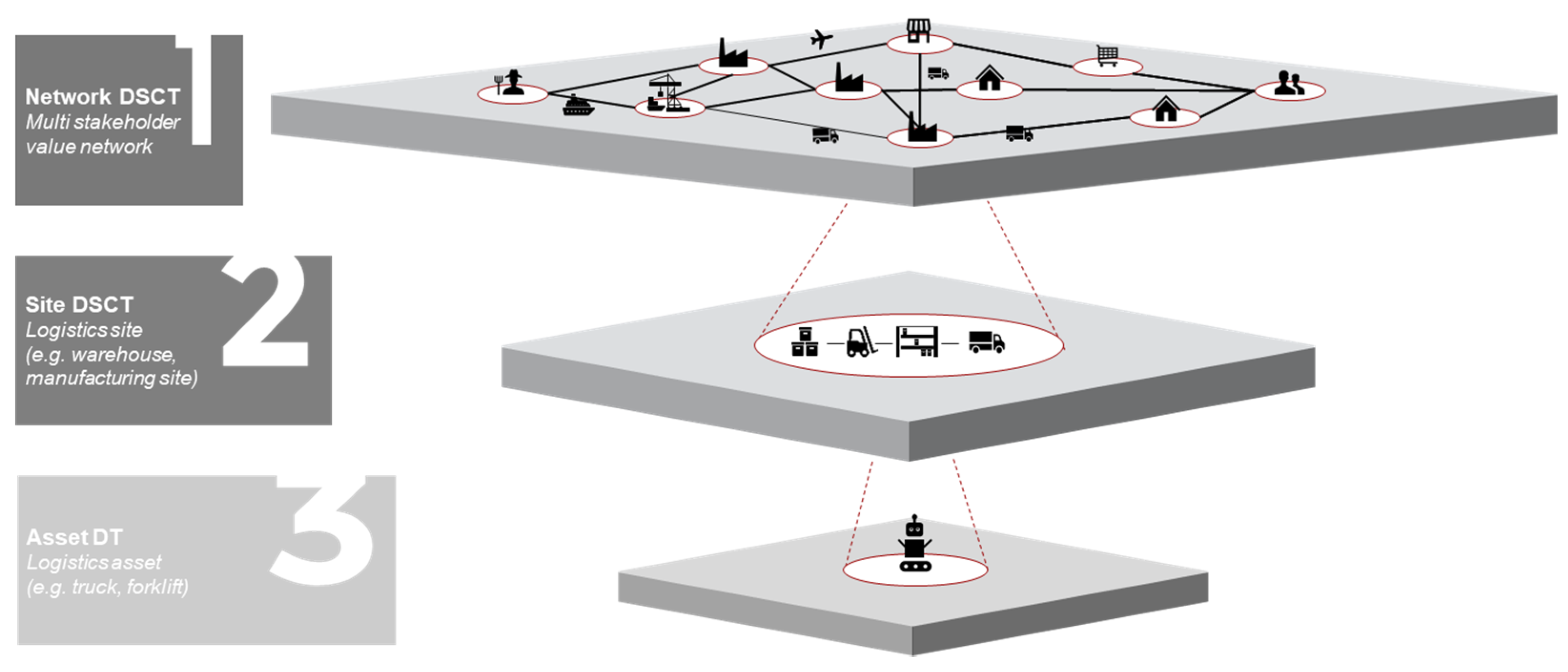

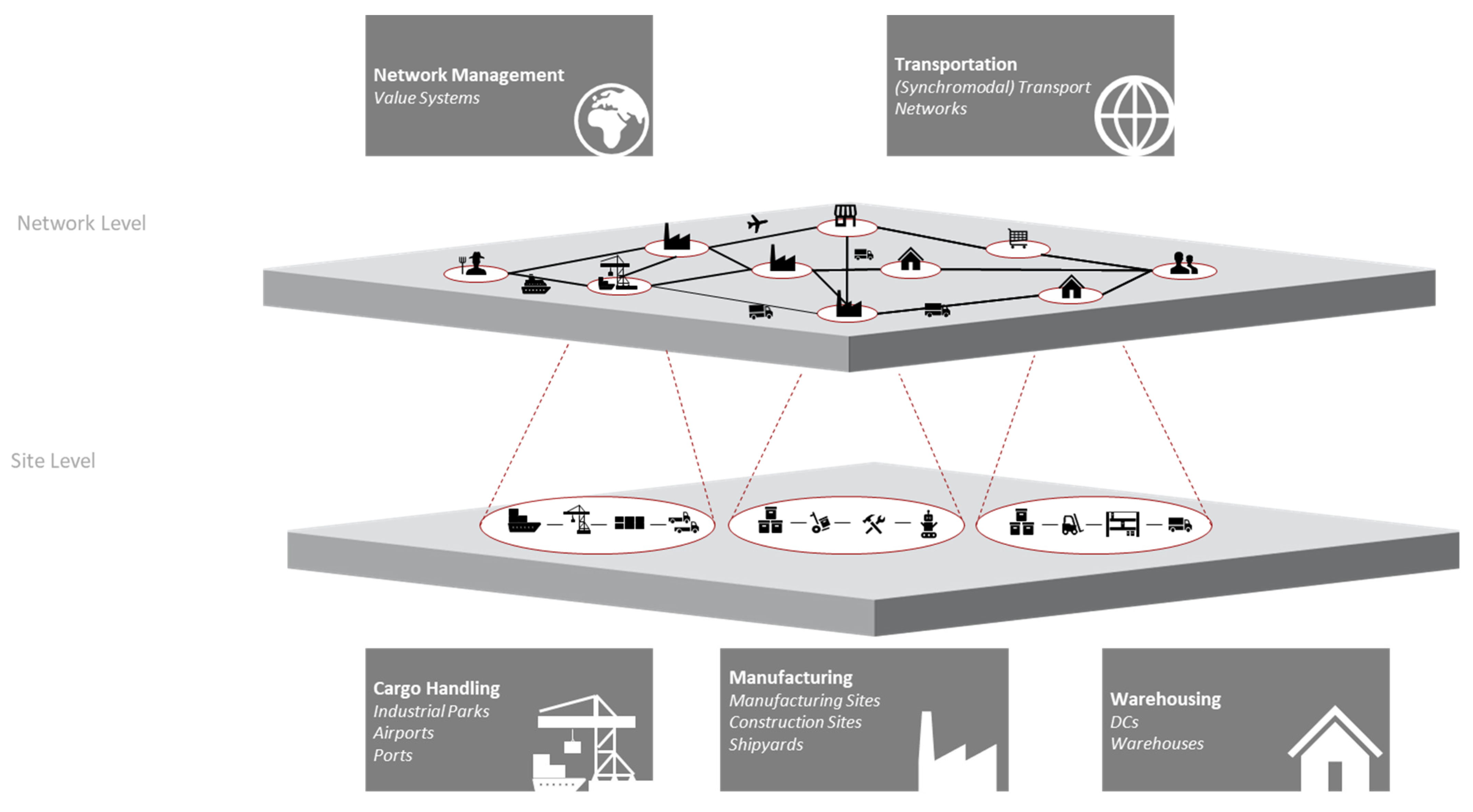

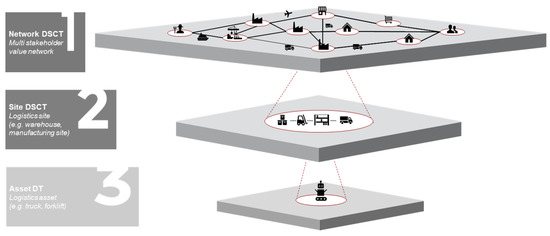

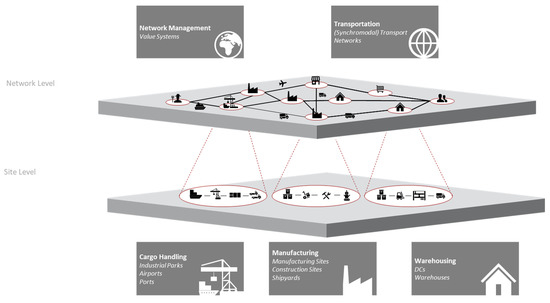

The scope of any DSCT is, in general, a logistics system. Still, the boundaries of different logistics systems may vary greatly. Accordingly, the scope of a DSCT can also vary, depending on whether an entire value network is examined, or merely a part of that network. Following a top-down approach, different scopes are conceivable (see Figure 2):

Figure 2.

Scopes of DSCTs.

- Network level: DSCT of a multi-stakeholder value network;

- Site level: DSCT of a logistics site (warehouses, production facilities, …);

- Asset level: DT of a logistics asset (trucks, forklifts, …).

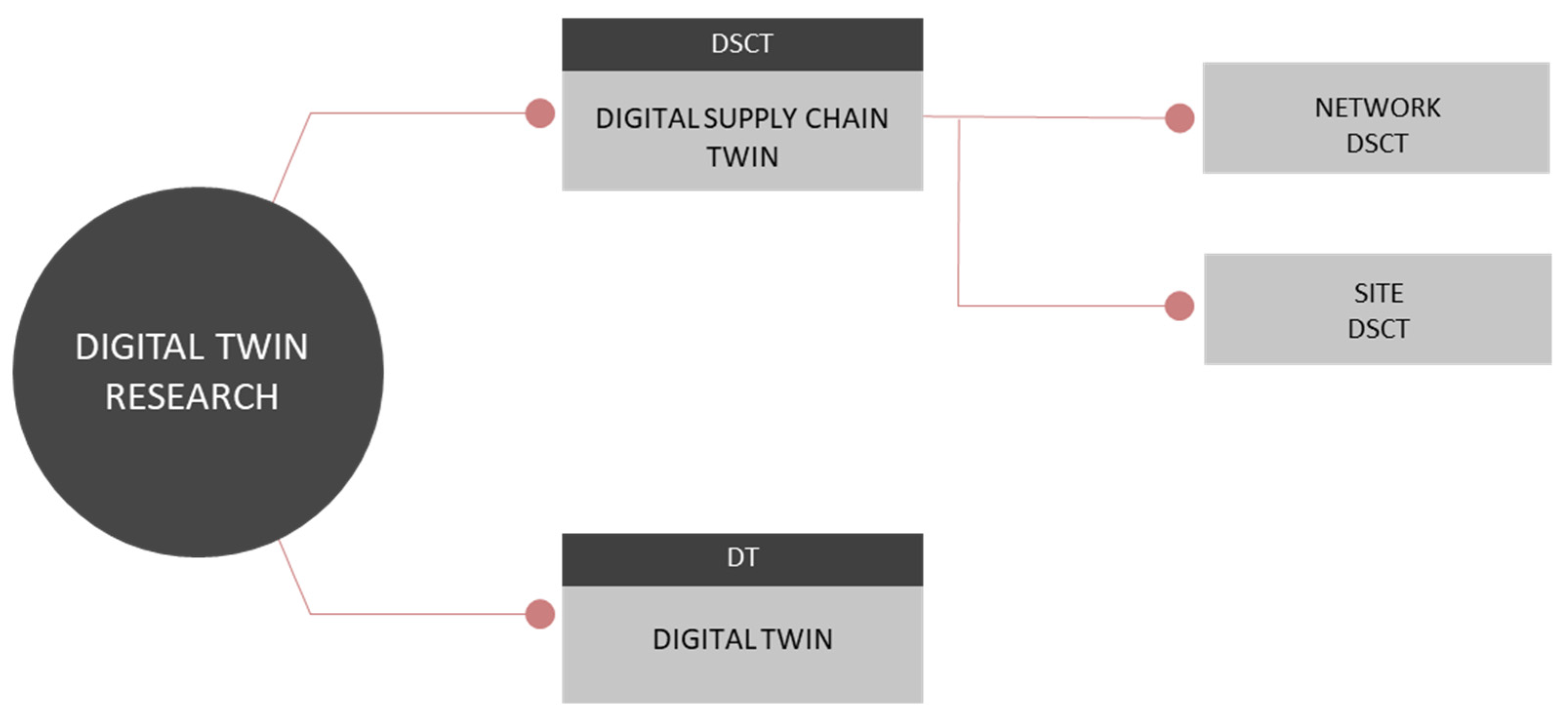

First, it should be noted that logistics assets (such as trucks and forklifts) represent atomic elements of a logistics system, but are not themselves considered logistics systems. Therefore, the application of the DT concept to logistics assets falls within the domain of generic DT research. Such digital models should not be referred to as DSCT. Thus, this research is clearly distinguished from generic research on digital twins (asset twins).

A distinct terminology is proposed to help classify DSCTs along a rough subdivision regarding their scope. A twin at the network level of a logistics system (value network) is defined as a “DSCT of a value network” or “network DSCT” for short. A network DSCT might refer to a multi-stakeholder value network. A DSCT at the site level is referred to as a “DSCT of a logistics site” or “site DSCT” for short. These twins might represent, for example, warehouses or production facilities. Many use cases, which are often referred to as “manufacturing twins” in literature, fall under this category.

One might find this counterintuitive at first, since “manufacturing twins” seems to be a more accurate description of these cases. However, the authors’ intention is to emphasize the fact that logistics systems on a site level are merely a part of a greater logistics system on the macro level. Speaking of DSCTs on different levels, therefore, underlines the holistic approach of LSCM. As in other comparable terms, the expression “supply chain” in DSCT is used as a synonym for “in the field of LSCM” rather than “applied to supply chains”. The term “supply chain analytics”, for example, describes the use of analytics in the field of LSCM, without being limited to network level applications [38].

All subsystems of a given logistics system, whether at the macro or site level, can also be depicted with a DSCT. However, this does not include atomic elements within the logistics system, which may instead be subject to an asset twin. For example: a twin of a tier 1 supplier network might be considered a network DSCT. A twin of an assembly line or a picking area might be considered a site DSCT. A twin of a picking robot on the other hand is considered an asset twin and therefore not a DSCT. The following Figure 3 shall clarify the examined field of research.

Figure 3.

Research field of DT/DSCT.

3. Research Design

The methodological approach of this research is an SLR aiming to give an overview of the current state of DSCT literature and more specifically the identification of application areas, use cases and benefits of DSCT. The collected data are consequently aggregated, following a systematic approach which is described later in this section. To conduct a clearly structured literature analysis, the authors follow the methodology of Durach et al. (2017) [39], who provide a coherent guideline for conducting SLR in LSCM. Similar approaches have been conducted by other researchers in the field to answer comparably equivalent research questions [40]. The process is divided into six procedural steps. The first five steps are described in this section. The sixth step, reporting the results, is described in Section 4.

3.1. Define Research Question

A clear research question is first defined, which is considered the research objective and is to be answered with the help of the SLR. Other stakeholders are involved in the process at an early stage in order to highlight research gaps. In discussions with business experts from a wide range of companies and industries as well as other researchers, the authors have identified the need for a structured analysis of current DSCT literature.

For once, recent studies have emphasized the lack of a common understanding of the term DSCT [6,15,16,23,28]. This was also confirmed through several expert interviews. The interviewees were chosen based on expertise in LSCM innovations and/or advanced experience in DSCT, simulation and supply chain analytics. A total of six interviews were conducted. A uniform definition was established in Section 2.1, which subsequently was challenged by the experts as well as the researchers. Accordingly, the first goal of this SLR is to compare the authors’ definition with the existing literature to give a detailed overview of the current state of the DSCT research field (RO1). Furthermore, even though there are already some DSCTs being used in practice today [41], analyzing recent literature shows the lack of consistent collections of application areas, use cases and benefits of DSCTs. Hence, the primary research objective of this SLR is to identify application areas, use cases and benefits of DSCT examined in current scientific literature (RO2 and RO3).

3.2. Determine Required Characteristics of Primary Studies

In this process, clear inclusion and/or exclusion criteria will be defined in order to be able to clearly filter the literature to be examined on that basis. In this way, only relevant literature is included. Additionally, limitations (e.g., restrictions on literature selection or a specific time period) are defined and justified. A list of inclusion criteria is provided in Table 2.

Table 2.

Inclusion Criteria for the SLR.

3.3. Retrieve Sample of Potentially Relevant Literature (“Baseline Sample”)

The analysis included two search methods. First, a database search method with a predefined search string was conducted. The search string was created by the authors and challenged by four additional researchers. This resulted in the following appropriate search string. It combines key words from the fields of DSCT, DT and LSCM in the following manner:

DSCT OR (DT AND LSCM)

More specifically, it was composed as follows:

(“Digital Supply Chain Twin” OR “Digital Twin Supply Chain” OR “Supply Chain Digital Twin” OR “Supply Chain Twin” OR “Logistics Twin” OR “Digitaler Supply Chain Zwilling” OR “Digitaler Logistik Zwilling”)

OR

((“Digital Twin” OR “Digitaler Zwilling”)

AND

(“Logistics” OR “Supply Chain” OR “Supply Network” OR “Supply Chain Management” OR “SCM” OR “Value Chain” OR “Value Network” OR “Supply*”)).

OR

((“Digital Twin” OR “Digitaler Zwilling”)

AND

(“Logistics” OR “Supply Chain” OR “Supply Network” OR “Supply Chain Management” OR “SCM” OR “Value Chain” OR “Value Network” OR “Supply*”)).

The search string was then used to scan three electronic databases:

- Web of Science (126 articles, 8 January 2021);

- EBCSO (74 articles, 8 January 2021);

- IEEE (56 articles, 8 January 2021);

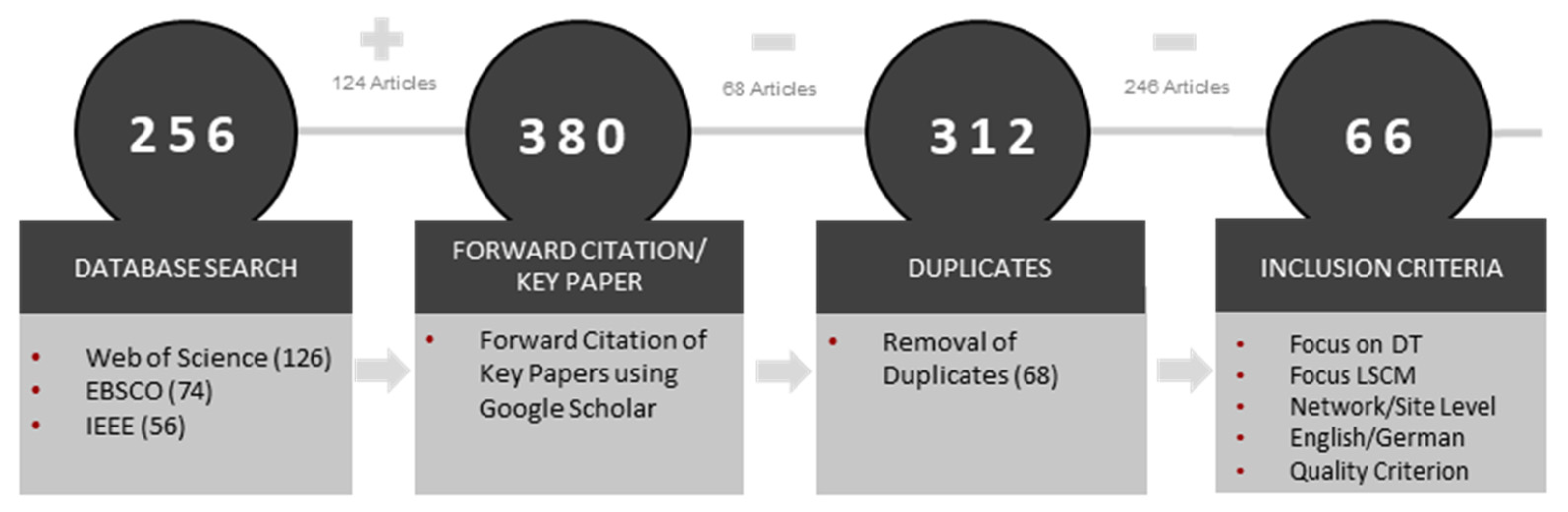

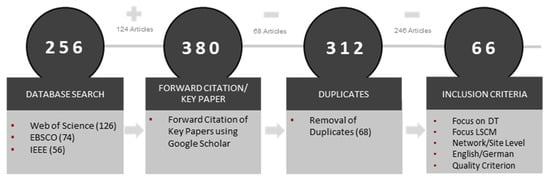

Which resulted in a total of 256 articles.

Secondly, a forward citation method was used. For that purpose, 10 key papers have been identified by the authors beforehand. These key papers have been selected by the authors as being the most relevant in the field of DSCT research. To minimize the risk of missing relevant literature, the forward citation method was then applied to all key papers, using the following database:

- Google Scholar (124 articles, 31 January 2021);

Which resulted in a total of 124 articles. Altogether, the two search methods resulted in a total of 380 articles. After removing the duplicates, a final baseline sample of 312 articles remained.

3.4. Select Pertinent Literature (“Synthesis Sample”)

The prior established inclusion criteria were then applied to the baseline sample. Two researchers reviewed the collection of papers that arose from the prior step independently. If there was a disagreement between the two researchers, a third independent researcher was consulted for his or her assessment. To check for a selector bias, Cohen’s Kappa was calculated: Kappa = 0.73 [42]. A significant selector bias was therefore ruled out.

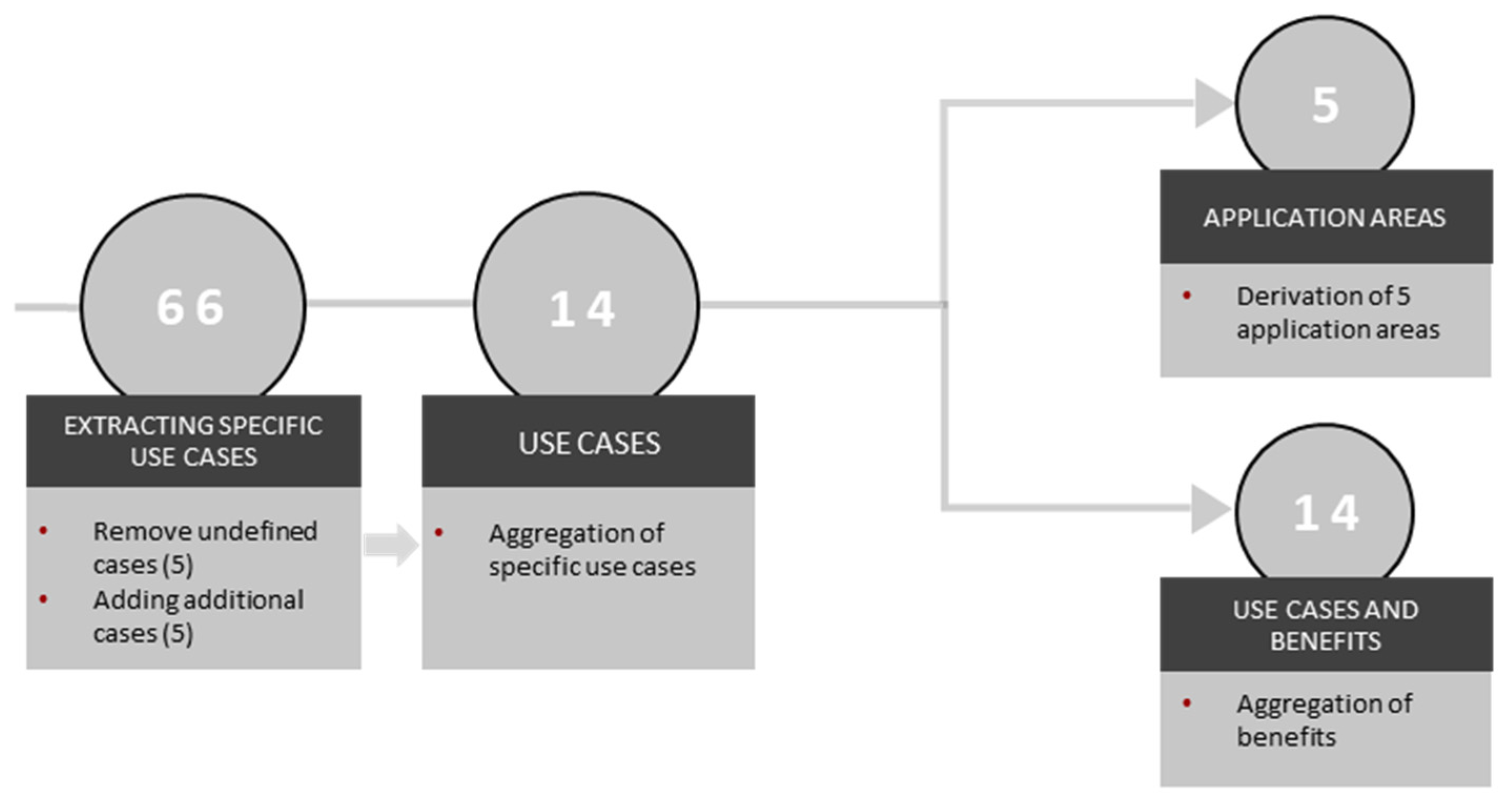

In this step, 246 articles were removed. Mostly, the first inclusion criterion was violated. A great number of articles merely mention the DT concept in their abstract, but have an overall different focus of research. Because some of the articles failed to meet not just one but multiple criteria, further analysis of the literature selection was not conducted. After applying the inclusion criteria, a final synthesis sample of 66 articles remained (see Figure 4).

Figure 4.

Selection of literature.

3.5. Synthesize Literature

The selected literature was brought together following a systematic analysis and integration. Again, three researchers were involved in the process to minimize subjectivity. First, a descriptive analysis of the data is described in Section 4.1 in accordance with RO1.

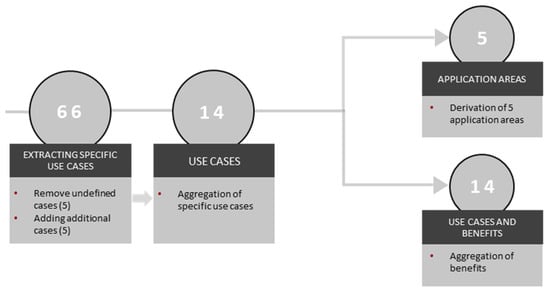

RO2 and RO3 of this work were to identify application areas of DSCTs as well as individual use cases and their respective intended benefits. For this purpose, the literature was first split according to its scope (network level or site level). Secondly, it was scanned for specific use cases of DSCT. A use case was defined as a business process in the LSCM context, which was supported through the use of a DSCT. While some articles did not mention a specific DSCT use case [10,11], other articles mentioned more than one [32]. This resulted in a list of 66 specific use cases.

This list was then scanned for use cases which were similar in regard to their aim, scope and the respective processes they support. These cases were then aggregated, which resulted in a conclusive list of 14 distinct use cases, each being described by one or more papers. For each of these use cases, a list of benefits was derived from the respective articles by three independent researchers. A benefit was defined as a positive impact on a performance measure of the given logistics system. The use cases and benefits are further described in Section 4.3, following RO3.

Furthermore, application areas were derived from the list of use cases. To this end, three researchers independently used a bottom-up approach to group the use cases into application areas. An application area was defined as a distinct area in the field of LSCM, including the type of logistics system that was depicted by the DSCT. This resulted in a conclusive list of five application areas. The application areas are further described in Section 4.2, following RO2. An overview of the synthetization process is shown in Figure 5.

Figure 5.

Selection of literature.

4. Results

4.1. Descriptive Analysis of Existing Literature

To gain insight into the current developments in DSCT research, a descriptive analysis of existing literature is executed. It examines to what extent the literature focuses on network and site DSCTs, what methodological approaches are being applied to investigate DSCTs and also to what extent the current literature is consistent with the proposed definition.

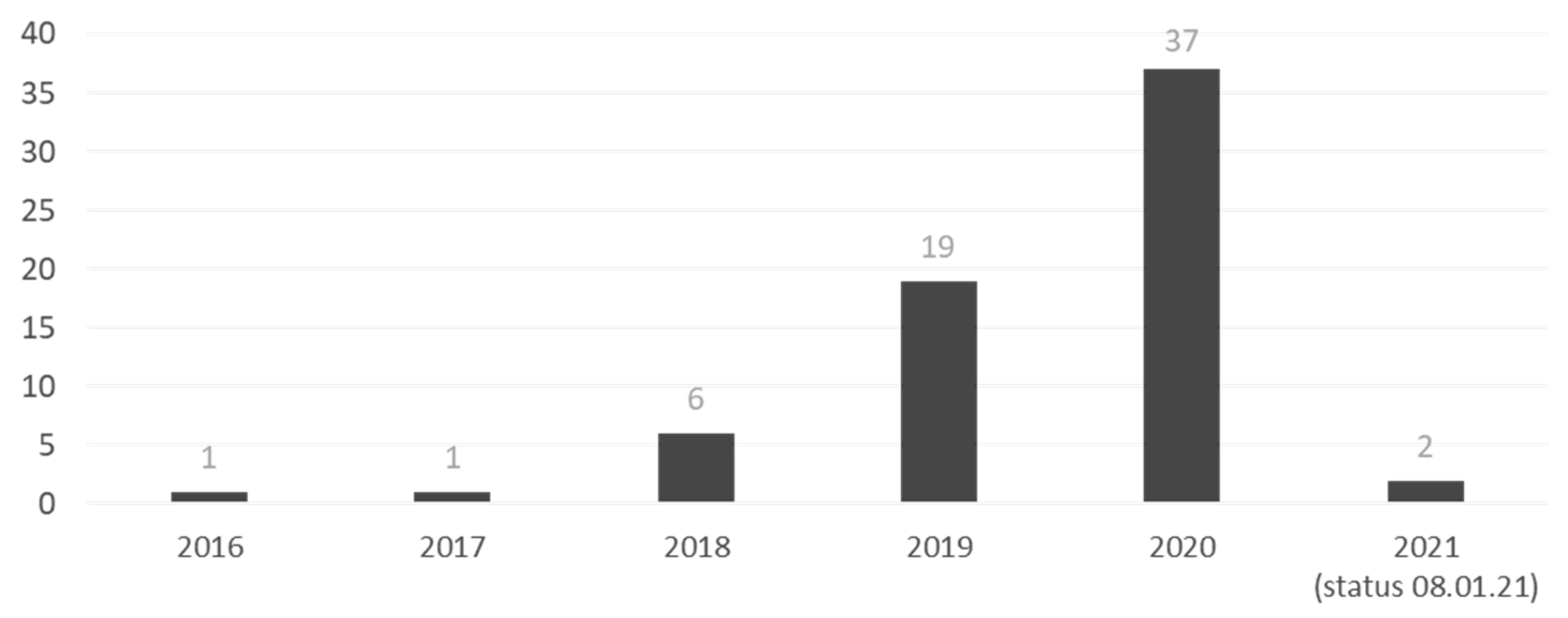

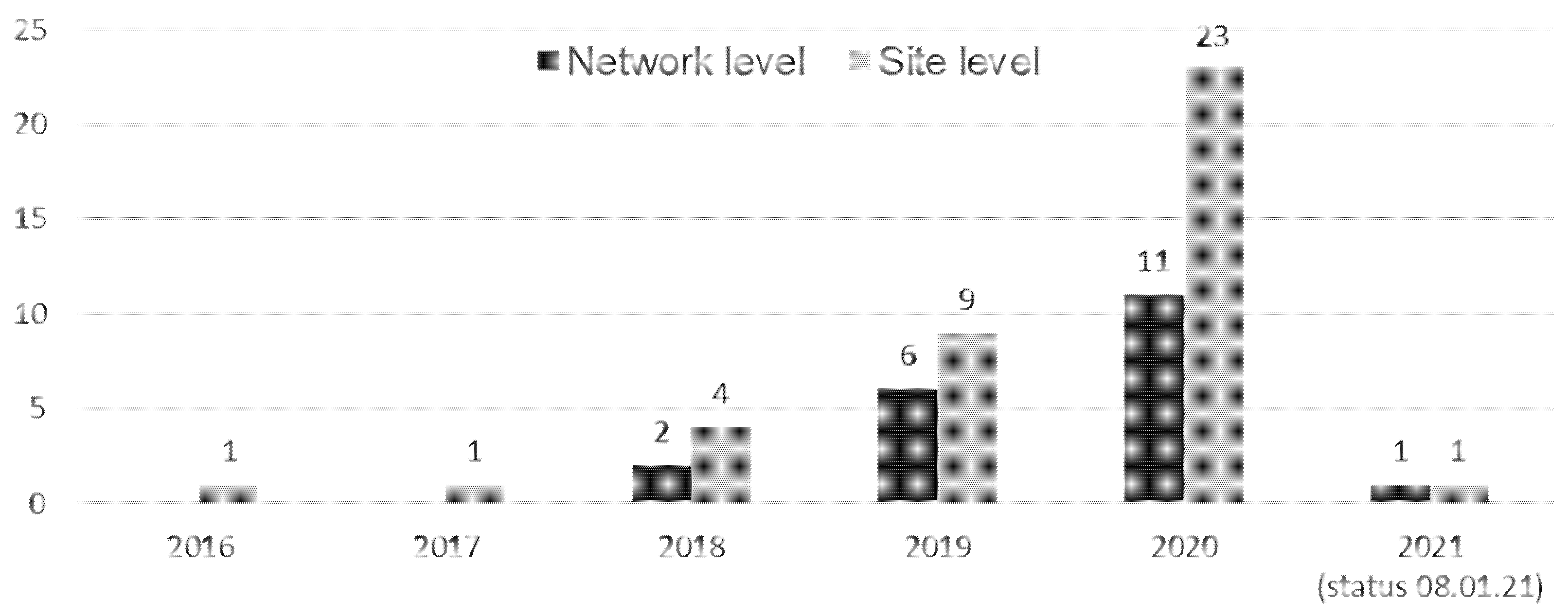

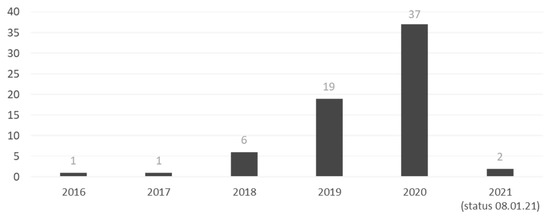

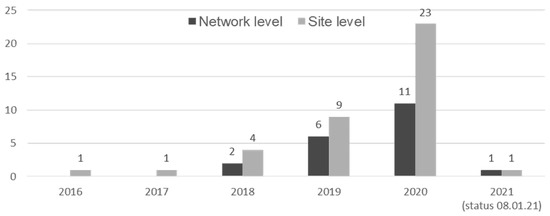

Figure 6 shows the distribution of articles across the years of publication. In 2016 and 2017 only one article was identified each. From 2018 on, a noticeable positive trend has been evident. In 2021 only two articles were found, which is due to the time in which the literature search was conducted (8 January 2021). Accordingly, the number of articles is expected to rise in 2021 as well.

Figure 6.

Publications per year.

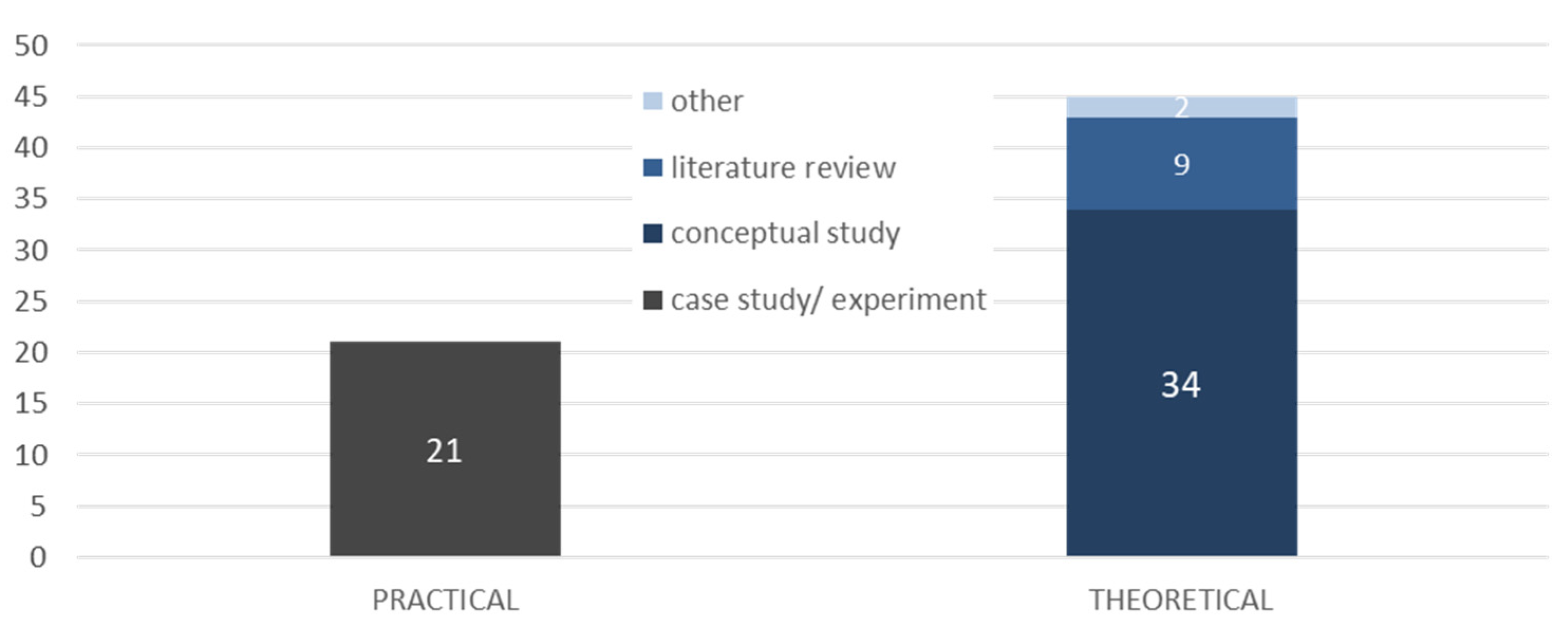

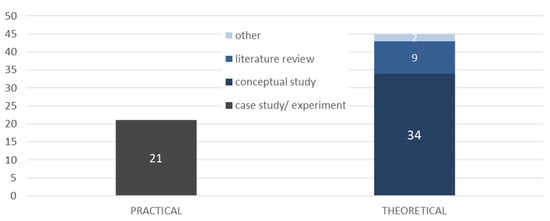

An analysis of the research methodologies used shows that the majority of articles (68%) follow a theoretical approach. Aside from a few literature reviews and others, most of the articles are conceptual studies. In conceptual studies, the authors first develop a theoretical model, framework or concept. They then often apply that concept to a practical case for validation. However, these practical applications usually have a reduced level of complexity and thus never exceed the level of a simple proof of concept. Some articles, for example, describe the framework of a DSCT that is connected with a real-world supply chain via IoT technology and is updated in real time. For validation, the respective authors then merely create a digital simulation model (not a DSCT), which is neither connected with the real world through sensors nor updated in real time.

As far as practical approaches go, all of the articles used case studies or experiments as their primary method of data collection. In these studies, the respective authors conducted experiments or case studies in real-world or lab environments. The particular DSCTs focused mainly on the site level. They often ran simulation experiments and sometimes even evaluated the positive effects of the DSCT use on their LSCM performance. An overview is given in Figure 7.

Figure 7.

Methodologies in DSCT research.

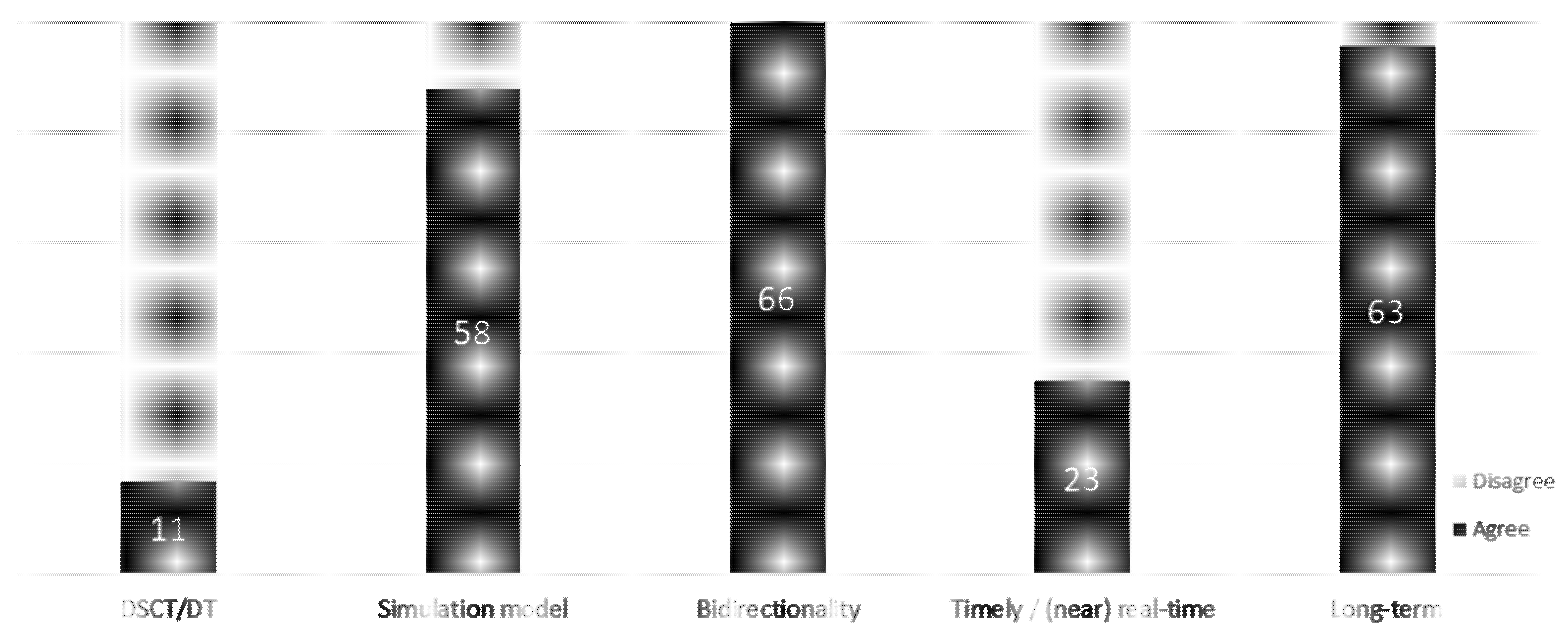

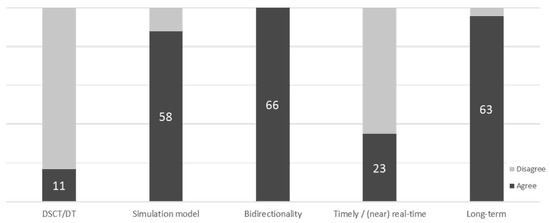

To validate the authors’ definition of DSCT, an analysis was carried out to evaluate the agreement of current scientific literature with different aspects of our definition. When no specific definition was given in the article, a general understanding of DSCT was derived from the contents of the article.

Only 11 articles (17%) speak of DSCT or comparable expressions like “Digital Twin Supply Chain” or “Supply Chain Digital Twin”. The majority of articles talk about “Digital Twins”, even in the context of LSCM. This underlines the authors’ argument for the need for a distinct term, as it makes it difficult to distinguish this research from the research on asset twins. Most of the articles (88%) include simulation capabilities in their concept of a DSCT. Concerning the data link, all the articles support the idea of it being bidirectional, and most of them (95%) say this data link has to be long term. Concerning the update frequency, 65% of articles specify the real-time capabilities of the DSCT. Only 35% of the articles do not specifically talk about real-time but rather about timely updates. The authors conclude that most of the articles’ understanding of the term DSCT is in accordance with the definition given in Section 2.1 (see Figure 8). Although most of the articles stress the (near) real-time capabilities of a DSCT, this does not contradict the proposed definition, as it is solely a specification for these specific use cases.

Figure 8.

Agreement with the DSCT definition in literature.

Lastly, in accordance with Section 2.2, an analysis of the described scopes of DSCTs was carried out. Some articles, which did not specify a scope, were not included.

Only 36% of articles describe a DSCT on the network level. Most articles discuss DSCT on the site level. The first occurrence of a DSCT on the network level was in 2018. Since then, a noticeable positive trend has been evident. Still, site DSCT has risen even more sharply since 2018. In 2020, there were more than twice as many articles on site DSCT in comparison to network DSCT. An overview is given in Figure 9.

Figure 9.

Scope of DSCTs over the years.

It should be noted that the search string was designed to especially identify DSCT on the network level. Key words like “Manufacturing Twin” or “Factory Twin” would have probably found even more site DSCT. Therefore, network DSCT is probably even more underrepresented in scientific literature than this analysis might imply.

4.2. Application Areas of DSCT

Based on the above-mentioned systematic research process involving three researchers, five application areas were identified in total, which are shown in Figure 10.

Figure 10.

Application areas of DSCT.

On the network level, two application areas were identified: network management and transportation. Network management deals with management and supervision of value networks. This includes tasks like risk management, multi-echelon inventory management and sustainability assessment. This area is very broad and tackles LSCM problems holistically. The adequate DSCT represents the whole value system including all relevant stakeholders. Users of this area might be, for example, companies in the manufacturing industry with a (globally) distributed network of sites and suppliers, including stakeholders from other links in the value system.

The area of transportation includes use cases related to the transportation of goods and materials on the network level. Only a single use case was identified in the given data: transport management. Strictly speaking, transportation is of course part of network management and could therefore be included in the former category. However, the according DSCT describes not the whole value system, but merely a part of it: a (synchromodal) transport network. While still being on the network level, this DSCT, in contrast, depicts only the network entities needed for transportation purposes. Value-adding processes like manufacturing are therefore not included. The authors of this work conclude that this application area should be viewed distinctively due to its different requirements concerning stakeholders and processes. Users of this area could be, for example, digital freight forwarding companies.

On the site level, there were three application areas identified: manufacturing, warehousing and cargo handling. Manufacturing is the area with by far the most use cases. Manufacturing involves tasks which are related to the production of goods, like production planning and controlling or shopfloor management. A DSCT in this area represents a production facility, which can be a manufacturing site, a construction site or a shipyard. Users of this area might be production planners or factory managers.

Warehousing includes use cases which are related to facilities that store, move and retrieve goods and materials. Two use cases of this area were found in the data: warehouse management and material handling. The respective DSCT depicts a warehouse or distribution center (DC). Users of this area might be LSCM executives at these facilities.

Lastly, there is the area of cargo handling. Cargo handling takes place at sites which are considered to be logistics infrastructure, such as airports, ports or industrial parks. Two use cases were identified in the data: outdoor vehicle dispatching and cargo load planning. The fitting DSCT consists of the site as well as the throughput.

Until further research concludes otherwise, this list of application areas seems to be exhaustive given the authors’ definition of DSCT. Each area is distinctive concerning the users, possible use cases and specific scope of the DSCT. This consequently leads to different technological and processual requirements for each area. Further research should look into these requirements, as it will give researchers and practitioners a better sense of the implementation costs of a DSCT in any given application area.

4.3. Use Cases and Benefits of DSCT

Through the SLR process, 14 use cases have been synthesized, building on 66 concrete applications documented in the literature. Table 3 and Table 4 outline the main characteristics and main benefits of applications in each use case cluster on the network and site level. On the network level, there were six use cases described in the analyzed papers: transport planning, material lifecycle management, multi-echelon inventory management and production planning, risk management and sustainability assessment.

Table 3.

Use cases and benefits of network DSCT.

Table 4.

Use cases and benefits of site DSCT.

Risk management, being the most prominent use case on the network level, is mentioned in six articles. As one of the key capabilities of a DSCT is to run what-if scenarios, the assessment of risks and the testing of contingency plans seem to be a sensible application. Multi-echelon inventory management and production planning also benefit from the use of a DSCT, as it not only provides a network-wide transparency of inventory and production, but also provides the analytical capabilities to optimize production and inventory strategies. More exceptional use cases are material lifecycle management and sustainability assessment. Both of these applications increase the ecological sustainability of the value system. Lastly, there is the use case of transport planning. It is the only use case in the application area of transportation, where the DSCT depicts not a whole value system, but only a transport network. Still, this case seems to benefit greatly from the use of a DSCT, as it can guide decision-makers in the face of dynamic changes in transportation processes.

As far as the benefits go, all identified use cases of network DSCT seem to have similar potential. The use of a DSCT first improves supply chain transparency, since it is an accurate representation of the real value system. Secondly, it achieves improved supply chain performance through a higher reaction speed, and overall improved flexibility and resilience. The simulation capabilities once again play a major role in the DSCT’s value creation, since they allow the user to test how the logistics system will react under certain circumstances. This knowledge improves the user’s ability to make fact-based decisions.

The use cases and their respective benefits are described in detail in the following table.

Furthermore, there were eight use cases identified on the site level: cargo load planning, warehouse management, material handling, outdoor and indoor vehicle dispatching, shopfloor management, production planning and production controlling.

Production controlling and production planning are by far the most prominent use cases. This was to be expected, as the use of cyber-physical systems (CPS) in digital factories has been relevant in academia and practice for years, laying the foundation for the implementation of site DSCT in manufacturing. Other use cases in this application area are shopfloor management, where the DSCT is used as a digital meeting point for executives, and indoor vehicle dispatching, where a fleet of vehicles is monitored and controlled using a DSCT. In the area of warehousing, warehouse management uses the DSCT of a DC or warehouse to plan all processes related to on-site inventory, while material handling deals with operative process efficiency in parts of storing facilities. Lastly, in the area of cargo handling, there is outdoor vehicle dispatching, where the DSCT is used to optimize the scheduling of a fleet of vehicles, and cargo load planning, where a certain process is being supported through the use of a DSCT depicting a certain section of the site.

As opposed to network DSCT, the identified use cases of site DSCT often concentrate on a specific process within the value system and aim for improvements in terms of process efficiency. Still, transparency is found in all use cases as a basic benefit. Other than that, the benefits depend largely on the given use case. Increased site-wide flexibility and resilience are mentioned rather frequently as benefits as well.

The use cases and their respective benefits are described in detail in the following table.

Regarding this list of use cases, the authors make no claim of completeness, neither at the network level nor at the site level. This combined list of use cases is merely a collection of distinctive examples, which have been described in past scientific literature. The authors could easily think of several more use cases in some of the application areas, especially on the site level. Indoor vehicle dispatching, for example, is also conceivable in a warehousing context, but no such use case has been found during our research.

Moreover, the extent of these scientific investigations differs widely across the different use cases. While some have only been described by one paper, others have up to twelve references. This list is therefore not considered exhaustive, though it gives a good overview of the current state of use cases of DSCT which are being discussed in scientific literature.

5. Implications

This review gives a broad overview of the current state of DSCT research. While literature reviews concerning this topic have already been conducted in the past [10,11,55], they were either brief or focused on certain aspects of the DSCT concept like the use of agent-based modeling. A broad overview with a focus on the holistic approach of LSCM is therefore new and of great use to researchers and practitioners who are concerned with DSCT.

The conceptual clarification should help to frame the field of DSCT research and give readers a clear understanding of the concept, since current scientific literature shows the lack of common understanding of the term. Moreover, it was made clear that DT concepts in the context of LSCM differ greatly from asset-based DTs and must therefore be addressed distinctively in scientific research. This field of research, as proposed by the authors, should follow a unified definition, which was suggested in Section 2.1. Furthermore, possible scopes of DSCT were derived from theoretical and practical knowledge of logistics systems in Section 2.2. This will help researchers and practitioners as it defines the boundaries and provides a distinct vocabulary for discussing the topic of DSCT.

The analyzed literature mostly agrees with the authors’ understanding of DSCT, even though the term “Digital Supply Chain Twin” is rarely used. It is evident that the simulation capability is a key characteristic of a DSCT, since it allows the performance of what-if analyses in a dynamic environment. This is an important feature when it comes to handling complex systems such as the ones evident in LSCM. When it comes to real-time capabilities, most sources name them as an important feature of the DSCT. The authors agree that this is definitely the case in some applications, where real-time updates are of great importance. Still, there are also cases where a timely update is enough. Think about the container vessel, which transports goods from Asia to Europe. There is no need to update its location in real time; still, it can be of importance in a DSCT. All in all, the authors did not find any evidence that greatly contradicts the given definition. Still, it should be stated that this conceptual clarification is merely a first attempt at describing the DSCT and therefore requires further discussion and clarification. DSCT research is still in its infancy and the proposed approach has to evolve with future research.

The literature showed a positive trend in the amount of research on DSCT. That work is, as of now, mostly theoretical. As more practical DSCT applications are being implemented in the real world, research should move into a practical direction as well, to put all the theoretical models, frameworks and concepts to work. It was also evident that most use cases are on the site level. Since the authors searched for DSCT in particular and did not include search terms like “Manufacturing Twins” or “Factory Twins”, site DSCTs probably outnumber network DSCTs by an even greater amount than shown in this analysis. To put this into the perspective of our research, manufacturing seems to be, as of now, the most extensively researched application area of DSCTs. It can be assumed that due to further technological development, increasingly complex systems can be mapped with the help of a DSCT. Thus, the representation of an entire value system is the logical conclusion of this development. Future practical implementations of site and especially network DSCT will show if the DSCT concept is as disruptive as the past theoretical work implies.

Five application areas have been identified during this research, two on the network level and three on the site level. These areas depict different scopes and components of value systems and therefore have different processual and technological requirements, different users and different use cases. Acknowledging these application areas will allow researchers to direct their research more precisely. Practitioners might benefit from this by identifying the fitting DSCT for their business application. Further research should look into the distinct requirements for DSCTs of different application areas to give users an even better idea of what is needed for a practical implementation. As opposed to current trend studies from the industry [6], the five application areas do not only put DSCT into perspective of LSCM, but also put the different application areas into perspective to one another. This underlines the holistic approach of LSCM. One can think of a network DSCT of a value system, where a DC is merely an element with a specific location, capacity, process times, etc. Combining this with a site DSCT of a DC would therefore improve the level of detail of the whole system. The interdependencies of DSCTs of different application areas are yet to be explored.

Furthermore, 14 use cases have been identified. An extensive collection like this is new in DSCT literature. Six of the use cases are on the network level, while eight are on the site level. The authors once more want to emphasize that this is not an exhaustive list. Many more use cases are feasible given the five application areas. On the network level, most use cases are in the area of network management, the most prominent one being risk management. These cases differ due to the different business processes they support. Still, it is evident that all DSCTs are decision support tools, which draw great value from running what-if scenarios and testing outcomes of different actions. In the area of transportation, there is the use case of transport planning. An interesting finding is that even though this DSCT is also on the network level, it differs from the area of network management in respect to what the simulation model depicts.

On the site level, most use cases are found in manufacturing. However, as there are similar time-critical processes in warehousing and cargo handling, it seems logical for practitioners and researchers to shift their attention to these application areas as well. Most use cases in site DSCTs concentrate on a certain process within the value system to achieve process efficiency. Therefore, several use cases on the site level might be combined to improve the overall performance of a given site. Due to the small-scaled nature of site DSCT, their real-time capability seems to be of greater importance than it is in network DSCT.

Together with the 14 use cases, a collection of benefits has been derived from literature. A collection like this is also new in DSCT literature. On the network level the benefits provided by the DSCT are mostly strategic. Network DSCTs improve supply chain visibility as well as resilience and flexibility. These benefits seem to apply to the value system as a whole and add to an overall increased supply chain performance. Benefits on the site level on the other hand seem to be more small-scaled, tactical and operational improvements. Site DSCTs improve site visibility, reduce lead and reaction times and improve process efficiency.

Managerial implications are that network and site DSCTs seem to have different technological requirements and also aim to improve different dimensions of supply chain performance. Depending on the use case, a DSCT must have a certain set of capabilities and a sufficiently detailed simulation model. This leads to different levels of expense for the implementation of a DSCT. To put this into perspective with the value generated, a simulation model might be used beforehand as a means of quantifying the intended benefits. When deciding on the right DSCT, this should be kept in mind.

These findings should present a basis for future research in the field of DSCT and make it easier for researchers and practitioners in LSCM to discuss DSCTs by providing a common understanding of the term and its subject terminology. By providing an extensive overview of use cases, application areas and benefits of DSCT, this paper is a first attempt at making the broad field of DSCT research tangible.

6. Conclusions and Final Remarks

In conclusion, the aim of this paper was to describe the distinct characteristics and scopes of DSCT in LSCM literature and derive a unified definition of DSCT (RO1), to synthesize the application areas of DSCT in LSCM (RO2) and to consolidate specific DSCT use cases and their intended individual benefits (RO3). All RO have been met sufficiently by the authors. The conceptual clarification in Section 2 provides a clear understanding of DSCTs and is in line with the majority of literature. Furthermore, the identified application areas of DSCT provide a broad categorization of applications in LSCM. They also put the different application areas into perspective with one another, which underlines the holistic approach of LSCM. Lastly, the identified use cases form a first collection of possible applications of DSCT, given the vast amount of possibilities in LSCM, while also providing a list of intended benefits for each use case. In doing so, the authors also give an overview of the different potential of network and site DSCT.

Still, this study is not without limitations which shall be addressed in the following paragraph. First, when conducting the search string, the included terms clearly pointed in the direction of network DSCT. Therefore, site DSCT might be underrepresented in comparison to all current literature on DSCT. However, as the authors’ intentions were to identify use cases of both network and site DSCT, going into detail for some use cases in manufacturing would not have provided much additional value. Secondly, the examined literature consisted mostly of scientific papers, while empirical studies from the industry are necessary to gain more knowledge about the use cases and the actual benefits of DSCTs. Still, this procedure seems to be in line with the SLR method, which was used in this paper. Lastly, the identified list of use cases is not exhaustive and the number of article references is unevenly distributed among them. It is debatable if use cases, which are only being described by one paper, can be seen as a use case cluster (e.g., shopfloor management). Therefore, this list has to be viewed as a work in progress.

This work lays the foundation for a variety of future research. First, researchers should look into the five identified application areas. This paper has outlined the distinct scope of these areas. Their different processual and technological requirements should be examined. Next, the list of use cases needs to be extended, as it is solely a work in progress. In the future, as the amount of use cases increases in size, it should be further categorized. Lastly, the benefits collected were merely quantitative. Future research should quantify them and subsequently put them into perspective with the costs of implementation of a DSCT [22]. For this purpose, it would be beneficial to conduct an extensive empirical study of the degree of maturity and the level of realized implementation in the industry. This study should help to give an overview of the state of DSCTs which are currently being used in practice, as well as the readiness of LSCM companies to implement a DSCT.

All in all, while DSCTs are extensively being applied in manufacturing, implementing a network DSCT is still very rare. In academia, there are therefore not many examinations of network DSCT. As they promise strategic improvements in terms of supply chain performance they should gain more attention in the future, in both academia and practice. The authors of this paper hope to have underlined the potential of network and site DSCTs in LSCM as well as their interdependencies and thereby provide guidance for researchers and managers who have an interest in the subject of DSCTs.

Author Contributions

Conceptualization, B.G. and S.Z.; methodology, B.G., S.Z. and B.N.; software, B.G. and S.Z.; validation, B.G., S.Z. and B.N.; formal analysis, B.G. and S.Z.; investigation, B.G. and S.Z.; data curation, B.G., S.Z. and B.N.; writing—original draft preparation, B.G., S.Z. and B.N.; writing—review and editing, B.G., S.Z., B.N. and F.S.; visualization, B.G. and S.Z.; supervision, B.N. and F.S.; project administration, B.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All relevant data can be obtained by following the links in the references section.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Junge, A.L.; Verhoeven, P.; Reipert, J.; Mansfeld, M. Pathway of Digital Transformation in Logistics: Best Practice Concepts and Future Developments; Universitätsverlag der TU Berlin: Berlin, Germany, 2019; ISBN 978-3-7983-3095-5. [Google Scholar]

- Shaw, S. Using a Supply Chain Digital Twin to Improve Logistics. Available online: https://clarkstonconsulting.com/insights/supply-chain-digital-twin/ (accessed on 12 September 2021).

- Straube, F.; Nitsche, B. Heading into “The New Normal”: Potential Development Paths of International Logistics Networks in the Wake of the Coronavirus Pandemic. Int. Verk. 2020, 72, 31–35. [Google Scholar]

- Gartner. Gartner Top 8 Supply Chain Technology Trends for 2019. Available online: https://www.gartner.com/smarterwithgartner/gartner-top-8-supply-chain-technology-trends-for-2019/ (accessed on 12 September 2021).

- Gartner. Gartner Top 8 Supply Chain Technology Trends for 2020. Available online: https://www.gartner.com/smarterwithgartner/gartner-top-8-supply-chain-technology-trends-for-2020/ (accessed on 12 September 2021).

- DHL. Digital Twins in Logistics: A DHL Perspective on the Impact of Digital Twins on the Logistics Industry 2019. Available online: https://www.dhl.com/content/dam/dhl/global/core/documents/pdf/glo-core-digital-twins-in-logistics.pdf (accessed on 12 September 2021).

- Aivaliotis, P.; Georgoulias, K.; Arkouli, Z.; Makris, S. Methodology for Enabling Digital Twin Using Advanced Physics-Based Modelling in Predictive Maintenance. Procedia CIRP 2019, 81, 417–422. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Wang, L.; Nee, A.Y.C. Digital Twins and Cyber–Physical Systems toward Smart Manufacturing and Industry 4.0: Correlation and Comparison. Engineering 2019, 5, 653–661. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, M. Digital Twin Shop-Floor: A New Shop-Floor Paradigm Towards Smart Manufacturing. IEEE Access 2017, 5, 20418–20427. [Google Scholar] [CrossRef]

- Marmolejo-Saucedo, J.A.; Hurtado-Hernandez, M.; Suarez-Valdes, R. Digital Twins in Supply Chain Management: A Brief Literature Review. In Intelligent Computing and Optimization; Vasant, P., Zelinka, I., Weber, G.-W., Eds.; Springer: Cham, Switzerland, 2020; pp. 653–661. ISBN 978-3-030-33584-7. [Google Scholar]

- Orozco-Romero, A.; Arias-Portela, C.Y.; Saucedo, J.A.M. The Use of Agent-Based Models Boosted by Digital Twins in the Supply Chain: A Literature Review. In Intelligent Computing and Optimization; Vasant, P., Zelinka, I., Weber, G.-W., Eds.; Springer: Cham, Switzerland, 2020; pp. 642–652. ISBN 978-3-030-33584-7. [Google Scholar]

- Cook, E. Digitalising the Supply Chain: The Digital Twin. Available online: https://www.supplychaindigital.com/technology-4/digitalising-supply-chain-digital-twin (accessed on 12 September 2021).

- El Saddik, A. Digital Twins: The Convergence of Multimedia Technologies. IEEE MultiMedia 2018, 25, 87–92. [Google Scholar] [CrossRef]

- Costello, K. Gartner Survey Reveals Digital Twins Are Entering Mainstream Use. 2019. Available online: https://www.gartner.com/en/newsroom/press-releases/2019-02-20-gartner-survey-reveals-digital-twins-are-entering-mai (accessed on 12 September 2021).

- Klostermeier, R.; Haag, S.; Benlian, A. Geschäftsmodelle Digitaler Zwillinge: HMD Best Paper Award 2018, 1st ed.; Springer: Wiesbaden, Germany, 2020; ISBN 978-3-658-28353-7. [Google Scholar]

- Ashtari Talkhestani, B.; Jung, T.; Lindemann, B.; Sahlab, N.; Jazdi, N.; Schloegl, W.; Weyrich, M. An Architecture of an Intelligent Digital Twin in a Cyber-Physical Production System. Automatisierungstechnik 2019, 67, 762–782. [Google Scholar] [CrossRef] [Green Version]

- Fischer, M.; Agrawal, A. Digital Twin for Construction. Available online: https://cife.stanford.edu/Seed2019%20DigitalTwin (accessed on 12 September 2021).

- Straube, F.; Reipert, J.; Schöder, D. City-Logistik der Zukunft—Im Spannungsfeld Von Elektromobilität Und Digitalisierung. Wirtsch Inf. Manag. 2017, 9, 28–35. [Google Scholar] [CrossRef]

- Nitsche, B.; Straube, F. Efficiently Managing Supply Chain Volatility—A Management Framework for the Manufacturing Industry. Procedia Manuf. 2020, 43, 320–327. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. A Digital Supply Chain Twin for Managing the Disruption Risks and Resilience in the Era of Industry 4.0. Prod. Plan. Control 2020, 32, 775–788. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, Z. Digital Twin-Based Production Scheduling System for Heavy Truck Frame Shop. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 6, 095440622091330. [Google Scholar] [CrossRef]

- Ambra, T.; Macharis, C. Agent-Based Digital Twins (ABM-Dt) In Synchromodal Transport and Logistics: The Fusion of Virtual and Pysical Spaces. In Proceedings of the 2020 Winter Simulation Conference (WSC), Orlando, FL, USA, 14–18 December 2020; pp. 159–169. [Google Scholar]

- van der Valk, H.; Haße, H.; Möller, F.; Arbter, M. A Taxonomy of Digital Twins 2020. Available online: https://www.researchgate.net/publication/341235159_A_Taxonomy_of_Digital_Twins (accessed on 12 September 2021).

- Enders, M.R.; Hoßbach, N. Dimensions of Digital Twin Applications—A Literature Review 2019. Available online: http://publica.fraunhofer.de/documents/N-630222.html (accessed on 12 September 2021).

- Grieves, M.; Vickers, J. Digital Twin: Mitigating Unpredictable, Undesirable Emergent Behavior in Complex Systems; Springer: Cham, Switzerland, 2017; ISBN 978-3-319-38754-3. [Google Scholar]

- Glaessgen, E.H.; Stargel, D.S. The Digital Twin Paradigm for Future NASA and U.S. Air Force Vehicles 2012. Available online: https://ntrs.nasa.gov/citations/20120008178 (accessed on 12 September 2021).

- Miller, P. Grasp the Challenge of Implementing Digital Twins At Scale: Digital Twins Show Great Promise, but Early Adopters Struggle with Technical and Organizational Barriers as They Scale. 2020. Available online: https://www.forrester.com/report/Grasp-The-Challenge-Of-Implementing-Digital-Twins-At-Scale/RES158396 (accessed on 12 September 2021).

- Srai, J.S.; Settanni, E.; Tsolakis, N.; Parminder, K.A. Supply Chain Digital Twins: Opportunities and Challenges Beyond the Hype. 2019. Available online: https://www.researchgate.net/publication/336216891_Supply_Chain_Digital_Twins_Opportunities_and_Challenges_Beyond_the_Hype (accessed on 12 September 2021).

- Ivanov, D.; Dolgui, A.; Das, A.; Sokolov, B. Digital Supply Chain Twins: Managing the Ripple Effect, Resilience, and Disruption Risks by Data-Driven Optimization, Simulation, and Visibility. In Handbook of Ripple Effects in the Supply Chain; Ivanov, D., Dolgui, A., Sokolov, B., Eds.; Springer: Cham, Switzerland, 2019; pp. 309–332. ISBN 978-3-030-14301-5. [Google Scholar]

- AnyLogic. An Introduction to Digital Twin Development. 2018. Available online: https://www.anylogic.de/resources/white-papers/an-introduction-to-digital-twin-development/ (accessed on 12 September 2021).

- Korth, B.; Schwede, C.; Zajac, M. Simulation-Ready Digital Twin for Realtime Management of Logistics Systems. In Proceedings of the 2018 IEEE International Conference on Big Data, Seattle, WA, USA, 10–13 December 2018; pp. 4194–4196. [Google Scholar]

- Ding, Y. Brief Analysis about Digital Twin Supply Chain Model and Application. 2019. Available online: https://www.clausiuspress.com/article/319.html (accessed on 12 September 2021).

- Fuller, A.; Fan, Z.; Day, C.; Barlow, C. Digital Twin: Enabling Technologies, Challenges and Open Research. IEEE Access 2020, 8, 108952–108971. [Google Scholar] [CrossRef]

- Haße, H.; Li, B.; Weißenberg, N.; Cirullies, J.; Otto, B. Digital Twin for Real-Time Data Processing in Logistics. 2019. Available online: https://tore.tuhh.de/handle/11420/3717 (accessed on 12 September 2021).

- Agrawal, P.; Narain, R. Digital Supply Chain Management: An Overview. IOP Conf. Ser. Mater. Sci. Eng. 2018, 455, 12074. [Google Scholar] [CrossRef] [Green Version]

- Gutenschwager, K.; Rabe, M.; Spieckermann, S.; Wenzel, S. Simulation in Produktion und Logistik; Springer: Heidelberg, Germany, 2017; ISBN 978-3-662-55744-0. [Google Scholar]

- Wright, L.; Davidson, S. How to Tell the Difference between a Model and a Digital Twin. Adv. Model. Simul. Eng. Sci. 2020, 7, 13. [Google Scholar] [CrossRef]

- Herden, T.T. Managing Supply Chain Analytics Management: Guiding Organizations to Execute Analytics Initiatives in Logistics and Supply Chain. Berlin, 2020. Available online: https://depositonce.tu-berlin.de/bitstream/11303/11137/4/herden_tino.pdf (accessed on 12 September 2021).

- Durach, C.F.; Kembro, J.; Wieland, A. A New Paradigm for Systematic Literature Reviews in Supply Chain Management. J. Supply Chain Manag. 2017, 53, 67–85. [Google Scholar] [CrossRef]

- Nitsche, B.; Durach, C.F. Much Discussed, Little Conceptualized: Supply Chain Volatility. IJPDLM 2018, 48, 866–886. [Google Scholar] [CrossRef]

- Rusch, B. In the Tetra Pak warehouse in Singapore, the Twin is in Charge. Available online: https://www.hannovermesse.de/en/news/news-articles/in-the-tetra-pak-warehouse-in-singapore-the-twin-is-in-charge (accessed on 19 July 2021).

- Cohen, J. A Coefficient of Agreement for Nominal Scales. Educ. Psychol. Meas. 1960, 20, 37–46. [Google Scholar] [CrossRef]

- Carvalho, A.; Melo, P.; Oliveira, M.A.; Barros, R. The 4-Corner Model as a Synchromodal and Digital Twin Enabler in the Transportation Sector. In Proceedings of the 2020 IEEE International Conference on Engineering, Technology and Innovation, Cardiff, UK, 15–17 June 2020; pp. 1–8. [Google Scholar]

- Semenov, Y.; Semenova, O.; Kuvataev, I. Solutions for Digitalization of the Coal Industry Implemented in UC Kuzbassrazrezugol. E3S Web Conf. 2020, 174, 01042. [Google Scholar] [CrossRef]

- Pehlken, A.; Baumann, S. Urban Mining: Applying Digital Twins for Sustainable Product Cascade Use. In Proceedings of the 2020 IEEE International Conference, Cardiff, UK, 15–17 June 2020; pp. 1–7. [Google Scholar]

- Ivanov, D.; Dolgui, A. New Disruption Risk Management Perspectives in Supply Chains: Digital Twins, the Ripple Effect, and Resileanness. IFAC PapersOnLine 2019, 52, 337–342. [Google Scholar] [CrossRef]

- Barykin, S.Y.; Bochkarev, A.A.; Kalinina, O.V.; Yadykin, V.K. Concept for a Supply Chain Digital Twin. Int. J. Math. Eng. Manag. Sci. 2020, 5, 1498–1515. [Google Scholar] [CrossRef]

- Marmolejo-Saucedo, J.A. Design and Development of Digital Twins: A Case Study in Supply Chains. Mob. Netw. Appl. 2020, 25, 2141–2160. [Google Scholar] [CrossRef]

- Park, K.T.; Son, Y.H.; Noh, S.D. The Architectural Framework of a Cyber Physical Logistics System for Digital-Twin-Based Supply Chain Control. Int. J. Prod. Res. 2020, 5, 5721–5742. [Google Scholar] [CrossRef]

- Barni, A.; Fontana, A.; Menato, S.; Sorlini, M.; Canetta, L. Exploiting the Digital Twin in the Assessment and Optimization of Sustainability Performances. In Proceedings of the 2018 International Conference on Intelligent Systems (IS), Funchal, Portugal, 25–27 September 2018; pp. 706–713. [Google Scholar]

- Hofmann, W.; Branding, F. Implementation of an IoT- and Cloud-Based Digital Twin for Real-Time Decision Support in Port Operations. IFAC PapersOnLine 2019, 52, 2104–2109. [Google Scholar] [CrossRef]

- Pan, Y.H.; Wu, N.Q.; Qu, T.; Li, P.Z.; Zhang, K.; Guo, H.F. Digital-Twin-Driven Production Logistics Synchronization System for Vehicle Routing Problems with Pick-up and Delivery in Industrial Park. Int. J. Comput. Integr. Manuf. 2020, 1805, 1–15. [Google Scholar] [CrossRef]

- Wong, E.Y.C.; Mo, D.Y.; So, S. Closed-Loop Digital Twin System for Air Cargo Load Planning Operations. Int. J. Comput. Integr. Manuf. 2020, 34, 801–813. [Google Scholar] [CrossRef]

- Baruffaldi, G.; Accorsi, R.; Manzini, R. Warehouse Management System Customization and Information Availability in 3pl Companies: A Decision-Support Tool. IMDS 2018, 119, 251–273. [Google Scholar] [CrossRef]

- Agalianos, K.; Ponis, S.T.; Aretoulaki, E.; Plakas, G.; Efthymiou, O. Discrete Event Simulation and Digital Twins: Review and Challenges for Logistics. Procedia Manuf. 2020, 51, 1636–1641. [Google Scholar] [CrossRef]

- Ashrafian, A.; Pettersen, O.-G.; Kuntze, K.N.; Franke, J.; Alfnes, E.; Henriksen, K.F.; Spone, J. Full-Scale Discrete Event Simulation of an Automated Modular Conveyor System for Warehouse Logistics. In Advances in Production Management Systems. Towards Smart Production Management Systems; Ameri, F., Stecke, K.E., Cieminski, G., von Kiritsis, D., Eds.; Springer: Cham, Switzerland, 2019; pp. 35–42. ISBN 978-3-030-29995-8. [Google Scholar]

- Boschert, S.; Rosen, C.H.R. Next Generation Digital Twin. In Tools and Methods of Competitive Engineering: Proceedings of theTwelfth International Symposium on Tools and Methods of Competitive Engineering—TMCE, Las Palmas de Gran Canaria, Spain, 7–11 May 2018; Horváth, I., Suárez Rivero, J.P., Hernández Castellano, P.M., Eds.; Delft University of Technology: Delft, The Netherlands, 2018; pp. 209–217. ISBN 9789461869104. [Google Scholar]

- Rosen, R.; Fischer, J.; Boschert, S. Next Generation Digital Twin: An Ecosystem for Mechatronic Systems? IFAC PapersOnLine 2019, 52, 265–270. [Google Scholar] [CrossRef]

- Lu, Y.; Min, Q.; Liu, Z.; Wang, Y. An IoT-Enabled Simulation Approach for Process Planning and Analysis: A Case from Engine Re-Manufacturing Industry. Int. J. Comput. Integr. Manuf. 2019, 32, 413–429. [Google Scholar] [CrossRef]

- Zhou, G.; Zhang, C.; Li, Z.; Ding, K.; Wang, C. Knowledge-Driven Digital Twin Manufacturing Cell towards Intelligent Manufacturing. Int. J. Prod. Res. 2019, 58, 1034–1051. [Google Scholar] [CrossRef]

- Hauge, J.B.; Zafarzadeh, M.; Jeong, Y.; Li, Y.; Khilji, W.A.; Wiktorsson, M. Employing digital twins within production logistics. In Proceedings of the 2020 IEEE International Conference, Cardiff, UK, 15–17 June 2020; pp. 1–8. [Google Scholar]

- Park, Y.; Woo, J.; Choi, S. A Cloud-Based Digital Twin Manufacturing System based on an Interoperable Data Schema for Smart Manufacturing. Int. J. Comput. Integr. Manuf. 2020, 33, 1259–1276. [Google Scholar] [CrossRef]

- Gallego-García, S.; Reschke, J.; García-García, M. Design and Simulation of a Capacity Management Model Using a Digital Twin Approach Based on the Viable System Model: Case Study of an Automotive Plant. Appl. Sci. 2019, 9, 5567. [Google Scholar] [CrossRef] [Green Version]

- Makarova, I.; Buyvol, P.; Gubacheva, L. Creation of a Digital Twin of a Truck Assembly Process. In Proceedings of the 2020 International Russian Automation Conference (RusAutoCon), Sochi, Russia, 6–12 September 2020; pp. 1063–1068. [Google Scholar]

- Dolgov, V.A.; Arkhangelskii, V.E.; Nikishechkin, P.A. Method of Analysis of Production and Logistics Systems of Discrete Production Based on Product-Process-Resource Model, External Module for Manufacturing Control Logic and Simulation of Work Execution. In Proceedings of the 2020 International Multi-Conference on Industrial Engineering and Modern Technologies (FarEastCon), Vladivostok, Russia, 6–9 October 2020; pp. 1–6. [Google Scholar]

- Wang, P.; Liu, W.; Liu, N.; You, Y. Digital Twin-Driven System for Roller Conveyor line: Design and Control. J. Ambient. Intell. Hum. Comput. 2020, 11, 5419–5431. [Google Scholar] [CrossRef]

- Agostino, Í.R.S.; Broda, E.; Frazzon, E.M.; Freitag, M. Using a Digital Twin for Production Planning and Control in Industry 4.0. In Scheduling in Industry 4.0 and Cloud Manufacturing; Sokolov, B., Ivanov, D., Dolgui, A., Eds.; Springer: Cham, Switzerland, 2020; pp. 39–60. ISBN 978-3-030-43176-1. [Google Scholar]

- Jeong, Y.; Flores-Garcia, E.; Wiktorsson, M. A Design of Digital Twins for Supporting Decision-Making in Production Logistics. In Proceedings of the 2020 Winter Simulation Conference (WSC), Orlando, FL, USA, 14–18 December 2020; pp. 2683–2694. [Google Scholar]

- Zhang, K.; Qu, T.; Zhou, D.; Jiang, H.; Lin, Y.; Li, P.; Guo, H.; Liu, Y.; Li, C.; Huang, G.Q. Digital Twin-Based Opti-State Control Method for a Synchronized Production Operation System. Robot. Comput.-Integr. Manuf. 2020, 63, 101892. [Google Scholar] [CrossRef]

- Min, Q.; Lu, Y.; Liu, Z.; Su, C.; Wang, B. Machine Learning Based Digital Twin Framework for Production Optimization in Petrochemical Industry. Int. J. Inf. Manag. 2019, 49, 502–519. [Google Scholar] [CrossRef]

- Guo, D.; Zhong, R.Y.; Lin, P.; Lyu, Z.; Rong, Y.; Huang, G.Q. Digital Twin-Enabled Graduation Intelligent Manufacturing System for Fixed-Position Assembly Islands. Robot. Comput. Integr. Manuf. 2020, 63, 101917. [Google Scholar] [CrossRef]

- Herakovič, N.; Zupan, H.; Pipan, M.; Protner, J.; Šimic, M. Distributed Manufacturing Systems with Digital Agent. J. Mech. Eng. 2019, 65, 650–657. [Google Scholar] [CrossRef] [Green Version]

- Mykoniatis, K.; Harris, G.A. A Digital Twin Emulator of a Modular Production System Using a Data-Driven Hybrid Modeling and Simulation Approach. J. Intell. Manuf. 2021, 32, 1899–1911. [Google Scholar] [CrossRef]

- Pang, T.Y.; Pelaez Restrepo, J.D.; Cheng, B.; Yasin, A.; Lim, H.; Miletic, M. Developing a Digital Twin and Digital Thread Framework for an ‘Industry 4.0’ Shipyard. Appl. Sci. 2021, 11, 1097. [Google Scholar] [CrossRef]

- Yao, F.; Keller, A.; Ahmad, M.; Ahmad, B.; Harrison, R.; Colombo, A.W. Optimizing the Scheduling of Autonomous Guided Vehicle in a Manufacturing Process. In Proceedings of the 2018 IEEE 16th International Conference on Industrial Informatics (INDIN), Porto, Portugal, 18–20 July 2018; pp. 264–269. [Google Scholar]

- Eschemann, P.; Borchers, P.; Feeken, L.; Stierand, I.; Zernickel, J.S.; Neumann, M. Towards Digital Twins for Optimizing the Factory of the Future. 2020. Available online: https://www.researchgate.net/publication/345308959_Towards_Digital_Twins_for_Optimizing_the_Factory_of_the_Future (accessed on 12 September 2021).

- Brenner, B.; Hummel, V. Digital Twin as Enabler for an Innovative Digital Shopfloor Management System in the ESB Logistics Learning Factory at Reutlingen-University. Procedia Manuf. 2017, 9, 198–205. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).