A Systematic Review on Technologies and Industry 4.0 in the Forest Supply Chain: A Framework Identifying Challenges and Opportunities

Abstract

1. Introduction

- (1)

- To investigate state-of-the-art technologies developed for or applied to the forest supply chain;

- (2)

- To assess improvements of the forest supply chain provided by technologies in Industry 4.0 era;

- (3)

- To provide an understanding of the benefits and impacts of technologies and Industry 4.0 with regard to the forest supply chain;

- (4)

- To identify the key challenges and future research directions in the related area.

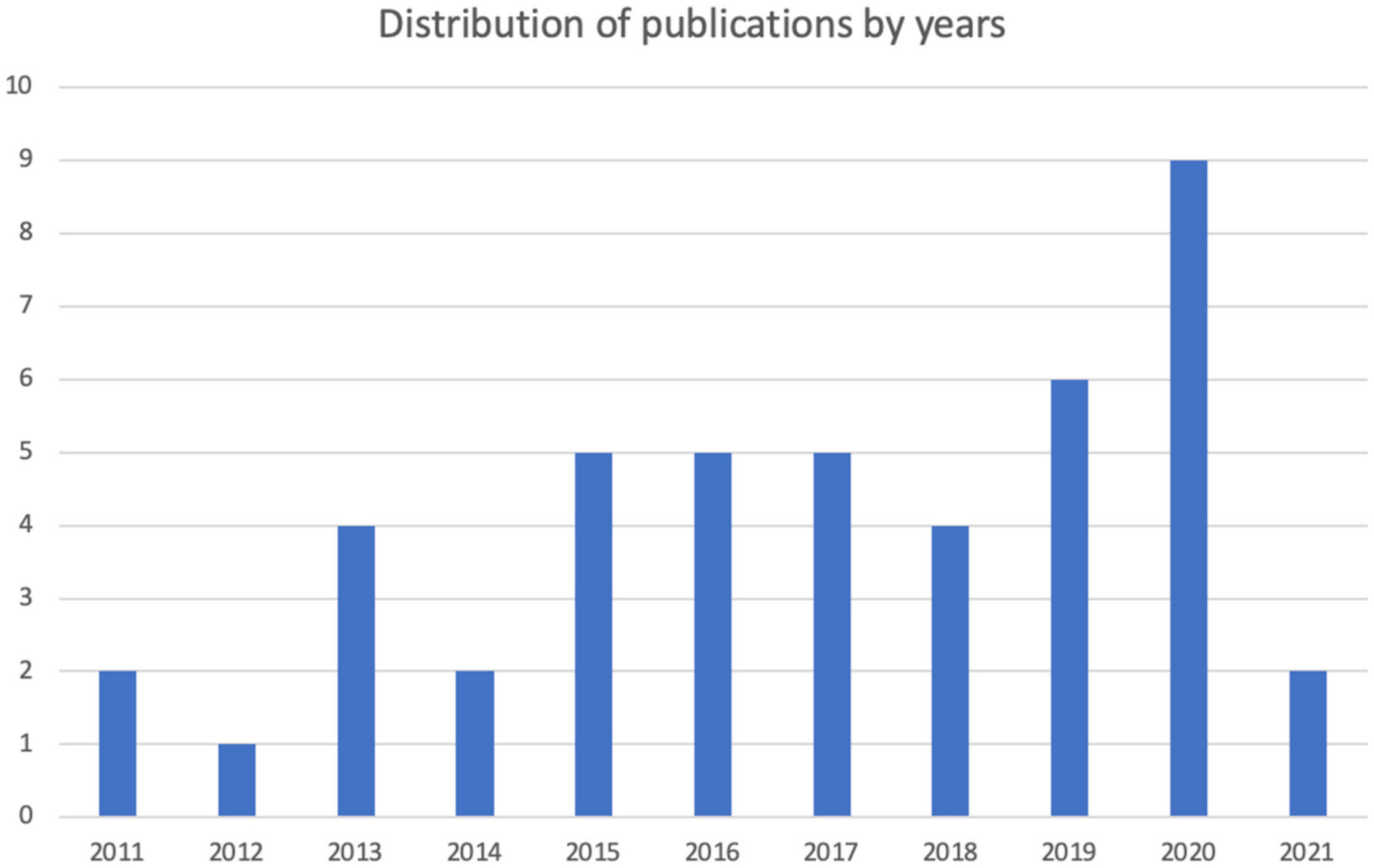

2. Research Method

2.1. Research Questions

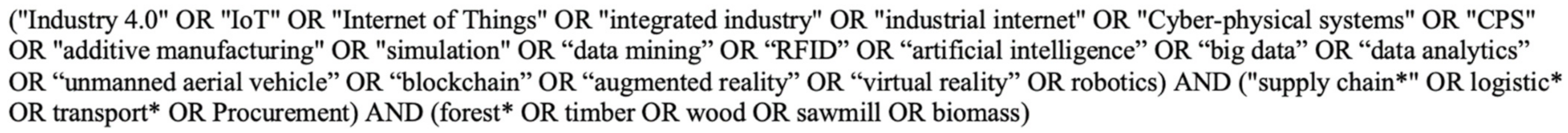

2.2. Search Strategy

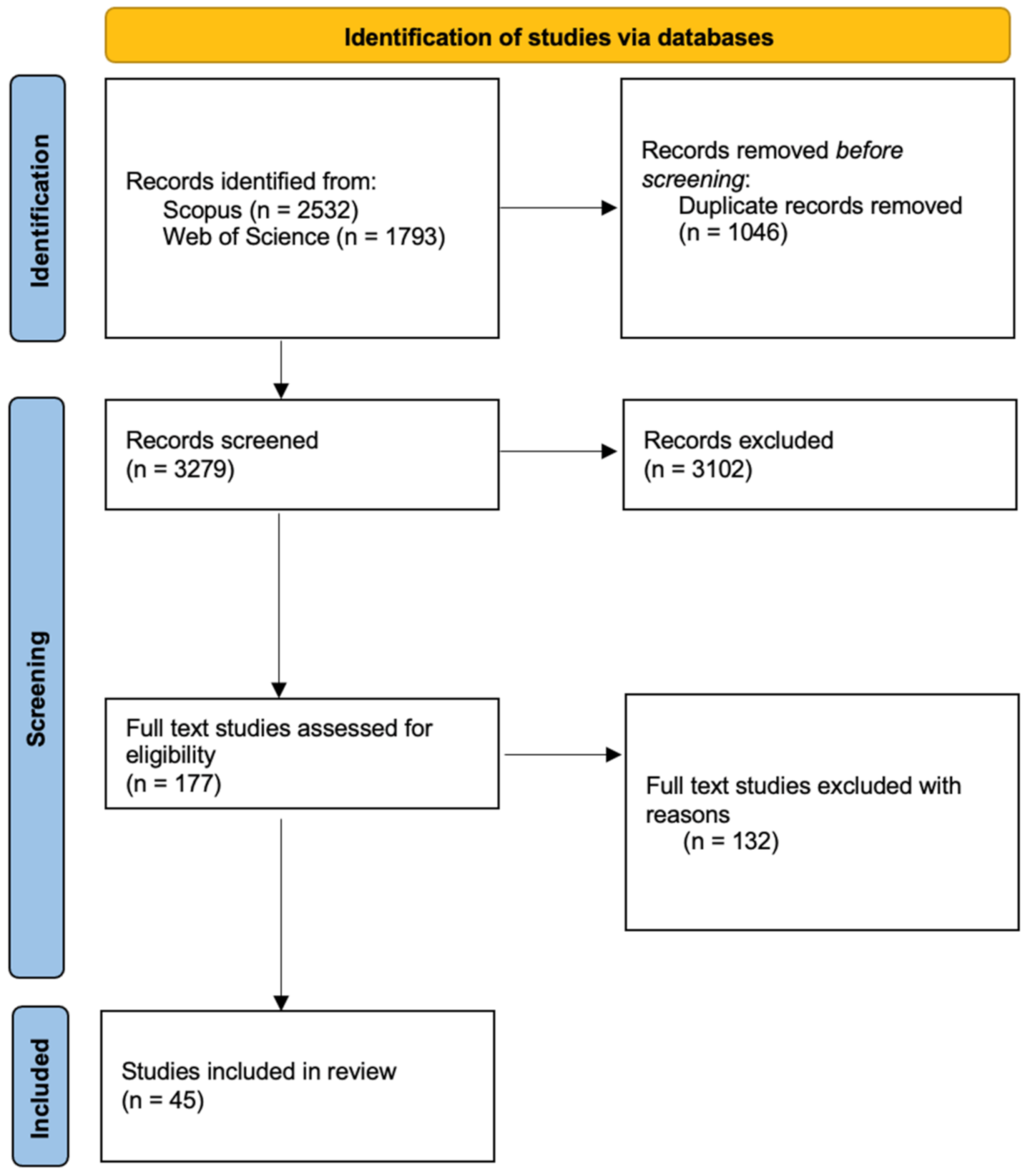

2.3. Data Selection

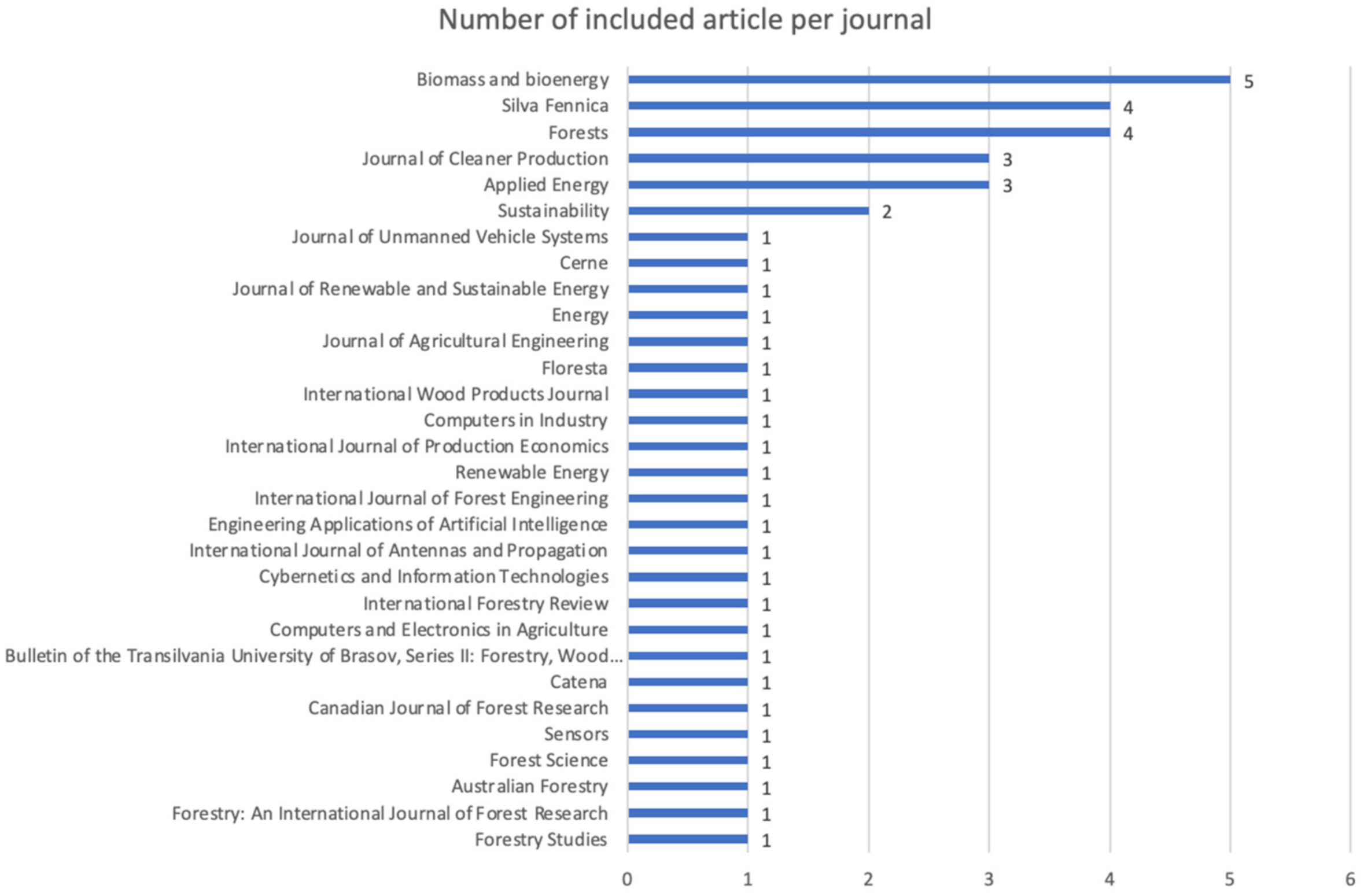

2.4. Analysis, Synthesis and Reporting

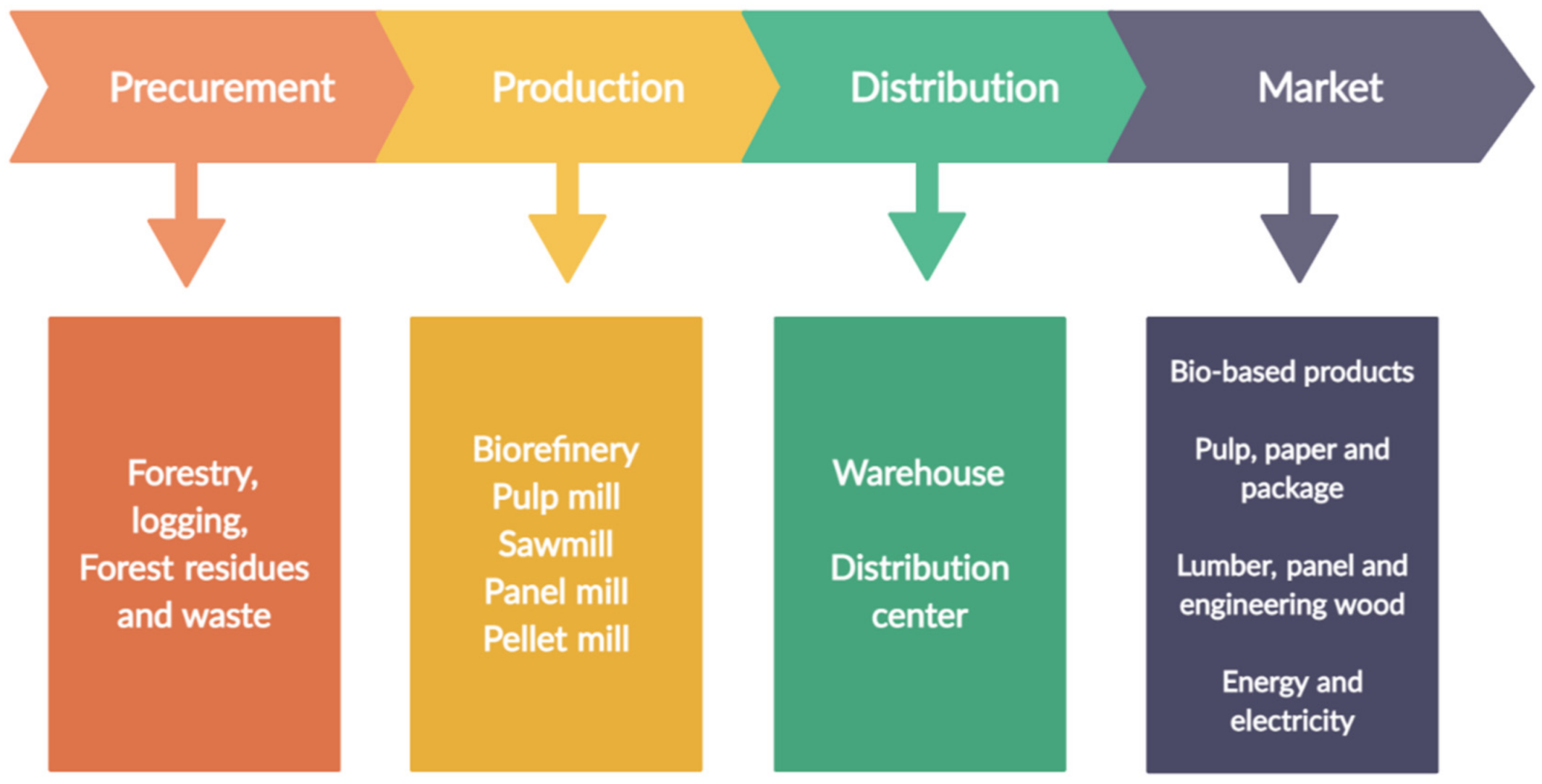

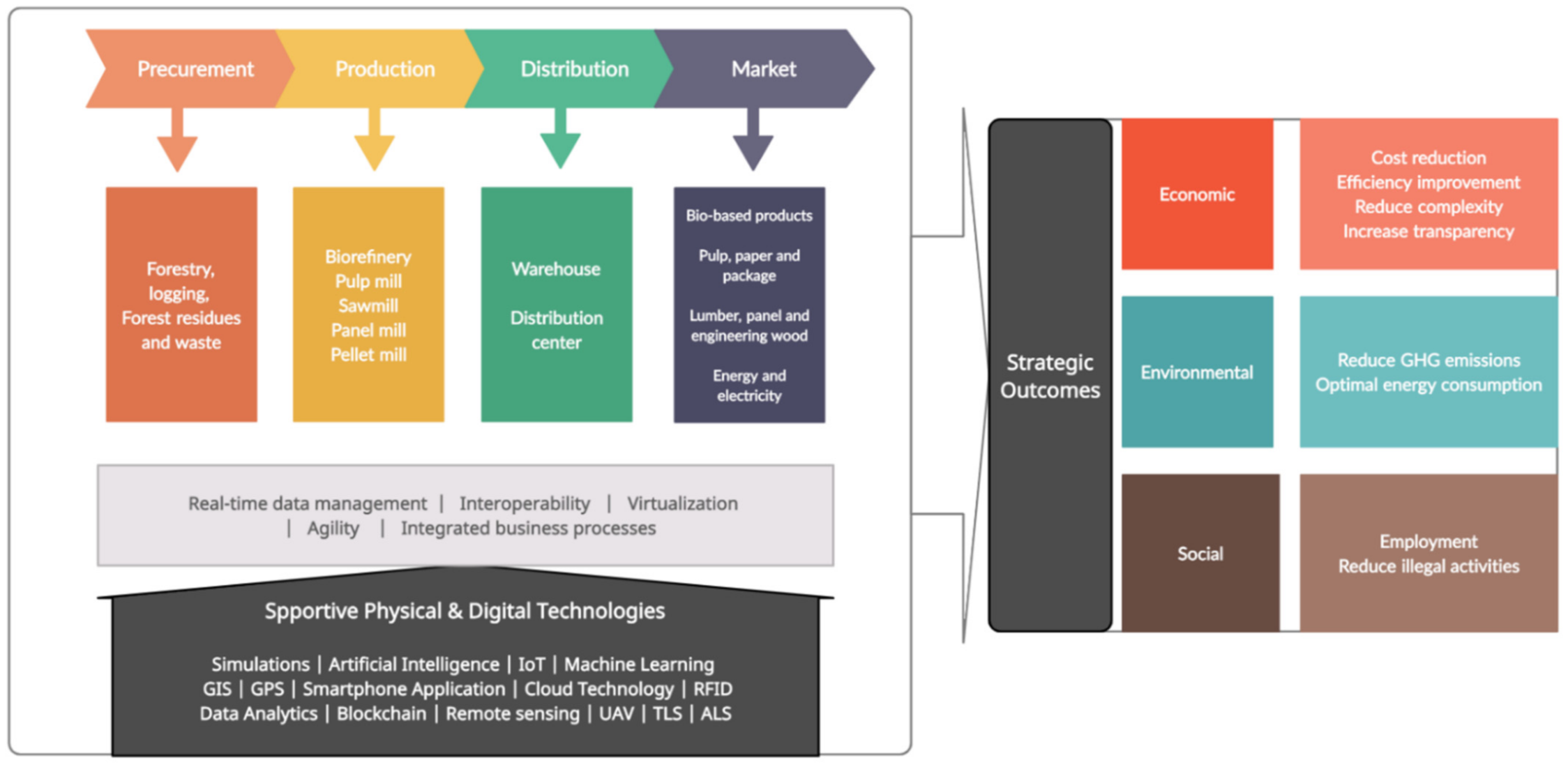

3. Development of a Framework

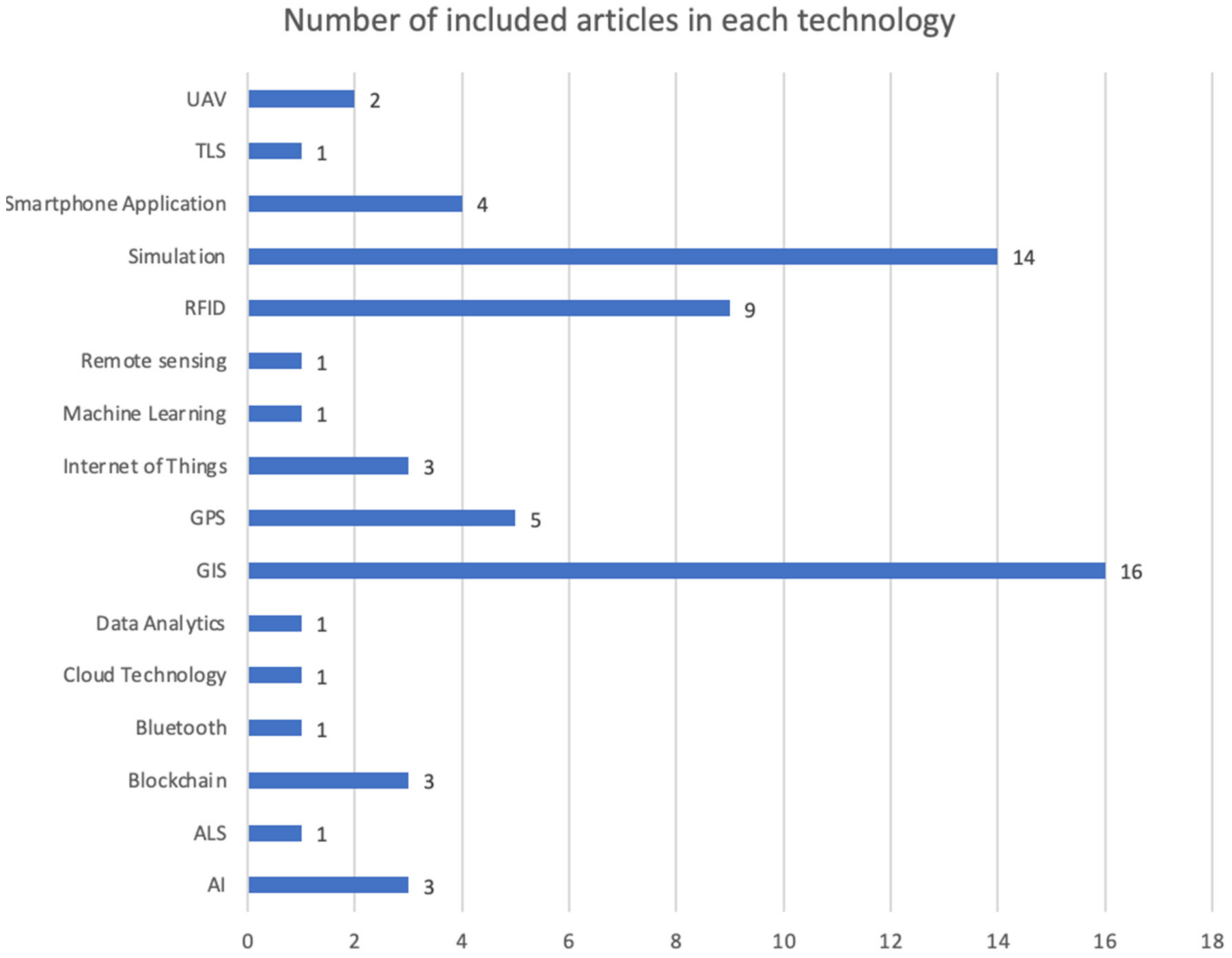

3.1. Supportive Physical and Digital Technologies Implemented in the Forest Supply Chain

3.1.1. Tools of Supportive Technologies in the Forest Supply Chain

3.1.2. Supportive Technologies Implemented in Different Phases of the Forest Supply Chain

| Processes | Technologies |

|---|---|

| Forest management | Simulation [36,69] IoT [54] UAV [51,52] Data analytics [52] TLS [51] GPS [51] Smartphone application [51] |

| Forest inventory | ALS [53] UAV [51] TLS [51] Smartphone application [53] |

| Planning | Simulation [40] Machine learning [55] |

| Procurement | Simulation [56,57] Blockchain [70] |

| Harvesting | Simulation [56] UAV [51] TLS [51] RFID [51] GPS [51] Smartphone application [51] |

| Production—sawmill | Simulation [36] AI [59,60] Machine learning [55] IoT [58] GPS [58] RFID [58] Smartphone application [58] Could technology [58] |

| Production—biofuel factory | Simulation [50,61] GIS [50,61] |

| Production—bioethanol factory | GIS [44] |

| Production—biomass energy plants | GIS [46] |

| Transportation—forest chips | Simulation [32,35,39,42,43,63], GPS [42], GIS [39,42,43,63] |

| Transportation—wood/timber | Simulation [33,37,45,48], GIS [44,45,48,62] GPS [45] AI [62] Remote sensing [64] |

| Transportation—forest biomass | Simulation [47], GIS [47] RFID [66] |

| Sales | Blockchain [71] |

| Entire supply chain | Simulation [34,38,41,49,72,73], GIS [38,49,72,73] RFID [28,65,67,74,75] Blockchain [68] IoT [68] GPS [68] Bluetooth [68] Smartphone applications [68] |

3.2. Improvement and Characteristics of the FbSC in Industry 4.0

3.3. Strategic Outcomes

| Strategic Outcomes | Main Focus | Reference |

|---|---|---|

| Economic level | Efficiency | [33,35,36,37,39,45,63,65,73,75] |

| Cost reduction or profitability | [28,33,35,37,39,40,41,43,44,45,47,48,49,58,61,62,63,65,73,75] | |

| Reduce Complexity | [55,59] | |

| Transparency | [43,44,51,70] | |

| Environmental level | Reduce greenhouse gas (GHG) emissions | [33,38,44,61,65] |

| Energy consumption | [44,61] | |

| Social level | Increase job opportunity | [50] |

| Reduce illegal activity | [51,71,74] |

4. Challenges

5. Conclusions

- Identifying the reliability and risk of systems and network infrastructures in Industry 4.0 applied in the forest supply chain;

- Assessing the adaptability of Industry 4.0 for small and medium-sized enterprises in the forest supply chain;

- Investigating the barriers to small and medium-sized enterprises in the forest supply chain to implement new technologies in Industry 4.0;

- Investigating the solution to improve cyber security in the forest supply chain;

- Assessing emerging technologies to eliminate illegal logging/timber-trading activities worldwide.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| No. | Author(s) | Year | Title | Journal |

|---|---|---|---|---|

| [56] | Gautam, S. et al. | 2015 | Value-adding through silvicultural flexibility: an operational level simulation study | Forestry: An International Journal of Forest Research |

| [64] | Spreitzer, G. et al. | 2019 | SmartWood: Laboratory experiments for assessing the effectiveness of smart sensors for monitoring large wood movement behaviour | Catena |

| [36] | Shahi, S., and Pulkki, R. | 2015 | A simulation-based optimization approach to integrated inventory management of a sawlog supply chain with demand uncertainty | Canadian Journal of Forest Research |

| [32] | Karttunen, K. et al. | 2012 | The operational efficiency of waterway transport of forest chips on Finland’s Lake Saimaa | Silva Fennica |

| [33] | Vaatainen, K. et al. | 2020 | The influence of gross vehicle weight (GVW) and transport distance on timber trucking performance indicators—Discrete event simulation case study in Central Finland | International Journal of Forest Engineering |

| [40] | Fernandez-Lacruz, R. et al. | 2020 | Simulation-based cost analysis of industrial supply of chips from logging residues and small-diameter trees | Forests |

| [41] | Mobini, M. et al. | 2013 | A simulation model for the design and analysis of wood pellet supply chains | Applied Energy |

| [37] | Kogler, C. et al. | 2020 | Simulating Combined Self-Loading Truck and Semitrailer Truck Transport in the Wood Supply Chain | Forests |

| [58] | Šulyová, D., and Koman, G. | 2020 | The Significance of IoT Technology in Improving Logistical Processes and Enhancing Competitiveness: A Case Study on the World’s and Slovakia’s Wood-Processing Enterprises | Sustainability |

| [59] | Thomas, P., and Thomas, A. | 2011 | Multilayer perceptron for simulation models reduction: Application to a sawmill workshop | Engineering Applications of Artificial Intelligence |

| [47] | Simon, F. et al. | 2021 | Modelling and simulation of the wood biomass supply from the sustainable management of natural forests | Journal of Cleaner Production |

| [42] | Simwanda, M. et al. | 2015 | Modeling biomass transport on single-lane forest roads | Forest Science |

| [43] | Sosa, A. et al. | 2015 | Managing the moisture content of wood biomass for the optimization of Ireland’s transport supply strategy to bioenergy markets and competing industries | Energy |

| [55] | Morin, M. et al. | 2020 | Machine learning-based models of sawmills for better wood allocation planning | International Journal of Production Economics |

| [38] | Raghu, K. C. et al. | 2020 | Lifecycle Assessment of Biomass Supply Chain with the Assistance of Agent-Based Modelling | Sustainability |

| [54] | Yu, Z. et al. | 2014 | IoT forest environmental factors collection platform based on ZigBee | Cybernetics and Information Technologies |

| [44] | Zhang, F. et al. | 2017 | Integrating GIS with optimization method for a biofuel feedstock supply chain | Biomass and Bioenergy |

| [48] | Fernandes, D.L. et al. | 2019 | Influence of wood stacking location on forest transport costs | Floresta |

| [49] | Laurén, A. et al. | 2018 | Improving the financial performance of solid forest fuel supply using a simple moisture and dry matter loss simulation and optimization | Biomass and bioenergy |

| [69] | Broz, D. et al. | 2017 | Forest management decision making based on a real options approach: An application to a case in northeastern Argentina | Forestry Studies |

| [50] | Lin, C.C. et al. | 2020 | Forest biomass-to-biofuel factory location problem with multiple objectives considering environmental uncertainties and social enterprises | Journal of Cleaner Production |

| [72] | Aalto, M. et al. | 2019 | Feedstock availability and moisture content data processing for multi-year simulation of forest biomass supply in energy production | Silva Fennica |

| [73] | Aalto, M. et al. | 2017 | Dynamic simulation of bioenergy facility locations with large geographical datasets-a case study in European region | Bulletin of the Transilvania University of Brasov, Series II: Forestry, Wood Industry, Agricultural Food Engineering |

| [34] | Windisch, J. et al. | 2015 | Discrete-event simulation of an information-based raw material allocation process for increasing the efficiency of an energy wood supply chain | Applied energy |

| [61] | Zhang, F. et al. | 2016 | Decision support system integrating GIS with simulation and optimization for a biofuel supply chain | Renewable Energy |

| [39] | Karttunen, K. et al. | 2013 | Cost-efficiency of intermodal container supply chain for forest chips | Silva Fennica |

| [63] | Laitila, J. et al. | 2016 | Cost analysis of transporting forest chips and forest industry by-products with large truck-trailers in Finland | Biomass and Bioenergy |

| [57] | Windisch, J., et al. | 2013 | Business process mapping and discrete-event simulation of two forest biomass supply chains | Biomass and Bioenergy |

| [68] | Figorilli, S. et al. | 2018 | A blockchain implementation prototype for the electronic open source traceability of wood along the whole supply chain | Sensors |

| [71] | Vilkov, A., and Tian, G. | 2019 | Blockchain as a solution to the problem of illegal timber trade between Russia and China: SWOT analysis | International Forestry Review |

| [35] | Prinz, R., et al. | 2019 | Analysis of energy efficiency of forest chip supply systems using discrete-event simulation | Applied energy |

| [45] | Marinello, F. et al. | 2013 | Analysis of a double steering forest trailer for long wood log transportation | Journal of Agricultural Engineering |

| [53] | Siipilehto J. et al. | 2016 | Reliability of the predicted stand structure for clear-cut stands using optional methods: airborne laser scanning-based methods, smartphone-based forest inventory application Trestima and pre-harvest measurement tool EMO | Silva Fennica |

| [51] | Pichler, G. et al. | 2017 | Comparison of remote sensing based RFID and standard tree marking for timber harvesting | Computers and Electronics in Agriculture |

| [66] | Ranta, T. et al. | 2014 | Radio frequency identification and composite container technology demonstration for transporting logistics of wood biomass | Journal of Renewable and Sustainable Energy |

| [65] | Björk, A. et al. | 2011 | Monitoring environmental performance of the forestry supply chain using RFID | Computers in Industry |

| [28] | Appelhanz, S. et al. | 2016 | Traceability system for capturing, processing and providing consumer-relevant information about wood products: system solution and its economic feasibility | Journal of Cleaner Production |

| [67] | Sipilä, E. et al. | 2016 | Experimental study on brush-painted passive RFID-based humidity sensors embedded into plywood structures | International Journal of Antennas and Propagation |

| [46] | Woo, H. et al. | 2018 | Optimizing the location of biomass energy facilities by integrating Multi-Criteria Analysis (MCA) and Geographical Information Systems (GIS) | Forests |

| [75] | Sundberg, P. et al. | 2018 | Traceability of bulk biomass: Application of radio frequency identification technology on a bulk pellet flow | Biomass and Bioenergy |

| [74] | Kaakkurivaara, T., and Kaakkurivaara, N. | 2019 | Comparison of radio frequency identification tag housings in a tropical forestry work environment | Australian Forestry |

| [70] | Morten Komdeur, E., and Ingenbleek, P. T. | 2021 | The potential of blockchain technology in the procurement of sustainable timber products | International Wood Products Journal |

| [60] | Alexandru Borz, S., and Păun, M. | 2020 | Integrating offline object tracking, signal processing, and artificial intelligence to classify relevant events in sawmilling operations | Forests |

| [62] | Araújo, C. A. et al. | 2017 | A multi-agent system for forest transport activity planning | Cerne |

| [52] | Puliti, S., and Granhus, A | 2020 | Drone data for decision making in regeneration forests: from raw data to actionable insights1 | Journal of Unmanned Vehicle Systems |

References

- Oztemel, E.; Gursev, S. Literature review of Industry 4.0 and related technologies. J. Intell. Manuf. 2020, 31, 127–182. [Google Scholar] [CrossRef]

- Abdirad, M.; Krishnan, K. Industry 4.0 in Logistics and Supply Chain Management: A Systematic Literature Review. Eng. Manag. J. 2021, 33, 187–201. [Google Scholar] [CrossRef]

- Rojko, A. Industry 4.0 Concept: Background and Overview. Int. J. Interact. Mob. Technol. 2017, 11, 14. [Google Scholar] [CrossRef]

- Liao, Y.X.; Deschamps, F.; Loures, E.D.R.; Ramos, L.F.P. Past, present and future of Industry 4.0—A systematic literature review and research agenda proposal. Int. J. Prod. Res. 2017, 55, 3609–3629. [Google Scholar] [CrossRef]

- Qin, J.; Liu, Y.; Grosvenor, R. A Categorical Framework of Manufacturing for Industry 4.0 and Beyond. Procedia Cirp 2016, 52, 173–178. [Google Scholar] [CrossRef]

- Stokey, N.L. In A quantitative model of the British industrial revolution, 1780–1850. In Carnegie-Rochester Conference Series on Public Policy; Elsevier: Amsterdam, The Netherlands, 2001; pp. 55–109. [Google Scholar]

- Mokyr, J.; Strotz, R.H. The second industrial revolution, 1870–1914. Stor. Dell’economia Mond. 1998, 21945, 1. [Google Scholar]

- Drath, R.; Horch, A. Industrie 4.0: Hit or hype? [industry forum]. IEEE Ind. Electron. Mag. 2014, 8, 56–58. [Google Scholar] [CrossRef]

- Lasi, H.; Fettke, P.; Kemper, H.-G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Cordeiro, G.A.; Ordóñez, R.E.C.; Ferro, R. Theoretical proposal of steps for the implementation of the Industry 4.0 concept. Braz. J. Oper. Prod. Manag. 2019, 16, 166–179. [Google Scholar] [CrossRef]

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The expected contribution of Industry 4.0 technologies for industrial performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Xu, L.D.; Xu, E.L.; Li, L. Industry 4.0: State of the art and future trends. Int. J. Prod. Res. 2018, 56, 2941–2962. [Google Scholar] [CrossRef]

- Frederico, G.F.; Garza-Reyes, J.A.; Anosike, A.; Kumar, V. Supply Chain 4.0: Concepts, maturity and research agenda. Supply Chain. Manag. 2020, 25, 262–282. [Google Scholar] [CrossRef]

- Bai, C.G.; Dallasega, P.; Orzes, G.; Sarkis, J. Industry 4.0 technologies assessment: A sustainability perspective. Int. J. Prod. Econ. 2020, 229, 107776. [Google Scholar] [CrossRef]

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Tjahjono, B.; Esplugues, C.; Ares, E.; Pelaez, G. What does industry 4.0 mean to supply chain? Procedia Manuf. 2017, 13, 1175–1182. [Google Scholar] [CrossRef]

- Baghizadeh, K.; Zimon, D.; Jum’a, L. Modeling and Optimization Sustainable Forest Supply Chain Considering Discount in Transportation System and Supplier Selection under Uncertainty. Forests 2021, 12, 964. [Google Scholar] [CrossRef]

- D’Amours, S.; Ronnqvist, M.; Weintraub, A. Using Operational Research for Supply Chain Planning in the Forest Products Industry. INFOR 2008, 46, 265–281. [Google Scholar] [CrossRef]

- Scholz, J.; De Meyer, A.; Marques, A.S.; Pinho, T.M.; Boaventura-Cunha, J.; Van Orshoven, J.; Rosset, C.; Kunzi, J.; Kaarle, J.; Nummila, K. Digital Technologies for Forest Supply Chain Optimization: Existing Solutions and Future Trends. Environ. Manag. 2018, 62, 1108–1133. [Google Scholar] [CrossRef]

- Sowlati, T. Modeling of forest and wood residues supply chains for bioenergy and biofuel production. In Biomass Supply Chains for Bioenergy and Biorefining; Elsevier: Amsterdam, The Netherlands, 2016; pp. 167–190. [Google Scholar]

- Liu, W.Y.; Lin, C.C.; Yeh, T.L. Supply chain optimization of forest biomass electricity and bioethanol coproduction. Energy 2017, 139, 630–645. [Google Scholar] [CrossRef]

- Ouhimmou, M.; Ronnqvist, M.; Lapointe, L.A. Assessment of sustainable integration of new products into value chain through a generic decision support model: An application to the forest value chain. Omega-Int. J. Manag. S 2021, 99, 102173. [Google Scholar] [CrossRef]

- Feng, Y.; Audy, J.-F. Forestry 4.0: A framework for the forest supply chain toward Industry 4.0. Gest. Prod. 2020, 27, e5677. [Google Scholar] [CrossRef]

- Muller, F.; Jaeger, D.; Hanewinkel, M. Digitization in wood supply—A review on how Industry 4.0 will change the forest value chain. Comput. Electron. Agric. 2019, 162, 206–218. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations (FAO). The Russian Federation Forest Sector: Out-Look Study to 2030. Rome, Italy. 2012. Available online: https://agris.fao.org/agris-search/search.do?recordID=XF2013001279 (accessed on 26 April 2021).

- Torres-Rojo, J.M. Illegal Logging and the Productivity Trap of Timber Production in Mexico. Forests 2021, 12, 838. [Google Scholar] [CrossRef]

- Pizzi, A.; Despres, A.; Mansouri, H.-R.; Leban, J.-M.; Rigolet, S. Wood joints by through-dowel rotation welding: Microstructure, 13C-NMR and water resistance. J. Adhes. Sci. Technol. 2006, 20, 427–436. [Google Scholar] [CrossRef]

- Appelhanz, S.; Osburg, V.-S.; Toporowski, W.; Schumann, M. Traceability system for capturing, processing and providing consumer-relevant information about wood products: System solution and its economic feasibility. J. Clean. Prod. 2016, 110, 132–148. [Google Scholar] [CrossRef]

- Mallett, R.; Hagen-Zanker, J.; Slater, R.; Duvendack, M. The benefits and challenges of using systematic reviews in international development research. J. Dev. Eff. 2012, 4, 445–455. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; Group, P. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef]

- Karttunen, K.; Väätäinen, K.; Asikainen, A.; Ranta, T. The operational efficiency of waterway transport of forest chips on Finland’s lake Saimaa. Silva Fenn. 2012, 46, 395–413. [Google Scholar] [CrossRef]

- Vaatainen, K.; Laitila, J.; Anttila, P.; Kilpelainen, A.; Asikainen, A. The influence of gross vehicle weight (GVW) and transport distance on timber trucking performance indicators—Discrete event simulation case study in Central Finland. Int. J. For. Eng. 2020, 31, 156–170. [Google Scholar]

- Windisch, J.; Väätäinen, K.; Anttila, P.; Nivala, M.; Laitila, J.; Asikainen, A.; Sikanen, L. Discrete-event simulation of an information-based raw material allocation process for increasing the efficiency of an energy wood supply chain. Appl. Energy 2015, 149, 315–325. [Google Scholar] [CrossRef]

- Prinz, R.; Väätäinen, K.; Laitila, J.; Sikanen, L.; Asikainen, A. Analysis of energy efficiency of forest chip supply systems using discrete-event simulation. Appl. Energy 2019, 235, 1369–1380. [Google Scholar] [CrossRef]

- Shahi, S.; Pulkki, R. A simulation-based optimization approach to integrated inventory management of a sawlog supply chain with demand uncertainty. Can. J. For. Res. 2015, 45, 1313–1326. [Google Scholar] [CrossRef]

- Kogler, C.; Stenitzer, A.; Rauch, P. Simulating combined self-loading truck and semitrailer truck transport in the wood supply chain. Forests 2020, 11, 1245. [Google Scholar] [CrossRef]

- Raghu, K.C.; Aalto, M.; Korpinen, O.J.; Ranta, T.; Proskurina, S. Lifecycle Assessment of Biomass Supply Chain with the Assistance of Agent-Based Modelling. Sustainability 2020, 12, 14. [Google Scholar]

- Karttunen, K.; Lattila, L.; Korpinen, O.J.; Ranta, T. Cost-efficiency of intermodal container supply chain for forest chips. Silva Fenn. 2013, 47, 24. [Google Scholar] [CrossRef]

- Fernandez-Lacruz, R.; Eriksson, A.; Bergström, D. Simulation-based cost analysis of industrial supply of chips from logging residues and small-diameter trees. Forests 2020, 11, 1. [Google Scholar] [CrossRef]

- Mobini, M.; Sowlati, T.; Sokhansanj, S. A simulation model for the design and analysis of wood pellet supply chains. Appl. Energy 2013, 111, 1239–1249. [Google Scholar] [CrossRef]

- Simwanda, M.; Sessions, J.; Boston, K.; Wing, M.G. Modeling biomass transport on single-lane forest roads. For. Sci. 2015, 61, 763–773. [Google Scholar] [CrossRef]

- Sosa, A.; Acuna, M.; McDonnell, K.; Devlin, G. Managing the moisture content of wood biomass for the optimisation of Ireland’s transport supply strategy to bioenergy markets and competing industries. Energy 2015, 86, 354–368. [Google Scholar] [CrossRef]

- Zhang, F.L.; Wang, J.J.; Liu, S.H.; Zhang, S.M.; Sutherland, J.W. Integrating GIS with optimization method for a biofuel feedstock supply chain. Biomass Bioenergy 2017, 98, 194–205. [Google Scholar] [CrossRef]

- Marinello, F.; Grigolato, S.; Sartori, L.; Cavalli, R. Analysis of a double steering forest trailer for long wood log transportation. J. Agric. Eng. 2013, 44, 10–15. [Google Scholar] [CrossRef]

- Woo, H.; Acuna, M.; Moroni, M.; Taskhiri, M.S.; Turner, P. Optimizing the location of biomass energy facilities by integrating Multi-Criteria Analysis (MCA) and Geographical Information Systems (GIS). Forests 2018, 9, 585. [Google Scholar] [CrossRef]

- Simon, F.; Girard, A.; Krotki, M.; Ordoñez, J. Modelling and simulation of the wood biomass supply from the sustainable management of natural forests. J. Clean. Prod. 2021, 282, 124487. [Google Scholar] [CrossRef]

- Fernandes, D.L.; Matos, L.M.A.; Magalhães, E.C.; Cabacinha, C.D.; de Assis, A.L.; Araújo Júnior, C.A. Influence of wood stacking location on forest transport costs. Floresta 2020, 50, 1047–1052. [Google Scholar] [CrossRef]

- Laurén, A.; Asikainen, A.; Kinnunen, J.P.; Palviainen, M.; Sikanen, L. Improving the financial performance of solid forest fuel supply using a simple moisture and dry matter loss simulation and optimization. Biomass Bioenergy 2018, 116, 72–79. [Google Scholar] [CrossRef]

- Lin, C.C.; Kang, J.R.; Huang, G.L.; Liu, W.Y. Forest biomass-to-biofuel factory location problem with multiple objectives considering environmental uncertainties and social enterprises. J. Clean. Prod. 2020, 262, 15. [Google Scholar] [CrossRef]

- Pichler, G.; Poveda Lopez, J.A.; Picchi, G.; Nolan, E.; Kastner, M.; Stampfer, K.; Kühmaier, M. Comparison of remote sensing based RFID and standard tree marking for timber harvesting. Comput. Electron. Agric. 2017, 140, 214–226. [Google Scholar] [CrossRef]

- Puliti, S.; Granhus, A. Drone data for decision making in regeneration forests: From raw data to actionable insights1. J. Unmanned Veh. Sys. 2020, 9, 45–58. [Google Scholar] [CrossRef]

- Siipilehto, J.; Lindeman, H.; Vastaranta, M.; Yu, X.; Uusitalo, J. Reliability of the predicted stand structure for clear-cut stands using optional methods: Airborne laser scanning-based methods, smartphone-based forest inventory application trestima and pre-harvest measurement tool EMO. Silva Fenn. 2016, 50, 1568. [Google Scholar] [CrossRef]

- Yu, Z.; Xugang, L.; Xue, G.; Dan, L. IoT forest environmental factors collection platform based on ZIGBEE. Cybern. Inf. Technol. 2014, 14, 51–62. [Google Scholar] [CrossRef]

- Morin, M.; Gaudreault, J.; Brotherton, E.; Paradis, F.; Rolland, A.; Wery, J.; Laviolette, F. Machine learning-based models of sawmills for better wood allocation planning. Int. J. Prod. Econ. 2020, 222, 107508. [Google Scholar] [CrossRef]

- Gautam, S.; LeBel, L.; Beaudoin, D. Value-adding through silvicultural flexibility: An operational level simulation study. Forestry 2015, 88, 213–223. [Google Scholar] [CrossRef]

- Windisch, J.; Röser, D.; Mola-Yudego, B.; Sikanen, L.; Asikainen, A. Business process mapping and discrete-event simulation of two forest biomass supply chains. Biomass Bioenergy 2013, 56, 370–381. [Google Scholar] [CrossRef]

- Šulyová, D.; Koman, G. The significance of IoT technology in improving logistical processes and enhancing competitiveness: A case study on the World’s and Slovakia’s wood-processing enterprises. Sustainability 2020, 12, 7804. [Google Scholar] [CrossRef]

- Thomas, P.; Thomas, A. Multilayer perceptron for simulation models reduction: Application to a sawmill workshop. Eng. Appl. Artif. Intell. 2011, 24, 646–657. [Google Scholar] [CrossRef]

- Alexandru Borz, S.; Păun, M. Integrating offline object tracking, signal processing, and artificial intelligence to classify relevant events in sawmilling operations. Forests 2020, 11, 1333. [Google Scholar] [CrossRef]

- Zhang, F.; Johnson, D.; Johnson, M.; Watkins, D.; Froese, R.; Wang, J. Decision support system integrating GIS with simulation and optimisation for a biofuel supply chain. Renew. Energy 2016, 85, 740–748. [Google Scholar] [CrossRef]

- Araújo, C.A.; Leite, H.G.; Soares, C.P.B.; Binoti, D.H.B.; Souza, A.P.d.; Santana, A.F.; Torre, C.M.M.E. A multi-agent system for forest transport activity planning. Cerne 2017, 23, 329–337. [Google Scholar] [CrossRef]

- Laitila, J.; Asikainen, A.; Ranta, T. Cost analysis of transporting forest chips and forest industry by-products with large truck-trailers in Finland. Biomass Bioenergy 2016, 90, 252–261. [Google Scholar] [CrossRef]

- Spreitzer, G.; Gibson, J.; Tang, M.; Tunnicliffe, J.; Friedrich, H. SmartWood: Laboratory experiments for assessing the effectiveness of smart sensors for monitoring large wood movement behaviour. Catena 2019, 182, 104145. [Google Scholar] [CrossRef]

- Björk, A.; Erlandsson, M.; Häkli, J.; Jaakkola, K.; Nilsson, Å.; Nummila, K.; Puntanen, V.; Sirkka, A. Monitoring environmental performance of the forestry supply chain using RFID. Comput. Ind. 2011, 62, 830–841. [Google Scholar] [CrossRef]

- Ranta, T.; Föhr, J.; Karttunen, K.; Knutas, A. Radio frequency identification and composite container technology demonstration for transporting logistics of wood biomass. J. Renew. Sustain. Energy 2014, 6, 013115. [Google Scholar] [CrossRef]

- Sipilä, E.; Virkki, J.; Sydänheimo, L.; Ukkonen, L. Experimental study on brush-painted passive RFID-based humidity sensors embedded into plywood structures. Int. J. Antennas Propag. 2016, 2016, 1203673. [Google Scholar] [CrossRef][Green Version]

- Figorilli, S.; Antonucci, F.; Costa, C.; Pallottino, F.; Raso, L.; Castiglione, M.; Pinci, E.; Del Vecchio, D.; Colle, G.; Proto, A.R.; et al. A blockchain implementation prototype for the electronic open source traceability of wood along the whole supply chain. Sensors 2018, 18, 3133. [Google Scholar] [CrossRef]

- Broz, D.; Milanesi, G.; Rossit, D.A.; Rossit, D.G.; Tohmé, F. Forest management decision making based on a real options approach: An application to a case in northeastern Argentina. For. Stud. 2017, 67, 97–108. [Google Scholar] [CrossRef][Green Version]

- Morten Komdeur, E.; Ingenbleek, P.T. The potential of blockchain technology in the procurement of sustainable timber products. Int. Wood Prod. J. 2021, 12, 249–257. [Google Scholar] [CrossRef]

- Vilkov, A.; Tian, G. Blockchain as a Solution to the Problem of Illegal Timber Trade between Russia and China: SWOT Analysis. Int. For. Rev. 2019, 21, 385–400. [Google Scholar] [CrossRef]

- Aalto, M.; Korpinen, O.J.; Ranta, T. Feedstock availability and moisture content data processing for multi-year simulation of forest biomass supply in energy production. Silva Fenn. 2019, 53, 10147. [Google Scholar] [CrossRef]

- Aalto, M.; Korpinen, O.J.; Ranta, T. Dynamic simulation of bioenergy facility locations with large geographical datasets—A case study in European region. Bull. Transilvania Univ. Brasov Ser. For. Wood Ind. Agric. Food Eng. 2017, 10, 1–10. [Google Scholar]

- Kaakkurivaara, T.; Kaakkurivaara, N. Comparison of radio frequency identification tag housings in a tropical forestry work environment. Aust. Forest 2019, 82, 181–188. [Google Scholar] [CrossRef]

- Sundberg, P.; Hermansson, S.; Tullin, C.; Ohman, M. Traceability of bulk biomass: Application of radio frequency identification technology on a bulk pellet flow. Biomass Bioenergy 2018, 118, 149–153. [Google Scholar] [CrossRef]

- Masood, T.; Sonntag, P. Industry 4.0: Adoption challenges and benefits for SMEs. Comput. Ind. 2020, 121, 103261. [Google Scholar] [CrossRef]

| Criteria | Description |

|---|---|

| Language | English |

| Publication year | Not earlier than 2011 |

| Publication type | Peer-reviewed journal article |

| Subject/content | Research related to topics of Industry 4.0 AND technologies AND forest supply chain |

| Reference | Sim | AI | GIS | GPS | ML | IoT | RFID | SA | CT | BC | BT | RS | UAV | TLS | ALS | DA |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [28] | X | |||||||||||||||

| [32] | X | |||||||||||||||

| [33] | X | |||||||||||||||

| [34] | X | |||||||||||||||

| [35] | X | |||||||||||||||

| [36] | X | |||||||||||||||

| [37] | X | |||||||||||||||

| [38] | X | X | ||||||||||||||

| [39] | X | X | ||||||||||||||

| [40] | X | |||||||||||||||

| [41] | X | |||||||||||||||

| [42] | X | X | ||||||||||||||

| [43] | X | |||||||||||||||

| [44] | X | |||||||||||||||

| [45] | X | X | X | |||||||||||||

| [46] | X | |||||||||||||||

| [47] | X | |||||||||||||||

| [48] | X | |||||||||||||||

| [49] | X | |||||||||||||||

| [50] | X | |||||||||||||||

| [51] | X | X | X | X | X | |||||||||||

| [52] | X | X | ||||||||||||||

| [53] | X | X | ||||||||||||||

| [54] | X | |||||||||||||||

| [55] | X | |||||||||||||||

| [56] | X | |||||||||||||||

| [57] | X | |||||||||||||||

| [58] | X | X | X | X | X | |||||||||||

| [59] | X | |||||||||||||||

| [60] | X | |||||||||||||||

| [61] | X | |||||||||||||||

| [62] | X | X | ||||||||||||||

| [63] | X | |||||||||||||||

| [64] | X | |||||||||||||||

| [65] | X | |||||||||||||||

| [66] | X | |||||||||||||||

| [67] | X | |||||||||||||||

| [68] | X | X | X | X | X | X | ||||||||||

| [69] | X | |||||||||||||||

| [70] | X | |||||||||||||||

| [71] | X | |||||||||||||||

| [72] | X | |||||||||||||||

| [73] | X | |||||||||||||||

| [74] | X | |||||||||||||||

| [75] | X | |||||||||||||||

| Total | 14 | 3 | 16 | 5 | 1 | 3 | 9 | 4 | 1 | 3 | 1 | 1 | 2 | 1 | 1 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Z.; Turner, P. A Systematic Review on Technologies and Industry 4.0 in the Forest Supply Chain: A Framework Identifying Challenges and Opportunities. Logistics 2021, 5, 88. https://doi.org/10.3390/logistics5040088

He Z, Turner P. A Systematic Review on Technologies and Industry 4.0 in the Forest Supply Chain: A Framework Identifying Challenges and Opportunities. Logistics. 2021; 5(4):88. https://doi.org/10.3390/logistics5040088

Chicago/Turabian StyleHe, Zhaoyuan, and Paul Turner. 2021. "A Systematic Review on Technologies and Industry 4.0 in the Forest Supply Chain: A Framework Identifying Challenges and Opportunities" Logistics 5, no. 4: 88. https://doi.org/10.3390/logistics5040088

APA StyleHe, Z., & Turner, P. (2021). A Systematic Review on Technologies and Industry 4.0 in the Forest Supply Chain: A Framework Identifying Challenges and Opportunities. Logistics, 5(4), 88. https://doi.org/10.3390/logistics5040088