A Systematic Review on Technologies for Data-Driven Production Logistics: Their Role from a Holistic and Value Creation Perspective

Abstract

1. Introduction

1.1. Related Works and Research Gaps

1.2. Research Purpose, Motivation and Article Structure

- What are the data-driven enabling technologies and their use cases in production logistics activities, as described in the literature?

- How does the data-driven enabling technologies contribute to value creation in production logistics from a system perspective?

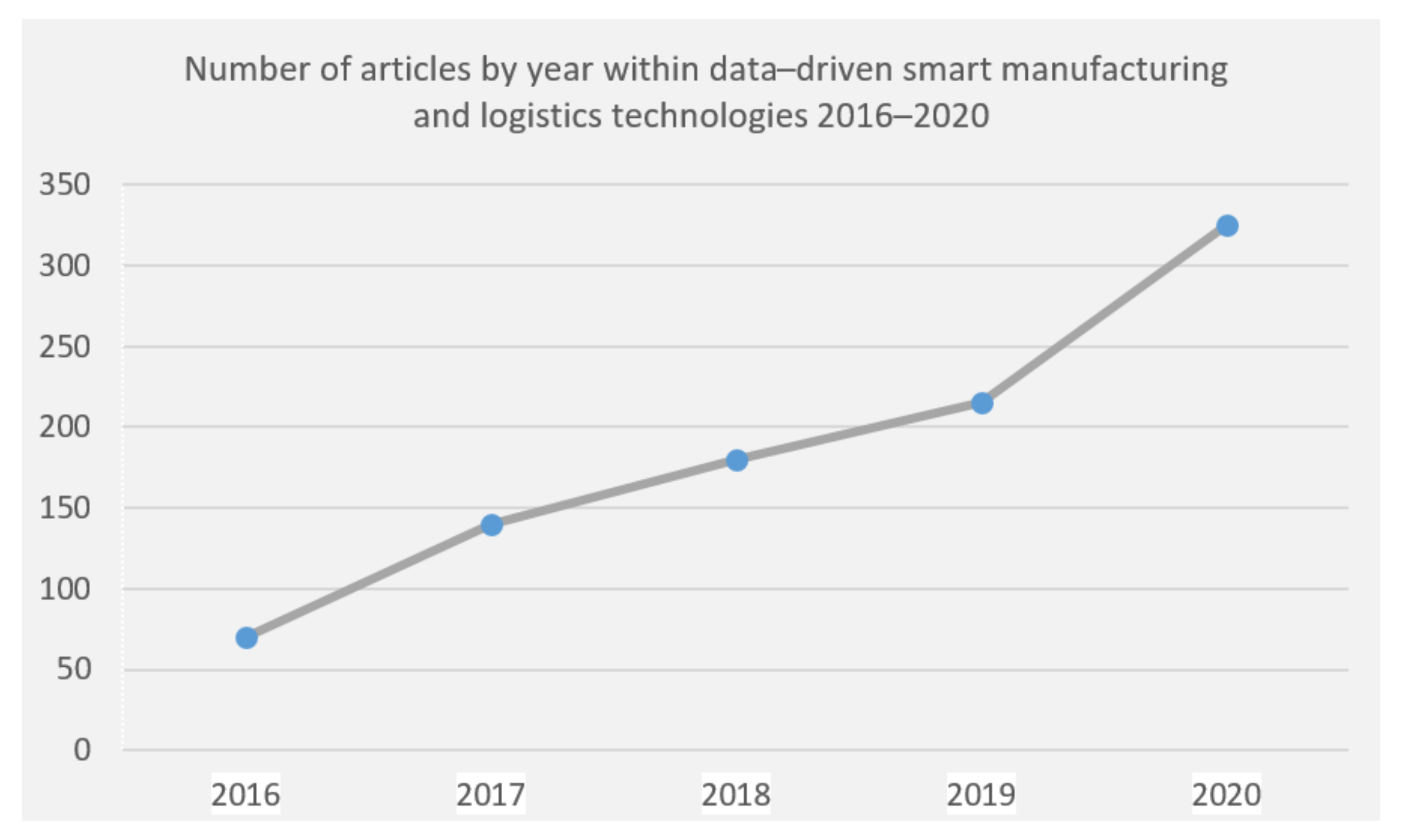

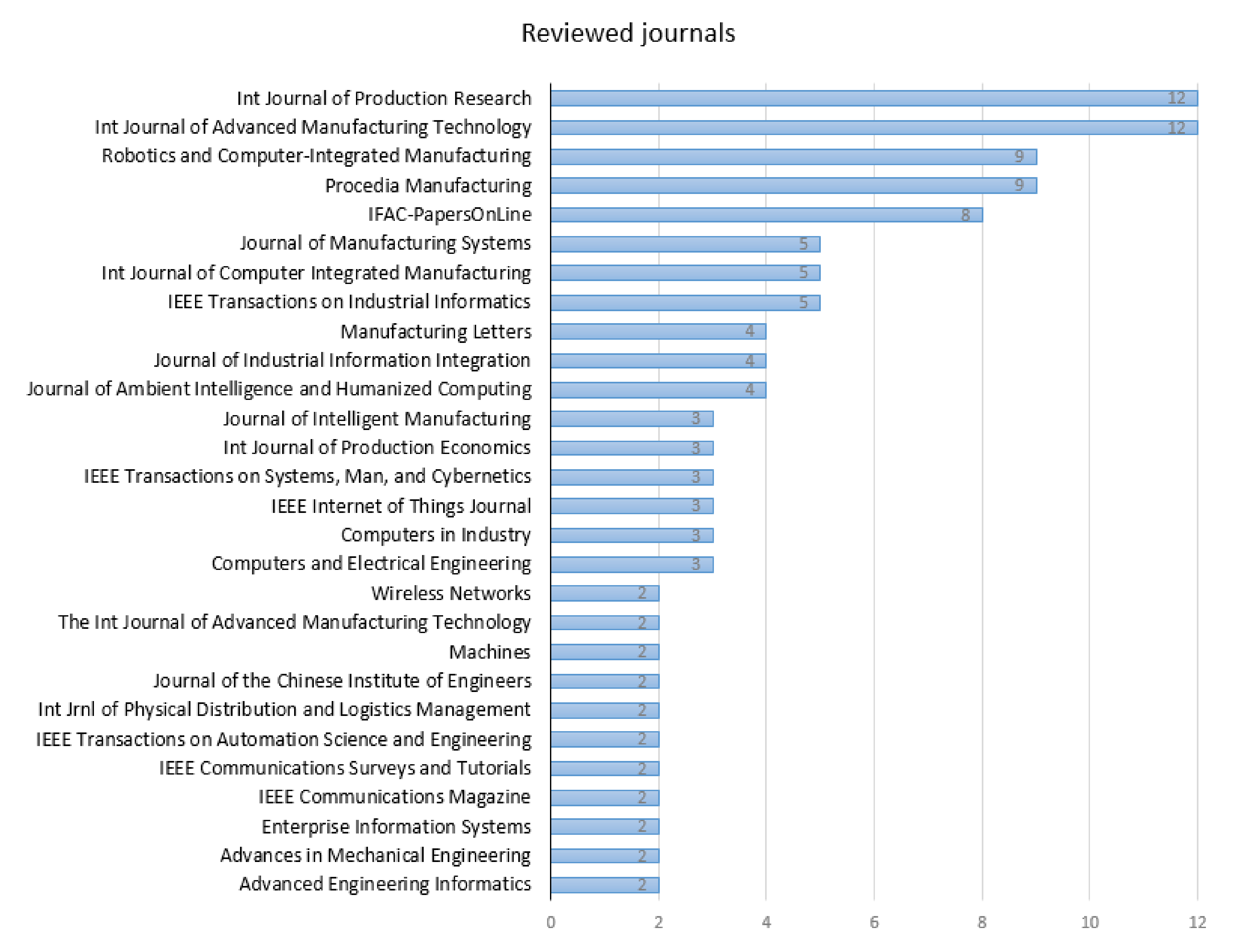

2. Methodology

2.1. Planning the Review

Initial Scoping

2.2. Conducting the Review

- Engineering;

- Computer Science;

- Business, Management and Accounting;

- Decision Sciences;

- Mathematics;

- Social Sciences;

- Economics, Econometrics and Finance;

- Environmental Science.

- Clarified aims and RQs;

- Clarity in study design and method;

- Contribution to the research field;

- Connection to the research field;

- Good theoretical alignment, and data quality.

3. Identified Technologies and Related Production Logistics Activities

- Category 1: Shopfloor operational-related activities including activities that have a direct impact on material movement and material handling. The activities concern physical flow of material. In a PL system with a low level of automation and digitalization, usually these activities involve physical effort. From goods receiving until delivery to internal customers, all activates that involve direct contact with physical goods and material fall under this category.

- Category 2: Planning and scheduling-related activities are regarded as those logistics activities that are aimed to guide the overall operation, and make plans and schedules for an efficient production flow. While the first category concerns physical material flow, this category is about those activities that are known as planning and scheduling. Activities in this category are designed to assure PL system efficiency.

- Category 3: Control, track and trace-related activities are mainly focused on activities that monitor the behavior of logistics system elements such as resources, goods movement and inventory level. Activities in this category control the physical flow of material from items identification until conditions monitoring. This category is essential to increase efficiency of the activities in the two other categories.

3.1. Category 1: Shopfloor Operational-Related Activities

3.2. Category 2: Planning and Scheduling-Related Activities

3.3. Category 3: Control, Track and Trace-Related Activities

4. Discussion

4.1. Share Assessment of the Identified Technologies

4.2. The Role of Data Life Cycle in Value Creation

4.3. PL Activities Correlation Assessment for Value Creation

5. Conclusions and Future Research

- This study did not investigate the impact of each technology on PL system performance. Thus, for future research, it is suggested to study and measure how system performance can be affected after the PL system is transited towards a data-driven state. The outcome of this paper is beneficial to suggest technologies enabling the transition towards a data-driven state. In particular and considering Figure 6, those technologies related to PL planning and scheduling have a shorter history of implementation compared to the two other categories. As a result, it is hard to judge the efficiency of the technologies in the planning and scheduling category within different industrial situations. It is therefore interesting for future research to examine the efficiency and implementation feasibility of technologies related to planning and scheduling from a production logistics perspective.

- Even though this study has discussed the supporting role of identified technologies to complete the data-life cycle and value creation, still, the corresponding role of each technology in each phase of data-life cycle needs further investigation. By performing such a study in future, it will be clear which areas need more attention from a technology developers’ perspective.

- This study carried out a quantitative assessment on technology share for PL activity categories. Thus, it will be interesting to investigate which of these use cases has been already proven and are feasible for implementation and which technologies require further approval. This can be significant to recognize the challenges ahead of a digitalization transition.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cámara, S.B.; Fuentes, J.M.; Marín, J.M.M. Cloud computing, Web 2.0, and operational performance. Mediat. Role Supply Chain Integr. 2015, 26, 3. [Google Scholar]

- Novais, L.; Marín, J.M.M.; Moyano-Fuentes, J. Lean Production implementation, Cloud-Supported Logistics and Supply Chain Integration: Interrelationships and effects on business performance. Int. J. Logist. Manag. 2020, 31, 629–663. [Google Scholar] [CrossRef]

- Barreto, L.; Amaral, A.; Pereira, T. Industry 4.0 implications in logistics: An overview. Procedia Manuf. 2017, 13, 1245–1252. [Google Scholar] [CrossRef]

- Treiblmaier, H.; Mirkovski, K.; Lowry, P.B.; Zacharia, Z.G. The physical internet as a new supply chain paradigm: A systematic literature review and a comprehensive framework. Int. J. Logist. Manag. 2020, 31, 239–287. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Liu, A.; Kusiak, A. Data-driven smart manufacturing. J. Manuf. Syst. 2018, 48, 157–169. [Google Scholar] [CrossRef]

- Nitsche, B. Unravelling the Complexity of Supply Chain Volatility Management. Logistics 2018, 2, 14. [Google Scholar] [CrossRef]

- Horňáková, N.; Jurík, L.; Chovanová, H.H.; Cagáňová, D.; Babčanová, D. AHP method application in selection of appropriate material handling equipment in selected industrial enterprise. Wirel. Netw. 2019, 1–9. [Google Scholar] [CrossRef]

- Davich, T. Material Handling Solutions: A Look into Automated Robotics. Resource Document. 2010. Available online: https://tctest.wiscweb.wisc.edu/wp-content/uploads/sites/142/2017/04/Davich2010.pdf (accessed on 6 April 2021).

- Kang, H.S.; Lee, J.Y.; Choi, S.; Kim, H.; Park, J.H.; Son, J.Y.; Kim, B.H.; Noh, S.D. Smart manufacturing: Past research, present findings, and future directions. Int. J. Precis. Eng. Manuf. Technol. 2016, 3, 111–128. [Google Scholar] [CrossRef]

- Winkelhaus, S.; Grosse, E.H. Logistics 4.0: A systematic review towards a new logistics system. Int. J. Prod. Res. 2020, 58, 18–43. [Google Scholar] [CrossRef]

- Klingenberg, C.O.; Borges, M.A.V.; Antunes, J.A.V., Jr. Industry 4.0 as a data-driven paradigm: A systematic literature review on technologies. J. Manuf. Technol. Manag. 2019. Ahead of Publication. [Google Scholar] [CrossRef]

- Cao, W.; Jiang, P.; Lu, P.; Liu, B. Real-time data-driven monitoring in job-shop floor based on radio frequency identification. Int. J. Adv. Manuf. Technol. 2017, 92, 2120–2357. [Google Scholar] [CrossRef]

- Wan, J.; Tang, S.; Hua, Q.; Li, D.; Liu, C.; Lloret, J. Context-Aware Cloud Robotics for Material Handling in Cognitive Industrial Internet of Things. IEEE Internet Things J. 2017, 5, 2272–2281. [Google Scholar] [CrossRef]

- Lee, C.; Lv, Y.; Ng, K.; Ho, W.; Choy, K. Design and application of Internet of things-based warehouse management system for smart logistics. Int. J. Prod. Res. 2018, 56, 2753–2768. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Determinants of information and digital technology implementation for smart manufacturing. Int. J. Prod. Res. 2020, 58, 2384–2405. [Google Scholar] [CrossRef]

- Alcácer, V.; Cruz-Machado, V. Scanning the Industry 4.0: A Literature Review on Technologies for Manufacturing Systems. Eng. Sci. Technol. Int. J. 2019, 22, 899–919. [Google Scholar] [CrossRef]

- Lagorio, A.; Zenezini, G.; Mangano, G.; Pinto, R. A systematic literature review of innovative technologies adopted in logistics management in logistics management. Int. J. Logist. Res. Appl. 2020. [Google Scholar] [CrossRef]

- Martinez, S.; Astrid, J. Evaluation of the Feasibility of Implementing Industry 4.0 Technologies in the Intralogistic Processes of the Logistics Operators of the Department of the Atlantic, a Look Towards the Continuous Improvement of Organizational Efficiency. In Data Analysis and Optimization for Engineering and Computing Problems; Vasant, P., Litvinchev, I., Marmolejo-Saucedo, J.A., Rodriguez-Aguilar, R., Martinez-Rios, F., Eds.; Springer International Publishing: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Mittal, S.; Khan, M.A.; Romero, D.; Wuest, T. Smart manufacturing: Characteristics, technologies and enabling factors. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2019, 233, 1342–1361. [Google Scholar] [CrossRef]

- Oztemel, E.; Gursev, S. Literature review of Industry 4.0 and related technologies. J. Intell. Manuf. 2020, 31, 127–182. [Google Scholar] [CrossRef]

- Thoben, K.D.; Wiesner, S.A.; Wuest, T. ‘Industrie 4.0’ and smart manufacturing-a review of research issues and application examples. Int. J. Autom. Technol. 2017, 11, 4–16. [Google Scholar] [CrossRef]

- Chien, C.-F.; Hong, T.-Y.; Guo, H.-Z. An empirical study for smart production for TFT-LCD to empower Industry 3.5. J. Chin. Inst. Eng. 2017, 40, 552–561. [Google Scholar] [CrossRef]

- Lin, K.C.; Shyu, J.Z.; Ding, K. A Cross-Strait Comparison of Innovation Policy under Industry 4.0 and Sustainability Development Transition. Sustainability 2017, 9, 786. [Google Scholar] [CrossRef]

- Chiarello, F.; Trivelli, L.; Bonaccorsi, A.; Fantoni, G. Extracting and mapping industry 4.0 technologies using wikipedia. Comput. Ind. 2018, 100, 244–257. [Google Scholar] [CrossRef]

- Chavez, R.; Yu, W.; Jacobs, M.A.; Feng, M. Data-driven supply chains, manufacturing capability and customer satisfaction. Prod. Plan. Control 2017, 28, 906–918. [Google Scholar] [CrossRef]

- Rossit, D.A.; Tohmé, F.; Frutos, M. A data-driven scheduling approach to smart manufacturing. J. Ind. Inf. Integr. 2019, 15, 69–79. [Google Scholar] [CrossRef]

- Woo, J.; Shin, S.-J.; Seo, W.; Meilanitasari, P. Developing a big data analytics platform for manufacturing systems: Architecture, method, and implementation. Int. J. Adv. Manuf. Technol. 2018, 99, 2193–2217. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Ching, N.T. Adoption of digital technologies of smart manufacturing in SMEs. J. Ind. Inf. Integr. 2019, 16, 100107. [Google Scholar] [CrossRef]

- Strandhagen, J.W.; Alfnes, E.; Vallandingham, L.R. The fit of Industry 4.0 applications in manufacturing logistics: A multiple case study. Adv. Manuf. 2017, 5, 344–358. [Google Scholar] [CrossRef]

- Nagy, G.; Illés, B.; Bányai, Á. Impact of Industry 4.0 on production logistics. IOP Conf. Series: Mater. Sci. Eng. 2018, 448, 012013. [Google Scholar] [CrossRef]

- Collins Dictionary. 2020. Available online: https://www.collinsdictionary.com/dictionary/english/technology#:~:text=Technologyreferstomethods%2Csystems (accessed on 1 June 2020).

- Thorpe, R.; Holt, R.; Macpherson, A.; Pittaway, L. Using Knowledge within Small and Medium-sized Firms: A Systematic Review of the Evidence. Int. J. Manag. Rev. 2005, 4, 257–281. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Hofmann, E.; Rüsch, M. Industry 4.0 and the current status as well as future prospects on logistics. Comput. Ind. 2017, 89, 23–34. [Google Scholar] [CrossRef]

- Eklund, J.; Palm, K.; Bergman, A.; Rosenblad, C.; Aronsson, G. Work environment of the future—Trends, digitalization and employment forms: Three systematic reviews. Available online: https://sawee.se/publications/work-environment-of-the-future-trends-digitalization-and-employment-forms/ (accessed on 6 April 2021).

- Park, K.T.; Nam, Y.W.; Lee, H.S.; Im, S.J.; Noh, S.D.; Son, J.Y.; Kim, H. Design and implementation of a digital twin application for a connected micro smart factory. Int. J. Comput. Integr. Manuf. 2019, 32, 596–614. [Google Scholar] [CrossRef]

- Ren, S.; Zhao, X.; Huang, B.; Wang, Z.; Song, X. A framework for shopfloor material delivery based on real-time manufacturing big data. J. Ambient. Intell. Humaniz. Comput. 2018, 10, 1093–1108. [Google Scholar] [CrossRef]

- Sanders, A.; Elangeswaran, C.; Wulfsberg, J. Industry 4.0 implies lean manufacturing: Research activities in industry 4.0 function as enablers for lean manufacturing. J. Ind. Eng. Manag. 2016, 9, 811–833. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, C.; Liu, C.; Li, D.; Tang, H. Cloud-assisted interaction and negotiation of industrial robots for the smart factory. Comput. Electr. Eng. 2017, 63, 66–78. [Google Scholar] [CrossRef]

- Zhang, Y.; Qian, C.; Lv, J.; Liu, Y. Agent and Cyber-Physical System Based Self-Organizing and Self-Adaptive Intelligent Shopfloor. IEEE Trans. Ind. Inform. 2017, 13, 737–747. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, W.; Wu, N.; Qian, C. IoT-Enabled Real-Time Production Performance Analysis and Exception Diagnosis Model. IEEE Trans. Autom. Sci. Eng. 2016, 13, 1318–1332. [Google Scholar] [CrossRef]

- Zheng, M.; Ming, X. Construction of cyber-physical system–integrated smart manufacturing workshops: A case study in automobile industry. Adv. Mech. Eng. 2017, 9, 1–17. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, C.; Chen, C.; Huang, G.Q. Big Data Analytics for Physical Internet-based intelligent manufacturing shop floors. Int. J. Prod. Res. 2017, 55, 2610–2621. [Google Scholar] [CrossRef]

- Zhuang, C.; Liu, J.; Xiong, H. Digital twin-based smart production management and control framework for the complex product assembly shop-floor. Int. J. Adv. Manuf. Technol. 2018, 96, 1149–1163. [Google Scholar] [CrossRef]

- Chen, W. Intelligent manufacturing production line data monitoring system for industrial internet of things. Comput. Commun. 2020, 151, 31–41. [Google Scholar] [CrossRef]

- Qu, T.; Thürer, M.; Wang, J.; Wang, Z.; Fu, H.; Li, C.; Huang, G.Q. System dynamics analysis for an Internet-of-Things-enabled production logistics system. Int. J. Prod. Res. 2017, 55, 2622–2649. [Google Scholar] [CrossRef]

- Ding, K.; Chan, F.T.; Zhang, X.; Zhou, G.; Zhang, F. Defining a Digital Twin-based Cyber-Physical Production System for autonomous manufacturing in smart shop floors. Int. J. Prod. Res. 2019, 57, 6315–6334. [Google Scholar] [CrossRef]

- Dai, H.-N.; Wang, H.; Xu, G.; Wan, J.; Imran, M. Big data analytics for manufacturing internet of things: Opportunities, challenges and enabling technologies. Enterp. Inf. Syst. 2020, 14, 1279–1303. [Google Scholar] [CrossRef]

- Chung, K.; Yoo, H.; Choe, D.; Jung, H. Blockchain Network Based Topic Mining Process for Cognitive Manufacturing. Wirel. Pers. Commun. 2019, 105, 583–597. [Google Scholar] [CrossRef]

- Chang, H. Performance evaluation framework design for smart sensor business. J. Supercomput. 2017, 74, 4481–4496. [Google Scholar] [CrossRef]

- Bortolini, M.; Ferrari, E.; Gamberi, M.; Pilati, F.; Faccio, M. Assembly system design in the Industry 4.0 era: A general framework. IFAC-PapersOnLine 2017, 50, 5700–5705. [Google Scholar] [CrossRef]

- Trappey, A.J.C.; Trappey, C.V.; Fan, C.-Y.; Hsu, A.P.T.; Li, X.-K.; Lee, I.J.Y. IoT patent roadmap for smart logistic service provision in the context of Industry 4.0. J. Chin. Inst. Eng. 2017, 40, 593–602. [Google Scholar] [CrossRef]

- Sicari, S.; Rizzardi, A.; Coen-Porisini, A. How to evaluate an Internet of Things system: Models, case studies, and real developments. Software: Pract. Exp. 2019, 49, 1663–1685. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q. New IT Driven Service-Oriented Smart Manufacturing: Framework and Characteristics. IEEE Trans. Syst. Man Cybern. Syst. 2017, 49, 81–91. [Google Scholar] [CrossRef]

- Lyu, Z.; Lin, P.; Guo, D.; Huang, G.Q. Towards Zero-Warehousing Smart Manufacturing from Zero-Inventory Just-In-Time production. Robot. Comput. Manuf. 2020, 64, 101932. [Google Scholar] [CrossRef]

- De Sousa Jabbour, A.B.L.; Jabbour, C.J.C.; Godinho-Filho, M.; Roubaud, D. Industry 4.0 and the circular economy: A proposed research agenda and original roadmap for sustainable operations. Ann. Oper. Res. 2018, 270, 273–286. [Google Scholar] [CrossRef]

- Mehmood, Y.; Marwat, S.N.K.; Kuladinithi, K.; Förster, A.; Zaki, Y.; Görg, C.; Timm-Giel, A. M2M Potentials in logistics and transportation industry. Logist. Res. 2016, 9, 15. [Google Scholar] [CrossRef][Green Version]

- Kolberg, D.; Knobloch, J.; Zühlke, D. Towards a lean automation interface for workstations. Int. J. Prod. Res. 2017, 55, 2845–2856. [Google Scholar] [CrossRef]

- Li, X.; Li, D.; Wan, J.; Vasilakos, A.V.; Lai, C.-F.; Wang, S. A review of industrial wireless networks in the context of Industry 4.0. Wirel. Netw. 2017, 23, 23–41. [Google Scholar] [CrossRef]

- Dotoli, M.; Fay, A.; Miśkowicz, M.; Seatzu, C. An overview of current technologies and emerging trends in factory automation. Int. J. Prod. Res. 2019, 57, 5047–5067. [Google Scholar] [CrossRef]

- Egger, J.; Masood, T. Augmented reality in support of intelligent manufacturing—A systematic literature review. Comput. Ind. Eng. 2020, 140, 106195. [Google Scholar] [CrossRef]

- Al-Jaroodi, J.; Mohamed, N.; Jawhar, I. A service-oriented middleware framework for manufacturing industry 4.0. ACM SIGBED Rev. 2018, 15, 29–36. [Google Scholar] [CrossRef]

- Kovalenko, I.; Saez, M.; Barton, K.; Tilbury, D. SMART: A System-Level Manufacturing and Automation Research Testbed. Smart Sustain. Manuf. Syst. 2017, 1, 20170006. [Google Scholar] [CrossRef]

- Kembro, J.H.; Danielsson, V.; Smajli, G. Network video technology: Exploring an innovative approach to improving warehouse operations. Int. J. Phys. Distrib. Logist. Manag. 2017, 47, 623–645. [Google Scholar] [CrossRef]

- Tu, M.; Lim, M.K.; Yang, M.F. IoT-based production logistics and supply chain system—Part 2 IoT-based cyber-physical system: A framework and evaluation. Ind. Manag. Data Syst. 2018, 118, 96–125. [Google Scholar] [CrossRef]

- Mahmud, B. Internet of things (IoT) for manufacturing logistics on SAP ERP applications. J. Telecommun. Electron. Comput. Eng. 2017, 9, 43–47. [Google Scholar]

- Kant, K.; Pal, A. Internet of Perishable Logistics. IEEE Internet Comput. 2017, 21, 22–31. [Google Scholar] [CrossRef]

- Meng, Z.; Wu, Z.; Gray, J. RFID-Based Object-Centric Data Management Framework for Smart Manufacturing Applications. IEEE Internet Things J. 2019, 6, 2706–2716. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, X.; Liu, A.; Lu, Q.; Xu, L.; Tao, F. Blockchain-Based Trust Mechanism for IoT-Based Smart Manufacturing System. IEEE Trans. Comput. Soc. Syst. 2019, 6, 1386–1394. [Google Scholar] [CrossRef]

- Hao, Y.; Helo, P. The role of wearable devices in meeting the needs of cloud manufacturing: A case study. Robot. Comput. Manuf. 2017, 45, 168–179. [Google Scholar] [CrossRef]

- Trentesaux, D.; Borangiu, T.; Thomas, A. Emerging ICT concepts for smart, safe and sustainable industrial systems. Comput. Ind. 2016, 81, 1–10. [Google Scholar] [CrossRef]

- Costanzo, M.; De Maria, G.; Lettera, G.; Natale, C.; Pirozzi, S. Motion Planning and Reactive Control Algorithms for Object Manipulation in Uncertain Conditions. Robotics 2018, 7, 76. [Google Scholar] [CrossRef]

- Culler, D.; Long, J. A Prototype Smart Materials Warehouse Application Implemented Using Custom Mobile Robots and Open Source Vision Technology Developed Using EmguCV. Procedia Manuf. 2016, 5, 1092–1106. [Google Scholar] [CrossRef]

- Liao, Y.; Panetto, H.; Stadzisz, P.C.; Simão, J.M. A notification-oriented solution for data-intensive enterprise information systems—A cloud manufacturing case. Enterp. Inf. Syst. 2018, 12, 942–959. [Google Scholar] [CrossRef]

- Stark, R.; Fresemann, C.; Lindow, K. Development and operation of Digital Twins for technical systems and services. CIRP Ann. 2019, 68, 129–132. [Google Scholar] [CrossRef]

- Mueller, E.; Chen, X.-L.; Riedel, R. Challenges and Requirements for the Application of Industry 4.0: A Special Insight with the Usage of Cyber-Physical System. Chin. J. Mech. Eng. 2017, 30, 1050–1057. [Google Scholar] [CrossRef]

- Wang, X.; Yew, A.; Ong, S.; Nee, A. Enhancing smart shop floor management with ubiquitous augmented reality. Int. J. Prod. Res. 2019, 58, 2352–2367. [Google Scholar] [CrossRef]

- Masood, T.; Egger, J. Augmented reality in support of Industry 4.0—Implementation challenges and success factors. Robot. Comput. Manuf. 2019, 58, 181–195. [Google Scholar] [CrossRef]

- Leung, K.; Choy, K.; Siu, P.K.; Ho, G.; Lam, H.; Lee, C.K. A B2C e-commerce intelligent system for re-engineering the e-order fulfilment process. Expert Syst. Appl. 2018, 91, 386–401. [Google Scholar] [CrossRef]

- Wahrmann, D.; Hildebrandt, A.-C.; Schuetz, C.; Wittmann, R.; Rixen, D. An Autonomous and Flexible Robotic Framework for Logistics Applications. J. Intell. Robot. Syst. 2017, 93, 419–431. [Google Scholar] [CrossRef]

- Schuhmacher, J.; Baumung, W.; Hummel, V. An Intelligent Bin System for Decentrally Controlled Intralogistic Systems in Context of Industrie 4.0. Procedia Manuf. 2017, 9, 135–142. [Google Scholar] [CrossRef]

- Huang, B.; Wang, W.; Ren, S.; Zhong, R.Y.; Jiang, J. A proactive task dispatching method based on future bottleneck prediction for the smart factory. Int. J. Comput. Integr. Manuf. 2019, 32, 278–293. [Google Scholar] [CrossRef]

- Hohmann, C.; Posselt, T. Design challenges for CPS-based service systems in industrial production and logistics. Int. J. Comput. Integr. Manuf. 2018, 32, 329–339. [Google Scholar] [CrossRef]

- Leng, J.; Zhang, H.; Yan, D.; Liu, Q.; Chen, X.; Zhang, D. Digital twin-driven manufacturing cyber-physical system for parallel controlling of smart workshop. J. Ambient. Intell. Humaniz. Comput. 2019, 10, 1155–1166. [Google Scholar] [CrossRef]

- Liu, B.; Zhang, Y.; Zhang, G.; Zheng, P. Edge-cloud orchestration driven industrial smart product-service systems solution design based on CPS and IIoT. Adv. Eng. Inform. 2019, 42, 100984. [Google Scholar] [CrossRef]

- Li, G.; Zeng, B.; Liao, W.; Li, X.; Gao, L. A new AGV scheduling algorithm based on harmony search for material transfer in a real-world manufacturing system. Adv. Mech. Eng. 2018, 10. [Google Scholar] [CrossRef]

- Küsters, D.; Praß, N.; Gloy, Y.-S. Textile Learning Factory 4.0—Preparing Germany’s Textile Industry for the Digital Future. Procedia Manuf. 2017, 9, 214–221. [Google Scholar] [CrossRef]

- Lu, S.; Xu, C.; Zhong, R.Y.; Wang, L. A RFID-enabled positioning system in automated guided vehicle for smart factories. J. Manuf. Syst. 2017, 44, 179–190. [Google Scholar] [CrossRef]

- Madsen, O.; Møller, C. The AAU Smart Production Laboratory for Teaching and Research in Emerging Digital Manufacturing Technologies. Procedia Manuf. 2017, 9, 106–112. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing Smart Factory of Industrie 4.0: An Outlook. Int. J. Distrib. Sens. Netw. 2016, 12. [Google Scholar] [CrossRef]

- Wan, J.; Chen, B.; Imran, M.; Tao, F.; Li, D.; Liu, C.; Ahmad, S. Toward dynamic resources management for IoT-based manufacturing. IEEE Commun. Mag. 2018, 56, 52–59. [Google Scholar] [CrossRef]

- Tang, D.; Zheng, K.; Zhang, H.; Zhang, Z.; Sang, Z.; Zhang, T.; Espinosa-Oviedo, J.-A.; Vargas-Solar, G. Using autonomous intelligence to build a smart shop floor. Int. J. Adv. Manuf. Technol. 2017, 94, 1597–1606. [Google Scholar] [CrossRef]

- Rojko, A. Industry 4.0 Concept: Background and Overview. Int. J. Interact. Mob. Technol. 2017, 11, 77–90. [Google Scholar] [CrossRef]

- Yan, H.; Hua, Q.; Wang, Y.; Wei, W.; Imran, M. Cloud robotics in Smart Manufacturing Environments: Challenges and countermeasures. Comput. Electr. Eng. 2017, 63, 56–65. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, Z.; Lv, J. CPS-Based Smart Control Model for Shopfloor Material Handling. IEEE Trans. Ind. Inform. 2018, 14, 1764–1775. [Google Scholar] [CrossRef]

- Da Silva, V.L.; Kovaleski, J.L.; Pagani, R.N. Technology transfer in the supply chain oriented to industry 4.0: A literature review. Technol. Anal. Strat. Manag. 2018, 31, 546–562. [Google Scholar] [CrossRef]

- Chen, G.; Wang, P.; Feng, B.; Li, Y.; Liu, D. The framework design of smart factory in discrete manufacturing industry based on cyber-physical system. Int. J. Comput. Integr. Manuf. 2019, 33, 79–101. [Google Scholar] [CrossRef]

- Cadavid, J.P.U.; Lamouri, S.; Grabot, B.; Pellerin, R.; Fortin, A. Machine learning applied in production planning and control: A state-of-the-art in the era of industry 4.0. J. Intell. Manuf. 2020, 31, 1531–1558. [Google Scholar] [CrossRef]

- Suginouchi, S.; Kokuryo, D.; Kaihara, T. Value Co-creative Manufacturing System for Mass Customization: Concept of Smart Factory and Operation Method Using Autonomous Negotiation Mechanism. Procedia CIRP 2017, 63, 727–732. [Google Scholar] [CrossRef]

- Gröhn, L.; Metsälä, S.; Nyholm, M.; Saikko, L.; Väänänen, E.; Gulzar, K.; Vyatkin, V. Manufacturing System Upgrade with Wireless and Distributed Automation. Procedia Manuf. 2017, 11, 1012–1018. [Google Scholar] [CrossRef]

- Szafir, D.; Mutlu, B.; Fong, T. Designing planning and control interfaces to support user collaboration with flying robots. Int. J. Robot. Res. 2017, 36, 514–542. [Google Scholar] [CrossRef]

- Semwal, T.; Jha, S.S.; Nair, S.B. On Ordering Multi-Robot Task Executions within a Cyber Physical System. ACM Trans. Auton. Adapt. Syst. 2018, 12, 1–27. [Google Scholar] [CrossRef]

- Cheng, J.; Chen, W.; Tao, F.; Lin, C.-L. Industrial IoT in 5G environment towards smart manufacturing. J. Ind. Inf. Integr. 2018, 10, 10–19. [Google Scholar] [CrossRef]

- Damiani, L.; Demartini, M.; Guizzi, G.; Revetria, R.; Tonelli, F. Augmented and virtual reality applications in industrial systems: A qualitative review towards the industry 4.0 era. IFAC PapersOnLine 2018, 51, 624–630. [Google Scholar] [CrossRef]

- Avventuroso, G.; Silvestri, M.; Pedrazzoli, P. A Networked Production System to Implement Virtual Enterprise and Product Lifecycle Information Loops. IFAC-PapersOnLine 2017, 50, 7964–7969. [Google Scholar] [CrossRef]

- Zhong, X.; Xu, R.Y.; Wang, L. IoT-enabled Smart Factory Visibility and Traceability Using Laser-scanners. Procedia Manuf. 2017, 10, 1–14. [Google Scholar] [CrossRef]

- Závadská, Z.; Závadský, J. Quality managers and their future technological expectations related to Industry 4.0. Total. Qual. Manag. Bus. Excel. 2018, 31, 717–741. [Google Scholar] [CrossRef]

- Guo, D.; Zhong, R.Y.; Lin, P.; Lyu, Z.; Rong, Y.; Huang, G.Q. Digital twin-enabled Graduation Intelligent Manufacturing System for fixed-position assembly islands. Robot. Comput. Manuf. 2020, 63, 101917. [Google Scholar] [CrossRef]

- Zhang, K.; Wan, M.; Qu, T.; Jiang, H.; Li, P.; Chen, Z.; Xiang, J.; He, X.; Li, C.; Huang, G.Q. Production service system enabled by cloud-based smart resource hierarchy for a highly dynamic synchronized production process. Adv. Eng. Inform. 2019, 42, 100995. [Google Scholar] [CrossRef]

- Zheng, P.; Lin, Y.; Chen, C.-H.; Xu, X. Smart, connected open architecture product: An IT-driven co-creation paradigm with lifecycle personalization concerns. Int. J. Prod. Res. 2018, 57, 2571–2584. [Google Scholar] [CrossRef]

- Zhang, K.; Qu, T.; Zhou, D.; Thürer, M.; Liu, Y.; Nie, D.; Li, C.; Huang, G.Q. IoT-enabled dynamic lean control mechanism for typical production systems. J. Ambient Intell. Humaniz. Comput. 2019, 10, 1009–1023. [Google Scholar] [CrossRef]

- Yang, H.; Kumara, S.; Bukkapatnam, S.T.; Tsung, F. The internet of things for smart manufacturing: A review. IISE Trans. 2019, 51, 1190–1216. [Google Scholar] [CrossRef]

- Priya, B.; Malhotra, J. 5GAuNetS: An autonomous 5G network selection framework for Industry 4.0. Soft Comput. 2020, 24, 9507–9523. [Google Scholar] [CrossRef]

- Mahroof, K. A human-centric perspective exploring the readiness towards smart warehousing: The case of a large retail distribution warehouse. Int. J. Inf. Manag. 2019, 45, 176–190. [Google Scholar] [CrossRef]

- Hopkins, J.; Hawking, P. Big Data Analytics and IoT in logistics: A case study. Int. J. Logist. Manag. 2018, 29, 575–591. [Google Scholar] [CrossRef]

- Li, J.-Q.; Yu, F.R.; Deng, G.; Luo, C.; Ming, Z.; Yan, Q. Industrial Internet: A Survey on the Enabling Technologies, Applications, and Challenges. IEEE Commun. Surv. Tutorials 2017, 19, 1504–1526. [Google Scholar] [CrossRef]

- Feng, J.; Li, F.; Xu, C.; Zhong, R.Y. Data-Driven Analysis for RFID-Enabled Smart Factory: A Case Study. IEEE Trans. Syst. Man, Cybern. Syst. 2018, 50, 81–88. [Google Scholar] [CrossRef]

- Ding, K.; Jiang, P. RFID-based production data analysis in an IoT-enabled smart job-shop. IEEE/CAA J. Autom. Sin. 2018, 5, 128–138. [Google Scholar] [CrossRef]

- Zhou, W.; Piramuthu, S.; Chu, F.; Chu, C. RFID-enabled flexible warehousing. Decis. Support Syst. 2017, 98, 99–112. [Google Scholar] [CrossRef]

- Kim, J.-Y.; Park, D.-J. Internet-of-Things Based Approach for Warehouse Management System. Int. J. Multimedia Ubiquitous Eng. 2016, 11, 159–166. [Google Scholar] [CrossRef]

- Franceschini, F.; Galetto, M.; Maisano, L.; Mastrogiacomo, D. Towards the use 20 of augmented reality techniques for assisted acceptance sampling. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 230, 1870–1884. [Google Scholar] [CrossRef]

- Sarupuri, B.; Lee, G.A.; Billinghurst, M. Using augmented reality to assist forklift operation. In Proceedings of the 28th Australian Conference on Computer-Human Interaction—OzCHI ’16, Launceston, Tasmania, 29 November–2 December 2016; pp. 16–24. [Google Scholar]

- Mättig, B.; Lorimer, I.; Kirks, T.; Jost, J. Analysis of the application of Augmented Reality in the packaging process considering specific requirements on the visualization of information as well as the ergonomic integration of humans into the process. Logist. J. Proc. 2016, 2016. [Google Scholar]

- Gregor, M.; Medvecky, S.; Grznar, P.; Gregor, T. Smart Industry Requires Fast Response from Research to Innovation. Commun. Sci. Lett. Univ. Zilina 2017, 19, 68–73. [Google Scholar]

- Mueller, R.; Vette, M.; Hoerauf, L.; Speicher, C.; Burkhard, D. Lean information and communication tool to connect shop and top floor in small and medium-sized enterprises. In Proceedings of the 27th International Conference on Flexible Automation and Intelligent Manufacturing, Modena, Italy, 27–30 June 2017; Volume 11, pp. 1043–1052. [Google Scholar]

- Lee, J.; Davari, H.; Singh, J.; Pandhare, V. Industrial Artificial Intelligence for industry 4.0-based manufacturing systems. Manuf. Lett. 2018, 18, 20–23. [Google Scholar] [CrossRef]

- Ramakrishnan, R.; Gaur, L.; Singh, G. Feasibility and Efficacy of BLE Beacon IoT Devices in Inventory Management at the Shop Floor. Int. J. Electr. Comput. Eng. (IJECE) 2016, 6, 2362. [Google Scholar] [CrossRef]

- Zhang, J.; Ding, G.; Zou, Y.; Qin, S.; Fu, J. Review of job shop scheduling research and its new perspectives under Industry 4.0. J. Intell. Manuf. 2019, 30, 1809–1830. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital Twin in Industry: State-of-the-Art. IEEE Trans. Ind. Inform. 2019, 15, 2405–2415. [Google Scholar] [CrossRef]

- Qu, T.; Lei, S.P.; Wang, Z.Z.; Nie, D.X.; Chen, X.; Huang, G.Q. IoT-based real-time production logistics synchronization system under smart cloud manufacturing. Int. J. Adv. Manuf. Technol. 2016, 84, 147–164. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, S.; Liu, Y.; Li, R. Smart box-enabled product–service system for cloud logistics. Int. J. Prod. Res. 2016, 54, 6693–6706. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, W.; Du, W.; Qian, C.; Yang, H. Coloured Petri net-based active sensing system of real-time and multi-source manufacturing information for smart factory. Int. J. Adv. Manuf. Technol. 2017, 94, 3427–3439. [Google Scholar] [CrossRef]

- Qu, Y.J.; Ming, X.G.; Liu, Z.W.; Zhang, X.Y.; Hou, Z.T. Smart manufacturing systems: State of the art and future trends. Int. J. Adv. Manuf. Technol. 2019, 103, 3751–3768. [Google Scholar] [CrossRef]

- Wilkesmann, M.; Wilkesmann, U. Industry 4.0—Organizing routines or innovations? VINE J. Inf. Knowl. Manag. Syst. 2018, 48, 238–254. [Google Scholar] [CrossRef]

- Ding, K.; Lei, J.; Chan, F.T.; Hui, J.; Zhang, F.; Wang, Y. Hidden Markov model-based autonomous manufacturing task orchestration in smart shop floors. Robot. Comput. Manuf. 2020, 61, 101845. [Google Scholar] [CrossRef]

- Pujo, P.; Ounnar, F.; Power, D.; Khader, S. Wireless Holon Network for job shop isoarchic control. Comput. Ind. 2016, 83, 12–27. [Google Scholar] [CrossRef]

- Lin, C.-C.; Yang, J.-W. Cost-Efficient Deployment of Fog Computing Systems at Logistics Centers in Industry 4.0. IEEE Trans. Ind. Inform. 2018, 14, 4603–4611. [Google Scholar] [CrossRef]

- Zulkifli, C.Z.; Semunab, S.N.; Ibrahim, A.B.; Noor, N.M. Implementation of Wireless Mobile Rfid Reader in Real World Industry Environment. J. Teknol. 2016, 78, 74–82. [Google Scholar] [CrossRef][Green Version]

- Leusin, M.E.; Kück, M.; Frazzon, E.M.; Maldonado, M.U.; Freitag, M. Potential of a Multi-Agent System Approach for Production Control in Smart Factories. IFAC-PapersOnLine 2018, 51, 1459–1464. [Google Scholar] [CrossRef]

- Cui, Y.; Kara, S.; Chan, K.C. Manufacturing big data ecosystem: A systematic literature review. Robot. Comput. Manuf. 2020, 62, 101861. [Google Scholar] [CrossRef]

- Turner, C.J.; Hutabarat, W.; Oyekan, J.; Tiwari, A. Discrete Event Simulation and Virtual Reality Use in Industry: New Opportunities and Future Trends. IEEE Trans. Human-Machine Syst. 2016, 46, 882–894. [Google Scholar] [CrossRef]

- Ren, S.; Zhang, Y.; Liu, Y.; Sakao, T.; Huisingh, D.; Almeida, C.M.V.B. A comprehensive review of big data analytics throughout product lifecycle to support sustainable smart manufacturing: A framework, challenges and future research directions. J. Clean. Prod. 2019, 210, 1343–1365. [Google Scholar] [CrossRef]

- Hwang, G.; Lee, J.; Park, J.; Chang, T.-W. Developing performance measurement system for Internet of Things and smart factory environment. Int. J. Prod. Res. 2017, 55, 2590–2602. [Google Scholar] [CrossRef]

- Hwang, S. A network clock model for time awareness in the Internet of things and artificial intelligence applications. J. Supercomput. 2019, 75, 4309–4328. [Google Scholar] [CrossRef]

- Yu, Q. Design of Logistics Tracking and Monitoring System Based on Internet of Things. J. Residuals Sci. Technol. 2016, 13, 43.1–43.4. [Google Scholar]

- Yi, Y.; Yan, Y.; Liu, X.; Ni, Z.; Feng, J.; Liu, J. Digital twin-based smart assembly process design and application framework for complex products and its case study. J. Manuf. Syst. 2021, 58, 94–107. [Google Scholar] [CrossRef]

- Kamagaew, A.; Stenzel, J.; Nettstrater, A.; Hompel, M.T. Concept of Cellular Transport Systems in facility logistics. In Proceedings of the The 5th International Conference on Automation, Robotics and Applications, Wellington, New Zealand, 6–8 December 2011; pp. 40–45. [Google Scholar]

- Gilchrist, A. Industry 4.0, 1st ed.; O’Reilly Safari Learning Platform: Academic Edition; Apress: New York, NY, USA, 2016. [Google Scholar]

- Cheng, Y.; Zhang, Y.; Ji, P.; Xu, W.; Zhou, Z.; Tao, F. Cyber-physical integration for moving digital factories forward towards smart manufacturing: A survey. Int. J. Adv. Manuf. Technol. 2018, 97, 1209–1221. [Google Scholar] [CrossRef]

- Kim, J.; Tang, K.; Kumara, S.; Yee, S.T.; Tew, J. Value analysis of location-enabled radio-frequency identification information on delivery chain performance. Int. J. Prod. Econ. 2008, 112, 403–415. [Google Scholar] [CrossRef]

- Yang, M.; Mahmood, M.; Zhou, X.; Shafaq, S.; Zahid, L. Design and Implementation of Cloud Platform for Intelligent Logistics in the Trend of Intellectualization. China Commun. 2017, 14, 180–191. [Google Scholar] [CrossRef]

- Trappey, A.J.; Trappey, C.V.; Wu, J.-L.; Wang, J.W. Intelligent compilation of patent summaries using machine learning and natural language processing techniques. Adv. Eng. Inform. 2020, 43, 101027. [Google Scholar] [CrossRef]

- Liu, Y.; Tong, K.; Mao, F.; Yang, J. Research on digital production technology for traditional manufacturing enterprises based on industrial Internet of Things in 5G era. Int. J. Adv. Manuf. Technol. 2020, 107, 1101–1114. [Google Scholar] [CrossRef]

- Meroni, G.; Baresi, L.; Montali, M.; Plebani, P. Multi-party business process compliance monitoring through IoT-enabled artifacts. Inf. Syst. 2018, 73, 61–78. [Google Scholar] [CrossRef]

- Westerkamp, M.; Victor, F.; Küpper, A. Tracing manufacturing processes using blockchain-based token compositions. Digit. Commun. Netw. 2020, 6, 167–176. [Google Scholar] [CrossRef]

- Wigger, B.; Meissner, T.; Winkler, M.; Foerste, A.; Jetter, V.; Buchholz, A.; Zimmermann, A. Label-/tag-free traceability of electronic PCB in SMD assembly based on individual inherent surface patterns. Int. J. Adv. Manuf. Technol. 2018, 98, 3081–3090. [Google Scholar] [CrossRef]

- Wigger, B.; Koinzer, I.; Meissner, T.; Barth, M.; Zimmermann, A. Robust and fast part traceability in a production chain exploiting inherent, individual surface patterns. Robot. Comput. Manuf. 2020, 63, 101925. [Google Scholar] [CrossRef]

- Rajagopalan, A.K.; Shyamala, C. A lightweight inter-zonal authentication protocol for moving objects in low powered RF systems. J. Intell. Fuzzy Syst. 2019, 36, 2345–2354. [Google Scholar] [CrossRef]

- Tu, M.; Lim, M.K.; Yang, M.F. IoT-based production logistics and supply chain system—Part 1 modeling IoT-based manufacturing IoT supply chain. Ind. Manag. Data Syst. 2018, 118, 65–95. [Google Scholar] [CrossRef]

- Li, S.; Da Xu, L.; Zhao, S. The internet of things: A survey. Inf. Syst. Front. 2015, 17, 243–259. [Google Scholar] [CrossRef]

- Cannizzaro, D.; Zafiri, M.; Pagliari, D.J.; Patti, E.; Macii, E.; Poncino, M.; Acquaviva, A. A Comparison Analysis of BLE-Based Algorithms for Localization in Industrial Environments. Electronics 2019, 9, 44. [Google Scholar] [CrossRef]

- Cheffena, M. Industrial wireless communications over the millimeter wave spectrum: Opportunities and challenges. IEEE Commun. Mag. 2016, 54, 66–72. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, C.; Wang, K.I.-K.; Huang, H.; Xu, X. Digital Twin-driven smart manufacturing: Connotation, reference model, applications and research issues. Robot. Comput. Manuf. 2020, 61, 101837. [Google Scholar] [CrossRef]

- Kurniadi, K.A.; Ryu, K. Development of IOT-based Reconfigurable Manufacturing System to solve Reconfiguration Planning Problem. Procedia Manuf. 2017, 11, 965–972. [Google Scholar] [CrossRef]

- Lai, J.; Luo, C.; Wu, J.; Li, J.; Wang, J.; Chen, J.; Feng, G.; Song, H. TagSort: Accurate Relative Localization Exploring RFID Phase Spectrum Matching for Internet of Things. IEEE Internet Things J. 2020, 7, 389–399. [Google Scholar] [CrossRef]

- Gurtu, A.; Johny, J. Potential of blockchain technology in supply chain management: A literature review. Int. J. Phys. Distrib. Logist. Manag. 2019, 49, 881–900. [Google Scholar] [CrossRef]

- Krishnamurthy, R.; Cecil, J. A next-generation IoT-based collaborative framework for electronics assembly. Int. J. Adv. Manuf. Technol. 2018, 96, 39–52. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q. IIHub: An Industrial Internet-of-Things Hub toward Smart Manufacturing Based on Cyber-Physical System. IEEE Trans. Ind. Inform. 2018, 14, 2271–2280. [Google Scholar] [CrossRef]

- La Scalia, G.; Settanni, L.; Micale, R.; Enea, M. Predictive shelf life model based on RF technology for improving the management of food supply chain: A case study. Int. J. RF Technol. Res. Appl. 2016, 7, 31–42. [Google Scholar] [CrossRef]

- Crnjac, M.; Veža, I.; Banduka, N. From concept to the introduction of industry 4.0. Int. J. Ind. Eng. Manag. 2017, 8, 21–30. [Google Scholar]

- Goudos, S.K.; Dallas, P.I.; Chatziefthymiou, S.; Kyriazakos, S.A. A Survey of IoT Key Enabling and Future Technologies: 5G, Mobile IoT, Sematic Web and Applications. Wirel. Pers. Commun. 2017, 97, 1645–1675. [Google Scholar] [CrossRef]

- De Felice, F.; Petrillo, A.; Zomparelli, F. Prospective design of smart manufacturing: An Italian pilot case study. Manuf. Lett. 2018, 15, 81–85. [Google Scholar] [CrossRef]

- Georgakopoulos, D.; Jayaraman, P.P. Internet of things: From internet scale sensing to smart services. Comput. 2016, 98, 1041–1058. [Google Scholar] [CrossRef]

- Diez-Olivan, A.; Del Ser, J.; Galar, D.; Sierra, B. Data fusion and machine learning for industrial prognosis: Trends and perspectives towards Industry 4.0. Inf. Fusion 2019, 50, 92–111. [Google Scholar] [CrossRef]

- Qiu, T.; Chen, N.; Li, K.; Atiquzzaman, M.; Zhao, W. How Can Heterogeneous Internet of Things Build Our Future: A Survey. IEEE Commun. Surv. Tutorials 2018, 20, 2011–2027. [Google Scholar] [CrossRef]

- Kousi, N.; Koukas, S.; Michalos, G.; Makris, S. Scheduling of smart intra—Factory material supply operations using mobile robots. Int. J. Prod. Res. 2018, 57, 801–814. [Google Scholar] [CrossRef]

- Cheng, Y.; Chen, K.; Sun, H.; Zhang, Y.; Tao, F. Data and knowledge mining with big data towards smart production. J. Ind. Inf. Integr. 2018, 9, 1–13. [Google Scholar] [CrossRef]

- Jeble, S.; Dubey, R.; Childe, S.J.; Papadopoulos, T.; Roubaud, D.; Prakash, A. Impact of big data and predictive analytics capability on supply chain sustainability. Int. J. Logist. Manag. 2018, 29, 513–538. [Google Scholar] [CrossRef]

| Inclusions | Exclusions | |

|---|---|---|

| Production logistics | Any research related to internal logistics of production or manufacturing companies. | City logistics, cargos, road transportations, machining, assembly, product development, retailing, production planning, product design, maintenance, housing construction. |

| Enabling technologies | Any relevant technologies that might enable data collection, data processing, data storage, data streaming and data analysis or data visualization. | Automation technologies such as introduction of robots that are only focused on physical aspects of the flow. |

| Production logistics activities | Any relevant activities such as kitting, route planning, warehousing, packaging, material movement, which is associated with enabling technologies | Mathematical modeling optimization and data security. |

| Technology Group | Technologies |

|---|---|

| Auto Identification | RFID (Radio Frequency Identification) |

| Barcode | |

| QR code | |

| FOT (Fingerprint of Things) and tag free traceability | |

| Vision systems and image processing | Vision systems |

| Point cloud | |

| Mobile and industrial robots | Industrial robots |

| Drones | |

| AGV and mobile robots | |

| Internet-of-Things/ Internet-of-Services | IoT |

| IoS | |

| RTLS (Real-Time Locating system) | |

| Node-RED | |

| Smart devices | AR (Augmented Reality) |

| VR (Virtual Reality) | |

| Pick by X (Voice or light) | |

| Smart glass | |

| Smart gloves | |

| Smart watches | |

| Tablet, mobile phone, etc. | |

| Artificial intelligence and Big data | BD analytics |

| AI | |

| Machine learning | |

| Apache Flume | |

| Apache Hadoop | |

| Apache Kafka | |

| MQTT | |

| Wireless connection and communication networks | Cellular networks (2G/3G/4G/5G) |

| Wireless connection | |

| Bluetooth | |

| Ultra sound | |

| Ultrawide band | |

| Wi-Fi | |

| ZigBee | |

| Industrial communication networks | |

| GPS (Global positioning system) | |

| Industrial wireless networks | |

| Sensor networks | |

| Cloud and Fog/Edge computing | Cloud computing |

| Fog/Edge computing | |

| Cyber physical systems and simulation | CPS |

| Digital twin | |

| Embedded systems | |

| Holonic manufacturing and Multi agent systems | |

| Simulation | |

| SoA (Service Oriented Architecture) | |

| Blockchain | |

| Production Logistics Activities | Described Technologies | References | ||

|---|---|---|---|---|

| Category 1. Shopfloor operational- related activities | Material ordering and buffer replenishment |

|

| [10,12,15,22,28,35,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60] |

| Goods receiving quality control and registration |

|

| [34,51,61,62,63,64,65,66,67] | |

| Kitting |

| [62] | ||

| Packaging |

|

| [10,14,36,62,68,69,70] | |

| Palletization |

| [62] | ||

| Picking and Pick and place |

|

| [10,14,62,65,69,71,72,73,74,75,76,77,78,79,80,81,82] | |

| Material transportation and internal transportation optimization |

|

| [12,13,15,34,40,62,71], [72,74,75,77,83,84,85,86,87,88,89,90,91,92,93,94,95,96,97,98,99,100,101,102,103] | |

| Warehousing |

|

| [10,14,27,28,43,45,46,49,50,51,52,53,58,62,63,68,71,73,74,75,79,91,98,103,104,105,106,107,108,109,110,111,112,113,114,115,116,117,118,119,120,121] | |

| Production Logistics Activities | Described Technologies | References | ||

|---|---|---|---|---|

| Category 2. Planning and scheduling- related activities | Logistics resource planning |

|

| [10,22,44,48,50,53,55,67,68,84,85,97,104,107,110,113,129,130,131] |

| Route planning |

|

| [10,12,13,49,61,67,74,83,84,115,119,129,131,132,133,134,135,136,137,138] | |

| Delivery planning and scheduling |

|

| [10,15,38,39,40,44,45,48,54,63,86,93,98,106,112,113,115,116,129,132,133,134,135,137,139,140] | |

| Workflow analysis |

|

| [40,44,53,65,83,85,119] | |

| Modeling and simulation |

|

| [48,72,141] | |

| Layout planning and optimization |

|

| [119,142] | |

| Production Logistics Activities | Described Technologies | References | ||

|---|---|---|---|---|

| Category 3. Control, track and trace related activities | Items identification |

|

| [12,14,15,19,27,37,43,46,47,48,49,52,54,58,65,67,69,75,84,90,91,98,104,107,109,119,120,121,131,132,140,154,155,156,157,158,159,160,161] |

| Items positioning (localization) |

|

| [10,12,15,19,37,43,46,48,54,58,64,67,69,72,74,75,82,83,84,86,89,98,104,107,109,111,114,119,121,132,140,141,150,159,161,162,163,164,165,166] | |

| Items tracing (flow) |

|

| [5,10,12,14,15,19,27,34,43,45,46,48,49,51,53,56,58,64,65,67,68,69,72,74,76,82,83,98,104,107,109,111,119,120,121,134,139,140,141,154,155,156,157,158,160,163,165,166,167,168,169,170,171,172] | |

| Inventory level controlling |

|

| [10,12,14,15,27,34,38,41,49,50,51,52,54,56,57,59,67,72,76,97,98,99,104,109,115,116,119,121,139,141,155,156,161,173,174,175,176,177] | |

| Items condition monitoring |

|

| [53,54,55,67,70,121,170] | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zafarzadeh, M.; Wiktorsson, M.; Baalsrud Hauge, J. A Systematic Review on Technologies for Data-Driven Production Logistics: Their Role from a Holistic and Value Creation Perspective. Logistics 2021, 5, 24. https://doi.org/10.3390/logistics5020024

Zafarzadeh M, Wiktorsson M, Baalsrud Hauge J. A Systematic Review on Technologies for Data-Driven Production Logistics: Their Role from a Holistic and Value Creation Perspective. Logistics. 2021; 5(2):24. https://doi.org/10.3390/logistics5020024

Chicago/Turabian StyleZafarzadeh, Masoud, Magnus Wiktorsson, and Jannicke Baalsrud Hauge. 2021. "A Systematic Review on Technologies for Data-Driven Production Logistics: Their Role from a Holistic and Value Creation Perspective" Logistics 5, no. 2: 24. https://doi.org/10.3390/logistics5020024

APA StyleZafarzadeh, M., Wiktorsson, M., & Baalsrud Hauge, J. (2021). A Systematic Review on Technologies for Data-Driven Production Logistics: Their Role from a Holistic and Value Creation Perspective. Logistics, 5(2), 24. https://doi.org/10.3390/logistics5020024