The Effect of Different Oak Products Used during Fermentation and Ageing on the Sensory Properties of a White Wine over Time

Abstract

1. Introduction

2. Materials and Methods

2.1. Grape Origin and Vinification Procedures

2.2. Wood Treatments

2.3. Wine Sampling and Storage

2.4. Sensory Evaluation

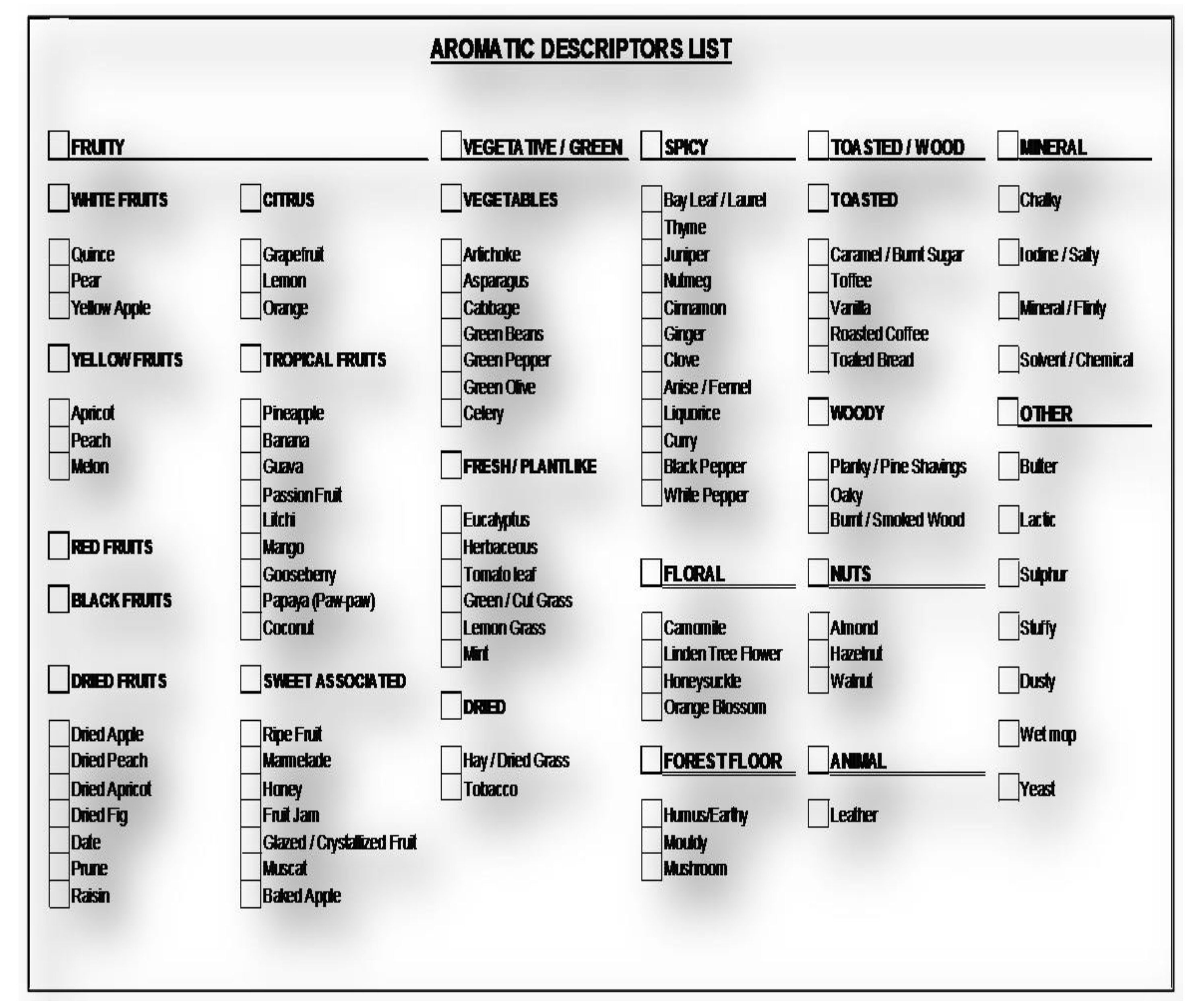

2.5. Pick-K-Attributes Using a Trained Panel

2.5.1. Panel

2.5.2. Panel Training

2.5.3. Evaluation

2.6. Statistical Analysis

3. Results and Discussion

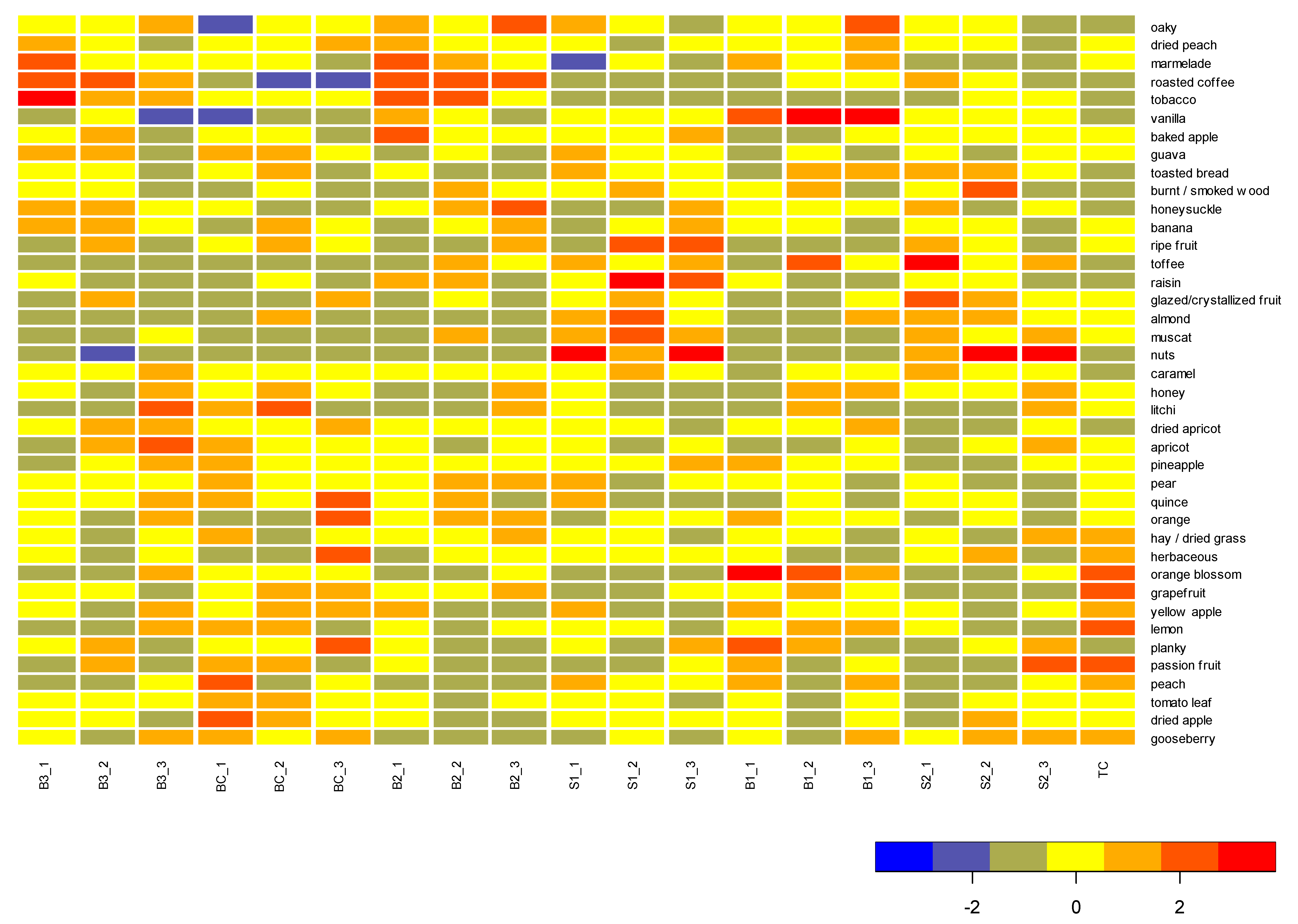

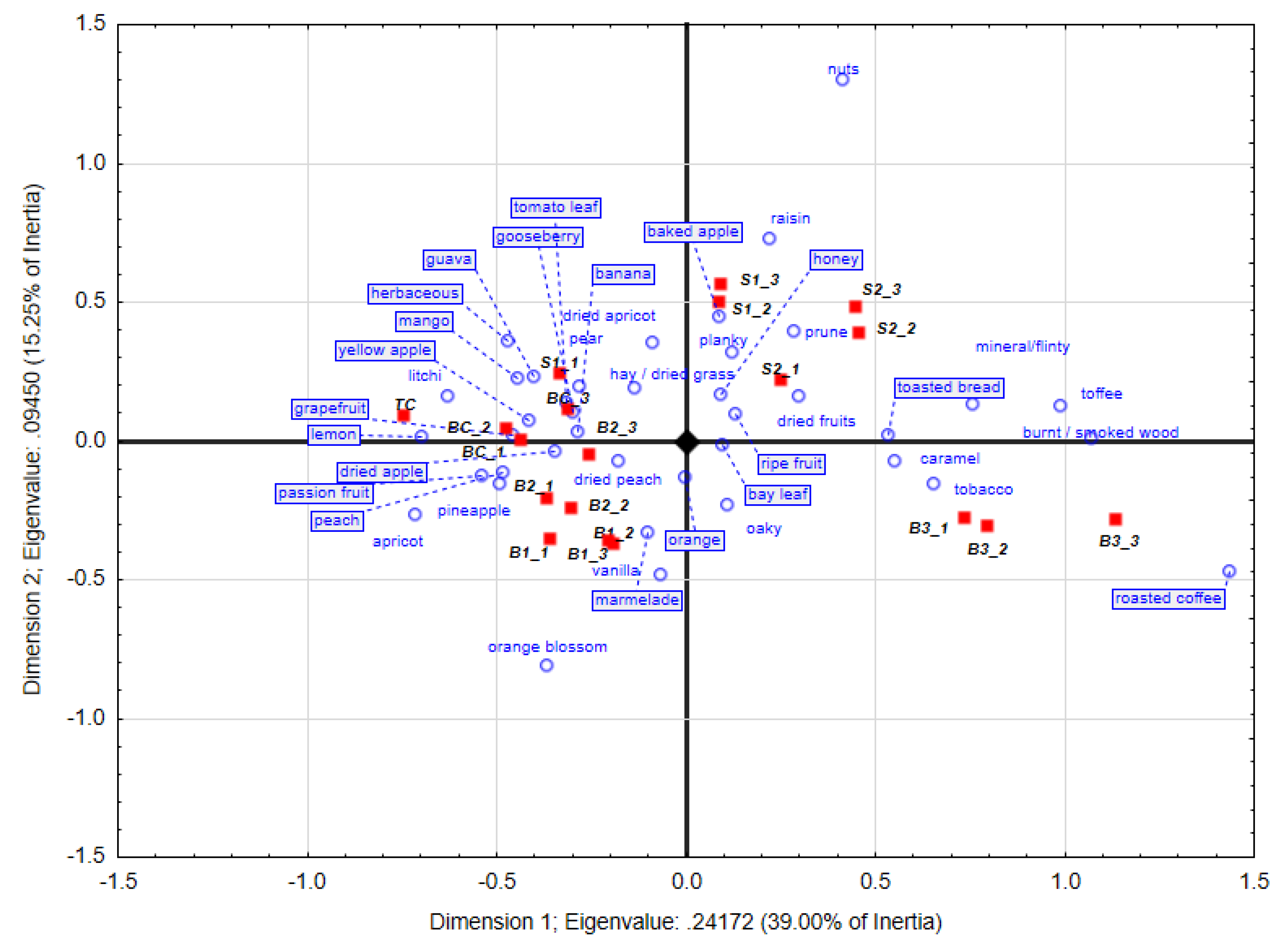

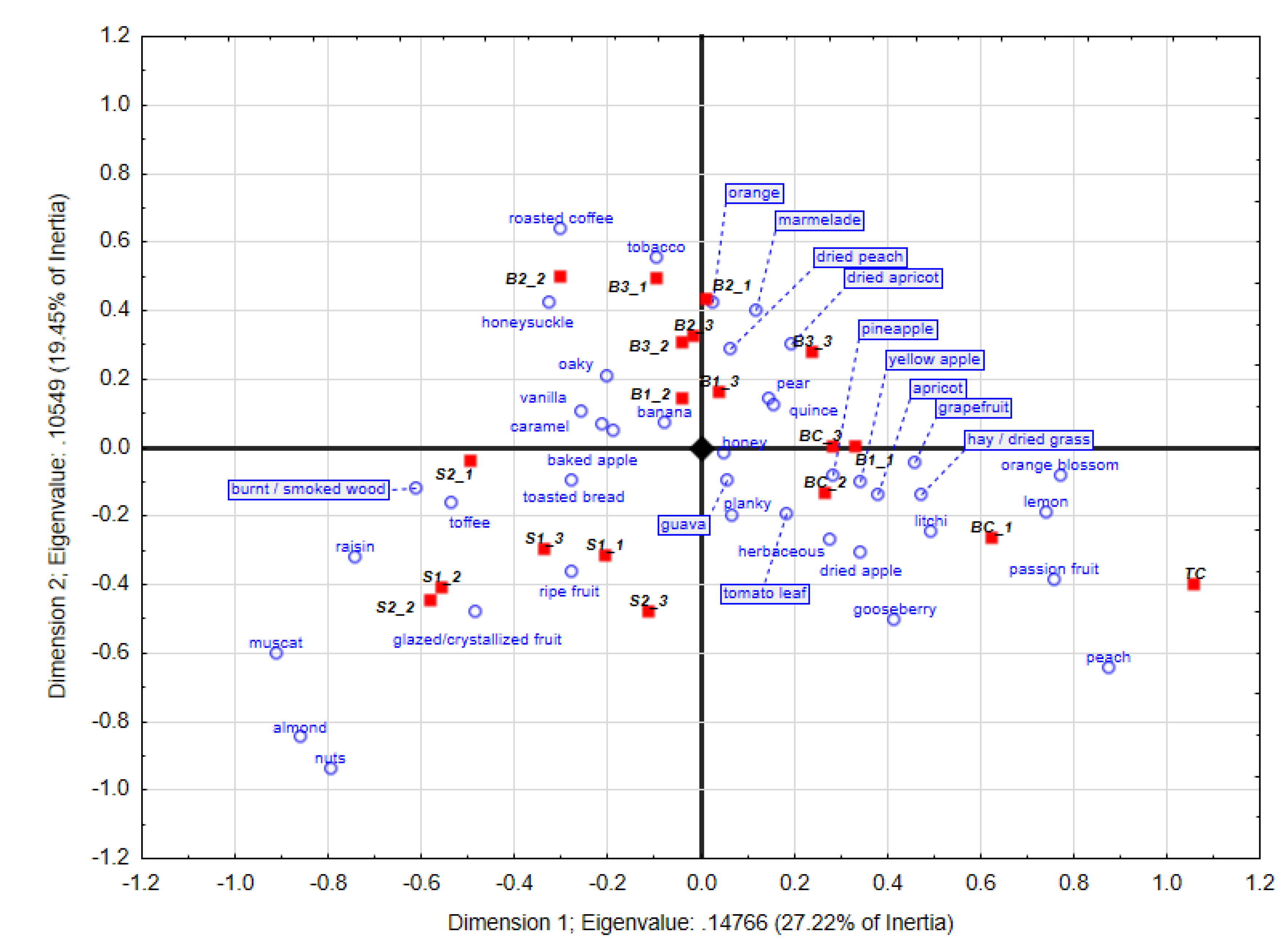

3.1. Chenin Blanc Wine’ s Sensory Profile after 4 Months Oak Maturation

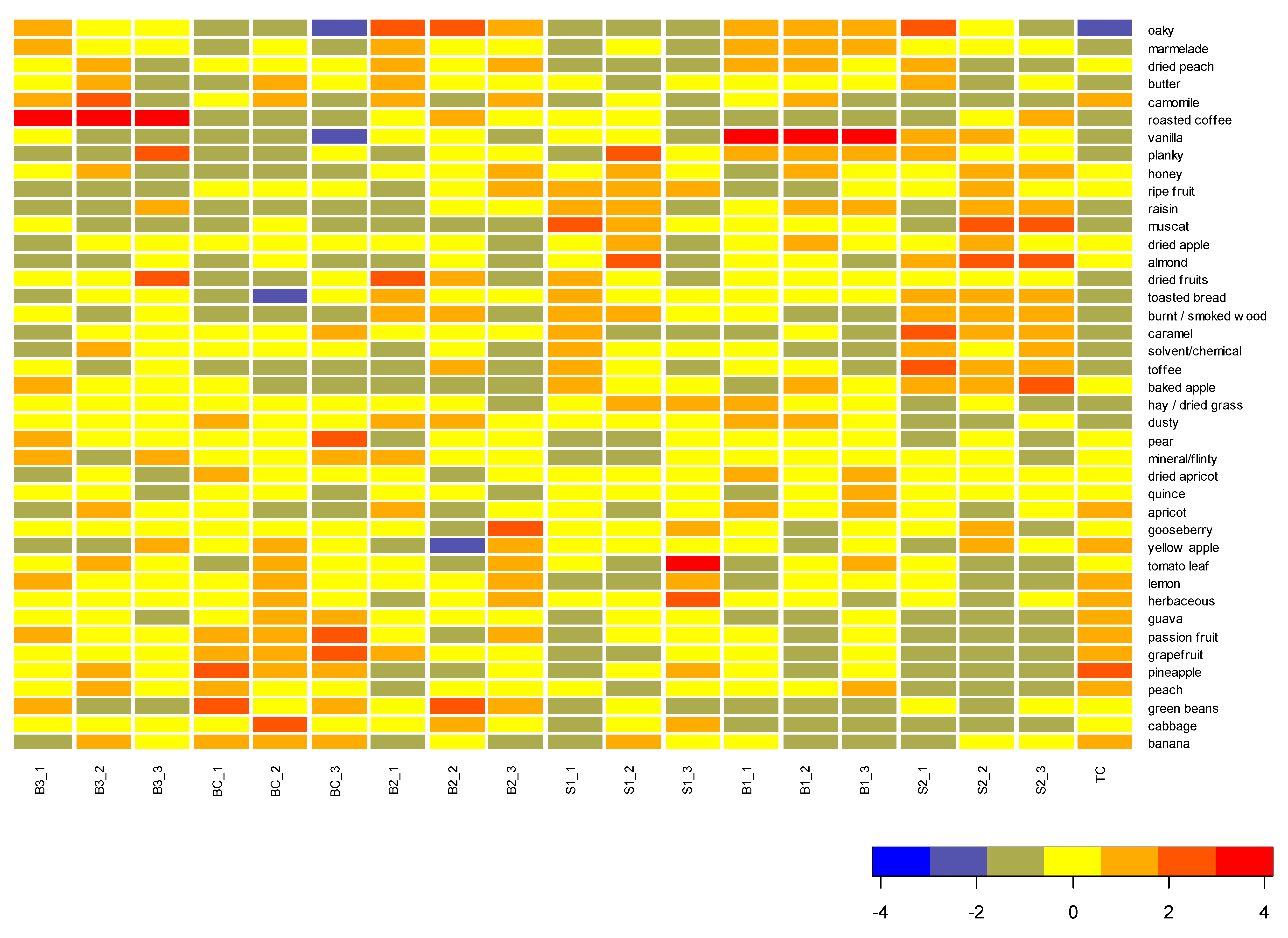

3.2. Chenin Blanc Wine’ s Sensory Profile after 9 Months Oak Maturation

3.3. Chenin Blanc Wine’ s Sensory Profile after 6 Months of Bottle Ageing

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Aroma Family | Sensory Attribute | Reference Standard Composition | Amount |

|---|---|---|---|

| Citrus | Lemon | Fresh lemon * | ¼ slice |

| Orange | Fresh orange * | ¼ slice | |

| Grapefruit | Fresh grapefruit * | ¼ slice | |

| White/Yellow fruit | Peach | Peach juice (Liquifruit) | 20 mL |

| Apricot | Apricot juice (Liquifruit) | 20 mL | |

| Melon | Fresh melon * | 1 cm3 piece | |

| Pear | Canned pear (Koo) | 2 × 3 cm piece | |

| Quince | Fresh quince * | 1 cm3 piece | |

| Yellow apple | Fresh apple (golden delicious) * | 1 cm wedge | |

| Tropical | Banana | Isoamyl acetate (Merck) + 30mL distilled water | 1 µL |

| Litchi | Canned litchi syrup (Pot’O Gold) | 5 mL | |

| Passion fruit | Fresh passion fruit pulp and 4 pips * | 5 mL pulp | |

| Pineapple | Fresh pineapple * | 4 cm3 piece | |

| Guava | Fresh ripe guava * | 2 × 3 cm3 pieces | |

| Mango | Dried mango roll (Montague) | 2 cm2 square | |

| Gooseberry | Gooseberries-(Hillcrest) | 2 | |

| Papaya | Fresh papaya * | 1 cm wedge | |

| Coconut | Desiccated coconut (Imbo) | 5 mL | |

| Vegetative | Fresh cut grass | Freshly cut grass | A handful |

| Green beans | Fresh green beans (chopped) * | 2 | |

| Green pepper | Green pepper (chopped) * | 2 × 3 cm piece | |

| Mint | Fresh mint (crushed) * | 1 sprig | |

| Eucalyptus | Eucalyptus leaves (crushed) | 5 | |

| Celery | Celery stick (chopped) * | 1 × 10 cm | |

| Dried | Dry grass/Hay | Dry grass (local petshop) | A handful |

| Tobacco | Dried tobacco (Peter Stuyvesant) | 2 cigarettes | |

| Sweet Associated | Honey | Acacia honey (Luna de Miel, France) | 5 mL |

| Marmalade | Ceville orange marmalade (Koo) | 5 mL | |

| Dried fruit | Dried apple, apricot, peach, prune, pear-chopped (Safari) | 1 piece each | |

| Raisin | Raisins-chopped (Safari) | 5 | |

| Nutty | Nutty | Walnut flavour (MANE) + 10 mL distilled water | 2 drops |

| Floral | Orange blossom | Orange blossom flavour on cotton wool (Vanhiné) | 2 drops |

| Linden Tree Flower | Liden tree tea (Twinings) | ½ teabag | |

| Toasted/Oaky | Oak | Medium toasted French oak (NT Bois, RX South Africa) | 3 g |

| Planky | Pine wood shavings (Timber city) | 3 g | |

| Toasted bread | Toasted white bread (Sasko) | 1 cm3 | |

| Caramel | Caramel sauce (Ilovo) + 5 mL distilled water | 5 mL | |

| Toffee | Ttoffee chopped (Toff-O-Lux) + 5 mL hot water | 1 | |

| Vanilla | Vanilla essence (Robertson) in 10 mL distilled water | 2.5 mL | |

| Roasted Coffee | Roasted coffee beans (LavAzza) | 4 | |

| Spicy | Black pepper | Black pepper—grinded (Robertson) | 5 mL |

| White pepper | White pepper (Robertson) | 5 mL | |

| Bay leaves | Dry bay leave (Robertson) | 1 | |

| Cinnamon | Cinnamon powder (Robertson) | 2.5 mL | |

| Thyme | Dry thyme (Robertson) | 2.5 mL | |

| Cloves | Cloves (Robertson) | 2.5 mL | |

| Juniper | Juniper berries (Robertson) | 4 | |

| Aniseed | Whole aniseed (Robertson) | 2.5 mL | |

| Nutmeg | Ground nutmeg (Robertson) | 2.5 mL | |

| Ginger | Ginger powder (Robertson) | 2.5 mL | |

| Liquorice | Liquorice (Mister sweet) | 1 cm piece | |

| Curry | 2.5 mL curry powder (Rajah) | 2.5 mL | |

| Forest floor | Mouldy/mushroom | Fresh mushroom in 10 mL distilled water | ½ mushroom |

| Earthy | Wet soil | 25 mL | |

| Other | Butter/lactic | Butter (Clover) | 2 cm3 |

| Sulphur | SO2 solution (Protea) in 15 mL distilled water | 15% | |

| Yeast | Rehydrated yeast (VIN 13, Anchor) | 20 mL |

References

- Augustyn, O.P.H.; Rapp, A. Aroma Components of Vitis vinifera L. cv. Chenin blanc Grapes and Their Changes during maturation. S. Afr. J. Enol. Vitic. 1982, 3, 47–51. [Google Scholar] [CrossRef]

- Van Rooyen, P.C.; De Wet, P.; Van Wyk, C.J.; Tromp, A. Chenin blanc Wine Volatiles and the Intensity of a Guava-like flavour. S. Afr. J. Enol. Vitic. 1982, 3, 1–7. [Google Scholar] [CrossRef]

- Coetzee, C.; Du Toit, W.J. A comprehensive review of Sauvignon blanc aroma with focus on certain positive volatile thiols. Food Res. Int. 2012, 45, 287–298. [Google Scholar] [CrossRef]

- Coetzee, C.; Lisjak, K.; Nicolau, L.; Kilmartin, P.; Du Toit, W.J. Oxygen and sulphur dioxide additions to Sauvignon blanc must: Effect on must and wine composition. Flavour Fragr. J. 2013, 28, 155–167. [Google Scholar] [CrossRef]

- Aleixandre-Tudo, J.L.; Weightman, C.; Panzeri, V.; Niewoudt, H.H.; du Toit, W.J. Effect of Skin Contact Before and During Alcoholic Fermentation on the Chemical and Sensory Profile of South African Chenin Blanc White Wines. S. Afr. J. Enol. Vitic. 2015, 36, 366–377. [Google Scholar] [CrossRef]

- Weightman, C.J. Characterization of Chenin Blanc Wines Produced by Natural Fermentation and Skin Contact: Focus on Application of Rapid Sensory Profiling Methods. Master’s Thesis, University of Stellenbosch, Stellenbosch, South Africa, 2014. [Google Scholar]

- Rous, C.; Alderson, B. Phenolic extraction curves for white wines aged in French and American Oak Barrels. Am. J. Enol. Vitic. 1983, 34, 211–215. [Google Scholar]

- Towey, J.P.; Waterhouse, A.L. Barrel-to-Barrel Variation of Volatile Oak Extractives in Barrel-Fermented Chardonnay. Am. J. Enol. Vitic. 1996, 47, 17–20. [Google Scholar]

- Perez-Coello, M.S.; Sanchez, M.A.; Garcia, E.; Gonzalez-Vinas, M.A.; Sanz, J.; Cabezudo, M.D. Fermentation of White Wines in the Presence of Wood Chips of American and French Oak. J. Agric. Food Chem. 2000, 48, 885–889. [Google Scholar] [CrossRef]

- Spillman, P.J.; Sefton, M.A.; Gawel, R. The contribution of volatile compounds derived during oak barrel maturation to the aroma of Chardonnay and Cabernet Sauvignon wine. Aust. J. Grape Wine Res. 2004, 10, 227–235. [Google Scholar] [CrossRef]

- Herrero, P.; Saenz-Navajas, M.P.; Avizcuri, J.M.; Culleré, L.; Balda, P.; Antón, E.C.; Ferreira, V.; Escudero., A. Study of Chardonnay and Sauvignon blanc wines from D.O.Ca Rioja (Spain) aged in different French oak wood barrels: Chemical and aroma quality aspects. Food Res. Int. 2016, 89, 227–236. [Google Scholar] [CrossRef]

- Jarauta, I.; Cacho, J.; Ferreira, V. Concurrent Phenomena Contributing to the Formation of the Aroma of Wine during Aging in Oak Wood: An Analytical Study. J. Agric. Food Chem. 2005, 53, 4166–4177. [Google Scholar] [CrossRef] [PubMed]

- Spillman, P.J.; Iland, P.G.; Sefton, M.A. Accumulation of volatile oak compounds in a model wine stored in American and Limousin oak barrels. Aust. J. Grape Wine Res. 1998, 4, 67–74. [Google Scholar] [CrossRef]

- De Beer, D.E.; Joubert Marais, J.; Du Toit, W.; Manley, M. Characterisation of Pinotage wine during maturation on different oak products. S. Afr. J. Enol. Vitic. 2008, 29, 39–49. [Google Scholar] [CrossRef][Green Version]

- Rodriguez, R.; Gomez-Plaza, E. Differences in the extraction of volatile compounds from oak chips in wine and model solutions. Am. J. Enol. Vitic. 2011, 62, 127–132. [Google Scholar] [CrossRef]

- Du Toit, W.J. Micro-oxygenation, oak alternatives and added tannins and wine quality. In Managing Wine Quality: Oenology and Wine Quality; Reynolds, A.G., Ed.; Woodhead Publishing Limited: Cambridge, UK, 2011; Volume 2. [Google Scholar]

- Fernandez de Simon, B.; Muino, I.; Cadahia, E. Characterization of Volatile Constituents in Commercial Oak Wood Chips. J. Agric. Food Chem. 2010, 58, 9587–9596. [Google Scholar] [CrossRef] [PubMed]

- Crump, A.M.; Johnson, T.E.; Wilkinson, K.L.; Bastian, S.E.P. Influence of Oak Maturation Regimen on Composition, Sensory Properties, Quality, and Consumer Acceptability of Cabernet Sauvignon Wines. J. Agric. Food Chem. 2015, 63, 1593–1600. [Google Scholar] [CrossRef] [PubMed]

- Machado, N.M.; Rineiro, T.G.; Barone, B.; Barros, A.P.A.; Biasoto Marques, A.T.; Behrmens, J.H. Sensory profile and check-all-that- apply (cata) as tools for evaluating ad characterizing Syrah wines aged in oak chips. Food Res. Int. 2019, 124, 156–164. [Google Scholar]

- Campo, E.; Ballester, J.; Dacremont, C.; Valentin, D. Comparison of conventional descriptive analysis and a citation frequency based descriptive method for odor profiling: An application to Burgundy Pinot noir wines. Food Qual. Prefer. 2010, 21, 44–55. [Google Scholar] [CrossRef]

- Valentin, D.; Chollet, S.; Lelièvre, M.; Abdi, H. Quick and dirty but still pretty good: A review of new descriptive methods in food science. Int. J. Food Sci. Technol. 2012, 47, 1563–1578. [Google Scholar] [CrossRef]

- Campo, E.; Ferreira, V.; Valentin, D. Aroma properties of young Spanish monovarietal white wines: A study using sorting task, list of terms and frequency of citation. Aust. J. Grape Wine Res. 2008, 14, 104–115. [Google Scholar] [CrossRef]

- Lawless, H.T.; Heymann, H. Sensory Evaluation of Food: Principles and Practices; Springer: New York, NY, USA, 2010. [Google Scholar]

- Coetzee, C.; Schulze, A.; Mokwena, L.; du Toit, W.; Buica, A. Investigation of thiol levels in young commercial South African Sauvignon Blanc and Chenin Blanc wines using propiolate derivatization and GC-MS/MS. S. Afr. J. Enol. Vitic. 2018, 39, 180–184. [Google Scholar] [CrossRef]

- Wilson, C.; Brand, J.; du Toit, W.; Buica, A. Matrix effects influencing the perception of 3-mercaptohexan-1-ol (3MH) and 3-mercaptohexyl acetate (3MHA) in different Chenin Blanc wines by Projective Mapping (PM) with Ultra Flash profiling (UFP) intensity ratings. Food Res. Int. 2019, 121, 633–640. [Google Scholar] [CrossRef] [PubMed]

- Gonzales-Centeno, M.R.; Chira, K.; Teissedre, P. Comparison between Malolactic fermentation Container and Barrel Toasting Effects on Phenolic, Volatile, and Sensory Profiles of Red Wines. J. Agric. Food Chem. 2017, 65, 3320–3329. [Google Scholar] [CrossRef] [PubMed]

- Dumitriu (Gabur), G.; Peinado, R.A.; Cotea, V.V.; López de Lerma, N. Volatilome fingerprint of red wines aged with chips or staves: Influence of the aging time and toasting degree. Food Chem. 2020, 310, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Singleton, V.L. Maturation of Wines and Spirits: Comparisons, Facts, and Hypotheses. Am. J. Enol. Vitic. 1995, 46, 98–115. [Google Scholar]

- Perez-Prieto, L.J.; Lopez-Roca, J.M.; Martinez-Cutillas, A.; Minguez, E.P.; Gomez-Plaza, E. Maturing Wine in Oak Barrels. Effects of Origin, Volume, and Age of the Barrel on the Wine Volatile Composition. J. Agric. Food Chem. 2002, 50, 3272–3276. [Google Scholar] [CrossRef]

- Vivas, N.; Glories, Y. Mod_elisation et calcul du bilan des apports d’oxyg_ene au cours de l’_elevage des vins rouges. II. Les apports lies au passage d’oxygene au travers de la barrique. Progr. Agricole Viticole 1997, 114, 315–316. [Google Scholar]

- Chatonnet, P.; Dubourdieau, D. Identification of Substances Responsible for the “Sawdust” Aroma in Oak Wood. J. Sci. Food Agric. 1998, 76, 179–188. [Google Scholar] [CrossRef]

- Blanchard, L.; Tominaga, T.; Dubourdieu, D. Formation of Furfurylthiol exhibiting a strong coffee aroma during oak barrel fermentation from furfural released by toasted staves. J. Agric. Food Chem. 2001, 49, 4833–4835. [Google Scholar] [CrossRef]

- Garde-Cerdán, T.; Ancín-Azpilicueta, C. Review of quality factors on wine ageing in oak barrels. Trends Food Sci. Technol. 2006, 17, 438–447. [Google Scholar] [CrossRef]

- Prida, A.; Chatonnet, P. Impact of Oak-Derived Compounds on the Olfactory Perception of Barrel-Aged Wines. Am. J. Enol. Vitic. 2010, 61, 408–413. [Google Scholar]

- Canas, S.; Caldeira, I.; Anjos, O.; Lino, J.; Soares, A.; Belchior, A.P. Physical and sensory evaluation of wine brandies aged using oak and chestnut wood simultaneously in wooden and in stainless steel tanks. Int. J. Food Sci. Technol. 2016, 51, 2537–2545. [Google Scholar] [CrossRef]

| Treatment and Volume/Dimension | Abbreviation | Repeats |

|---|---|---|

| Tank control (2000 L) | TC | Only one tank, no repeats |

| Old barrels (300 L) | BC | BC_1, 2 and 3 |

| New barrel cooper 1 (300 L) | B1 | B1_1, 2 and 3 |

| New barrel cooper 2 (300 L) | B2 | B2_1, 2 and 3 |

| New barrel cooper 3 (300 L) | B3 | B3_1, 2 and 3 |

| Old barrels with staves cooper 4 (300 L) | S1 | S1_1, 2 and 3 |

| Old barrels with staves cooper 5 (300 L) | S2 | S2_1, 2 and 3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Botha, A.; du Toit, W.; Brand, J.; Kidd, M.; Groenewald, N. The Effect of Different Oak Products Used during Fermentation and Ageing on the Sensory Properties of a White Wine over Time. Foods 2020, 9, 1220. https://doi.org/10.3390/foods9091220

Botha A, du Toit W, Brand J, Kidd M, Groenewald N. The Effect of Different Oak Products Used during Fermentation and Ageing on the Sensory Properties of a White Wine over Time. Foods. 2020; 9(9):1220. https://doi.org/10.3390/foods9091220

Chicago/Turabian StyleBotha, Anri, Wessel du Toit, Jeanne Brand, Martin Kidd, and Niël Groenewald. 2020. "The Effect of Different Oak Products Used during Fermentation and Ageing on the Sensory Properties of a White Wine over Time" Foods 9, no. 9: 1220. https://doi.org/10.3390/foods9091220

APA StyleBotha, A., du Toit, W., Brand, J., Kidd, M., & Groenewald, N. (2020). The Effect of Different Oak Products Used during Fermentation and Ageing on the Sensory Properties of a White Wine over Time. Foods, 9(9), 1220. https://doi.org/10.3390/foods9091220