Comparison of Supercritical CO2-Drying, Freeze-Drying and Frying on Sensory Properties of Beetroot

Abstract

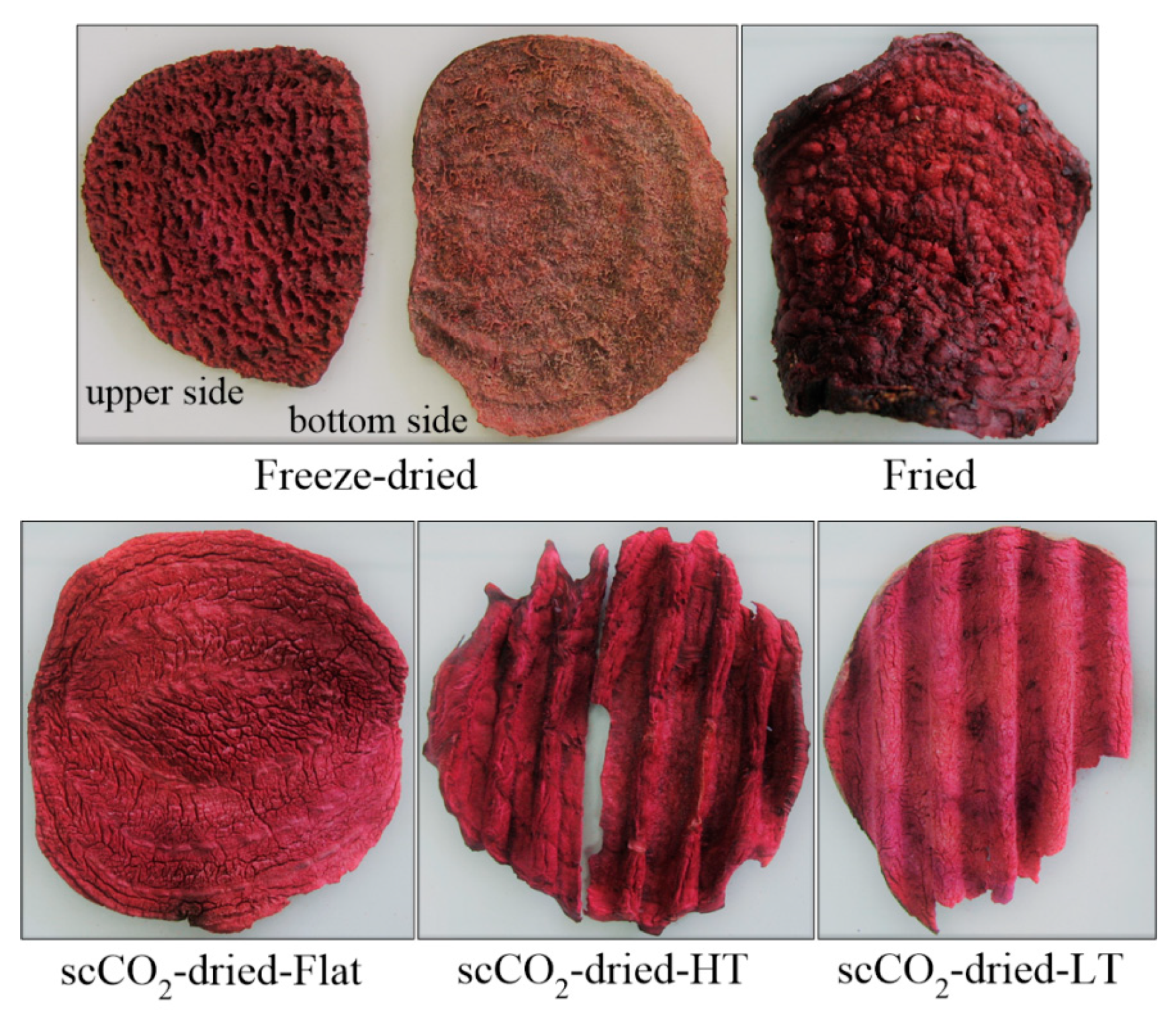

:1. Introduction

2. Materials and Methods

2.1. Dried Beetroot Samples

2.2. Sensory Analysis

2.2.1. Descriptive Sensory Testing

2.2.2. Sensory Quality Rating

2.2.3. Consumer Sensory Testing

2.3. Statistical Analysis

2.3.1. Descriptive Data and PREFMAP

2.3.2. Quality Data

2.3.3. Consumer Data

2.3.4. Software

3. Results and Discussion

3.1. PREFMAP

3.2. Mean Drop Analysis

3.3. Sensory Quality Rating

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Aguilera, J.M.; Chiralt, A.; Fito, P. Food dehydration and product structure. Trends Food Sci. Technol. 2003, 14, 432–437. [Google Scholar] [CrossRef]

- Berk, Z. Chapter 22—Dehydration. In Food Process Engineering and Technology, 2nd ed.; Berk, Z., Ed.; Academic Press: San Diego, CA, USA, 2013; pp. 511–566. [Google Scholar]

- Brown, Z.K.; Fryer, P.J.; Norton, I.T.; Bakalis, S.; Bridson, R.H. Drying of foods using supercritical carbon dioxide—Investigations with carrot. Innov. Food Sci. Emerg. Technol. 2008, 9, 280–289. [Google Scholar] [CrossRef]

- Witrowa-Rajchert, D.; Rząca, M. Effect of Drying Method on the Microstructure and Physical Properties of Dried Apples. Dry. Technol. 2009, 27, 903–909. [Google Scholar] [CrossRef]

- Nijhuis, H.H.; Torringa, H.M.; Muresan, S.; Yuksel, D.; Leguijt, C.; Kloek, W. Approaches to improving the quality of dried fruit and vegetables. Trends Food Sci. Technol. 1998, 9, 13–20. [Google Scholar] [CrossRef]

- Rizzolo, A.; Vanoli, M.; Cortellino, G.; Spinelli, L.; Contini, D.; Herremans, E.; Bongaers, E.; Nemeth, A.; Leitner, M.; Verboven, P.; et al. Characterizing the tissue of apple air-dried and osmo-air-dried rings by X-CT and OCT and relationship with ring crispness and fruit maturity at harvest measured by TRS. Innov. Food Sci. Emerg. Technol. 2014, 24, 121–130. [Google Scholar] [CrossRef] [Green Version]

- Mayor, L.; Sereno, A.M. Modelling shrinkage during convective drying of food materials: A review. J. Food Eng. 2004, 61, 373–386. [Google Scholar] [CrossRef]

- Jayaraman, K.S.; Das Gupta, D.K. Drying of Fruits and Vegetables. In Handbook of Industrial Drying, 4th ed.; Mujumdar, A.S., Ed.; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2015; pp. 611–635. [Google Scholar]

- Bourdoux, S.; Li, D.; Rajkovic, A.; Devlieghere, F.; Uyttendaele, M. Performance of Drying Technologies to Ensure Microbial Safety of Dried Fruits and Vegetables. Compr. Rev. Food Sci. Food Saf. 2016, 15, 1056–1066. [Google Scholar] [CrossRef]

- Szczesniak, A.S. Texture is a sensory property. Food Qual. Prefer. 2002, 13, 215–225. [Google Scholar] [CrossRef]

- Krokida, M.K.; Maroulis, Z.B. Effect of drying method on shrinkage and porosity. Dry. Technol. 1997, 15, 2441–2458. [Google Scholar] [CrossRef]

- Nistor, O.-V.; Seremet, L.; Andronoiu, D.G.; Rudi, L.; Botez, E. Influence of different drying methods on the physicochemical properties of red beetroot (Beta vulgaris L. var. Cylindra). Food Chem. 2017, 236, 59–67. [Google Scholar] [CrossRef]

- Oreopoulou, V.; Krokida, M.; Marinos-Kouris, D. Frying of Foods. In Handbook of Industrial Drying, 4th ed.; Mujumdar, A.S., Ed.; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2015; pp. 1189–1207. [Google Scholar]

- Pei, F.; Shi, Y.; Mariga, A.M.; Yang, W.-J.; Tang, X.-Z.; Zhao, L.-Y.; An, X.-X.; Hu, Q.-H. Comparison of Freeze-Drying and Freeze-Drying Combined with Microwave Vacuum Drying Methods on Drying Kinetics and Rehydration Characteristics of Button Mushroom (Agaricus bisporus) Slices. Food Bioprocess Technol. 2014, 7, 1629–1639. [Google Scholar] [CrossRef]

- Berk, Z. Chapter 23—Freeze Drying (Lyophilization) and Freeze Concentration. In Food Process Engineering and Technology, 2nd ed.; Berk, Z., Ed.; Academic Press: San Diego, CA, USA, 2013; pp. 567–581. [Google Scholar]

- Donsì, G.; Ferrari, G.; Matteo, D.I. Utilization of Combined Processes in Freeze-Drying of Shrimps. Food Bioprod. Process. 2001, 79, 152–159. [Google Scholar] [CrossRef]

- Benali, M.; Boumghar, Y. Supercritical Fluid-Assisted Drying. In Handbook of Industrial Drying, 4th ed.; Mujumdar, A.S., Ed.; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2015; pp. 1261–1270. [Google Scholar]

- Knez, Ž.; Markočič, E.; Leitgeb, M.; Primožič, M.; Knez Hrnčič, M.; Škerget, M. Industrial applications of supercritical fluids: A review. Energy 2014, 77, 235–243. [Google Scholar] [CrossRef]

- Brunner, G. Supercritical fluids: Technology and application to food processing. J. Food Eng. 2005, 67, 21–33. [Google Scholar] [CrossRef]

- Djas, M.; Henczka, M. Reactive extraction of carboxylic acids using organic solvents and supercritical fluids: A review. Sep. Purif. Technol. 2018, 201, 106–119. [Google Scholar] [CrossRef]

- Sabirzyanov, A.N.; Il’in, A.P.; Akhunov, A.R.; Gumerov, F.M. Solubility of Water in Supercritical Carbon Dioxide. High Temp. 2002, 40, 203–206. [Google Scholar] [CrossRef]

- Tomic, N.; Djekic, I.; Zambon, A.; Spilimbergo, S.; Bourdoux, S.; Holtze, E.; Hofland, G.; Sut, S.; Dall’Acqua, S.; Smigic, N.; et al. Challenging chemical and quality changes of supercritical CO2 dried apple during long-term storage. LWT 2019, 110, 132–141. [Google Scholar] [CrossRef]

- Djekic, I.; Tomic, N.; Bourdoux, S.; Spilimbergo, S.; Smigic, N.; Udovicki, B.; Hofland, G.; Devlieghere, F.; Rajkovic, A. Comparison of three types of drying (supercritical CO2, air and freeze) on the quality of dried apple—Quality index approach. LWT Food Sci. Technol. 2018, 94, 64–72. [Google Scholar] [CrossRef]

- Zambon, A.; Tomic, N.; Djekic, I.; Hofland, G.; Rajkovic, A.; Spilimbergo, S. Supercritical CO2 Drying of Red Bell Pepper. Food Bioprocess Technol. 2020, 13, 753–763. [Google Scholar] [CrossRef]

- Şahin, İ.; Özbakır, Y.; İnönü, Z.; Ulker, Z.; Erkey, C. Kinetics of Supercritical Drying of Gels. Gels 2018, 4, 3. [Google Scholar] [CrossRef] [Green Version]

- Giobbe, G.G.; Zambon, A.; Vetralla, M.; Urbani, L.; Deguchi, K.; Pantano, M.F.; Pugno, N.M.; Elvassore, N.; De Coppi, P.; Spilimbergo, S. Preservation over time of dried acellular esophageal matrix. Biomed. Phys. Eng. Express 2018, 4, 65021. [Google Scholar] [CrossRef] [Green Version]

- Braeuer, A.; Schuster, J.; Gebrekidan, M.; Bahr, L.; Michelino, F.; Zambon, A.; Spilimbergo, S. In Situ Raman Analysis of CO2—Assisted Drying of Fruit-Slices. Foods 2017, 6, 37. [Google Scholar] [CrossRef] [PubMed]

- Michelino, F.; Zambon, A.; Vizzotto, M.T.; Cozzi, S.; Spilimbergo, S. High power ultrasound combined with supercritical carbon dioxide for the drying and microbial inactivation of coriander. J. CO2 Util. 2018, 24, 516–521. [Google Scholar] [CrossRef] [Green Version]

- Vetralla, M.; Ferrentino, G.; Zambon, A.; Spilimbergo, S. A study about the effects of supercritical carbon dioxide drying on apple pieces. Int. J. Food Eng. 2018, 4, 186–190. [Google Scholar] [CrossRef] [Green Version]

- Djekic, I.; Tomic, N.; Smigic, N.; Udovicki, B.; Hofland, G.; Rajkovic, A. Hygienic design of a unit for supercritical fluid drying—Case study. Br. Food J. 2018, 120, 2155–2165. [Google Scholar] [CrossRef]

- Režek Jambrak, A.; Vukušić, T.; Donsi, F.; Paniwnyk, L.; Djekic, I. Three Pillars of Novel Nonthermal Food Technologies: Food Safety, Quality, and Environment. J. Food Qual. 2018, 2018, 18. [Google Scholar] [CrossRef]

- Ferrentino, G.; Spilimbergo, S. High pressure carbon dioxide pasteurization of solid foods: Current knowledge and future outlooks. Trends Food Sci. Technol. 2011, 22, 427–441. [Google Scholar] [CrossRef]

- Bourdoux, S.; Rajkovic, A.; De Sutter, S.; Vermeulen, A.; Spilimbergo, S.; Zambon, A.; Hofland, G.; Uyttendaele, M.; Devlieghere, F. Inactivation of Salmonella, Listeria monocytogenes and Escherichia coli O157:H7 inoculated on coriander by freeze-drying and supercritical CO2 drying. Innov. Food Sci. Emerg. Technol. 2018, 47, 180–186. [Google Scholar] [CrossRef]

- Zambon, A.; Michelino, F.; Bourdoux, S.; Devlieghere, F.; Sut, S.; Dall’Acqua, S.; Rajkovic, A.; Spilimbergo, S. Microbial inactivation efficiency of supercritical CO2 drying process. Dry. Technol. 2018, 36, 2016–2021. [Google Scholar] [CrossRef] [Green Version]

- Agterof, W.G.M.; Bhatia, R.; Hofland, G.W. Dehydration Method. European Patent Bulletin 2009/42 EP 1,771,074 B1, 14 October 2009. [Google Scholar]

- Forde, C.G.; van Kuijk, N.; Thaler, T.; de Graaf, C.; Martin, N. Oral processing characteristics of solid savoury meal components, and relationship with food composition, sensory attributes and expected satiation. Appetite 2013, 60, 208–219. [Google Scholar] [CrossRef]

- ASTM. Manual on Descriptive Analysis Testing for Sensory Evaluation. In ASTM Manual Series: MNL 13; Hootman, R.C., Ed.; ASTM—American Society for Testing and Materials: Philadelpfia, PA, USA, 1992. [Google Scholar]

- Romano, R.; Brockhoff, P.B.; Hersleth, M.; Tomic, O.; Næs, T. Correcting for different use of the scale and the need for further analysis of individual differences in sensory analysis. Food Qual. Prefer. 2008, 19, 197–209. [Google Scholar] [CrossRef]

- Lawless, H.T.; Heymann, H. Sensory Evaluation of Food: Principles and Practices, 2nd ed.; Springer Science+Business Media, LLC: New York, NY, USA, 2010. [Google Scholar]

- Meilgaard, M.; Civille, G.V.; Carr, T.B. Sensory Evaluation Techniques, 3rd ed.; CRC Press LLC: Boca Raton, FL, USA, 1999. [Google Scholar]

- Rothman, L.; Parker, M.J. Structure and Use of Just-About-Right Scales. In ASTM Manual Series: MNL 63—Just-About-Right (JAR) Scales: Design, Usage, Benefits and Risks; Rothman, L., Parker, M.J., Eds.; ASTM International—American Society for Testing and Materials: Bridgeport, NJ, USA, 2009; pp. 1–13. [Google Scholar]

- McEwan, J.A. Preference mapping for product optimization. In Multivariate Analysis of Data in Sensory Science; Naes, T., Risvik, E., Eds.; Elsevier Science B.V.: Amsterdam, The Netherlands, 1996; pp. 71–102. [Google Scholar]

- Schraidt, M. Appendix L: Penalty analysis or mean drop analysis. In ASTM Manual Series: MNL 63—Just-About-Right (JAR) Scales: Design, Usage, Benefits and Risks; Rothman, L., Parker, M.J., Eds.; ASTM International—American Society for Testing and Materials: Bridgeport, NJ, USA, 2009; pp. 50–53. [Google Scholar]

- Grice, J.W. Idiogrid: Software for the management and analysis of repertory grids. Behav. Res. Methods Instrum. Comput. 2002, 34, 338–341. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Grice, J.W.; Assad, K.K. Generalized Procrustes Analysis: A tool for exploring aggregates and persons. Appl. Multivar. Res. 2009, 13, 93–112. [Google Scholar] [CrossRef]

- Stevens, J.P. Applied Multivariate Statistics for the Social Sciences, 5th ed.; Taylor & Francis Group, LLC: New York, NY, USA, 2009. [Google Scholar]

- Rahman, M.S. Dried Food Properties: Challenges Ahead. Dry. Technol. 2005, 23, 695–715. [Google Scholar] [CrossRef]

- Figiel, A. Drying kinetics and quality of beetroots dehydrated by combination of convective and vacuum-microwave methods. J. Food Eng. 2010, 98, 461–470. [Google Scholar] [CrossRef]

- Kaur, K.; Singh, A.K. Drying kinetics and quality characteristics of beetroot slices under hot air followed by microwave finish drying. Afr. J. Agric. Res. 2014, 9, 1036–1044. [Google Scholar]

- Ravichandran, K.; Saw, N.M.M.T.; Mohdaly, A.A.A.; Gabr, A.M.M.; Kastell, A.; Riedel, H.; Cai, Z.; Knorr, D.; Smetanska, I. Impact of processing of red beet on betalain content and antioxidant activity. Food Res. Int. 2013, 50, 670–675. [Google Scholar] [CrossRef]

- Kowalski, S.J.; Szadzińska, J. Kinetics and Quality Aspects of Beetroots Dried in Non-Stationary Conditions. Dry. Technol. 2014, 32, 1310–1318. [Google Scholar] [CrossRef]

- Ferrentino, G.; Balzan, S.; Spilimbergo, S. Supercritical Carbon Dioxide Processing of Dry Cured Ham Spiked with Listeria monocytogenes: Inactivation Kinetics, Color, and Sensory Evaluations. Food Bioprocess Technol. 2013, 6, 1164–1174. [Google Scholar] [CrossRef]

| Attribute | Definition | Anchors |

|---|---|---|

| APPEARANCE | ||

| Flesh color intensity | The intensity or color strength of the flesh. | light-dark |

| Surface deformation | Presence of furrows, cracks, or holes on the flesh surface. | none-lots of |

| Degree of shape deformation | Deformation of the shape in relation to the flat disc (distortion, bending). | none-much |

| ODOR (orthonasal olfaction) | ||

| Overall odor intensity | The intensity of the overall odor of the product. | none-intensive |

| Beetroot odor | The intensity of the beetroot-like odor. | none-intensive |

| Hay-like odor | The intensity of the hay-like and dried vegetables-like odor. | none-intensive |

| Musty odor 1 | The intensity of odor associated with a damp cellar, or stale vegetables. | none-intensive |

| Oil odor | The intensity of the fried vegetable oil odor. | none-intensive |

| Nasal pungency | The intensity of nasal pungent and sourish feelings. | none-intensive |

| FLAVOR | ||

| Overall flavor intensity | The intensity of the overall flavor of the product. | none-intensive |

| Beetroot flavor | The intensity of the beetroot-like flavor. | none-intensive |

| Sweetness | The taste stimulated by sugars. | none-intensive |

| Overburnt/Grime flavor | The intensity of the overburnt, grime-like flavor. | none-intensive |

| Bitterness | The taste stimulated by chemical substances such as caffeine or quinine. | none-intensive |

| TEXTURE | ||

| Flesh surface roughness | Degree to which the surface is uneven, related to the amount of irregularity, bumps, grains, or protrusions present on the surface. | smooth-rough |

| Hardness | The force required to bite through the dried beetroot disc. | soft-hard |

| Cohesiveness | Amount of product that deforms rather than breaks during chewing. | breaks-deforms |

| Denseness 1 | Cross-section compactness. | airy-dense/compact |

| Crispiness | The force and noise with which the beetroot slice breaks during chewing. | not crispy-very crispy |

| Adhesiveness | Degree to which mass sticks to the teeth. | not sticky-very sticky |

| Beetroot Samples | Consumers 2 (N = 102) | ||

|---|---|---|---|

| Cluster 1 (41.2%) | Cluster 2 (33.3%) | Cluster 3 (25.5%) | |

| Overall Liking | |||

| CO2-dried Flat | 5.9 ± 2.8 b,B,C | 4.3 ± 2.1 a,A | 7.5 ± 1.3 c,C |

| CO2-dried LT | 5.2 ± 2.5 a,A,B,C | 7.5 ± 1.5 b,C | 4.0 ± 2.0 a,A |

| CO2-dried HT | 4.0 ± 2.2 a,A | 5.0 ± 2.2 a,b,A,B | 5.7 ± 1.8 b,B |

| Fried | 6.6 ± 2.7 C | 6.5 ± 2.7 B,C | 7.3 ± 2.1 C |

| Freeze-dried | 4.9 ± 2.6 A,B | 5.2 ± 2.6 A,B | 4.6 ± 2.0 A,B |

| Appearance Liking | |||

| CO2-dried Flat | 7.3 ± 2.1 a,b,C | 6.7 ± 1.9 a,B,C | 8.2 ± 1.1 b,B |

| CO2-dried LT | 6.6 ± 2.4 a,B,C | 7.4 ± 1.5 b,C | 5.5 ± 2.3 a,b,A |

| CO2-dried HT | 5.8 ± 2.8 A,B | 5.9 ± 2.3 A,B | 6.5 ± 2.1 A |

| Fried | 5.9 ± 2.7 A,B,C | 5.7 ± 2.6 A,B | 5.9 ± 2.5 A |

| Freeze-dried | 5.0 ± 2.5 A | 4.7 ± 2.6 A | 4.9 ± 2.4 A |

| Flavor Liking | |||

| CO2-dried Flat | 5.5 ± 2.7 a,b,B | 4.8 ± 2.2 a,A | 6.6 ± 2.1 b,B |

| CO2-dried LT | 5.1 ± 2.4 a,B | 7.1 ± 1.8 b,C | 4.5 ± 2.4 a,A |

| CO2-dried HT | 3.1 ± 2.4 a,A | 4.8 ± 2.3 b,A | 5.0 ± 2.2 b,A,B |

| Fried | 6.2 ± 3.1 B | 6.5 ± 2.9 B,C | 6.7 ± 2.7 B |

| Freeze-dried | 5.1 ± 2.8 B | 5.1 ± 2.8 A,B | 4.4 ± 2.9 A |

| Beetroot Samples | Overall Quality | Appearance | Odor | Texture | Flavor |

|---|---|---|---|---|---|

| CO2-dried Flat | 3.7 ± 0.6 b | 4.3 ± 0.6 c | 2.6 ± 1.2 a,b | 3.9 ± 0.7 a,b | 4.0 ± 0.7 b |

| CO2-dried LT (Curvy) | 3.7 ± 0.6 b | 3.9 ± 0.7 c | 2.5 ± 1.3 a | 4.2 ± 0.8 b | 3.9 ± 0.8 b |

| CO2-dried HT (Curvy) | 2.9 ± 0.6 a | 3.8 ± 0.8 c | 2.3 ± 0.8 a | 3.4 ± 0.8 a | 2.4 ± 1.0 a |

| Fried | 3.0 ± 0.9 a | 2.8 ± 0.7 b | 2.3 ± 1.2 a | 4.1 ± 0.8 b | 2.6 ± 1.4 a |

| Freeze-dried | 3.0 ± 1.0 a | 1.8 ± 1.1 a | 3.2 ± 1.1 b | 3.4 ± 0.9 a | 2.9 ± 1.4 a |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tomic, N.; Djekic, I.; Hofland, G.; Smigic, N.; Udovicki, B.; Rajkovic, A. Comparison of Supercritical CO2-Drying, Freeze-Drying and Frying on Sensory Properties of Beetroot. Foods 2020, 9, 1201. https://doi.org/10.3390/foods9091201

Tomic N, Djekic I, Hofland G, Smigic N, Udovicki B, Rajkovic A. Comparison of Supercritical CO2-Drying, Freeze-Drying and Frying on Sensory Properties of Beetroot. Foods. 2020; 9(9):1201. https://doi.org/10.3390/foods9091201

Chicago/Turabian StyleTomic, Nikola, Ilija Djekic, Gerard Hofland, Nada Smigic, Bozidar Udovicki, and Andreja Rajkovic. 2020. "Comparison of Supercritical CO2-Drying, Freeze-Drying and Frying on Sensory Properties of Beetroot" Foods 9, no. 9: 1201. https://doi.org/10.3390/foods9091201

APA StyleTomic, N., Djekic, I., Hofland, G., Smigic, N., Udovicki, B., & Rajkovic, A. (2020). Comparison of Supercritical CO2-Drying, Freeze-Drying and Frying on Sensory Properties of Beetroot. Foods, 9(9), 1201. https://doi.org/10.3390/foods9091201