High Biological Value Compounds Extraction from Citrus Waste with Non-Conventional Methods

Abstract

1. Introduction

2. Principal Non-Conventional Technologies to Extract High Biological Value Compounds from Citrus Waste

2.1. Ultrasound Assisted Extraction

2.2. Microwave Assisted Extraction

2.3. Supercritical Fluid Extraction

2.4. Pressurized Water Extraction

2.5. Pulsed Electric Field

2.6. High Voltage Electric Discharges

2.7. High Hydrostatic Pressures

3. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Zou, Z.; Xi, W.; Hu, Y.; Nie, C.; Zhou, Z. Antioxidant activity of Citrus fruits. Food Chem. 2016, 196, 885–896. [Google Scholar] [CrossRef] [PubMed]

- FAO. Citrus Fruit Fresh and Processed—Statistical Bulletin 2016. 2017. Available online: http://www.fao.org/3/a-i8092e.pdf (accessed on 24 January 2020).

- Lv, X.; Zhao, S.; Ning, Z.; Zeng, H.; Shu, Y.; Tao, O.; Xiao, C.; Lu, C.; Liu, Y. Citrus fruits as a treasure trove of active natural metabolites that potentially provide benefits for human health. Chem. Central J. 2015, 9, 68. [Google Scholar] [CrossRef] [PubMed]

- Caristi, C.; Bellocco, E.; Gargiulli, C.; Toscano, G.; Leuzzi, U. Flavone-di-C-glycosides in citrus juices from Southern Italy. Food Chem. 2006, 95, 431–437. [Google Scholar] [CrossRef]

- Zema, D.A.; Calabrò, P.S.; Folino, A.; Tamburino, V.; Zappia, G.; Zimbone, S.M. Valorisation of citrus processing waste: A review. Waste Manag. 2018, 80, 252–273. [Google Scholar] [CrossRef]

- Balu, A.M.; Budarin, V.; Shuttleworth, P.S.; Pfaltzgraff, L.A.; Waldron, K.; Luque, R.; Clark, J.H. Valorisation of orange peel residues: Waste to biochemicals and nanoporous materials. Chem. Sus. Chem. 2012, 5, 1694–1697. [Google Scholar] [CrossRef]

- Satari, B.; Karimi, K. Citrus processing wastes: Environmental impacts, recent advances, and future perspectives in total valorization. Resour. Conserv. Recycl. 2018, 129, 153–167. [Google Scholar] [CrossRef]

- Taghizadeh-Alisaraei, A.; Hosseini, S.H.; Ghobadian, B.; Motevali, A. Biofuel production from citrus wastes: A feasibility study in Iran. Renew. Sustain. Energy Rev. 2017, 69, 1100–1112. [Google Scholar] [CrossRef]

- Mahato, N.; Sharma, K.; Sinha, M.; Cho, M.H. Citrus waste derived nutra-/pharmaceuticals for health benefits: Current trends and future perspectives. J. Funct. Foods 2018, 40, 307–316. [Google Scholar] [CrossRef]

- Zema, D.A.; Fòlino, A.; Zappia, G.; Calabrò, P.S.; Tamburino, V.; Zimbone, S.M. Anaerobic digestion of orange peel in a semi-continuous pilot plant: An environmentally sound way of citrus waste management in agro-ecosystems. Sci. Total Environ. 2018, 630, 401–408. [Google Scholar] [CrossRef]

- Tripodo, M.M.; Lanuzza, F.; Micali, G.; Coppolino, R.; Nucita, F. Citrus waste recovery: A new environmentally friendly procedure to obtain animal feed. Bioresour. Technol. 2004, 91, 111–115. [Google Scholar] [CrossRef]

- Siles, J.A.; Vargas, F.; Gutiérrez, M.C.; Chica, A.F.; Martín, M.A. Integral valorisation of waste orange peel using combustion, biomethanisation and co-composting technologies. Bioresour. Technol. 2016, 211, 173–182. [Google Scholar] [CrossRef] [PubMed]

- Negro, V.; Mancini, G.; Ruggeri, B.; Fino, D. Citrus waste as feedstock for bio-based products recovery: Review on limonene case study and energy valorization. Bioresour. Technol. 2016, 214, 806–815. [Google Scholar] [CrossRef] [PubMed]

- Official Journal of the European Union. Directive (EU) 2018/851 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2008/98/EC on waste, L 150/109—140, 14 June 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=OJ:L:2018:150:FULL&from=EN (accessed on 15 December 2019).

- Campos, D.A.; Gómez-García, R.; Vilas-Boas, A.A.; Madureira, A.R.; Pintado, M.M. Management of Fruit Industrial By-Products—A Case Study on Circular Economy Approach. Molecules 2020, 25, 320. [Google Scholar] [CrossRef] [PubMed]

- Sagar, N.A.; Pareek, S.; Sharma, S.; Yahia, E.M.; Lobo, M.G. Fruit and vegetable waste: Bioactive compounds, their extraction, and possible utilization. Compr. Rev. Food Sci. Food Saf. 2018, 17, 512–531. [Google Scholar] [CrossRef]

- Mirzaei-Aghsaghali, A.; Maheri-Sis, N. Nutritive value of some agro-industrial by-products for ruminants—A review. World J. Zoöl. 2008, 3, 40–46. [Google Scholar]

- Bernal-Vicente, A.; Ros, M.; Tittarelli, F.; Intrigliolo, F.; Pascual, J.A. Citrus compost and its water extract for cultivation of melon plants in greenhouse nurseries. Evaluation of nutriactive and biocontrol effects. Bioresour. Technol. 2008, 99, 8722–8728. [Google Scholar] [CrossRef]

- Casquete, R.; Castro, S.M.; Martín, A.; Ruiz-Moyano, S.; Saraiva, J.A.; Córdoba, M.G.; Teixeira, P. Evaluation of the effect of high pressure on total phenolic content, antioxidant and antimicrobial activity of citrus peels. Innov. Food Sci. Emerg. Technol. 2015, 31, 37–44. [Google Scholar] [CrossRef]

- Mariño, M.; Lopes da Silva, L.; Durán, N.; Tasic, L. Enhanced materials from nature: Nanocellulose from citrus waste. Molecules 2015, 20, 5908–5923. [Google Scholar] [CrossRef]

- Garzón, C.G.; Hours, R.A. Citrus waste: An alternative substrate for pectinase production in solid-state culture. Bioresour. Technol. 1992, 39, 93–95. [Google Scholar] [CrossRef]

- Ahmed, I.; Zia, M.A.; Hussain, M.A.; Akram, Z.; Naveed, M.T.; Nowrouzi, A. Bioprocessing of citrus waste peel for induced pectinase production by Aspergillus niger; its purification and characterization. J. Radiat. Res. Appl. Sci. 2016, 9, 148–154. [Google Scholar] [CrossRef]

- Din, S.; Akram, W.; Khan, H.A.A.; Hussain, A.; Hafeez, F. Citrus Waste-Derived Essential Oils: Alternative Larvicides for Dengue Fever Mosquito, Aedes albopictus (Skuse)(Culicidae: Diptera). Pak. J. Zoöl. 2011, 43, 367–372. [Google Scholar]

- Boluda-Aguilar, M.; López-Gómez, A. Production of bioethanol by fermentation of lemon (Citrus limon L.) peel wastes pretreated with steam explosion. Ind. Crop. Prod. 2013, 41, 188–197. [Google Scholar] [CrossRef]

- Choi, I.S.; Kim, J.H.; Wi, S.G.; Kim, K.H.; Bae, H.J. Bioethanol production from mandarin (Citrus unshiu) peel waste using popping pretreatment. Appl. Energy. 2013, 102, 204–210. [Google Scholar] [CrossRef]

- Lohrasbi, M.; Pourbafrani, M.; Niklasson, C.; Taherzadeh, M.J. Process design and economic analysis of a citrus waste biorefinery with biofuels and limonene as products. Bioresour. Technol. 2010, 101, 7382–7388. [Google Scholar] [CrossRef] [PubMed]

- Pourbafrani, M.; Forgács, G.; Horváth, I.S.; Niklasson, C.; Taherzadeh, M.J. Production of biofuels, limonene and pectin from citrus wastes. Bioresour. Technol. 2010, 101, 4246–4250. [Google Scholar] [CrossRef] [PubMed]

- Alvarez, J.; Hooshdaran, B.; Cortazar, M.; Amutio, M.; Lopez, G.; Freire, F.B.; Haghshenasfard, M.; Hosseini, S.H.; Olazar, M. Valorization of citrus wastes by fast pyrolysis in a conical spouted bed reactor. Fuel 2018, 224, 111–120. [Google Scholar] [CrossRef]

- Wei, Y.; Fang, Z.; Zheng, L.; Tan, L.; Tsang, E.P. Green synthesis of Fe nanoparticles using Citrus maxima peels aqueous extracts. Mater. Lett. 2016, 185, 384–386. [Google Scholar] [CrossRef]

- Ahmed, S.; Kaur, G.; Sharma, P.; Singh, S.; Ikram, S. Fruit waste (peel) as bio-reductant to synthesize silver nanoparticles with antimicrobial, antioxidant and cytotoxic activities. J. Appl. Biomed. 2018, 16, 221–231. [Google Scholar] [CrossRef]

- Singh, B.; Singh, J.P.; Kaur, A.; Singh, N. Phenolic composition, antioxidant potential and health benefits of citrus peel. Food Res. Int. 2020, 132, 109114. [Google Scholar] [CrossRef] [PubMed]

- Figuerola, F.; Hurtado, M.L.; Estévez, A.M.; Chiffelle, I.; Asenjo, F. Fibre concentrates from apple pomace and citrus peel as potential fibre sources for food enrichment. Food Chem. 2005, 91, 395–401. [Google Scholar] [CrossRef]

- Rafiq, S.; Kaul, R.; Sofi, S.A.; Bashir, N.; Nazir, F.; Nayik, G.A. Citrus peel as a source of functional ingredient: A review. J. Saudi Soc. Agric. Sci. 2018, 17, 351–358. [Google Scholar] [CrossRef]

- Putnik, P.; Bursać Kovačević, D.; Režek Jambrak, A.; Barba, F.J.; Cravotto, G.; Binello, A.; Lorenzo, J.M.; Shpigelman, A. Innovative “green” and novel strategies for the extraction of bioactive added value compounds from citrus wastes—A review. Molecules 2017, 22, 680. [Google Scholar] [CrossRef]

- Hosseini, S.S.; Khodaiyan, F.; Yarmand, M.S. Aqueous extraction of pectin from sour orange peel and its preliminary physicochemical properties. Int. J. Biol. Macromol. 2016, 82, 920–926. [Google Scholar] [CrossRef] [PubMed]

- Sharma, K.; Mahato, N.; Cho, M.H.; Lee, Y.R. Converting citrus wastes into value-added products: Economic and environmently friendly approaches. Nutrition 2017, 34, 29–46. [Google Scholar] [CrossRef] [PubMed]

- Das, S.; Sarmah, S.; Lyndem, S.; Singha Roy, A. An investigation into the identification of potential inhibitors of SARS-CoV-2 main protease using molecular docking study. J. Biomol. Struct. Dyn. 2020. [Google Scholar] [CrossRef] [PubMed]

- Utomo, R.Y.; Ikawati, M.; Meiyanto, E. Revealing the Potency of Citrus and Galangal Constituents to Halt SARS-CoV-2 Infection. Preprints 2020. [Google Scholar] [CrossRef]

- Meneguzzo, F.; Ciriminna, R.; Zabini, F.; Pagliaro, M. Accelerated Production of Hesperidin-rich Citrus Pectin from Waste Citrus Peel for Prevention and Therapy of COVID-19. Preprints 2020. [Google Scholar] [CrossRef]

- Meneguzzo, F.; Ciriminna, R.; Zabini, F.; Pagliaro, M. Hydrodynamic Cavitation-based Rapid Expansion of Hesperidin-rich Products from Waste Citrus Peel as a Potential Tool Against COVID-19. Preprints 2020, 2020040152. [Google Scholar] [CrossRef]

- Chemat, F.; Abert-Vian, M.; Fabiano-Tixier, A.S.; Strube, J.; Uhlenbrock, L.; Gunjevic, V.; Cravotto, G. Green extraction of natural products. Origins, current status, and future challenges. Trends Anal. Chem. 2019, 118, 248–263. [Google Scholar] [CrossRef]

- M’hiri, N.; Ioannou, I.; Ghoul, M.; Boudhrioua, N.M. Extraction methods of citrus peel phenolic compounds. Food Rev. Int. 2014, 30, 265–290. [Google Scholar] [CrossRef]

- Sharmila, G.; Nikitha, V.S.; Ilaiyarasi, S.; Dhivya, K.; Rajasekar, V.; Kumar, N.M.; Muthukumaran, K.; Muthukumaran, C. Ultrasound assisted extraction of total phenolics from Cassia auriculata leaves and evaluation of its antioxidant activities. Ind. Crops Prod. 2016, 84, 13–21. [Google Scholar] [CrossRef]

- Chen, J.; Li, Y.; Wang, X.; Liu, W. Application of Deep Eutectic Solvents in Food Analysis: A Review. Molecules 2019, 24, 4594. [Google Scholar] [CrossRef] [PubMed]

- Torres-Valenzuela, L.S.; Ballesteros-Gómez, A.; Rubio, S. Green solvents for the extraction of high added-value compounds from agri-food waste. Food Eng. Rev. 2020, 12, 83–100. [Google Scholar] [CrossRef]

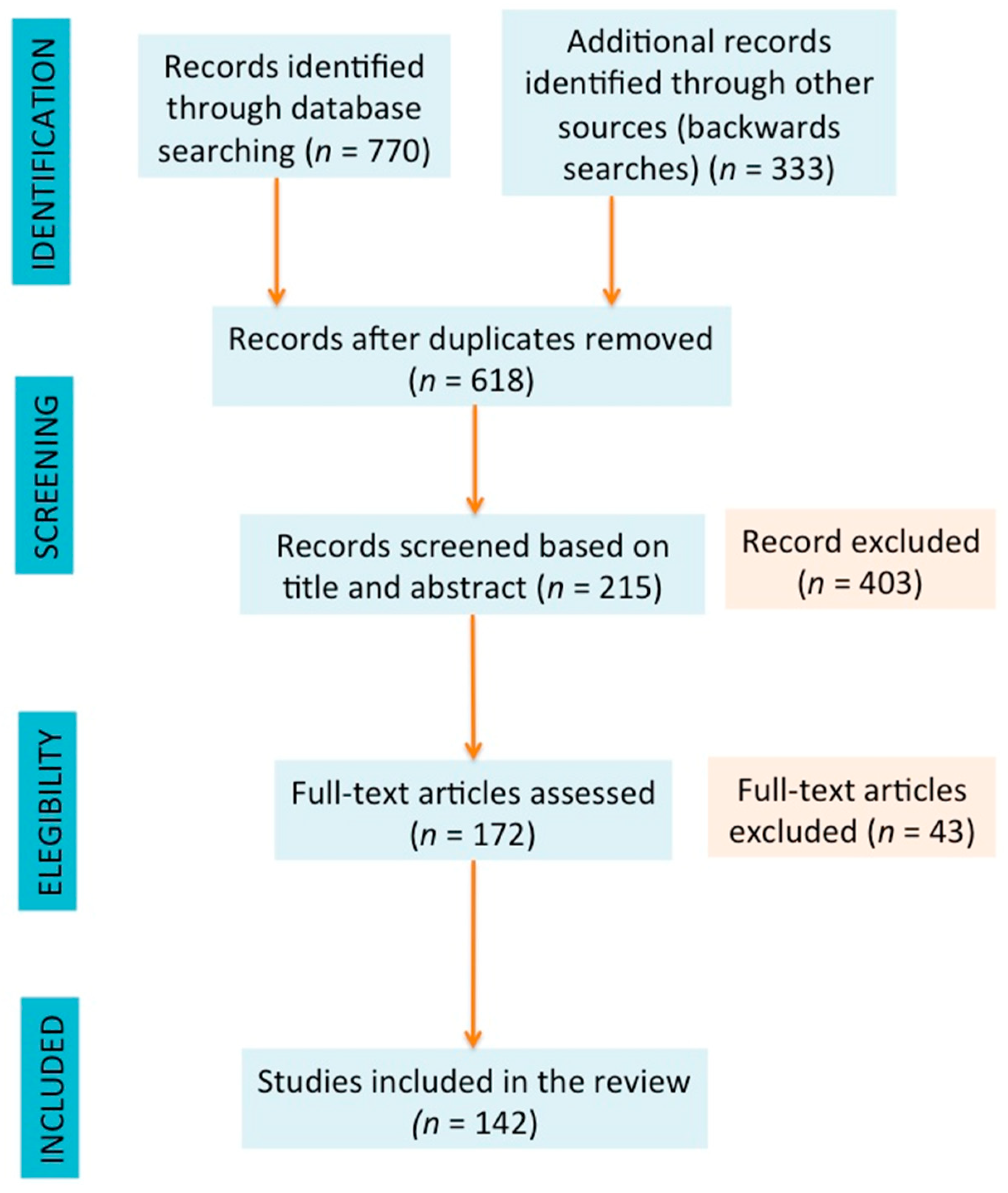

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef]

- Chandrapala, J.; Leong, T. Ultrasonic processing for dairy applications: Recent advances. Food Eng. Rev. 2015, 7, 143–158. [Google Scholar] [CrossRef]

- Chemat, F.; Rombaut, N.; Sicaire, A.G.; Meullemiestre, A.; Fabiano-Tixier, A.S.; Abert-Vian, M. Ultrasound assisted extraction of food and natural products. Mechanisms, techniques, combinations, protocols and applications. A review. Ultrason. Sonochem. 2017, 34, 540–560. [Google Scholar] [CrossRef]

- Kaderides, K.; Goula, A.M.; Adamopoulos, K.G. A process for turning pomegranate peels into a valuable food ingredient using ultrasound-assisted extraction and encapsulation. Innov. Food Sci. Emerg. Technol. 2015, 31, 204–215. [Google Scholar] [CrossRef]

- Wijngaard, H.; Hossain, M.B.; Rai, D.K.; Brunton, N. Techniques to extract bioactive compounds from food by-products of plant origin. Food Res. Int. 2012, 46, 505–513. [Google Scholar] [CrossRef]

- Knorr, D.; Froehling, A.; Jaeger, H.; Reineke, K.; Schlueter, O.; Schoessler, K. Emerging technologies in food processing. Annu. Rev. Food Sci. Technol. 2011, 2, 203–235. [Google Scholar] [CrossRef]

- Galanakis, C. Emerging technologies for the production of nutraceuticals from agricultural by-products: A viewpoint of opportunities and challenges. Food Bioprod. Process. 2013, 91, 575–579. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, D.; Chen, J.; Ye, X.; Yu, D. Effects of different factors of ultrasound treatment on the extraction yield of the all-trans-β-carotene from citrus peels. Ultrason. Sonochem. 2011, 18, 243–249. [Google Scholar] [CrossRef] [PubMed]

- Saini, A.; Panesar, P.S.; Bera, M. Valuation of Citrus reticulata (kinnow) peel for the extraction of lutein using ultrasonication technique. Biomass Convers. Bioref. 2020. [Google Scholar] [CrossRef]

- Boukroufa, M.; Boutekedjiret, C.; Chemat, F. Development of a green procedure of citrus fruits waste processing to recover carotenoids. Resour. Effic. Technol. 2017, 3, 252–262. [Google Scholar] [CrossRef]

- Montero-Calderon, A.; Cortes, C.; Zulueta, A.; Frigola, A.; Esteve, M.J. Green solvents and Ultrasound-Assisted Extraction of bioactive orange (Citrus sinensis) peel compounds. Sci. Rep. 2019, 9, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Murador, D.C.; Braga, A.R.C.; Martins, P.L.; Mercadante, A.Z.; de Rosso, V.V. Ionic liquid associated with ultrasonic-assisted extraction: A new approach to obtain carotenoids from orange peel. Food Res. Int. 2019, 126, 108653. [Google Scholar] [CrossRef] [PubMed]

- Wu, T.; Guan, Y.; Ye, J. Determination of flavonoids and ascorbic acid in grapefruit peel and juice by capillary electrophoresis with electrochemical detection. Food Chem. 2007, 100, 1573–1579. [Google Scholar] [CrossRef]

- Nishad, J.; Saha, S.; Dubey, A.K.; Varghese, E.; Kaur, C. Optimization and comparison of non-conventional extraction technologies for Citrus paradisi L. peels: A valorization approach. J. Food Sci. Technol. 2019, 56, 1221–1233. [Google Scholar] [CrossRef]

- Van Hung, P.; Yen Nhi, N.H.; Ting, L.Y.; Lan Phi, N.T. Chemical Composition and Biological Activities of Extracts from Pomelo Peel By-Products under Enzyme and Ultrasound-Assisted Extractions. J. Chem. 2020, 2020. [Google Scholar] [CrossRef]

- Dahmoune, F.; Boulekbache, L.; Moussi, K.; Aoun, O.; Spigno, G.; Madani, K. Valorization of Citrus limon residues for the recovery of antioxidants: Evaluation and optimization of microwave and ultrasound application to solvent extraction. Ind. Crop. Prod. 2013, 50, 77–87. [Google Scholar] [CrossRef]

- Jagannath, A.; Biradar, R. Comparative Evaluation of Soxhlet and Ultrasonics on the Structural Morphology and Extraction of Bioactive Compounds of Lemon (Citrus limon L.) Peel. J. Food Chem Nanotechnol. 2019, 5, 56–64. [Google Scholar] [CrossRef]

- Ma, Y.Q.; Chen, J.C.; Liu, D.H.; Ye, X.Q. Simultaneous extraction of phenolic compounds of citrus peel extracts: Effect of ultrasound. Ultrason. Sonochem. 2009, 16, 57–62. [Google Scholar] [CrossRef] [PubMed]

- Singanusong, R.; Nipornram, S.; Tochampa, W.; Rattanatraiwong, P. Low power ultrasound-assisted extraction of phenolic compounds from mandarin (Citrus reticulata Blanco cv. Sainampueng) and lime (Citrus aurantifolia) peels and the antioxidant. Food Anal. Methods 2015, 8, 1112–1123. [Google Scholar] [CrossRef]

- Safdar, M.N.; Kausar, T.; Jabbar, S.; Mumtaz, A.; Ahad, K.; Saddozai, A.A. Extraction and quantification of polyphenols from kinnow (Citrus reticulate L.) peel using ultrasound and maceration techniques. J. Food Drug Anal. 2017, 25, 488–500. [Google Scholar] [CrossRef] [PubMed]

- Nipornram, S.; Tochampa, W.; Rattanatraiwong, P.; Singanusong, R. Optimization of low power ultrasound-assisted extraction of phenolic compounds from mandarin (Citrus reticulata Blanco cv. Sainampueng) peel. Food Chem. 2018, 241, 338–345. [Google Scholar] [CrossRef]

- Xu, M.; Ran, L.; Chen, N.; Fan, X.; Ren, D.; Yi, L. Polarity-dependent extraction of flavonoids from citrus peel waste using a tailor-made deep eutectic solvent. Food Chem. 2019, 297, 124970. [Google Scholar] [CrossRef]

- Saini, A.; Panesar, P.S.; Bera, M. Comparative study on the extraction and quantification of polyphenols from citrus peels using maceration and ultrasonic technique. Curr. Res. Nutr. Food Sci. 2019, 7, 678–685. [Google Scholar] [CrossRef]

- Khan, M.K.; Abert-Vian, M.; Fabiano-Tixier, A.S.; Dangles, O.; Chemat, F. Ultrasound-assisted extraction of polyphenols (flavanone glycosides) from orange (Citrus sinensis L.) peel. Food Chem. 2010, 119, 851–858. [Google Scholar] [CrossRef]

- Dahmoune, F.; Moussi, K.; Remini, H.; Belbahi, A.; Aoun, O.; Spigno, G.; Madani, K. Optimization of Ultrasound-Assisted Extraction of Phenolic Compounds from Citrus sinensis L. peels using Response Surface Methodology. Chem. Eng. 2014, 37, 889–894. [Google Scholar] [CrossRef]

- Boukroufa, M.; Boutekedjiret, C.; Petigny, L.; Rakotomanomana, N.; Chemat, F. Bio-refinery of orange peels waste: A new concept based on integrated green and solvent free extraction processes using ultrasound and microwave techniques to obtain essential oil, polyphenols and pectin. Ultrason. Sonochem. 2015, 24, 72–79. [Google Scholar] [CrossRef]

- Nishad, J.; Saha, S.; Kaur, C. Enzyme-and ultrasound-assisted extractions of polyphenols from Citrus sinensis (cv. Malta) peel: A comparative study. J. Food Process. Preserv. 2019, 43, e14046. [Google Scholar] [CrossRef]

- Londoño-Londoño, J.; Rodrigues de Lima, V.; Lara, O.; Gil, A.; Crecsynski, C.; Jaime Arango, G.; Ramirez, J. Clean recovery of antioxidant flavonoids from citrus peel: Optimizing an aqueous ultrasound-assisted extraction method. Food Chem. 2010, 119, 81–87. [Google Scholar] [CrossRef]

- Garrido, G.; Chou, W.H.; Vega, C.; Goïty, L.; Valdés, M. Influence of extraction methods on fatty acid composition, total phenolic content and antioxidant capacity of Citrus seed oils from the Atacama Desert, Chile. J. Pharm. Pharmacog. Res. 2019, 7, 389–407. [Google Scholar]

- Omar, J.; Alonso, I.; Garaikoetxea, A.; Etxebarria, N. Optimization of focused ultrasound extraction (FUSE) and supercritical fluid extraction (SFE) of citrus peel volatile oils and antioxidants. Food Anal. Methods 2013, 6, 1244–1252. [Google Scholar] [CrossRef]

- Bagherian, H.; Ashtiani, F.Z.; Fouladitajar, A.; Mohtashamy, M. Comparisons between conventional, microwave-and ultrasound-assisted methods for extraction of pectin from grapefruit. Chem. Eng. Process. Process Intensif. 2011, 50, 1237–1243. [Google Scholar] [CrossRef]

- Wang, W.; Ma, X.; Xu, Y.; Cao, Y.; Jiang, Z.; Ding, T.; Ye, X.; Liu, D. Ultrasound-assisted heating extraction of pectin from grapefruit peel: Optimization and comparison with the conventional method. Food Chem. 2015, 178, 106–114. [Google Scholar] [CrossRef] [PubMed]

- Hosseini, S.S.; Khodaiyan, F.; Kazemi, M.; Najari, Z. Optimization and characterization of pectin extracted from sour orange peel by ultrasound assisted method. Int. J. Biol. Macromol. 2019, 125, 621–629. [Google Scholar] [CrossRef] [PubMed]

- Kirti, K.; Amita, S.; Priti, S.; Mukesh Kumar, A.; Jyoti, S. Colorful world of microbes: Carotenoids and their applications. Adv. Biol. 2014. [Google Scholar] [CrossRef]

- Martins, N.; Ferreira, I.C. Wastes and by-products: Upcoming sources of carotenoids for biotechnological purposes and health-related applications. Trends Food Sci. Technol. 2017, 62, 33–48. [Google Scholar] [CrossRef]

- Dai, J.; Mumper, R.J. Plant Phenolics: Extraction, Analysis and Their Antioxidant and Anticancer Properties. Mol. 2010, 15, 7313–7352. [Google Scholar] [CrossRef]

- Tsao, R. Chemistry and Biochemistry of Dietary Polyphenols. Nutrition 2010, 2, 1231–1246. [Google Scholar] [CrossRef]

- Zuorro, A.; Maffei, G.; Lavecchia, R. Reuse potential of artichoke (Cynara scolimus L.) waste for the recovery of phenolic compounds and bioenergy. J. Clean. Prod. 2016, 111, 279–284. [Google Scholar] [CrossRef]

- Khan, M.K.; Ahmad, K.; Hassan, S.; Imran, M.; Ahmad, N.; Xu, C. Effect of novel technologies on polyphenols during food processing. Innov. Food Sci. Emerg. Technol. 2018, 45, 361–381. [Google Scholar] [CrossRef]

- Putnik, P.; Barba, F.J.; Lorenzo, J.M.; Gabrić, D.; Shpigelman, A.; Cravotto, G.; Bursać Kovačević, D. An integrated approach to mandarin processing: Food safety and nutritional quality, consumer preference, and nutrient bioaccessibility. Compr. Rev. Food Sci. Food Saf. 2017, 16, 1345–1358. [Google Scholar] [CrossRef]

- Benvenutti, L.; Zielinski, A.A.F.; Ferreira, S.R.S. Which is the best food emerging solvent: IL, DES or NADES? Trends Food Sci. Technol. 2019, 90, 133–146. [Google Scholar] [CrossRef]

- Maran, J.P.; Sivakumar, V.; Thirugnanasambandham, K.; Sridhar, R. Optimization of microwave assisted extraction of pectin from orange peel. Carbohydr. Polym. 2013, 97, 703–709. [Google Scholar] [CrossRef]

- Liew, S.Q.; Ngoh, G.C.; Yusoff, R.; Teoh, W.H. Sequential ultrasound-microwave assisted acid extraction (UMAE) of pectin from pomelo peels. Int. J. Biol. Macromol. 2016, 93, 426–435. [Google Scholar] [CrossRef]

- Azmir, J.; Zaidul, I.S.M.; Rahman, M.M.; Sharif, K.M.; Mohamed, A.; Sahena, F.; Jahurulb, M.H.A.; Ghafoorc, K.; Norulainid, N.A.N.; Omar, A.K.M. Techniques for extraction of bioactive compounds from plant materials: A review. J. Food Eng. 2013, 117, 426–436. [Google Scholar] [CrossRef]

- Wang, L.; Weller, C.L. Recent advances in extraction of nutraceuticals from plants. Trends Food Sci. Technol. 2006, 17, 300–312. [Google Scholar] [CrossRef]

- Gil-Chávez, G.J.; Villa, J.A.; Ayala-Zavala, J.F.; Heredia, J.B.; Sepulveda, D.; Yahia, E.M.; González-Aguilar, G.A. Technologies for extraction and production of bioactive compounds to be used as nutraceuticals and food ingredients: An overview. Compr. Rev. Food Sci. Food Saf. 2013, 12, 5–23. [Google Scholar] [CrossRef]

- Bouras, M.; Chadni, M.; Barba, F.J.; Grimi, N.; Bals, O.; Vorobiev, E. Optimization of microwave-assisted extraction of polyphenols from Quercus bark. Ind. Crop. Prod. 2015, 77, 590–601. [Google Scholar] [CrossRef]

- Hayat, K.; Hussain, S.; Abbas, S.; Farooq, U.; Ding, B.; Xia, S.; Jia, C.; Zhang, X.; Xia, W. Optimized microwave-assisted extraction of phenolic acids from citrus mandarin peels and evaluation of antioxidant activity in vitro. Sep. Purif. Technol. 2009, 70, 63–70. [Google Scholar] [CrossRef]

- Hayat, K.; Zhang, X.; Chen, H.; Xia, S.; Jia, C.; Zhong, F. Liberation and separation of phenolic compounds from citrus mandarin peels by microwave heating and its effect on antioxidant activity. Sep. Purif. Technol. 2010, 73, 371–376. [Google Scholar] [CrossRef]

- Inoue, T.; Tsubaki, S.; Ogawa, K.; Onishi, K.; Azuma, J.I. Isolation of hesperidin from peels of thinned Citrus unshiu fruits by microwave-assisted extraction. Food Chem. 2010, 123, 542–547. [Google Scholar] [CrossRef]

- Ahmad, J.; Langrish, T.A.G. Optimisation of total phenolic acids extraction from mandarin peels using microwave energy: The importance of the Maillard reaction. J. Food Eng. 2012, 109, 162–174. [Google Scholar] [CrossRef]

- Nayak, B.; Dahmoune, F.; Moussi, K.; Remini, H.; Dairi, S.; Aoun, O.; Khodir, M. Comparison of microwave, ultrasound and accelerated-assisted solvent extraction for recovery of polyphenols from Citrus sinensis peels. Food Chem. 2015, 187, 507–516. [Google Scholar] [CrossRef]

- Di Donna, L.; Gallucci, G.; Malaj, N.; Romano, E.; Tagarelli, A.; Sindona, G. Recycling of industrial essential oil waste: Brutieridin and Melitidin, two anticholesterolaemic active principles from bergamot albedo. Food Chem. 2011, 125, 438–441. [Google Scholar] [CrossRef]

- Franco-Vega, A.; Ramírez-Corona, N.; Palou, E.; López-Malo, A. Estimation of mass transfer coefficients of the extraction process of essential oil from orange peel using microwave assisted extraction. J. Food Eng. 2016, 170, 136–143. [Google Scholar] [CrossRef]

- Bustamante, J.; van Stempvoort, S.; García-Gallarreta, M.; Houghton, J.A.; Briers, H.K.; Budarin, V.L.; Matharu, A.S.; Clark, J.H. Microwave assisted hydro-distillation of essential oils from wet citrus peel waste. J. Clean. Prod. 2016, 137, 598–605. [Google Scholar] [CrossRef]

- Ferhat, M.A.; Meklati, B.Y.; Smadja, J.; Chemat, F. An improved microwave Clevenger apparatus for distillation of essential oils from orange peel. J. Chromatogr. 2006, 1112, 121–126. [Google Scholar] [CrossRef]

- Farhat, A.; Fabiano-Tixier, A.S.; El Maataoui, M.; Maingonnat, J.F.; Romdhane, M.; Chemat, F. Microwave steam diffusion for extraction of essential oil from orange peel: Kinetic data, extract’s global yield and mechanism. Food Chem. 2011, 125, 255–261. [Google Scholar] [CrossRef]

- González-Rivera, J.; Spepi, A.; Ferrari, C.; Duce, C.; Longo, I.; Falconieri, D.; Piras, A.; Tine, M.R. Novel configurations for a citrus waste based biorefinery: From solventless to simultaneous ultrasound and microwave assisted extraction. Green Chem. 2016, 18, 6482–6492. [Google Scholar] [CrossRef]

- Auta, M.; Musa, U.; Tsado, D.G.; Faruq, A.A.; Isah, A.G.; Raji, S.; Nwanisobi, C. Optimization of citrus peels D-limonene extraction using solvent-free microwave green technology. Chem. Eng. Commun. 2018, 205, 789–796. [Google Scholar] [CrossRef]

- Hosseini, S.S.; Khodaiyan, F.; Yarmand, M.S. Optimization of microwave assisted extraction of pectin from sour orange peel and its physicochemical properties. Carbohydr. Polym. 2016, 140, 59–65. [Google Scholar] [CrossRef] [PubMed]

- Caputo, L.; Quintieri, L.; Cavalluzzi, M.M.; Lentini, G.; Habtemariam, S. Antimicrobial and antibiofilm activities of citrus water-extracts obtained by microwave-assisted and conventional methods. Biomedical 2018, 6, 70. [Google Scholar] [CrossRef]

- Ruiz, B.; Flotats, X. Citrus essential oils and their influence on the anaerobic digestion process: An overview. Waste Manag. 2014, 34, 2063–2079. [Google Scholar] [CrossRef] [PubMed]

- Mehl, F.; Marti, G.; Boccard, J.; Debrus, B.; Merle, P.; Delort, E.; Baroux, L.; Raymo, V.; Velazco, M.I.; Sommer, H.; et al. Differentiation of lemon essential oil based on volatile and non-volatile fractions with various analytical techniques: A metabolomic approach. Food Chem. 2014, 143, 325–335. [Google Scholar] [CrossRef]

- Amorim, J.L.; Simas, D.L.R.; Pinheiro, M.M.G.; Moreno, D.S.A.; Alviano, C.S.; da Silva, A.J.R.; Fernandes, P.D. Anti-inflammatory properties and chemical characterization of the essential oils of four citrus species. PLoS ONE 2016, 11, e0153643. [Google Scholar] [CrossRef]

- Díaz-Reinoso, B.; Moure, A.; Domínguez, H.; Parajó, J.C. Supercritical CO2 extraction and purification of compounds with antioxidant activity. J. Agric. Food. Chem. 2006, 54, 2441–2469. [Google Scholar] [CrossRef]

- Stratakos, A.C.; Koidis, A. Methods for Extracting Essential Oils. In Essential Oils in Food Preservation, Flavor and Safety; Academic Press: Waltham, MA, USA, 2016; pp. 31–38. [Google Scholar] [CrossRef]

- Hedrick, J.L.; Mulcahey, L.J.; Taylor, L.T. Supercritical fluid extraction. Microchim. Acta 1992, 108, 115–132. [Google Scholar] [CrossRef]

- Ndayishimiye, J.; Lim, D.J.; Chun, B.S. Antioxidant and antimicrobial activity of oils obtained from a mixture of citrus by-products using a modified supercritical carbon dioxide. J. Ind. Eng. Chem. 2018, 57, 339–348. [Google Scholar] [CrossRef]

- Tsitsagi, M.; Ebralidze, K.; Chkhaidze, M.; Rubashvili, I.; Tsitsishvili, V. Sequential extraction of bioactive compounds from tangerine (Citrus unshiu) peel. Anna. Agrar. Sci. 2018, 16, 236–241. [Google Scholar] [CrossRef]

- Trabelsi, D.; Aydi, A.; Zibetti, A.W.; Della Porta, G.; Scognamiglio, M.; Cricchio, V.; Langa, E.; Abderrabba, M.; Mainar, A.M. Supercritical extraction from Citrus aurantium amara peels using CO2 with ethanol as co-solvent. J. Supercrit. Fluids 2016, 117, 33–39. [Google Scholar] [CrossRef]

- Menichini, F.; Tundis, R.; Bonesi, M.; De Cindio, B.; Loizzo, M.R.; Conforti, F.; Statti, G.A.; Menabeni, R.; Bettini, R.; Menichini, F. Chemical composition and bioactivity of Citrus medica L. cv. Diamante essential oil obtained by hydrodistillation, cold-pressing and supercritical carbon dioxide extraction. Nat. Prod. Res. 2011, 25, 789–799. [Google Scholar] [CrossRef]

- Lopresto, C.G.; Meluso, A.; Di Sanzo, G.; Chakraborty, S.; Calabrò, V. Process-intensified waste valorization and environmentally friendly d-limonene extraction. Euro. Mediterr. J. Environ. Integr. 2019, 4, 31. [Google Scholar] [CrossRef]

- Teo, C.C.; Tan, S.N.; Yong, J.W.H.; Hew, C.S.; Ong, E.S. Pressurized hot water extraction (PHWE). J. Chromatogr. 2010, 1217, 2484–2494. [Google Scholar] [CrossRef]

- Plaza, M.; Turner, C. Pressurized hot water extraction of bioactives. Trends Anal. Chem. 2015, 71, 39–54. [Google Scholar] [CrossRef]

- Cravotto, G.; Cintas, P. Extraction of flavourings from natural sources. In Modifying Flavour in Food; Woodhead Publishing: Cambridge, UK, 2007; pp. 41–63. [Google Scholar] [CrossRef]

- Çam, M.; Hışıl, Y. Pressurised water extraction of polyphenols from pomegranate peels. Food Chem. 2010, 123, 878–885. [Google Scholar] [CrossRef]

- Cheigh, C.I.; Chung, E.Y.; Chung, M.S. Enhanced extraction of flavanones hesperidin and narirutin from Citrus unshiu peel using subcritical water. J. Food Eng. 2012, 110, 472–477. [Google Scholar] [CrossRef]

- Lachos-Perez, D.; Baseggio, A.M.; Mayanga-Torres, P.C.; Junior, M.R.M.; Rostagno, M.A.; Martínez, J.; Forster-Carneiro, T. Subcritical water extraction of flavanones from defatted orange peel. J. Supercrit. Fluids 2018, 138, 7–16. [Google Scholar] [CrossRef]

- Wang, X.; Chen, Q.; Lü, X. Pectin extracted from apple pomace and citrus peel by subcritical water. Food Hydrocoll. 2014, 38, 129–137. [Google Scholar] [CrossRef]

- Barrales, F.M.; Silveira, P.; Barbosa, P.D.P.M.; Ruviaro, A.R.; Paulino, B.N.; Pastore, G.M.; Alves, G.; Martinez, J. Recovery of phenolic compounds from citrus by-products using pressurized liquids—An application to orange peel. Food Bioprod. Process. 2018, 112, 9–21. [Google Scholar] [CrossRef]

- Barbosa-Cánovas, G.V.; Pierson, M.D.; Zhang, Q.H.; Schaffner, D.W. Pulsed electric fields. J. Food Sci. 2000, 65, 65–79. [Google Scholar] [CrossRef]

- Toepfl, S.; Mathys, A.; Heinz, V.; Knorr, D. Potential of high hydrostatic pressure and pulsed electric fields for energy efficient and environmentally friendly food processing. Food Rev. Int. 2006, 22, 405–423. [Google Scholar] [CrossRef]

- Kotnik, T.; Kramar, P.; Pucihar, G.; Miklavcic, D.; Tarek, M. Cell membrane electroporation-Part 1: The phenomenon. IEEE Electr. Insul. Mag. 2012, 28, 14–23. [Google Scholar] [CrossRef]

- Kumari, B.; Tiwari, B.K.; Hossain, M.B.; Brunton, N.P.; Rai, D.K. Recent advances on application of ultrasound and pulsed electric field technologies in the extraction of bioactives from agro-industrial by-products. Food Bioprocess. Technol. 2018, 11, 223–241. [Google Scholar] [CrossRef]

- Luengo, E.; Álvarez, I.; Raso, J. Improving the pressing extraction of polyphenols of orange peel by pulsed electric fields. Innov. Food Sci. Emerg. Technol. 2013, 17, 79–84. [Google Scholar] [CrossRef]

- El Kantar, S.; Boussetta, N.; Lebovka, N.; Foucart, F.; Rajha, H.N.; Maroun, R.G.; Louka, N.; Vorobiev, E. Pulsed electric field treatment of citrus fruits: Improvement of juice and polyphenols extraction. Innov. Food Sci. Emerg. Technol. 2018, 46, 153–161. [Google Scholar] [CrossRef]

- Boussetta, N.; Vorobiev, E. Extraction of valuable biocompounds assisted by high voltage electrical discharges: A review. Comptes Rendus Chimie 2014, 17, 197–203. [Google Scholar] [CrossRef]

- Boussetta, N.; Lesaint, O.; Vorobiev, E. A study of mechanisms involved during the extraction of polyphenols from grape seeds by pulsed electrical discharges. Innov. Food Sci. Emerg. Technol. 2013, 19, 124–132. [Google Scholar] [CrossRef]

- Buniowska, M.; Carbonell-Capella, J.; Zulueta, A.; Frigola, A.; Esteve, M.J. Bioaccessibility of Bioactive Compounds and Antioxidant Capacity from Orange Peel after Pulsed Electric Fields and High Voltage Electrical Discharges. MOJ Food Process. Technol. 2015, 1, 00017. [Google Scholar] [CrossRef][Green Version]

- El Kantar, S.; Rajha, H.N.; Boussetta, N.; Vorobiev, E.; Maroun, R.G.; Louka, N. Green extraction of polyphenols from grapefruit peels using high voltage electrical discharges, deep eutectic solvents and aqueous glycerol. Food Chem. 2019, 295, 165–171. [Google Scholar] [CrossRef] [PubMed]

- Prasad, K.N.; Yang, E.; Yi, C.; Zhao, M.; Jiang, Y. Effects of high pressure extraction on the extraction yield, total phenolic content and antioxidant activity of longan fruit pericarp. Innov. Food Sci. Emerg. Technol. 2009, 10, 155–159. [Google Scholar] [CrossRef]

- Gómez, B.; Munekata, P.E.S.; Barba, F.J.; Pinto, C.A.; Saraiva, J.A.; Lorenzo, J.M. Influence of high-pressure processing on the nutritional changes of treated foods. Ref. Modul. Food Sci. 2019. [Google Scholar] [CrossRef]

- Casquete, R.; Castro, S.M.; Villalobos, M.C.; Serradilla, M.J.; Queirós, R.P.; Saraiva, J.A.; Córdoba, M.G.; Teixeira, P. High pressure extraction of phenolic compounds from citrus peels. High Press. Res. 2014, 34, 447–451. [Google Scholar] [CrossRef]

- Tejada-Ortigoza, V.; Garcia-Amezquita, L.E.; Serment-Moreno, V.; Torres, J.A.; Welti-Chanes, J. Moisture sorption isotherms of high pressure treated fruit peels used as dietary fiber sources. Innov. Food Sci. Emerg. Technol. 2017, 43, 45–53. [Google Scholar] [CrossRef]

- Naghshineh, M.; Olsen, K.; Georgiou, C.A. Sustainable production of pectin from lime peel by high hydrostatic pressure treatment. Food Chem. 2013, 136, 472–478. [Google Scholar] [CrossRef]

- Sanz-Puig, M.; Moreno, P.; Pina-Pérez, M.C.; Rodrigo, D.; Martínez, A. Combined effect of high hydrostatic pressure (HHP) and antimicrobial from agro-industrial by-products against S. Typhimurium. LWT 2017, 77, 126–133. [Google Scholar] [CrossRef]

| Compound | Sample | Extraction Conditions | Solvent | Results | References |

|---|---|---|---|---|---|

| Carotenoids | Mandarin peel (Citrus spp. N/A) | 66.7% amplitude 25 °C 544.59 W/cm2 ratio 3:30 (g/mL) 20–120 min | Ethanol | The use of ultrasound increases the extraction performance of all-trans-β-carotene compared to CE | [53] |

| Kinnow mandarin peel (Citrus reticulata) | 32.8% amplitude 43.14 °C 33.71 min ratio 1:6.16 (g/mL) | N/A | Maximum lutein yield 2.97 mg/100 g | [54] | |

| Orange peel (Citrus spp. N/A) | 208 W/cm2 20 °C 5 min | Limonene (previous extraction) | Total carotenoids: 1.13 mg β-carotene/100 mL of extraction 40% higher yield than conventional extraction | [55] | |

| Orange peel (Citrus sinensis) | 400 W 30 min 40 °C ratio1:10 (g/mL) | Ethanol 50% | Total carotenoids: 0.63 mg β-carotene/100 g | [56] | |

| Orange peel (Citrus spp. N/A) | 200 W 5 min ratio 1:3 (g/mL) 80% amplitude | ILs[BMIM][CL] | Total carotenoids: 3.20 β-carotene/100 g | [57] | |

| Phenolic compounds | Grapefruit peel (Citrus spp. N/A) | 2 h ratio 1:10 | Ethanol 99.7% | Naringin: 1400 mg/100 g Hesperidin: 7.14 mg/100 g | [58] |

| Grapefruit peel (Citrus paradise L.) | 71.11% amplitude 33.12 min ratio 1:39.63 | Ethanol 70% | TPC: 2116.71 mg GAE/100 g TF: 276.53 mg GAE/100 g Naringin: 4203 mg/100 g Quercitin: 12.097 mg/100 g | [59] | |

| Grapefruit peel (Citrus grandis limonia Osbeck species) | 40 kHz 60 min room temperature ratio 1:40 (g/mL) | Water | TPC: 408–687 mg GAE/100 g TF: 93–190 mg RE/100 g Naringin: 13–49 mg/100 g Hesperidin: 62–109 mg/100 g | [60] | |

| Lemon peel (Citrus limon) | 77.79% amplitude 15.05 min | Ethanol 63.93% | TPC: 1522 mg GAE/100 g | [61] | |

| Lemon peel (Citrus limon L.) | 200 W 80% duty cicle 60 min 48 °C ratio 1:6 (g/mL) | Methanol 80% | TPC: 67.17 mg GAE/100 g TF: 4.52 mg catequin equivalent/100 g | [62] | |

| Mandarin peel (Citrus unshiu marc) | 60 kHz 3.2–30 W 15–40 °C 10–60 min | Methanol 80% | High yield at 15 °C and 60 min, compared to maceration and ultrasound at 40 °C and 60 min | [63] | |

| Mandarin peel (Citrus reticulata Blanco cv) and lime peel (Citrus aurantifolia) | 50.93 W | Acetone 80% | Mandarin TPC: 3083.61 mg GAE/100 g TF: 2539.82 mg QE/100 g Hesperidin: 1374 mg/100 g Lime Naringin: 53.39 mg/100 g | [64] | |

| Mandarin peel (Citrus spp. N/A) | 35 kHz 45 °C ratio 1:20 (g/mL) 60 min | Methanol 80% | TPC: 3248 mg GAE/100 g Hesperidin: 5.21 mg/100 g | [65] | |

| Mandarin peel (Citrus reticulata Blanco cv. Sainampueng) | 56.71 W 48 °C 40 min | Acetone 80% | Extraction yield 26,52%, 1.77 times higher than CE TPC: 15256.64 mg GAE/100 g Hesperidin: 6444.84 mg/100 g | [66] | |

| Mandarin peel (Citrus unshiu) | 200 W 25 min 50 °C | ChCl-Lea-MU 80% | TF: 6582 mg/100 g polymethoxylated flavonoids (PMFs): 1875 mg/100 g glycosides of flavonoids (GoFs): 4707 mg/100 g | [67] | |

| Kinnow mandarin peel (Citrus reticulata) and sweet lemon “mousambi” peel (Citrus limetta) | ratio 1:3 (g/mL) Other parameters N/A | Acetone 100% | Mandarin Extraction yield 5.85% TPC: 2800 mg GAE/100 g TF: 440 mg GAE/100 g Sweet lemon Extraction yield 12.95% TPC: 2199 mg GAE/100 g TF: 207 mg GAE/100 g | [68] | |

| Orange peel (Citrus sinensis) | 150 W 40 °C 30 min ratio 0.25:1 (g/mL) 2 cm2 particle size | Ethanol 80% | Extraction yield TFC: 275.8 mg GAE/100 g Extraction yield: 10.9% higher compared CE Naringin: 70.3 mg/100 g Hesperidin: 205.2 mg/100 g | [69] | |

| Orange peel (Citrus spp. N/A) | 8.33 min 65.94% amplitude | Acetone 75.79% | TPC: 1357 mg GAE/100 g | [70] | |

| Orange peel (Citrus spp. N/A) | 0.956 W/cm2 59.83 °C ratio 1:10 (g/mL) 30 min 2cm2 particle size | Water (previous extraction) | TPC: 50.02 mg GA/100 g | [71] | |

| Sweet orange peel (Citrus sinensis cv. Malta) | 70.89% amplitude 35 min room temperature ratio 1:40 (g/mL) | Etanol 70% | TPC: 1590 mg GAE/100 g TF: 104 mg QE/100 g Naringin: 1.10 g/100 mL of extract | [72] | |

| Lime, orange, mandarin peel (Citrus spp. N/A) | 60 kHz 30 min 40 °C ratio 1:10 (g/mL) | Water | TPC 7480 mg GAE/100 g lime 6636 mg GAE/100 g orange 5868 mg GAE/100 g mandarin | [73] | |

| Lime and orange seed oil (Citrus spp. N/A) | 100 W 90 min 25 °C | n-Hexane | Lime seeds TPC: 65.3 mg GAE/100 g oil Orange seeds: TPC: 68.2 mg GAE/100 g oil | [74] | |

| Citrus fruits peel (Citrus spp. N/A) | 5 min 30% amplitude Ciclo 5 s−1 | Ethanol | TPC: 1259 mg GAE/100 g (orange) 1248 mg GAE/100 g (grapefruit) 1812 mg GAE/100 g (lemon) 793 mg GAE/100 g (mandarin) | [75] | |

| Essential oils | Mandarin, orange, grapefruit and lemon peel (Citrus spp. N/A) | 5 min 30% amplitude ratio 0.25: 15 (g/mL) cycles 5 sec−1 | Ethanol 100% | Limonene: 3010 mg/100 g (mandarin) 1360 mg/100 g (grapefruit) 1280 mg/100 g (orange) 140 mg/100 g (lemon) | [75] |

| Lime and orange seed oil (Citrus spp. N/A) | 100 W 90 min 25 °C | n-Hexane | Lime seeds Oil yield: 22.07% Linoleic acid: 34.07% α-linoleic: 11.45% Orange seeds: Oil yield 22.84% Linoleic acid: 34.07% α-linoleic: 11.45% | [74] | |

| Pectins | Grapefruit peel (Citrus spp. N/A) | 25 min 70 °C | Acidified water | Pectin yield: 17.92% | [76] |

| Grapefruit peel (Citrus spp. N/A) | 12.56 W/cm2 28 min 67.7 °C ratio 3:150 (g/mL) | Acidified water | Pectin yield: 27.34% Degree of Esterification: 65.52% | [77] | |

| Sour Orange peel (citrus aurantium L.) | 150 W 10 min pH 1.5 ratio 1:20 (g/mL) <30 °C | Acidified water (cítric acid) | Pectin yield: 28.07% Galacturonic acid: 65.3% Sugars: 0.4% (74% galactose) TPC: 3995 mg GAE/100 g of pectin | [78] |

| Compound | Sample | Extraction Conditions | Solvent | Results | References |

|---|---|---|---|---|---|

| Phenolic compounds | Lemon peel (Citrus limon) | Ratio 1:28 (g/mL) 400 W 120 s | Ethanol 48% | TPC: 1574 mg GAE/100 g | [61] |

| Mandarin peel (Citrus reticulata Blanco cv. Kinnow) | 152 W 49 s | Methanol 66% | Free phenolic compounds: 1162.8 mg/100 g Free phenolic acids: 114.23 mg/100 g | [93] | |

| Mandarin peel (Citrus reticulata Blanco cv. Kinnow) | 250 W 10 min | Methanol 80% | TFs: 637.59 mg QE/100 g Total phenolic acids fraction: 131.57 mg/100 g | [94] | |

| Mandarin peel (Citrus inshiu) | Ratio 2:20 (g/mL) 7 min 140 °C | Ethanol 70% | Hesperidin: 5860 mg/100 g Narirutin: 1310 mg/100 g | [95] | |

| Mandarin peel (Citrus spp. N/A) | Ratio 1:2 (g/mL) 400 W 3 min 135 °C | Deionized water | TPC: 2320 mg GAE/100 g | [96] | |

| Orange peel (Citrus sinensis) | Ratio 1:25 (g/mL) 500 W 122 s | Acetone 51% | TPC: 1220 mg GAE/100 g Cafeic acid: 81.59 mg/100 g Ferulic acid: 145.5 mg/100 g | [97] | |

| Essential oils | Bergamot albedo (Citrus bergamia Risso) | 500 W 1–5 min <48 °C Ratio 3:20 (g/mL) | Water | Brutieridin Melitidin | [98] |

| Mandarin peel (Citrus sinensis var. Valencia) | Particle size 40 µm 540 W 10–20 min | N/A | EOs yield: 2.73% | [99] | |

| Mandarin peel (Citrus sinensis var. Navel Navelate) | Ratio 1:1,5 (g/mL) Part 1: −785 W −5 min Part 2: −250 W −15 min | Water | EOs yield: 1.8% Monoterpene hydrocarbons: 99.34% Limonene: 97.38% | [100] | |

| Orange peel (Citrus sinensis L. Osbeck) | 30 min 100 °C | N/A | EOs yield: 0.42% Limonene: 76.7% Oxygenated monoterpenes: 7.0% | [101] | |

| Orange peel (Citrus sinensis L. Osbeck) | 200 W 12 min | N/A | EOs yield: 1.54% Monoterpene hydrocarbons: 98.23% Limonene: 94.88% Oxygenated monoterpenes: 0.43% | [102] | |

| Orange peel (Citrus spp. N/A) | 250 W 5 min | N/A | EOs yield: 1.16% Limonene: 95.2 Valencene: 0.2% | [103] | |

| Orange peel and lemon peel (Citrus spp. N/A) | 1000 W 10 min | N/A | D-limonene yield: 3.7% in orange 2.0% in lemon | [104] | |

| Pectins | Grapefruit peel (Citrus spp. N/A) | 900 W 6 min | N/A | Pectins yields: 27.81% | [76] |

| Orange peel (Citrus reticulata) | 422 W 169 s pH 1.4 ratio 1:16.9 (g/mL) | Distilled water | Pectins yields: 19.19% | [87] | |

| Orange peel (Citrus sinensis L. Osbeck) | 500 W 3 min | Distilled water | Pectins yields: 24.2% | [71] | |

| Sour Orange Peel (Citrus aurantium L.) | 700W 3 min pH 1.5 ratio 1:15 (g/mL) | Acidified distilled water | Pectins yields: 29.1% Galacturonic acid: 71% | [105] |

| Compound | Sample | Extraction Conditions | Solvent | Results | References |

|---|---|---|---|---|---|

| Carotenoids | Mandarin peel (Citrus unshiu) | Pressure 150 atm Flow rate 2 mL/min 40 °C 1 h of balance + 1 h of extraction | CO2-acetone (7%) | β-carotene: 0.04−0.39 mg/100 g | [114] |

| Phenolic compounds | Mandarin peel (Citrus unshiu) | Pressure 250 atm Flow rate 2 mL/min 60 °C 1 h balanced 30 min extraction time | CO2-methanol (7%) | Hesperidin 1.6–1.8% | [94] |

| Mandarin, orange, lemon, and grapefruit peel (Citrus spp. N/A) | Pressure 160 atm Flow rate 1 mL/min 35 °C | Ethanol 40% | TPC: 0.67 mg GAE/100 g grapefruit 0.66 mg GAE/100 g lemon 0.45 mg GAE/100 g orange 0.38 mg GAE/100 g tangerine | [75] | |

| Sour orange peel (Citrus aurantium amara) | 170 bar Flow rate 2.7kg CO2/h 50 min balanced time 120 min extraction time | CO2-ethanol (3%) | Osthol 47% | [115] | |

| Essential oils | Citron peel (Citrus medica) | 100 bar Flow rate 5 mmol/min 40 °C 6 h | CO2 | Oil yield: 28% Citropten: 84.5% | [116] |

| Lemon peel (Citrus lemon) | 15 MPa Flow rate 8 L/min 40 °C 40 min Particle size 0.125–1 mm | CO2 | D-limonene yield: 4.5% | [117] | |

| Mandarin peel (Citrus unshiu) | Pressure 100 atm 15 °C 15 min of equilibrium | CO2 | EOs yield: 0.85% | [114] | |

| Mandarin, orange, lemon and grapefruit peel (Citrus spp. N/A) | Flow rate 1 mL/min 35 °C | N/A | Limonene: 3010 mg/100 g mandarin 990 mg/100 g orange 810 mg/100 g grapefruit 70 mg/100 g lemon β-pineno: 39 mg/100 g mandarin 14 mg/100 g orange 10 mg/100 g grapefruit 11 mg/100 g lemon | [75] |

| Method | Sample | Extraction Conditions | Solvent | Results | References |

|---|---|---|---|---|---|

| Pressurized water extraction | Mandarin peel (Citrus inshiu) | 160 °C 10 min 100 atm | Water | Hesperidin 7200 mg/100 g Narirutin 11,700 mg/100 g | [122] |

| Mandarin peel (Citrus reticulata) | 120 °C 5 min Ratio 1:30 | Water | Pectin yield: 21.95% Galacturonic acid: 68.88% | [123] | |

| Orange peel (Citrus spp. N/A) | 150 °C Flow rate 10 mL/min | Water | TPC: 3170 mg GAE/100 g Hesperidin 2000 mg/100 g Narirutin 233 mg/100 g Pectins yield: 18.53% | [124] | |

| Pressurized liquids extraction | Orange peel (Citrus spp. N/A) | 65 °C 40 min 10 MPa Flow rate 2.37 g/min Ratio 1:47 kg/kg | Ethanol 75% | TPC: 1590 mg GAE/100 g Hesperidin: 5400 mg/100 g Naringin: 22.6 mg/100 g Narirutin: 42 mg/100 g Tangeretin: 54 mg/100 g Naringenin: 54 mg/100 g Hesperitin: 26 mg/100 g | [125] |

| Pulse electric field | Orange peel (Citrus spp. N/A) | 1, 3, 5, and 7 kV/cm 1 Khz frequency 30 min 5 bars | N/A | Phenolic compounds yield: 20%, 129%, 153%, and 159% Antioxidant capacity: 51%, 94%, 148%, and 192% A 5kV/cm 1–3.1 mg/100 g naringin 1.3–4.6 mg/100 hesperidin | [130] |

| Orange, grapefruit, and lemon peel (Citrus spp. N/A) | First treatment 3kV/cm Second treatment 10 kV/cm | Ethanol 50% | TPC: 2200 mg GAE/100 g orange peel Hesperidin: 507 mg/100 g orange (flavedo) 482 mg/100 g orange (albedo) Naringin: 1036 mg/100 g grapefruit (flavedo) 2686 mg/100 g grapefruit (albedo) Eriocitrin: 144 mg/100 g lemon (flavedo) 197 mg/100 g lemon (albedo) | [131] |

| Compound | Sample | Extraction Conditions | Solvent | Results | References |

|---|---|---|---|---|---|

| Carotenoids | Mandarin peel (Navel Navelate) | 40kV 10 µs 55 kJ/kg and 364 kJ/kg | N/A | Total carotenoids: 0.369 mg β-carotene/100 mL of extract (55 kJ/kg) 0.286 mg β-carotene/100 mL of extract (364 kJ/kg) | [134] |

| Phenolics compounds | Grapefruit peel (Citrus spp. N/A) | Ratio 1:10 (g/mL) 10–300 pulses | Glicerol (20%) | TPC: 1880 mg GAE/100 g | [135] |

| Mandarin peel (Navel Navelate) | 40kV 10 µs 55–364 kJ/kg | N/A | TPC: 184.2 mg GAE/100 mL of extract (55 kJ/kg) 692.1 mg GAE/100 mL of extract (364 kJ/kg) | [134] |

| Compounds | Sample | Extraction Conditions | Solvent | Results | References |

|---|---|---|---|---|---|

| Phenolic compounds | Orange and lemon peel (Citrus spp. N/A) | 300 MPa 10 min 10 °C 500 MPa 3 min 10 °C | N/A | TPC: 136.85 mg GAE/100 mL orange 344.53 mg GAE/100 mL lemon | [138] |

| Lemon, lime, mandarin and orange peel (Citrus spp. N/A) | 300 MPa | N/A | TPC: 266.23 mg GAE/100 g lemon 397.21 mg GAE/100 g lime 587.28 mg GAE/100 g tangerine 288.16 mg GAE/100 g orange | [19] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anticona, M.; Blesa, J.; Frigola, A.; Esteve, M.J. High Biological Value Compounds Extraction from Citrus Waste with Non-Conventional Methods. Foods 2020, 9, 811. https://doi.org/10.3390/foods9060811

Anticona M, Blesa J, Frigola A, Esteve MJ. High Biological Value Compounds Extraction from Citrus Waste with Non-Conventional Methods. Foods. 2020; 9(6):811. https://doi.org/10.3390/foods9060811

Chicago/Turabian StyleAnticona, Mayra, Jesus Blesa, Ana Frigola, and Maria Jose Esteve. 2020. "High Biological Value Compounds Extraction from Citrus Waste with Non-Conventional Methods" Foods 9, no. 6: 811. https://doi.org/10.3390/foods9060811

APA StyleAnticona, M., Blesa, J., Frigola, A., & Esteve, M. J. (2020). High Biological Value Compounds Extraction from Citrus Waste with Non-Conventional Methods. Foods, 9(6), 811. https://doi.org/10.3390/foods9060811