The Effect of Sodium Reduction by Sea Salt and Dry Sourdough Addition on the Wheat Flour Dough Rheological Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Rheological Properties of Dough during Mixing and Extension

2.3. Pasting Properties

2.4. Rheological Properties of Dough during Fermentation

2.5. Experimental Design and Statistical Analysis

3. Results and Discussion

3.1. Fitting Models

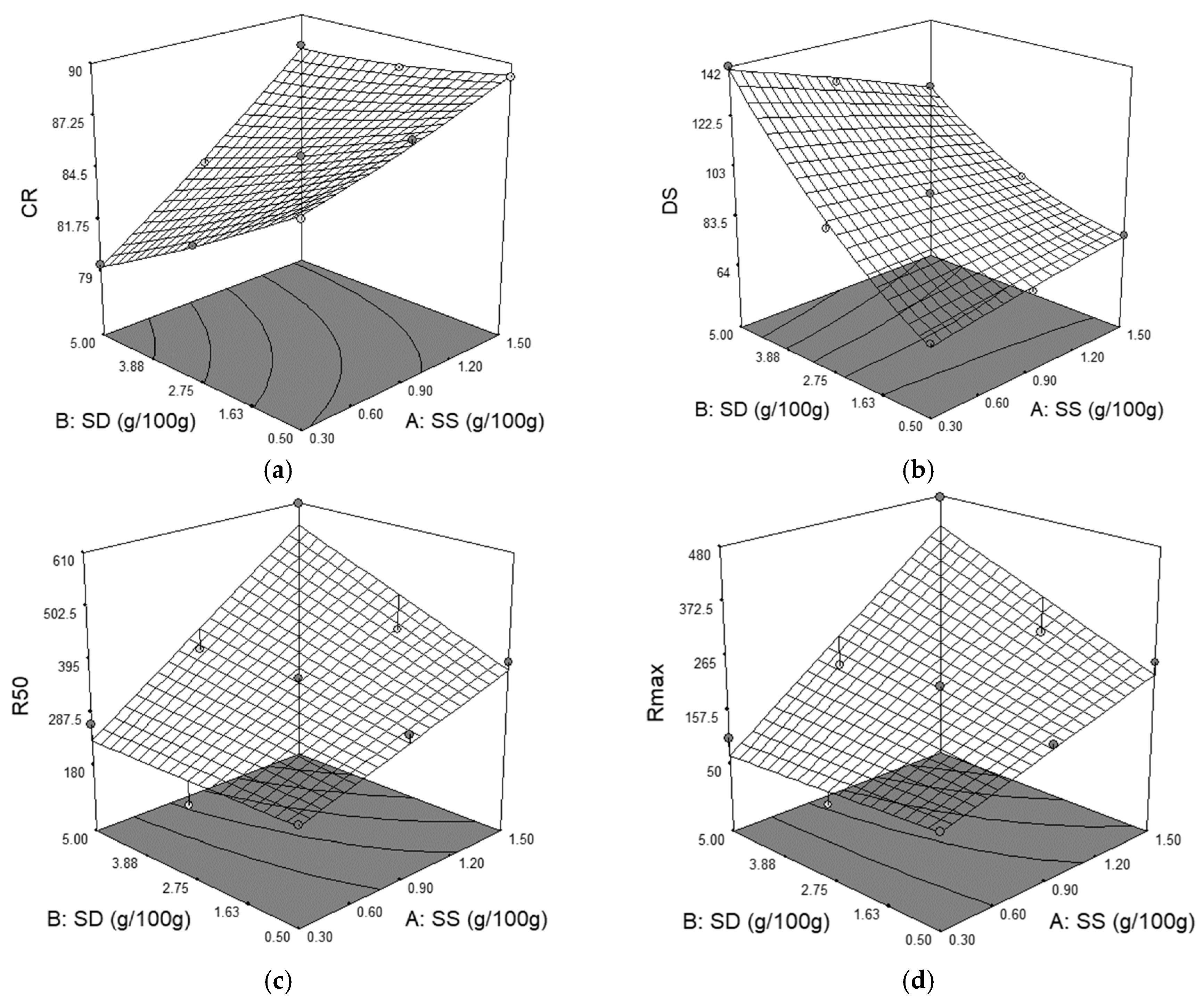

3.2. Mixing and Extension Values for the Formulation Samples

3.3. Pasting Parameters Values of the Formulation Samples

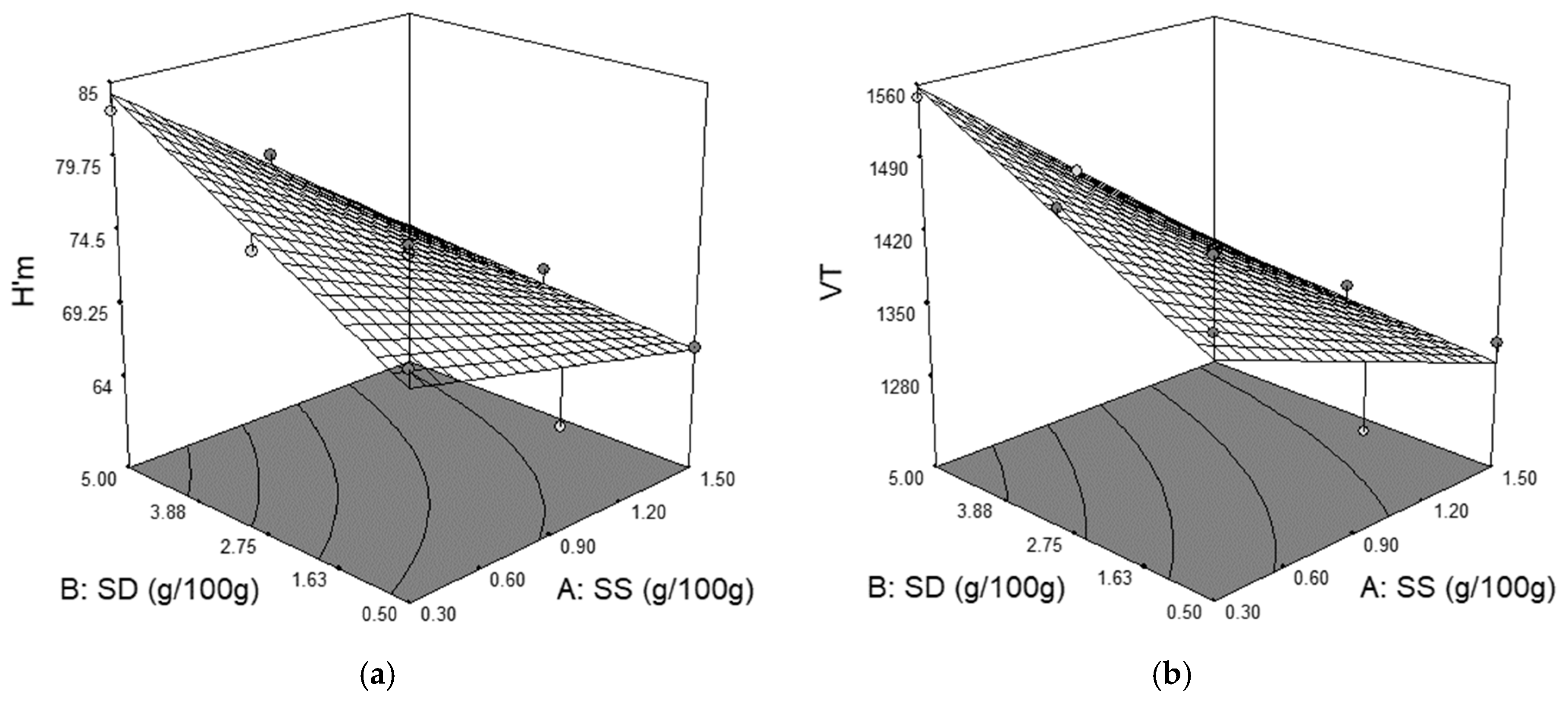

3.4. Fermentation Parameters Values of the Formulation Samples

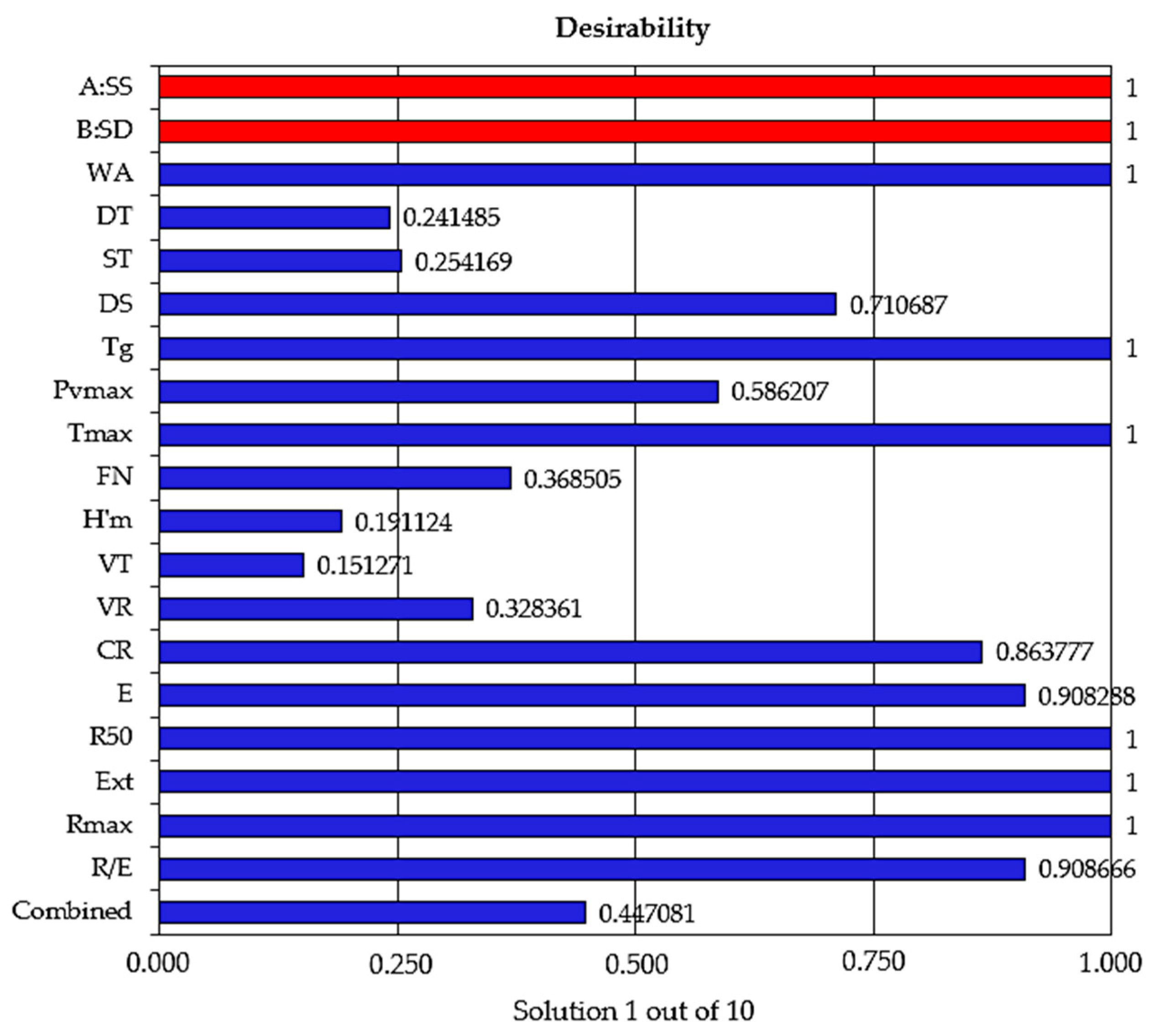

3.5. Optimization of Sea Salt and Dry Sourdough Formulation

3.6. Sodium Chloride Reduction from Bakery Products by Sea Salt and Dry Sourdough Optimum Formulation

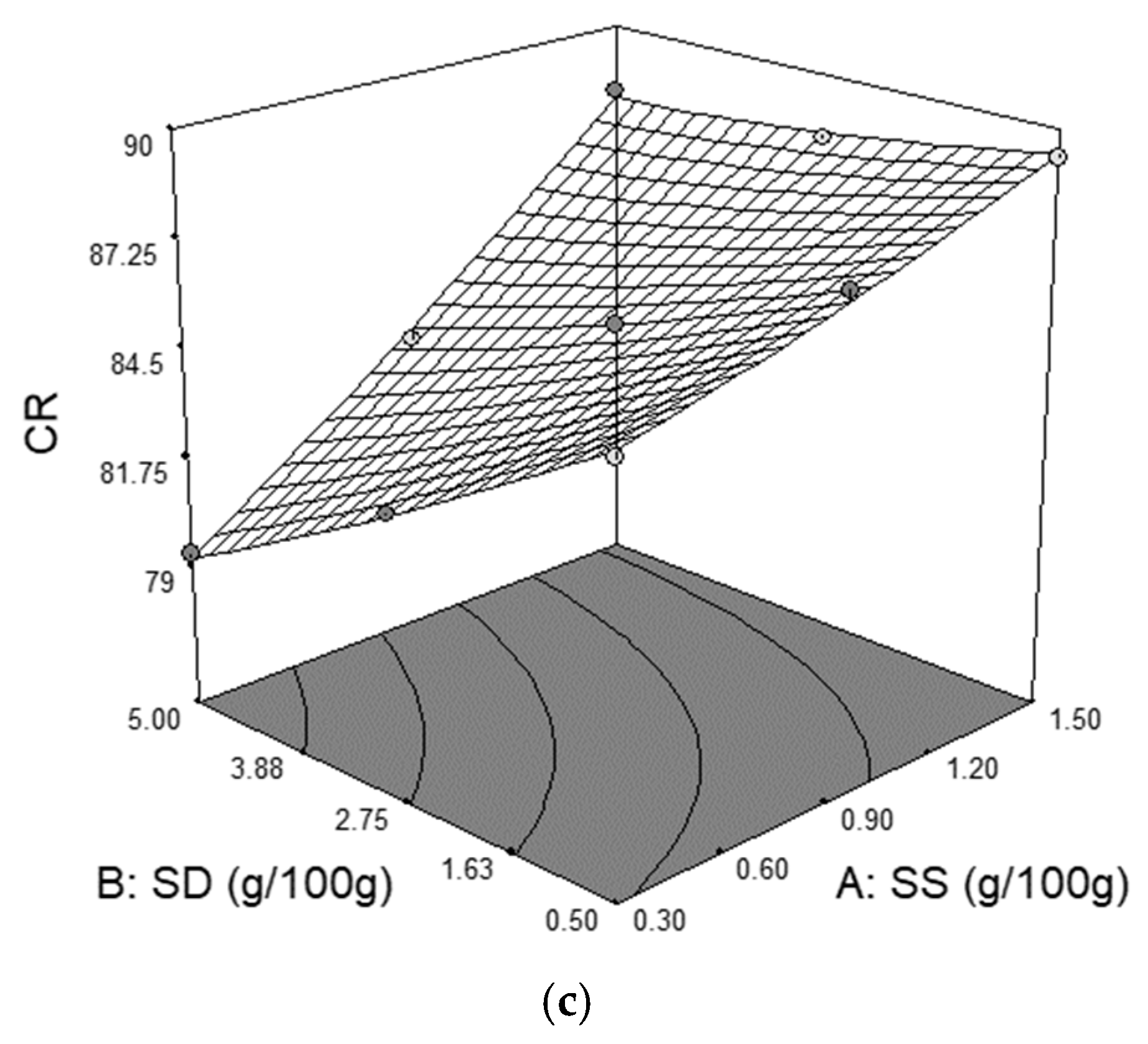

3.7. Effect of Sodium Chloride Addition on Dough Rheological Properties Compared to the Optimum Amounts of SS and SD Obtained through Response Surface Methodology

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zandstra, E.H.; Lion, R.; Newson, R.S. Salt reduction: Moving from consumer awareness to action. Food Qual. Prefer. 2016, 48, 376–381. [Google Scholar] [CrossRef]

- Costa, R.G.B.; Sobrala, D.; Aglaê, V.; Teodoro, M.; Costa Junior, L.C.G.; de Paula, J.C.J.; Landin, T.B.; Oliveira, M.B. Sodium substitutes in Prato cheese: Impact on the physicochemical parameters, rheology aspects and sensory acceptance. LWT Food Sci. Tehcnol. 2018, 90, 643–649. [Google Scholar] [CrossRef]

- Ferrão, L.L.; Silva, E.B.; Silva, H.L.A.; Silva, R.; Mollakhalili, N.; Granato, D.; Freitas, M.Q.; Silva, M.C.; Raices, R.S.L.; Padilha, M.C.; et al. Strategies to develop healthier processed cheeses: Reduction of sodium and fat contents and use of prebiotics. Food Res. Int. 2016, 86, 93–102. [Google Scholar] [CrossRef]

- Townsend, N.; Nichols, M.; Scarborough, P.; Rayner, M. Cardiovascular disease in Europe—Epidemiological update 2015. Eur. Heart J. 2015, 36, 2696–2705. [Google Scholar] [CrossRef] [PubMed]

- Jekle, M.; Necula, A.; Jekle, M.; Becker, T. Concentration dependent rate constants of sodium substitute functionalities during wheat dough development. Food Res. Int. 2019, 116, 346–353. [Google Scholar] [CrossRef] [PubMed]

- Belc, N.; Smeu, I.; Macri, A.; Vallauri, D.; Flynn, K. Reformulating foods to meet current scientific knowledge about salt, sugar and fats. Trends Food Sci. Technol. 2019, 84, 25–28. [Google Scholar] [CrossRef]

- Silow, C.; Axel, C.; Zannini, E.; Arendt, E.K. Current status of salt reduction in bread and bakery products—A review. J. Cereal Sci. 2016, 72, 135–145. [Google Scholar] [CrossRef]

- Raffo, A.; Carcea, M.; Moneta, E.; Narducci, V.; Nicoli, S. Influence of different levels of sodium chloride of a reduced sodium salt substitute on volatiles formation and sensory quality of wheat bread. J. Cereal Sci. 2018, 79, 519–526. [Google Scholar] [CrossRef]

- Valerio, F.; Conte, A.; Di Base, M.; Lattanzio, V.M.T.; Lonigro, S.L.; Padalino, L.; Pontonio, E.; Lavermicocca, P. Fromulation of yeast-leavened bread with reduced salt content by using a Lactobacillus plantarum fermentation product. Food Chem. 2017, 221, 582–589. [Google Scholar] [CrossRef]

- Bassett, M.N.; Palacios, T.P.; Cipriano, I.; Cardoso, P.; Ferreira, I.M.P.L.V.O.; Samman, N.; Pinho, O. Development of bread with NaCl reduction and calcium fortification: Study of its quality. J. Food Qual. 2013, 37, 107–116. [Google Scholar] [CrossRef]

- Belz, M.C.E.; Ryan, L.A.M.; Arendt, E.K. The Impact of salt reduction in bread: A review. Crit. Rev. Food Sci. Nutr. 2012, 52, 514–524. [Google Scholar] [CrossRef] [PubMed]

- Miller, R.A.; Hoseney, R.C. Role of salt in baking. Cereal Foods World 2008, 53, 4–6. [Google Scholar] [CrossRef]

- Nogueira, A.C.; Kussano, J.T.; Steel, C.J. Sourdough reduces sodium in wheat flour doughs. Int. J. Food Sci. Technol. 2015, 50, 2621–2629. [Google Scholar] [CrossRef]

- Jimenez-Maroto, L.A.; Sato, T.; Rankin, S.A. Saltiness potentiation in white bread by substituting sodium chloride with a fermented soy ingredient. J. Cereal Sci. 2013, 58, 313–317. [Google Scholar] [CrossRef]

- Israr, T.; Rakha, A.; Sohail, M.; Rashid, S.; Shehzad, A. Salt reduction in baked products: Strategies and constraints. Trends Food Sci. Technol. 2016, 51, 98–105. [Google Scholar] [CrossRef]

- Diler, G.; Le-Bail, A.; Chevallier, S. Salt reduction in sheeted dough: A successful technological approach. Food Res. Int. 2016, 88, 10–15. [Google Scholar] [CrossRef]

- Lynch, E.J.; Dal Bello, F.; Sheehan, E.M.; Cashman, K.D.; Arendt, E.K. Fundamental studies on the reduction of salt on dough and bread characteristics. Food Res. Int. 2009, 42, 885–891. [Google Scholar] [CrossRef]

- Moreau, L.; Lagrange, J.; Bindzus, W.; Hill, S. Influence of sodium chloride on colour, residual volatiles and acrylamide formation in model systems and breakfast cereals. Int. J. Food Sci. Technol. 2009, 44, 2407–2416. [Google Scholar] [CrossRef]

- Miller, R.A.; Jeong, J. Sodium reduction in bread using low-sodium sea salt. Cereal Chem. 2014, 9, 41–44. [Google Scholar] [CrossRef]

- Simsek, S.; Martinez, M.O. Quality of dough and bread prepared with sea salt or sodium chloride. J. Food Process Eng. 2016, 39, 44–52. [Google Scholar] [CrossRef]

- Zhao, C.J.; Kinner, M.; Wismer, W.; Ganzle, M.G. Effect of glutamate-accumulation during sourdough fermentation with Lactobacillus reuteri on the taste of bread and sodium-reduced bread. Cereal Chem. 2014, 92, 224–230. [Google Scholar] [CrossRef]

- Belz, M.C.E.; Mairinger, R.; Zannini, E.; Ryan, L.A.M.; Cashman, K.D.; Arendt, E.K. The effect of sourdough and calcium propionate on the microbial shelf-life of salt-reduced bread. Appl. Microbiol. Biotechnol. 2012, 96, 493–501. [Google Scholar] [CrossRef] [PubMed]

- Badwaik, L.S.; Prasad, K.; Seth, D. Optimization of ingredient levels for the development of peanut based fiber rich pasta. J. Food Sci. Technol. 2014, 51, 2713–2719. [Google Scholar] [CrossRef] [PubMed]

- McCann, T.H.; Day, L. Effect of sodium chloride on gluten network formation, dough microstructure and rheology in relation to breadmaking. J. Cereal Sci. 2013, 57, 444–452. [Google Scholar] [CrossRef]

- Beck, M.; Jekle, M.; Becker, T. Impact of sodium chloride on wheat flour dough for yeast-leavened products. I. Rheological attributes. J. Food Sci. Agric. 2012, 92, 585–592. [Google Scholar] [CrossRef]

- Beck, M.; Jekle, M.; Becker, T. Impact of sodium chloride on wheat flour dough for yeast-leavened products. II. Baking quality parameters and their relationship. J. Food Sci. Agric. 2012, 92, 299–306. [Google Scholar] [CrossRef] [PubMed]

- Uthayakumaran, S.; Batey, I.L.; Day, L.; Wrigley, C.W. Salt reduction in wheat-based foods-technical challenges and opportunities. Food Aust. 2011, 63, 137–140. [Google Scholar]

- Lopes, M.; Cavaleiro, C.; Ramos, F. Sodium reduction in bread: A role for glasswort (Salicornia ramosissima J. woods). Compr. Rev. Food Sci. Food 2017, 16, 1056–1071. [Google Scholar] [CrossRef]

- Bernklau, I.; Neußer, C.; Moroni, A.V.; Gysler, C.; Spagnolello, A.; Chung, W.; Becker, T. Structural, textural and sensory impact of sodium reduction on long fermented pizza. Food Chem. 2017, 234, 398–407. [Google Scholar] [CrossRef]

- Wellner, N.; Bianchini, D.; Mills, E.N.C.; Belton, P.S. Effect of selected hofmeister anions on the secondary structure and dynamics of wheat prolamins in gluten. Cereal Chem. 2003, 80, 596–600. [Google Scholar] [CrossRef]

- Codină, G.G.; Zaharia, D.; Stroe, S.G.; Ropciuc, S. Influence of calcium ions addition from gluconate and lactate salts on refined wheat flour dough rheological properties. CyTA J. Food 2018, 16, 884–891. [Google Scholar] [CrossRef]

- Codină, G.G.; Zaharia, D.; Mironeasa, S.; Ropciuc, S. Evaluation of wheat flour dough rheological properties by magnesium lactate salt addition. Bull. UASVM Food Sci. Tehnol. 2018, 75, 21–26. [Google Scholar] [CrossRef]

- Ortolan, F.; Corream, G.P.; da Cunha, R.L.; Steel, C.J. Rheological properties of vital wheat glutens with water or sodium chloride. LWT Food Sci. Tehcnol. 2017, 79, 647–654. [Google Scholar] [CrossRef]

- Pasqualone, A.; Caponio, F.; Pagani, M.A.; Summo, C.; Paradiso, V.M. Effect of salt reduction on quality and acceptability. Food Chem. 2019, 289, 575–581. [Google Scholar] [CrossRef] [PubMed]

- Clarke, C.I.; Shober, T.J.; Angst, E.; Arendt, E.K. Use of response surface methodology to investigate the effects of processing conditions on sourdough bread quality. Eur. Food Res. Technol. 2003, 217, 23–33. [Google Scholar]

- Yildirim-Mavis, C.; Yilmaz, M.T.; Dertli, E.; Arici, M.; Ozmen, D. Non-liniar rheological (LAOS) behavior of sourdough-based dough. Food Hydrocoll. 2019, 96, 481–492. [Google Scholar] [CrossRef]

- Candioti, L.V.; De Zan, M.M.; Cámara, M.S.; Héctor, C.G. Experimental design and multiple response optimization. Using the desirability function in analytical methods development Talanta 2014, 124, 123–138. [Google Scholar]

- Salvador, A.; Sanz, T.; Fiszman, S.M. Dynamic rheological characteristics of wheat flour-water doughs. Effect of adding NaCl, sucrose and yeast. Food Hydrocoll. 2006, 20, 780–786. [Google Scholar] [CrossRef]

| Run | Coded Value | Real Value | ||

|---|---|---|---|---|

| X1 | X2 | SS (g/100 g) | SD (mg/100 g) | |

| 1 | 0 | 0 | 0.9 | 2.75 |

| 2 | 0 | 0 | 0.9 | 2.75 |

| 3 | 0 | 0 | 0.9 | 2.75 |

| 4 | 0 | 0 | 0.9 | 2.75 |

| 5 | 0 | 1 | 0.9 | 5.00 |

| 6 | 1 | 1 | 1.5 | 5.00 |

| 7 | 1 | −1 | 1.5 | 0.50 |

| 8 | −1 | 0 | 0.3 | 2.75 |

| 9 | 0 | −1 | 0.9 | 0.50 |

| 10 | 0 | 0 | 0.9 | 2.75 |

| 11 | −1 | 1 | 0.3 | 5.00 |

| 12 | 1 | 0 | 1.5 | 2.75 |

| 13 | −1 | −1 | 0.3 | 0.50 |

| Factors | Parameters | ||||||

|---|---|---|---|---|---|---|---|

| Farinograph | Extensograph (Proving Time 135 min) | ||||||

| WA (%) | ST (min) | DS (UB) | E (cm2) | R50 (BU) | Ext (mm) | Rmax (BU) | |

| Constant | 60.49 | 1.27 | 92.31 | 66.00 | 350.08 | 122.69 | 201.08 |

| A | −0.85 *** | 0.0000 | −4.00 *** | 20.50 *** | 119.17 *** | −0.1667 | 122.63 *** |

| B | 1.45 *** | −0.7333 *** | 28.50 *** | −6.00 ** | 46.17 ** | 15.33 *** | 40.18 ** |

| A × B | 0.05 | −0.0250 | −9.50 *** | - | 47.25 ** | - | 53.53 ** |

| A2 | 0.3983 *** | 0.0586 | −0.5862 | - | - | - | - |

| B2 | −0.3017 *** | 0.4586 *** | 6.91 *** | - | - | - | - |

| Adjusted R2 | 0.9964 | 0.9816 | 0.9937 | 0.9038 | 0.8407 | 0.7443 | 0.8340 |

| p-value | <0.0001 *** | <0.0001 *** | <0.0001 *** | <0.0001 *** | 0.0002 *** | 0.0004 *** | 0.0002 *** |

| Factors | Parameters | ||||

|---|---|---|---|---|---|

| PVmax (BU) | Tmax (OC) | H’m (mm) | VT (mL) | CR (%) | |

| Constant | 1112.55 | 88.92 | 72.47 | 1394.00 | 85.19 |

| A | 32.83 ** | 0.3833 *** | −5.30 *** | −86.00 *** | 3.10 *** |

| B | 25.50 * | 0.2833 *** | 3.80 *** | 46.17 *** | −2.00 *** |

| A × B | 38.00 ** | 0.1000 ** | −2.62 ** | −31.00 ** | 1.35 *** |

| A2 | 2.57 | 0.2776 *** | - | - | 0.2241 |

| B2 | 67.57 *** | 0.1776 *** | - | - | 0.2241 |

| Adjusted R2 | 0.7258 | 0.9711 | 0.8514 | 0.8833 | 0.9942 |

| p-value | 0.0104 ** | <0.0001 *** | <0.0001 *** | <0.0001 *** | <0.0001 *** |

| NaCl Level (g/100 g) | Parameters | |||||||

|---|---|---|---|---|---|---|---|---|

| Farinograph | Extensograph (Proving Time 135 min) | |||||||

| WA (%) | DT (min) | ST (min) | DS (UB) | E (cm2) | R50 (BU) | Ext (mm) | Rmax (BU) | |

| 0.0 | 60.5 ± 0.2 a | 1.9 ± 0.1 a | 2.0 ± 0.1 a | 76 ± 3.2 a | 57 ± 0.9 ab | 327 ± 2.3 ab | 115 ± 1.3 a | 226 ± 2.1 ab |

| 0.3 | 59.9 ± 0.1 a | 2.0 ± 0.1 a | 2.2 ± 0.1 a | 72 ± 2.1 a | 61 ± 1.2 ab | 331 ± 1.6 ab | 119 ± 1.4 a | 230 ± 2.9 ab |

| 0.6 | 58.7 ± 0.2 a | 2.1 ± 0.1 a | 2.4 ± 0.1 a | 69 ± 1.4 a | 66 ± 1.6 ab | 347 ± 3.9 ab | 124 ± 1.2 a | 238 ± 2.2 ab |

| 0.9 | 58.2 ± 0.1 a | 2.2 ± 0.1 a | 2.7 ± 0.2 a | 66 ± 1.5 a | 75 ± 2.1 ab | 371 ± 6.2 ab | 135 ± 1.6 a | 254 ± 3.1 ab |

| 1.2 | 57.6 ± 0.1 a | 2.3 ± 0.1 a | 3.2 ± 0.2 a | 64 ± 2.2 a | 81 ± 1.7 a | 395 ± 5.6 a | 126 ± 1.4 a | 277 ± 4.3 a |

| 1.5 | 57.2 ± 0.1 b | 2.7 ± 0.2 a | 3.6 ± 0.2 a | 61 ± 1.3 b | 85 ± 2.2 b | 416 ± 3.9 b | 122 ± 1.1 b | 298 ± 5.6 b |

| NaCl Level (g/100 g) | Parameters | |||||||

|---|---|---|---|---|---|---|---|---|

| FN (s) | Tg (°C) | PVmax (BU) | Tmax (°C) | H’m (mm) | VT (mL) | VR (mL) | CR (%) | |

| 0.0 | 322 ± 2.0 ab | 62.3 ± 0.12 a | 1081 ± 4.7 ab | 88.4 ± 0.18 a | 67.3 ± 1.8 a | 1287 ± 8.3 a | 1066 ± 7.3 a | 82.8 ± 1.3 ab |

| 0.3 | 331 ± 0.9 a | 62.7 ± 0.09 a | 1097 ± 2.2 ab | 88.9 ± 0.22 a | 73.2 ± 1.4 a | 1429 ± 6.9 a | 1130 ± 5.4 a | 79.0 ± 0.9 ab |

| 0.6 | 338 ± 1.3 a | 63.2 ± 0.10 a | 1141 ± 3.9 ab | 89.2 ± 0.32 a | 77.7 ± 0.9 a | 1512 ± 7.9 a | 1166 ± 6.3 a | 77.1 ± 1.0 ab |

| 0.9 | 347 ± 1.2 a | 63.6 ± 0.13 a | 1179 ± 5.9 ab | 89.5 ± 0.22 a | 66.3 ± 1.3 a | 1227 ± 6.7 a | 1045 ± 7.4 a | 85.2 ± 1.4 a |

| 1.2 | 352 ± 0.4 a | 63.8 ± 0.07 a | 1267 ± 6.8 a | 89.7 ± 0.38 a | 61.6 ± 1.7 a | 1114 ± 9.8 a | 970 ± 6.7 a | 87.1 ± 1.6 a |

| 1.5 | 358 ± 1.6 b | 63.9 ± 0.10 b | 1290 ± 3.1 b | 89.9 ± 0.24 b | 50.6 ± 1.8 b | 939 ± 3.5 b | 855 ± 2.3 b | 91.0 ± 1.1 b |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Voinea, A.; Stroe, S.-G.; Codină, G.G. The Effect of Sodium Reduction by Sea Salt and Dry Sourdough Addition on the Wheat Flour Dough Rheological Properties. Foods 2020, 9, 610. https://doi.org/10.3390/foods9050610

Voinea A, Stroe S-G, Codină GG. The Effect of Sodium Reduction by Sea Salt and Dry Sourdough Addition on the Wheat Flour Dough Rheological Properties. Foods. 2020; 9(5):610. https://doi.org/10.3390/foods9050610

Chicago/Turabian StyleVoinea, Andreea, Silviu-Gabriel Stroe, and Georgiana Gabriela Codină. 2020. "The Effect of Sodium Reduction by Sea Salt and Dry Sourdough Addition on the Wheat Flour Dough Rheological Properties" Foods 9, no. 5: 610. https://doi.org/10.3390/foods9050610

APA StyleVoinea, A., Stroe, S.-G., & Codină, G. G. (2020). The Effect of Sodium Reduction by Sea Salt and Dry Sourdough Addition on the Wheat Flour Dough Rheological Properties. Foods, 9(5), 610. https://doi.org/10.3390/foods9050610