Confocal Laser Scanning Microscopy and Image Analysis for Elucidating Crumb and Crust Microstructure of Bran-Enriched South African Fried Dough and Batter

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fried Dough (Magwinya) Production and Frying Process

2.3. Microstructural Observation

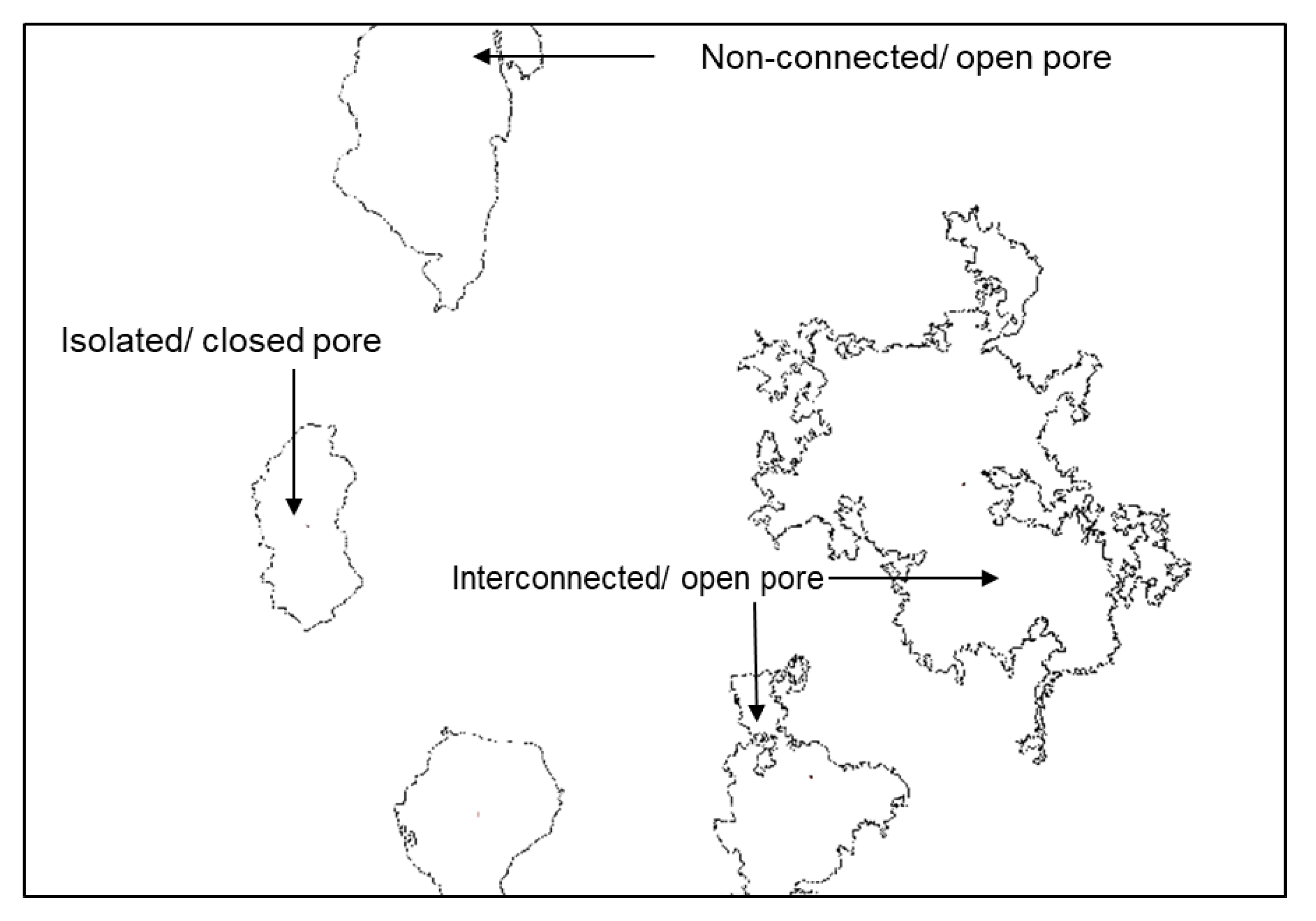

2.4. Image Segmentation and Analysis

2.5. Quantification of Surface Roughness of Magwinya Using Fractal Analysis

2.6. Determination of Oil Content by Soxhlet Extraction

2.7. Statistical Analysis

3. Results and Discussion

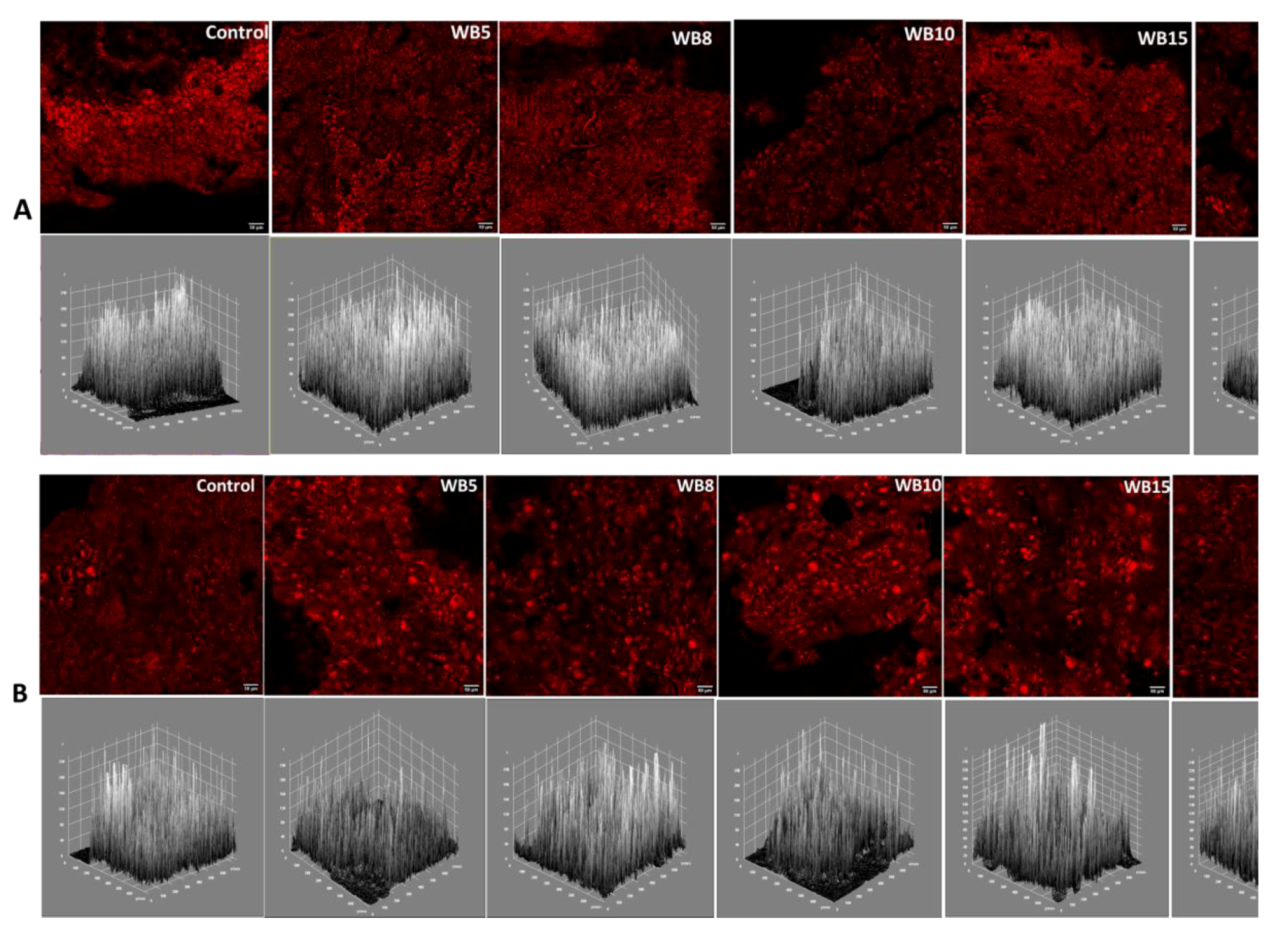

3.1. Qualitative Analysis of Microstructure

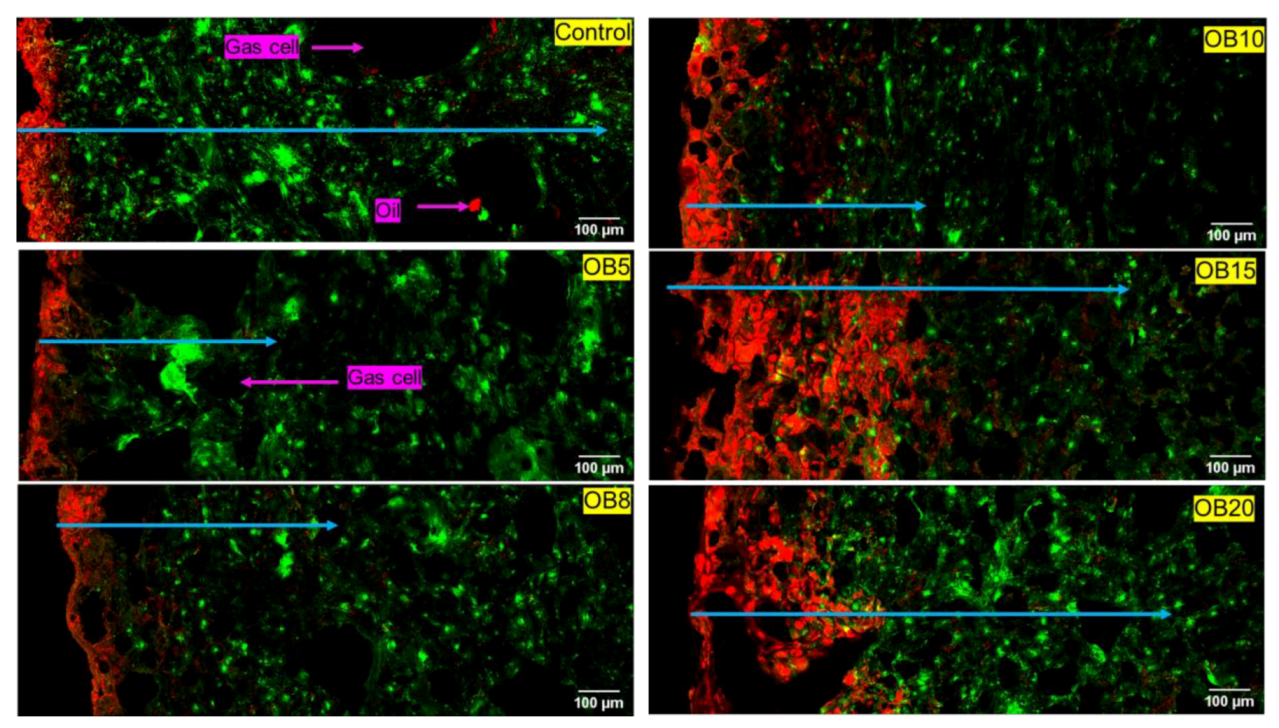

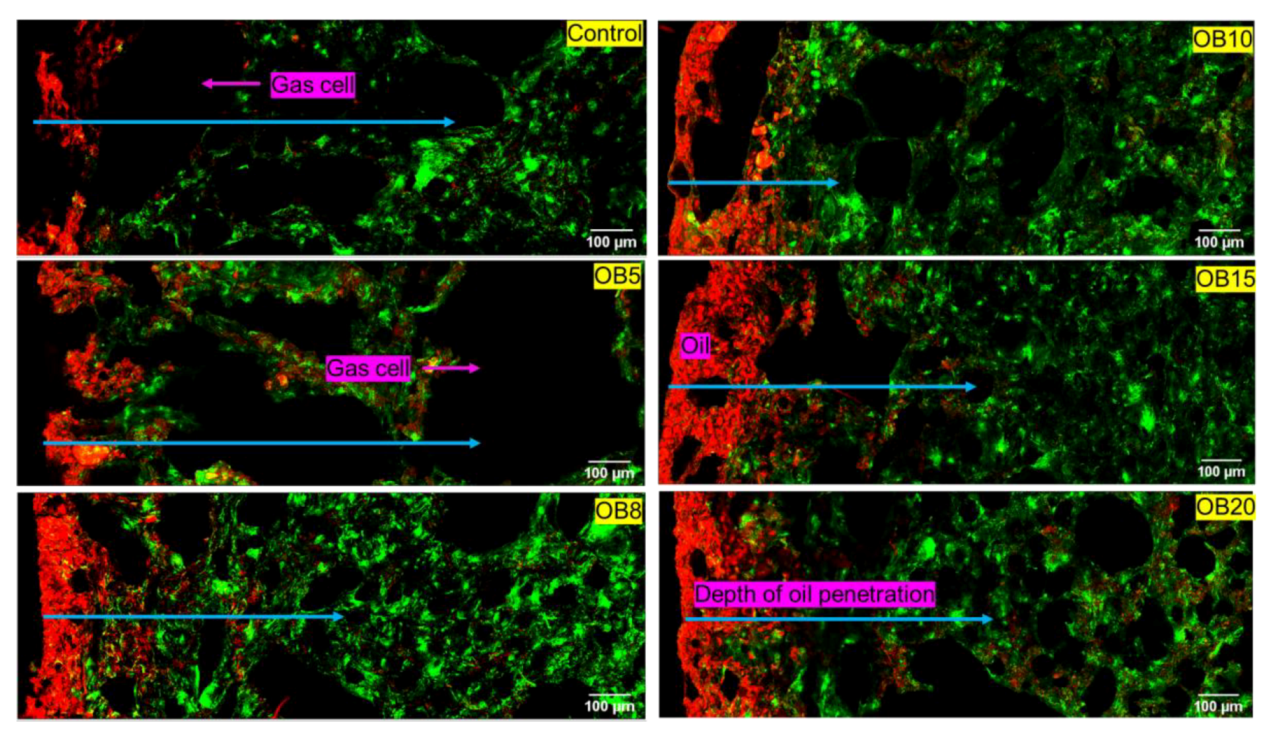

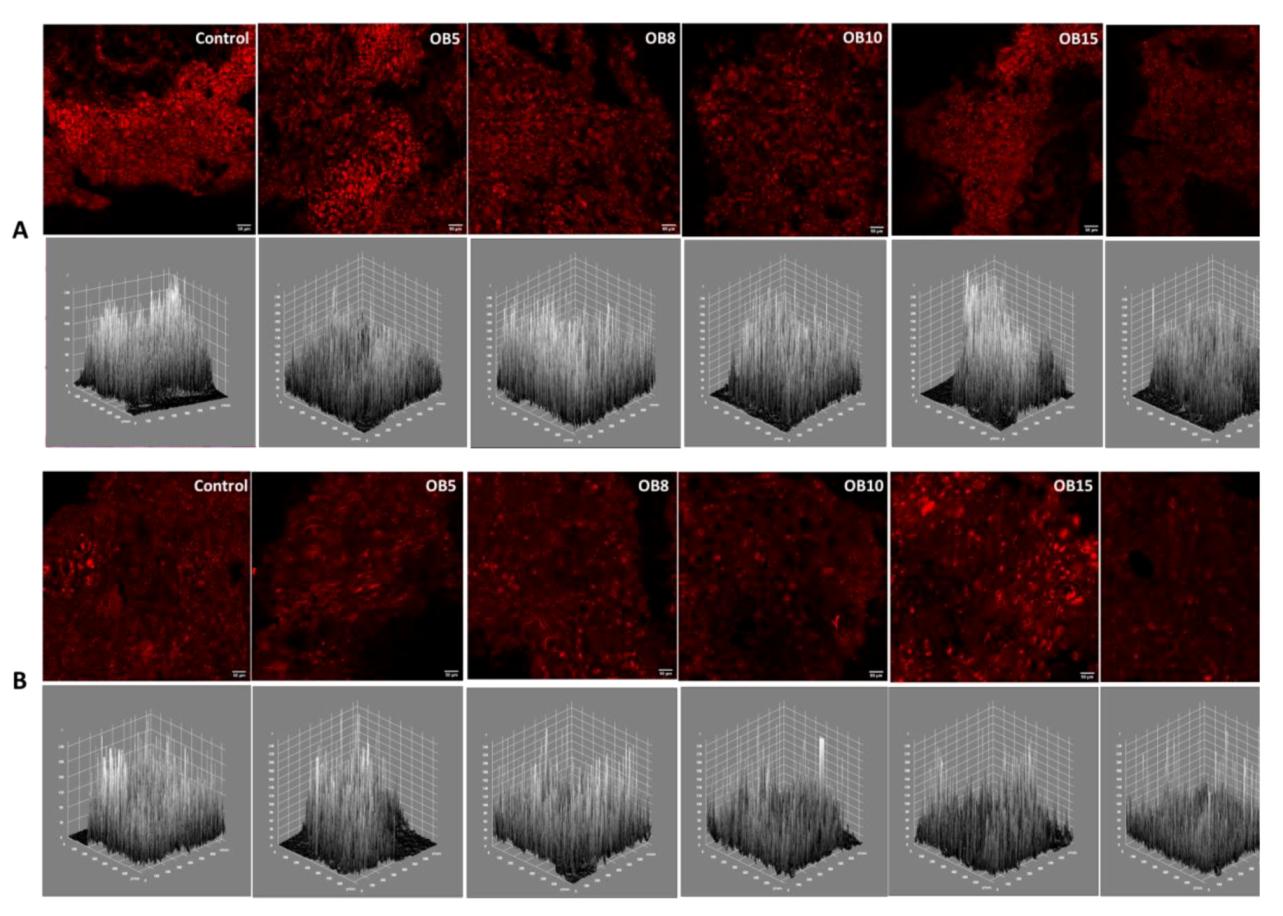

3.1.1. Oat Bran (OB) Magwinya

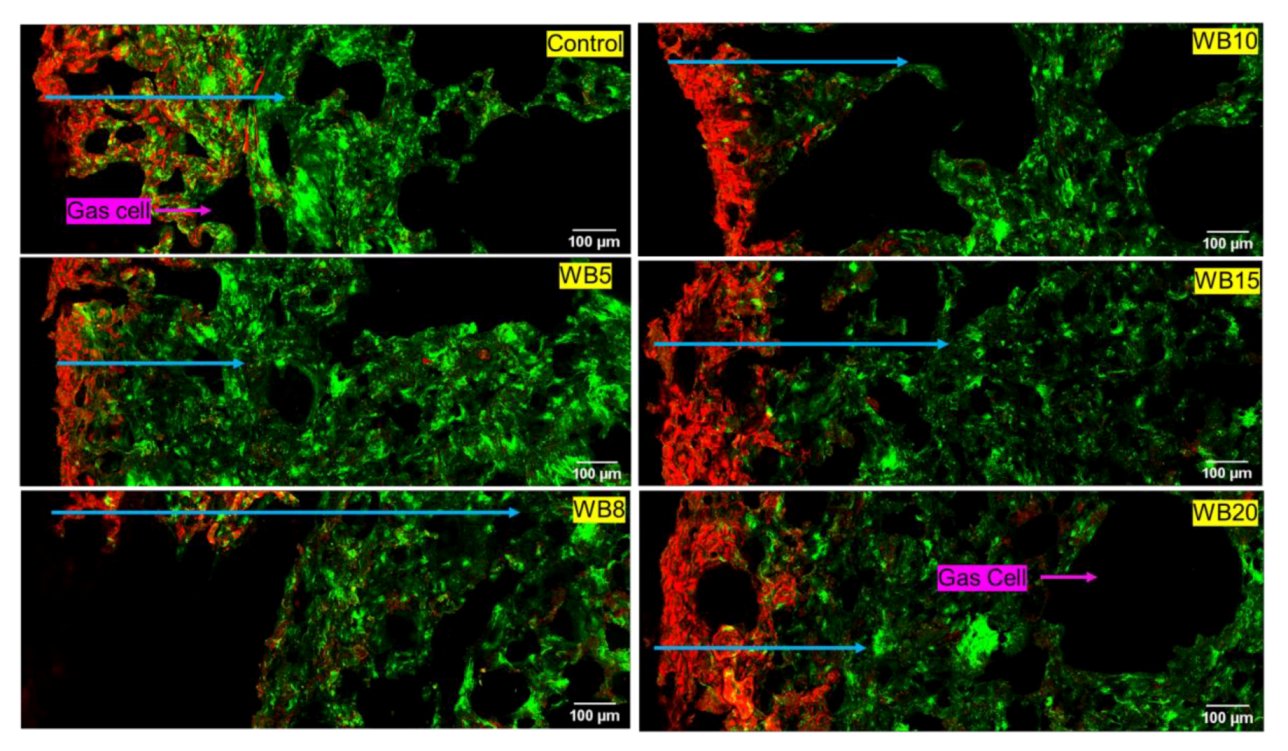

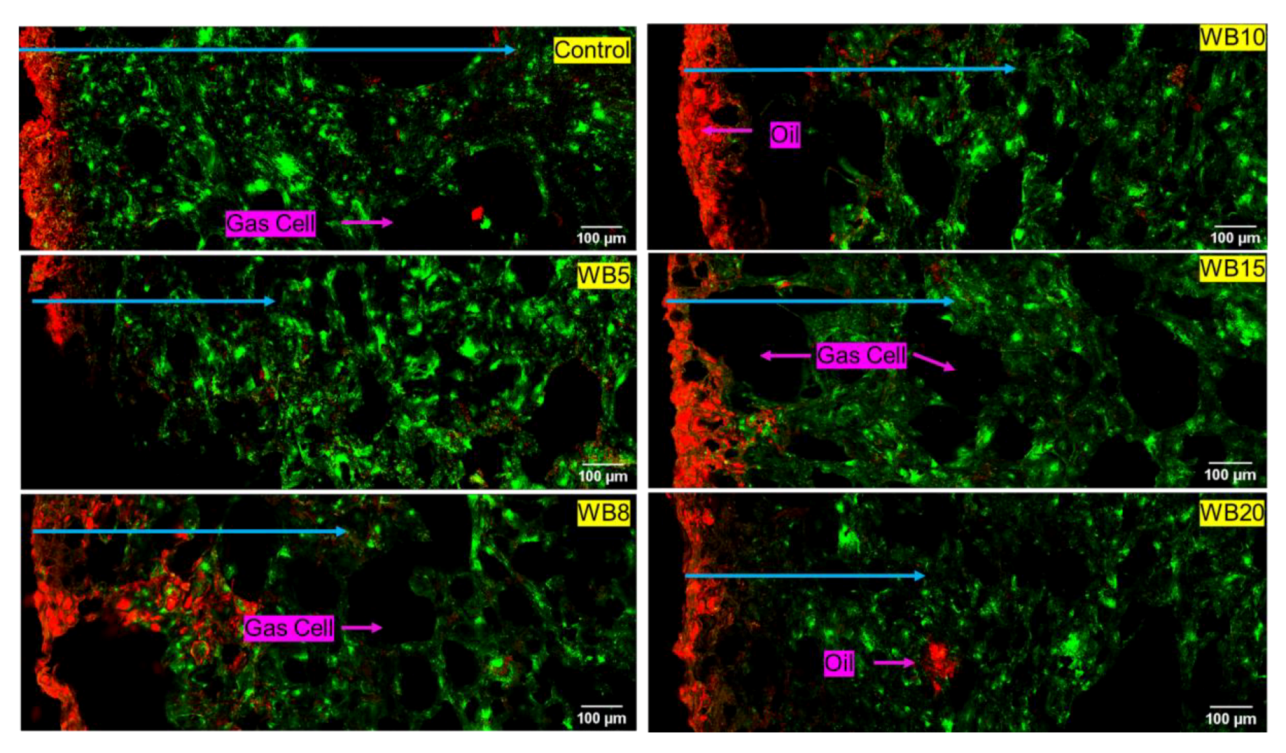

3.1.2. Wheat Bran (WB) Magwinya

3.2. Penetrated Oil Content by Image Analysis

3.2.1. Oat Bran Magwinya

3.2.2. Wheat Bran Magwinya

3.3. Porosity of Magwinya

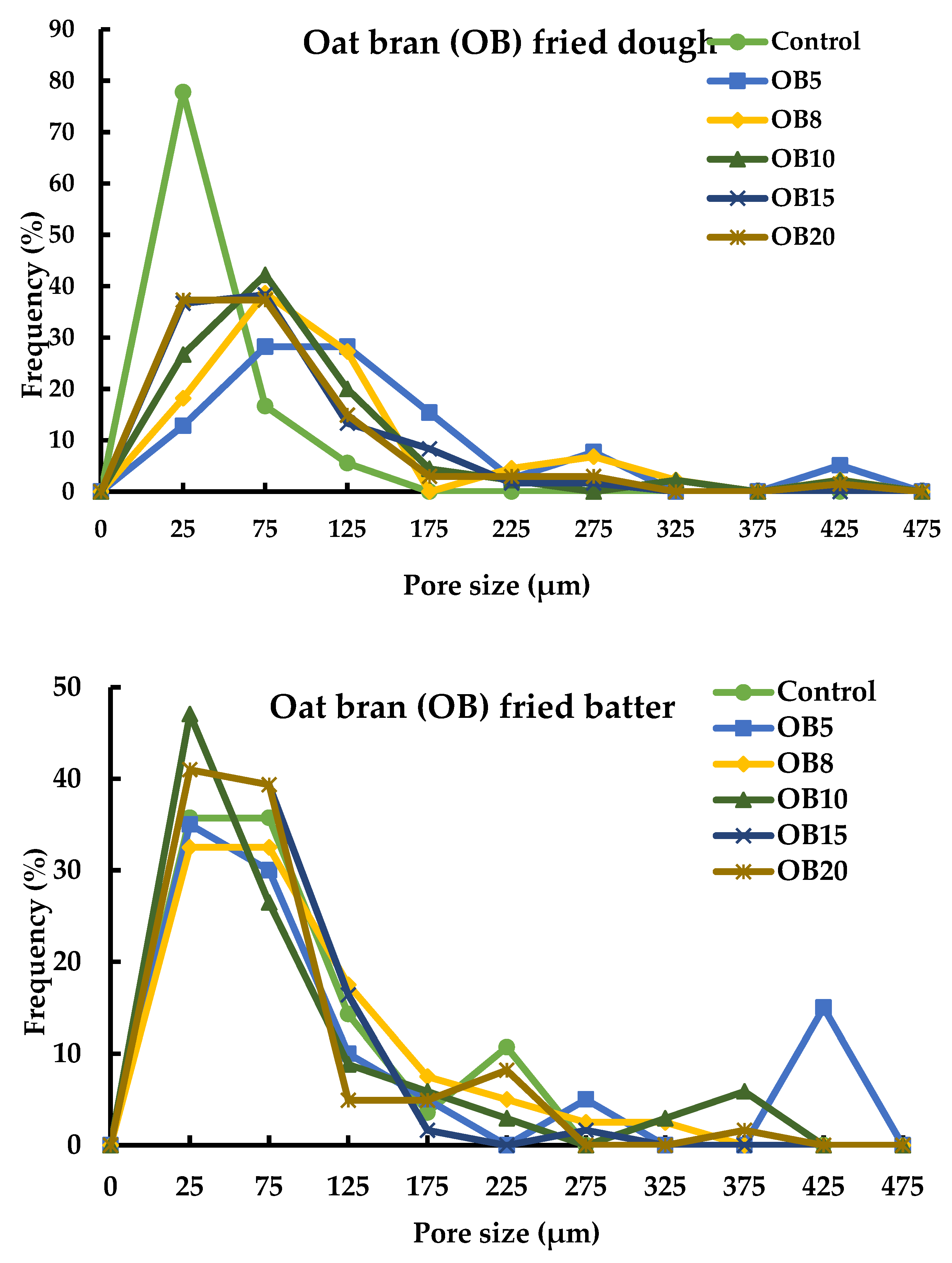

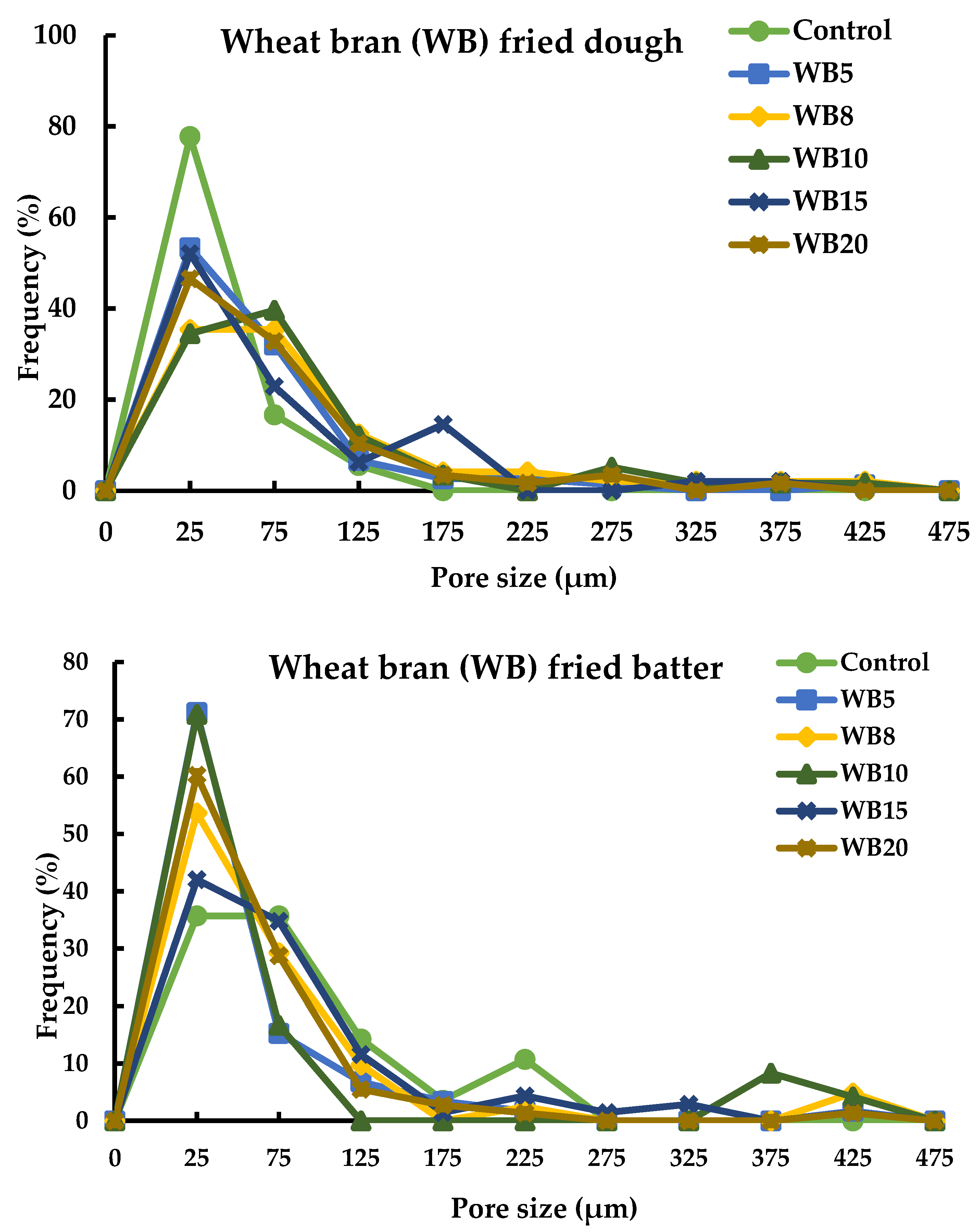

3.4. Pore Distribution

3.4.1. Pore Distribution in Fried Dough

3.4.2. Pore Distribution in Fried Batter

3.5. Relationship between Microstructural Properties against Soxhlet Fat Extraction

3.5.1. Oat Bran Fried Batter

3.5.2. Oat Bran Fried Dough

3.5.3. Wheat Bran Fried Dough

3.5.4. Wheat Bran Fried Batter

3.6. Crust Surface Roughness of Magwinya

3.7. Surface Roughness Using Fractal Metrics

3.8. Correlation of FD to Surface Oil and Texture of Fried Products

3.8.1. Fractal Dimension vs. Surface Oil

3.8.2. Fractal Dimension vs. Crust Hardness

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pérez-Nieto, A.; Chanona-Perez, J.J.; Farrera-Rebollo, R.R.; Gutierrez-Lopez, G.F.; Alamilla-Beltran, L.; Calderon-Dominguez, G. Image analysis of structural changes in dough during baking. LWT Food Sci. Technol. 2010, 43, 535–543. [Google Scholar] [CrossRef]

- Dürrenberger, M.B.; Handschin, S.; Conde-Petit, B.; Escher, F. Visualisation of food structure by confocal laser scanning microscopy (CLSM). LWT Food Sci. Technol. 2001, 34, 11–17. [Google Scholar] [CrossRef]

- Adedeji, A.A.; Liu, L.; Ngadi, M.O. Microstructural evaluation of deep-fat fried chicken nugget batter coating using confocal laser scanning microscopy. J. Food Eng. 2011, 102, 49–57. [Google Scholar] [CrossRef]

- Moreno, M.C.; Bouchon, P. Microstructural characterisation of deep-fat fried formulated products using confocal scanning laser microscopy and a non-invasive double staining procedure. J. Food Eng. 2013, 118, 238–246. [Google Scholar] [CrossRef]

- Ghaitaranpour, A.; Koocheki, A.; Mohebbi, M.; Ngadi, M.O. Effect of deep fat and hot air frying on doughnuts physical properties and kinetic of crust formation. J. Cereal Sci. 2018, 83, 25–31. [Google Scholar] [CrossRef]

- Bouchon, P.B.; Aguilera, J.M.; Pyle, D.L. Structure oil-absorption relationships during deep-fat frying. J. Food Sci. 2003, 68, 2711–2716. [Google Scholar] [CrossRef]

- Pedreschi, F.; Cocio, C.; Moyano, P.; Troncoso, E. Oil distribution in potato slices during frying. J. Food Eng. 2008, 87, 200–212. [Google Scholar] [CrossRef]

- Wasnik, P.G.; Menon, R.R.; Meshram, B.D. Digital Image Analysis: Tool for Food Quality Evaluation. In Processing Technologies for Milk and Milk Products, 1st ed.; Agrawal, A.K., Goyal, M.R., Eds.; Apple Academic Press: Florida, FL, USA, 2017; pp. 65–104. [Google Scholar]

- Jekle, M.; Becker, T. Dough microstructure: Novel analysis by quantification using confocal laser scanning microscopy. Food Res. Int. 2011, 44, 984–991. [Google Scholar] [CrossRef]

- Mandelbrot, B.B. The Fractal Geometry of Nature; WH Freeman: New York, NY, USA, 1983; p. 51. [Google Scholar]

- Cáez Ramírez, G.; Téllez-Medina, D.I.; García-Armenta, E.; López, G.F. Digital image analysis and fractal metrics as potential tools to monitor colour changes in fresh-cut papaya (Carica papaya L.). Int. J. Food Prop. 2017, 18, 177–189. [Google Scholar] [CrossRef]

- Moreno, M.C.; Brown, C.A.; Bouchon, P. Effect of food surface roughness on oil uptake by deep-fat fried products. J. Food Eng. 2010, 101, 179–186. [Google Scholar] [CrossRef]

- Rahimi, J.; Ngadi, M.O. Structure and irregularities of surface of fried batters studied by fractal dimension and lacunarity analysis. Food Struct. 2016, 9, 13–21. [Google Scholar] [CrossRef]

- Thanatuksorn, P.; Pradistsuwana, C.; Jantawat, P.; Suzuki, T. Effect of surface roughness on post-frying oil absorption in wheat flour and water food model. J. Sci. Food Agric. 2005, 85, 2574–2580. [Google Scholar] [CrossRef]

- Onipe, O.O.; Beswa, D.; Jideani, V.A.; Jideani, A.I.O. Development of a low-fat, high-fibre snack: Effect of bran particle sizes and processing conditions. Heliyon 2019, 5, e01364. [Google Scholar] [CrossRef] [PubMed]

- Kwinda, O.; Onipe, O.O.; Jideani, A.I.O. The effect of oat bran and psyllium husk fibre on oil reduction and some physicochemical properties of magwinya—A deep-fried dough. CyTA J. Food. 2018, 16, 247–254. [Google Scholar] [CrossRef]

- Ndlala, F.N.; Onipe, O.O.; Mokhele, T.M.; Anyasi, T.A.; Jideani, A.I.O. Effect of wheat bran incorporation on the physical and sensory properties of a South African cereal fried dough. Foods 2019, 8, 559. [Google Scholar] [CrossRef]

- Abramoff, M.D.; Magalhaes, P.J.; Ram, S.J. Image processing with ImageJ. Biophotonics Int. 2004, 11, 36–42. [Google Scholar]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. "NIH Image to ImageJ: 25 years of image analysis". Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef]

- Otsu, N. A threshold selection method from gray-level histograms. IEEE Trans. Syst. Man Cybern. 1979, 9, 62–66. [Google Scholar] [CrossRef]

- Smith, T.G., Jr.; Lange, G.D.; Marks, W.B. Fractal methods and results in cellular morphology—dimensions, lacunarity and multifractals. J. Neurosci. Methods 1996, 69, 123–136. [Google Scholar] [CrossRef]

- AACC (American Association of Cereal Chemists) International. Approved Methods of the AACC. St. Paul. 2000. Available online: http://methods.aaccnet.org/methods/30-25.pdf (accessed on 16 July 2015).

- Scanlon, M.G.; Zghal, M.C. Bread properties and crumb structure. Food Res. Int. 2001, 34, 841–864. [Google Scholar] [CrossRef]

- Mills, E.N.C.; Wilde, P.J.; Salt, L.J.; Skeggs, P. Bubble formation and stabilisation in bread dough. Food Bioprod. Process. 2003, 81, 189–193. [Google Scholar] [CrossRef]

- Bonnand-Ducasse, M.; Della Valle, G.; Lefebvre, J.; Saulnier, L. Effect of wheat dietary fibres on bread dough development and rheological properties. J. Cereal Sci. 2010, 52, 200–206. [Google Scholar] [CrossRef]

- Noort, M.W.; van Haaster, D.; Hemery, Y.; Schols, H.A.; Hamer, R.J. The effect of particle size of wheat bran fractions on bread quality–Evidence for fibre–protein interactions. J. Cereal Sci. 2010, 52, 59–64. [Google Scholar] [CrossRef]

- Yadav, D.N.; Rajan, A. Fibres as an additive for oil reduction in deep fat fried poori. J. Food Sci. Technol. 2012, 49, 767–773. [Google Scholar] [CrossRef] [PubMed]

- Kim, B.K.; Chun, Y.G.; Cho, A.R.; Park, D.J. Reduction in fat uptake of doughnut by microparticulated wheat bran. Int. J. Food Sci. Nutr. 2012, 63, 987–995. [Google Scholar] [CrossRef]

- Pedreschi, F.; Aguilera, J.M.; Brown, C.A. Characterisation of food surfaces using scale-sensitive fractal analysis. J. Food Process Eng. 2000, 23, 127–143. [Google Scholar] [CrossRef]

- Lawrence, M.; Jiang, Y. Porosity, pore size distribution, micro-structure. In Bio-aggregates Based Building Materials, 1st ed.; Amziane, S., Collet, F., Eds.; Springer: Berlin, Germany, 2017; Volume 23, pp. 39–71. [Google Scholar]

- Sabanis, D.; Lebesi, D.; Tzia, C. Effect of dietary fibre enrichment on selected properties of gluten-free bread. LWT Food Sci. Technol. 2009, 42, 1380–1389. [Google Scholar] [CrossRef]

- Wang, S.; Austin, P.; Bell, S. It’s a maze: The pore structure of breadcrumbs. J. Cereal Sci. 2011, 54, 203–210. [Google Scholar] [CrossRef]

- Ghaitaranpour, A.; Mohebbi, M.; Koocheki, A. Characterising the cellular structure of air and deep fat fried doughnut using image analysis techniques. J. Food Eng. 2018, 237, 231–239. [Google Scholar] [CrossRef]

- Ziaiifar, A.M.; Courtois, F.; Trystram, G. Porosity development and its effect on oil uptake during frying process. J. Food Process Eng. 2010, 33, 191–212. [Google Scholar] [CrossRef]

- Wirth, M.A. Shape Analysis and Measurement. Ph.D. Thesis, University of Guelph Computing and Information Science Image Processing Group, Guelph, ON, Canada, 2001. [Google Scholar]

- Olson, E. Particle shape factors and their use in image analysis part 1: Theory. J. GXP Compliance 2011, 15, 85–96. [Google Scholar]

- Sroan, B.S.; MacRitchie, F. Mechanism of gas cell stability in breadmaking. In Bubbles in Food 2 Novelty, Health and Luxury, 2nd ed.; Campbell, G.M., Scanlon, M.G., Pyle, D.L., Eds.; Eagan Press: St. Paul, MN, USA, 2008; pp. 299–306. [Google Scholar]

- Verheyen, C. Structural investigations of yeasted wheat dough–the impact of CO2 and glutathione. Ph.D. Thesis, Technische Universität München, München, Germany, 2016. [Google Scholar]

- Shimiya, Y.; Nakamura, K. Changes in size of gas cells in dough and bread during breadmaking and calculation of critical size of gas cells that expand. J. Texture Stud. 1997, 28, 273–288. [Google Scholar] [CrossRef]

- Van Duynhoven, J.P.; van Kempen, G.M.; van Sluis, R.; Rieger, B.; Weegels, P.; van Vliet, L.J.; Nicolay, K. Quantitative assessment of gas cell development during the proofing of dough by magnetic resonance imaging and image analysis. Cereal Chem. 2003, 80, 390–395. [Google Scholar] [CrossRef]

- Sroan, B.S.; Bean, S.R.; MacRitchie, F. Mechanism of gas cell stabilisation in bread making. I. The primary gluten–starch matrix. J. Cereal Sci. 2019, 49, 32–40. [Google Scholar] [CrossRef]

- Turbin-Orger, A.; Boller, E.; Chaunier, L.; Chiron, H.; Della Valle, G.; Réguerre, A.L. Kinetics of bubble growth in wheat flour dough during proofing studied by computed X-ray micro-tomography. J. Cereal Sci. 2012, 56, 676–683. [Google Scholar] [CrossRef]

- Quevedo, R.; Carlos, L.G.; Aguilera, J.M.; Cadoche, L. Description of food surfaces and microstructural changes using fractal image texture analysis. J. Food Eng. 2002, 53, 361–371. [Google Scholar] [CrossRef]

- Van Koerten, K.N.; Schutyser, M.A.I.; Somsen, D.; Boom, R.M. Crust morphology and crispness development during deep-fat frying of potato. Food Res. Int. 2015, 78, 336–342. [Google Scholar] [CrossRef]

| Bran Concentration (g) | Fried Batter (%) | Fried Dough (%) | ||||

|---|---|---|---|---|---|---|

| POia | POSox | Porosity | POia | POSox | Porosity | |

| Control | 19.66 b ± 0.92 | 8.67 b ± 0.08 | 81.84 b ± 1.24 | 8.29 b ± 0.74 | 8.20 e ± 0.05 | 80.03 d ± 4.31 |

| OB5 | 16.55 ab ± 0.47 | 9.47 c ± 0.08 | 67.10 a ± 2.62 | 5.56 a ± 0.34 | 6.67 bc ± 0.16 | 69.21 c ± 1.35 |

| OB8 | 16.03 ab ± 1.21 | 8.80 b ± 0.14 | 73.66 ab ± 0.84 | 14.28 d ± 0.37 | 7.13 cd ± 0.11 | 54.94 a ± 1.53 |

| OB10 | 14.52 a ± 0.61 | 7.47 a ± 0.08 | 76.77 b ± 1.79 | 11.31 c ± 0.20 | 6.33 b ± 0.15 | 58.58 ab ± 1.41 |

| OB15 | 18.22b ab ± 0.60 | 8.60 b ± 0.30 | 80.68 b ± 1.05 | 18.92 e ± 0.48 | 5.27 a ± 0.06 | 65.93 bc ± 2.79 |

| OB20 | 14.97 a ± 1.63 | 7.87 a ± 0.11 | 65.91 a ± 1.68 | 11.73 c ± 0.42 | 7.53 d ± 0.08 | 60.76 ab ± 2.68 |

| Control | 19.66 c ± 0.74 | 8.53 b ± 0.46 | 81.84 c ± 1.24 | 8.29 bc ± 0.16 | 7.07 c ± 0.31 | 80.03 d ± 4.31 |

| WB5 | 13.18 a ± 0.47 | 9.93 c ± 0.61 | 55.71 ab ± 3.92 | 4.57 a ± 0.22 | 8.00 d ± 0.26 | 52.15 a ± 0.59 |

| WB8 | 13.81 ab ± 0.30 | 7.67 a ± 0.08 | 53.12 a ± 2.69 | 9.29 c ± 0.03 | 7.73 d ± 0.57 | 73.08 cd ±1.22 |

| WB10 | 16.00 b ± 0.53 | 9.87 c ± 0.09 | 70.56 bc ± 2.10 | 6.43 b ± 0.03 | 6.07 b ± 0.31 | 54.68 ab ± 2.69 |

| WB15 | 13.52 a ± 0.31 | 10.13 c ± 0.31 | 75.69 c ±2.57 | 7.58 bc ± 0.11 | 6.20 b ± 0.40 | 56.88 ab ± 2.33 |

| WB20 | 15.31 b ± 0.30 | 8.73 b ± 0.98 | 76.05 c ± 2.23 | 7.94 bc ± 0.17 | 5.00 a ± 0.15 | 65.15 bc ± 2.66 |

| Source | Dependent Variable (%) | Type III Sum of Squares | df | Mean Square | F | Significance c |

|---|---|---|---|---|---|---|

| Corrected Model | PorosityPOia | 29879 a | 23 | 1299.09 | 20.04 | <0.001 |

| 4661 b | 23 | 202.67 | 55.83 | <0.001 | ||

| Intercept | Porosity | 825,377 | 1 | 825,377 | 12,732.53 | <0.001 |

| POia | 27,124 | 1 | 27,124.72 | 7471.72 | <0.001 | |

| X | Porosity | 88 | 1 | 88.427 | 1.36 | 0.244 |

| POia | 1000 | 1 | 1000.281 | 275.54 | <0.001 | |

| Y | Porosity | 6938 | 1 | 6938.65 | 107.04 | <0.001 |

| POia | 1104 | 1 | 1104.91 | 304.36 | <0.001 | |

| Z | Porosity | 13,384 | 5 | 2676.86 | 41.29 | <0.001 |

| POia | 715 | 5 | 143.034 | 39.4 | <0.001 | |

| X * Y | Porosity | 2256 | 1 | 2256.54 | 34.81 | <0.001 |

| POia | 1.56 | 1 | 1.56 | 0.43 | 0.513 | |

| X * Z | Porosity | 1005 | 5 | 201.12 | 3.10 | 0.01 |

| POia | 533 | 5 | 106.52 | 29.34 | <0.001 | |

| Y * Z | Porosity | 2927 | 5 | 585.48 | 9.03 | <0.001 |

| POia | 1047 | 5 | 209.32 | 57.66 | <0.001 | |

| X * Y * Z | Porosity | 3278 | 5 | 655.62 | 10.11 | <0.001 |

| POia | 261 | 5 | 52.05 | 14.34 | <0.001 | |

| Error | Porosity | 10,891 | 168 | 64.82 | ||

| POia | 610 | 168 | 3.63 | |||

| Total | Porosity | 866,147 | 192 | |||

| POia | 32,396 | 192 | ||||

| Corrected Total | Porosity | 40,769 | 191 | |||

| POia | 5271 | 191 |

| Bran Concentration (g) | Fried Dough | |||||

|---|---|---|---|---|---|---|

| Particle Count (ΣP) | Total Area (×104 µm2) | Average Size (µm2) | Perimeter (µm) | Circularity (C) | Solidity (S) | |

| Control | 18 | 12 | 728 | 150 | 0.29 | 0.73 |

| OB5 | 44 | 27 | 6120 | 948 | 0.10 | 0.64 |

| OB8 | 44 | 23 | 5216 | 1119 | 0.15 | 0.67 |

| OB10 | 45 | 12 | 2746 | 696 | 0.13 | 0.65 |

| OB15 | 60 | 15 | 2503 | 435 | 0.18 | 0.73 |

| OB20 | 67 | 22 | 3303 | 551 | 0.15 | 0.69 |

| WB5 | 76 | 23 | 3085 | 611 | 0.14 | 0.64 |

| WB8 | 48 | 29 | 6036 | 566 | 0.19 | 0.77 |

| WB10 | 59 | 28 | 4756 | 545 | 0.16 | 0.70 |

| WB15 | 49 | 26 | 5237 | 389 | 0.24 | 0.75 |

| WB20 | 59 | 22 | 3703 | 606 | 0.14 | 0.66 |

| Fried batter | ||||||

| Control | 28 | 25 | 3470 | 343 | 0.42 | 0.81 |

| OB5 | 20 | 42 | 2102 | 861 | 0.15 | 0.72 |

| OB8 | 40 | 17 | 4207 | 415 | 0.34 | 0.84 |

| OB10 | 34 | 20 | 5846 | 508 | 0.19 | 0.77 |

| OB15 | 62 | 17 | 2692 | 430 | 0.16 | 0.67 |

| OB20 | 62 | 23 | 3690 | 495 | 0.18 | 0.72 |

| WB5 | 59 | 17 | 2836 | 319 | 0.16 | 0.66 |

| WB8 | 41 | 43 | 10,288 | 564 | 0.20 | 0.74 |

| WB10 | 24 | 38 | 15,662 | 544 | 0.19 | 0.73 |

| WB15 | 69 | 27 | 3890 | 558 | 0.14 | 0.66 |

| WB20 | 73 | 25 | 3361 | 311 | 0.22 | 0.72 |

| Fried Dough | Porosity vs. POia | POia vs. POSoxhlet | POSoxhlet vs. Porosity |

|---|---|---|---|

| OB | y = 0.0976x3 − 3.3741x2 + 34.041x − 30.943 | y = −1.4146x3 + 32.453x2 − 242.33x + 601.78 | y = 5.757x3 − 110.56x2 + 698.29x − 1386.4 |

| R2 | 0.84 | 0.70 | 0.72 |

| WB | y = −1.1344x3 + 24.837x2 − 169.76x + 417.88 | y = 0.0276x3 − 0.2017x2 − 1.3834x + 15.904 | y = −16.047x3 + 309.49x2 − 1957.3x + 4120.2 |

| R2 | 0.76 | 0.73 | 0.99 |

| Fried batter | |||

| OB | y = −0.6708x3 + 35.179x2 − 608.8x + 3551 | y = 0.0603x3 − 3.2654x2 + 58.596x − 339.77 | y = −22.873x3 + 577.36x2 − 4839.6x + 13544 |

| R2 | 0.73 | 0.91 | 0.71 |

| WB | y = 0.0001x3 + 0.0038x2 − 2.3198x + 105.18 | y = 6.1133x3 − 164.02x2 + 1457.5x − 4274.8 | y = 0.0009x3 − 0.2033x2 + 14.426x − 325.69 |

| R2 | 0.95 | 0.84 | 0.71 |

| Bran Concentration (g) | Fried Dough | Fried Batter | Significance |

|---|---|---|---|

| Control | 2.69 b ± 0.13 | 2.58 ab ± 0.04 | 0.02 |

| OB5 | 2.73 b ± 0.05 | 2.55 a ± 0.04 | 0.001 |

| OB8 | 2.74 b ± 0.02 | 2.62 bc ± 0.05 | 0.01 |

| OB10 | 2.76 b ± 0.08 | 2.61 abc ± 0.05 | 0.01 |

| OB15 | 2.57 a ± 0.08 | 2.58 ab ± 0.03 | 0.95 |

| OB20 | 2.73 b ± 0.04 | 2.66 c ± 0.04 | 0.05 |

| Control | 2.69 c ± 0.13 | 2.58 a ± 0.04 | 0.02 |

| WB5 | 2.67 bc ± 0.03 | 2.64 a ± 0.09 | 0.53 |

| WB8 | 2.57 ab ± 0.09 | 2.64 a ± 0.06 | 0.30 |

| WB10 | 2.66 abc ± 0.02 | 2.65 a ± 0.07 | 0.95 |

| WB15 | 2.56 a ± 0.07 | 2.67 a ± 0.09 | 0.12 |

| WB20 | 2.63 abc ± 0.06 | 2.64 a ± 0.05 | 0.60 |

| Sample | Cubic Polynomial Regression Model Equations | R2 |

|---|---|---|

| WB fried dough | A = 67.39B3 − 51.454B2 + 12.752B + 1.6384 | 0.9822 |

| Y = −3E + 06X3 + 2E+07X2 − 5E+07X + 4E+07 | 0.5615 | |

| WB fried batter | A = 653.52B3 − 335.94B2 + 54.869B − 0.2328 | 0.9568 |

| Y = −3E−10X3 + 1E−06X2 − 0.0008X + 2.5568 | 0.8451 | |

| OB fried dough | A = 7.3707B3 − 14.254B2 + 5.9505B + 2.0324 | 0.9736 |

| Y = 1E − 09X3 − 7E−06X2 + 0.0155X − 8.7206 | 0.8072 | |

| OB fried batter | A = −291.74B3 + 158.88B2 − 28.375B + 4.2429 | 0.8771 |

| Y = 465122X3 − 4E + 06X2 + 9E+06X − 8E + 06 | 0.9853 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Onipe, O.O.; Beswa, D.; Jideani, A.I.O. Confocal Laser Scanning Microscopy and Image Analysis for Elucidating Crumb and Crust Microstructure of Bran-Enriched South African Fried Dough and Batter. Foods 2020, 9, 605. https://doi.org/10.3390/foods9050605

Onipe OO, Beswa D, Jideani AIO. Confocal Laser Scanning Microscopy and Image Analysis for Elucidating Crumb and Crust Microstructure of Bran-Enriched South African Fried Dough and Batter. Foods. 2020; 9(5):605. https://doi.org/10.3390/foods9050605

Chicago/Turabian StyleOnipe, Oluwatoyin O., Daniso Beswa, and Afam I. O. Jideani. 2020. "Confocal Laser Scanning Microscopy and Image Analysis for Elucidating Crumb and Crust Microstructure of Bran-Enriched South African Fried Dough and Batter" Foods 9, no. 5: 605. https://doi.org/10.3390/foods9050605

APA StyleOnipe, O. O., Beswa, D., & Jideani, A. I. O. (2020). Confocal Laser Scanning Microscopy and Image Analysis for Elucidating Crumb and Crust Microstructure of Bran-Enriched South African Fried Dough and Batter. Foods, 9(5), 605. https://doi.org/10.3390/foods9050605