Computer Simulation with a Temperature-Step Frying Approach to Mitigate Acrylamide Formation in French Fries

Abstract

1. Introduction

2. Methodology

2.1. Governing Equations and Assumptions

2.1.1. Heat Transfer

2.1.2. Moisture Transfer

2.2. Kinetics of Acrylamide Formation and Degradation

2.3. Material Properties

2.3.1. Density

2.3.2. Heat Capacity

2.3.3. Thermal Conductivity

2.3.4. Diffusivity

3. Results and Discussion

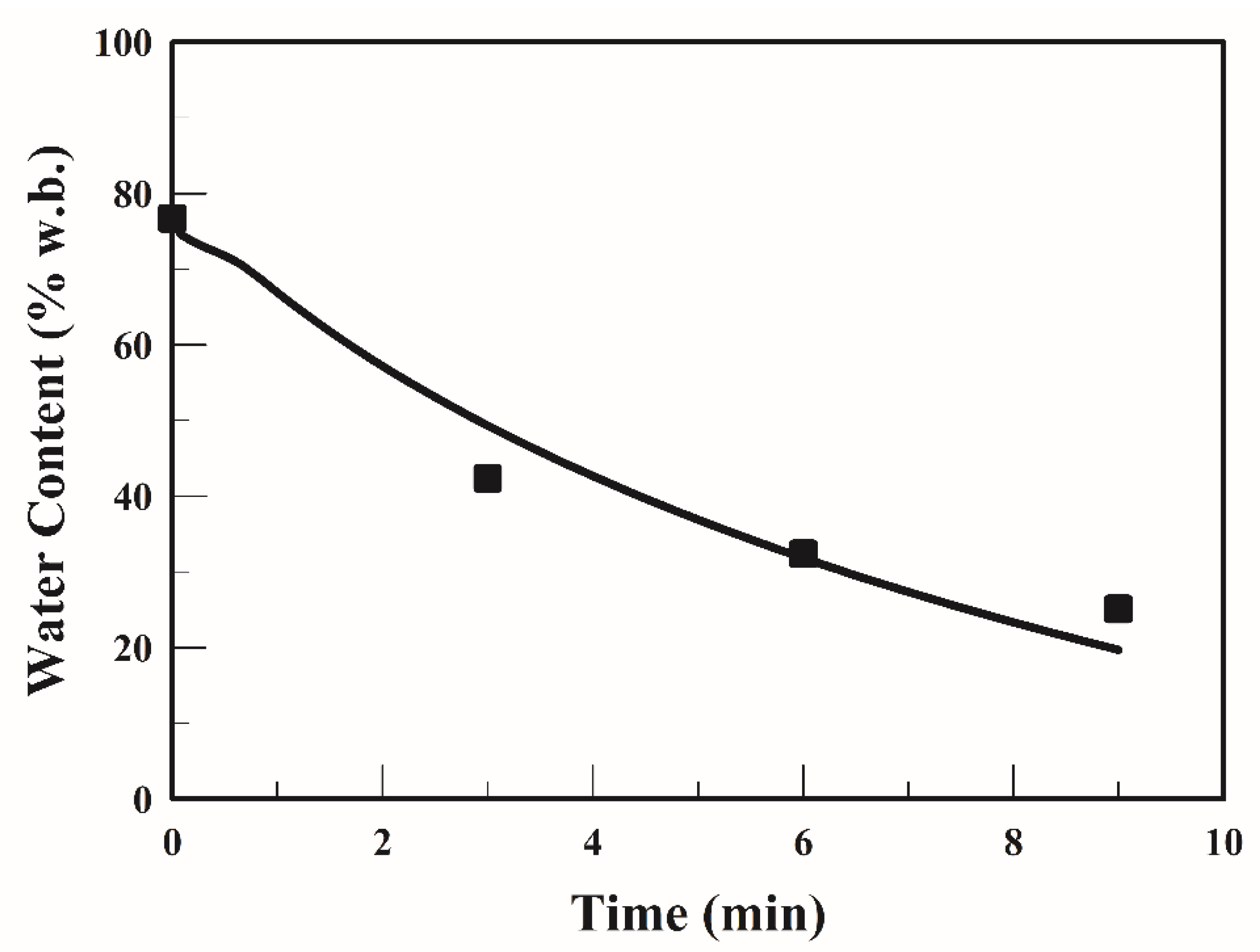

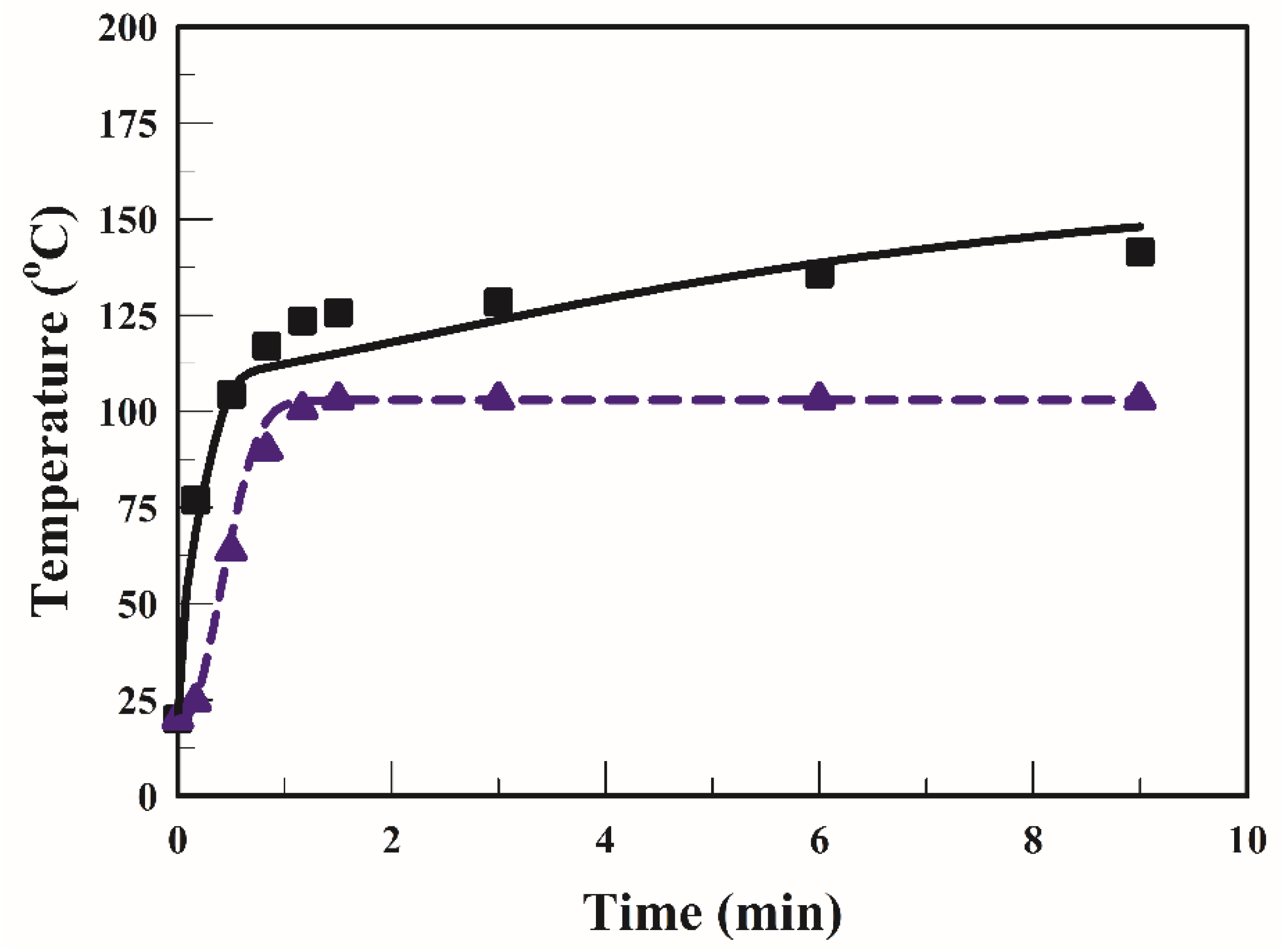

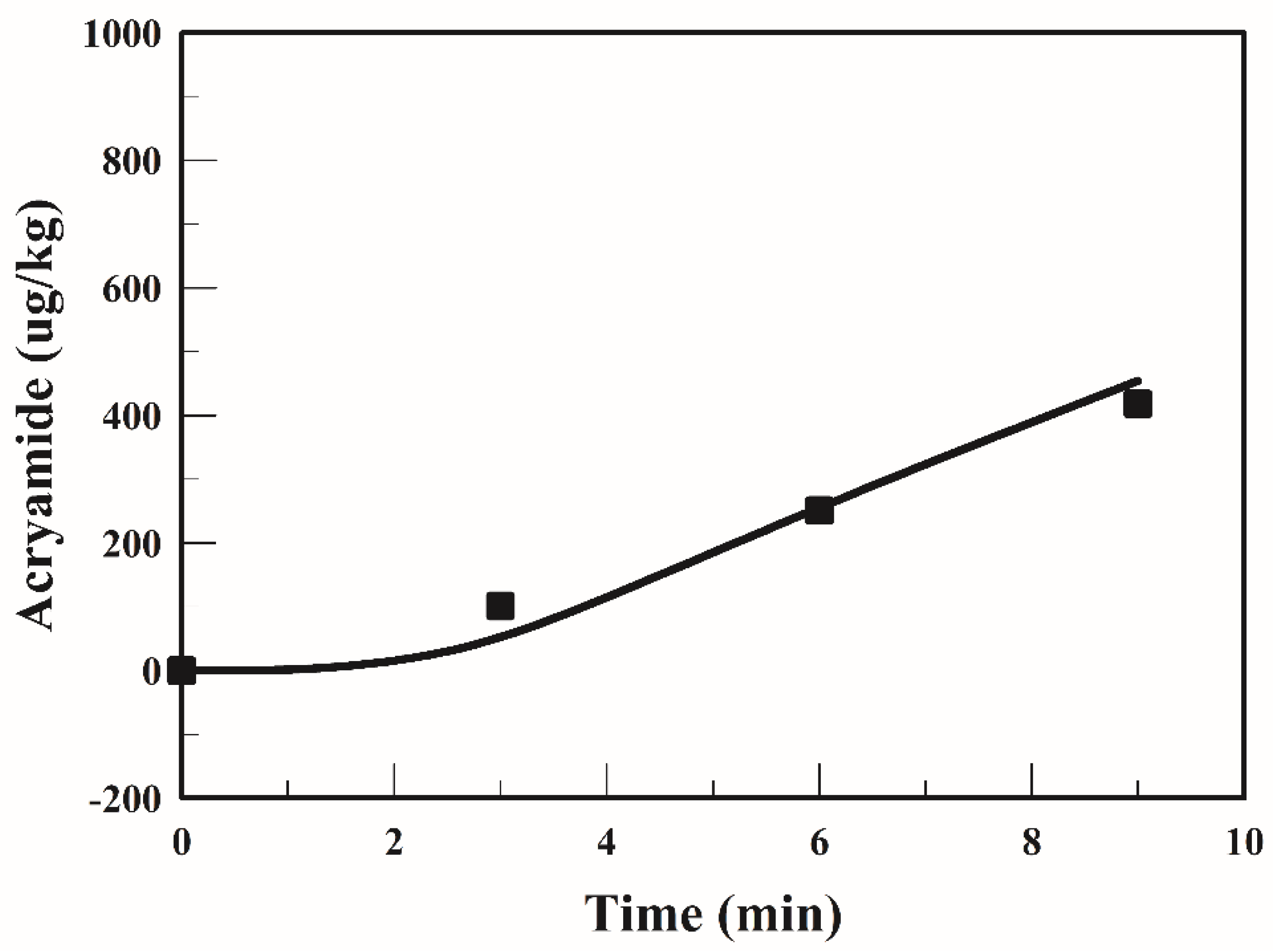

3.1. Model Validation

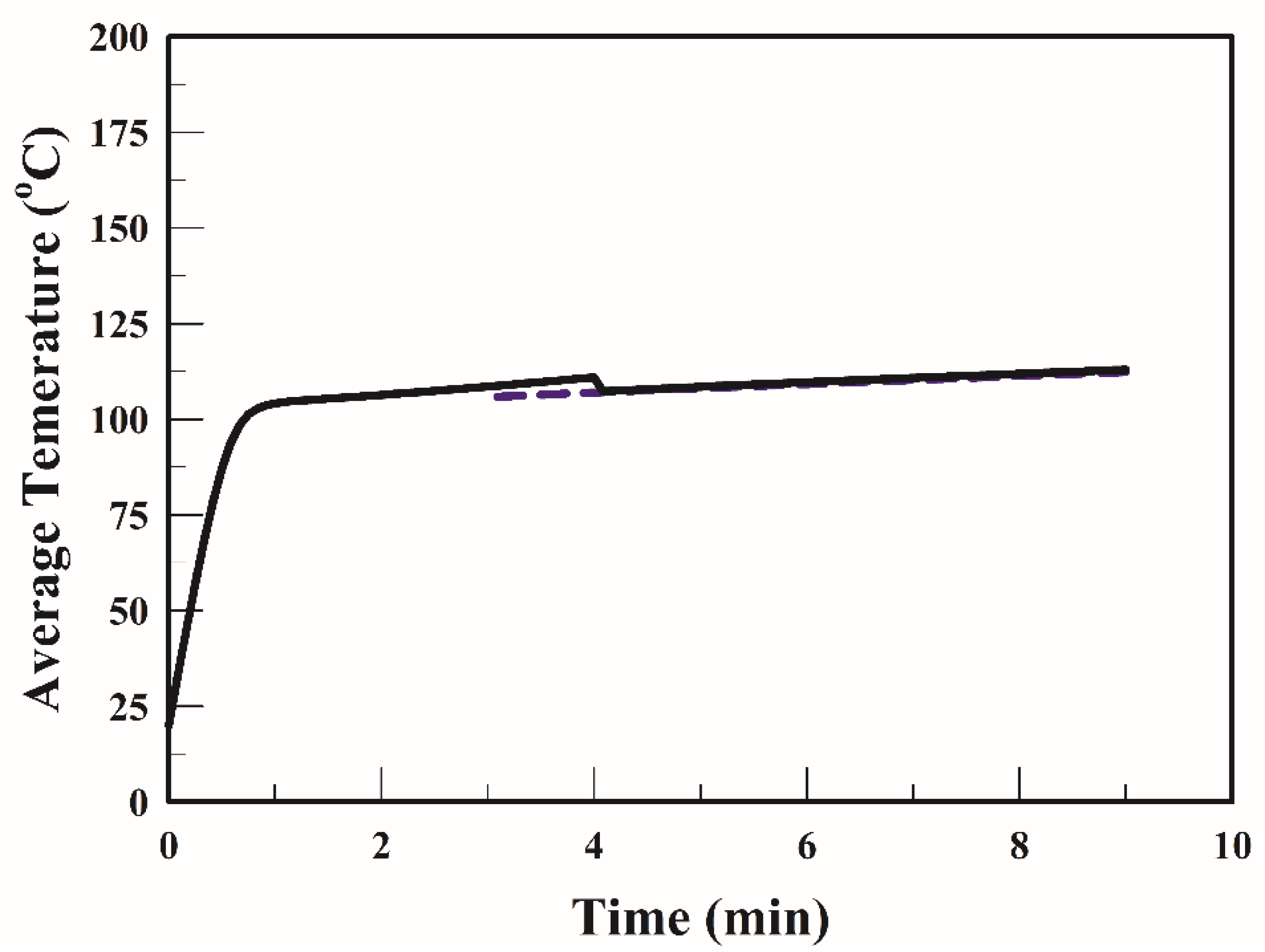

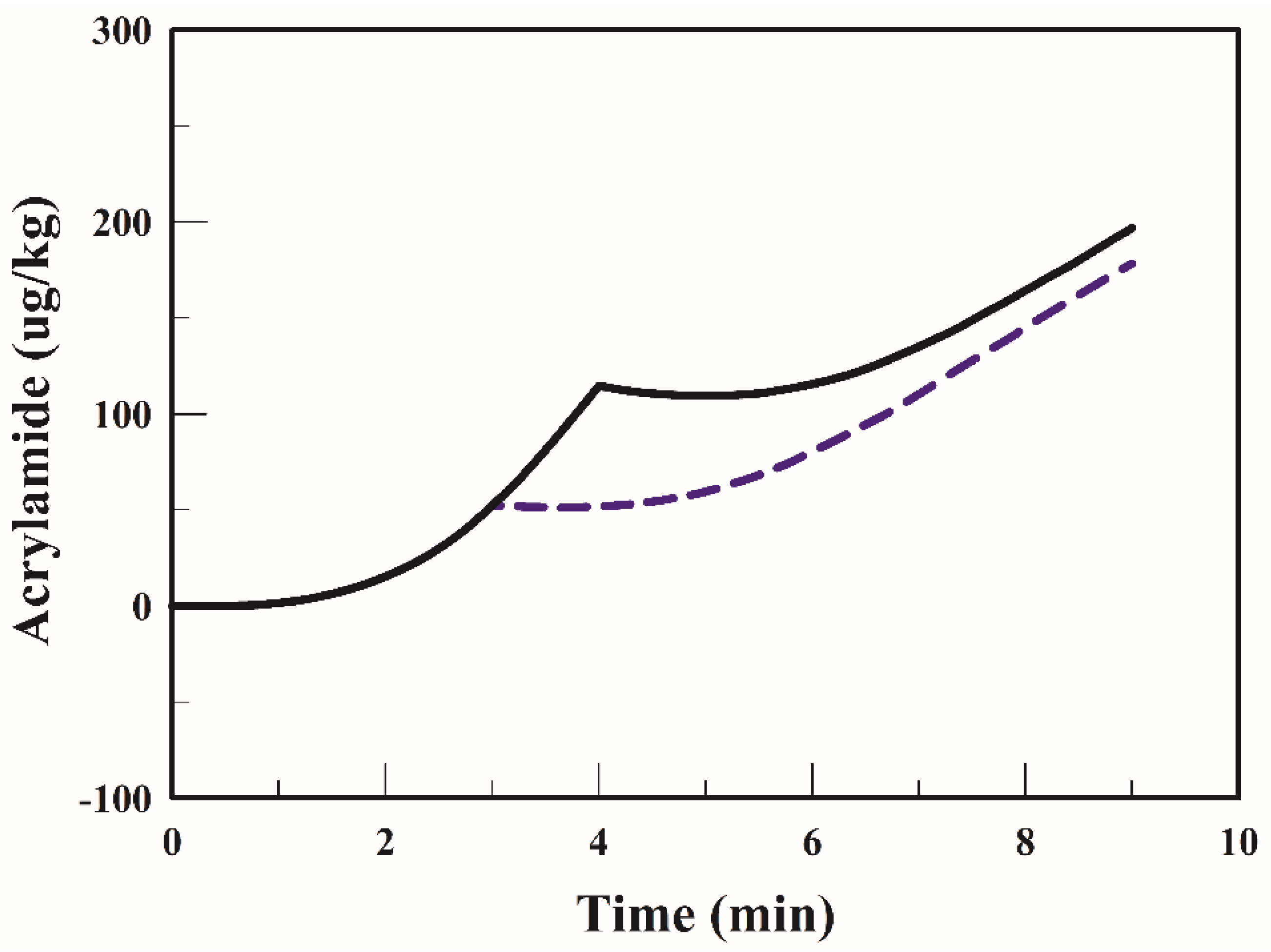

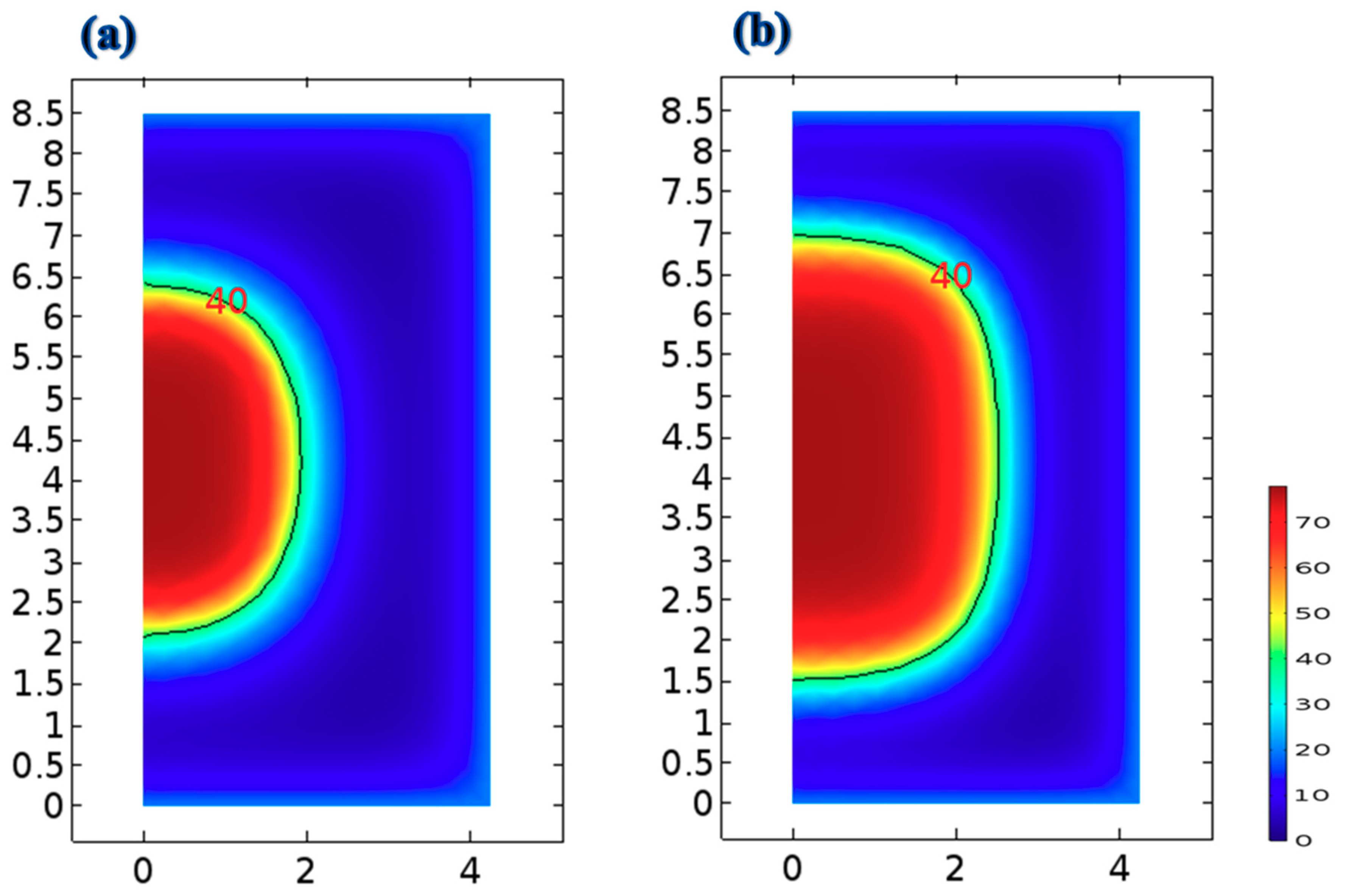

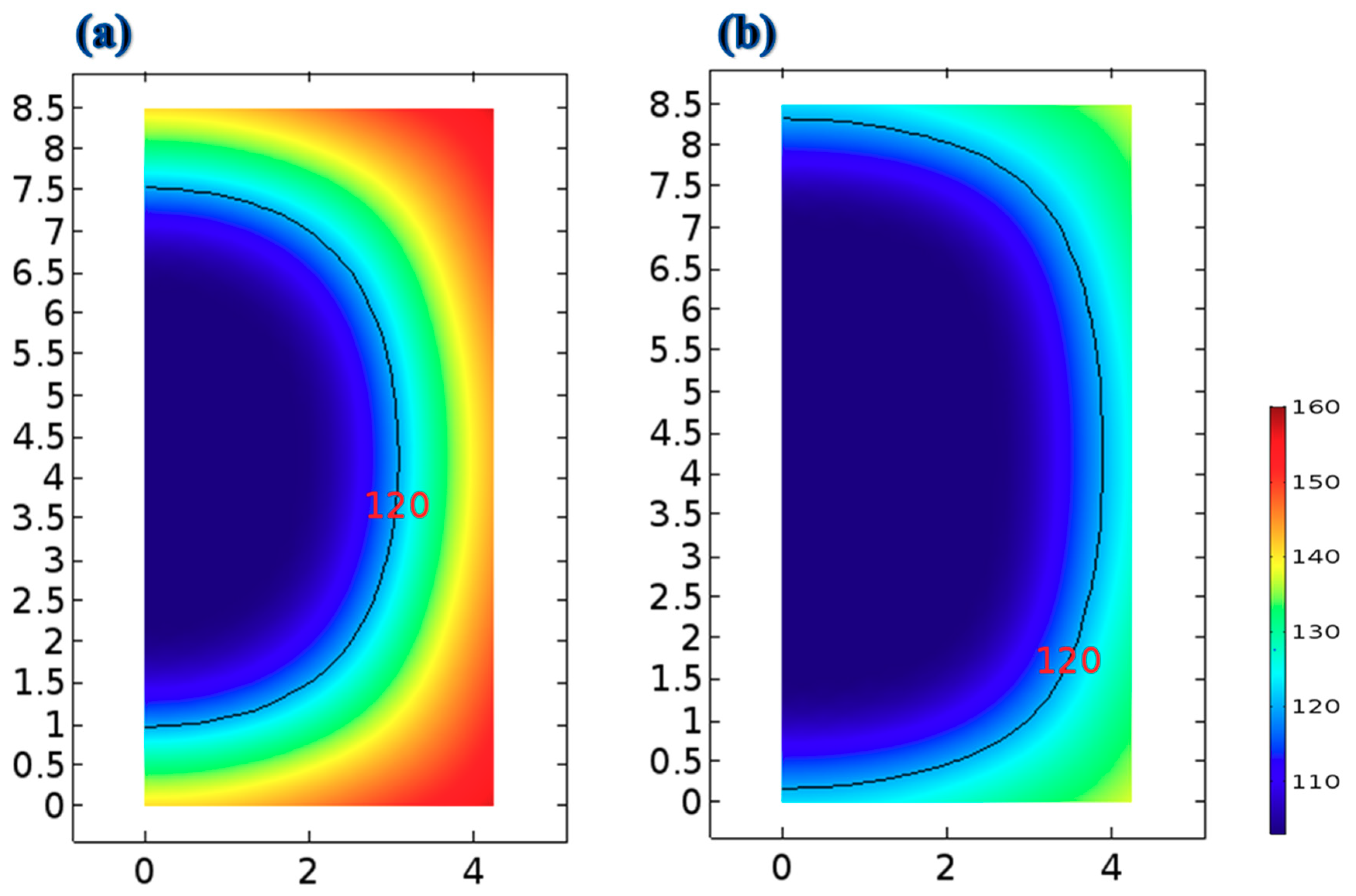

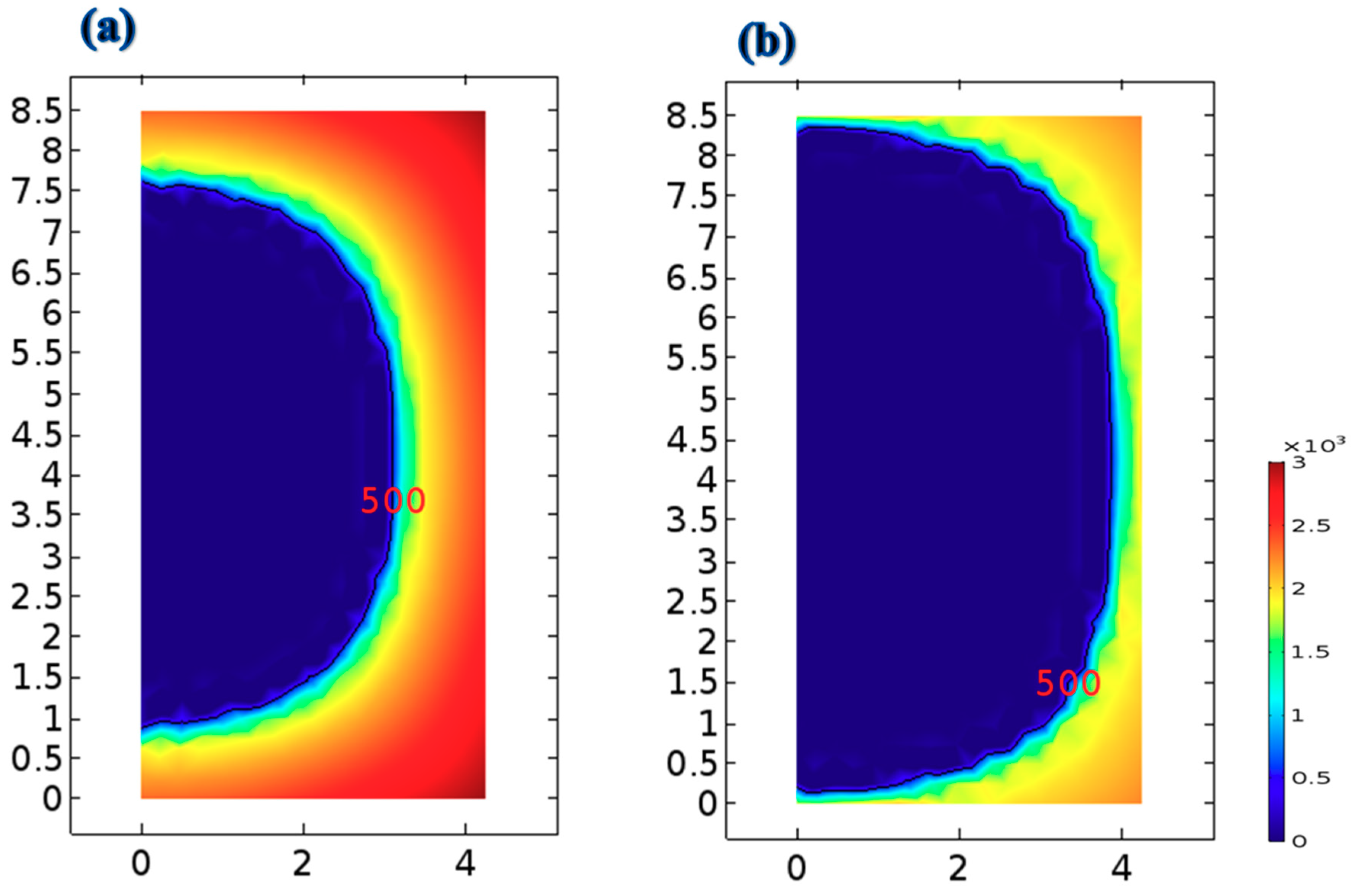

3.2. Simulation of Frying with a Temperature-Step Frying Approach

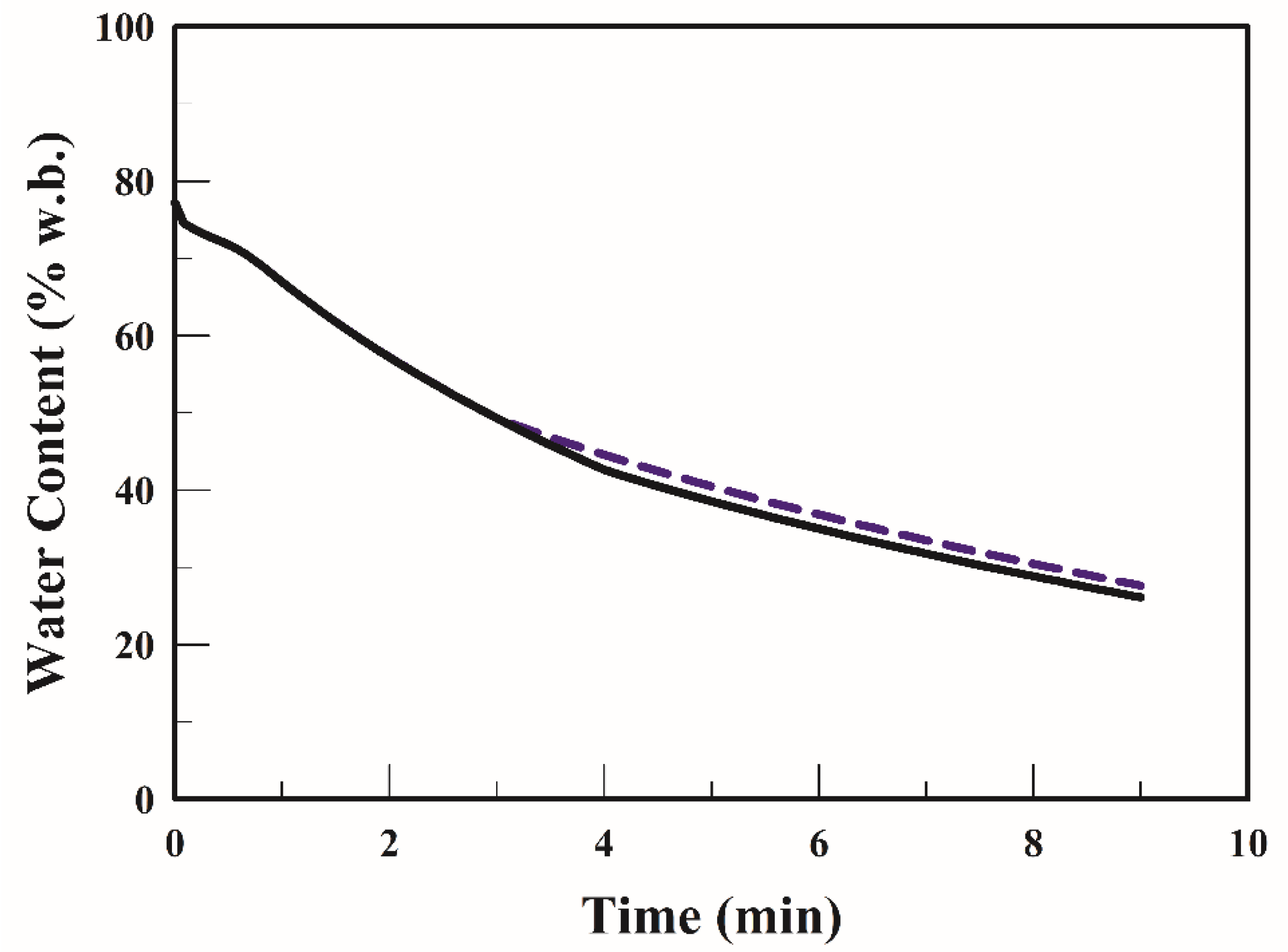

3.3. Comparison of Frying with and without the Temperature-Step Frying Approach

4. Conclusions

Funding

Conflicts of Interest

Nomenclature

| Symbol | Meaning, units |

| concentration, mol/m3 | |

| equilibrium water content, mol/m3 | |

| heat capacity, J/(kg K) | |

| compound heat capacity, J/(kg K) | |

| effective diffusivity of water, m2/s | |

| activation energy for acrylamide, kJ/mol | |

| activation energy for degraded products, kJ/mol | |

| numerical parameter for step frying temperature | |

| height of strip sample, m | |

| latent heat of water vaporization, J/kg | |

| convective heat transfer coefficient at surface, W/(m2 K) | |

| water evaporation rate constant, 1/s | |

| rate constant, 1/s | |

| convective mass transfer coefficient, m/s | |

| pre-exponential factor, 1/s | |

| the molecular weight, kg/mol | |

| rate of evaporation, mol/(m3 s) | |

| gas constant, 8.314 J/(mol K) | |

| acrylamide numerical step function parameter | |

| temperature step frying parameter | |

| heating numerical step function parameter | |

| temperature, K unless it is specified in °C | |

| t | time, s |

| initial heating of step frying process | |

| width of strip, m | |

| x, y | coordination |

| Greek symbols | |

| κ | thermal conductivity, W/(m K) |

| ω | mass fraction |

| ρ | density, kg/m3 |

| Subscript | |

| reducing sugar | |

| acrylamide | |

| carbohydrate | |

| degraded products | |

| dif | diffusion |

| effective | |

| equilibrium | |

| heating | |

| initial | |

| jth compound | |

| fry | frying |

| pro | protein |

| water |

References

- Pedreschi, F.; Mariotti, M.S.; Granby, K. Current Issues in dietary acrylamide: Formation, mitigation and risk assessment. J. Sci. Food Agric. 2014, 94, 9–20. [Google Scholar] [CrossRef] [PubMed]

- Palermo, M.; Gökmen, V.; De Meulenaer, B.; Ciesarová, Z.; Zhang, Y.; Pedreschif, F.; Fogliano, V. Acrylamide mitigation strategies: Critical appraisal of the FoodDrinkEurope toolbox. Food Funct. 2016, 7, 2516–2525. [Google Scholar] [CrossRef] [PubMed]

- JECFA. Safety evaluation of certain contaminants in food. In Acrylamide. 72nd Meeting of the Joint FAO/WHO Expert Committee on Food Additives (JECFA); WHO Food Additive Series 63; FAO JECFA Monograph: Rome, Italy, 2006. [Google Scholar]

- FDA. Guidance for Industry on How to Reduce Acrylamide in Certain Foods. 2016. Available online: https://www.fda.gov/regulatory-information/search-fda-guidance-documents/guidance-industry-acrylamide-foods (accessed on 20 December 2019).

- EFSA. Scientific opinion on acrylamide in food. EFSA J. 2015, 13, 4104. [Google Scholar]

- EC. Establishing mitigation measures and benchmark levels for the reduction of the presence of acrylamide in food. In COMMISSION REGULATION (EU)/2158; EU: Brussels, Belgium, 2017. [Google Scholar]

- Claus, A.; Carle, R.; Schieber, A. Acrylamide in cereal products: A review. J. Cereal Sci. 2008, 47, 118–133. [Google Scholar] [CrossRef]

- FoodDrinkEurope (FDE). Acrylamide Toolbox. 2013. Available online: http://fooddrinkeurope.eu/uploads/publications_documents/AcrylamideToolbox_2013.pdf (accessed on 20 December 2019).

- Konings, E.J.; Ashby, P.; Hamlet, C.G.; Thompson, G.A. Acrylamide in cereal and cereal products: A review on progress in level reduction. Food Addit. Contam. 2007, 24, 47–59. [Google Scholar] [CrossRef]

- Codex Alimentarius. Code of Practice for the Reduction of Acrylamide in Foods. CAC/RCP. 2009. Available online: http://www.codexalimentarius.org/input/download/standards/11258/CXP_067e.pdf (accessed on 20 December 2019).

- Shojaee-Aliabadi, S.; Nikoopour, S.H.; Kobarfard, F.; Parsapour, M.; Moslehishad, M.; Hassanabadi, H.; Frias, J.; Hashemia, M.; Dahaghin, E. Acrylamide Reduction in Potato Chips by Selection of Potato Variety Grown in Iran and Processing Conditions. J. Sci. Food Agric. 2013, 93, 2556–2561. [Google Scholar] [CrossRef]

- Truong, V.D.; Pascua, Y.T.; Reynolds, R.; Thompson, R.L.; Palazoğlu, T.K.; Mogol, B.A.; Gökmen, V. Processing Treatments for Mitigating Acrylamide Formation in Sweetpotato French Fries. J. Agric. Food Chem. 2014, 62, 310–316. [Google Scholar] [CrossRef]

- Friedman, M.; Levin, C.E. Review of methods for reduction of dietary content and toxicity of acrylamide. J. Agric. Food Chem. 2008, 56, 6113–6140. [Google Scholar] [CrossRef]

- Pathare, P.B.; Opara, U.L.; Al-Said, F.A.J. Colour Measurement and Analysis in Fresh and Processed Foods: A Review. Food Bioprocess Technol. 2013, 6, 36–60. [Google Scholar] [CrossRef]

- Palazoğlu, T.K.; Gökmen, V. Reduction of acrylamide level in French fries by employing a temperature program during frying. J. Agric. Food Chem. 2008, 56, 6162–6166. [Google Scholar] [CrossRef]

- Moghaddam, M.R.A.; Rafe, A.; Taghizadeh, M. Kinetics of Color and Physical Attributes of Cracker during Deep-fat Frying by Image Processing Techniques. J. Food Process. Preserv. 2015, 39, 91–99. [Google Scholar] [CrossRef]

- Isleroglu, H.; Kemerli, T.; Sakin-Yilmazer, M.; Guven, G.; Ozdestan, O.; Uren, A.; Kaymak-Ertekin, F. Effect of Steam Baking on Acrylamide Formation and Browning Kinetics of Cookies. J. Food Sci. 2012, 77, E257–E263. [Google Scholar] [CrossRef]

- Rydberg, P.; Eriksson, S.; Tareke, E.; Karlsson, P.; Ehrenberg, L.; Törnqvist, M. Investigations of factors that influence the acrylamide content of heated foodstuffs. J. Agric. Food Chem. 2003, 51, 7012–7018. [Google Scholar] [CrossRef]

- Krishnakumar, T.; Visvanathan, M. Acrylamide in Food Products: A review. J. Food Process Technol. 2014, 5, 1000344. [Google Scholar]

- Gökmen, V.; Palazoğlu, T.K.; Şenyuva, H.Z. Relation between the acrylamide formation and time—Temperature history of surface and core regions of French fries. J. Food Eng. 2006, 77, 972–976. [Google Scholar] [CrossRef]

- Yıldız, A.; Palazoğlu, T.K.; Erdoğdu, F. Determination of heat and mass transfer parameters during frying of potato slices. J. Food Eng. 2007, 79, 11–17. [Google Scholar] [CrossRef]

- Erdoğdu, S.B.; Palazoğlu, T.K.; Gökmen, V.; Şenyuva, H.Z.; Ekiz, H.I. Reduction of acrylamide in French fries by microwave pre-cooking of potato strips. J. Sci. Food Agric. 2007, 87, 133–137. [Google Scholar]

- Keramat, J.; LeBail, A.; Prost, C.; Jafari, M. Acrylamide in Baking Products: A Review Article. Food Bioprocess Technol. 2011, 4, 530–543. [Google Scholar] [CrossRef]

- Shin, D.C.; Kim, C.T.; Lee, Y.C.; Choi, W.J.; Na, Y.J.; Lee, K.W. Reduction of acrylamide by taurine in aqueous and potato chip model systems. Food Res. Int. 2010, 43, 1356–1360. [Google Scholar] [CrossRef]

- Palazoğlu, T.K.; Gökmen, V. Development and Experimental Validation of a Frying Model to Estimate Acrylamide Levels in French Fries. J. Food Sci. 2008, 73, E109–E114. [Google Scholar] [CrossRef]

- Chhanwal, N.; Indrani, D.; Raghavarao, K.S.M.S.; Anandharamakrishnan, C. Computational fluid dynamics modeling of bread baking process. Food Res. Int. 2011, 44, 978–983. [Google Scholar] [CrossRef]

- Purlis, E. Bread baking: Technological considerations based on process modelling and simulation. J. Food Eng. 2011, 103, 92–102. [Google Scholar] [CrossRef]

- Purlis, E. Baking process design based on modelling and simulation: Towards optimization of bread baking. Food Control. 2012, 27, 45–52. [Google Scholar] [CrossRef]

- Carrieri, G.; De Bonis, M.V.; Pacella, C.; Pucciarelli, A.; Ruocco, G. Modeling and validation of local acrylamide formation in a model food during frying. J. Food Eng. 2009, 95, 90–98. [Google Scholar] [CrossRef]

- Pedreschi, F.; Cocio, C.; Moyano, P.; Troncoso, E. Oil distribution in potato slices during frying. J. Food Eng. 2008, 87, 200–212. [Google Scholar] [CrossRef]

- Mondal, A.; Datta, A.K. Two-dimensional CFD modeling and simulation of crustless bread baking process. J. Food Eng. 2010, 99, 166–174. [Google Scholar] [CrossRef]

- Feyissa, A.H.; Gernaey, K.V.; Ashokkumar, S.; Adler-Nissen, J. Modelling of coupled heat and mass transfer during a contact baking process. J. Food Eng. 2011, 106, 228–235. [Google Scholar] [CrossRef]

- Bassama, J.; Brat, P.; Bohuon, P.; Hocine, B.; Boulanger, R.; Günata, Z. Acrylamide kinetic in plantain during heating process: Precursors and effect of water activity. Food Res. Int. 2011, 44, 1452–1458. [Google Scholar] [CrossRef]

- Corradini, M.G.; Peleg, M. Linear and Non-Linear Kinetics in the Synthesis and Degradation of Acrylamide in Foods and Model Systems. Crit. Rev. Food Sci. Nutr. 2006, 46, 489–517. [Google Scholar] [CrossRef]

- Papasidero, D.; Manenti, F.; Pierucci, S. Bread baking modeling: Coupling heat transfer and weight loss by the introduction of an explicit vaporization term. J. Food Eng. 2015, 147, 79–88. [Google Scholar] [CrossRef]

- Chen, H.; Marks, B.P.; Murphy, R.Y. Modeling coupled heat and mass transfer for convection cooking of chicken patties. J. Food Eng. 1999, 42, 139–146. [Google Scholar] [CrossRef]

- De Bonis, M.V.; Ruocco, G. A generalized conjugate model for forced convection drying based on an evaporative kinetics. J. Food Eng. 2008, 89, 232–240. [Google Scholar] [CrossRef]

| Par. Value | Par. Value | Par. Value | Par. Value | ||||

|---|---|---|---|---|---|---|---|

| 6.8 mol/m3 a | 44.5 kJ/mol e | 2.3 × 106 J/kg d | 22 1/s e | ||||

| 9265 mol/m3 e | 21.3 kJ/mol e | 105 W/(m2 K) e | 0.172 kg/mol e | ||||

| 35,778 mol/m3 b | 27.6 kJ/mol e | 8.0 × 10−3 1/s e | 8.5 × 10−3 m e | ||||

| 5.0 × 10−6 m2/s e | 8.5 × 10−3 m a | 5.2 × 10−4 m/s e | 293.15 K s | ||||

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chan, D.-S. Computer Simulation with a Temperature-Step Frying Approach to Mitigate Acrylamide Formation in French Fries. Foods 2020, 9, 200. https://doi.org/10.3390/foods9020200

Chan D-S. Computer Simulation with a Temperature-Step Frying Approach to Mitigate Acrylamide Formation in French Fries. Foods. 2020; 9(2):200. https://doi.org/10.3390/foods9020200

Chicago/Turabian StyleChan, Der-Sheng. 2020. "Computer Simulation with a Temperature-Step Frying Approach to Mitigate Acrylamide Formation in French Fries" Foods 9, no. 2: 200. https://doi.org/10.3390/foods9020200

APA StyleChan, D.-S. (2020). Computer Simulation with a Temperature-Step Frying Approach to Mitigate Acrylamide Formation in French Fries. Foods, 9(2), 200. https://doi.org/10.3390/foods9020200