Parboiled Paddy Drying with Different Dryers: Thermodynamic and Quality Properties, Mathematical Modeling Using ANNs Assessment

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Drying Techniques

2.3. Hybrid Infrared-Convection (IRC)

2.4. Infrared Convective-Microwave (IRCM)

2.5. Microwave (MIC)

2.6. Drying Kinetics Modeling

2.7. Mathematical Modeling

2.8. Determination of Effective Moisture Diffusivity (Deff)

2.9. Specific Energy Consumption

2.9.1. IRC Drying

2.9.2. MIC Drying

2.9.3. IRCM Drying

2.10. Artificial Neural Networks (ANN) Modeling

2.10.1. ANN 1: IRC DRYER

2.10.2. ANN 2: IRCM Drying

2.10.3. ANN 3: MIC Drying

2.11. Quality Properties

2.11.1. Head Rice Yield (HRY)

2.11.2. Color Value and Lightness

3. Results and Discussion

3.1. Drying Time

3.1.1. Hybrid IRC Drying

3.1.2. IRCM Drying

3.1.3. Microwave Drying

3.2. Mathematical Modeling

3.3. Effective Moisture Diffusivity (Deff)

3.4. Specific Energy Consumption (SEC)

3.5. ANN Modeling

3.5.1. IRC Drying

3.5.2. IRCM Drying

3.5.3. Microwave Drying

3.6. Quality Properties

3.6.1. Head Rice Yield (HRY)

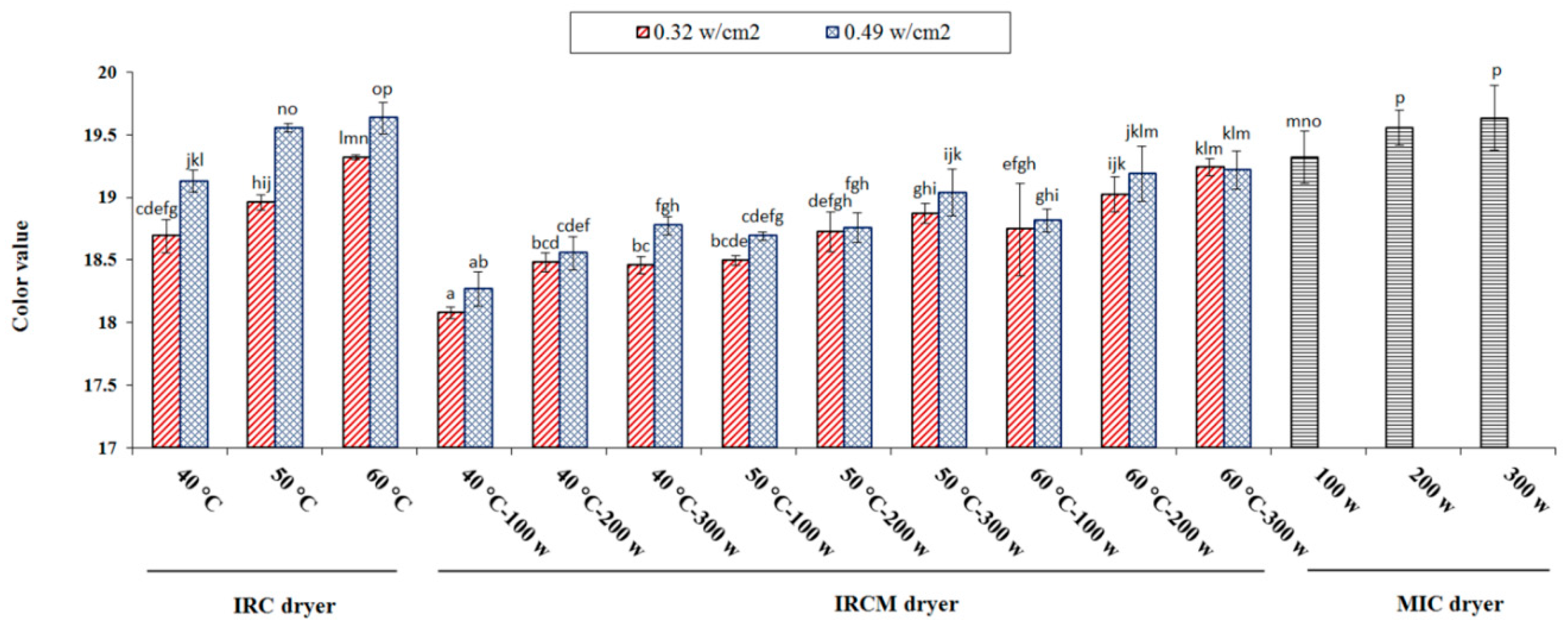

3.6.2. Color Value

3.6.3. Lightness

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Abbreviations | |

| ANN | Artificial Neural Network |

| bj | The bias of j-th neuron for FFBP and CFBP |

| HA | Hot air |

| HRY | Head rice yield |

| IR | Infrared |

| IRC | Hybrid infrared-convective |

| IRCM | Infrared-convective-microwave |

| MIC | Microwave |

| MR | Moisture ratio |

| SEC | Specific energy consumption |

| w.b. | Wet bulb |

| N0 | Number of output neurons |

| MAE | Mean absolute error |

| MSE | Mean squared error |

| RMSE | Root mean square error |

| Symbols | |

| A | Cross sectional area of container in which sample was placed (m2) |

| C | Specific heat (kJ/kg °K) |

| D0 | Pre-exponential factor of the Arrhenius equation (m2/s) |

| Deff | Effective moisture diffusivity (m2/s) |

| EU | Energy consumption (kJ) |

| K | Lamp power |

| MC | Moisture content (gwater g−1 dry matter) |

| MR | Moisture ratio (decimal) |

| M | Moisture content (% d.b.) |

| Mw | Weight of loss water (kg) |

| n | number of training patterns |

| N | Number of observations |

| N0 | Number of output neurons |

| P | Power (kW) |

| R2 | Determination coefficient |

| r | The radius of paddy (m) |

| RH | Relative humidity (%) |

| Sk | Network output for kth pattern |

| t | Drying time (s) |

| Tc | Air temperature (°C) |

| Tk | Target output for kth pattern |

| v | Air velocity (m/s) |

| z | Number of drying constants |

| W | Amount of evaporated moisture (g) |

| Wt | Initial weight of sample (g) |

| We | Dry matter content of sample (g) |

| Wij | Weight of between i-th and j-th layers |

| Xi | The i-th input neuron |

| Yj | The j-th output neuron |

| Greek Symbols | |

| χ2 | Chi-square |

| ρ | Density (kg/m3) |

| ΔT | Temperature difference |

| ΔP | Pressure difference (mbar) |

| Subscripts | |

| a | air |

| ther | Thermal |

| mec | Mechanical |

| t | Total |

| i | Initial |

| e | Equilibrium |

| Exp,i | Experimental ith data |

| Pre,i | Predicted ith data |

References

- Taghinezhad, E.; Brenner, T. Mathematical modeling of starch gelatinization and some quality properties of parboiled rice based on parboiling indicators using RSM. J. Food Process Eng. 2017, 40. [Google Scholar] [CrossRef]

- Swasdisevi, T.; Sriariyakula, W.; Tia, W.; Soponronnarit, S. Effect of pre-steaming on production of partially-parboiled rice using hot-air fluidization technique. J. Food Eng. 2010, 96, 455–462. [Google Scholar] [CrossRef]

- Del-Rosario, A.J.; VÍctor, O.P.; Abel, C.G. Hot air drying kinetics of thin layers of prickly pear fruit paste. Sains Malays. 2019, 48, 361–367. [Google Scholar]

- Wu, B.; Ma, H.; Qu, W.; Wang, B.; Zhang, X.; Wang, P.; Wang, J.; Atungulu, G.G.; Pan, Z. Catalytic infrared and hot air dehydration of carrot slices. J. Food Process Eng. 2014, 37, 111–121. [Google Scholar] [CrossRef]

- Nejadi, J.; Nikbakht, A.M. Numerical Simulation of Corn Drying in a Hybrid Fluidized Bed-Infrared Dryer. J. Food Process Eng. 2016. [Google Scholar] [CrossRef]

- Onwude, D.I.; Hashim, N.; Abdan, K.; Janius, R.; Chen, G. Investigating the influence of novel drying methods on sweet potato (Ipomoea batatas L.): Kinetics, energy consumption, color, and microstructure. J. Food Process Eng. 2018, 41, e12686. [Google Scholar] [CrossRef]

- Özdemir, M.B.; Aktaş, M.; Şevik, S.; Khanlari, A. Modeling of a convective-infrared kiwifruit drying process. Int. J. Hydrogen Energy 2017, 42, 18005–18013. [Google Scholar] [CrossRef]

- Deepika, S.; Sutar, P.P. Combining osmotic–steam blanching with infrared–microwave–hot air drying: Production of dried lemon (Citrus limon L.) slices and enzyme inactivation. Dry. Technol. 2018, 36, 1719–1737. [Google Scholar] [CrossRef]

- Dehghannya, J.; Farshad, P.; Heshmati, M.K. Three-stage hybrid osmotic–intermittent microwave–convective drying of apple at low temperature and short time. Dry. Technol. 2018, 36, 1982–2005. [Google Scholar] [CrossRef]

- Kowalski, S.J.; Pawłowski, A. Modeling of kinetics in stationary and intermittent drying. Dry. Technol. 2010, 28, 1023–1031. [Google Scholar] [CrossRef]

- Assar, M.; Golmohammadi, M.; Rajabi-Hamaneh, M.; Hassankiadeh, M.N. A Combined experimental and theoretical approach to study temperature and moisture dynamic characteristics of intermittent paddy rice drying. Chem. Eng. Commun. 2016, 203, 1242–1250. [Google Scholar] [CrossRef]

- Ghasemi, A.; Sadeghi, M.; Mireei, S.A. Multi-stage intermittent drying of rough rice in terms of tempering and stress cracking indices and moisture gradients interpretation. Dry. Technol. 2017, 36, 109–117. [Google Scholar] [CrossRef]

- Kaveh, M.; Amiri Chayjan, R.; Nikbakht, A.M. Mass transfer characteristics of eggplant slices during length of continuous band dryer. Heat Mass Transf. 2017, 53, 2045–2059. [Google Scholar] [CrossRef]

- Doymaz, I.; Demir, H.; Yildirim, A. Drying of quince slices: Effect of pretreatments on drying and rehydration characteristics. Chem. Eng. Commun. 2015, 202, 1271–1279. [Google Scholar] [CrossRef]

- Prakash, O.; Kumar, A. Application of artificial neural network for the prediction of jaggery mass during drying inside the natural convection greenhouse dryer. Int. J. Ambient. Energy 2014, 35, 186–192. [Google Scholar] [CrossRef]

- Prakash, O.; Kumar, A.; Kaviti, A.K.; Kumar, P.V. Prediction of the rate of moisture evaporation from jaggery in greenhouse drying using the fuzzy logic. Heat Transf. Res. 2015, 46, 923–935. [Google Scholar] [CrossRef]

- Jahed Armaghani, D.; Tonnizam Mohamad, E.; Hajihassani, M.; Yagiz, S.; Motaghedi, H. Application of several non-linear prediction tools for estimating uniaxial compressive strength of granitic rocks and comparison of their performances. Eng. Comput. 2016, 32, 189–206. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Hosseinpour, S.; Mujumdar, A.S. Application of artificial neural networks (anns) in drying technology: A comprehensive review. Dry. Technol. 2015, 33, 1397–1462. [Google Scholar] [CrossRef]

- Saraceno, A.; Aversa, M.; Curcio, S. Advanced modeling of food convective drying: A comparison between artificial neural networks and hybrid approaches. Food Bioprocess Technol. 2012, 5, 1694–1705. [Google Scholar] [CrossRef]

- Chasiotis, V.K.; Tzempelikos, D.A.; Filios, A.E.; Moustris, K.P. Artificial neural network modelling of moisture content evolution for convective drying of cylindrical quince slices. Comput. Electron. Agric. 2019. [Google Scholar] [CrossRef]

- Chayjan, R.A.; Kaveh, M.; Khayati, S. Modeling some drying characteristics of sour cherry (Prunus cerasus L.) under infrared radiation using mathematical models and artificial neural networks. Agric. Eng. Int. CIGR J. 2014, 16, 265–279. [Google Scholar]

- Karakaplan, N.; Goz, E.; Tosun, E.; Yuceer, E. Kinetic and artificial neural network modeling techniques to predict the drying kinetics of Mentha spicata L. J. Food Process. Preserv. 2019, 43, e14142. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 16th ed.; Association of Official Analytical Chemists: Arlington, VA, USA, 1995. [Google Scholar]

- Islam, M.R.; Roy, P.; Shimizu, N.; Kimura, T. Effect of processing conditions on physical properties of parboiled rice. Food Sci. Technol. Res. 2002, 8, 106–112. [Google Scholar] [CrossRef]

- Aquerreta, J.; Iguaz, A.; Arroqui, C.; Virseda, P. Effect of high temperature intermittent drying and tempering on rough rice quality. J. Food Eng. 2007, 80, 611–618. [Google Scholar] [CrossRef]

- Seremet, L.; Botez, E.; Nistor, O.-V.; Andronoiu, D.G.; Mocanu, G.-D. Effect of different drying methods on moisture ratio and rehydration of pumpkin slices. Food Chem. 2016, 195, 104–109. [Google Scholar] [CrossRef] [PubMed]

- Ondier, G.O.; Siebenmorgen, T.J.; Bautista, R.C.; Mauromoustakos, A. Equilibrium moisture contents of pureline, hybrid and parboiled rice. Am. Soc. Agric. Biol. Eng. (ASABE) 2011, 54, 1007–1013. [Google Scholar] [CrossRef]

- Yang, X.-H.; Deng, L.-Z.; Mujumdar, A.S.; Xiao, H.-W.; Zhang, Q.; Kan, Z. Evolution and modeling of colour changes of red pepper (Capsicum annuum L.) during hot air drying. J. Food Eng. 2018, 231, 101–108. [Google Scholar] [CrossRef]

- Kaveh, M.; Amiri Chayjan, R. Modeling thin-layer drying of turnip slices under semi-industrial continuous band dryer. J. Food Process. Preserv. 2017, 41, e12778. [Google Scholar] [CrossRef]

- Amiri Chayjan, R.; Amiri Parian, J.; Esna-Ashari, M. Modeling of moisture diffusivity, activation energy and specific energy consumption of high moisture corn in a fixed and fluidized bed convective dryer. Span. J. Agric. Res. 2011, 9, 13. [Google Scholar] [CrossRef]

- Aktas, M.; Sevik, S.; Aktekeli, B. Development of heat pump and infrared-convective dryer and performance analysis for stale bread drying. Energy Convers. Manag. 2016, 113, 82–94. [Google Scholar] [CrossRef]

- Torki-Harchegani, M.; Ghanbarian, D.; Ghasemi Pirbalouti, A.; Sadeghi, M. Dehydration behaviour, mathematical modelling, energy efficiency and essential oil yield of peppermint leaves undergoing microwave and hot air treatments. Renew. Sustain. Energy Rev. 2016, 58, 407–418. [Google Scholar] [CrossRef]

- Motevali, A.; Tabatabaee Koloor, R. A comparison between pollutants and greenhouse gas emissions from operation of different dryers based on energy consumption of power plants. J. Clean. Prod. 2017, 154, 445–461. [Google Scholar] [CrossRef]

- Lohani Umesh, C.; Muthukumarappan, K. Modeling of continuous ultrasonication to improve total phenolic content and antioxidant activity in sorghum flour: A comparison between response surface methodology and artificial neural network. Int. J. Food Eng. 2017, 13. [Google Scholar] [CrossRef]

- Nasirahmadi, A.; Emadi, B.; Abbaspour-Fard, M.H.; Aghagolzade, H. Influence of moisture content, variety and parboiling on milling quality of rice grains. Rice Sci. 2014, 21, 116–122. [Google Scholar] [CrossRef]

- Islam, M.R.; Shimizu, N.; Kimura, T. Energy requirement in parboiling and its relationship to some important quality indicators. J. Food Eng. 2004, 63, 433–439. [Google Scholar] [CrossRef]

- Paengkanya, S.; Soponronnarit, S.; Nathakaranakule, A. Application of microwaves for drying of durian chips. Food Bioprod. Process. 2015, 96, 1–11. [Google Scholar] [CrossRef]

- Kayran, S.; Doymaz, İ. Determination of drying kinetics and physicochemical characterization of apricot pomace in hot-air dryer. J. Therm. Anal. Calorim. 2017, 130, 1163–1170. [Google Scholar] [CrossRef]

- Aydogdu, A.; Sumnu, G.; Sahin, S. Microwave—Infrared combination drying of eggplants. Food Bioprocess Technol. 2015, 6, 1198–1210. [Google Scholar] [CrossRef]

- Khoshtaghaza, M.H.; Darvishi, H.; Minaei, S. Effects of microwave—Fluidized bed drying on quality, energy consumption and drying kinetics of soybean kernels. J. Food Sci. Technol. 2015, 52, 4749–4760. [Google Scholar] [CrossRef]

- Doymaz, İ.; Karasu, S.; Baslar, M. Effects of infrared heating on drying kinetics, antioxidant activity, phenolic content, and color of jujube fruit. J. Food Meas. Charact. 2016, 10, 283–291. [Google Scholar] [CrossRef]

- Jafari, H.; Kalantari, D.; Azadbakht, M. Energy consumption and qualitative evaluation of a continuous band microwave dryer for rice paddy drying. Energy 2018, 142, 647–654. [Google Scholar] [CrossRef]

- Salarikia, A.; Miraei Ashtiani, S.-H.; Golzarian, M.R. Comparison of drying characteristics and quality of peppermint leaves using different drying methods. J. Food Process. Preserv. 2017, 41, e12930. [Google Scholar] [CrossRef]

- Lechtańska, J.M.; Szadzińska, J.; Kowalski, S.J. Microwave- and infrared-assisted convective drying of green pepper: Quality and energy considerations. Chem. Eng. Process. Process Intensif. 2015, 98, 155–164. [Google Scholar] [CrossRef]

- Singh, N.; Paul, P.; Virdi, A.S.; Kaur, P.; Mahajan, G. Influence of early and delayed transplantation of paddy on physicochemical, pasting, cooking, textural, and protein characteristics of milled rice. Cereal Chem. 2014, 91, 389–397. [Google Scholar] [CrossRef]

- Tirawanichakul, S.; Bualuang, O.; Tirawanichakul, Y. Study of drying kinetics and qualities of two parboiled rice varieties: Hot air convection and infrared irradiation. Songklanakarin J. Sci. Technol. 2012, 34, 557–568. [Google Scholar]

- Sareepuang, K.; Siriamornpun, S.; Wiset, L.; Meeso, N. Effect of soaking temperature on physical, chemical and cooking properties of parboiled Fragrant rice. World J. Agric. Sci. 2008, 4, 409–415. [Google Scholar]

- Ayamdoo, A.J.; Demuyakor, B.; Dogbe, W.; Owusu, R.; Ofosu, M.A. Effect of varying parboiling conditions on physical qualities of Jasmine 85 and Nerica 14 rice varieties. Am. J. Food Technol. 2013, 8, 31–42. [Google Scholar] [CrossRef]

- Ahmadi Ghavidelan, M.; Amiri Chayjan, R. Modeling engineering characteristics of hazelnut kernel during infrared fluidized bed drying. Food Meas. 2016, 11, 460–478. [Google Scholar] [CrossRef]

- Elbert, G.; Tolaba, M.P.; Suárez, C. Effects of drying conditions on head rice yield and browning index of parboiled rice. J. Food Eng. 2001, 47, 37–41. [Google Scholar] [CrossRef]

- Lv, B.; Li, B.; Chen, S.; Chen, J.; Zhu, B. Comparison of color techniques to measure the color of parboiled rice. J. Cereal Sci. 2009, 50, 262–265. [Google Scholar] [CrossRef]

- Lamberts, L.; Brijs, K.M.R.; Verhelst, N.; Delcour, J.A. Impact of browning reactions and bran pigments on color of parboiled rice. J. Agric. Food Chem. 2006, 54, 9924–9929. [Google Scholar] [CrossRef]

- Parnsakhorn, S.; Noomhorm, A. Changes in physicochemical properties of parboiled brown rice during heat treatment. Agric. Eng. Int. CIGR J. 2008. Available online: https://cigrjournal.org/index.php/Ejounral/article/view/1221 (accessed on 10 August 2019).

| Models | Equation |

|---|---|

| Aghbashlo | |

| Page | |

| logistic | |

| Demir | |

| Midili |

| Drying Type | Network | Training Algorithm | Threshold Function | Number of Layers and Neurons | MSE | Train | Test | ||

|---|---|---|---|---|---|---|---|---|---|

| R2 | MAE | R2 | MAE | ||||||

| Infrared- convective drying | FFBP | LM | TAN-PUR-TAN | 3-8-8-1 | 0.00057 | 0.9992 | 0.0059 | 0.9993 | 0.0048 |

| FFBP | BR | TAN-TAN-TAN | 3-12-1 | 0.00145 | 0.9984 | 0.0109 | 0.9986 | 0.0089 | |

| CFBP | LM | TAN-TAN-TAN | 3-12-12-1 | 0.00101 | 0.9990 | 0.0080 | 0.9991 | 0.0064 | |

| CFBP | BR | TAN-TAN-LOG | 3-18-1 | 0.00062 | 0.9992 | 0.0067 | 0.9992 | 0.0052 | |

| Infrared- convective- microwave drying | FFBP | LM | TAN-TAN-LOG | 4-15-15-1 | 0.00108 | 0.9982 | 0.0114 | 0.9983 | 0.0106 |

| FFBP | BR | LOG-TAN-PUR | 4-5-5-1 | 0.00074 | 0.9987 | 0.0095 | 0.9988 | 0.0092 | |

| CFBP | LM | TAN-TAN-TAN | 4-8-1 | 0.00067 | 0.9991 | 0.0069 | 0.9991 | 0.0061 | |

| CFBP | BR | TAN-TAN-TAN | 4-10-10-1 | 0.00052 | 0.9994 | 0.0044 | 0.9995 | 0.0039 | |

| Microwave drying | FFBP | LM | PUR-TAN-TAN | 2-20-1 | 0.00079 | 0.9986 | 0.0088 | 0.9988 | 0.0069 |

| FFBP | BR | TAN-TAN-TAN | 2-10-10-1 | 0.00065 | 0.9989 | 0.0073 | 0.9990 | 0.0054 | |

| CFBP | LM | TAN-TAN-TAN | 2-10-10-1 | 0.00101 | 0.9981 | 0.0111 | 0.9982 | 0.0105 | |

| CFBP | BR | TAN-LOG-PUR | 2-15-10-1 | 0.00981 | 0.9985 | 0.0098 | 0.9987 | 0.0084 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Taghinezhad, E.; Szumny, A.; Kaveh, M.; Rasooli Sharabiani, V.; Kumar, A.; Shimizu, N. Parboiled Paddy Drying with Different Dryers: Thermodynamic and Quality Properties, Mathematical Modeling Using ANNs Assessment. Foods 2020, 9, 86. https://doi.org/10.3390/foods9010086

Taghinezhad E, Szumny A, Kaveh M, Rasooli Sharabiani V, Kumar A, Shimizu N. Parboiled Paddy Drying with Different Dryers: Thermodynamic and Quality Properties, Mathematical Modeling Using ANNs Assessment. Foods. 2020; 9(1):86. https://doi.org/10.3390/foods9010086

Chicago/Turabian StyleTaghinezhad, Ebrahim, Antoni Szumny, Mohammad Kaveh, Vali Rasooli Sharabiani, Anil Kumar, and Naoto Shimizu. 2020. "Parboiled Paddy Drying with Different Dryers: Thermodynamic and Quality Properties, Mathematical Modeling Using ANNs Assessment" Foods 9, no. 1: 86. https://doi.org/10.3390/foods9010086

APA StyleTaghinezhad, E., Szumny, A., Kaveh, M., Rasooli Sharabiani, V., Kumar, A., & Shimizu, N. (2020). Parboiled Paddy Drying with Different Dryers: Thermodynamic and Quality Properties, Mathematical Modeling Using ANNs Assessment. Foods, 9(1), 86. https://doi.org/10.3390/foods9010086