Banana Powder as an Additive to Common Wheat Pasta

Abstract

1. Introduction

2. Materials and Methods

2.1. Research Materials

2.2. Banana Powder Preparation

2.3. Pasta Preparation

2.4. Physical Properties of the Pasta

2.4.1. Colour

2.4.2. Texture Analysis

2.5. Hydration Properties

2.6. Total Phenolics Content and Antioxidant Properties

2.6.1. Extract Preparation

2.6.2. Total Phenolics Content

2.6.3. Antioxidant Activity

2.7. Cooking Characteristics of Pasta

2.7.1. Optimal Cooking Time (OCT)

2.7.2. Weight Increase Index (WI) and Cooking Loss (CL)

2.8. Sensory Evaluation of Raw and Cooked Pasta and Banana Powder

2.9. Statistical Analysis

3. Results and Discussion

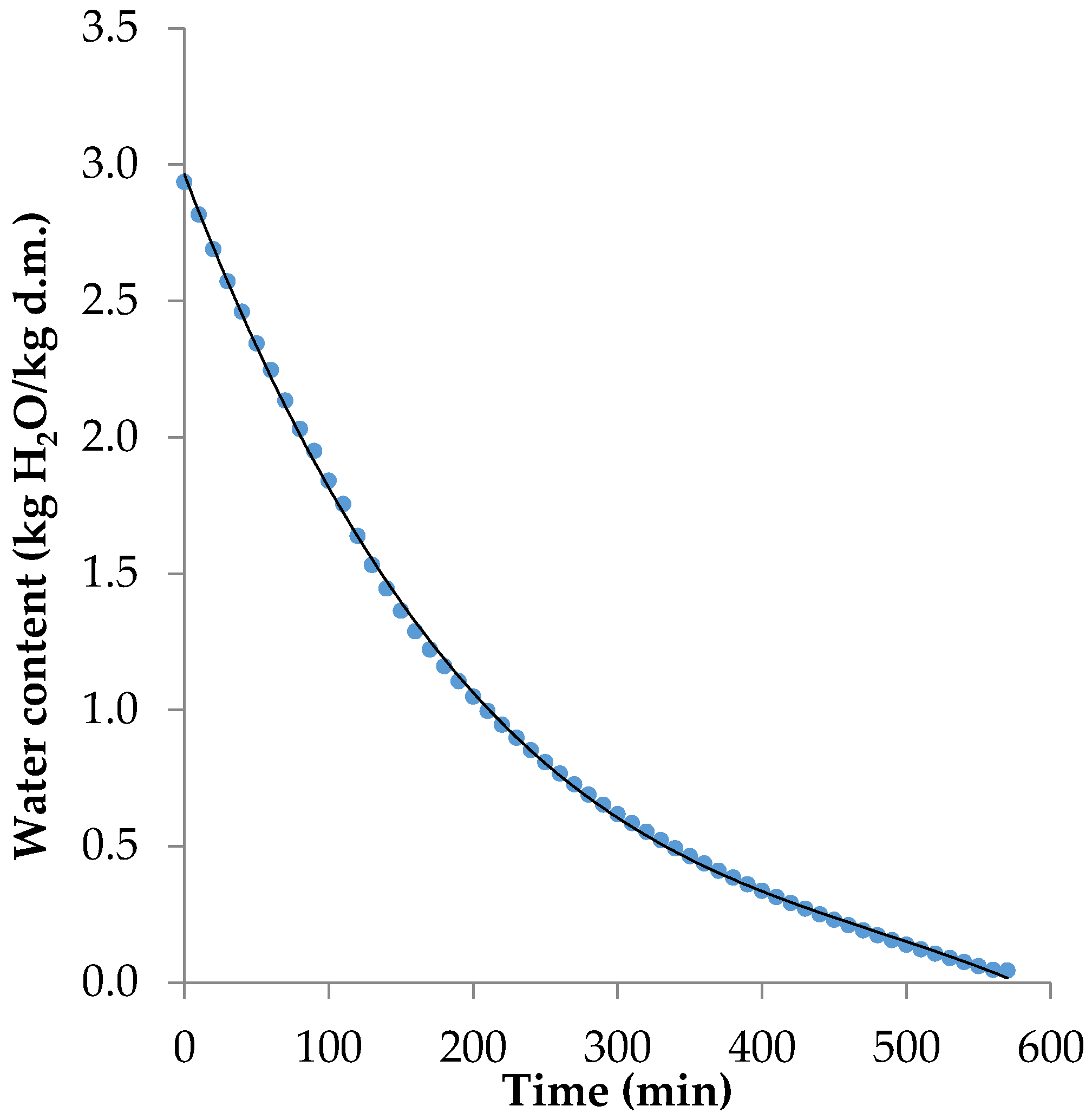

3.1. Drying Curve for Banana

3.2. Colour Parameters

3.3. Cutting Force

3.4. Hydration Properties

3.5. TPC and Antioxidant Properties of Pasta

3.6. Cooking Properties

3.7. Sensory Evaluation of BP

3.8. Sensory Evaluation of Cooked Pasta

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lu, X.; Brennana, M.A.; Serventia, L.; Liuc, J.; Guanc, W.; Brennana, C.S. Addition of mushroom powder to pasta enhances the antioxidant content and modulates the predictive glycaemic response of pasta. Food Chem. 2018, 264, 199–209. [Google Scholar] [CrossRef] [PubMed]

- Agama-Acevedo, E.; Bello-Perez, L.A.; Osorio-Diaz, P.; Utrilla-Coello, R.G.; Garcia-Suarez, F.J. Flour and Breads and Their Fortification in Health and Disease Prevention; Elsevier: Amsterdam, The Netherlands, 2011; pp. 235–245. [Google Scholar]

- Dib, A.; Wójtowicz, A.; Benatallah, L.; Bouasla, A.; Zidoune, M.N. Effect of hydrothermal treated corn flour addition on the quality of corn-field bean gluten-free pasta. BIO Web Conf. Contemp. Res. Trends Agric. Eng. 2018, 10, 02003. [Google Scholar] [CrossRef]

- Marti, A.; Pagani, M.A.; Seetharaman, K. Textural attributes of wheat and gluten free pasta. In Food Texture Design and Optimization; Lal Dar, Y., Light, J.M., John, W., Eds.; John Wiley & Sons Ltd.: New York, NY, USA, 2014; Volume 4, pp. 222–224. [Google Scholar]

- Larrosa, V.; Lorenzo, G.; Zaritzky, N.; Califano, A. Improvement of the texture and quality of cooked gluten-free pasta. LWT-Food Sci. Technol. 2016, 70, 96. [Google Scholar] [CrossRef]

- Lucisano, M.; Pagania, M.A.; Mariottia, M.; Locatellib, D.P. Influence of the material on pasta characteristics. Food Res. Int. 2008, 41, 646–652. [Google Scholar] [CrossRef]

- Dziki, D.; Różyło, R.; Biernacka, B. Wpływ czasu gotowania na właściwości fizyczne makaronów formy spaghetti. Acta Agrophys. 2010, 16, 35–48. [Google Scholar]

- Del-Nobile, M.A.; Baiano, A.; Conte, A.; Mocci, G. Influence of protein content on spaghetti cooking quality. J. Cereal Sci. 2005, 41, 347–356. [Google Scholar] [CrossRef]

- Sobota, A.; Rzedzicki, Z.; Zarzycki, P.; Kuzawińska, E. Application of common wheat bran for the industrial production of high-fibre pasta. Int. J. Food Sci. Technol. 2015, 50, 111–119. [Google Scholar] [CrossRef]

- Biernacka, B.; Dziki, D.; Gawlik-Dziki, U.; Różyło, R.; Siastała, M. Physical, sensorial and antioxidant properties of common wheat pasta enriched with carob fiber. LWT-Food Sci. Technol. 2017, 77, 186–192. [Google Scholar] [CrossRef]

- Wójtowicz, A. Wpływ dodatku fasoli na wybrane cechy ekstrudowanych makaronów podgotowanych. Acta Agrophys. 2009, 13, 533–542. [Google Scholar]

- Dziki, D.; Cacak-Pietrzak, G.; Gawlik-Dziki, U.; Sułek, A.; Kocira, S.; Biernacka, B. Effect of Moldavian dragonhead (Dracocephalum moldavica L.) leaves on the baking properties of wheat flour and quality of bread. Cyta-J. Food 2019, 17, 536–543. [Google Scholar] [CrossRef]

- Wójtowicz, A. Wpływ dodatku kwasu askorbinowego na teksturę ekstrudowanych makaronów podgotowanych. Acta Agrophys. 2008, 12, 245–254. [Google Scholar]

- Qamar, S.; Shaikh, A. Therapeutic potentials and compositional changes of valuable compounds from banana-A review. Trends Food Sci. Technol. 2018, 79, 1–9. [Google Scholar] [CrossRef]

- Aurore, G.; Parfait, B.; Fahrasmane, L. Bananas raw materials for making processed food products. Trends Food Sci. Technol. 2009, 20, 78–91. [Google Scholar] [CrossRef]

- Cassettari, V.M.G.; Machado, N.C.; Lourenção, P.L.T.A.; Carvalho, M.A.; Ortolan, E.V.P. Combinations of laxatives and green banana biomass on the treatment of functional constipation in children and adolescents: A randomized study. J. Pediatr. (Rio J.) 2019, 95, 27–33. [Google Scholar] [CrossRef] [PubMed]

- Kanazawa, K.; Sakakibara, H. High content of dopamine. A strong antioxidant. in cavendish banana. J. Agric. Food Chem. 2000, 48, 844–848. [Google Scholar] [CrossRef] [PubMed]

- Rayo, L.M.; Chaguri e Carvalho, L.; Sarda, F.A.; Dacanal, G.C.; Menezes, E.W.; Tadini, C.C. Production of instant green banana flour (Musa cavendischii. var. Nanicao) by a pulsed-fluidized bed agglomeration. LWT-Food Sci. Technol. 2015, 63, 461–469. [Google Scholar] [CrossRef]

- Ovando-Martinez, M.; Sáyago-Ayerdi, S.; Agama-Acevedo, E.; Goñi, I.; Bello-Pérez, L.A. Unripe banana flour as an ingredient to increase the undigestible carbohydrates of pasta. Food Chem. 2009, 113, 121–126. [Google Scholar] [CrossRef]

- Amini Khoozani, A.; Birch, J.; Bekhit, A.E.A. Production, application and health effects of banana pulp and peel flour in the food industry. J. Food Sci. Technol. 2019, 56, 548–559. [Google Scholar] [CrossRef]

- Cunniff, P. (Ed.) Official Methods of Analysis, 16th ed.; AOAC: Gaithersburg, MD, USA, 1997; Volume 1, 1141p. [Google Scholar]

- Dziki, D.; Polak, R.; Rudy, S.; Krzykowski, A.; Gawlik-Dziki, U.; Różyło, R.; Miś, A.; Combrzyński, M. Simulation of the process kinetics and analysis of physicochemical properties in the freeze drying of kale. Int. Agrophys. 2018, 32, 49–56. [Google Scholar] [CrossRef]

- Rudy, S.; Dziki, D.; Krzykowski, A.; Gawlik-Dziki, U.; Polak, R.; Różyło, R.; Kulig, R. Influence of pre-treatments and freeze-drying temperature on the process kinetics and selected physico-chemical properties of cranberries (Vaccinium macrocarpon Ait.). LWT-Food Sci. Technol. 2015, 63, 497–503. [Google Scholar] [CrossRef]

- Miceli, A.; Francescan, N.; Moschetti, G.; Settanni, L. The influence of addition of Borago officinalis with antibacterial activity on the sensory quality of fresh pasta. Int. J. Gastron. Food Sci. 2015, 2, 93–97. [Google Scholar] [CrossRef][Green Version]

- Elkhalifa, A.E.O.; Bernhardt, R. Influence of grain germination on functional properties of sorghum flour. Food Chem. 2010, 121, 387–392. [Google Scholar] [CrossRef]

- Wójtowicz, A.; Mościcki, L. Influence of legume type and addition level on quality characteristics, texture and microstructure of enriched precooked pasta. LWT-Food Sci. Technol. 2014, 59, 1175–1185. [Google Scholar] [CrossRef]

- Gawlik-Dziki, U.; Kaszuba, K.; Piwowarczyk, K.; Świeca, M.; Dziki, D.; Czyż, J. Onion skin-raw material for the production of supplement that enhances the health-beneficial properties of wheat bread. Food Res. Int. 2015, 73, 97–106. [Google Scholar] [CrossRef]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant activity applying an improved ABTS radical cation decolourization assay. Free Radic. Bio. Med. 1999, 26, 1231–1237. [Google Scholar] [CrossRef]

- Bonomi, F.; D’Egidio, M.G.; Iametti, S.; Marengo, M.; Marti, A.; Pagani, M.A.; Ragg, E.M. Structure-quality relationship in commercial pasta: A molecular glimpse. Food Chem. 2012, 135, 348–355. [Google Scholar] [CrossRef] [PubMed]

- Rekha, M.N.; Chauhan, A.S.; Prabhasankar, P.; Ramteke, R.S.; Venkateswara Rao, G. Influence of vegetable purees on quality attributes of pastas made from bread wheat (T. aestivum). Cyta-J. Food 2013, 11, 142–149. [Google Scholar] [CrossRef]

- Švec, I.; Hrušková, M.; Vítová, M.; Sekerová, H. Colour evaluation of different pasta samples. Czech J. Food Sci. 2008, 26, 421–427. [Google Scholar] [CrossRef]

- Valdivia-López, M.Á.; Tecante, A. Chia (Salvia hispanica): A review of native mexican seed and its nutritional and functional properties. Adv. Food Nutr. Res. 2015, 75, 53–75. [Google Scholar]

- Lisiecka, K.; Wójtowicz, A.; Dziki, D.; Gawlik-Dziki, U. The influence of Cistus incanus L. Leaves on wheat pasta quality. J. Food Sci. Technol. 2019, 10, 1–12. [Google Scholar] [CrossRef]

- Bouasla, A.; Wójtowicz, A.; Zidoune, M.N.; Olech, M.; Nowak, R.; Mitrus, M.; Oniszczuk, A. Gluten-free precooked rice-yellow pea pasta: Effect of extrusion-cooking conditions on phenolic acids composition, selected properties and microstructure. J. Food Sci. 2016, 81, 1070–1079. [Google Scholar] [CrossRef] [PubMed]

- Dziki, D.; Laskowski, J. Evaluation of the cooking quality of spaghetti. Pol. J. Food Nutr. Sci. 2005, 14, 153–158. [Google Scholar]

- Hirawan, R.; Ser, W.Y.; Arntfield, S.D.; Beta, T. Antioxidant properties of commercial, regular-and whole-wheat spaghetti. Food Chem. 2010, 119, 258–264. [Google Scholar] [CrossRef]

- Sobota, A.; Zarzycki, P. Effect of pasta cooking time on the content and fractional composition of dietary fiber. J. Food Qual. 2013, 36, 127–132. [Google Scholar] [CrossRef]

- Wang, J.; Li, Y.Z.; Chen, R.R.; Bao, J.Y.; Yang, G. Comparison of volatiles of banana powder dehydrated by vacuum belt drying, freeze-drying and air-drying. Food Chem. 2007, 104, 1516–1521. [Google Scholar] [CrossRef]

- Cheok, C.Y.; Sulaiman, R.; Manan, N.A.; Zakora, A.J.; Chin, N.L.; Hussain, N. Pasting and physical properties of green banana flours and pastas. Int. Food Res. J. 2018, 25, 2587–2594. [Google Scholar]

| Ingredients and Pasta-Making Conditions | CP | PB1 | PB2 | PB3 | PB4 | PB5 |

|---|---|---|---|---|---|---|

| Wheat flour (g) | 500 | 495 | 490 | 485 | 480 | 475 |

| Banana powder (g) | 0 | 5 | 10 | 15 | 20 | 25 |

| Water | Up to the dough moisture content 45% (wb) | |||||

| Dough mixing time/speed | 5 min/150 rpm | |||||

| Dough drying conditions | 25 °C, RH 20%, 24 h | |||||

| Sample | Raw/Cooked | Parameter | |||

|---|---|---|---|---|---|

| L* | a* | b* | TDC | ||

| CP | Raw | 68.92 ± 0.81 a,b | 2.13 ± 0.15 a | 10.55 ± 0.45 a | - |

| PB1 | 72.34 ± 0.44 b | 2.45 ± 0.03 b | 12.30 ± 0.59 b | 3.86 ± 0.25 a,b | |

| PB2 | 72.12 ± 1.71 b | 2.37 ± 0.11 a,b | 12.00 ± 0.39 b | 3.53 ± 0.48 a | |

| PB3 | 64.32 ± 3.60 a | 2.60 ± 0.08 b | 10.09 ± 0.34 a | 4.64 ± 0.52 b | |

| PB4 | 69.67 ± 3.06 a,b | 2.38 ± 0.07 a,b | 10.55 ± 0.41 a | 4.79 ± 0.43 b | |

| PB5 | 73.09 ± 0.76 b | 2.50 ± 0.15 b | 11.27 ± 0.70 a,b | 4.25 ± 0.37 b | |

| CP | Cooked | 71.97 ± 0.55 c | 0.78 ± 0.06 a | 12.18 ± 0.27 b | - |

| PB1 | 72.48 ± 1.53 c | 0.92 ± 0.14 a,b | 10.84 ± 0.53 a,b | 1.44 ± 0.57 a | |

| PB2 | 70.32 ± 0.50 b,c | 0.90 ± 0.02 a,b | 9.54 ± 1.13 a | 3.12 ± 0.31 b | |

| PB3 | 69.77 ± 1.64 b,c | 1.56 ± 0.25 c | 10.16 ± 0.90 a | 3.09 ± 0.55 b | |

| PB4 | 67.98 ± 0.85 b | 1.32 ± 0.12 b,c | 9.38 ± 0.89 a | 4.91 ± 0.46 c | |

| PB5 | 62.82 ± 1.50 a | 1.71 ± 0.17 c | 9.10 ± 0.16 a | 9.70 ± 0.64 d | |

| Parameter/Sample | CP | PB1 | PB2 | PB3 | PB4 | PB5 |

|---|---|---|---|---|---|---|

| WAI (g/g) | 7.27 ± 0.19 a | 7.35 ± 0.02 a | 7.32 ± 0.03 a | 7.35 ± 0.01 a | 7.43 ± 0.06 a | 7.34 ± 0.01 a |

| WSI (%) | 43.94 ± 0.13 b | 40.62 ± 0.04 a | 41.53 ± 1.01 a | 41.54 ± 0.98 a | 41.06 ± 0.35 a | 42.13 ± 0.54 b |

| Sample | Total Phenolics Content and Antioxidant Activity | Water Extract (WE) | Buffered Extract (BE) | ||

|---|---|---|---|---|---|

| Raw | Cooked | Raw | Cooked | ||

| CP | Total phenolics content (mg GEA/g d.m.) | 9.2 ± 0.43 B,a | 7.1 ± 0.27 A,a,b | 15.4 ± 0.67 D,a | 12.0 ± 0.15 C,a |

| PB1 | 9.6 ± 0.45 B,a | 7.5 ± 0.19 A,a,b | 16.6 ± 0.58 D,a | 13.3 ± 0.32 C,b | |

| PB2 | 9.9 ± 0.51 B,b | 7.9 ± 0.31 A,b | 19.5 ± 0.75 D,b | 16.5 ± 0.20 C,c | |

| PB3 | 10.1 ± 0.64 B,b | 8.5 ± 0.19 A,c | 24.3 ± 0.94 D,c | 19.6 ± 0.57 C,d | |

| PB4 | 11.3 ± 0.72 B,c | 9.6 ± 0.17 A,d | 26.6 ± 1.20D,d | 21.7 ± 0.63 C,e | |

| PB5 | 13.4 ± 0.85 B,d | 10.4 ± 0.24 A,e | 30.3 ± 2.30 D,e | 25.9 ± 0.79 C,f | |

| CP | Radical scavenging activity ABTS EC50 (mg d.m./mL) | 41.3 ± 2.16 B,d | 46.8 ± 2.21 C,e | 37.7 ± 1.15 A,d | 42.3 ± 2.21 B,e |

| PB1 | 40.2 ± 1.95 B,c,d | 45.6 ± 1.56 C,e | 36.8 ± 1.63 A,d | 41.5 ± 1.05 B,d,e | |

| PB2 | 38.9 ± 1.52 B,c | 42.1 ± 0.89 C,d | 35.7 ± 0.94 A,c,d | 40.4 ± 0.52 B,C,d | |

| PB3 | 36.5 ± 1.63 A,b | 40.0 ± 0.73 B,c | 34.3 ± 1.15 A,a,b,c | 39.3 ± 0.27 B,c | |

| PB4 | 34.9 ± 1.27 A,a,b | 37.6 ± 1.02 B,b | 33.9 ± 0.98 A,a,b | 38.7 ± 0.66 B,b | |

| PB5 | 33.0 ± 1.41 A,a | 37.2 ± 0.86 B,a | 32.7 ± 0.86 A,a | 36.1 ± 0.42 B,a | |

| CP | Antiradical activity, DPPH EC50 (mg d.m./mL) | 332.4 ± 15.2 A,e | 353.4 ± 13.4 B,e | 436.0 ± 18.3 C,e | 458.0 ± 14.8 D,f |

| PB1 | 278.0 ± 13.2 A,d | 342.7 ± 12.5 C,d,e | 328.0 ± 15.1 B,d | 412.6 ± 10.3 D,e | |

| PB2 | 259.2 ± 10.6 B,c,d | 331.2 ± 10.7 D,d | 213.0 ± 12.7 A,c | 325.3 ± 7.2 D,d | |

| PB3 | 237.6 ± 10.8 B,c | 310.6 ± 5.6 C,c | 178.0 ± 11.3 A,b | 312.7 ± 8.2 C,c | |

| PB4 | 175.2 ± 11.3 A,b | 256.6 ± 7.2 B,b | 166.0 ± 12.2 A,a,b | 265.2 ± 4.6 B,b | |

| PB5 | 150.8 ± 8.7 A,a | 223.3 ± 8.0 B,a | 152.0 ± 10.7 A,a | 212.8 ± 9.4 B,a | |

| Parameter/Sample | CP | PB1 | PB2 | PB3 | PB4 | PB5 |

|---|---|---|---|---|---|---|

| OCT (min) | 6.5 ± 0.2 b | 6.5 ± 0.3 b | 5.5 ± 0.4 a,b | 5.5 ± 0.5 a,b | 4.5 ± 0.5 a | 4.5 ± 0.5 a |

| WI (kg CP/kg RP) | 2.88 ± 0.007 a | 3.08 ± 0.002 b | 3.42 ± 0.002 c | 3.49 ± 0.001 d | 3.97 ± 0.001 f | 3.55 ± 0.001 e |

| CL (%) | 5.2 ± 0.07 a | 5.4 ± 0.18 a,b | 5.5 ± 0.11 b,c | 5.7 ± 0.13 c | 6.1 ± 0.10 d | 6.4 ± 0.14 e |

| Sensory Attribute | Smell | Taste | Colour | Appearance | Texture |

|---|---|---|---|---|---|

| BP | 6.70 ± 0.09 | 6.41 ± 0.11 | 6.22 ± 0.02 | 6.50 ± 0.13 | 6.38 ± 0.10 |

| Sample | Smell | Taste | Colour | Firmness | Adhesiveness | Overall Acceptability |

|---|---|---|---|---|---|---|

| CP | 6.01 ± 0.10 d | 6.30 ± 0.10 d | 6.82 ± 0.03 d | 6.31 ± 0.12 bc | 6.48 ± 0.12 cd | 6.52 ± 0.14 e |

| PB1 | 5.91 ± 0.12 d | 5.94 ± 0.07 c | 6.56 ± 0.15 d | 6.41 ± 0.10 c | 6.59 ± 0.10 d | 6.12 ± 0.16 d |

| PB2 | 6.19 ± 0.10 d | 6.04 ± 0.15 cd | 5.68 ± 0.16 c | 6.15 ± 0.05 b | 6.33 ± 0.06 c | 5.93 ± 0.21 cd |

| PB3 | 6.22 ± 0.07 d | 6.22 ± 0.16 cd | 5.52 ± 0.16 c | 6.41 ± 0.10 c | 6.41 ± 0.10 cd | 5.82 ± 0.26 c |

| PB4 | 5.16 ± 0.05 b | 5.49 ± 0.10 b | 4.19 ± 0.12 b | 5.71 ± 0.10 a | 6.12 ± 0.03 b | 5.12 ± 0.14 b |

| PB5 | 4.80 ± 0.10 a | 4.57 ± 0.06 a | 3.16 ± 0.12 a | 5.52 ± 0.07 a | 5.67 ± 0.06 a | 4.38 ± 0.12 a |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Biernacka, B.; Dziki, D.; Różyło, R.; Gawlik-Dziki, U. Banana Powder as an Additive to Common Wheat Pasta. Foods 2020, 9, 53. https://doi.org/10.3390/foods9010053

Biernacka B, Dziki D, Różyło R, Gawlik-Dziki U. Banana Powder as an Additive to Common Wheat Pasta. Foods. 2020; 9(1):53. https://doi.org/10.3390/foods9010053

Chicago/Turabian StyleBiernacka, Beata, Dariusz Dziki, Renata Różyło, and Urszula Gawlik-Dziki. 2020. "Banana Powder as an Additive to Common Wheat Pasta" Foods 9, no. 1: 53. https://doi.org/10.3390/foods9010053

APA StyleBiernacka, B., Dziki, D., Różyło, R., & Gawlik-Dziki, U. (2020). Banana Powder as an Additive to Common Wheat Pasta. Foods, 9(1), 53. https://doi.org/10.3390/foods9010053