Procedures for Breadmaking Quality Assessment of Rye Wholemeal Flour

Abstract

:1. Introduction

2. Material and Methods

2.1. Material

2.2. Methods

2.2.1. Tests of Flour Quality

2.2.2. Swelling Curve (SC)

2.2.3. Baking Test

2.2.4. Bread Characteristics

2.2.5. Statistical Analysis

3. Results and Discussion

3.1. Flour Properties

3.2. The Swelling Curve Parameters

3.3. Bread Characteristics

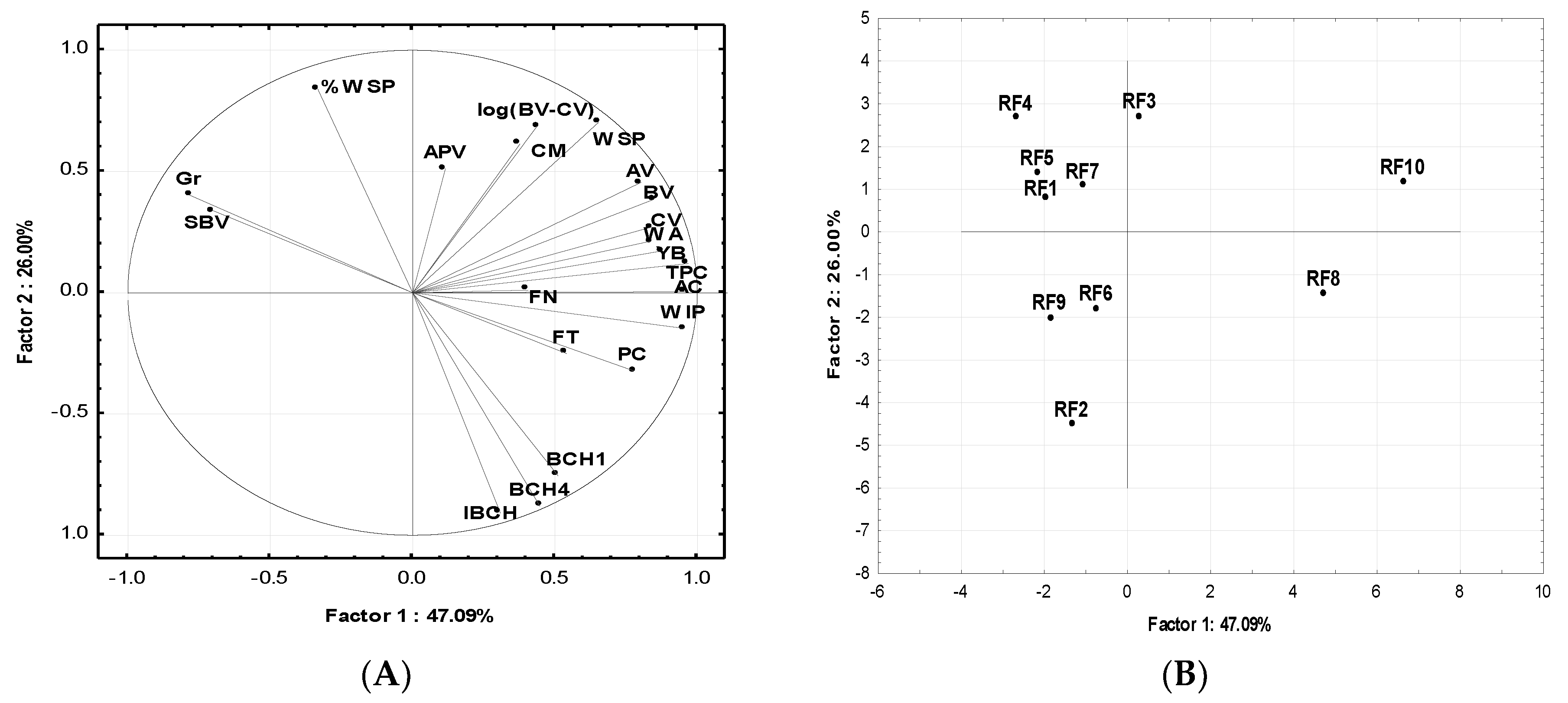

3.4. Principal Component Analysis (PCA)

4. Conclusions

- The tested industrial wholemeal rye flours were significantly different in terms of all parameters that characterize their baking value. Many significant relationships were found between flour and bread properties.

- The study revealed that for commercial rye flours, the falling number and the amylograph properties are not sufficient parameters for predicting the quality of wholemeal rye bread. To produce wholemeal rye bread with high volume, low crumb hardness, and a small increase in hardness during storage, it is recommend to use rye flour with fine granulation, low protein content, low total and water-insoluble pentosans content, and a high percentage of water-soluble pentosans content.

- Bread with a higher volume was generally obtained from rye flour characterized by lower protein content, lower total pentosans content and water-insoluble pentosans content, and a higher percentage of water-soluble pentosans content. Further, flour granulation and the percentage of water-soluble pentosans content had a significant impact on bread crumb hardness, and its increase during storage of bread. Generally, breads with lower crumb hardness were obtained from flours with finer granulation and with a higher percentage of water-soluble pentosans content. Moreover, a positive correlation was found between crumb moisture and water-soluble pentosans content.

Author Contributions

Funding

Conflicts of Interest

References

- Poutanen, K.; Katina, K.; Heiniö, R.; Rye, L. Bakery Products Science and Technology; Simpson, B.K., Ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2014; pp. 75–87. [Google Scholar]

- Gräber, S. The influence of enzyme treatment on the rheology of rye dough. Food Nahrung. 1999, 43, 249–252. [Google Scholar] [CrossRef]

- Arendt, E.K.; Ryan, L.A.M.; Dal Bello, F. Impact of sourdough on the texture of bread. Food Microbiol. 2007, 24, 165–174. [Google Scholar] [CrossRef]

- Beck, M.; Jeakle, M.; Selmair, P.L.; Koehler, P.; Becker, T. Rheological properties and baking performance of rye dough as affected by transglutaminase. J. Cereal Sci. 2011, 54, 29–36. [Google Scholar] [CrossRef]

- Fabritius, M.; Gates, F.; Salovaara, H.; Autio, K. Structural changes in insoluble cell walls in wholemeal rye doughs. Lebensm. Wiss. Technol. 1997, 30, 367–372. [Google Scholar] [CrossRef]

- Hemalatha, M.S.; Manohar, R.S.; Salimath, P.V.; Rao, U.J.S. Effect of addes arabinoxylans isolated from good and poor chapatti making wheat varieties on rheological properties of dough and chapatti making quality. Food Nut. Sci. 2013, 4, 884–892. [Google Scholar]

- Vinkx, C.J.A.; Delcour, J.A. Rye (Secale cereal L.) arabinoxylans: A critical review. J. Cereal Sci. 1996, 24, 1–14. [Google Scholar] [CrossRef]

- Bucsella, B.; Molnár, D.; Harasztos, A.H.; Tömösközi, S. Comparison of the rheological and end-product properties of an industrial aleurone-rich wheat flour, whole grain wheat and rye flour. J. Cereal Sci. 2016, 69, 40–48. [Google Scholar] [CrossRef]

- Döring, C.; Nuber, C.H.; Stukenborg, F.; Jeakle, M.; Becker, T. Impact of arabinoxylans addition on protein microstructure formation in wheat and rye dough. J. Food Eng. 2015, 54, 10–16. [Google Scholar] [CrossRef]

- Buksa, K.; Ziobro, R.; Nowotna, A.; Gambuś, H. The influence of native and modified arabinoxylan preparation on baking properties of rye flour. J. Cereal Sci. 2013, 58, 23–30. [Google Scholar] [CrossRef]

- Finnie, S.M.; Bettge, A.D.; Morris, C.F. Influence of cultivar and environment on water-soluble and water-insoluble arabinoxylans in soft wheat. Cereal Chem. 2006, 83, 617–623. [Google Scholar] [CrossRef]

- Buksa, K.; Nowotna, A.; Praznik, W.; Gambuś, H.; Ziobro, R.; Krawontka, J. The role of pentosans and starch in baking of wholemeal rye bread. Food Res. Int. 2010, 43, 2045–2051. [Google Scholar] [CrossRef]

- Denli, E.; Ercan, R. Effect of added pentosans isolated from wheat and rye grain on same properties of bread. Eur. Food Res. Technol. 2001, 212, 374–376. [Google Scholar] [CrossRef]

- Cyran, M.; Cygankiewicz, A. Variability in the content of water-extractable and water-unextractable non-starch polysaccharides in rye flour and their relationship to baking quality parameters. Cereal Res. Commun. 2004, 32, 143–150. [Google Scholar]

- Weipert, D. Processing performance of rye as compared to wheat. Cereal Food World. 1997, 42, 706–771. [Google Scholar]

- Stępniewska, S.; Słowik, E.; Cacak-Pietrzak, G.; Romankiewicz, D.; Szafrańska, A.; Dziki, D. Prediction of rye flour baking quality based on parameters of swelling curve. Eur. Food Res. Technol. 2018, 244, 989–997. [Google Scholar] [CrossRef]

- Banu, I. Baking quality of rye flour. Bull. USAMV-CN 2007, 63, 488–492. [Google Scholar]

- Salmenkallio-Marttila, M.; Hovinen, S. Enzyme activities, dietary fibre components and rheological properties of wholemeal flours from rye cultivars grown in Finland. J. Sci. Food Agric. 2005, 85, 1350–1356. [Google Scholar] [CrossRef]

- ISO 20483:2013. Cereals and Pulses Determination of the Nitrogen Content and Calculation of the Crude Protein Content Kjeldahl Method; ISO: Geneva, Switzerland, 2013. [Google Scholar]

- ISO 2171:2007. Cereals, Pulses and By-Products Determination of Ash Yield by Incineration; ISO: Geneva, Switzerland, 2007. [Google Scholar]

- ISO 3093:2009. Wheat, Rye and Their Flours, Durum Wheat and Durum Wheat Semolina Determination of the Falling Number According to Hagberg-Perten; ISO: Geneva, Switzerland, 2009. [Google Scholar]

- ISO 7973:1992. Cereals and Milled Cereal Products Determination of the Viscosity of Flour Method Using an Amylograph; ISO: Geneva, Switzerland, 1992. [Google Scholar]

- Hashimoto, S.; Shogren, M.D.; Pomeranz, Y. Cereal pentosans: Their estimation and significance. I. Pentosans in wheat and milled wheat products. Cereal Chem. 1987, 64, 30–34. [Google Scholar]

- Hansen, H.B.; Møller, B.; Andersen, S.B.; Jørgensen, J.R.; Hansen, Å. Grain characteristics, chemical composition, and functional properties of rye (Secale cereale L.) as influenced by genotype and harvest year. J. Agric. Food Chem. 2004, 52, 2282–2291. [Google Scholar] [CrossRef]

- Drews, E. Quellkurven von Roggenmahlprodukten. Die Muehle. 1971, 108, 723–724. [Google Scholar]

- Słowik, E.; Mielcarz, M.; Kot, M. The impact on rye flour particle size on the quality of rye bread. Przegl. Zboż Młyn. 2010, 1, 10–13. (In Polish) [Google Scholar]

- Sapirstein, H.; Wu, Y.; Koksel, F.; Graf, R.J. A study of factors influencing the water absorption capacity of Canadian hard red winter wheat flour. J. Cereal Sci. 2018, 81, 52–59. [Google Scholar] [CrossRef]

- Michalska, A.; Ceglińska, A.; Zieliński, H. Bioactive compounds in rye flours with different extraction rates. Eur. Food Res. Technol. 2007, 225, 545–551. [Google Scholar] [CrossRef]

- Verwimp, T.; Courtin, C.M.; Delcour, J.A. Rye constituents and their impact on rye processing. In Food Biochemistry and Food Processing; Simpson, B.K., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2012; pp. 654–672. [Google Scholar]

- Banu, I.; Vasilean, I.; Constantin, O.E.; Aprodu, I. Prediction of rye dough behavior and bread quality using response surface methodology. Irish J. Agric. Food Res. 2011, 50, 239–247. [Google Scholar]

- Buksa, K.; Nowotna, A.; Ziobro, R.; Praznik, W. Molecular properties of arabinoxylan fractions isolated from rye grain of different quality. J. Cereal Sci. 2014, 60, 368–373. [Google Scholar] [CrossRef]

- Buksa, K.; Praznik, W.; Loeppert, R.; Nowotna, A. Characterization of water and alkali extractable arabinoxylans from wheats and rye under standardized condition. J. Food Sci. Technol. 2016, 53, 1389–1398. [Google Scholar] [CrossRef]

- Cyran, M.R.; Dynkowska, W.M. Mode of endosperm and wholemeal arabinoxylans solubilisation during rye breadmaking: Genotypic diversity in level, substitution degree and macromolecular characteristics. Food Chem. 2014, 145, 356–364. [Google Scholar] [CrossRef]

- Dornez, E.; Gebruers, K.; Delcour, J.A.; Courtin, C.M. Grain-associated xynalases: Occurrence, variability, and implication for cereal processing. Trends Food Sci. Technol. 2009, 20, 495–510. [Google Scholar] [CrossRef]

| Rye Flour | PC (Nx6.25) (% d.m.) | AC (% d.m.) | Gr (%) | WA (%) | FN (s) | APV (BU) | FT (°C) |

|---|---|---|---|---|---|---|---|

| RF1 | 10.4 b,* ± 0.01 | 1.51 b ± 0.03 | 29.4 d ± 0.5 | 54.0 a ± 0.4 | 201 c ± 7 | 290 ab ± 14 | 71.0 cd ± 0.4 |

| RF2 | 11.7 f ± 0.04 | 1.60 c ± 0.01 | 30.2 de ± 0.2 | 58.9 c ± 0.3 | 260 f ± 6 | 290 ab ± 7 | 74.5 f ± 0.0 |

| RF3 | 10.6 bc ± 0.02 | 1.84 e ± 0.01 | 34.2 e ± 0.7 | 63.6 e ± 0.1 | 278 g ± 8 | 480 c ± 7 | 76.0 g ± 0.4 |

| RF4 | 9.2 a ± 0.01 | 1.43 a ± 0.01 | 39.0 g ± 0.4 | 59.2 c ± 0.3 | 222 d ± 6 | 450 c ± 20 | 70.0 bc ± 0.4 |

| RF5 | 10.6 bc ± 0.01 | 1.72 d ± 0.01 | 32.7 ef ± 0.7 | 60.4 d ± 0.1 | 180 b ± 4 | 290 ab ± 3 | 68.0 a ± 0.0 |

| RF6 | 11.3 def ± 0.02 | 1.59 c ± 0.01 | 23.5 c ± 0.4 | 58.6 c ± 0.1 | 160 a ± 8 | 250 a ± 7 | 68.5 ab ± 0.4 |

| RF7 | 11.0 cd ± 0.03 | 1.74 d ± 0.01 | 33.7 e ± 0.5 | 58.8 c ± 0.3 | 244 e ± 4 | 340 b ± 18 | 72.5 de ± 0.7 |

| RF8 | 11.4 ef ± 0.02 | 2.34 f ± 0.02 | 13.6 a ± 0.1 | 65.3 f ± 0.4 | 254 ef ± 7 | 430 c ± 14 | 83.0 h ± 0.4 |

| RF9 | 11.2 de ± 0.01 | 1.74 d ± 0.01 | 19.7 b ± 0.3 | 55.8 b ± 0.1 | 228 d ± 3 | 260 a ± 7 | 73.5 ef ± 0.7 |

| RF10 | 14.0 g ± 0.05 | 2.42 f ± 0.03 | 12.5 a ± 0.4 | 66.6 g ± 0.2 | 247 ef ± 8 | 280 a ± 11 | 72.0 de ± 0.4 |

| Rye Flour | TPC (% d.m.) | WSP (% d.m.) | WIP (% d.m.) | %WSP | AV (BU) | BV (BU) | CV (BU) | Log (BV − CV) |

|---|---|---|---|---|---|---|---|---|

| RF1 | 9.1 b ± 0.12 | 3.2 bc ± 0.08 | 5.4 a ± 0.02 | 35 cd ± 1 | 290 c ± 3 | 290 cd ± 7 | 280 d ± 7 | 15 b ± 1 |

| RF2 | 9.5 cd ± 0.11 | 2.4 a ± 0.09 | 7.0 e ± 0.20 | 25 a ± 1 | 100 a ± 11 | 110 a ± 7 | 145 a ± 7 | 120 a ± 7 |

| RF3 | 10.2 f ± 0.02 | 3.6 cd ± 0.16 | 6.5 cde ± 0.14 | 35 cd ± 2 | 335 d ± 7 | 325 e ± 7 | 255 d ± 7 | 105 d ± 3 |

| RF4 | 9.4 bcd ± 0.11 | 3.2 bc ± 0.13 | 6.1 bc ± 0.24 | 34 cd ± 2 | 280 c ± 3 | 280 bc ± 3 | 250 cd ± 3 | 50 c ± 1 |

| RF5 | 9.1 b ± 0.06 | 3.2 bc ± 0.11 | 5.9 abc ± 0.17 | 35 cd ± 1 | 290 c ± 14 | 270 bc ± 14 | 200 b ± 14 | 131 e ± 8 |

| RF6 | 9.6 de ± 0.06 | 2.8 ab ± 0.05 | 6.8 de ± 0.01 | 29 ab ± 1 | 300 c ± 7 | 315 de ± 7 | 275 d ± 7 | 59 c ± 1 |

| RF7 | 9.9 ef ± 0.11 | 3.7 d ± 0.10 | 6.2 bcd ± 0.21 | 37 d ± 2 | 270 c ± 7 | 260 bc ± 11 | 200 b ± 11 | 115 de ± 5 |

| RF8 | 12.2 g ± 0.13 | 3.5 cd ± 0.11 | 9.7 f ± 0.24 | 29 ab ± 1 | 360 d ± 3 | 400 f ± 7 | 350 e ± 7 | 58 c ± 1 |

| RF9 | 8.3 a ± 0.06 | 2.6 a ± 0.10 | 5.6 ab ± 0.09 | 31 bc ± 1 | 230 b ± 7 | 250 b ± 7 | 220 bc ± 7 | 56 c ± 2 |

| RF10 | 13.4 h ± 0.02 | 3.9 d ± 0.06 | 9.2 f ± 0.05 | 29 ab ± 1 | 670 e ± 14 | 635 g ± 7 | 410 f ± 7 | 190 f ± 3 |

| Parame-Ter | AC | Gr | FN | APV | FT | WA | TPC | WSP | WIP | %WSP | AV | BV | CV | BV − CV |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PC | 0.731 ** | −0.770 ** | N | N | N | N | 0.704 * | N | 0.768 ** | N | 0.633 * | N | N | N |

| AC | −0.790 ** | N | N | N | 0.827 ** | 0.893 ** | N | 0.864 ** | N | 0.740 * | 0.786 ** | 0.741 * | N | |

| Gr | N | N | N | N | −0.638 * | N | −0.720 * | N | N | −0.639 * | −0.697 * | N | ||

| FN | N | 0.721 * | N | N | N | N | N | N | N | N | N | |||

| APV | N | N | N | N | N | N | N | N | N | N | ||||

| FT | N | N | N | N | N | N | N | N | N | |||||

| WA | 0.868 ** | 0.639 * | 0.819 ** | N | 0.673 * | 0.685 * | N | N | ||||||

| TPC | 0.670 * | 0.959 ** | N | 0.817 ** | 0.842 ** | 0.811 ** | N | |||||||

| WSP | N | N | 0.752 * | 0.723 * | 0.818 ** | 0.769 ** | ||||||||

| WIP | N | 0.705 * | 0.747 * | 0.749 * | N | |||||||||

| %WSP | N | N | N | N | ||||||||||

| AV | 0.989 ** | 0.889 ** | 0.778 ** | |||||||||||

| BV | 0.939 ** | 0.741 * | ||||||||||||

| CV | N |

| Rye Flour | SBV (cm3/100 g) | YB (%) | BCH1 (N) | BCH4 (N) | IBCH (N) | CM (%) |

|---|---|---|---|---|---|---|

| RF1 | 172 c ± 1 | 145 abc ± 1 | 60.8 c ± 0.4 | 89.8 d ± 0.1 | 29.0 d ± 0.3 | 50.4 cde ± 0.2 |

| RF2 | 148 a ± 3 | 140 a ± 3 | 90.2 f ± 0.1 | 153.3 i ± 0.7 | 63.1 h ± 0.6 | 48.5 cd ± 0.1 |

| RF3 | 179 cd ± 1 | 150 cd ± 1 | 54.9 b ± 0.6 | 77.5 b ± 0.8 | 22.6 c ± 0.3 | 51.4 e ± 0.1 |

| RF4 | 186 de ± 1 | 143 abc ± 1 | 45.4 a ± 0.3 | 59.6 a ± 0.7 | 14.2 a ± 0.4 | 50.2 cde ± 0.3 |

| RF5 | 190 e ± 3 | 142 ab ± 2 | 54.9 b ± 0.7 | 84.4 c ± 0.8 | 29.5 d ± 0,1 | 49.5 cde ± 0.1 |

| RF6 | 187 e ± 1 | 149 bcd ± 3 | 80.9 d ± 0.1 | 132.0 h ± 0.3 | 51.1 f ± 0.1 | 46.0 ab ± 0.2 |

| RF7 | 177 c ± 1 | 145 abc ± 1 | 82.4 de ± 0.8 | 102.0 e ± 1.4 | 19.6 b ± 0.6 | 47.9 abc ± 0.6 |

| RF8 | 156 b ± 1 | 156 d ± 3 | 103.5 g ± 0.4 | 156.5 i ± 0.7 | 53.0 g ± 0.3 | 49.8 cde ± 1.2 |

| RF9 | 191 e ± 3 | 143 abc ± 1 | 89.0 f ± 0.6 | 128.0 g ± 0.9 | 39.0 e ± 0.4 | 45.6 a ± 1.1 |

| RF10 | 146 a ± 2 | 154 d ± 1 | 83.4 e ± 0.6 | 121.2 f ± 1.3 | 37.8 e ± 0.7 | 51.0 de ± 0.7 |

| Parameters | SBV | YB | BCH1 | BCH4 | IBCH | CM |

|---|---|---|---|---|---|---|

| PC | −0.689 * | N | N | N | N | N |

| AC | N | 0.790 ** | N | N | N | N |

| Gr | N | −0.636 * | −0.751 * | −0.720 * | −0.639 * | N |

| FN | N | N | N | N | N | N |

| APV | N | N | N | N | N | N |

| FT | N | N | N | N | N | N |

| WA | N | 0.713 * | N | N | N | N |

| TPC | −0.716 * | 0.809 ** | N | N | N | N |

| WSP | N | N | N | N | N | 0.643 * |

| WIP | −0.788 ** | 0.758 * | N | N | N | N |

| %WSP | 0.641 * | N | −0.648 * | −0.810 ** | −0.892 ** | N |

| AV | N | 0.716 * | N | N | N | N |

| BV | N | 0.784 ** | N | N | N | N |

| CV | N | 0.850 ** | N | N | N | N |

| log(BV − CV) | N | N | N | N | N | N |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stępniewska, S.; Hassoon, W.H.; Szafrańska, A.; Cacak-Pietrzak, G.; Dziki, D. Procedures for Breadmaking Quality Assessment of Rye Wholemeal Flour. Foods 2019, 8, 331. https://doi.org/10.3390/foods8080331

Stępniewska S, Hassoon WH, Szafrańska A, Cacak-Pietrzak G, Dziki D. Procedures for Breadmaking Quality Assessment of Rye Wholemeal Flour. Foods. 2019; 8(8):331. https://doi.org/10.3390/foods8080331

Chicago/Turabian StyleStępniewska, Sylwia, Waleed H. Hassoon, Anna Szafrańska, Grażyna Cacak-Pietrzak, and Dariusz Dziki. 2019. "Procedures for Breadmaking Quality Assessment of Rye Wholemeal Flour" Foods 8, no. 8: 331. https://doi.org/10.3390/foods8080331

APA StyleStępniewska, S., Hassoon, W. H., Szafrańska, A., Cacak-Pietrzak, G., & Dziki, D. (2019). Procedures for Breadmaking Quality Assessment of Rye Wholemeal Flour. Foods, 8(8), 331. https://doi.org/10.3390/foods8080331