The Role of Non-Caloric Sweeteners in Sensory Characteristics of Pastry Products

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sensory Analysis

2.3. Satiation and Satiety Evaluation

2.4. Energy and Nutrients

2.5. Physical Analysis

2.6. Humidity

2.7. Microbiological Analysis

2.8. Statistical Analysis

3. Results

3.1. Sensory Analysis

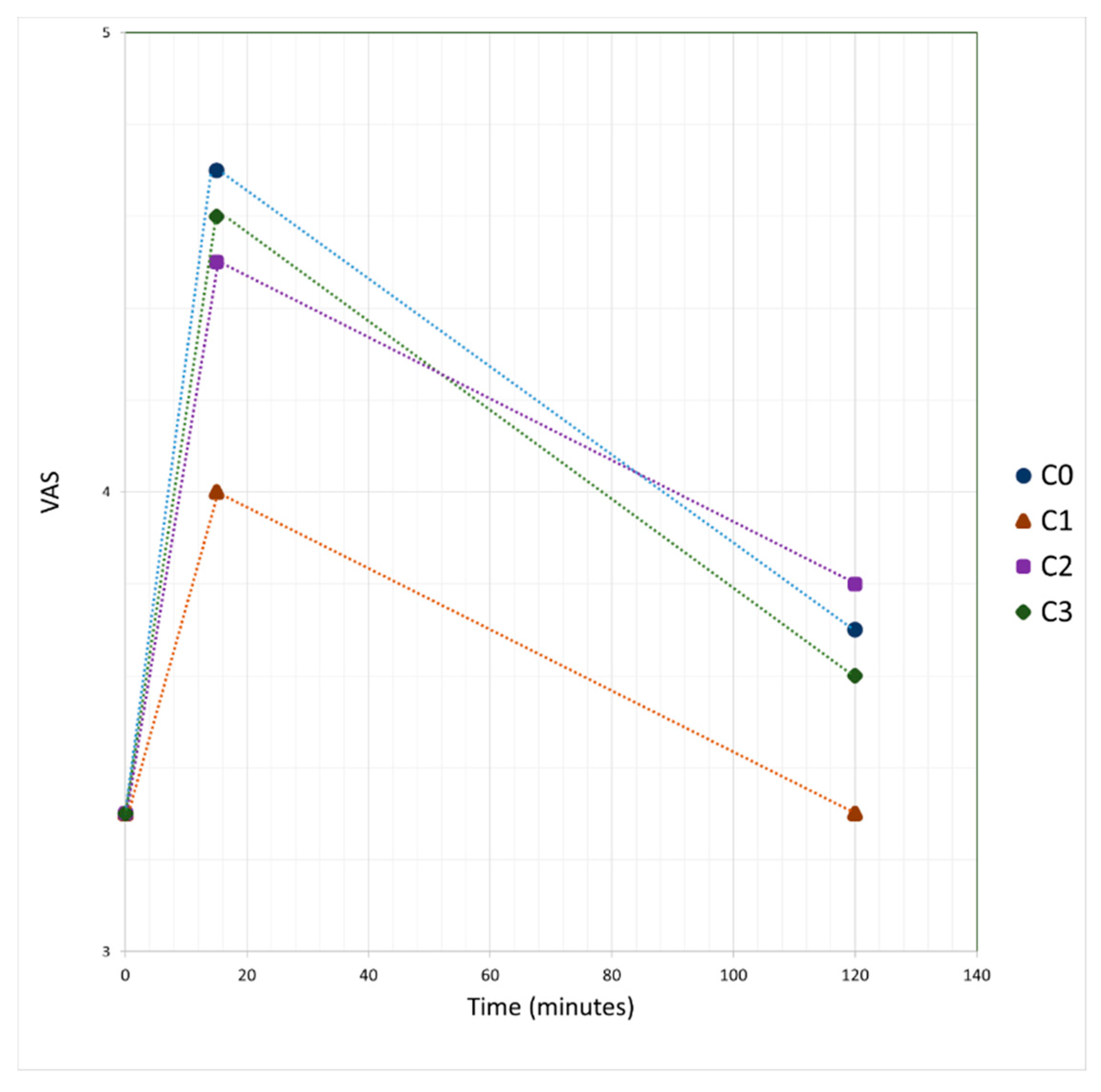

3.2. Satiation and Satiety Evaluation

3.3. Energy and Nutrients

3.4. Physical Analysis

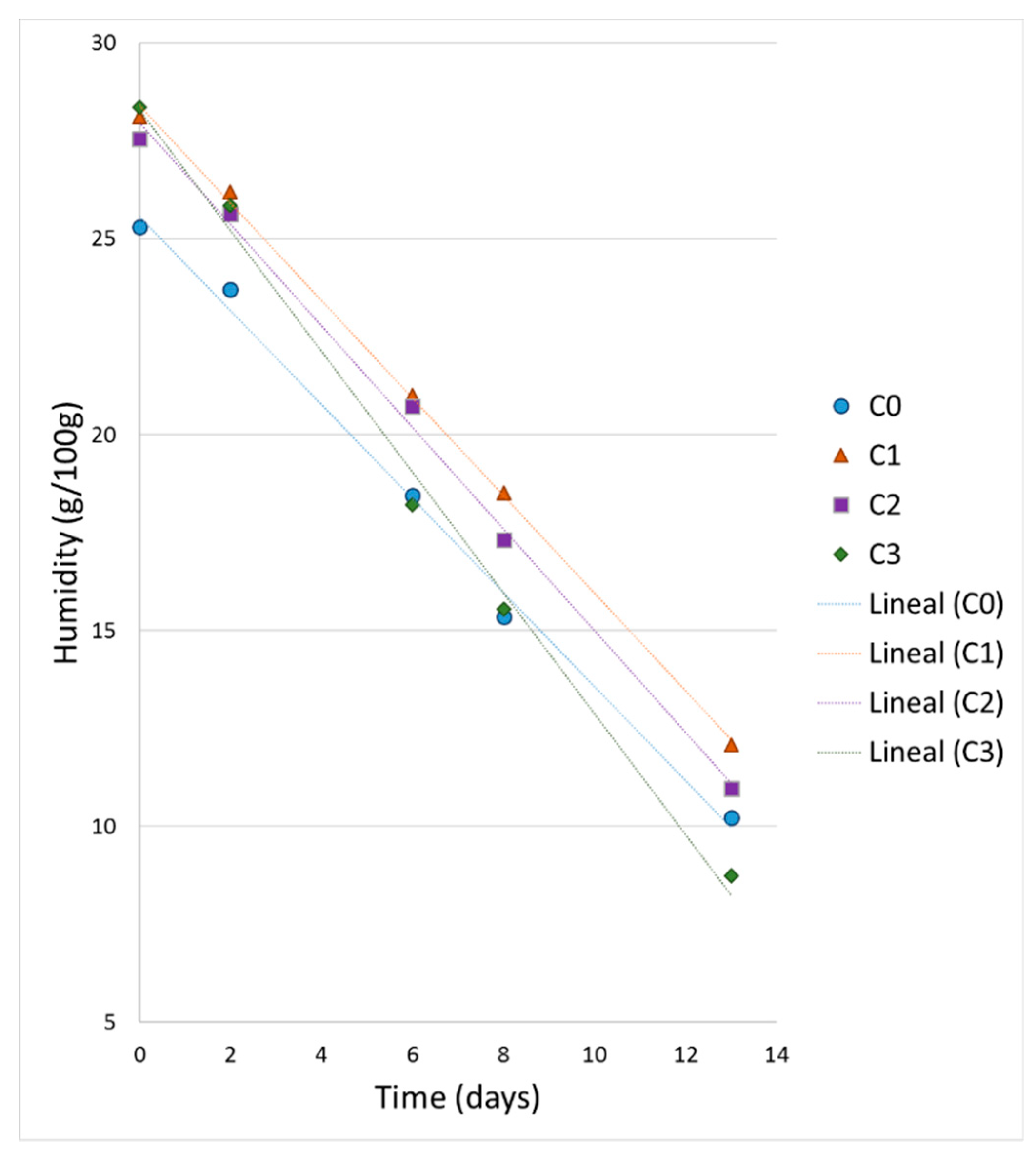

3.5. Humidity

3.6. Microbiological Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Shankar, P.; Ahuja, S.; Sriram, K. Non-nutritive sweeteners: Review and update. Nutrition 2013, 29, 1293–1299. [Google Scholar] [CrossRef] [PubMed]

- Di Monaco, R.; Miele, N.A.; Cabisidan, E.; Cavella, S. Strategies to reduce sugars in food. Curr. Opin. Food Sci. 2018, 19, 92–97. [Google Scholar] [CrossRef]

- Hesso, N.; Loisel, C.; Chevallier, S.; Le-Bail, A.; Queveau, D.; Pontoire, B.; Le-Bail, P. Monitoring cake baking by studying different ingredient interactions: From a model system to a real system. Food Hydrocoll. 2015, 51, 7–15. [Google Scholar] [CrossRef]

- Swithers, S.E. Artificial sweeteners are not the answer to childhood obesity. Appetite 2015, 93, 85–90. [Google Scholar] [CrossRef] [PubMed]

- Popkin, B.M.; Kenan, W.R.; Hawkes, C. The sweetening of the global diet, particularly beverages: Patterns, trends and policy responses for diabetes prevention. Lancet Diabetes Endocrinol. 2016, 4, 174–186. [Google Scholar] [CrossRef]

- Ortún, V.; López-Valcárcel, B.G.; Pinilla, J. El impuesto sobre bebidas azucaradas en España. Rev. Esp. Salud Pública 2016, 90, e20007. [Google Scholar]

- Mooradian, A.D.; Smith, M.; Tokuda, M. The role of artificial and natural sweeteners in reducing the consumption of table sugar: A narrative review. Clin. Nutr. ESPEN 2017, 18, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Lisbona, A.; Palma, S.; Parra, P.; Gómez, C. Obesidad y azúcar: Aliados o enemigos. Nutr. Hosp. 2013, 28, 81–87. [Google Scholar]

- Sylvetsky, A.C.; Rother, K.I. Trends in the Consumption of Low-Calorie Sweeteners. Physiol. Behav. 2016, 164, 446–450. [Google Scholar] [CrossRef]

- Wakida-Kuzunoki, G.H.; Aguiñaga-Villaseñor, R.G.; Avilés-Cobián, R.; Baeza-Bacab, M.A.; Cavagnari, B.M.; del Castillo-Ruiz, V. Edulcorantes no calóricos en la edad pediátrica: Análisis de la evidencia científica. Rev. Mex. Pediatría 2017, 84, s3–s23. [Google Scholar]

- O’Niones, K. Rheological, Foam, and Physical Properties of Low Sucrose Meringue and Angel Food Cake Formulated with Non-Nutritive Sweeteners and Polydextrose. Master’s Thesis, College of Agriculture, Food and Environment, University of Kentucky, Lexington, KY, USA, 2014; p. 35. [Google Scholar]

- Akesowan, A. Quality of Reduced-Fat Chiffon Cakes Prepared with Erythritol-Sucralose as Replacement for Sugar. Pak. J. Nutr. 2009, 8, 1383–1386. [Google Scholar] [CrossRef] [Green Version]

- Gwak, M.J.; Chung, S.J.; Kim, Y.J.; Lim, C.S. Relative sweetness and sensory characteristics of bulk and intense sweeteners. Food Sci. Biotechnol. 2012, 21, 889–894. [Google Scholar] [CrossRef]

- Struck, S.; Jaros, D.; Brennan, C.S.; Rohm, H. Sugar replacement in sweetened bakery goods. Int. J. Food Sci. Technol. 2014, 49, 1963–1976. [Google Scholar] [CrossRef]

- Chattopadhyay, S.; Raychaudhuri, U.; Chakraborty, R. Artificial sweeteners—A review. J. Food Sci. Technol. 2014, 51, 611–621. [Google Scholar] [CrossRef] [PubMed]

- Abdel-Rahman, A.; Anyangwe, N.; Carlacci, L.; Casper, S.; Danam, R.P.; Enongene, E.; Erives, G.; Fabricant, D.; Gudi, R.; Hilmas, C.J.; et al. The Safety and Regulation of Natural Products Used as Foods and Food Ingredients. Toxicol. Sci. 2011, 123, 333–348. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hoyos, A.E.O.; Otero, R.A.M.; Montealegre, R.O.; Vásquez, E.P.; Ibarbo, J.H.H.; Roa, J.D.A.; Caicedo, M.C.; Girón, J.M. Edulcorantes naturales utilizados en la elaboración de chocolates. Biotecnol. Sect. Agropecu. Agroind. 2017, 15, 116–152. [Google Scholar]

- The New Sweet Taste of Sugar Reduction. Available online: https://www.ingredion.us/Ingredients/ProductPages/bestevia.html (accessed on 1 July 2019).

- Jayamuthunagai, J.; Srisowmeya, G.; Chakravarthy, M.; Gautam, P. D-Tagatose production by permeabilized and immobilized Lactibacillus plantarum using whey permeate. Biosour. Technol. 2017, 235, 250–255. [Google Scholar] [CrossRef]

- Durán, S.; Cordón, K.; Rodríguez, M.P. Edulcorantes no nutritivos, riesgos, apetito y ganancia de peso. Rev. Chil. Nutr. 2013, 40, 309–314. [Google Scholar] [CrossRef] [Green Version]

- Martínez-Cervera, S.; Salvador, A.; Sanz, T. Comparison of different polyols as total sucrose replacers in muffins: Thermal, rheological, texture and acceptability properties. Food Hydrocoll. 2014, 35, 1–8. [Google Scholar] [CrossRef]

- Tan, V.W.K.; Wee, M.S.M.; Tomic, O.; Forde, C.G.; Kee, V.T.W.; Mei, M.W.S. Temporal sweetness and side tastes profiles of 16 sweeteners using temporal check-all-that-apply (TCATA). Food Res. Int. 2019, 121, 39–47. [Google Scholar] [CrossRef]

- Samaniego-Vaesken, M.L.; Partearroyo, T.; Cano, A.; Urrialde, R.; Varela-Moreiras, G. Novel database of declared low and no calorie sweeteners from foods and beverages available in Spain. J. Food Compos. Anal. 2019, 82, 103234. [Google Scholar] [CrossRef]

- Bellisle, F.; Drewnowski, A.; Anderson, G.H.; Westerterp-Plantenga, M.; Martin, C. Sweetness, Satiation, and Satiety. J. Nutr. 2012, 142, 1149S–1154S. [Google Scholar] [CrossRef] [PubMed]

- Blundell, J.; De Graaf, C.; Hulshof, T.; Jebb, S.; Livingstone, B.; Lluch, A.; Mela, D.; Salah, S.; Schuring, E.; Van Der Knaap, H.; et al. Appetite control: Methodological aspects of the evaluation of foods. Obes. Rev. 2010, 11, 251–270. [Google Scholar] [CrossRef] [PubMed]

- Mattes, M.Z.; Vickers, Z.M. Better-liked foods can produce more satiety. Food Qual. Prefer. 2018, 64, 94–102. [Google Scholar] [CrossRef]

- Yeomans, M.R.; Milton, M.R.; Chambers, L. Additive effects of sensory-enhanced satiety and memory for recent eating on appetite. Appetite 2017, 117, 335–341. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- UNE-ISO 8587:2010. Análisis Sensorial. Metodología. Ordenación. AENOR. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0045392 (accessed on 1 July 2019).

- Hein, K.A.; Jaeger, S.R.; Carr, B.T.; Delahunty, C.M. Comparison of five common acceptance and preference methods. Food Qual. Prefer. 2008, 19, 651–661. [Google Scholar] [CrossRef]

- AOACa 906.03,940. Official Methods of Analysis of Association of Official Analytical Chemists International, 16th ed.; AOAC: Rockville, MD, USA, 1995. [Google Scholar]

- AACC. Baking Quality. Method 10-05.01. Guidelines for Measurement of Volume by Rapessed Displacement. Available online: https://methods.aaccnet.org/summaries/10-05-01.aspx (accessed on 1 July 2019).

- AOACb 93401. Official Methods of Analysis of Association of Official Analytical Chemists International, 16th ed.; AOAC: Washington, DC, USA, 1995. [Google Scholar]

- Martínez-Cervera, S.; Sanz, T.; Salvador, A.; Fiszman, S. Rheological, textural and sensorial properties of low-sucrose muffins reformulated with sucralose/polydextrose. LWT 2012, 45, 213–220. [Google Scholar] [CrossRef]

- Gao, J.; Brennan, M.A.; Mason, S.L.; Brennan, C.S. Effects of Sugar Substitution with “Stevianna” on the Sensory Characteristics of Muffins. J. Food Qual. 2017, 2017, 8636043. [Google Scholar] [CrossRef]

- Quitral, V.; González, M.A.; Carrera, C.; Gallo, G.; Moyano, P.; Salinas, J.; Jiménez, P. Effect of non-caloric sweeteners in sensory acceptability of a baked product. Rev. Chil. Nutr. 2017, 44, 137–143. [Google Scholar] [CrossRef]

- Ronda, F.; Gómez, M.; Blanco, C.; Caballero, P.A. Effects of polyols and nondifestible oligosaccharides on the quality of sugar-free sponge cakes. Food Chem. 2005, 90, 549–555. [Google Scholar] [CrossRef]

- Purlis, E. Browning development in bakery products—A review. J. Food Eng. 2010, 99, 239–249. [Google Scholar] [CrossRef]

- Valencia, F.E.; Millán, L.; Estepa, C.; Botero, S. Effect of the substitution with polydextrose and CMC in the sensorial quality of cakes with a low sucrose content. Rev. Lasallista Investig. 2008, 5, 63–67. [Google Scholar]

- Martins, S.; Jongen, W.; Van Boekel, M. A review of Maillard reaction in food and implications to kinetic modelling. Trends Food Sci. Technol. 2001, 11, 364–373. [Google Scholar] [CrossRef]

- Nooshkam, M.; Varidi, M.; Bashash, M. The Maillard reaction products as food-born antioxidant and antibrowning agents in model and real food systems. Food Chem. 2019, 275, 644–660. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Wang, W.; Li, Y. Dough properties, bread quality, and associated interactions with added phenolic compounds: A review. J. Funct. Foods 2019, 52, 629–639. [Google Scholar] [CrossRef]

- De Souza, V.; Pereira, P.; Pinheiro, A.C.; Bolini, H.; Borges, S.; Queiroz, F. Analysis of various sweeteners in low-sugar mixed fruit jam: Equivalent sweetness, time-intensity analysis and acceptance test. Int. J. Food Sci. Technol. 2013, 48, 1541–1548. [Google Scholar] [CrossRef]

- Rubio-Arraez, S.; Benavent, C.; Ortolá, M.D.; Castelló, M.L. Influence of Low Glycaemic Index Sweeteners on Antioxidant, Sensory, Mechanical, and Physicochemical Properties of a Watermelon Jelly. J. Food Qual. 2018, 2018, 8412017. [Google Scholar] [CrossRef]

- Mogha, K.V.; Chaudhari, A.; Aparnathi, K. Tagatose: A low calorie multifunctional sweetener. J. Dairy Sci. Technol. 2016, 5, 29–35. [Google Scholar]

- Gomez, C.; Palma, S. A general up-to-date and critical approach about the importance of sugar in our food. Nutr. Hosp. 2013, 28 (Suppl. 4), 1–4. [Google Scholar]

- Wichchukit, S.; O’Mahony, M. Liking, Buying, Choosing and Take Away preference test for varying degrees of hedonic disparity. Food Qual. Prefer. 2011, 22, 60–65. [Google Scholar] [CrossRef]

- Campbell, C.L.; Wagoner, T.B.; Foegeding, E.A. Designing foods for satiety: The roles of food structure and oral processing in satiation and satiety. Food Struct. 2017, 13, 1–12. [Google Scholar] [CrossRef]

- Zamora, S.; Pérez, F. Importance of sucrose in cognitive functions knowledge and behavior. Nutr. Hosp. 2013, 28, 106–111. [Google Scholar]

- Cabezas-Zabala, C.; Hernández-Torres, B.; Vargas-Zárate, M. Sugars Added in Food: Health Effects and Global Regulation. Rev. Fac. Med. 2016, 64, 319–329. [Google Scholar]

- Beltrami, M.C.; Döring, T.; Lindner, J.D.D. Sweeteners and sweet taste enhancers in the food industry. Food Sci. Technol. 2018, 38, 181–187. [Google Scholar] [CrossRef] [Green Version]

- Calzada-León, R.; Ruiz-Reyes MLAltamirano-Bustamante, N.; Padrón-Martínez, M. Características de los edulcorantes no calóricos y su uso en niños. Acta Pediátrica México 2013, 34, 141–143. [Google Scholar]

- Gomes da Silva, M.F.; Dionisio, A.P.; Ferreira, A.; Silveira, L.; Oliveira, C.; Pinto, F.; Wurlitzer, N.; Araújo, I.M.; Dos Santos, D.; Ferreira, D. Yacon syrup: Food applications and impact on satiety in healthy volunteers. Food Res. Int. 2017, 100, 460–467. [Google Scholar] [CrossRef] [PubMed]

- Lunde, M.S.H.; Hjellset, V.T.; Holmboe-Ottesen, G.; Høstmark, A.T. Variations in Postprandial Blood Glucose Responses and Satiety after Intake of Three Types of Bread. J. Nutr. Metab. 2011, 2011, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Bellissimo, N.; Akhavan, T. Effect of Macronutrient Composition on Short-Term Food Intake and Weight Loss. Adv. Nutr. 2015, 6, 302S–308S. [Google Scholar] [CrossRef] [Green Version]

- Vázquez, M.C.; Guevara, R.; Aguirre, H.; Alvarado, A.; Da Romero, H. Current consumption of natural sweeteners (benefits and problems): Stevia. Rev. Med. Electrónica 2017, 39, 1153–1159. [Google Scholar]

- Alderete-Velasco, J.; López-García, R.; Zúñiga-Guajardo, S.; Riobó-Serván, P.; Serra-Majem, L.; Suverza-Fernández, A.; Esquivel-Flores, M.G.; Molina-Segui, F.; Pedroza-Islas, R.; Rascón-Hernández, M.; et al. Analysis of the available evidence for the intake of non-caloric sweeteners. Expert document. Med. Int. Méx. 2017, 33, 61–83. [Google Scholar]

- Villanueva, N.; Da Silva, M. Comparativ performance of the nine-point hedonic, hybrid and self-adjusting scales in the generation of internal preference maps. Food Qual. Prefer. 2009, 20, 1–12. [Google Scholar] [CrossRef]

- García-Almeida, J.M.; Casado, G.; García, J. A current and global review of sweeteners. Regulatory aspects. Nutr. Hosp. 2013, 28, 17–31. [Google Scholar] [PubMed]

- Cernuda, J.A.; Fernandez, A. Sweetener agents and their role on human metabolism. RqR Enfermería Comunitaria 2016, 4, 13–22. [Google Scholar]

- García-Flores, C.; Martínez, A.; Beltrán, C.; Zepeda-Salvador, A.P.; Solano, L. Satiation and satiety in the regulation of energy intake. Rev. Med. Chile 2017, 145, 1172–1178. [Google Scholar] [CrossRef] [PubMed]

- Tang, J.; Larsen, D.S.; Ferguson, L.R.; James, B.J. The effect of textural complexity of solid foods on satiation. Physiol. Behav. 2016, 163, 17–24. [Google Scholar] [CrossRef]

- Marchetti, L.; Califano, A.N.; Andrés, S.C. Partial replacement of wheat flour by pecan nut expeller meal on bakery products. Effect on muffins quality. LWT Food Sci. Technol. 2018, 95, 85–91. [Google Scholar] [CrossRef]

- Zhang, Y.; Guo, L.; Xu, D.; Li, D.; Yang, N.; Chen, F.; Jin, Z.; Xu, X. Effects of dextran with different molecular weights on the quality of wheat sourdough breads. Food Chem. 2018, 256, 373–379. [Google Scholar] [CrossRef]

- Matos, M.E.; Sanz, T.; Rosell, C.M. Establishing the function of proteins on the rheological and quality properties of rice based gluten free muffins. Food Hydrocoll. 2014, 35, 150–158. [Google Scholar] [CrossRef] [Green Version]

- Hao, Y.; Wang, F.; Huang, W.; Tang, X.; Zou, Q.; Li, Z.; Ogawa, A. Sucrose substitution by polyols in sponge cake and their effects on the foaming and thermal properties of egg protein. Food Hydrocoll. 2016, 57, 153–159. [Google Scholar] [CrossRef]

- Abdel-Salam, A.M.; Ammar, A.S.; Galal, W.K. Evaluation and properties of formulated low calories functional yoghurt cake. JFAE 2009, 7, 218–221. [Google Scholar]

- Manisha, G.; Soumya, C.; Indrani, D. Studies of interaction between stevioside, liquid sorbitol, hydrocolloids and emulsifiers for replacement of sugar in cakes. Food Hydrocoll. 2012, 29, 363–373. [Google Scholar]

- Larsen, D.S.; Tang, J.; Ferguson, L.R.; James, B.J. Increased textural complexity in food enhances satiation. Appetite 2016, 105, 189–194. [Google Scholar] [CrossRef] [PubMed]

- Cardoso, J.M.P.; Bolini, H.M.A. Descriptive profile of peach nectar sweetened with sucrose and different sweeteners. J. Sens. Stud. 2008, 23, 804–816. [Google Scholar] [CrossRef]

| Samples | ||||

|---|---|---|---|---|

| C0 | C1 | C2 | C3 | |

| White flour (g) | 100 | 100 | 100 | 100 |

| Eggs (units) | 1 | 1 | 1 | 1 |

| Milk (mL) | 80 | 80 | 80 | 80 |

| Butter (g) | 50 | 50 | 50 | 50 |

| Baking powder (g) | 10 | 10 | 10 | 10 |

| Sugar (g) | 95 | 0 | 0 | 0 |

| Stevia, maltitol, polydextrose (g) | 0 | 47.5 | 0 | 0 |

| Sucralose, maltitol, polydextrose (g) | 0 | 0 | 47.5 | 0 |

| Tagatose, isomaltitol, soluble fiber (g) | 0 | 0 | 0 | 47.5 |

| Sample | Preference | 9-Point Hedonic Scale Acceptability (Average) |

|---|---|---|

| C0 | 1° a | 8 a = I like very much |

| C1 | 2° b | 7 b = I like moderately |

| C2 | 3° bc | 7 b = I like moderately |

| C3 | 4° c | 7 b = I like moderately |

| Samples | C0 | C1 | C2 | C3 |

|---|---|---|---|---|

| Energy (kcal) | 399 b | 315 a | 292 a | 298 a |

| Proteins (g) | 6.4 a | 7.3 b | 6.8 ab | 7.0 ab |

| Total lipid (g) | 15.4 a | 17.6 c | 16.3 ab | 16.8 bc |

| Carbohydrate (g) | 58.6 b | 31.8 a | 29.6 a | 29.6 a |

| Sugars, total (g) | 30.8 c | 4.7 a | 2.8 a | 13.2 b |

| Samples | Yield (g/100 g) | Specific Volume (cm3/g) | Hardness N | Cohesiveness | Gum gf |

|---|---|---|---|---|---|

| C0 | 80.0 a | 6.5 a | 8.3 a | 0.26 a | 208 a |

| C1 | 80.1 a | 3.5 b | 25.8 b | 0.27 a | 704 b |

| C2 | 86.7 a | 3.2 b | 29.5 b | 0.24 a | 723 b |

| C3 | 84.0 a | 2.9 b | 23.3 b | 0.26 a | 624 b |

| Samples | ||||

|---|---|---|---|---|

| Time (Days) | C0 | C1 | C2 | C3 |

| 3 | − | − | − | − |

| 8 | − | − | − | − |

| 14 | − | − | − | − |

| 17 | − | − | + | − |

| 25 | − | + | + | + |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Quitral, V.; Valdés, J.; Umaña, V.; Gallardo, N.; Alcaino, M.J.; Araya, C.; Flores, M. The Role of Non-Caloric Sweeteners in Sensory Characteristics of Pastry Products. Foods 2019, 8, 329. https://doi.org/10.3390/foods8080329

Quitral V, Valdés J, Umaña V, Gallardo N, Alcaino MJ, Araya C, Flores M. The Role of Non-Caloric Sweeteners in Sensory Characteristics of Pastry Products. Foods. 2019; 8(8):329. https://doi.org/10.3390/foods8080329

Chicago/Turabian StyleQuitral, Vilma, Juanita Valdés, Valeska Umaña, Nicol Gallardo, María José Alcaino, Carolina Araya, and Marcos Flores. 2019. "The Role of Non-Caloric Sweeteners in Sensory Characteristics of Pastry Products" Foods 8, no. 8: 329. https://doi.org/10.3390/foods8080329

APA StyleQuitral, V., Valdés, J., Umaña, V., Gallardo, N., Alcaino, M. J., Araya, C., & Flores, M. (2019). The Role of Non-Caloric Sweeteners in Sensory Characteristics of Pastry Products. Foods, 8(8), 329. https://doi.org/10.3390/foods8080329