Effects of Different Drying Methods on Drying Kinetics, Microstructure, Color, and the Rehydration Ratio of Minced Meat

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Physicochemical Properties of Minced Meats

2.2.2. Drying of Minced Meats with Different Techniques

2.2.3. Drying Characteristic Analyses

Moisture Ratio

Effective Moisture Diffusivity (Deff) and Activation Energy

2.2.4. Rehydration Ratio of Dried Minced Meats

2.2.5. Shrinkage Ratio of Dried Minced Meats

2.2.6. Color Measurement

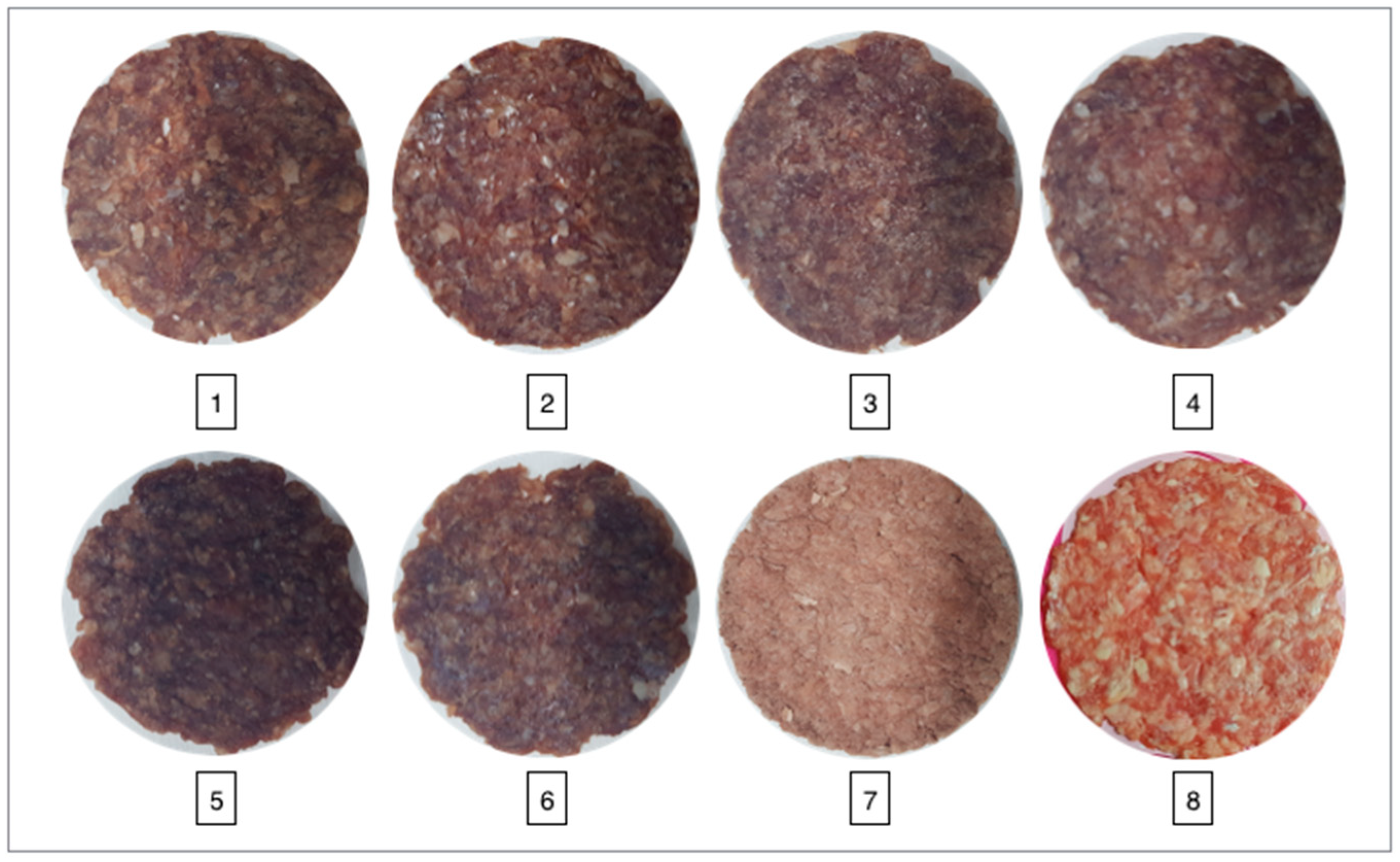

Surface Color

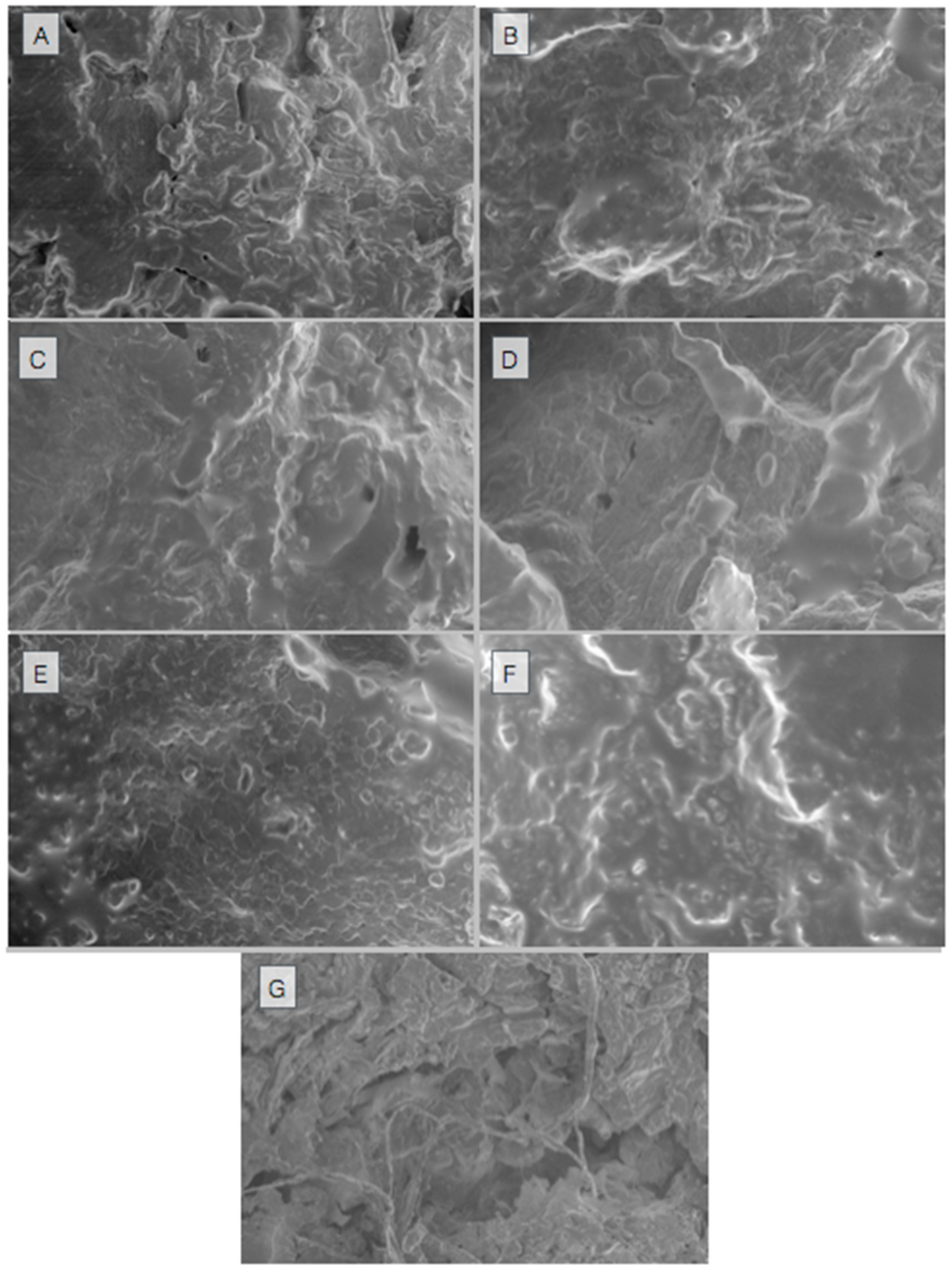

2.2.7. Microstructure

2.2.8. Statistical Analysis

3. Results and Discussion

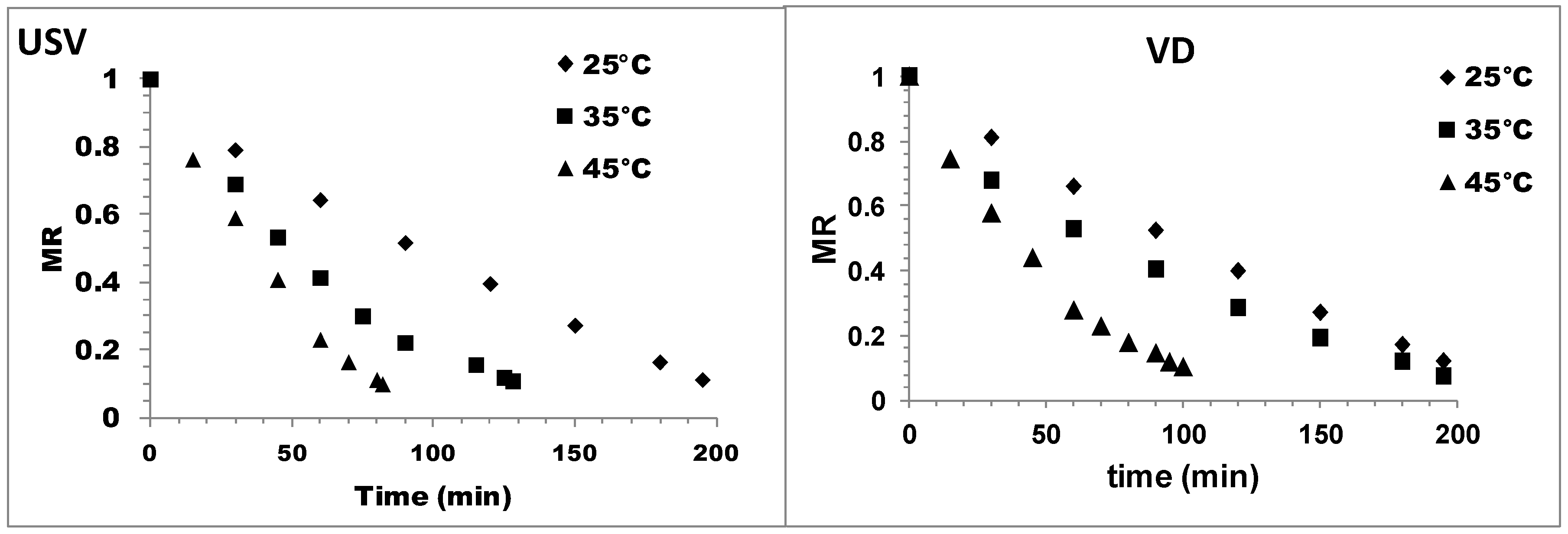

3.1. Drying Characteristics of Minced Meats

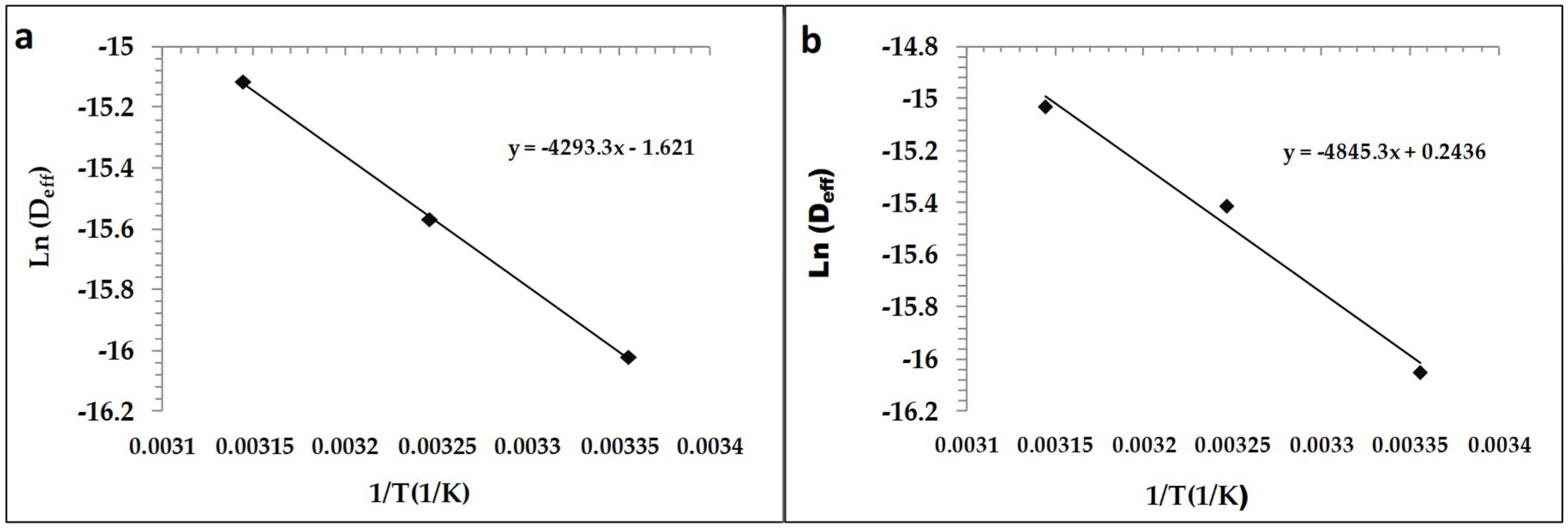

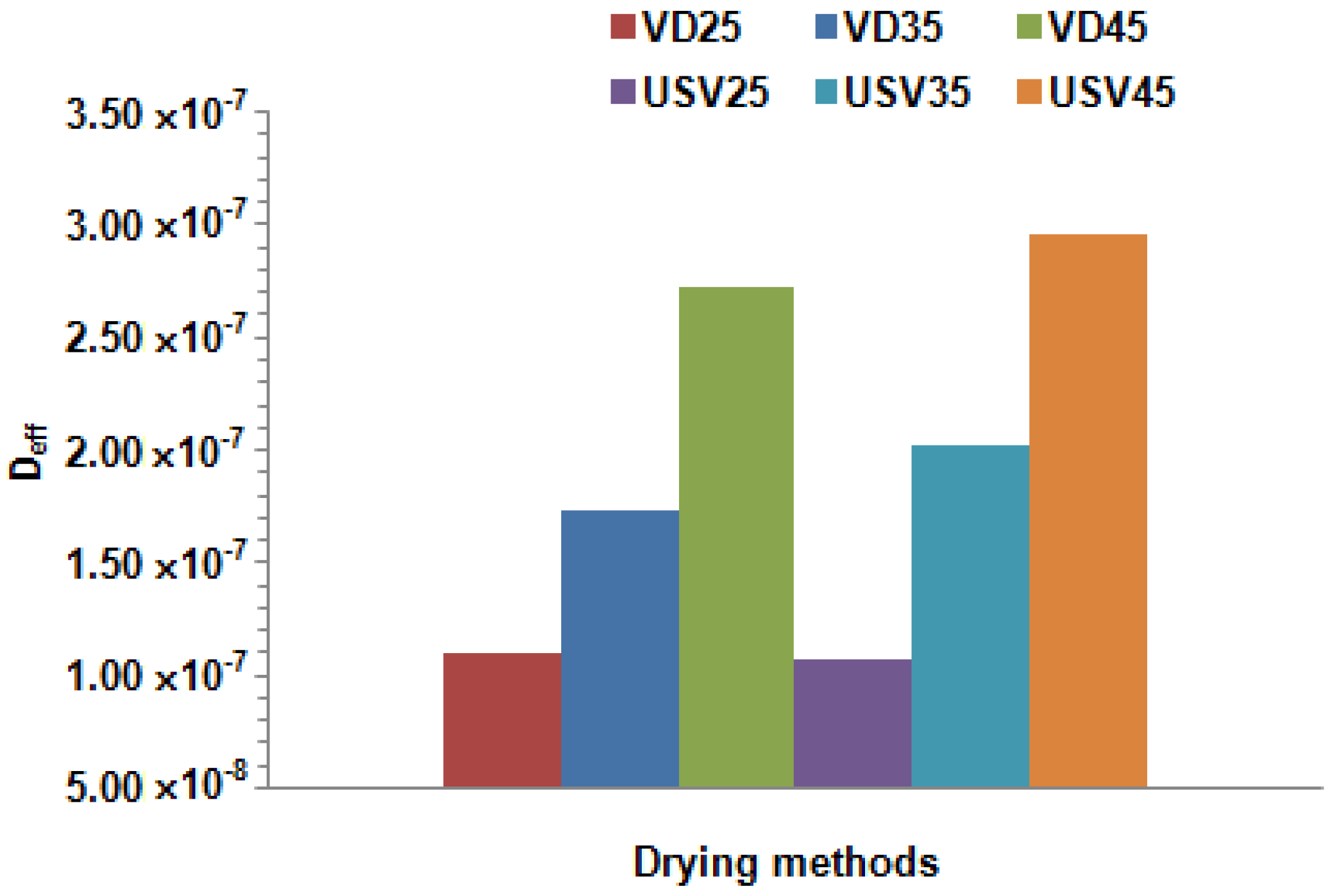

3.2. Effect of Temperature and Different Drying Techniques on Effective Moisture Diffusivity (Deff)

3.3. Peroxide Formation

3.4. Rehydration and Microstructural Properties and Shrinkage Values

3.5. Color Values of Dried Minced Meats

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Doulgeraki, A.I.; Ercolini, D.; Villani, F.; Nychas, G.-J.E. Spoilage microbiota associated to the storage of raw meat in different conditions. Int. J. Food Microbiol. 2012, 157, 130–141. [Google Scholar] [CrossRef] [PubMed]

- Djordjevic, J.; Boskovic, M.; Dokmanovic, M.; Lazic, I.; Ledina, T.; Suvajdzic, B.; Baltic, M. Vacuum and Modified Atmosphere Packaging Effect on Enterobacteriaceae Behaviour in Minced Meat: Vacuum and Modified Atmosphere Packaging Effect. J. Food Process. Preserv. 2017, 41, e12837. [Google Scholar] [CrossRef]

- Casaburi, A.; Piombino, P.; Nychas, G.-J.; Villani, F.; Ercolini, D. Bacterial populations and the volatilome associated to meat spoilage. Food Microbiol. 2015, 45, 83–102. [Google Scholar] [CrossRef] [PubMed]

- Modi, V.K.; Sachindra, N.M.; Nagegowda, P.; Mahendrakar, N.S.; Narasimha Rao, D. Quality changes during the storage of dehydrated chicken kebab mix. Int. J. Food Sci. Technol. 2007, 42, 827–835. [Google Scholar] [CrossRef]

- Doymaz, I.; Karasu, S.; Baslar, M. Effects of infrared heating on drying kinetics, antioxidant activity, phenolic content, and color of jujube fruit. J. Food Meas. Charact. 2016, 10, 283–291. [Google Scholar] [CrossRef]

- Aykın, E.; Erbas, M. Quality properties and adsorption behavior of freeze-dried beef meat from the Biceps femoris and Semimembranosus muscles. Meat Sci. 2016, 121, 272–277. [Google Scholar] [CrossRef]

- Laopoolkit, P.; Suwannaporn, P. Effect of pretreatments and vacuum drying on instant dried pork process optimization. Meat Sci. 2011, 88, 553–558. [Google Scholar] [CrossRef]

- Mousa, N.; Farid, M. Microwave vacuum drying of banana slices. Dry. Technol. 2002, 20, 2055–2066. [Google Scholar] [CrossRef]

- Tekin, Z.H.; Baslar, M. The effect of ultrasound-assisted vacuum drying on the drying rate and quality of red peppers. J. Therm. Anal. Calorim. 2018, 132, 1131–1143. [Google Scholar] [CrossRef]

- Tekin, Z.H.; Baslar, M.; Karasu, S.; Kilicli, M. Dehydration of green beans using ultrasound-assisted vacuum drying as a novel technique: Drying kinetics and quality parameters. J. Food Process. Preserv. 2017, 41. [Google Scholar] [CrossRef]

- Tao, Y.; Sun, D.-W. Enhancement of Food Processes by Ultrasound: A Review. Crit. Rev. Food Sci. Nutr. 2015, 55, 570–594. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Wu, X.; Zhang, Q.; Giovanni, V.; Meng, X. Key composition optimization of meat processed protein source by vacuum freeze-drying technology. Saudi J. Biol. Sci. 2018, 25, 724–732. [Google Scholar] [CrossRef] [PubMed]

- Sagar, V.R.; Kumar, S. Recent advances in drying and dehydration of fruits and vegetables: A review. J. Food Sci. Technol. 2010, 47, 15–26. [Google Scholar] [CrossRef] [PubMed]

- Baslar, M.; Kilicli, M.; Toker, O.S.; Sagdic, O.; Arici, M. Ultrasonic vacuum drying technique as a novel process for shortening the drying period for beef and chicken meats. Innov. Food Sci. Emerg. Technol. 2014, 26, 182–190. [Google Scholar] [CrossRef]

- Xu, L.; Fang, X.; Wu, W.; Chen, H.; Mu, H.; Gao, H. Effects of high-temperature pre-drying on the quality of air-dried shiitake mushrooms (Lentinula edodes). Food Chem. 2019, 285, 406–413. [Google Scholar] [CrossRef]

- Kilic, A. Low temperature and high velocity (LTHV) application in drying: Characteristics and effects on the fish quality. J. Food Eng. 2009, 91, 173–182. [Google Scholar] [CrossRef]

- Association of Analytical Communities. Official Methods of Analysis Proximate Analysis and Calculations Moisture (M) Meat—Item 108, 17th ed.; AOAC: Gaithersburg, MD, USA, 2006. [Google Scholar]

- Association of Analytical Communities. Fat (crude) or ether extract in meat. In Official Methods of Analysis of AOAC International; AOAC: Gaithersburg, MD, USA, 2012. [Google Scholar]

- Baslar, M.; Kilicli, M.; Yalinkilic, B. Dehydration kinetics of salmon and trout fillets using ultrasonic vacuum drying as a novel technique. Ultrason. Sonochem. 2015, 27, 495–502. [Google Scholar] [CrossRef]

- Akpinar, E.; Midilli, A.; Bicer, Y. Single layer drying behaviour of potato slices in a convective cyclone dryer and mathematical modeling. Energy Convers. Manag. 2003, 44, 1689–1705. [Google Scholar] [CrossRef]

- Mujaffar, S.; Sankat, C.K. Modeling the drying behavior of unsalted and salted catfish (Arius sp.) slabs. J. Food Process. Preserv. 2015, 39, 1385–1398. [Google Scholar] [CrossRef]

- Doymaz, I. Hot-air drying of purslane (Portulaca oleracea L.). Heat Mass Transf. 2013, 49, 835–841. [Google Scholar] [CrossRef]

- Mishra, B.P.; Chauhan, G.; Mendiratta, S.K.; Sharma, B.D.; Desai, B.A.; Rath, P.K. Development and quality evaluation of dehydrated chicken meat rings using spent hen meat and different extenders. J. Food Sci. Technol. Mysore 2015, 52, 2121–2129. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Kroehnke, J.; Szadzinska, J.; Stasiak, M.; Radziejewska-Kubzdela, E.; Bieganska-Marecik, R.; Musielak, G. Ultrasound- and microwave-assisted convective drying of carrots—Process kinetics and product’s quality analysis. Ultrason. Sonochem. 2018, 48, 249–258. [Google Scholar] [CrossRef] [PubMed]

- Gamboa-Santos, J.; Montilla, A.; Cárcel, J.A.; Villamiel, M.; Garcia-Perez, J.V. Air-borne ultrasound application in the convective drying of strawberry. J. Food Eng. 2014, 128, 132–139. [Google Scholar] [CrossRef]

- De la Fuente-Blanco, S.; Riera-Franco de Sarabia, E.; Acosta-Aparicio, V.M.; Blanco-Blanco, A.; Gallego-Juárez, J.A. Food drying process by power ultrasound. Ultrasonics 2006, 44, e523–e527. [Google Scholar] [CrossRef] [PubMed]

- Başlar, M.; Karasu, S.; Kiliçli, M.; Us, A.; Sagdic, O. Degradation Kinetics of Bioactive Compounds and Antioxidant Activity of Pomegranate Arils during the Drying Process. Int. J. Food Eng. 2014, 10, 839–848. [Google Scholar] [CrossRef]

- Doymaz, I.; Karasu, S. Effect of air temperature on drying kinetics, colour changes and total phenolic content of sage leaves (Salvia officinalis). Qual. Assur. Saf. Crop. Foods 2018, 10, 269–276. [Google Scholar] [CrossRef]

- Rahman, M.; Al’Nahdi, Z.; Kadim, I.; Mothershaw, A.; Hamad Al-Riziqi, M.; Guizani, N.; Mahgoub, O.; Ali, A. Microbial and PhysicoChemical Characteristics of Dried Meat Processed by Different Methods. Int. J. Food Eng. 2005, 1. [Google Scholar] [CrossRef]

- Rahman, M.S.; Al-Amri, O.S.; Al-Bulushi, I.M. Pores and physico-chemical characteristics of dried tuna produced by different methods of drying. J. Food Eng. 2002, 53, 301–313. [Google Scholar] [CrossRef]

- Amaral, A.B.; Silva, M.V.D.; Lannes, S.C.D.S. Lipid oxidation in meat: Mechanisms and protective factors a review. Food Sci. Technol. 2018, 38, 1–15. [Google Scholar] [CrossRef]

- Ricce, C.; Rojas, M.L.; Miano, A.C.; Siche, R.; Augusto, P.E.D. Ultrasound pre-treatment enhances the carrot drying and rehydration. Food Res. Int. 2016, 89, 701–708. [Google Scholar] [CrossRef]

- Amami, E.; Khezami, W.; Mezrigui, S.; Badwaik, L.S.; Bejar, A.K.; Perez, C.T.; Kechaou, N. Effect of ultrasound-assisted osmotic dehydration pretreatment on the convective drying of strawberry. Ultrason. Sonochem. 2017, 36, 286–300. [Google Scholar] [CrossRef] [PubMed]

- Jambrak, A.R.; Mason, T.J.; Paniwnyk, L.; Lelas, V. Accelerated drying of button mushrooms, Brussels sprouts and cauliflower by applying power ultrasound and its rehydration properties. J. Food Eng. 2007, 81, 88–97. [Google Scholar] [CrossRef]

- Kaveh, M.; Jahanbakhshi, A.; Abbaspour-Gilandeh, Y.; Taghinezhad, E.; Moghimi, M.B.F. The effect of ultrasound pre-treatment on quality, drying, and thermodynamic attributes of almond kernel under convective dryer using ANNs and ANFIS network. J. Food Process Eng. 2018, 41, e12868. [Google Scholar] [CrossRef]

- Nowacka, M.; Wiktor, A.; Sledz, M.; Jurek, N.; Witrowa-Rajchert, D. Drying of ultrasound pretreated apple and its selected physical properties. J. Food Eng. 2012, 113, 427–433. [Google Scholar] [CrossRef]

- Liu, H.H.; Zhang, Y.T.; Yang, L.; Wu, Z.H. Effects of Ultrasound Pretreatment on Microstructure and Drying Characteristics of Eucalyptus urophylla x E. grandis. Bioresources 2018, 13, 5953–5964. [Google Scholar]

- Rahman, M.S. Post-drying aspects for meat and horticultural products. In Drying Technologies in Food Processing; Chen, X.D., Mujumdar, A.S., Eds.; Blackwell Publishing: Hoboken, NJ, USA, 2008; pp. 226–260. [Google Scholar]

- Sabarez, H.; Gallego-Juarez, J.; Riera, E. Ultrasonic-Assisted Convective Drying of Apple Slices. Dry. Technol. 2012, 30, 989–997. [Google Scholar] [CrossRef]

- Rajewska, K.; Mierzwa, D. Influence of ultrasound on the microstructure of plant tissue. Innov. Food Sci. Emerg. Technol. 2017, 43, 117–129. [Google Scholar] [CrossRef]

- Mendez-Calderon, E.K.; Ocampo-Castano, J.C.; Orrego, C.E. Optimization of convective drying assisted by ultrasound for Mango Tommy (Mangifera indica L.). J. Food Process Eng. 2018, 41. [Google Scholar] [CrossRef]

| Drying Method | PV (mEqO2/kg) | ||

|---|---|---|---|

| 25 °C | 35 °C | 45 °C | |

| Fresh | 0.96 ± 0.02 D | 0.96 ± 0.02 D | 0.96 ± 0.02 D |

| VD | 5.71 ± 0.04 cB | 5.97 ± 0.04 bB | 6.91 ± 0.06 aB |

| USV | 5.02 ± 0.01 bC | 5.61 ± 0.01 aC | 5.63 ± 0.02 aC |

| FD | 10.42 ± 0.29 A | 10.42 ± 0.29 A | 10.42 ± 0.29 A |

| Methods | Shrinkage | RH * | ||||

|---|---|---|---|---|---|---|

| 25 °C | 35 °C | 45 °C | 25 °C | 35 °C | 45 °C | |

| VD | 22.14 ± 0.07 Ca | 30.00 ± 1.52 Ba | 37.14 ± 0.71 Aa | 1.40 ± 0.09 Bc | 1.45 ± 0.02 Ac | 1.27 ± 0.09 Cc |

| USV | 21.42 ± 0.06 Aa | 25.71 ± 0.58 Bb | 29.28 ± 0.87 Ab | 1.49 ± 0.04 Bb | 1.54 ± 0.05 Ab | 1.31 ± 0.03 Cb |

| FD | 17.14 ± 1.26 b | 17.14 ± 1.26 c | 17.14 ± 1.26 c | 1.93 ± 0.05 a | 1.93 ± 0.05 a | 1.93 ± 0.05 a |

| Drying Method | ΔL | Δa | Δb | ΔE | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 25 °C | 35 °C | 45 °C | 25 °C | 35 °C | 45 °C | 25 °C | 35 °C | 45 °C | 25 °C | 35 °C | 45 °C | |

| VD | 6.04 ± 0.07 cB | 10.00 ± 1.41 bB | 16.18 ± 0.10 aA | 4.39 ± 0.09 bB | 2.69 ± 0.02 cB | 9.73 ± 0.15 aA | 3.55 ± 0.07 cA | 4.55 ± 0.09 bA | 8.75 ± 0.09 aA | 8.27 ± 0.06 cB | 11.31 ± 0.03 bA | 20.81 ± 0.05 aA |

| USV | 7.8 ± 0.03 bA | 11.98 ± 0.10 aA | 12.18 ± 1.44 aB | 4.04 ± 0.07 bB | 0.74 ± 0.00 cC | 7.91 ± 0.09 aB | 3.82 ± 0.01b A | 3.05 ± 0.09 bB | 7.67 ± 0.10b B | 9.58 ± 0.09 cA | 12.38 ± 1.04 bA | 16.42 ± 1.28 aB |

| FD | 6.64 ± 0.01 B | 6.64 ± 0.01 C | 6.64 ± 0.01 C | 6.09 ± 0.01 A | 6.09 ± 0.01 A | 6.09 ± 0.01 C | 2.48 ± 0.00 B | 2.48 ± 0.00 C | 2.48 ± 0.00 C | 9.34 ± 0.80 A | 9.34 ± 0.80 B | 9.34 ± 0.80 C |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aksoy, A.; Karasu, S.; Akcicek, A.; Kayacan, S. Effects of Different Drying Methods on Drying Kinetics, Microstructure, Color, and the Rehydration Ratio of Minced Meat. Foods 2019, 8, 216. https://doi.org/10.3390/foods8060216

Aksoy A, Karasu S, Akcicek A, Kayacan S. Effects of Different Drying Methods on Drying Kinetics, Microstructure, Color, and the Rehydration Ratio of Minced Meat. Foods. 2019; 8(6):216. https://doi.org/10.3390/foods8060216

Chicago/Turabian StyleAksoy, Aslı, Salih Karasu, Alican Akcicek, and Selma Kayacan. 2019. "Effects of Different Drying Methods on Drying Kinetics, Microstructure, Color, and the Rehydration Ratio of Minced Meat" Foods 8, no. 6: 216. https://doi.org/10.3390/foods8060216

APA StyleAksoy, A., Karasu, S., Akcicek, A., & Kayacan, S. (2019). Effects of Different Drying Methods on Drying Kinetics, Microstructure, Color, and the Rehydration Ratio of Minced Meat. Foods, 8(6), 216. https://doi.org/10.3390/foods8060216