Influence of Carob Flour and Carob Bean Gum on Rheological Properties of Cocoa and Carob Pastry Fillings

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Pastry Filling Production

2.2.2. Rheological Analysis

2.2.3. Mathematical Modelling

2.2.4. Texture Analysis

2.2.5. Data Analysis and Statistics

3. Results and Discussion

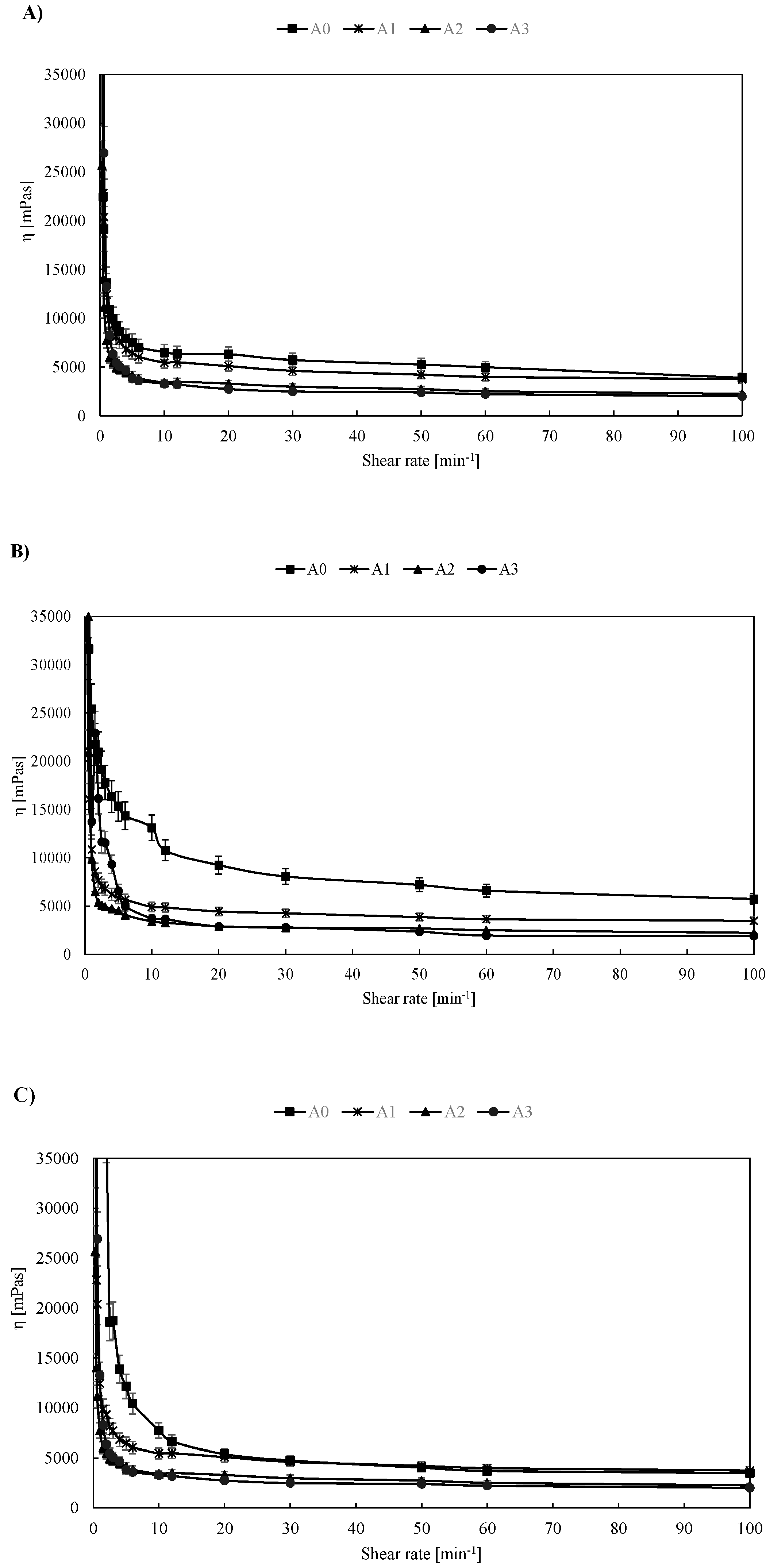

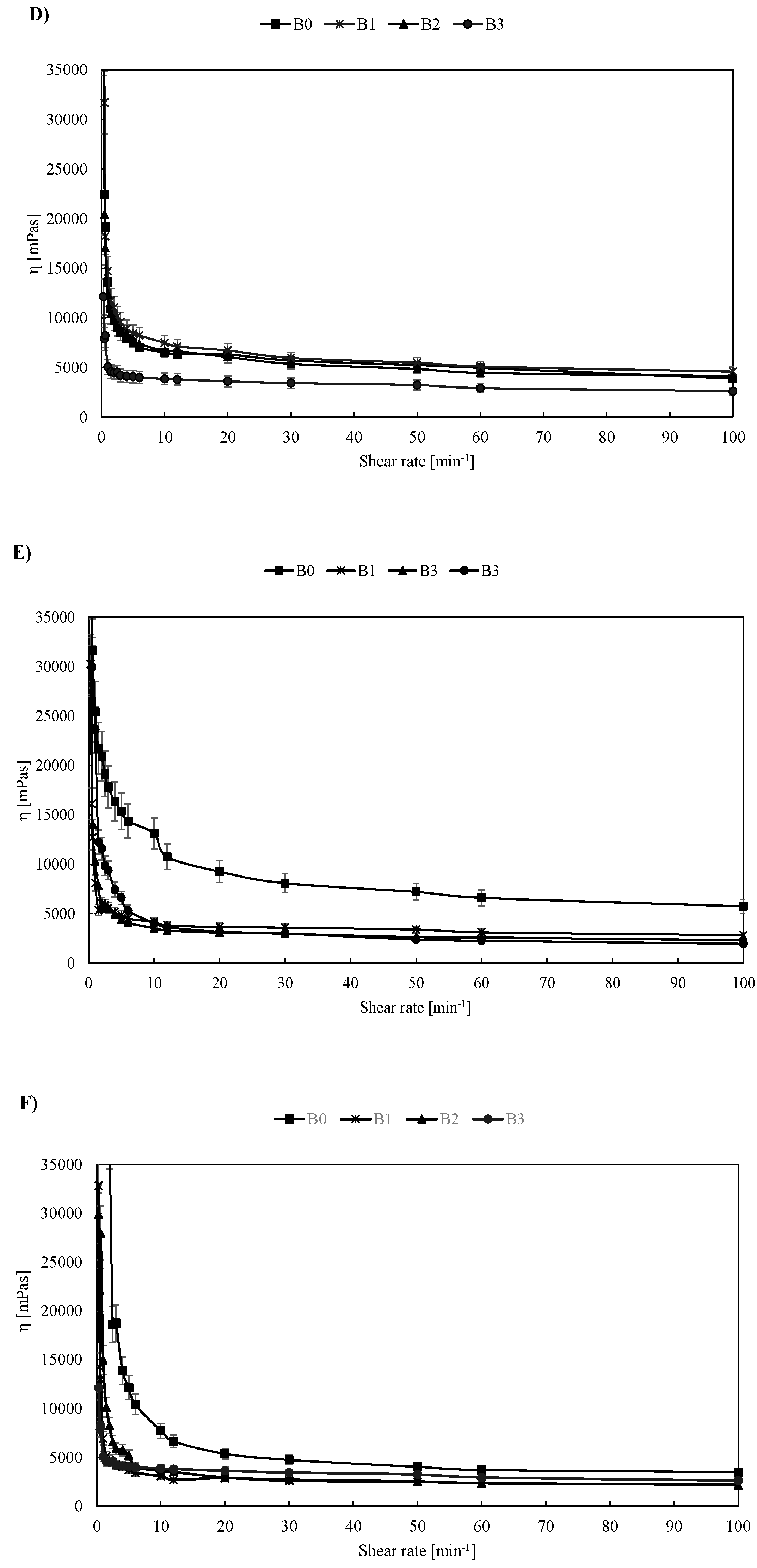

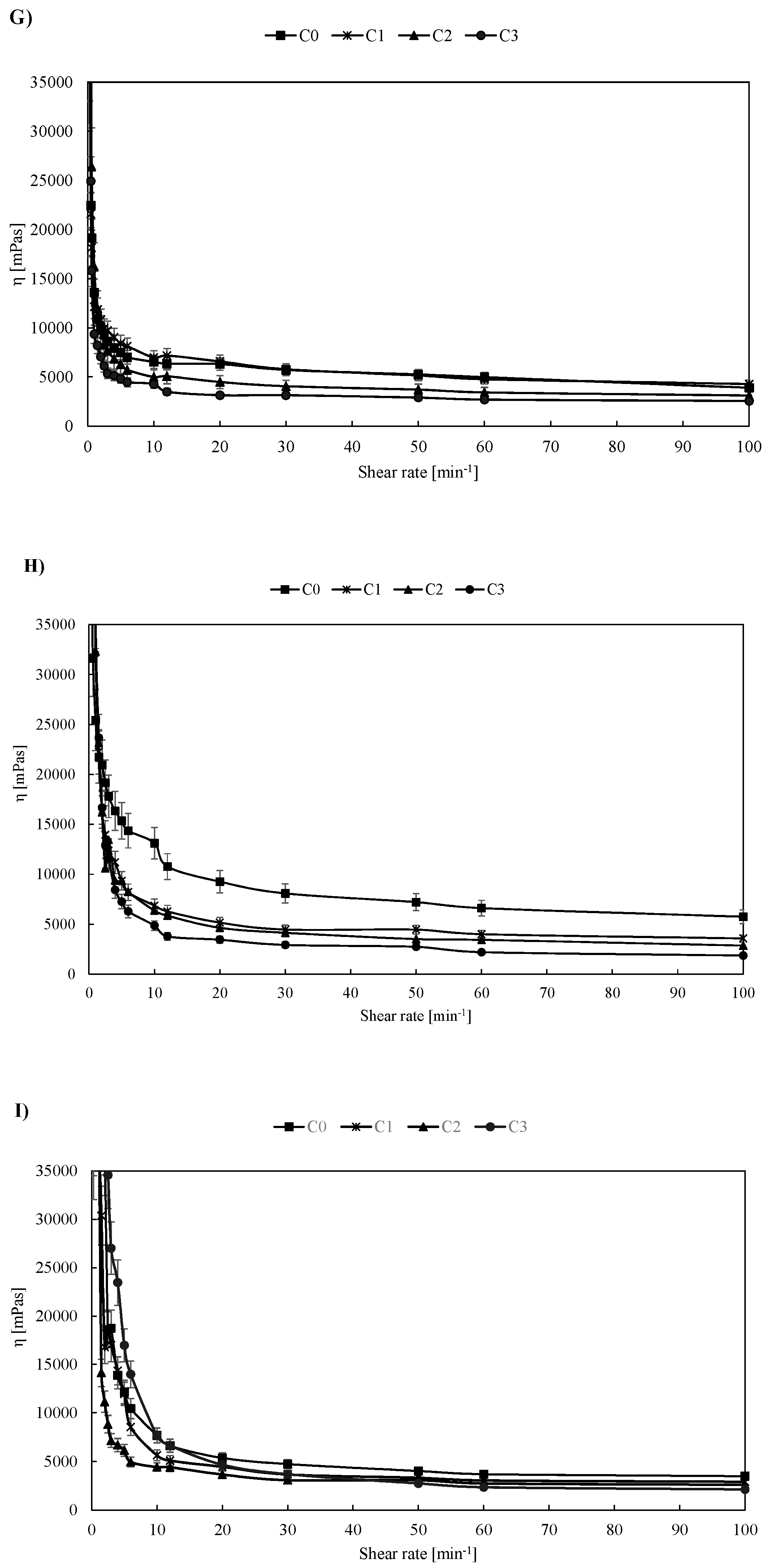

3.1. Flow Behavior

3.2. Model Fitting

3.2.1. The Ostwald de Waele Model

3.2.2. Herschel–Bulkley Model

3.2.3. Naturally Occurring LBG vs. Commercial LBG

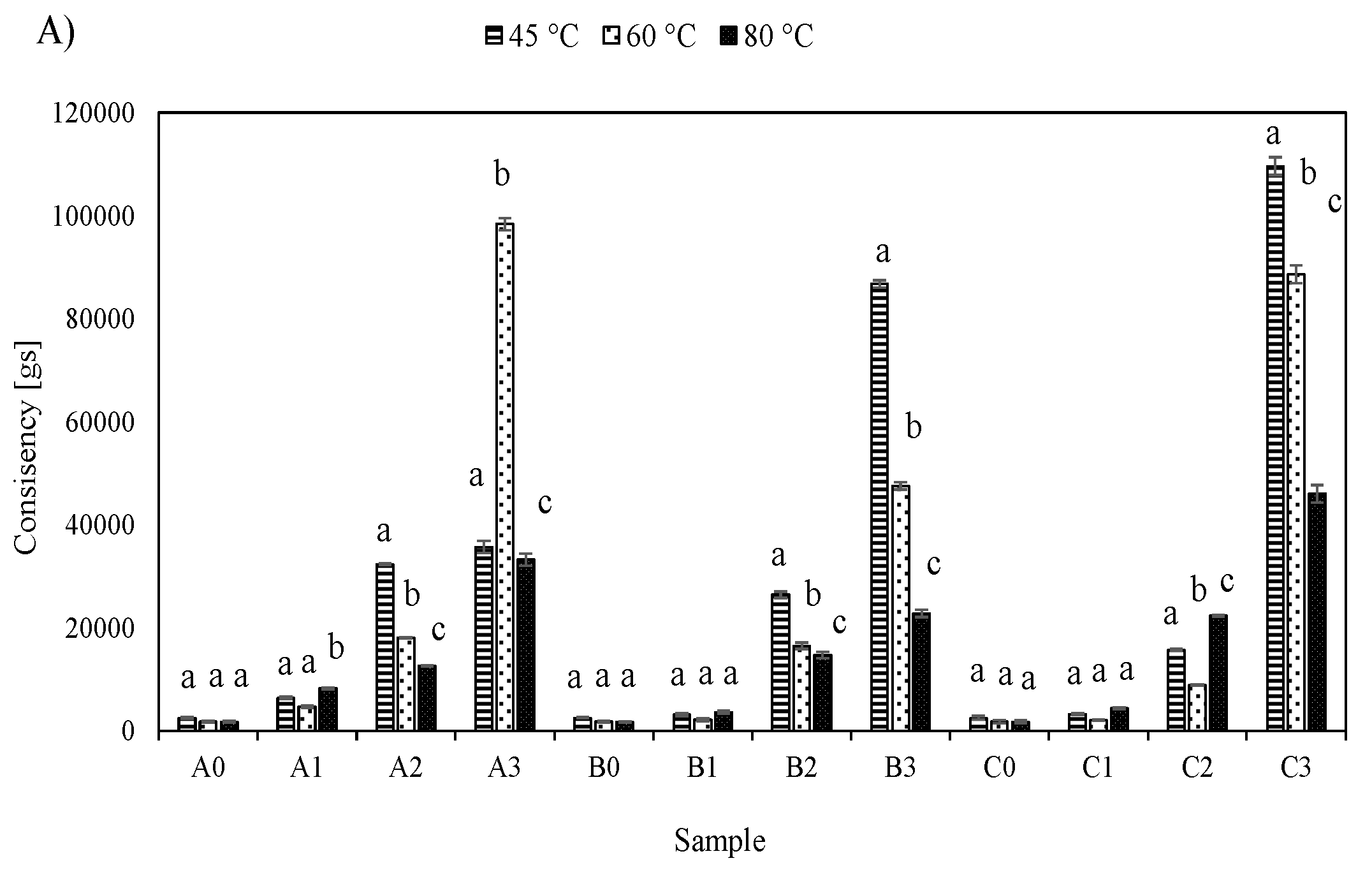

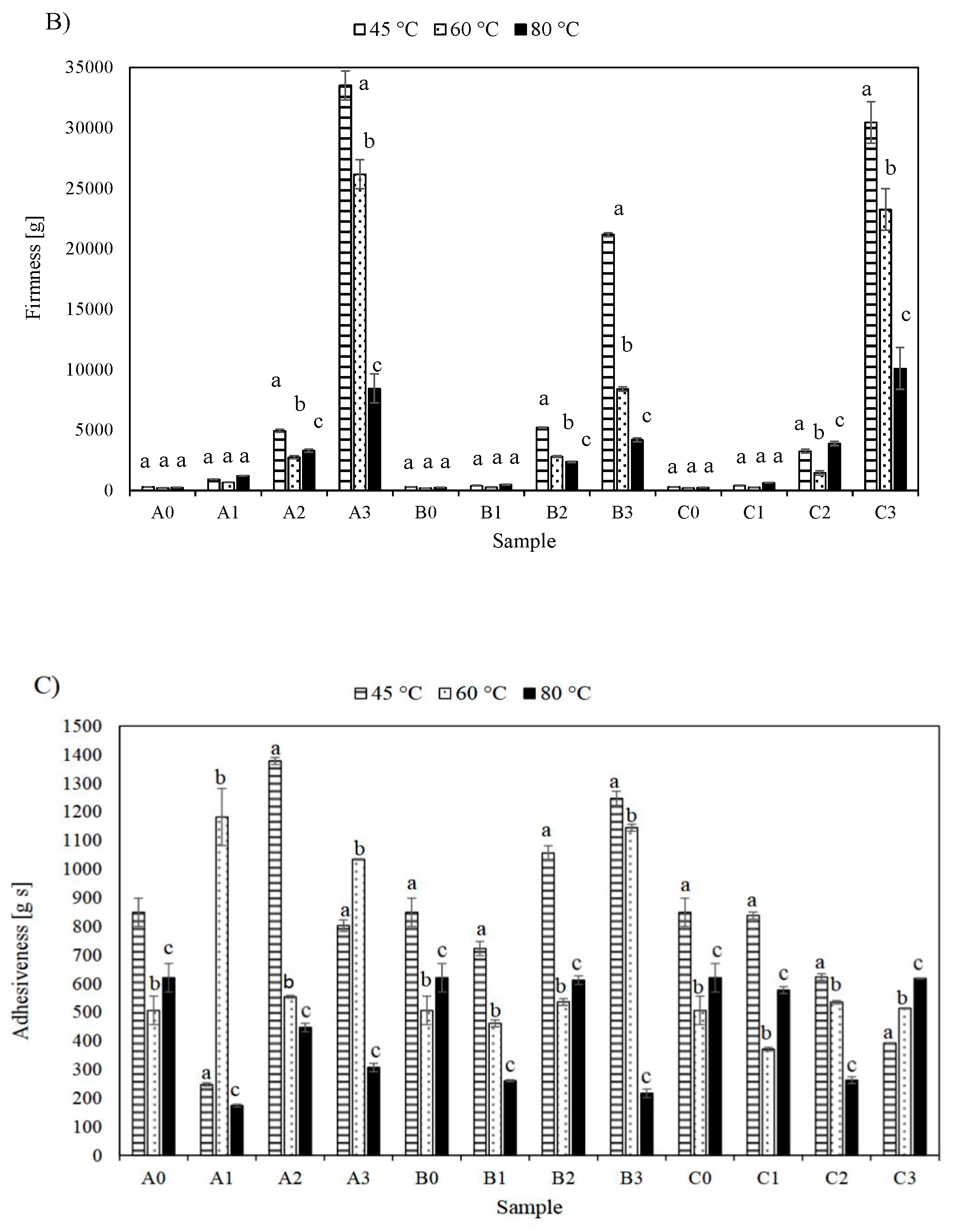

3.3. Textural Properties

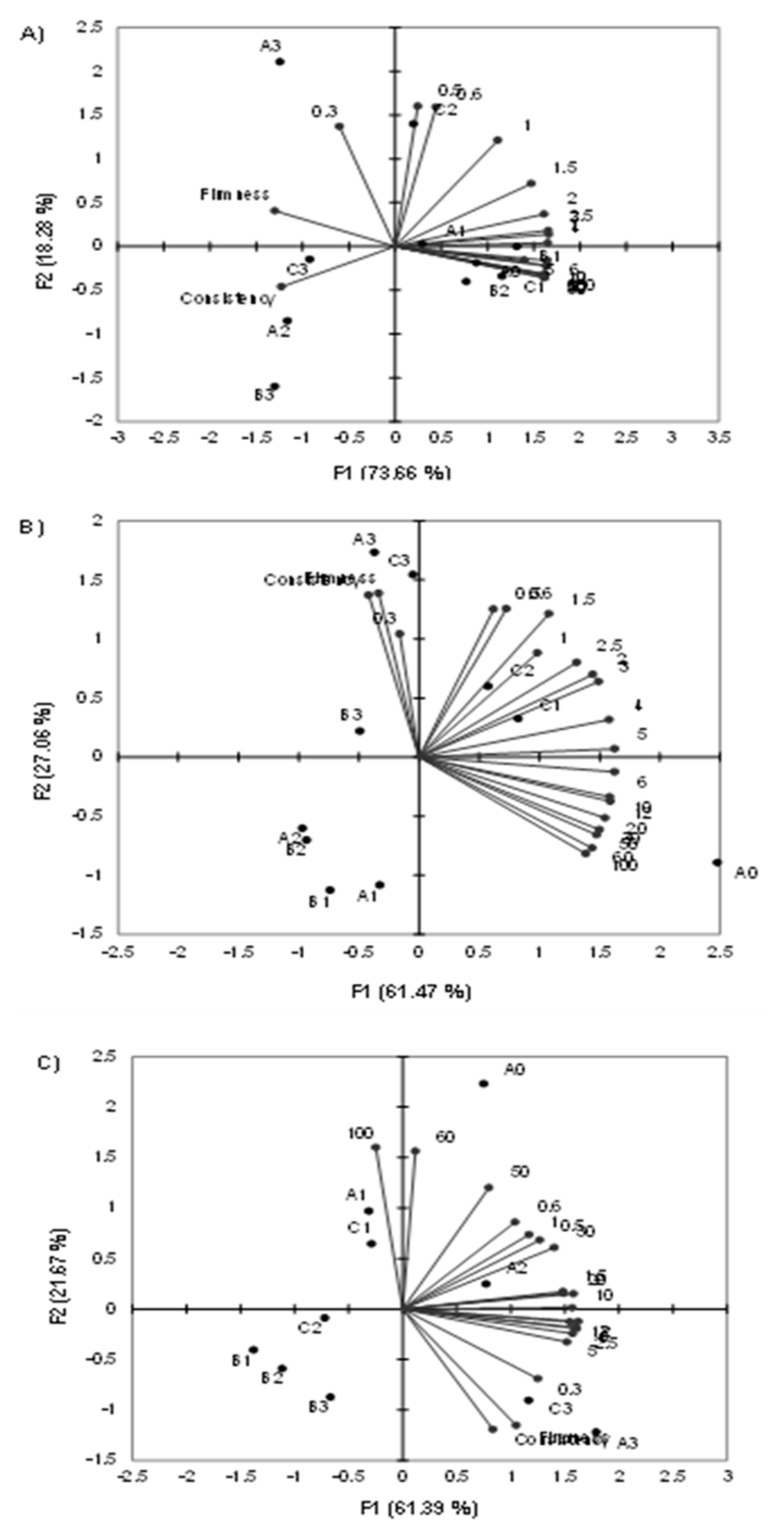

3.4. Principal Component Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pichler, A.; Pozderović, A.; Pavlović, J. Influence of sugars, modified starches and hydrocolloids additions on the rheological properties of raspberry cream filling. Czech J. Food Sci. 2012, 30, 227–235. [Google Scholar] [CrossRef]

- Avallone, R.; Cosenza, F.; Farina, F.; Baraldi, C.; Baraldi, M. Extraction and purification from Ceratonia siliqua of compounds acting on central and peripheral benzodiazepine receptors. Fitoterapia 2002, 73, 390–396. [Google Scholar] [CrossRef]

- Vitali Čepo, D.; Mornar, A.; Nigović, B.; Kremer, D.; Radanović, D.; Dragojević, I.V. Optimization of roasting conditions as an useful approach for increasing antioxidant activity of carob powder. LWT Food Sci. Technol. 2014, 58, 578–586. [Google Scholar] [CrossRef]

- Yousef, M.K.E.; El-Manfaloty, M.M.; Ali, H.M. Assessment of proximate chemical composition, nutritional status, fatty acid composition and phenolic compounds of carob (Ceratonia siliqua L.). Food Public Health 2013, 3, 304–308. [Google Scholar]

- Setser, C.S.; Brannan, G.D. Carbohydrates: Sensory properties. In Encyclopedia of Food Sciences and Nutrition; Caballero, B., Ed.; Academic Press: Cambridge, MA, USA, 2003; pp. 899–905. [Google Scholar]

- Hussain, R.; Singh, A.; Vatankhah, H.; Ramaswamy, H.S. Effect of locust bean gum on the structural and rheological properties of resistant corn starch. J. Food Sci. Technol. 2017, 54, 650–658. [Google Scholar] [CrossRef] [PubMed]

- Dakia, P.A.; Wathelet, B.; Paquot, M. Isolation and chemical evaluation of carob (Ceratonia siliqua L.) seed germ. Food Chem. 2007, 102, 1368–1374. [Google Scholar] [CrossRef]

- Benković, M.; Srečec, S.; Bauman, I.; Ježek, D.; Karlović, S.; Kremer, D.; Karlović, K.; Erhatić, R. Assessment of drying characteristics and texture in relation with micromorphological traits of carob pods and seeds (Ceratonia silliqua L.). Food Technol. Biotechnol. 2016, 54, 432–440. [Google Scholar] [CrossRef] [PubMed]

- Toğrul, H.; Arslan, N. Mathematical model for prediction of apparent viscosity of molasses. J. Food Eng. 2004, 62, 281–289. [Google Scholar] [CrossRef]

- Chai, T.; Draxler, R.R. Root mean square error (RMSE) or mean absolute error (MAE)?—Arguments against avoiding RMSE in the literature. Geosci. Model Dev. 2014, 7, 1247–1250. [Google Scholar] [CrossRef]

- Viswanath, D.S.; Ghosh, T.K.; Prasad, D.H.; Dutt, N.V.; Rani, K.Y. (Eds.) Viscosities of solutions and mixtures. In Viscosity of Liquids; Springer: Dordrecht, The Netherlands, 2007; pp. 407–442. [Google Scholar]

- Yaşar, K.; Kahyaoglu, T.; Şahan, N. Dynamic rheological characterization of salep glucomannan/galactomannan-based milk beverages. Food Hydrocoll. 2009, 23, 1305–1311. [Google Scholar] [CrossRef]

- Sittikijyothin, W.; Torres, D.; Gonçalves, M.P. Modelling the rheological behaviour of galactomannan aqueous solutions. Carbohydr. Poly. 2005, 59, 339–350. [Google Scholar] [CrossRef]

- Björn, A.; de La Monja, P.S.; Karlsson, A.; Ejlertsson, J.; Svensson, B.H. Rheological Characterization. In Biogas; Kumar, S., Ed.; InTech: London, UK, 2012. [Google Scholar]

- Rao, M. Flow and functional models for rheological properties of fluid foods. In Rheology of Fluid, Semisolid, and Solid Foods, 3rd ed.; Food Engineering Series; Springer: Boston, MA, USA, 2014; pp. 27–61. [Google Scholar]

- Swami, S.; Thakor, N.S.; Wagh, S.S. Effect of temperature on viscosity of kokum, karonda, mango pulp and cashew apple syrup. Agric. Eng. Int. CIGR J. 2013, 15, 281–287. [Google Scholar]

- Adebowale, A.-R.A.; Sanni, L.O. Effects of solid content and temperature on viscosity of tapioca meal. J. Food Sci. Technol. 2013, 50, 573–578. [Google Scholar] [CrossRef] [PubMed]

- Barak, S.; Mudgil, D. Locust bean gum: Processing, properties and food applications—A review. Int. J. Biol. Macromol. 2014, 66, 74–80. [Google Scholar] [CrossRef] [PubMed]

- Carpin, M.; Bertelsen, H.; Dalberg, A.; Bech, J.K.; Risbo, J.; Schuck, P.; Jeantet, R. How does particle size influence caking in lactose powder? J. Food Eng. 2017, 209, 61–67. [Google Scholar] [CrossRef]

- Konijn, B.J.; Sanderink, O.B.J.; Kruyt, N.P. Experimental study of the viscosity of suspensions: Effect of solid fraction, particle size and suspending liquid. Powder Technol. 2014, 266, 61–69. [Google Scholar] [CrossRef]

- Goulas, V.; Stylos, E.; Chatziathanasiadou, M.V.; Mavromoustakos, T.; Tzakos, A.G. Functional components of carob fruit: Linking the chemical and biological space. Int. J. Mol. Sci. 2016, 17, 1875. [Google Scholar] [CrossRef] [PubMed]

- Agudelo, A.; Varela, P.; Fiszman, S. Fruit fillings development: A multiparametric approach. LWT Food Sci. Technol. 2015, 61, 564–572. [Google Scholar] [CrossRef]

| SET (A) | SET (B) | SET (C) | |||

|---|---|---|---|---|---|

| Sample Name | Composition | Sample Name | Composition | Sample Name | Composition |

| A0 | 15 g cocoa powder | B0 | 15 g cocoa powder | C0 | 15 g cocoa powder |

| A1 | 10 g cocoa powder 5 g seedless carob flour | B1 | 10 g cocoa powder 5 g carob flour with naturally present seeds | C1 | 10 g cocoa powder 5 g seedless carob flour 0.15 g LBG |

| A2 | 5 g cocoa powder 10 g seedless carob flour | B2 | 5 g cocoa powder 10 g carob flour with naturally present seeds | C2 | 5 g cocoa powder 10 g seedless carob flour 0.3 g LBG |

| A3 | 15 g seedless carob flour | B3 | 15 g carob flour with naturally present seeds | C3 | 15 g seedless carob flour 0.45 g LBG |

| 45 °C | 60 °C | 80 °C | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sample | k (Pasn) | n | R2 | RMSE (Pa) | MPE (%) | k (Pasn) | n | R2 | RMSE (Pa) | MPE (%) | k (Pasn) | n | R2 | RMSE (Pa) | MPE (%) |

| A0 | 4.58 * | 0.74 * | 0.9971 | 0.13 | 12.84 | 6.78 * | 0.67 * | 0.9999 | 0.02 | 4.77 | 3.94 * | 0.53 * | 0.9266 | 0.51 | 25.78 |

| A1 | 4.08 * | 0.81 * | 0.9995 | 0.05 | 6.43 | 3.78 * | 0.80 * | 0.9993 | 0.05 | 9.24 | 3.55 * | 0.67 * | 0.9823 | 0.24 | 25.87 |

| A2 | 2.53 * | 0.78 * | 0.9992 | 0.04 | 12.67 | 2.49 * | 0.79 * | 0.9986 | 0.05 | 7.13 | 2.72 * | 0.39 * | 0.8669 | 0.42 | 30.51 |

| A3 | 2.24 * | 0.76 * | 0.9969 | 0.07 | 8.26 | 2.18 * | 0.55 * | 0.9653 | 0.20 | 19.13 | 2.61 * | 0.20 * | 0.9050 | 0.26 | 15.42 |

| B0 | 4.58 * | 0.74 * | 0.9971 | 0.13 | 10.00 | 6.78 * | 0.67 * | 0.9999 | 0.02 | 4.77 | 3.94 * | 0.53 * | 0.9266 | 0.51 | 25.78 |

| B1 | 5.15 * | 0.78 * | 0.9996 | 0.05 | 10.00 | 3.09 * | 0.82 * | 0.9996 | 0.03 | 5.13 | 2.37 * | 0.82 * | 0.9994 | 0.03 | 17.87 |

| B2 | 4.63 * | 0.78 * | 0.9999 | 0.03 | 9.14 | 2.56 * | 0.79 * | 0.9987 | 0.05 | 8.98 | 2.42 * | 0.74 * | 0.9954 | 0.09 | 23.43 |

| B3 | 2.90 * | 0.82 * | 0.9995 | 0.03 | 13.46 | 2.29 * | 0.60 * | 0.9906 | 0.11 | 20.97 | 2.32 * | 0.53 * | 0.9740 | 0.18 | 20.78 |

| C0 | 4.58 * | 0.74 * | 0.9971 | 0.13 | 10.00 | 6.78 * | 0.67 * | 0.9999 | 0.02 | 4.77 | 3.94 * | 0.53 * | 0.9266 | 0.51 | 25.78 |

| C1 | 4.84 * | 0.76 * | 0.9997 | 0.05 | 8.11 | 4.08 * | 0.67 * | 0.9874 | 0.23 | 11.58 | 3.25 * | 0.59 * | 0.9579 | 0.33 | 32.02 |

| C2 | 3.49 * | 0.76 * | 0.9989 | 0.06 | 11.65 | 3.37 * | 0.59 * | 0.9830 | 0.21 | 10.76 | 2.88 * | 0.73 * | 0.9889 | 0.16 | 25.49 |

| C3 | 2.77 * | 0.81 * | 0.9983 | 0.07 | 11.98 | 2.27 * | 0.48 * | 0.9651 | 0.19 | 24.29 | 2.08 * | 0.14 * | 0.8319 | 0.20 | 18.52 |

| 45 °C | 60 °C | 80 °C | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sample | τy | k (Pasn) | n | R2 | MPE (%) | RMSE (Pa) | τy | k (Pasn) | n | R2 | MPE (%) | RMSE (Pa) | τy | k (Pasn) | n | R2 | RMSE (Pa) | MPE (%) |

| A0 | −0.08 | 4.75 * | 0.71 * | 0.9969 | 9.69 | 0.15 | 0.07 | 6.62 * | 0.69 * | 0.9993 | 3.47 | 0.10 | 1.31 * | 2.31 | 1.36 | 0.8807 | 0.63 | 21.80 |

| A1 | 0.11 * | 3.93 * | 0.87 * | 0.9997 | 7.12 | 0.04 | 0.09 * | 3.63 * | 0.88 * | 0.9998 | 5.34 | 0.03 | 0.46 * | 2.97 * | 0.96 * | 0.9984 | 0.07 | 8.48 |

| A2 | 0.02 | 2.50 * | 0.80 * | 0.9993 | 7.83 | 0.04 | 0.13 | 2.32 * | 0.89 * | 0.9974 | 8.93 | 0.07 | 1.52 * | 0.90 * | 2.00 * | 0.7917 | 0.46 | 27.48 |

| A3 | 0.16 * | 2.04 * | 0.90 * | 0.9976 | 9.62 | 0.6 | 0.41 * | 1.70 * | 0.95 * | 0.9901 | 7.72 | 0.10 | 1.57 * | 0.91 | 0.62 | 0.3754 | 0.83 | 21.33 |

| B0 | −0.08 | 4.75 * | 0.71 * | 0.9969 | 9.69 | 0.15 | 0.07 | 6.62 * | 0.69 * | 0.9993 | 3.47 | 0.10 | 1.31 * | 2.31 | 1.36 | 0.8807 | 0.63 | 21.80 |

| B1 | 0.04 | 5.09 * | 0.79 * | 0.9997 | 7.67 | 0.05 | 0.03 | 3.08 * | 0.84 * | 0.9992 | 6.59 | 0.05 | 0.07 * | 2.28 * | 0.89 * | 0.9993 | 0.04 | 9.49 |

| B2 | 0.05 | 4.53 * | 0.80 * | 0.9995 | 7.61 | 0.06 | 0.12 * | 2.40 * | 0.88 * | 0.9986 | 7.64 | 0.05 | 0.17 * | 2.20 * | 0.89 * | 0.9994 | 0.03 | 6.70 |

| B3 | −0.05 | 2.99 * | 0.78 * | 0.9991 | 6.40 | 0.05 | 0.25 * | 2.00 * | 0.80 * | 0.9987 | 6.03 | 0.04 | 0.39 * | 1.88 * | 0.87 * | 0.9950 | 0.08 | 8.43 |

| C0 | −0.08 | 4.75 * | 0.71 * | 0.9969 | 9.69 | 0.15 | 0.07 | 6.62 * | 0.69 * | 0.9993 | 3.47 | 0.10 | 1.31 * | 2.31 | 1.36 | 0.8807 | 0.63 | 21.80 |

| C1 | 0.02 | 4.82 * | 0.76 * | 0.9997 | 7.78 | 0.05 | 0.45 * | 3.52 * | 0.90 * | 0.9981 | 7.22 | 0.09 | 0.57 * | 2.54 * | 1.02 * | 0.9880 | 0.17 | 10.64 |

| C2 | 0.19 * | 3.25 * | 0.86 * | 0.9986 | 8.75 | 0.07 | 0.45 * | 2.84 * | 0.85 * | 0.9973 | 8.55 | 0.09 | 0.34 * | 2.45 * | 0.98 * | 0.9926 | 0.13 | 12.49 |

| C3 | 0.15 * | 2.59 * | 0.91 * | 0.9976 | 9.32 | 0.07 | 0.44 * | 1.78 * | 0.83 * | 0.9919 | 7.66 | 0.09 | 1.45 * | 0.93 * | 1.59 * | 0.8862 | 0.27 | 11.67 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benković, M.; Bosiljkov, T.; Semić, A.; Ježek, D.; Srečec, S. Influence of Carob Flour and Carob Bean Gum on Rheological Properties of Cocoa and Carob Pastry Fillings. Foods 2019, 8, 66. https://doi.org/10.3390/foods8020066

Benković M, Bosiljkov T, Semić A, Ježek D, Srečec S. Influence of Carob Flour and Carob Bean Gum on Rheological Properties of Cocoa and Carob Pastry Fillings. Foods. 2019; 8(2):66. https://doi.org/10.3390/foods8020066

Chicago/Turabian StyleBenković, Maja, Tomislav Bosiljkov, Amela Semić, Damir Ježek, and Siniša Srečec. 2019. "Influence of Carob Flour and Carob Bean Gum on Rheological Properties of Cocoa and Carob Pastry Fillings" Foods 8, no. 2: 66. https://doi.org/10.3390/foods8020066

APA StyleBenković, M., Bosiljkov, T., Semić, A., Ježek, D., & Srečec, S. (2019). Influence of Carob Flour and Carob Bean Gum on Rheological Properties of Cocoa and Carob Pastry Fillings. Foods, 8(2), 66. https://doi.org/10.3390/foods8020066