Optimization of Cactus Pear Fruit Fermentation Process for Wine Production

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Cactus Pear Fruit Juice Extraction

2.3. Cactus Pear Fruit Must Development

2.4. Fermentation

2.4.1. Inoculum Preparation

2.4.2. Fermentation and Stabilization

2.5. Physicochemical Analysis of the Wine

2.5.1. Experimental Uncertainty

2.5.2. Total Acidity (TA)

2.5.3. Total Antioxidant Content

2.5.4. Estimating Alcohol Content

2.5.5. Sensory Evaluation

2.6. Experimental Design and Data Analysis

3. Results and Discussion

3.1. Statistical Analysis

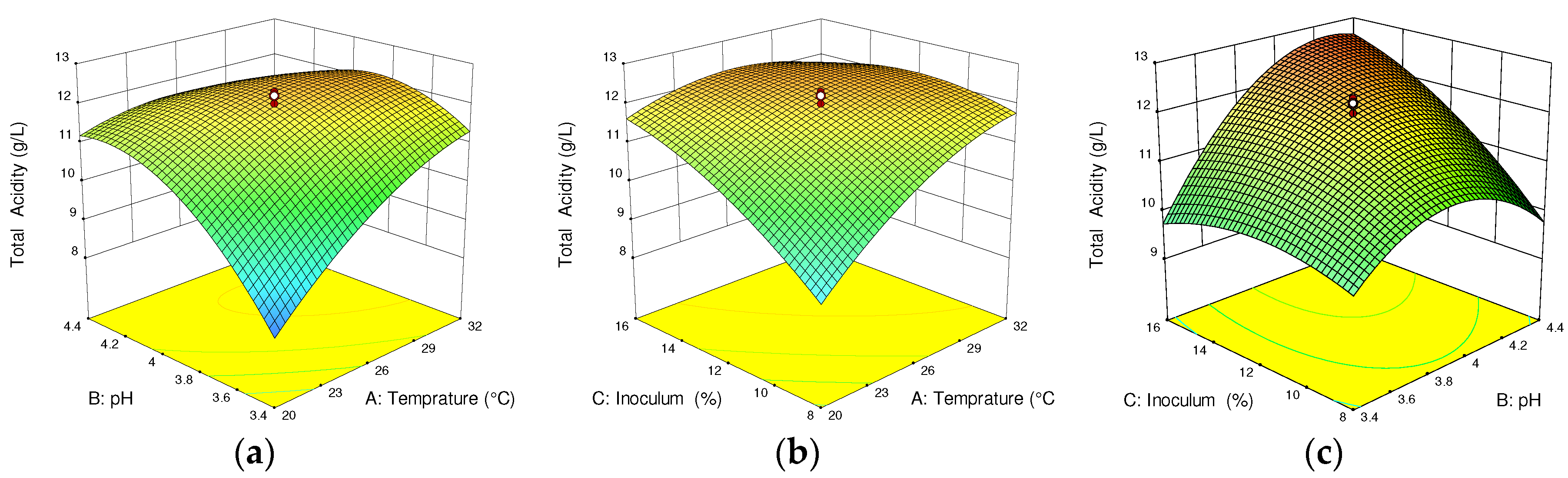

3.2. Effects of Independent Variables on the Final Wine

3.3. Optimization Process Parameters of the Fermentation

3.4. Validating Output Parameters of the Predictive Model

3.5. Simultaneous Optimization of the Fermentation Parameters for Overall Responses of the Wine

3.6. Validating the Fermentation Parameters’ Combined Effects on Desired Responses of the Wine

3.7. Limitation of the Study

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jeandet, P.; Heinzmann, S.S.; Roullier-Gall, C.; Cilindre, C.; Aron, A.; Deville, M.A.; Moritz, F.; Karbowiak, T.; Demarville, D.; Brun, C.; et al. Chemical messages in 170-year-old champagne bottles from the Baltic Sea: Revealing tastes from the past. Proc. Natl. Acad. Sci. USA 2015, 112, 5893–5898. [Google Scholar] [PubMed]

- Kosseva, M.; Joshi, V.; Panesar, P. Science and Technology of Fruit Wine Production; Academic Press: San Diego, CA, USA, 2017. [Google Scholar]

- Navarrete-Bolaños, J.; Fato-Aldeco, E.; Gutiérrez-Moreno, K.; Botello-Álvarez, J.; Jiménez-Islas, H.; Rico-Martínez, R. A Strategy to Design Efficient Fermentation Processes for Traditional Beverages Production: Prickly Pear Wine. J. Food Sci. 2013, 78, M1560–M1568. [Google Scholar] [PubMed]

- Galati, E.M.; Mondello, M.R.; Giuffrida, D.; Dugo, G.; Miceli, N.; Pergolizzi, S.; Taviano, M.F. Chemical characterization and biological effects of Sicilian Opuntia ficus indica (L.) Mill. fruit juice: antioxidant and antiulcerogenic activity. J. Agric. Food Chem. 2003, 51, 4903–4908. [Google Scholar] [CrossRef] [PubMed]

- Medina, E.D.; Rodríguez, E.R.; Romero, C.D. Chemical characterization of Opuntia dillenii and Opuntia ficus indica fruits. Food Chem. 2007, 103, 38–45. [Google Scholar] [CrossRef]

- Sáenz, C. Utilization of Opuntia spp. fruits in food products. Agro-industrial Utilization of Cactus Pear; FAO: Rome, Italy, 2013; pp. 31–43. [Google Scholar]

- Ayed, L.; Hamdi, M. Manufacture of a beverage from cactus pear juice using “tea fungus” fermentation. Ann. Microbiol. 2015, 65, 2293–2299. [Google Scholar] [CrossRef]

- Bustos, O.E. Alcoholic Beverage from Chilean (Opuntia Ficus Indica). Am. J. Enol. Vitic. 1981, 32, 228–229. [Google Scholar]

- Rodríguez-Lerma, G.K.; Gutiérrez-Moreno, K.; Cárdenas-Manríquez, M.; Botello-Álvarez, E.; Jiménez-Islas, H.; Rico-Martínez, R.; Navarrete-Bolaños, J.L. Microbial Ecology Studies of Spontaneous Fermentation: Starter Culture Selection for Prickly Pear Wine Production. J. Food Sci. 2011, 76, M346–M352. [Google Scholar] [CrossRef] [PubMed]

- Jacobson, J.L. Introduction to Wine Laboratory Practices and Procedures; Springer Science & Business Media: New York, NY, USA, 2006. [Google Scholar]

- Peng, B.; Lei, Y.; Zhao, H.; Cui, L. Response surface methodology for optimization of fermentation process parameters for improving apple wine quality. J. Food Sci. Technol. 2015, 52, 7513–7518. [Google Scholar] [CrossRef]

- Sharma, N.; Bhutia, S.P.; Aradhya, D. Process Optimization for Fermentation of Wine from Jackfruit (Artocarpus heterophyllus Lam). J. Food Process. Technol. 2013, 4, 204. [Google Scholar] [CrossRef]

- Oberoi, H.S.; Vadlani, P.V.; Nanjundaswamy, A.; Bansal, S.; Singh, S.; Kaur, S.; Babbar, N. Enhanced ethanol production from Kinnow mandarin (Citrus reticulata) waste via a statistically optimized simultaneous saccharification and fermentation process. Bioresour. Technol. 2011, 102, 1593–1601. [Google Scholar] [CrossRef] [PubMed]

- Sudheer Kumar, Y.; Prakasam, R.S.; Reddy, O.V.S. Optimisation of fermentation conditions for mango (Mangifera indica L.) wine production by employing response surface methodology. Int. J. Food Sci. Technol. 2009, 44, 2320–2327. [Google Scholar]

- International Organisation of Vine and Wine. Compendium of International Methods of Wine and Must Analysis; International Organisation of Vine and Wine: Paris, France, 2016; pp. 331–335. [Google Scholar]

- Nielsen, S.S. Phenol-sulfuric acid method for total carbohydrates. Food Analysis Laboratory Manual; Springer: Cham, Switzerland, 2010; pp. 47–53. [Google Scholar]

- International Organisation of Vine and Wine. Compendium of International Methods of Wine and Must Analysis; International Organisation of Vine and Wine: Paris, France, 2017. [Google Scholar]

- Colin, R.; Bridget, R. Standard Uncertainty of a Measurement. In Doubt-Free Uncertainty in Measurement: An Introduction for Engineers and Students; Springer International Publishing: Cham, Switzerland, 2015; pp. 19–31. [Google Scholar]

- Crowell, E.A.; Ough, C.S. A Modified Procedure for Alcohol Determination by Dichromate Oxidation. Am. J. Enol. Vitic. 1979, 30, 61–63. [Google Scholar]

- Babu, S.; Harinikumar, K.; Singh, R.K.; Pandey, A. Optimization of bioethanol production from fruit wastes using isolated microbial strains. Int. J. Adv. Biotechnol. Res. 2014, 5, 598–604. [Google Scholar]

- Wichchukit, S.; O’Mahony, M. The 9-point hedonic scale and hedonic ranking in food science: Some reappraisals and alternatives. J. Sci. Food Agric. 2015, 95, 2167–2178. [Google Scholar] [PubMed]

- Desai, K.M.; Survase, S.A.; Saudagar, P.S.; Lele, S.S.; Singhal, R.S. Comparison of artificial neural network (ANN) and response surface methodology (RSM) in fermentation media optimization: Case study of fermentative production of scleroglucan. Biochem. Eng. J. 2008, 41, 266–273. [Google Scholar] [CrossRef]

- Firew, T.; Peters, K.J.; Kijora, C. Current uses of cactus pear (Opuntia ficus-indica) as forage in Northern Ethiopia and farmers’ indigenous knowledge on its utilisation. Ethiop. J. Anim. Prod. 2008, 8, 10–21. [Google Scholar]

- Arrizon, J.; Calderón, C.; Sandoval, G. Effect of different fermentation conditions on the kinetic parameters and production of volatile compounds during the elaboration of a prickly pear distilled beverage. J. Ind. Microbiol. Biotechnol. 2006, 33, 921–928. [Google Scholar] [PubMed]

- Torija, M.J.; Rozès, N.; Poblet, M.; Guillamón, J.M.; Mas, A. Effects of fermentation temperature on the strain population of Saccharomyces cerevisiae. Int. J. Food Microbiol. 2003, 80, 47–53. [Google Scholar] [CrossRef]

- Stintzing, F.C.; Schieber, A.; Carle, R. Phytochemical and nutritional significance of cactus pear. Eur. Food Res. Technol. 2001, 212, 396–407. [Google Scholar] [CrossRef]

- Vilanova, M.; Masneuf-Pomarède, I.; Dubourdieu, D. Influence of Saccharomyces cerevisiae strains on general composition and sensorial properties of white wines made from Vitis vinifera cv. Albariño. Food Technol. Biotechnol. 2005, 43, 79–83. [Google Scholar]

- Phutela, U.G.; Kaur, J. Process Optimization for Ethanol Production from Sweet Sorghum Juice Using Saccharomyces cerevisiae Strain NRRL Y–2034 by Response Surface Methodology. Sugar Technol. 2014, 16, 411–421. [Google Scholar]

- Reynolds, A.G.; Edwards, C.G.; Cliff, M.A.; Thorngate, J.H.; Marr, J.C. Evaluation of Yeast Strains during Fermentation of Riesling and Chenin blanc Musts. Am. J. Enol. Vitic. 2001, 52, 336–344. [Google Scholar]

- Ivanova, V.; Vojnoski, B.; Stefova, M. Effect of winemaking treatment and wine aging on phenolic content in Vranec wines. J. Food Sci. Technol. 2012, 49, 161–172. [Google Scholar] [CrossRef] [PubMed]

- Wine and Spirits Board (WSB). European Wine Regulations (Guide to EU Wine Regulations Table Wine 2005). pp. 6–8. Available online: https://max.book118.com/html/2015/1009/26917176.shtm (accessed on 9 October 2015).

- International Organisation of Vine and Wine. Compendium of International Methods of Wine and Must Analysis; International Organisation of Vine and Wine: Paris, France, 2015; pp. 154–196. [Google Scholar]

- Kelebek, H.; Selli, S.; Canbas, A.; Cabaroglu, T. HPLC determination of organic acids, sugars, phenolic compositions and antioxidant capacity of orange juice and orange wine made from a Turkish cv. Kozan. Microchem. J. 2009, 91, 187–192. [Google Scholar] [CrossRef]

- Owusu, J.; Ma, H.; Wang, Z.; Afoakwah, N.A.; Zhou, C.; Amissah, A. Effect of pH and Temperature on Antioxidant Levels of Tomato Wine. J. Food Biochem. 2015, 39, 91–100. [Google Scholar] [CrossRef]

- De Castilhos, M.B.M.; Conti-Silva, A.C.; Del Bianchi, V.L. Effect of grape pre-drying and static pomace contact on physicochemical properties and sensory acceptance of Brazilian (Bordô and Isabel) red wines. Eur. Food Res. Technol. 2012, 235, 345–354. [Google Scholar] [CrossRef]

- Ray, R.C.; Panda, S.K.; Swain, M.R.; Sivakumar, P.S. Proximate composition and sensory evaluation of anthocyanin-rich purple sweet potato (Ipomoea batatas L.) wine. Intern. J. Food Sci. Technol. 2012, 47, 452–458. [Google Scholar]

- Montgomery, D.C. Design and Analysis of Experiments; Wiley: New York, NY, USA, 2002. [Google Scholar]

| Factors | Factor Levels | ||||

|---|---|---|---|---|---|

| −α | −1 | 0 | 1 | +α | |

| Temperature (°C) | 16 | 20 | 26 | 32 | 36 |

| pH | 3.1 | 3.4 | 3.9 | 4.4 | 4.7 |

| Inoculum concentration (%, v/v) | 5 | 8 | 12 | 16 | 19 |

| Std | Run | Temp. (°C) | pH | IC (%) | Y1 | Y2 | Y3 | Y4 |

|---|---|---|---|---|---|---|---|---|

| TA (g/L Tartaric Acid) | Alc (%, v/v) | Anc (mg/L AAE) | Sensory | |||||

| 1 | 20 | (−1)20 | (−1)3.4 | (−1)8 | 8.2 | 6.2 | 147.3 | 7.6 |

| 2 | 10 | (+1)32 | (−1)3.4 | (−1)8 | 11.9 | 7.3 | 190.5 | 6.3 |

| 3 | 14 | (−1)20 | (+1)4.4 | (−1)8 | 9.4 | 7.9 | 189.8 | 6.1 |

| 4 | 5 | (+1)32 | (+1)4.4 | (−1)8 | 10.9 | 7.4 | 187.6 | 5.8 |

| 5 | 11 | (−1)20 | (−1)3.4 | (+1)16 | 7.6 | 7.2 | 190.8 | 8 |

| 6 | 6 | (+1)32 | (−1)3.4 | (+1)16 | 9.8 | 8.8 | 238.6 | 7.7 |

| 7 | 3 | (−1)20 | (+1)4.4 | (+1)16 | 13.1 | 7.4 | 195.8 | 6.7 |

| 8 | 2 | (+1)32 | (+1)4.4 | (+1)16 | 10.5 | 9.4 | 239.3 | 7.4 |

| 9 | 12 | (−1.682)16 | (0)3.9 | (0)12 | 8.5 | 7.1 | 198.7 | 6.7 |

| 10 | 8 | (+1.682)36 | (0)3.9 | (0)12 | 11.8 | 9.4 | 254.7 | 5.6 |

| 11 | 1 | (0)26 | (−1.682)3.1 | (0)12 | 7.8 | 6.5 | 178.9 | 7.5 |

| 12 | 19 | (0)26 | (+1.682)4.7 | (0)12 | 9.7 | 8.3 | 210.6 | 7.7 |

| 13 | 9 | (0)26 | (0)3.9 | (−1.682)5 | 7.9 | 6.5 | 178.5 | 6.8 |

| 14 | 4 | (0)26 | (0)3.9 | (+1.682)19 | 13.1 | 8.4 | 220.9 | 7.6 |

| 15 | 18 | (0)26 | (0)3.9 | (0)12 | 12 | 7.8 | 205.8 | 8 |

| 16 | 7 | (0)26 | (0)3.9 | (0)12 | 11.6 | 7.9 | 201.3 | 7.9 |

| 17 | 13 | (0)26 | (0)3.9 | (0)12 | 12.3 | 8.1 | 205.7 | 7.8 |

| 18 | 17 | (0)26 | (0)3.9 | (0)12 | 12.2 | 8 | 211 | 7.7 |

| 19 | 16 | (0)26 | (0)3.9 | (0)12 | 11.9 | 7.9 | 214.3 | 7.9 |

| 20 | 15 | (0)26 | (0)3.9 | (0)12 | 11.8 | 8.1 | 208.7 | 7.7 |

| Statistical Parameters | Y1 | Y2 | Y3 | Y4 |

|---|---|---|---|---|

| TA (g/L Tartaric Acid) | Alc (%, v/v) | Antc (mg AAE/L) | Sensory | |

| Std. Dev. | 1.32 | 0.31 | 9.15 | 0.36 |

| Mean | 10.60 | 7.78 | 203.44 | 7.22 |

| C.V. % | 12.42 | 4.03 | 4.50 | 4.69 |

| PRESS | 56.11 | 3.73 | 4543.25 | 4.92 |

| R-Squared | 0.6237 | 0.9109 | 0.9159 | 0.8778 |

| Adjusted R-Squared | 0.4894 | 0.8697 | 0.8548 | 0.8066 |

| Predicted R-Squared | 0.1296 | 0.7397 | 0.5853 | 0.5629 |

| Adequacy of Precision | 7.267 | 16.496 | 14.317 | 11.340 |

| Two-sided Confidence = 95% n = 2 | ||||||||

|---|---|---|---|---|---|---|---|---|

| Factor | Name | Optimum Level | Low Level | High Level | Coding | |||

| A | Temp (°C) | 29.71 | 20.00 | 32.00 | Actual | |||

| B | pH | 3.90 | 3.40 | 4.40 | Actual | |||

| C | IC (%) | 16.00 | 8.00 | 16.00 | Actual | |||

| Response | Predicted Mean | Predicted Median | Std Dev | n | SE Pred | 95% PI Low | Measured Data Mean | 95% PI High |

| TA (g/L TTA | 12.3974 | 12.3974 | 1.31622 | 2 | 1.43 | 9.33 | 12.26 | 15.47 |

| Alc (%, v/v) | 8.98313 | 8.98313 | 0.313497 | 2 | 0.35 | 8.23 | 8.89 | 9.74 |

| Anc (mg/L AAE) | 235.304 | 235.304 | 9.14966 | 2 | 10.20 | 212.85 | 221.00 | 257.76 |

| Sensory | 7.74112 | 7.74112 | 0.338527 | 2 | 0.37 | 6.93 | 8.10 | 8.55 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsegay, Z.T.; Sathyanarayana, C.B.; Lemma, S.M. Optimization of Cactus Pear Fruit Fermentation Process for Wine Production. Foods 2018, 7, 121. https://doi.org/10.3390/foods7080121

Tsegay ZT, Sathyanarayana CB, Lemma SM. Optimization of Cactus Pear Fruit Fermentation Process for Wine Production. Foods. 2018; 7(8):121. https://doi.org/10.3390/foods7080121

Chicago/Turabian StyleTsegay, Zenebe Tadesse, Chanukya Basavanahally Sathyanarayana, and Solomon Mengistu Lemma. 2018. "Optimization of Cactus Pear Fruit Fermentation Process for Wine Production" Foods 7, no. 8: 121. https://doi.org/10.3390/foods7080121

APA StyleTsegay, Z. T., Sathyanarayana, C. B., & Lemma, S. M. (2018). Optimization of Cactus Pear Fruit Fermentation Process for Wine Production. Foods, 7(8), 121. https://doi.org/10.3390/foods7080121