Effect of Ultrasonic Treatment on Taste and Flavor Quality of Japonica Rice

Abstract

1. Introduction

2. Materials and Methods

2.1. Reagents

2.2. Sample Collection

2.3. Instruments and Equipment

2.4. Experimental Methodology

2.4.1. Sample Preparation

2.4.2. Resistant Starch Content

2.4.3. Methods of Textural Characterization

2.4.4. Determination of Pasting Characteristics

2.4.5. Electronic Nose Analysis

2.4.6. Determination of Volatile Compounds Based on SPME-GC-MS

Extraction Methods for Volatile Compounds

GC-MS Analytical Methods

2.5. Statistical Analysis

3. Results

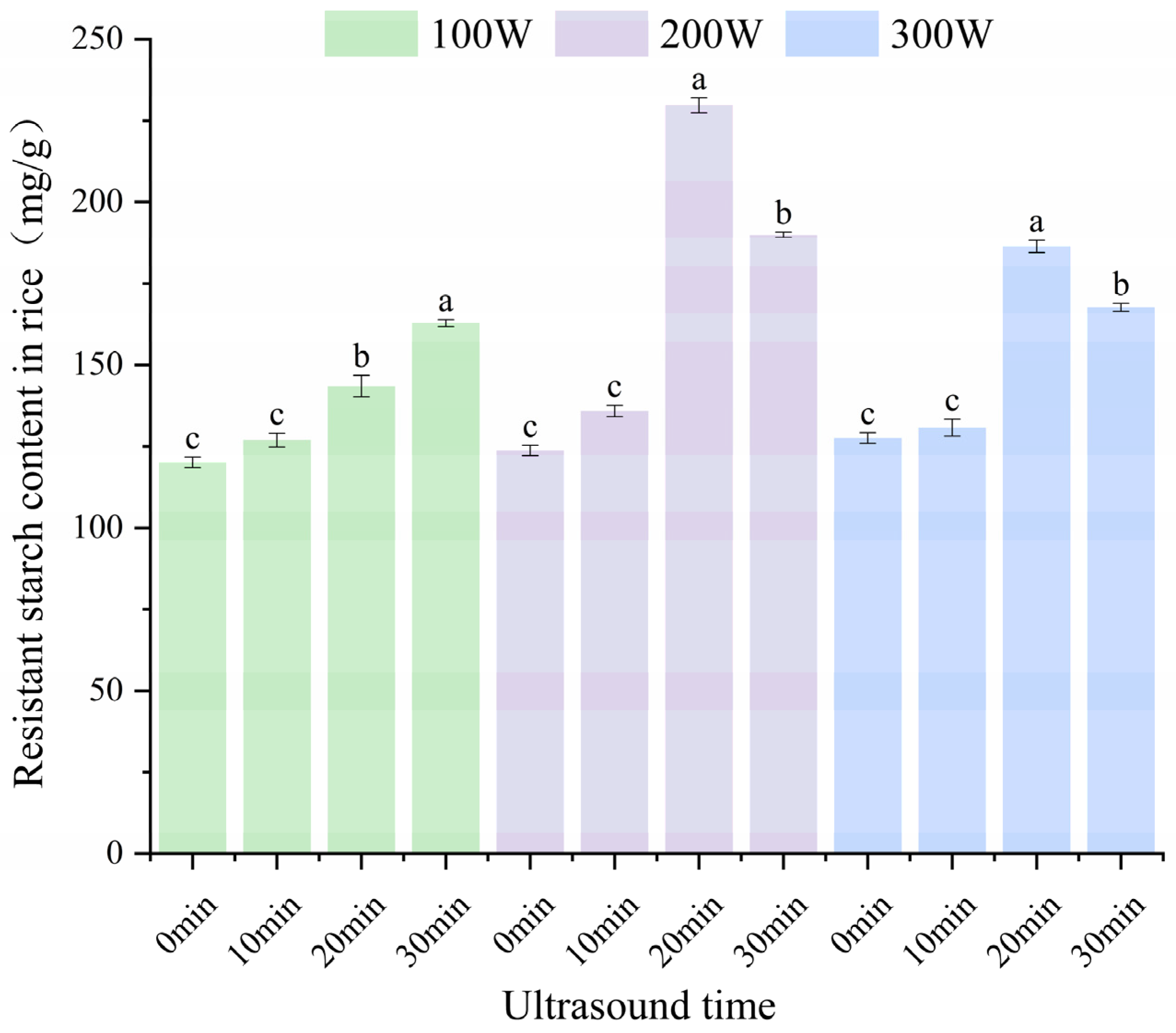

3.1. Changes in Resistant Starch Content

3.2. Properties of Textures

3.3. Pasting Characteristics

3.4. Analysis of Electronic Noses

3.5. GC-MS Data Analysis

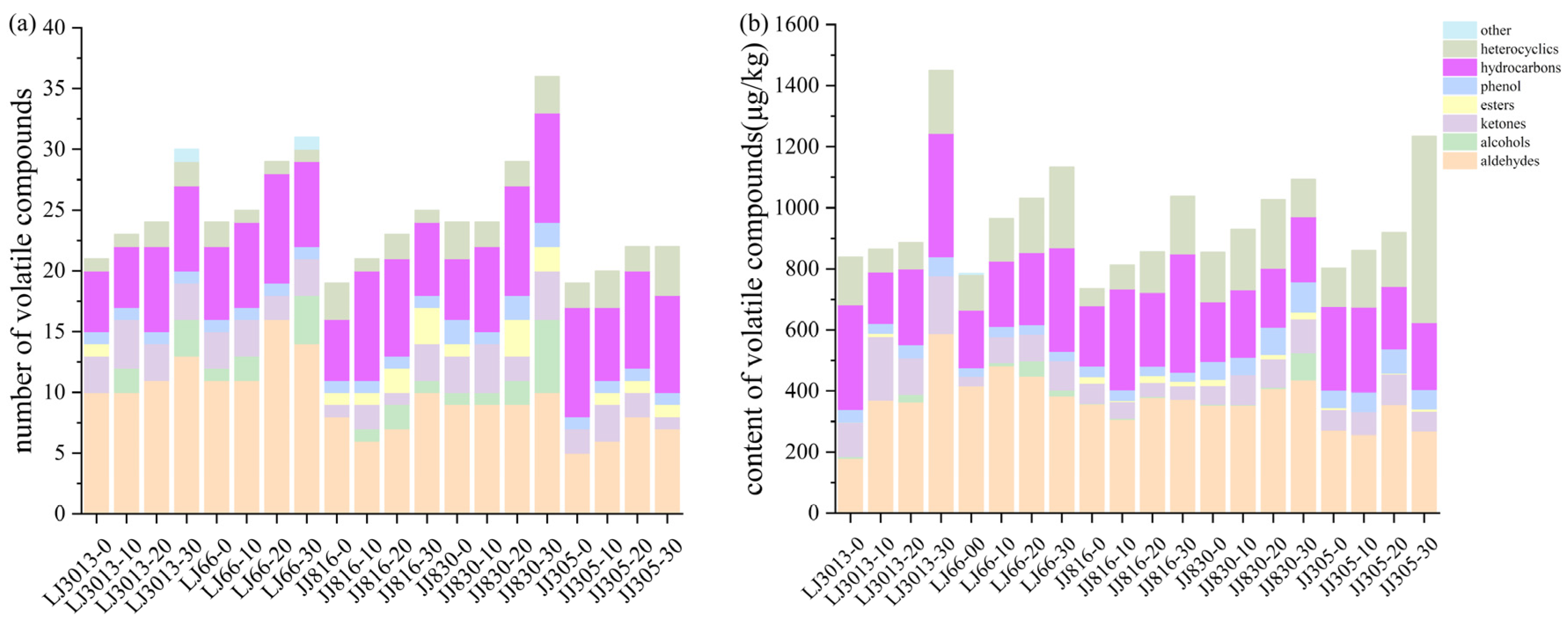

3.5.1. Composition of Aroma Compounds

3.5.2. Aroma Characteristics

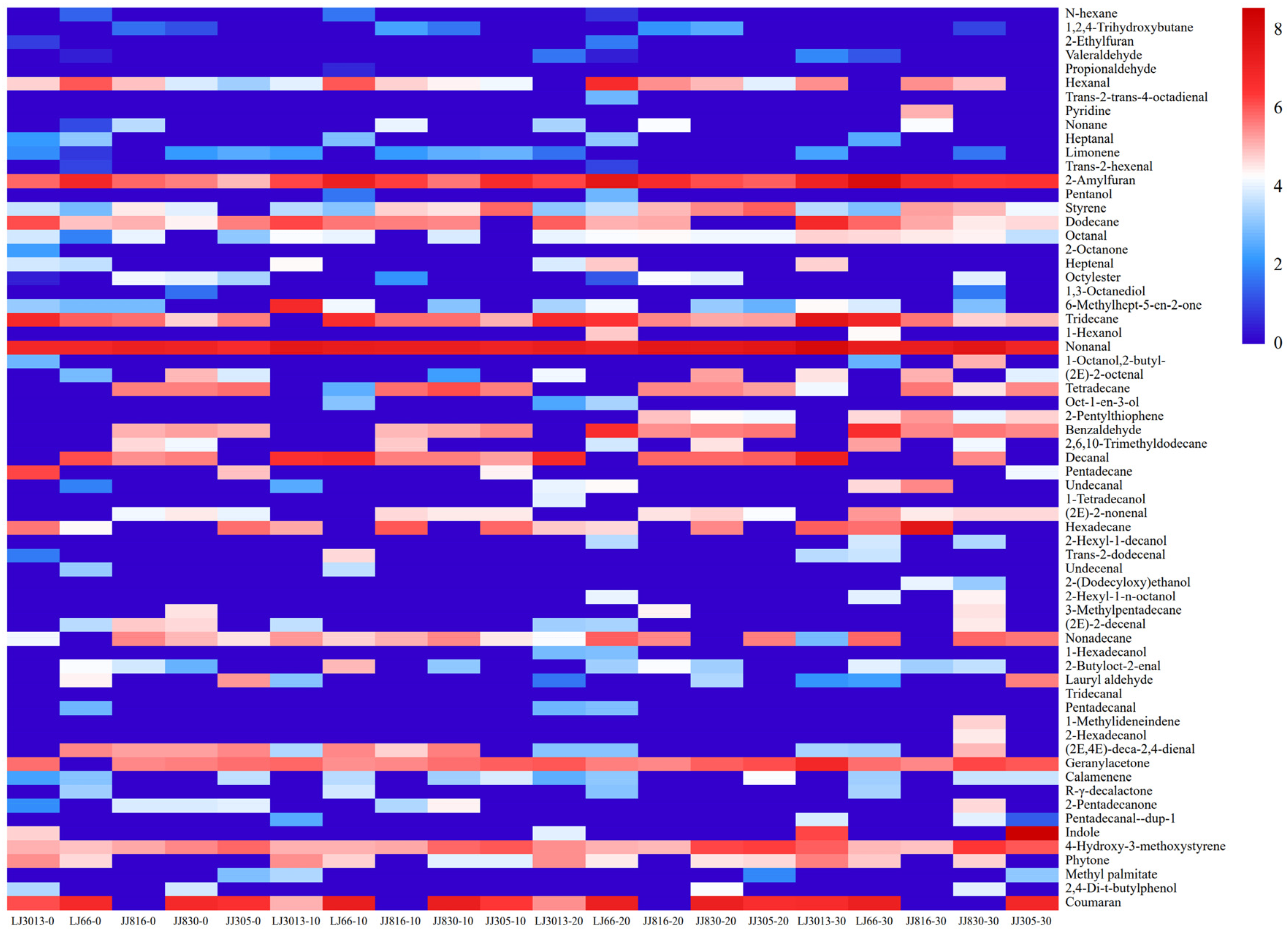

3.5.3. Analysis of Aroma Compounds

3.6. Correlation Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AOAC | Association of Official Analytical Chemists testing resistant starch |

Appendix A

| Sensor Number | Sensor Name | Substance Type | Sensitivity Levels |

|---|---|---|---|

| 1 | W1C | aromatic | Toluene, 10 ppm |

| 2 | W5S | broad range | NO2, 1 ppm |

| 3 | W3C | aromatic | Benzene, 10 ppm |

| 4 | W6S | hydrogen | H2, 100 ppb |

| 5 | W5C | arom-aliph | Propane, 1 ppb |

| 6 | W1S | broad-methane | CH3, 100 ppm |

| 7 | W1W | sulfur-organic | H2S, 1 ppm |

| 8 | W2S | broad-alcohol | CO, 100 ppm |

| 9 | W2W | sulph-chlor | H2S, 1 ppm |

| 10 | W3S | methane-aliph | CH3, 100 ppm |

References

- Hódsági, M.; Gelencsér, T.; Gergely, S.; Salgó, A. In Vitro Digestibility of Native and Resistant Starches: Correlation to the Change of its Rheological Properties. Food Bioprocess Technol. 2012, 5, 1038–1048. [Google Scholar] [CrossRef]

- Zheng, B.; Wang, T.; Wang, H.; Chen, L.; Zhou, Z. Studies on nutritional intervention of rice starch- oleic acid complex (resistant starch type V) in rats fed by high-fat diet. Carbohydr. Polym. 2020, 246, 116637. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Huang, Q.; Luo, F.-X.; Fu, X. Structural characterizations and digestibility of debranched high-amylose maize starch complexed with lauric acid. Food Hydrocoll. 2012, 28, 174–181. [Google Scholar] [CrossRef]

- Kang, X.; Liu, P.; Gao, W.; Wu, Z.; Yu, B.; Wang, R.; Cui, B.; Qiu, L.; Sun, C. Preparation of starch-lipid complex by ultrasonication and its film forming capacity. Food Hydrocoll. 2020, 99, 105340. [Google Scholar] [CrossRef]

- Mariscal-Moreno, R.M.; Figueroa-Cárdenas, J.d.D.; Santiago-Ramos, D.; Rayas-Duarte, P. Amylose lipid complexes formation as an alternative to reduce amylopectin retrogradation and staling of stored tortillas. Int. J. Food Sci. Technol. 2019, 54, 1651–1657. [Google Scholar] [CrossRef]

- De Pilli, T.; Derossi, A.; Talja, R.A.; Jouppila, K.; Severini, C. Study of starch-lipid complexes in model system and real food produced using extrusion-cooking technology. Innov. Food Sci. Emerg. Technol. 2011, 12, 610–616. [Google Scholar] [CrossRef]

- Wang, R.; Liu, P.; Cui, B.; Kang, X.; Yu, B. Effects of different treatment methods on properties of potato starch-lauric acid complex and potato starch-based films. Int. J. Biol. Macromol. 2019, 124, 34–40. [Google Scholar] [CrossRef]

- Ding, Y.; Luo, F.; Lin, Q. Insights into the relations between the molecular structures and digestion properties of retrograded starch after ultrasonic treatment. Food Chem. 2019, 294, 248–259. [Google Scholar] [CrossRef]

- Sit, N.; Misra, S.; Deka, S.C. Yield and Functional Properties of Taro Starch as Affected by Ultrasound. Food Bioprocess Technol. 2014, 7, 1950–1958. [Google Scholar] [CrossRef]

- Zhang, X.; Mi, T.; Gao, W.; Wu, Z.; Yuan, C.; Cui, B.; Dai, Y.; Liu, P. Ultrasonication effects on physicochemical properties of starch–lipid complex. Food Chem. 2022, 388, 133054. [Google Scholar] [CrossRef]

- GB/T 1354-2018; Rice. Standardization Administration of China: Beijing, China, 2018.

- GB/T 15682-2008; Inspection of Grain and Oils—Method for Sensory Evaluation of Paddy or Rice Cooking and Eating Quality. Standardization Administration of China: Beijing, China, 2018.

- Bryant, R.J.; McClung, A.M. Volatile profiles of aromatic and non-aromatic rice cultivars using SPME/GC–MS. Food Chem. 2011, 124, 501–513. [Google Scholar] [CrossRef]

- Liu, Q. Quality Changes and Processing Parameter Effects of Rice Cooker Cooking Indica Rice; Jiangnan University: Wuxi, China, 2018. [Google Scholar]

- Han, C.-M.; Shin, J.-H.; Kwon, J.-B.; Won, J.-G.; Kim, J.-S. Nitrogen fertilization levels influence the physicochemical properties of floury rice varieties. Cereal Chem. 2021, 98, 1259–1270. [Google Scholar] [CrossRef]

- Asimi, S.; Xin, R.; Min, Z.; Sixuan, L.; Lv, Q.; Lingqi, M. Screening new breeding japonica rice varieties by rice quality, three processing characteristics, and odor characteristics. J. Food Sci. 2023, 88, 133–146. [Google Scholar] [CrossRef]

- Ren, X.; Li, S.; Zhang, M.; Guan, L.; Han, W. Geographical discrimination of fresh instant rice according to non-destructive analysis of flavor profiles. Cereal Chem. 2023, 100, 414–423. [Google Scholar] [CrossRef]

- Kang, N.; Zuo, Y.J.; Hilliou, L.; Ashokkumar, M.; Hemar, Y. Viscosity and hydrodynamic radius relationship of high-power ultrasound depolymerised starch pastes with different amylose content. Food Hydrocoll. 2016, 52, 183–191. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Y.; Liu, T.; Wang, D.; Fan, H.; Zhao, H. Effect of Rice Retrogradation Resistant Starch on Processing Characteristics and Microstructure of Rice noodles. J. Jilin Agric. Univ. 2022, 44, 1–10. [Google Scholar] [CrossRef]

- Xu, S.; Sun, X.X.; Lu, H.Z.; Zhang, Q.Q. Detection of Type, Blended Ratio, and Mixed Ratio of Pu’er Tea by Using Electronic Nose and Visible/Near Infrared Spectrometer. Sensors 2019, 19, 2359. [Google Scholar] [CrossRef]

- Jing, M.; Huimin, S.; Min, Z. Analysis of the key flavor compounds in cooked rice. Food Sci. China 2016, 37, 82–86. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, L.; Cheng, M.; Wang, R.; Luo, X.; Li, Y.; Chen, Z. Influence of ultrasonic enzyme treatment on the cooking and eating quality of brown rice. J. Cereal Sci. 2015, 63, 140–146. [Google Scholar] [CrossRef]

- Ma, R.; Tian, Y.; Chen, L.; Jin, Z. Impact of cooling rates on the flavor of cooked rice during storage. Food Biosci. 2020, 35, 100563. [Google Scholar] [CrossRef]

- Dias, L.G.; Hacke, A.; Bergara, S.F.; Villela, O.V.; Mariutti, L.R.B.; Bragagnolo, N. Identification of volatiles and odor-active compounds of aromatic rice by OSME analysis and SPME/GC-MS. Food Res. Int. 2021, 142, 110206. [Google Scholar] [CrossRef]

- Verma, D.K.; Srivastav, P.P. A paradigm of volatile aroma compounds in rice and their product with extraction and identification methods: A comprehensive review. Food Res. Int. 2020, 130, 108924. [Google Scholar] [CrossRef] [PubMed]

- Choi, S.; Seo, H.-S.; Lee, K.R.; Lee, S.; Lee, J.; Lee, J. Effect of milling and long-term storage on volatiles of black rice (Oryza sativa L.) determined by headspace solid-phase microextraction with gas chromatography–mass spectrometry. Food Chem. 2019, 276, 572–582. [Google Scholar] [CrossRef]

- Zhao, Q.; Xi, J.; Xu, D.; Jin, Y.; Wu, F.; Tong, Q.; Yin, Y.; Xu, X. A comparative HS-SPME/GC-MS-based metabolomics approach for discriminating selected japonica rice varieties from different regions of China in raw and cooked form. Food Chem. 2022, 385, 132701. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Liu, K.; Zhang, C. Electronic nose for volatile organic compounds analysis in rice aging. Trends Food Sci. Technol. 2021, 109, 83–93. [Google Scholar] [CrossRef]

- Hu, X.; Lu, L.; Guo, Z.; Zhu, Z. Volatile compounds, affecting factors and evaluation methods for rice aroma: A review. Trends Food Sci. Technol. 2020, 97, 136–146. [Google Scholar] [CrossRef]

- Tananuwong, K.; Lertsiri, S. Changes in volatile aroma compounds of organic fragrant rice during storage under different conditions. J. Sci. Food Agric. 2010, 90, 1590–1596. [Google Scholar] [CrossRef]

- Lu, C.; Zhang, Y.; Zhan, P.; Wang, P.; Tian, H. Characterization of the key aroma compounds in four varieties of pomegranate juice by gas chromatography–mass spectrometry, gas chromatography-olfactometry, odor activity value, aroma recombination, and omission tests. Food Sci. Hum. Wellness 2023, 12, 151–160. [Google Scholar] [CrossRef]

- Zhang, Z.; Blank, I.; Wang, B.; Cao, Y. Changes in odorants and flavor profile of heat-processed beef flavor during storage. J. Food Sci. 2022, 87, 5208–5224. [Google Scholar] [CrossRef]

- Zhang, Z.Q.; Jiang, J.L.; Zang, M.W.; Zhang, K.H.; Li, D.; Li, X.M. Flavor Profile Analysis of Instant and Traditional Lanzhou Beef Bouillons Using HS-SPME-GC/MS, Electronic Nose and Electronic Tongue. Bioengineering 2022, 9, 582. [Google Scholar] [CrossRef]

- Ye, G.; Guan, L.; Zhang, M.; Li, S.; Mi, Y. Study on the correlation between aroma compounds and texture of cooked rice: A case study of 15 Japonica rice species from Northeast China. Cereal Chem. 2025, 102, 167–180. [Google Scholar] [CrossRef]

- Wang, J.; Wang, X.; Chen, Q.; Wang, F.; Li, X.; Yu, J.; Liu, Y. Study on oxidation degradation products of linoleic acid. Food Mach. 2016, 32, 5–10. [Google Scholar] [CrossRef]

| Sort | Ultrasound Time/min | Peak Viscosity/cP | Trough Viscosity/cP | Final Viscosity/cP | Retrogradation Value/cP |

|---|---|---|---|---|---|

| LJ3013 | 0 | 1590 ± 13 a | 1541 ± 12 a | 2333 ± 45 a | 743 ± 4 a |

| 10 | 1516 ± 13 b | 1482 ± 32 b | 2207 ± 23 b | 691 ± 8 b | |

| 20 | 1424 ± 28 c | 1387 ± 28 c | 2075 ± 8 c | 651 ± 13 c | |

| 30 | 1400 ± 18 | 1372 ± 16 c | 2032 ± 13 c | 632 ± 8 c | |

| LJ66 | 0 | 1499 ± 21 a | 1502 ± 23 a | 2209 ± 49 a | 710 ± 6 a |

| 10 | 1402 ± 16 b | 1406 ± 5 b | 2119 ± 17 b | 717 ± 9 a | |

| 20 | 1388 ± 5 b | 1389 ± 0 c | 2082 ± 11 c | 694 ± 1 a | |

| 30 | 1315 ± 22 c | 1318 ± 27 d | 1956 ± 13 d | 641 ± 21 b | |

| JJ816 | 0 | 1574 ± 9 a | 1541 ± 18 a | 2396 ± 13 a | 822 ± 21 a |

| 10 | 1406 ± 13 b | 1375 ± 1 b | 2130 ± 22 b | 724 ± 6 b | |

| 20 | 1170 ± 3 c | 1171 ± 70 c | 1827 ± 9 c | 657 ± 12 c | |

| 30 | 868 ± 98 d | 870 ± 111 d | 1365 ± 98 d | 497 ± 9 d | |

| JJ830 | 0 | 1769 ± 21 a | 1664 ± 49 a | 2684 ± 40 a | 1016 ± 22 a |

| 10 | 1672 ± 7 b | 1406 ± 52 c | 2527 ± 23 b | 915 ± 4 b | |

| 20 | 1571 ± 0 c | 1500 ± 24 b | 2457 ± 37 c | 886 ± 18 c | |

| 30 | 1424 ± 41 d | 1280 ± 45 d | 2440 ± 22 c | 855 ± 24 d | |

| JJ305 | 0 | 1975 ± 14 a | 1980 ± 27 a | 2942 ± 22 a | 983 ± 15 a |

| 10 | 1819 ± 28 b | 1818 ± 16 b | 2711 ± 13 b | 967 ± 1 b | |

| 20 | 1799 ± 22 b | 1804 ± 4 b | 2636 ± 19 c | 892 ± 18 c | |

| 30 | 1550 ± 71 c | 1550 ± 52 c | 2533 ± 62 d | 837 ± 34 d |

| No. | Aroma Compounds | Aroma Characteristics | Odor Threshold (μg/kg) | Before Ultrasound rOAV | After Ultrasound rOAV |

|---|---|---|---|---|---|

| 1 | Pentanal | Almond, malt, pungent | 20 | <1 | <1 |

| 2 | Hexanal | Grass | 5 | 2.83 | 20.89 |

| 3 | Heptanal | Fat, citrus, rancid | 6 | 0.61 | 1.31 |

| 4 | Pyridine | Sour, fishy | 2000 | <1 | <1 |

| 5 | 2-Pentylfuran | Beany | 5.8 | 5.47 | 41.46 |

| 6 | 1-Pentanol | Sweet bread | 150.2 | <1 | <1 |

| 7 | Styrene | Floral | 65 | <1 | <1 |

| 8 | Octanal | Citrus | 0.8 | 3.30 | 32.90 |

| 9 | (E)-2-Heptenal | Fresh, green | 3.75 | 2.97 | 7.41 |

| 10 | 6-Methyl-5-heptene-2-one | Citrus | 59 | <1 | <1 |

| 11 | Tridecane | Sweet | 42,000 | <1 | <1 |

| 12 | 1-Hexanol | Fruity | 5.6 | 3.50 | 5.08 |

| 13 | Nonanal | Citrus | 1.1 | 96.5 | 254.44 |

| 14 | (E)-2-Octenal | Cucumber | 3 | 1.23 | 12.26 |

| 15 | Decanal | Citrus | 3 | 12.35 | 47.06 |

| 16 | (E)-2-Nonenal | Cucumber | 0.19 | 82.58 | 205.58 |

| 17 | 1-Octen-3-ol | Raw mushroom | 1.5 | 2.97 | 6.16 |

| 18 | (E)-2-Decenal | Citrus | 17 | 0.51 | 1.63 |

| 19 | Undecanal | Sweet, floral | 12.5 | 0.20 | 3.58 |

| 20 | (E)-2-Dodecenal | Citrus, waxy | 7.3 | 0.31 | 3.31 |

| 21 | Geranyl acetone | Fresh, fruity | 186 | <1 | <1 |

| 22 | (E,E)-2,4-Decadienal | Citrus | 2.3 | 21.40 | 3.09 |

| 23 | n-Hexadecanol | Floral | 1100 | <1 | <1 |

| 24 | 2-Pentadecanone | Celery | 7 | 0.44 | 3.55 |

| 25 | Pentadecanal | Waxy | 1000 | <1 | <1 |

| 26 | 2-Methoxy-4-vinylphenol | Smoky | 12.02 | 2.39 | 7.01 |

| 27 | Indole | Floral | 40 | 0.38 | 9.48 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lian, K.; Guan, L.; Zhang, M.; Ye, G.; Li, S. Effect of Ultrasonic Treatment on Taste and Flavor Quality of Japonica Rice. Foods 2025, 14, 1627. https://doi.org/10.3390/foods14091627

Lian K, Guan L, Zhang M, Ye G, Li S. Effect of Ultrasonic Treatment on Taste and Flavor Quality of Japonica Rice. Foods. 2025; 14(9):1627. https://doi.org/10.3390/foods14091627

Chicago/Turabian StyleLian, Kaiqing, Lina Guan, Min Zhang, Guodong Ye, and Sixuan Li. 2025. "Effect of Ultrasonic Treatment on Taste and Flavor Quality of Japonica Rice" Foods 14, no. 9: 1627. https://doi.org/10.3390/foods14091627

APA StyleLian, K., Guan, L., Zhang, M., Ye, G., & Li, S. (2025). Effect of Ultrasonic Treatment on Taste and Flavor Quality of Japonica Rice. Foods, 14(9), 1627. https://doi.org/10.3390/foods14091627