Effect of Hawthorn Powder on Physical, Functional, and Sensory Characteristics of Set-Type Yogurt

Abstract

1. Introduction

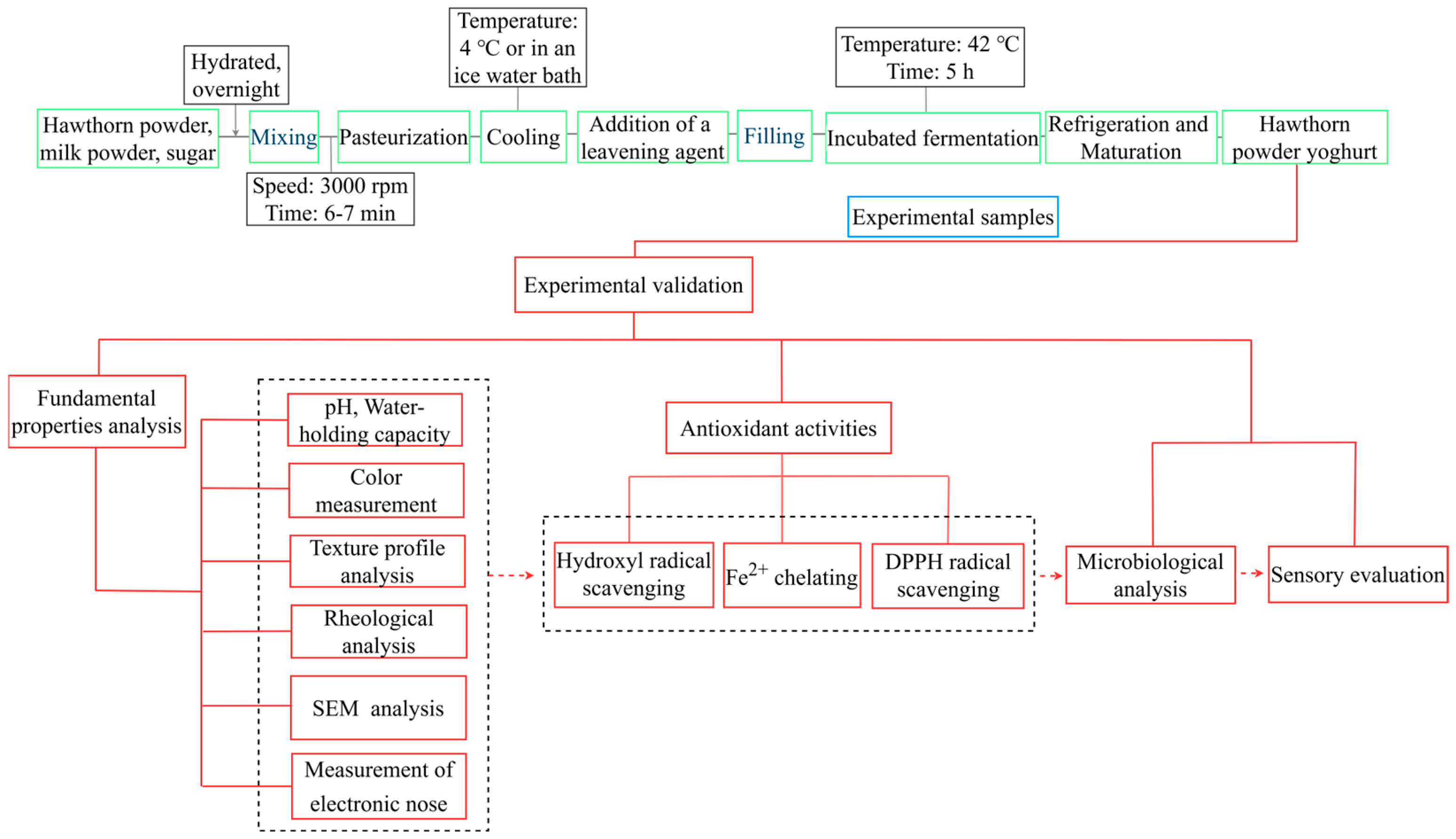

2. Materials and Methods

2.1. Materials

2.2. Yogurt Production

2.3. Preparation of Aqueous Extract of Yogurt

2.4. Measurement of pH and Water-Holding Capacity

2.5. Color Measurement

2.6. Rheological Analysis

2.7. Texture Profile Analysis (TPA)

2.8. Scanning Electron Microscopy (SEM) Analysis

2.9. Measurement of Electronic Nose

2.10. Antioxidant Properties

2.11. Assessment of Lactic Acid Bacteria Viability

2.12. Sensory Evaluation of Hawthorn Powder Yogurt

2.13. Data Processing and Analysis

3. Results and Discussion

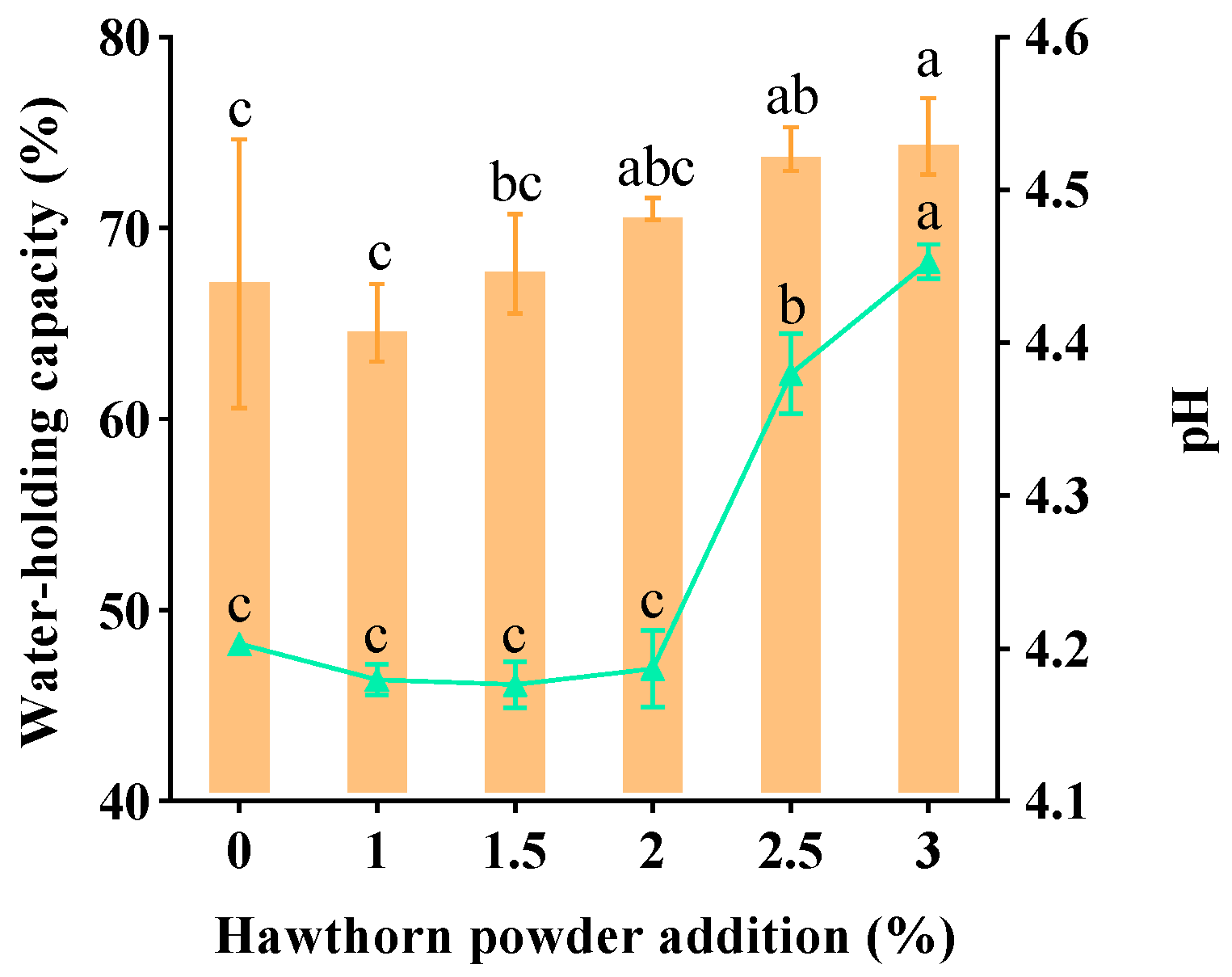

3.1. Effect of Hawthorn Powder on pH and Water-Holding Capacity of Yogurt

3.2. Effect of Hawthorn Powder on the Color of Yogurt

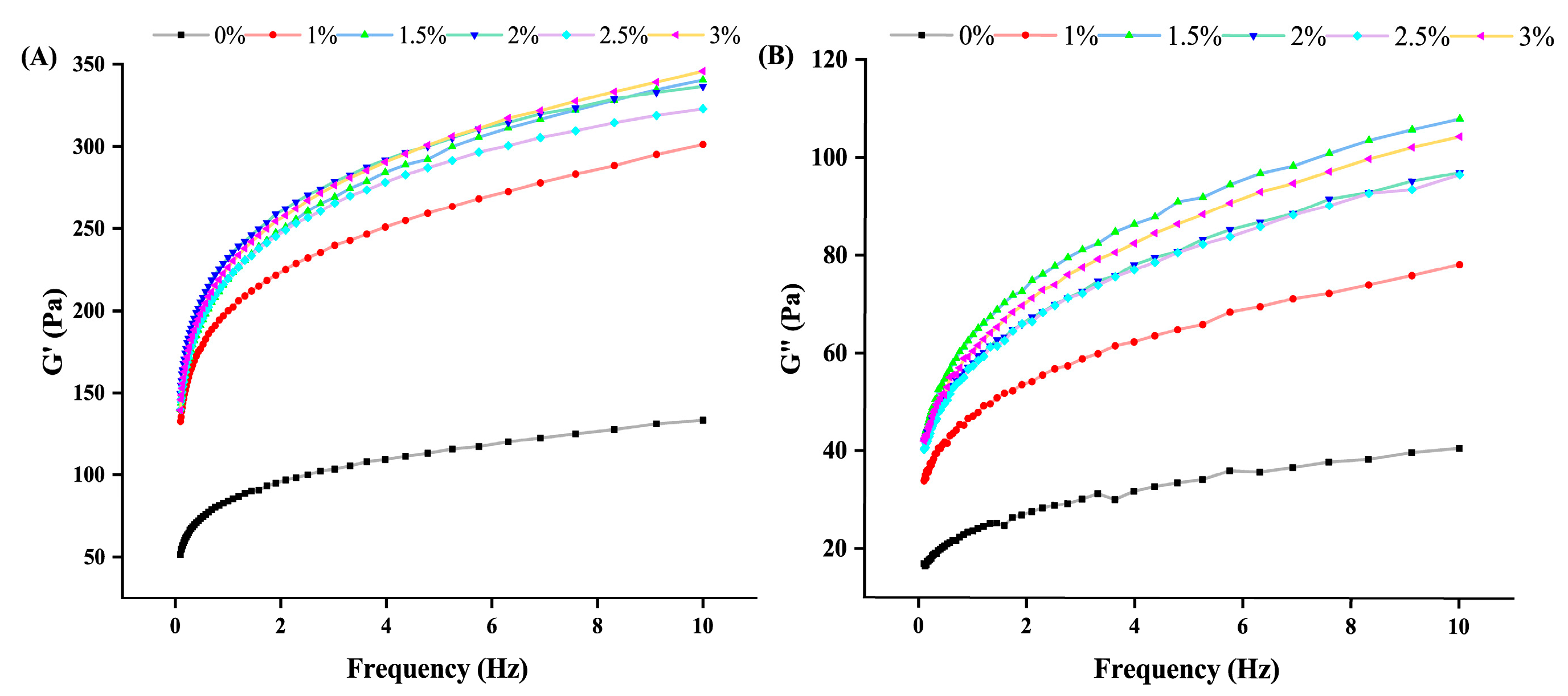

3.3. Effect of Hawthorn Powder on the Rheological Properties of Yogurt

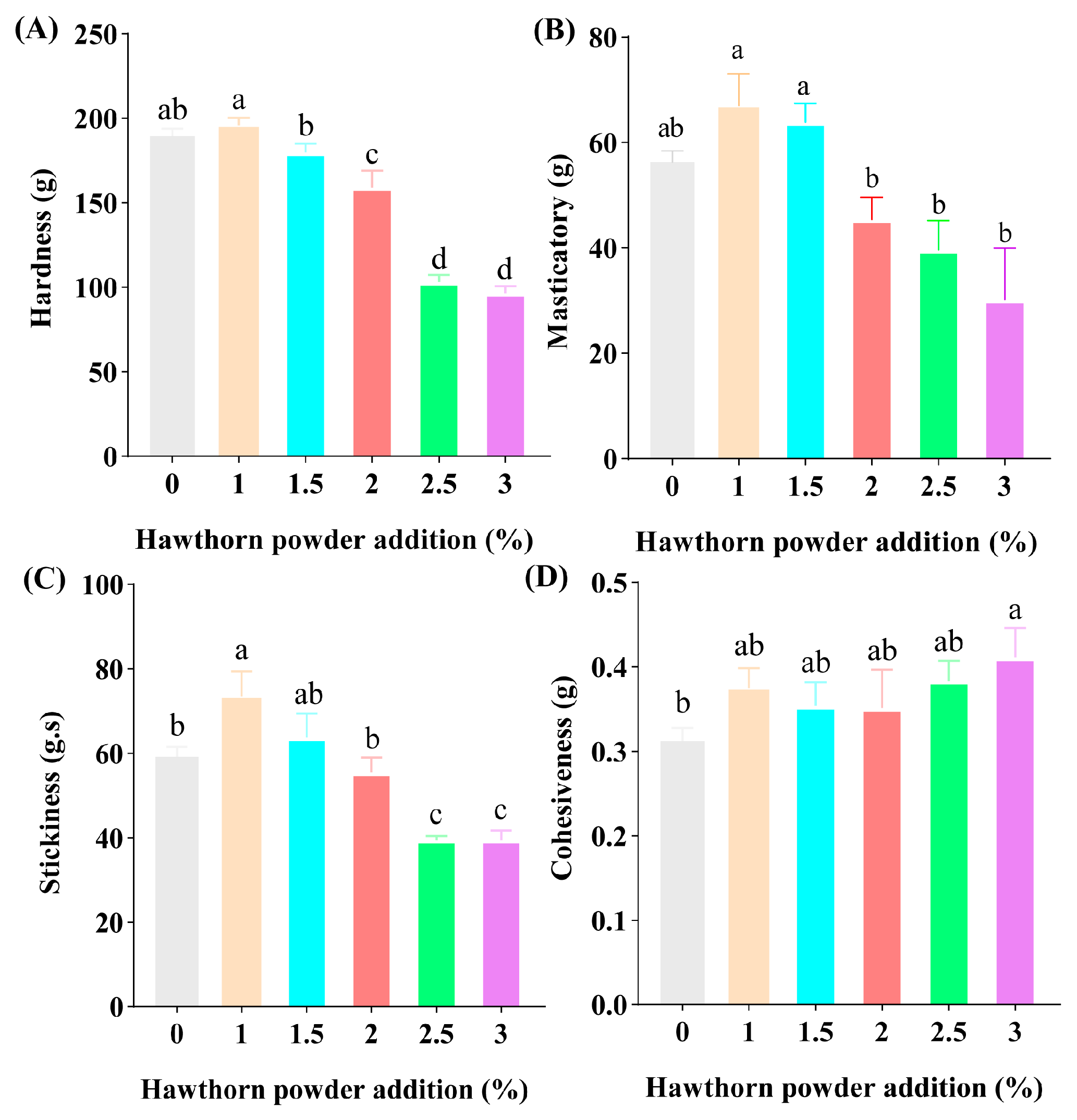

3.4. Effect of Hawthorn Powder on the Texture of Yogurt

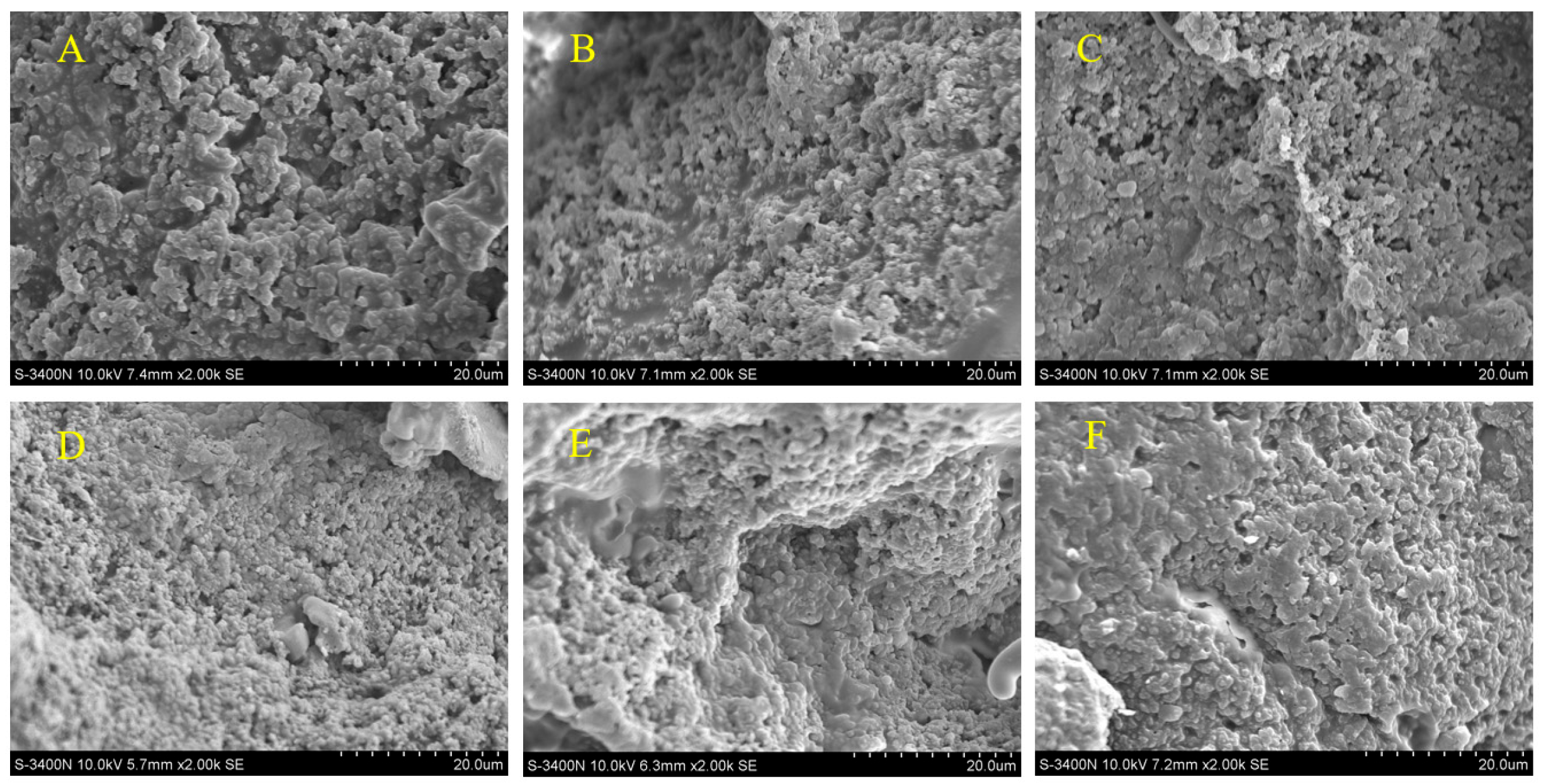

3.5. Scanning Electron Microscopy Analysis of Hawthorn Powder Yogurt

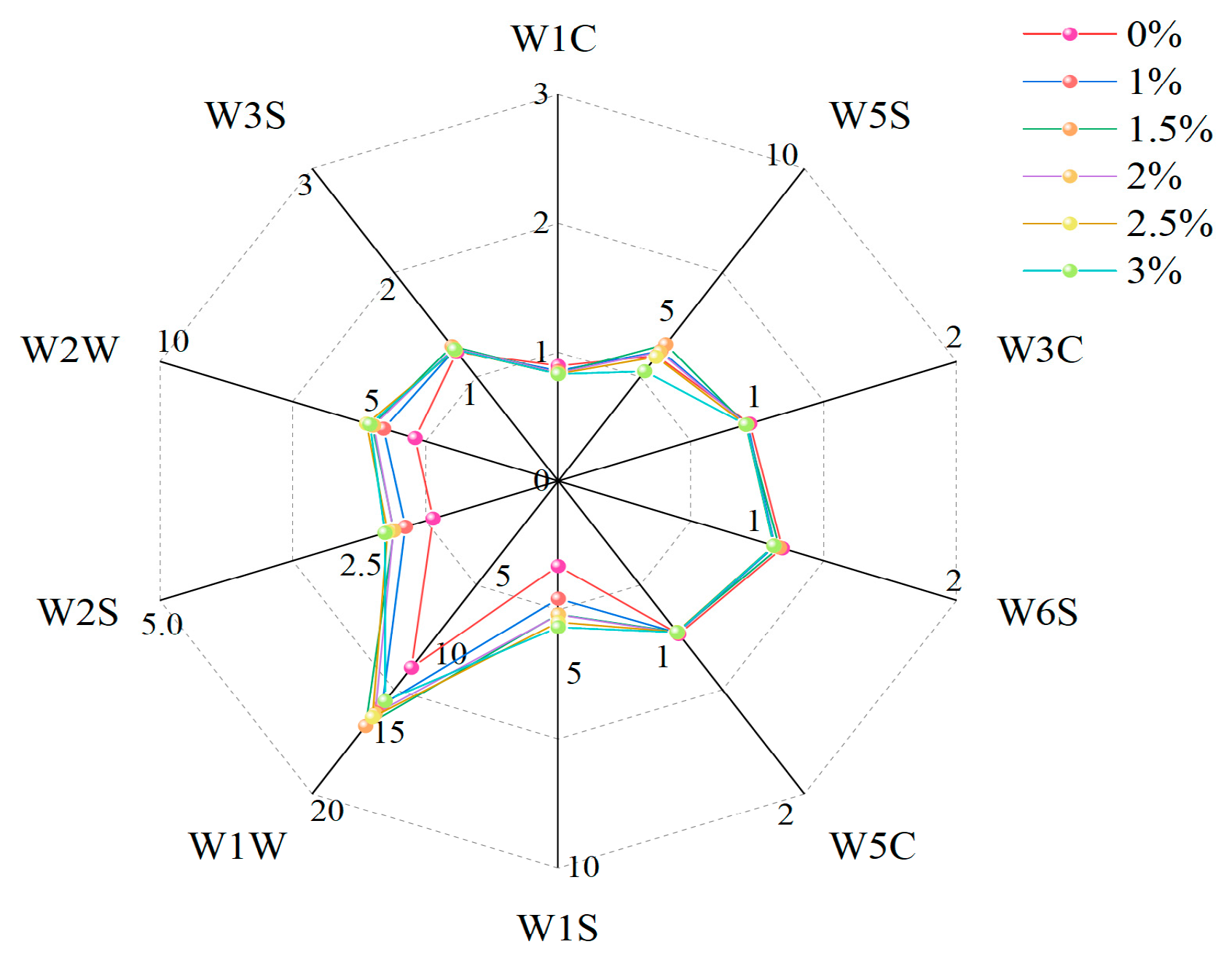

3.6. Hawthorn Powder Yogurt E-Nose Analysis

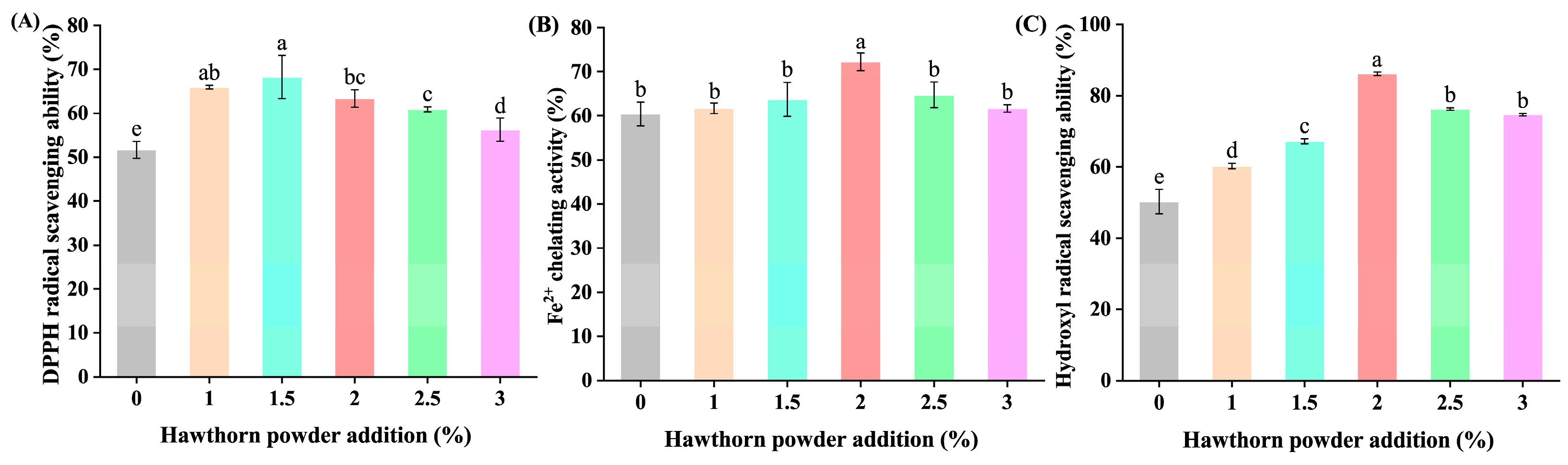

3.7. Effect of Hawthorn Powder on Antioxidant Activity of Yogurt

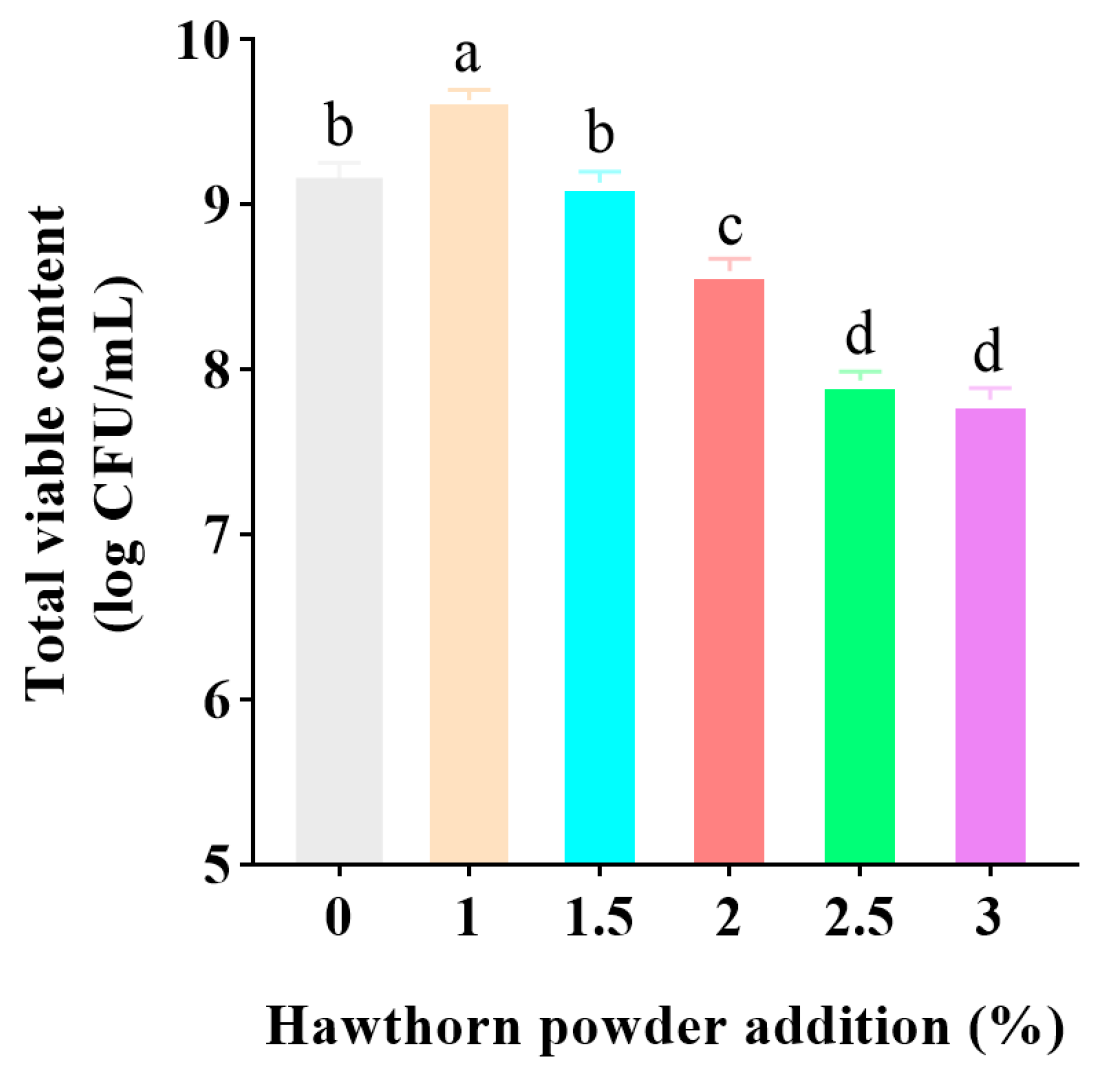

3.8. Analysis of Lactic Acid Bacteria Survival in Yogurt Samples

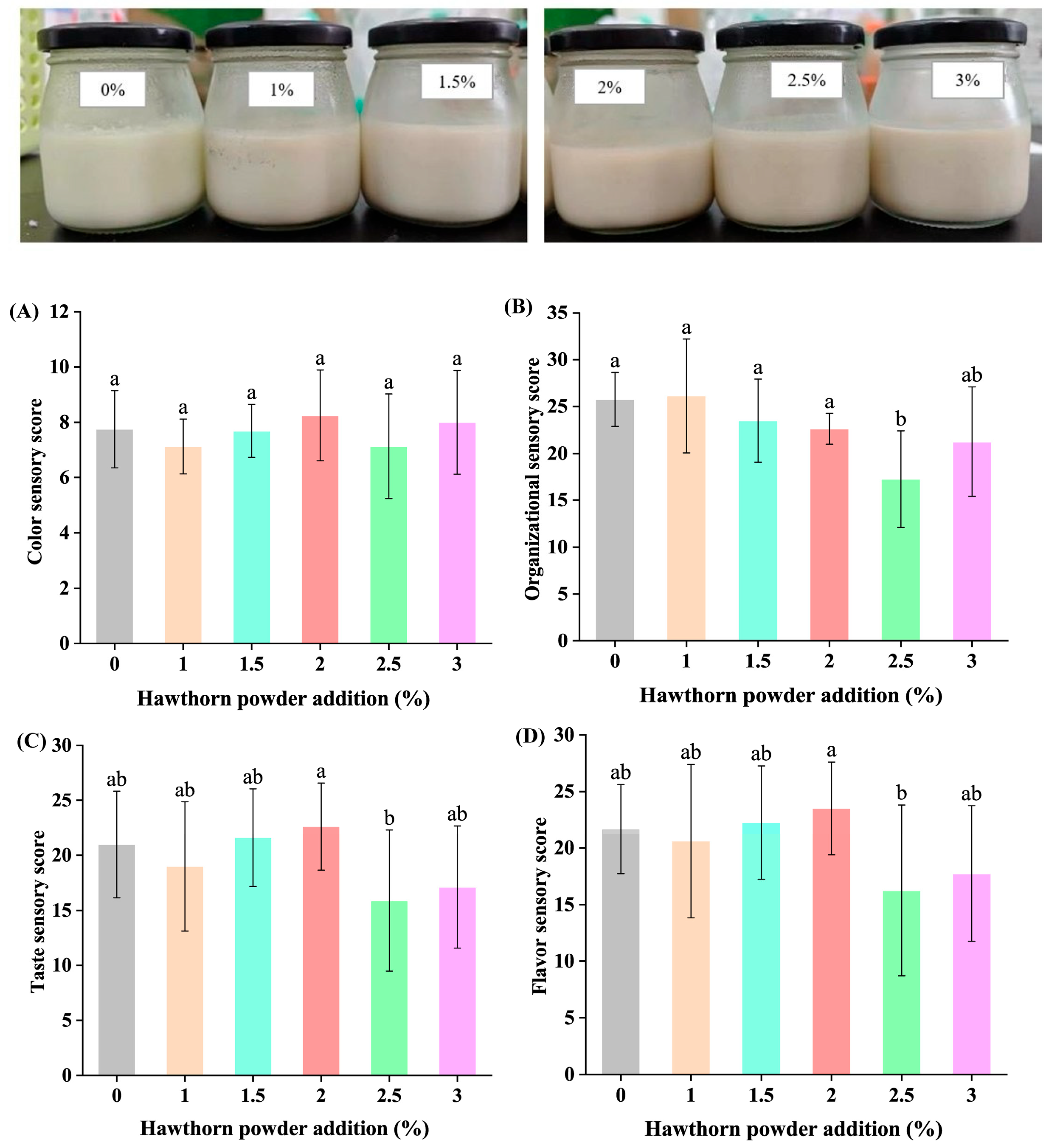

3.9. Effect of Hawthorn Powder on the Sensory Quality of Yogurt

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ROS | Reactive oxygen species |

| WHC | Water-holding capacity |

| TPA | Texture profile analysis |

| SEM | Scanning electron microscopy |

| DPPH | 2,2-Diphenyl-1-picrylhydrazyl |

References

- Hadjimbei, E.; Botsaris, G.; Chrysostomou, S. Beneficial Effects of Yoghurts and Probiotic Fermented Milks and Their Functional Food Potential. Foods 2022, 11, 2691. [Google Scholar] [CrossRef] [PubMed]

- Sabeena Farvin, K.H.; Baron, C.P.; Nielsen, N.S.; Jacobsen, C. Antioxidant activity of yoghurt peptides: Part 1-in vitro assays and evaluation in ω-3 enriched milk. Food Chem. 2010, 123, 1081–1089. [Google Scholar] [CrossRef]

- Pourrajab, B.; Fatahi, S.; Dehnad, A.; Kord Varkaneh, H.; Shidfar, F. The impact of probiotic yogurt consumption on lipid profiles in subjects with mild to moderate hypercholesterolemia: A systematic review and meta-analysis of randomized controlled trials. Nutr. Metab. Cardiovasc. Dis. NMCD 2020, 30, 11–22. [Google Scholar] [CrossRef] [PubMed]

- Adjei, M.L.; Boakye, A.; Deku, G.; Pepra-Ameyaw, N.B.; Jnr, A.S.A.; Oduro, I.N.; Ellis, W.O. Development of yoghurt incorporated with beetroot puree and its effect on the physicochemical properties and consumer acceptance. Heliyon 2024, 10, e25492. [Google Scholar] [CrossRef]

- An, G.; Park, S.; Ha, J. The enhancement effect of mungbean on the physical, functional, and sensory characteristics of soy yoghurt. Sci. Rep. 2024, 14, 3684. [Google Scholar] [CrossRef]

- Guemidi, C.; Ait Saada, D.; Ait Chabane, O.; Elmastas, M.; Erenler, R.; Yilmaz, M.A.; Tarhan, A.; Akkal, S.; Khelifi, H. Enhancement of yogurt functionality by adding Mentha piprita phenolic extract and evaluation of its quality during cold storage. Food Sci. Nutr. 2024, 12, 3007–3020. [Google Scholar] [CrossRef]

- Cui, M.; Cheng, L.; Zhou, Z.; Zhu, Z.; Liu, Y.; Li, C.; Liao, B.; Fan, M.; Duan, B. Traditional uses, phytochemistry, pharmacology, and safety concerns of hawthorn (Crataegus genus): A comprehensive review. J. Ethnopharmacol. 2024, 319, 117229. [Google Scholar] [CrossRef]

- Chai, Z.; Yin, X.; Zheng, Y.; Ye, X.; Tian, J. Effects of hawthorn addition on the physicochemical properties and hydrolysis of corn starch. Food Chem. X 2022, 16, 100478. [Google Scholar] [CrossRef]

- Vona, R.; Pallotta, L.; Cappelletti, M.; Severi, C.; Matarrese, P. The Impact of Oxidative Stress in Human Pathology: Focus on Gastrointestinal Disorders. Antioxidants 2021, 10, 201. [Google Scholar] [CrossRef]

- Shori, A.B.; Rashid, F.; Baba, A.S. Effect of the addition of phytomix-3+ mangosteen on antioxidant activity, viability of lactic acid bacteria, type 2 diabetes key-enzymes, and sensory evaluation of yogurt. LWT 2018, 94, 33–39. [Google Scholar] [CrossRef]

- Jia, S.; Zhao, H.; Tao, H.; Yu, B.; Liu, P.; Cui, B. Influence of corn resistant starches type III on the rheology, structure, and viable counts of set yogurt. Int. J. Biol. Macromol. 2022, 203, 10–18. [Google Scholar] [CrossRef] [PubMed]

- Tian, Y.; Zheng, S.; He, L.; Li, C.; Qiao, S.; Tao, H.; Wang, X.; Zeng, X. The effects of Trametes versicolor fermented Rosa roxburghii tratt and coix seed quild on the nutrition, sensory characteristics and physical and chemical parameters of yogurt. Food Chem. X 2023, 20, 100969. [Google Scholar] [CrossRef] [PubMed]

- Pachekrepapol, U.; Somboonchai, N.; Krimjai, W. Physicochemical, rheological, and microbiological properties of lactose-free functional yogurt supplemented with fructooligosaccharides. J. Food Process. Preserv. 2021, 45, e15017. [Google Scholar] [CrossRef]

- Meng, X.; Huang, Y.; Xiong, J.; Cheng, Z.; Yang, T.; Li, Z.; Tuo, R.; Zhang, Z.; Wang, G.; Gu, Q.; et al. Lactiplantibacillus plantarum ZFM55 improves texture and flavor of yogurt, increases beneficial metabolites, and the co-fermented yogurt promotes human gut microbiota health. LWT 2024, 198, 115929. [Google Scholar] [CrossRef]

- Li, W.; Shi, Y.; Sun, J.; Guo, X.; Bian, Y.; Ren, M.; Liu, Y.; Yan, Q.; Du, L.; Kwok, L.-Y.; et al. Differential effects of Lactococcus starter cultures on Cheddar cheese: Insights from texture, electronic sensory, and metabolomics analyses. Food Chem. 2025, 469, 142644. [Google Scholar] [CrossRef]

- Liu, D.; Guo, Y.; Wu, P.; Wang, Y.; Kwaku Golly, M.; Ma, H. The necessity of walnut proteolysis based on evaluation after in vitro simulated digestion: ACE inhibition and DPPH radical-scavenging activities. Food Chem. 2020, 311, 125960. [Google Scholar] [CrossRef]

- Gao, Q.; Liu, Z.-H.; Wu, J.-L.; Geng, Y.; Zhang, Q.; Tie, M.; Gu, X.-J.; Tanokura, M.; Xue, Y.-L. Foliar application is an effective method for incorporating selenium into peanut leaf proteins with antioxidant activities. Food Res. Int. 2019, 126, 108617. [Google Scholar] [CrossRef]

- Wang, S.; Mao, X.; Zhang, R.; Gao, Y.; Liu, D. Purification, characterization, and in vitro digestion of novel antioxidant peptides from chicken blood hemoglobin. J. Food Sci. 2024, 89, 1567–1581. [Google Scholar] [CrossRef]

- GB 4789.35-2023; National Food Safety Standard: Food Microbiological Examination: Examination of Lactic Acid Bacteria. National Health Commission of the People’s Republic of China, and State Administration for Market Regulation of the People’s Republic of China: Beijing, China, 2023.

- Seo, C.W.; Oh, N.S. Rheological, Physicochemical, Microbiological, and Aroma Characteristics of Sour Creams Supplemented with Milk Protein Concentrate. Food Sci. Anim. Resour. 2023, 43, 540–551. [Google Scholar] [CrossRef]

- Jiang, Y.; Du, J.; Zhang, L. Textural characteristics and sensory evaluation of yogurt fortified with pectin extracted from steeped hawthorn wine pomace. Int. J. Food Eng. 2021, 17, 131–140. [Google Scholar] [CrossRef]

- Muncan, J.; Tei, K.; Tsenkova, R. Real-Time Monitoring of Yogurt Fermentation Process by Aquaphotomics Near-Infrared Spectroscopy. Sensors 2020, 21, 177. [Google Scholar] [CrossRef] [PubMed]

- Bendig, T.; Ulmer, A.; Luzia, L.; Müller, S.; Sahle, S.; Bergmann, F.T.; Lösch, M.; Erdemann, F.; Zeidan, A.A.; Mendoza, S.N.; et al. The pH-dependent lactose metabolism of Lactobacillus delbrueckii subsp. bulgaricus: An integrative view through a mechanistic computational model. J. Biotechnol. 2023, 374, 90–100. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.; Wang, X.; Zhang, J.; Li, N.; Wu, R.; Wang, T.; Ding, W. Comparative metabolomic analysis of different-colored hawthorn berries (Crataegus pinnatifida) provides a new interpretation of color trait and antioxidant activity. LWT 2022, 163, 113623. [Google Scholar] [CrossRef]

- Sözeri Atik, D.; Öztürk, H.İ.; Akın, N. Perspectives on the yogurt rheology. Int. J. Biol. Macromol. 2024, 263, 130428. [Google Scholar] [CrossRef]

- Linares-García, J.A.; Ramos-Ramírez, E.G.; Salazar-Montoya, J.A. Viscoelastic properties and textural characterisation of high methoxyl pectin of hawthorn (Crataegus pubescens) in a gelling system. J. Food Sci. Technol. 2015, 50, 1484–1493. [Google Scholar] [CrossRef]

- Feng, C.; Wang, B.; Zhao, A.; Wei, L.; Shao, Y.; Wang, Y.; Cao, B.; Zhang, F. Quality characteristics and antioxidant activities of goat milk yogurt with added jujube pulp. Food Chem. 2019, 277, 238–245. [Google Scholar] [CrossRef]

- Sukhikh, S.; Astakhova, L.; Golubcova, Y.; Lukin, A.; Prosekova, E.; Milenteva, I.; Kostina, N.; Rasshchepkin, A. Functional dairy products enriched with plant ingredients. Foods Raw Mater. 2019, 7, 428–438. [Google Scholar] [CrossRef]

- Jany, J.F.; Nupur, A.H.; Akash, S.I.; Karmoker, P.; Mazumder, M.A.R.; Alim, M.A. Fortification of functional yogurt by the phytochemicals extracted from pomegranate peel. Appl. Food Res. 2024, 4, 100479. [Google Scholar] [CrossRef]

- Parada, J.; Aguilera, J.M. Food microstructure affects the bioavailability of several nutrients. J. Food Sci. 2007, 72, R21–R32. [Google Scholar] [CrossRef]

- Hong, R.; Yang, H.; Guo, Y.; Liu, Q.; Xu, N.; Xie, Y.; Li, M.; Yue, X. The application and mechanism of polysaccharides, proteins and their complexes on enhancing yogurt gel stability: A review. Food Sci. Anim. Prod. 2024, 2, 9240066. [Google Scholar] [CrossRef]

- Benmeziane, F.; Raigar, R.K.; Ayat, N.E.-H.; Aoufi, D.; Djermoune-Arkoub, L.; Chala, A. Lentil (Lens culinaris) flour addition to yogurt: Impact on physicochemical, microbiological and sensory attributes during refrigeration storage and microstructure changes. LWT 2021, 140, 110793. [Google Scholar] [CrossRef]

- Wilson, A.D.; Baietto, M. Applications and Advances in Electronic-Nose Technologies. Sensors 2009, 9, 5099–5148. [Google Scholar] [CrossRef] [PubMed]

- Loulier, J.; Lefort, F.; Stocki, M.; Asztemborska, M.; Szmigielski, R.; Siwek, K.; Grzywacz, T.; Hsiang, T.; Ślusarski, S.; Oszako, T.; et al. Detection of Fungi and Oomycetes by Volatiles Using E-Nose and SPME-GC/MS Platforms. Molecules 2020, 25, 5749. [Google Scholar] [CrossRef] [PubMed]

- Schieber, M.; Chandel, N.S. ROS Function in Redox Signaling and Oxidative Stress. Curr. Biol. 2014, 24, R453–R462. [Google Scholar] [CrossRef]

- Xu, Z.; Fu, L.; Feng, S.; Yuan, M.; Huang, Y.; Liao, J.; Zhou, L.; Yang, H.; Ding, C. Chemical Composition, Antioxidant and Antihyperglycemic Activities of the Wild Lactarius deliciosus from China. Molecules 2019, 24, 1357. [Google Scholar] [CrossRef]

- Rosa, G.B.; Sganzerla, W.G.; Ferreira, A.L.A.; Xavier, L.O.; Veloso, N.C.; da Silva, J.; de Oliveira, G.P.; Amaral, N.C.; Veeck, A.P.L.; Ferrareze, J.P. Investigation of Nutritional Composition, Antioxidant Compounds, and Antimicrobial Activity of Wild Culinary-Medicinal Mushrooms Boletus edulis and Lactarius deliciosus (Agaricomycetes) from Brazil. Int. J. Med. Mushrooms 2020, 22, 931–942. [Google Scholar] [CrossRef]

- Villaño, D.; Fernández-Pachón, M.S.; Moyá, M.L.; Troncoso, A.M.; García-Parrilla, M.C. Radical scavenging ability of polyphenolic compounds towards DPPH free radical. Talanta 2007, 71, 230–235. [Google Scholar] [CrossRef]

- Li, T.; Fu, S.; Huang, X.; Zhang, X.; Cui, Y.; Zhang, Z.; Ma, Y.; Zhang, X.; Yu, Q.; Yang, S.; et al. Biological properties and potential application of hawthorn and its major functional components: A review. J. Funct. Foods 2022, 90, 104988. [Google Scholar] [CrossRef]

- Helal, A.; Cattivelli, A.; Conte, A.; Tagliazucchi, D. In Vitro Bioaccessibility and Antioxidant Activity of Phenolic Compounds in Coffee-Fortified Yogurt. Molecules 2022, 27, 6843. [Google Scholar] [CrossRef]

- Sah, B.N.P.; Vasiljevic, T.; McKechnie, S.; Donkor, O.N. Effect of refrigerated storage on probiotic viability and the production and stability of antimutagenic and antioxidant peptides in yogurt supplemented with pineapple peel. J. Dairy Sci. 2015, 98, 5905–5916. [Google Scholar] [CrossRef]

- Li, M.; Chen, X.; Deng, J.; Ouyang, D.; Wang, D.; Liang, Y.; Chen, Y.; Sun, Y. Effect of thermal processing on free and bound phenolic compounds and antioxidant activities of hawthorn. Food Chem. 2020, 332, 127429. [Google Scholar] [CrossRef] [PubMed]

- Ortiz, A.O.; Rodríguez, L.H.; Calleros, C.L.; Castilla, O.S.; Mandujano, E.A. The influence of hawthorn (Crataegus spp.) composite on the functionality and quality attributes of stirred yogurt [pdf]. Acta Sci. Pol. Technol. Aliment. 2024, 23, 327–336. [Google Scholar] [CrossRef]

- Codex Alimentarius Commission. Codex Standard for Fermented Milks. Available online: https://dairyconsultant.co.uk/pdf/codex_standard_fermented_milks_yogurts.pdf (accessed on 28 February 2025).

- Ahmad, I.; Xiong, Z.; Hanguo, X.; Khalid, N.; Khan, R.S. Formulation and characterization of yogurt prepared with enzymatically hydrolyzed potato powder and whole milk powder. J. Food Sci. Technol. 2022, 59, 1087–1096. [Google Scholar] [CrossRef] [PubMed]

| Serial Number | Transducers Performance Description | Performance Description |

|---|---|---|

| 1 | W1C | Sensitivity to aromatic ingredients |

| 2 | W5S | High sensitivity, sensitive to nitrogen oxides |

| 3 | W3C | Sensitive to aromatic ingredients, ammonia |

| 4 | W6S | Mainly sensitive to hydrogens |

| 5 | W5C | Hypoallergenic to short-chain alkanes, aromatic components |

| 6 | W1S | Sensitive to hydrocarbons, sensitive to methyl groups |

| 7 | W1W | Sensitive to sulfur compounds, terpenes, and sulfur organic compounds |

| 8 | W2S | Sensitive to aldehydes, alcohols, and ketones |

| 9 | W2W | Sensitive to aromatic components, organic sulfides |

| 10 | W3S | Sensitive to alkanes, methane |

| Projects | Scoring Standard | Total Points |

|---|---|---|

| Color | Uniform and consistent color, with the characteristic light reddish-brown of hawthorn yogurt (7–10) | 10 |

| Varying shades of color, reddish-brown is lighter (3–6) | ||

| The color is uneven and does not have the characteristic light reddish-brown color of hawthorn yogurt (1–2) | ||

| Organizational state | Good coagulation, no or little whey precipitation, no or little flocculation, uniform texture (25–30) | 30 |

| Good coagulation, slight whey precipitation, small amounts of flocculent, layered (15–24) | ||

| Poor coagulation, large amounts of whey precipitated, more flocculent, with large granular clots (0–14) | ||

| Flavor | A pronounced hawthorn yogurt flavor, with a harmonious fermented milky and hawthorn aroma (25–30) | 30 |

| Light hawthorn yogurt flavor, with a harmonious fermented milky and hawthorn aroma (15–24) | ||

| Obvious hawthorn yogurt flavor, with a harmonious fermented milky and hawthorn aroma (0–14) | ||

| Taste | Moderately sweet and sour, strong palatability, even curd, fine texture, unique hawthorn flavor (25–30) | 30 |

| Average sweet and sour, more palatable, average curd, no graininess, weak hawthorn flavor (15–24) | ||

| Sour–sweet disharmony, unpleasant to the mouth, poor curd, poor taste, no hawthorn unique flavor (0–14) |

| Additive Quantity (%) | L* | a* | b* |

|---|---|---|---|

| 0 | 75.62 ± 0.83 ab | −1.60 ± 0.06 c | 9.11 ± 0.51 b |

| 1.0 | 75.98 ± 1.59 a | −0.18 ± 0.40 b | 9.63 ± 0.02 b |

| 1.5 | 71.91 ± 0.76 c | 0.22 ± 0.07 b | 9.52 ± 0.26 b |

| 2.0 | 72.92 ± 1.58 bc | 0.38 ± 0.47 b | 9.98 ± 0.64 b |

| 2.5 | 70.55 ± 1.05 cd | 1.18 ± 0.56 a | 11.53 ± 1.49 ab |

| 3.0 | 68.85 ± 2.48 d | 1.65 ± 0.11 a | 12.72 ± 0.40 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Kang, Z.; Tang, L.; Qiu, W.; Wang, Y.; Zhang, T.; Pan, D.; Tu, M. Effect of Hawthorn Powder on Physical, Functional, and Sensory Characteristics of Set-Type Yogurt. Foods 2025, 14, 1377. https://doi.org/10.3390/foods14081377

Wang J, Kang Z, Tang L, Qiu W, Wang Y, Zhang T, Pan D, Tu M. Effect of Hawthorn Powder on Physical, Functional, and Sensory Characteristics of Set-Type Yogurt. Foods. 2025; 14(8):1377. https://doi.org/10.3390/foods14081377

Chicago/Turabian StyleWang, Jingjing, Zeyuan Kang, Lifei Tang, Wenpei Qiu, Yuxin Wang, Tao Zhang, Daodong Pan, and Maolin Tu. 2025. "Effect of Hawthorn Powder on Physical, Functional, and Sensory Characteristics of Set-Type Yogurt" Foods 14, no. 8: 1377. https://doi.org/10.3390/foods14081377

APA StyleWang, J., Kang, Z., Tang, L., Qiu, W., Wang, Y., Zhang, T., Pan, D., & Tu, M. (2025). Effect of Hawthorn Powder on Physical, Functional, and Sensory Characteristics of Set-Type Yogurt. Foods, 14(8), 1377. https://doi.org/10.3390/foods14081377