Exploring the Use of Tenebrio molitor Larvae Proteins to Functionalize Durum Wheat Pasta

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials and Chemicals

2.2. Production Process of Durum Wheat Pasta

2.3. Flow Properties of the Blends

2.4. Pasting Properties

2.5. Cooking Properties

2.6. Texture Analysis

Cooked Pasta Adhesiveness and Hardness

2.7. Colourimetric Parameters

2.8. Fourier Transform Infrared Spectroscopy (FTIR) Analysis

2.9. Spectrophotometric Analyses

2.10. Statistical Analysis

3. Results and Discussion

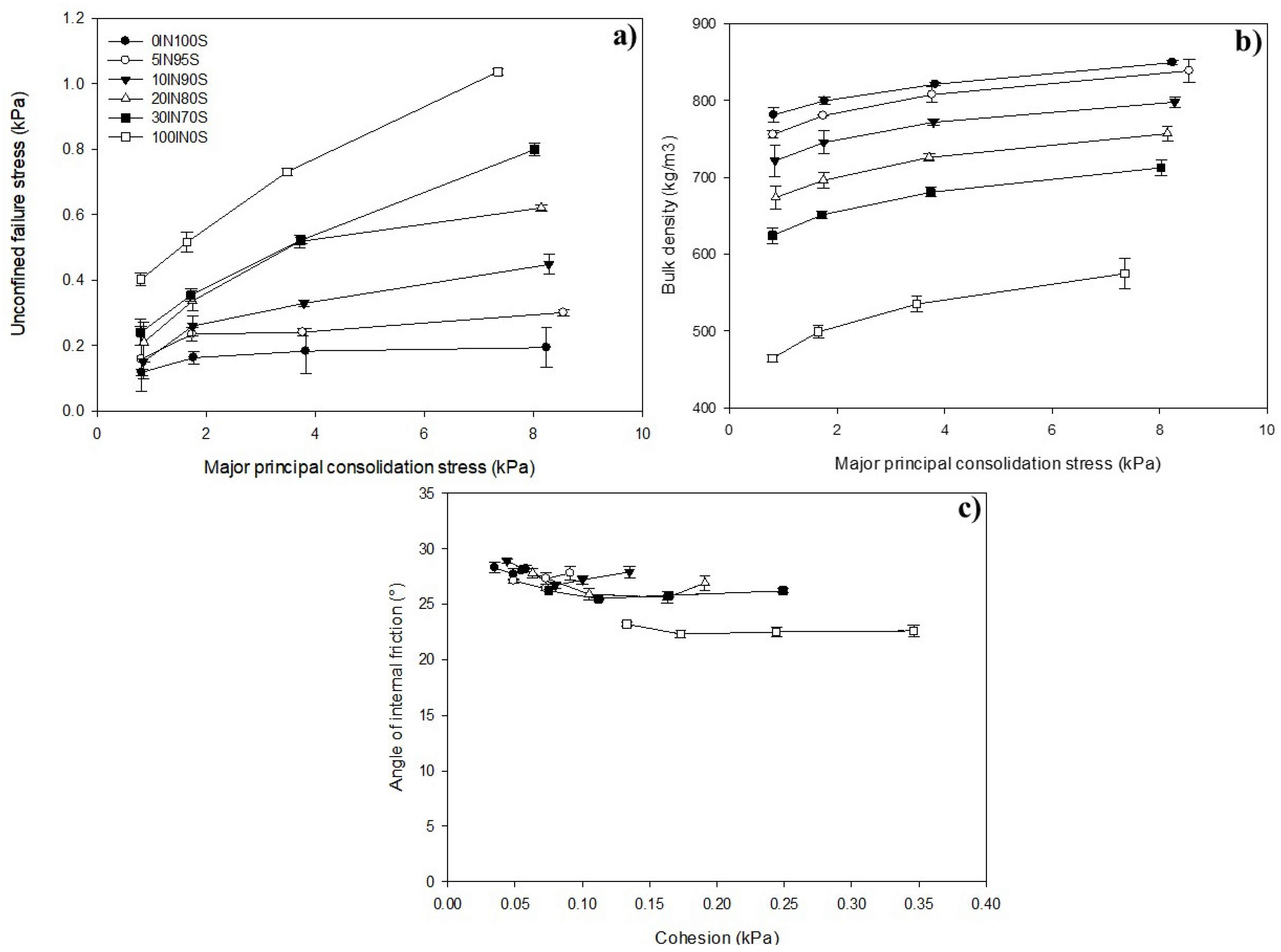

3.1. Flow Properties of the Blends

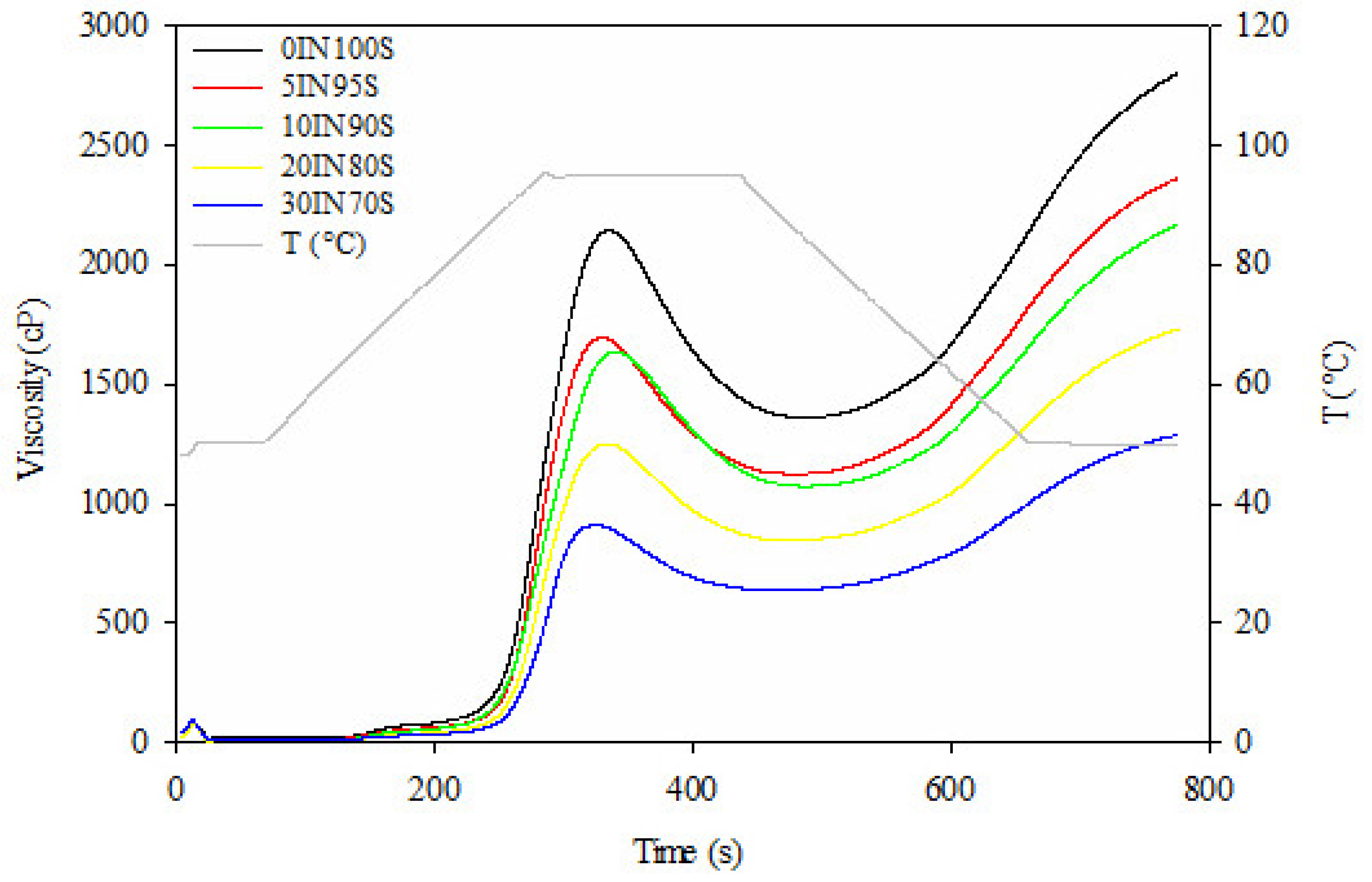

3.2. Pasting Properties

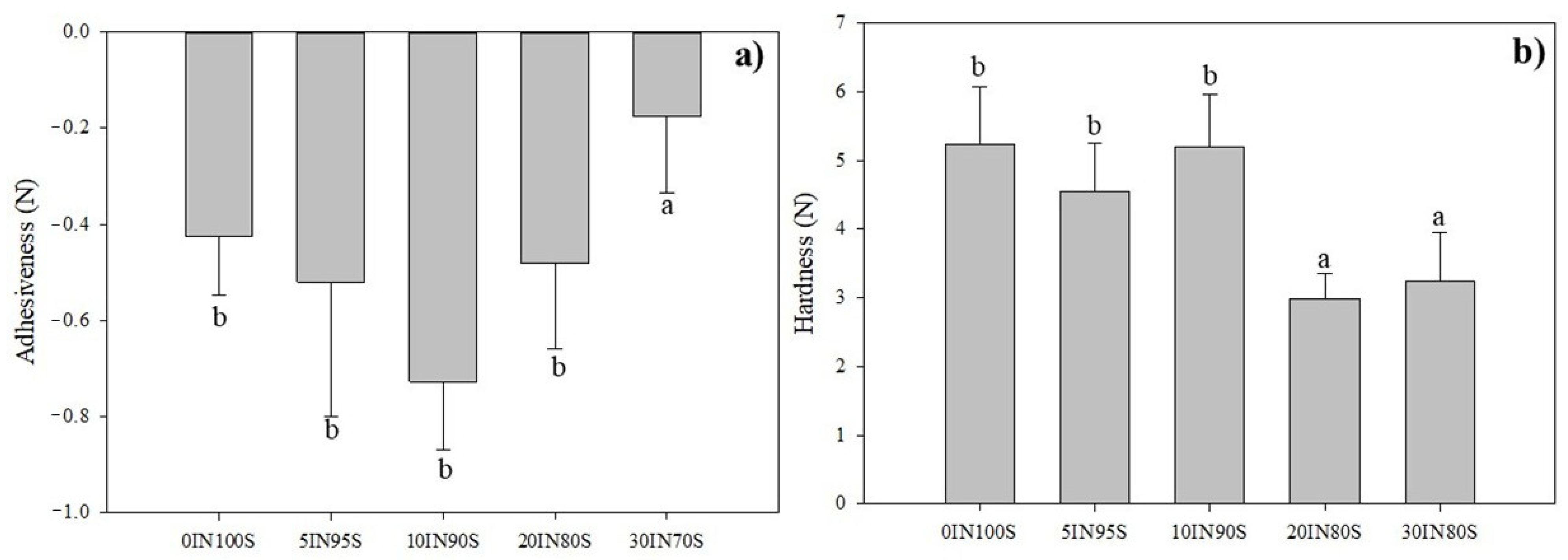

3.3. Cooking Properties and Texture Profile

3.4. Color Parameters

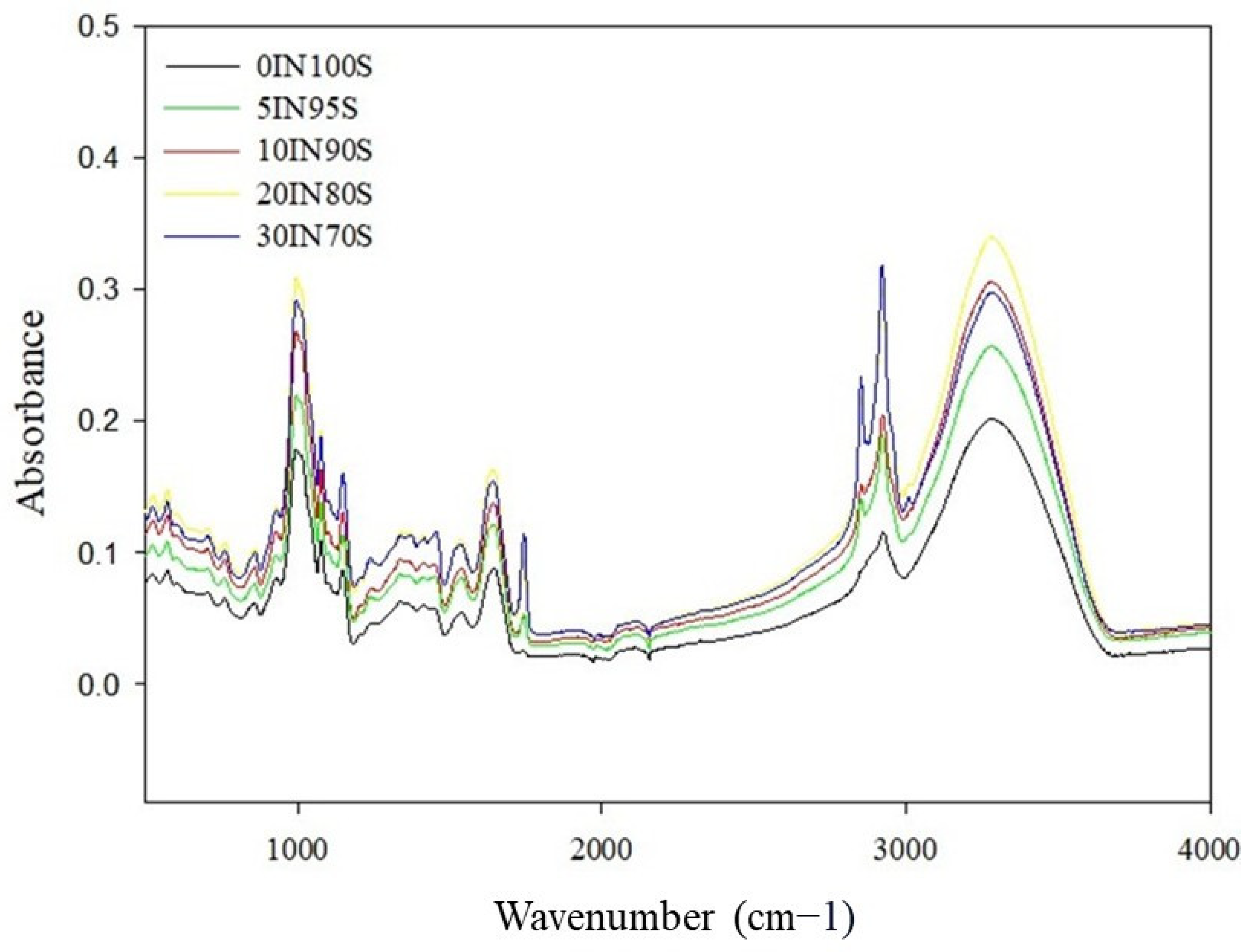

3.5. Fourier Transform Infrared Spectroscopy (FTIR) Results

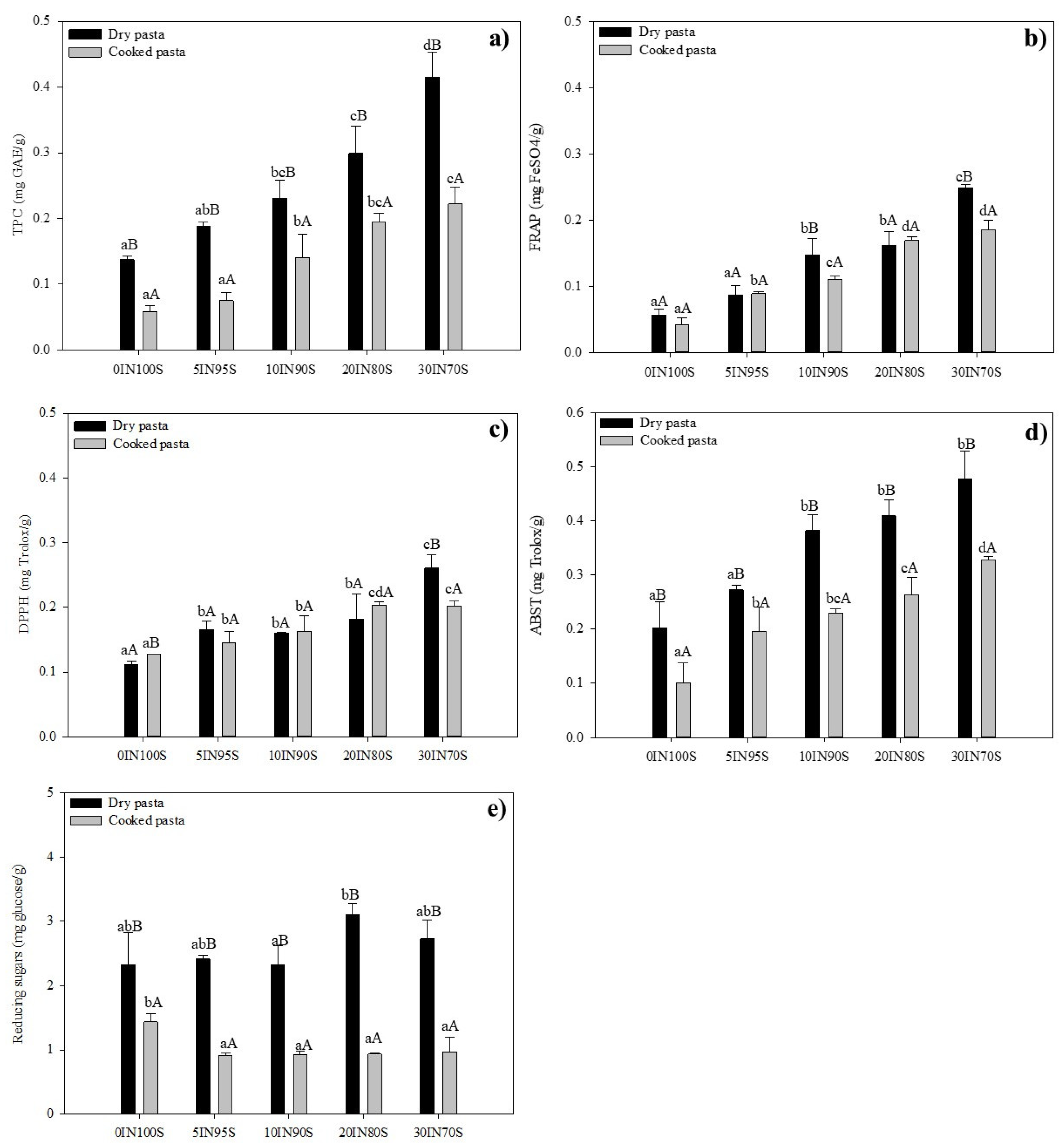

3.6. Bioactivity of Dry and Cooked Pasta Samples

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sharma, B.; Yadav, D.K.; Malakar, S.; Singh, S.; Sharma, M.; Suri, S.; Sridhar, K. Insect Proteins—Production Technologies, Bio-Functional, and Food Applications: A Perspective. Food Biosci. 2024, 61, 104560. [Google Scholar] [CrossRef]

- FAO. Edible Insects. Future Prospects for Food and Feed Security. In Food and Agriculture Organization of the United Nations; Wageningen, U.R., Ed.; Routledge: Rome, Italy, 2013; Volume 171, ISSN 0258-6150. [Google Scholar]

- Wallner, M.; Julius, N.; Pelayo, R.; Höfler, C.; Berner, S.; Rehorska, R.; Fahrner, L.; Maunz, S. Liking and Description of Pasta Sauces with Varying Mealworm Content. Foods 2023, 12, 3202. [Google Scholar] [CrossRef]

- Oonincx, D.G.A.B.; De Boer, I.J.M. Environmental Impact of the Production of Mealworms as a Protein Source for Humans—A Life Cycle Assessment. PLoS ONE 2012, 7, e51145. [Google Scholar] [CrossRef]

- Halloran, A.; Roos, N.; Eilenberg, J.; Cerutti, A.; Bruun, S. Life Cycle Assessment of Edible Insects for Food Protein: A Review. Agron. Sustain. Dev. 2016, 36, 57. [Google Scholar] [CrossRef] [PubMed]

- Vinci, G.; Prencipe, S.A.; Masiello, L.; Zaki, M.G. The Application of Life Cycle Assessment to Evaluate the Environmental Impacts of Edible Insects as a Protein Source. Earth 2022, 3, 925–938. [Google Scholar] [CrossRef]

- Chriki, S.; Hocquette, J.F. The Myth of Cultured Meat: A Review. Front. Nutr. 2020, 7, 7. [Google Scholar] [CrossRef]

- Gonzalez-de la Rosa, T.; Montserrat-de la Paz, S.; Rivero-Pino, F. Production, Characterisation, and Biological Properties of Tenebrio molitor-Derived Oligopeptides. Food Chem. 2024, 450, 139400. [Google Scholar] [CrossRef] [PubMed]

- Rumpold, B.A.; Schlüter, O. Insect-Based Protein Sources and Their Potential for Human Consumption: Nutritional Composition and Processing. Anim. Front. 2015, 5, 20–24. [Google Scholar] [CrossRef]

- Orkusz, A. Edible Insects versus Meat—Nutritional Comparison: Knowledge of Their Composition Is the Key to Good Health. Nutrients 2021, 13, 1207. [Google Scholar] [CrossRef]

- Gkinali, A.A.; Matsakidou, A.; Paraskevopoulou, A. Characterization of Tenebrio molitor Larvae Protein Preparations Obtained by Different Extraction Approaches. Foods 2022, 11, 3852. [Google Scholar] [CrossRef]

- Hammer, L.; Moretti, D.; Abbühl-Eng, L.; Kandiah, P.; Hilaj, N.; Portmann, R.; Egger, L. Mealworm Larvae (Tenebrio molitor) and Crickets (Acheta domesticus) Show High Total Protein in Vitro Digestibility and Can Provide Good-to-Excellent Protein Quality as Determined by in Vitro DIAAS. Front. Nutr. 2023, 10, 1150581. [Google Scholar] [CrossRef]

- Yi, L.; Lakemond, C.M.M.; Sagis, L.M.C.; Eisner-Schadler, V.; Van Huis, A.; Boekel, M.A.J.S.V. Extraction and Characterisation of Protein Fractions from Five Insect Species. Food Chem. 2013, 141, 3341–3348. [Google Scholar] [CrossRef] [PubMed]

- Gravel, A.; Doyen, A. The Use of Edible Insect Proteins in Food: Challenges and Issues Related to Their Functional Properties. Innov. Food Sci. Emerg. Technol. 2020, 59, 102272. [Google Scholar] [CrossRef]

- Kröger, T.; Dupont, J.; Büsing, L.; Fiebelkorn, F. Acceptance of Insect-Based Food Products in Western Societies: A Systematic Review. Front. Nutr. 2022, 8, 759885. [Google Scholar] [CrossRef]

- Andreani, G.; Sogari, G.; Banović, M. Snacking Insects? A Global Market Investigation. Food Humanit. 2024, 3, 100403. [Google Scholar] [CrossRef]

- Merlino, V.M.; Mosca, O.; Fornara, F.; Roma, R.; Bonerba, E.; Schiavone, A.; Passaro, R.L.; Tarantola, M. Which Factors Affect the Italian Consumer’s Intention to Insect-Eating? An Application of an Integrated Attitude-Intention-Eating Model. Food Qual. Prefer. 2024, 113, 105040. [Google Scholar] [CrossRef]

- Cappelli, A.; Oliva, N.; Bonaccorsi, G.; Lorini, C.; Cini, E. Assessment of the Rheological Properties and Bread Characteristics Obtained by Innovative Protein Sources (Cicer arietinum, Acheta domesticus, Tenebrio molitor): Novel Food or Potential Improvers for Wheat Flour? LWT 2020, 118, 108867. [Google Scholar] [CrossRef]

- Garciá-Segovia, P.; Igual, M.; Martínez-Monzó, J. Physicochemical Properties and Consumer Acceptance of Bread Enriched with Alternative Proteins. Foods 2020, 9, 933. [Google Scholar] [CrossRef]

- González, C.M.; Garzón, R.; Rosell, C.M. Insects as Ingredients for Bakery Goods. A Comparison Study of H. Illucens, A. Domestica and T. Molitor Flours. Innov. Food Sci. Emerg. Technol. 2019, 51, 205–210. [Google Scholar] [CrossRef]

- Roncolini, A.; Milanović, V.; Aquilanti, L.; Cardinali, F.; Garofalo, C.; Sabbatini, R.; Clementi, F.; Belleggia, L.; Pasquini, M.; Mozzon, M.; et al. Lesser Mealworm (Alphitobius diaperinus) Powder as a Novel Baking Ingredient for Manufacturing High-Protein, Mineral-Dense Snacks. Food Res. Int. 2020, 131, 109031. [Google Scholar] [CrossRef]

- Zielińska, E.; Pankiewicz, U.; Sujka, M. Nutritional, Physiochemical, and Biological Value of Muffins Enriched with Edible Insects Flour. Antioxidants 2021, 10, 1122. [Google Scholar] [CrossRef] [PubMed]

- Zielińska, E.; Pankiewicz, U. Nutritional, Physiochemical, and Antioxidative Characteristics of Shortcake Biscuits Enriched with Tenebrio molitor Flour. Molecules 2020, 25, 5629. [Google Scholar] [CrossRef]

- Xie, X.; Yuan, Z.; Fu, K.; An, J.; Deng, L. Effect of Partial Substitution of Flour with Mealworm (Tenebrio molitor L.) Powder on Dough and Biscuit Properties. Foods 2022, 11, 2156. [Google Scholar] [CrossRef]

- Azzollini, D.; Derossi, A.; Fogliano, V.; Lakemond, C.M.M.; Severini, C. Effects of Formulation and Process Conditions on Microstructure, Texture and Digestibility of Extruded Insect-Riched Snacks. Innov. Food Sci. Emerg. Technol. 2018, 45, 344–353. [Google Scholar] [CrossRef]

- Choi, Y.S.; Kim, T.K.; Choi, H.D.; Park, J.D.; Sung, J.M.; Jeon, K.H.; Paik, H.D.; Kim, Y.B. Optimization of Replacing Pork Meat with Yellow Worm (Tenebrio molitor L.) for Frankfurters. Korean J. Food Sci. Anim. Resour. 2017, 37, 617–625. [Google Scholar] [CrossRef]

- Kim, H.W.; Setyabrata, D.; Lee, Y.J.; Jones, O.G.; Kim, Y.H.B. Pre-Treated Mealworm Larvae and Silkworm Pupae as a Novel Protein Ingredient in Emulsion Sausages. Innov. Food Sci. Emerg. Technol. 2016, 38, 116–123. [Google Scholar] [CrossRef]

- Çabuk, B.; Yılmaz, B. Fortification of Traditional Egg Pasta (Erişte) with Edible Insects: Nutritional Quality, Cooking Properties and Sensory Characteristics Evaluation. J. Food Sci. Technol. 2020, 57, 2750–2757. [Google Scholar] [CrossRef]

- Pasini, G.; Cullere, M.; Vegro, M.; Simonato, B.; Dalle Zotte, A. Potentiality of Protein Fractions from the House Cricket (Acheta domesticus) and Yellow Mealworm (Tenebrio molitor) for Pasta Formulation. LWT 2022, 164, 113638. [Google Scholar] [CrossRef]

- Carpentieri, S.; Orkusz, A.; Ferrari, G.; Harasym, J. Effect of Replacing Durum Wheat Semolina with Tenebrio molitor Larvae Powder on the Techno-Functional Properties of the Binary Blends. Curr. Res. Food Sci. 2024, 8, 100672. [Google Scholar] [CrossRef]

- Salehi, H.; Barletta, D.; Poletto, M. A Comparison between Powder Flow Property Testers. Particuology 2017, 32, 10–20. [Google Scholar] [CrossRef]

- Bonomi, F.; D’Egidio, M.G.; Iametti, S.; Marengo, M.; Marti, A.; Pagani, M.A.; Ragg, E.M. Structure-Quality Relationship in Commercial Pasta: A Molecular Glimpse. Food Chem. 2012, 135, 348–355. [Google Scholar] [CrossRef] [PubMed]

- Jenike, A.W. Storage and Flow of Solids; Bulletin 123; Utah Engineering Experiment Station, University of Utah: Salt Lake City, UT, USA, 1966. [Google Scholar]

- Lopes Neto, J.P.; Meira, A.S.; Do Nascimento, J.W.B. Flow Properties and Pattern Flow Prediction of Food Industrial Powders. Eng. Agric. 2017, 37, 627–636. [Google Scholar] [CrossRef]

- Lanzerstorfer, C. Consideration of the Stress Dependence of the Bulk Density in Silo Storage of Dusts from Dry Off-Gas Cleaning. Adv. Powder Technol. 2017, 28, 115–121. [Google Scholar] [CrossRef]

- Bogusz, R.; Nowacka, M.; Bryś, J.; Rybak, K.; Szulc, K. Quality Assessment of Yellow Mealworm (Tenebrio molitor L.) Powders Processed by Pulsed Electric Field and Convective Drying. Sci. Rep. 2024, 14, 27792. [Google Scholar] [CrossRef]

- Deng, L.; Manthey, F.A. Flowability, Wet Agglomeration, and Pasta Processing Properties of Whole-Durum Flour: Effect of Direct Single-Pass and Multiple-Pass Reconstituted Milling Systems. Cereal Chem. 2019, 96, 708–716. [Google Scholar] [CrossRef]

- Combrzyński, M.; Oniszczuk, T.; Wójtowicz, A.; Biernacka, B.; Wojtunik-Kulesza, K.; Bąkowski, M.; Różyło, R.; Szponar, J.; Soja, J.; Oniszczuk, A. Nutritional Characteristics of New Generation Extruded Snack Pellets with Edible Cricket Flour Processed at Various Extrusion Conditions. Antioxidants 2023, 12, 1253. [Google Scholar] [CrossRef]

- Gull, A.; Prasad, K.; Kumar, P. Nutritional, Antioxidant, Microstructural and Pasting Properties of Functional Pasta. J. Saudi Soc. Agric. Sci. 2018, 17, 147–153. [Google Scholar] [CrossRef]

- Ocheme, O.B.; Adedeji, O.E.; Chinma, C.E.; Yakubu, C.M.; Ajibo, U.H. Proximate Composition, Functional, and Pasting Properties of Wheat and Groundnut Protein Concentrate Flour Blends. Food Sci. Nutr. 2018, 6, 1173–1178. [Google Scholar] [CrossRef]

- Nilsson, K.; Johansson, M.; Sandström, C.; Eriksson Röhnisch, H.; Hedenqvist, M.S.; Langton, M. Pasting and Gelation of Faba Bean Starch-Protein Mixtures. Food Hydrocoll. 2023, 138, 108494. [Google Scholar] [CrossRef]

- Villanueva, M.; De Lamo, B.; Harasym, J.; Ronda, F. Microwave Radiation and Protein Addition Modulate Hydration, Pasting and Gel Rheological Characteristics of Rice and Potato Starches. Carbohydr. Polym. 2018, 201, 374–381. [Google Scholar] [CrossRef]

- Piwińska, M.; Wyrwisz, J.; Kurek, M.A.; Wierzbicka, A. Effect of Drying Methods on the Physical Properties of Durum Wheat Pasta. CYTA J. Food 2016, 14, 523–528. [Google Scholar] [CrossRef]

- Wang, Y.; Ou, X.; Al-Maqtari, Q.A.; He, H.-J.; Othman, N. Evaluation of Amylose Content: Structural and Functional Properties, Analytical Techniques, and Future Prospects. Food Chem. X 2024, 24, 101830. [Google Scholar] [CrossRef]

- Duda, A.; Adamczak, J.; Chelminska, P.; Juszkiewicz, J.; Kowalczewski, P. Quality and Nutritional/Textural Properties of Durum Wheat Pasta Enriched with Cricket Powder. Foods 2019, 8, 46. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.; Guan, E.; Yang, Y.; Zhang, L.; Liu, Y.; Bian, K. Comparison and Mechanism Analysis of the Changes in Viscoelasticity and Texture of Fresh Noodles Induced by Wheat Flour Lipids. Food Chem. 2022, 397, 133567. [Google Scholar] [CrossRef]

- Simonato, B.; Trevisan, S.; Tolve, R.; Favati, F.; Pasini, G. Pasta Fortification with Olive Pomace: Effects on the Technological Characteristics and Nutritional Properties. LWT 2019, 114, 108368. [Google Scholar] [CrossRef]

- Singh, A.; Gupta, A.; Surasani, V.K.R.; Sharma, S. Influence of Supplementation with Pangas Protein Isolates on Textural Attributes and Sensory Acceptability of Semolina Pasta. J. Food Meas. Charact. 2021, 15, 1317–1326. [Google Scholar] [CrossRef]

- Sethi, S.; Nanda, S.K.; Bala, M. Quality Assessment of Pasta Enriched with Anthocyanin-Rich Black Rice Bran. J. Food Process Preserv. 2020, 44, e14952. [Google Scholar] [CrossRef]

- Foschia, M.; Peressini, D.; Sensidoni, A.; Brennan, M.A.; Brennan, C.S. Synergistic Effect of Different Dietary Fibres in Pasta on in Vitro Starch Digestion? Food Chem. 2015, 172, 245–250. [Google Scholar] [CrossRef]

- Gull, A.; Prasad, K.; Kumar, P. Effect of Millet Flours and Carrot Pomace on Cooking Qualities, Color and Texture of Developed Pasta. LWT 2015, 63, 470–474. [Google Scholar] [CrossRef]

- Iaconisi, V.; Marono, S.; Parisi, G.; Gasco, L.; Genovese, L.; Maricchiolo, G.; Bovera, F.; Piccolo, G. Dietary Inclusion of Tenebrio molitor Larvae Meal: Effects on Growth Performance and Final Quality Treats of Blackspot Sea Bream (Pagellus bogaraveo). Aquaculture 2017, 476, 49–58. [Google Scholar] [CrossRef]

- Kubo, M.T.K.; Augusto, P.E.D.; Cristianini, M. Effect of High Pressure Homogenization (HPH) on the Physical Stability of Tomato Juice. Food Res. Int. 2013, 51, 170–179. [Google Scholar] [CrossRef]

- Draszanowska, A.; Kurp, L.; Starowicz, M.; Paszczyk, B.; Czarnowska-Kujawska, M.; Olszewska, M.A. Effect of the Addition of Yellow Mealworm (Tenebrio molitor) on the Physicochemical, Antioxidative, and Sensory Properties of Oatmeal Cookies. Foods 2024, 13, 3166. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Valle, D.E.; Bello-Pérez, L.A.; Agama-Acevedo, E.; Alvarez-Ramirez, J. Structural Characteristics and in Vitro Starch Digestibility of Pasta Made with Durum Wheat Semolina and Chickpea Flour. LWT 2021, 145, 111347. [Google Scholar] [CrossRef]

- Anusha, S.; Negi, P.S. Characterization and Techno-Functional Properties of Tenebrio molitor Larvae Protein Concentrate. Food Biosci. 2023, 54, 102882. [Google Scholar] [CrossRef]

- Zhao, X.; Kim, I.; Kim, H.; Kim, Y. Protein Interactions and Rheological Properties of Heat-Induced Gels Containing Soy and Water-Soluble Mealworm (Tenebrio molitor Larvae) Protein Mixtures. Food Biosci. 2024, 58, 103718. [Google Scholar] [CrossRef]

- Zielińska, E.; Pečová, M.; Pankiewicz, U. Impact of Mealworm Powder (Tenebrio molitor) Fortification on Ice Cream Quality. Sustainability 2023, 15, 6041. [Google Scholar] [CrossRef]

- Carcea, M. Quality and Nutritional/Textural Properties of Durum Wheat Pasta Enriched with Cricket Powder. Foods 2020, 9, 1298. [Google Scholar] [CrossRef]

- Spinelli, S.; Padalino, L.; Costa, C.; Del Nobile, M.A.; Conte, A. Food By-Products to Fortified Pasta: A New Approach for Optimization. J. Clean. Prod. 2019, 215, 985–991. [Google Scholar] [CrossRef]

- Oh, E.; Park, W.J.; Kim, Y. Effects of Tenebrio molitor Larvae and Its Protein Derivatives on the Antioxidant and Anti-Inflammatory Capacities of Tofu. Food Biosci. 2022, 50, 102105. [Google Scholar] [CrossRef]

- Baek, M.; Kim, M.A.; Kwon, Y.S.; Hwang, J.S.; Goo, T.W.; Jun, M.; Yun, E.Y. Effects of Processing Methods on Nutritional Composition and Antioxidant Activity of Mealworm (Tenebrio molitor) Larvae. Entomol. Res. 2019, 49, 284–293. [Google Scholar] [CrossRef]

- Keil, C.; Grebenteuch, S.; Kröncke, N.; Kulow, F.; Pfeif, S.; Kanzler, C.; Rohn, S.; Boeck, G.; Benning, R.; Haase, H. Systematic Studies on the Antioxidant Capacity and Volatile Compound Profile of Yellow Mealworm Larvae (T. molitor L.) under Different Drying Regimes. Insects 2022, 13, 166. [Google Scholar] [CrossRef] [PubMed]

- Moruzzo, R.; Mancini, S.; Guidi, A. Edible Insects and Sustainable Development Goals. Insects 2021, 12, 557. [Google Scholar] [CrossRef]

- De Paula, R.; Abdel-Aal, E.S.M.; Messia, M.C.; Rabalski, I.; Marconi, E. Effect of Processing on the Beta-Glucan Physicochemical Properties in Barley and Semolina Pasta. J. Cereal Sci. 2017, 75, 124–131. [Google Scholar] [CrossRef]

- Biernacka, B.; Dziki, D.; Gawlik-Dziki, U.; Różyło, R. Common Wheat Pasta Enriched with Cereal Coffee: Quality and Physical and Functional Properties. LWT 2021, 139, 110516. [Google Scholar] [CrossRef]

- Parizad, P.A.; Marengo, M.; Bonomi, F.; Scarafoni, A.; Cecchini, C.; Pagani, M.A.; Marti, A.; Iametti, S. Bio-Functional and Structural Properties of Pasta Enriched with a Debranning Fraction from Purple Wheat. Foods 2020, 9, 163. [Google Scholar] [CrossRef] [PubMed]

- Verardo, V.; Arráez-Román, D.; Segura-Carretero, A.; Marconi, E.; Fernández-Gutiérrez, A.; Caboni, M.F. Determination of Free and Bound Phenolic Compounds in Buckwheat Spaghetti by RP-HPLC-ESI-TOF-MS: Effect of Thermal Processing from Farm to Fork. J. Agric. Food Chem. 2011, 59, 7700–7707. [Google Scholar] [CrossRef]

- Li, H.; Liu, Y.; Seephua, N.; Prakitchaiwattana, C.; Liu, R.X.; Zheng, J.S.; Siriamornpun, S. Fortification of Cricket and Silkworm Pupae Powders to Improve Nutritional Quality and Digestibility of Rice Noodles. Food Chem. X 2025, 26, 102279. [Google Scholar] [CrossRef]

- Giuntini, E.B.; Sardá, F.A.H.; de Menezes, E.W. The Effects of Soluble Dietary Fibers on Glycemic Response: An Overview and Futures Perspectives. Foods 2022, 11, 3934. [Google Scholar] [CrossRef]

- Rodríguez-Rodríguez, M.; Barroso, F.G.; Fabrikov, D.; Sánchez-Muros, M.J. In Vitro Crude Protein Digestibility of Insects: A Review. Insects 2022, 13, 682. [Google Scholar] [CrossRef]

| Sample | Peak Viscosity (cP) | Trough Viscosity (cP) | Breakdown Viscosity (cP) | Final Viscosity (cP) | Setback Viscosity (cP) | Peak Time (min) | Pasting Temperature (°C) |

|---|---|---|---|---|---|---|---|

| 0IN100S | 2147 ± 40 e | 1360 ± 28 e | 787 ± 12 d | 2802 ± 31 e | 1442 ± 3 e | 5.56 ± 0.05 b | 86.42 ± 0.04 a |

| 5IN95S | 1699 ± 57 d | 1125 ± 36 d | 574 ± 21 c | 2362 ± 35 d | 1238 ± 1 d | 5.50 ± 0.04 b | 87.6 ± 0.5 bc |

| 10IN90S | 1637 ± 13 c | 1074 ± 4 c | 563 ± 10 c | 2169 ± 5 c | 1095 ± 1 c | 5.67 ± 0.0001 c | 87.18 ± 0.04 ab |

| 20IN80S | 1252 ± 22 b | 846 ± 13 b | 406 ± 9 b | 1733 ± 25 b | 887 ± 12 b | 5.53 ± 0.0002 b | 88.4 ± 0.6 c |

| 30IN70S | 912 ± 11 a | 637 ± 6 a | 275 ± 4 a | 1289 ± 17 a | 653 ± 11 a | 5.37 ± 0.05 a | 89.65 ± 0.0001 d |

| Sample | 0IN100S | 5IN95S | 10IN90S | 20IN80S | 30IN70S |

|---|---|---|---|---|---|

| Cooking time = 1 min |  |  |  |  |  |

| OCT (min) | 10.0 | 11.5 | 12.0 | 15.0 | 16.5 |

|  |  |  |  | |

| CL (g/100 g pasta) | 5.7 ± 0.3 a | 5.0 ± 0.5 a | 5.6 ± 0.4 a | 9.5 ± 0.6 c | 7.2 ± 0.5 b |

| WAI (g/g) | 2.6 ± 0.4 b | 2.6 ± 0.2 b | 2.4 ± 0.2 ab | 2.2 ± 0.2 a | 2.1 ± 0.2 a |

| Sample | 0IN100S | 5IN95S | 10IN90S | 20IN80S | 30IN70S |

|---|---|---|---|---|---|

| L*dry | 77.79 ± 1.11 dA | 63.82 ± 2.85 cA | 56.044 ± 3.19 bA | 49.78 ± 2.60 aA | 48.067 ± 3.40 aA |

| L*cooked | 80.87± 1.86 eB | 70.82 ± 3.42 dB | 66.089 ± 1.94 cB | 59.96 ± 0.90 bB | 55.17 ± 3.15 aB |

| a*dry | 1.100 ± 0.10 aA | 3.37 ± 0.30 bB | 4.78 ± 0.62 cB | 4.74 ± 0.74 cA | 3.83 ± 0.60 bA |

| a*cooked | 1.089 ± 0.08 aA | 2.56 ± 0.15 bA | 3.38 ± 0.16 cA | 3.99 ± 0.45 dA | 4.44 ± 0.38 eA |

| b*dry | 15.18 ± 0.96 bA | 15.58 ± 0.91 bA | 17.31 ± 1.35 cA | 14.72 ± 0.95 bA | 12.40 ± 0.68 aA |

| b*cooked | 15.39 ± 0.84 aA | 17.27 ± 0.80 bB | 18.12 ± 0.56 bA | 17.83 ± 0.80 bB | 17.61 ± 1.40 bB |

| ΔE*dry | / | 14.16 ± 2.94 aA | 22.16 ± 2.73 bB | 28.25 ± 2.86 cB | 29.98 ± 3.10 cA |

| ΔE*cooked | / | 10.32 ± 2.64 aA | 15.20 ± 2.81 bA | 21.25 ± 2.50 cA | 26.01 ± 1.79 dA |

| ΔE*dry-cooked | 3.06 ± 2.00 a | 7.25 ± 2.50 ab | 10.17 ± 1.90 b | 10.67 ± 1.75 b | 8.83 ± 2.97 ab |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carpentieri, S.; Orkusz, A.; Harasym, J.; Ferrari, G. Exploring the Use of Tenebrio molitor Larvae Proteins to Functionalize Durum Wheat Pasta. Foods 2025, 14, 1194. https://doi.org/10.3390/foods14071194

Carpentieri S, Orkusz A, Harasym J, Ferrari G. Exploring the Use of Tenebrio molitor Larvae Proteins to Functionalize Durum Wheat Pasta. Foods. 2025; 14(7):1194. https://doi.org/10.3390/foods14071194

Chicago/Turabian StyleCarpentieri, Serena, Agnieszka Orkusz, Joanna Harasym, and Giovanna Ferrari. 2025. "Exploring the Use of Tenebrio molitor Larvae Proteins to Functionalize Durum Wheat Pasta" Foods 14, no. 7: 1194. https://doi.org/10.3390/foods14071194

APA StyleCarpentieri, S., Orkusz, A., Harasym, J., & Ferrari, G. (2025). Exploring the Use of Tenebrio molitor Larvae Proteins to Functionalize Durum Wheat Pasta. Foods, 14(7), 1194. https://doi.org/10.3390/foods14071194