The Preparation, Properties, and Characterization of Octenyl Succinic Anhydride-Modified Turmeric Starches and Their Emulsification for Pickering Emulsions

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals and Materials

2.2. Preparation and Process Optimization of Octenyl Succinic Anhydride-Modified Turmeric Starches (O-MTSs)

2.3. Determination of Degrees of Substitution (DS)

2.4. Determination of Solubility and Swelling Degree

2.5. Determination of Thaw Restability

2.6. Determination of Transparency

2.7. Characterization of Octenyl Succinic Anhydride-Modified Turmeric Starches (O-MTSs)

2.7.1. SEM Analysis

2.7.2. Particle Size Analysis

2.7.3. Fourier Transform Infrared Spectroscopy (FT-IR) Analysis

2.7.4. X-Ray Diffractometer (XRD) Analysis

2.7.5. Thermal Gravity Analysis

2.8. Preparation of Pickering Emulsions

2.9. Pickering Emulsion Stability Analysis

2.9.1. The Effect of DS Value on the Stability of Pickering Emulsions

2.9.2. The Effect of Starch Concentration on the Stability of Pickering Emulsions

2.9.3. Determination of the Emulsification Index (EI)

2.9.4. Super-Depth-of-Field Microscope (SDM) Detection

2.10. Data Statistics and Analysis

3. Results and Discussion

3.1. Results of Process Optimization

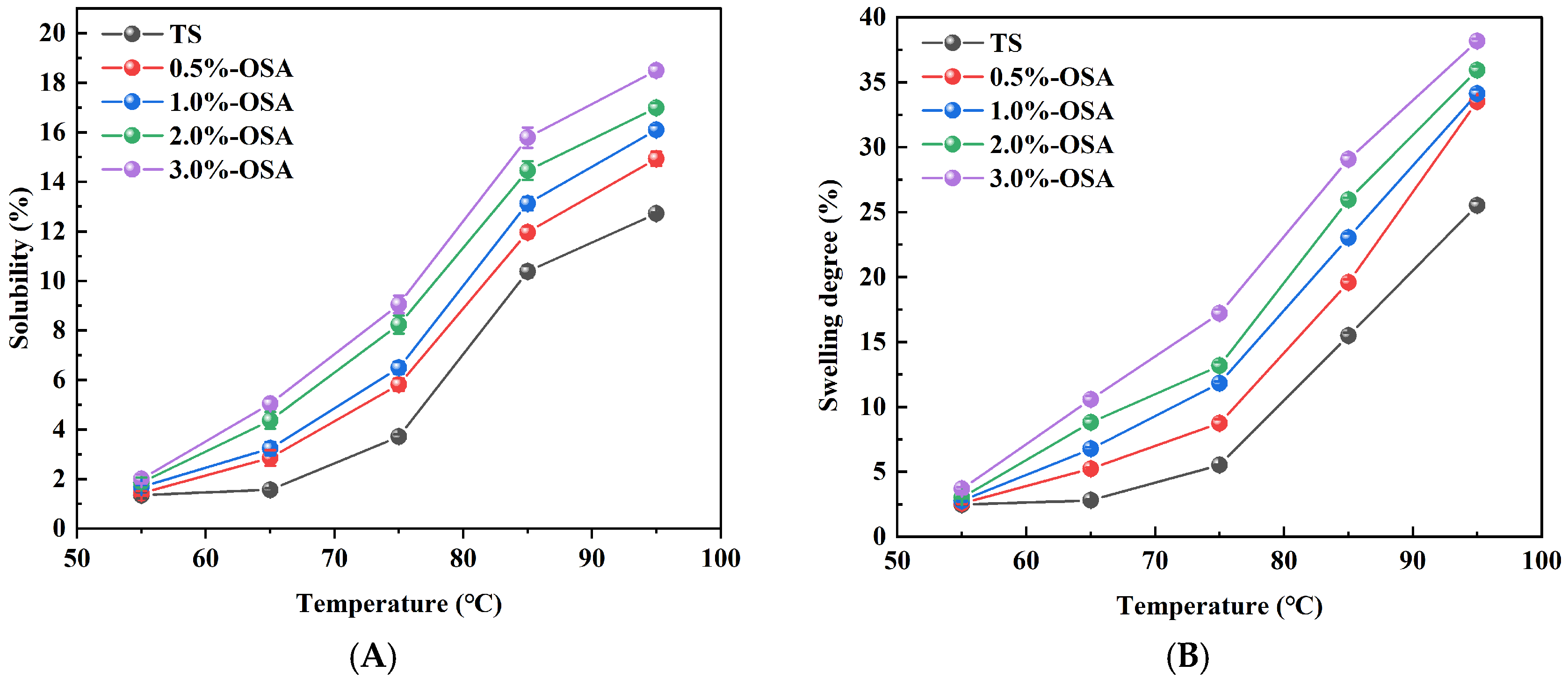

3.2. Changes in Solubility and Swelling Degree

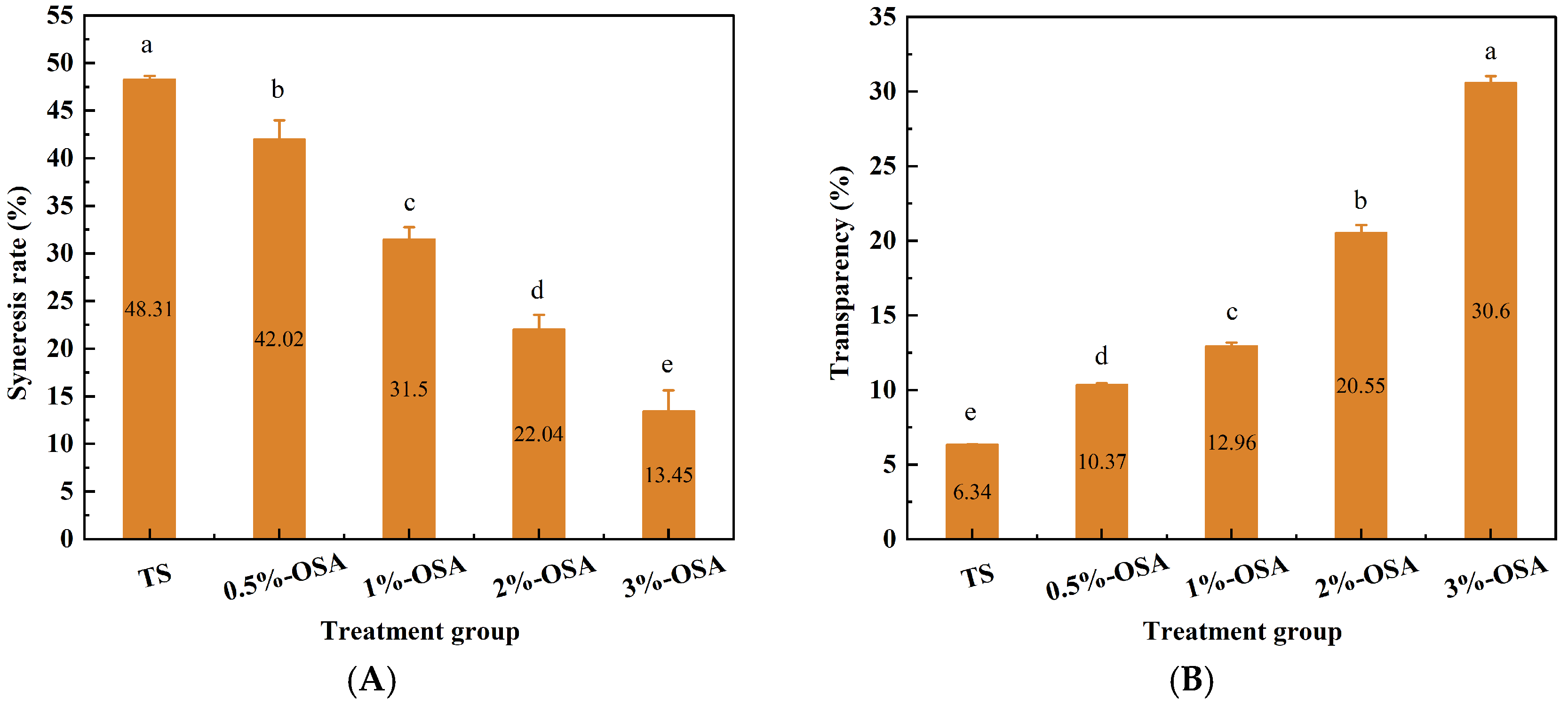

3.3. Changes in Freeze–Thaw Stability

3.4. Changes in Transparency

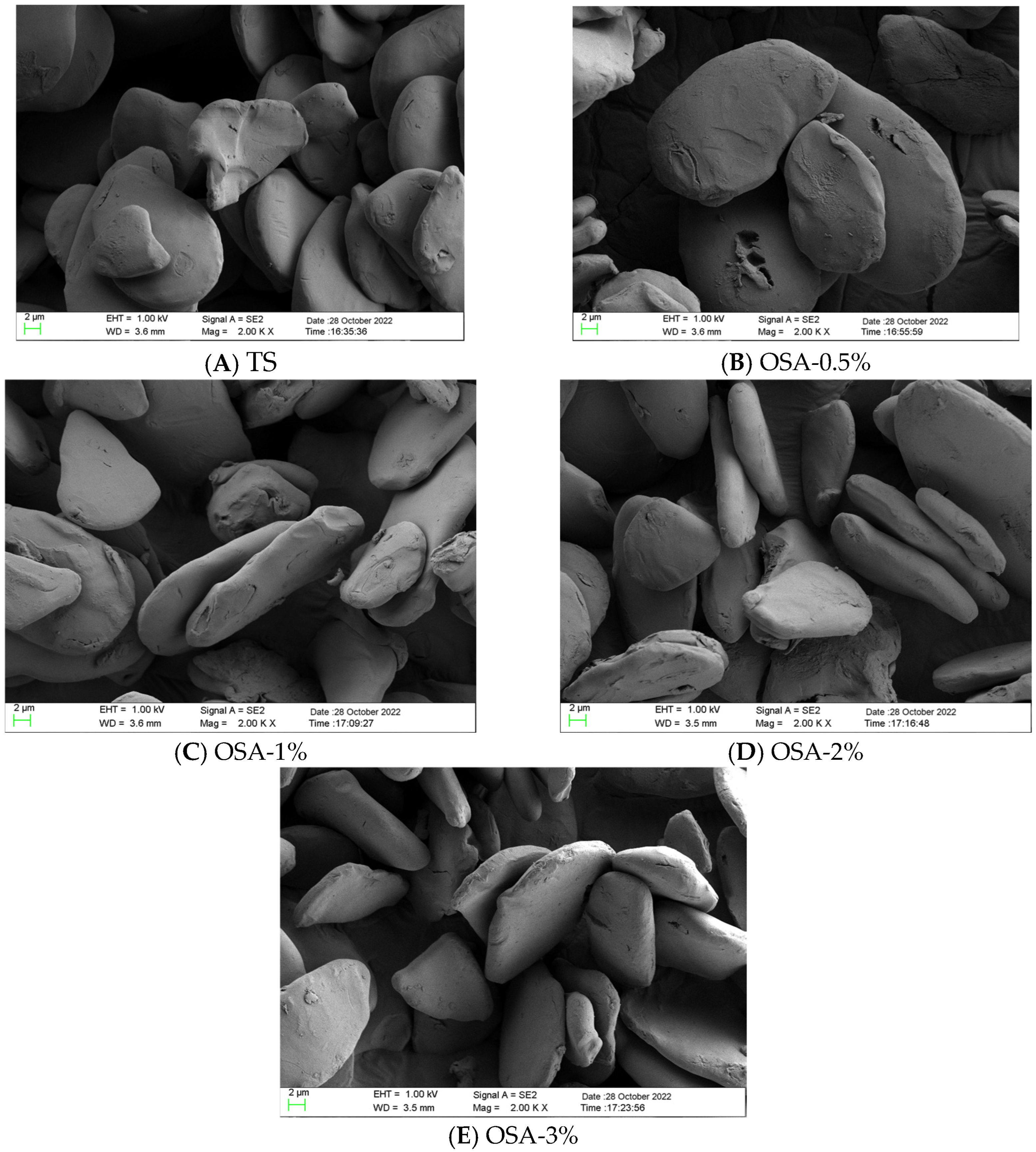

3.5. Changes in Particle Morphology

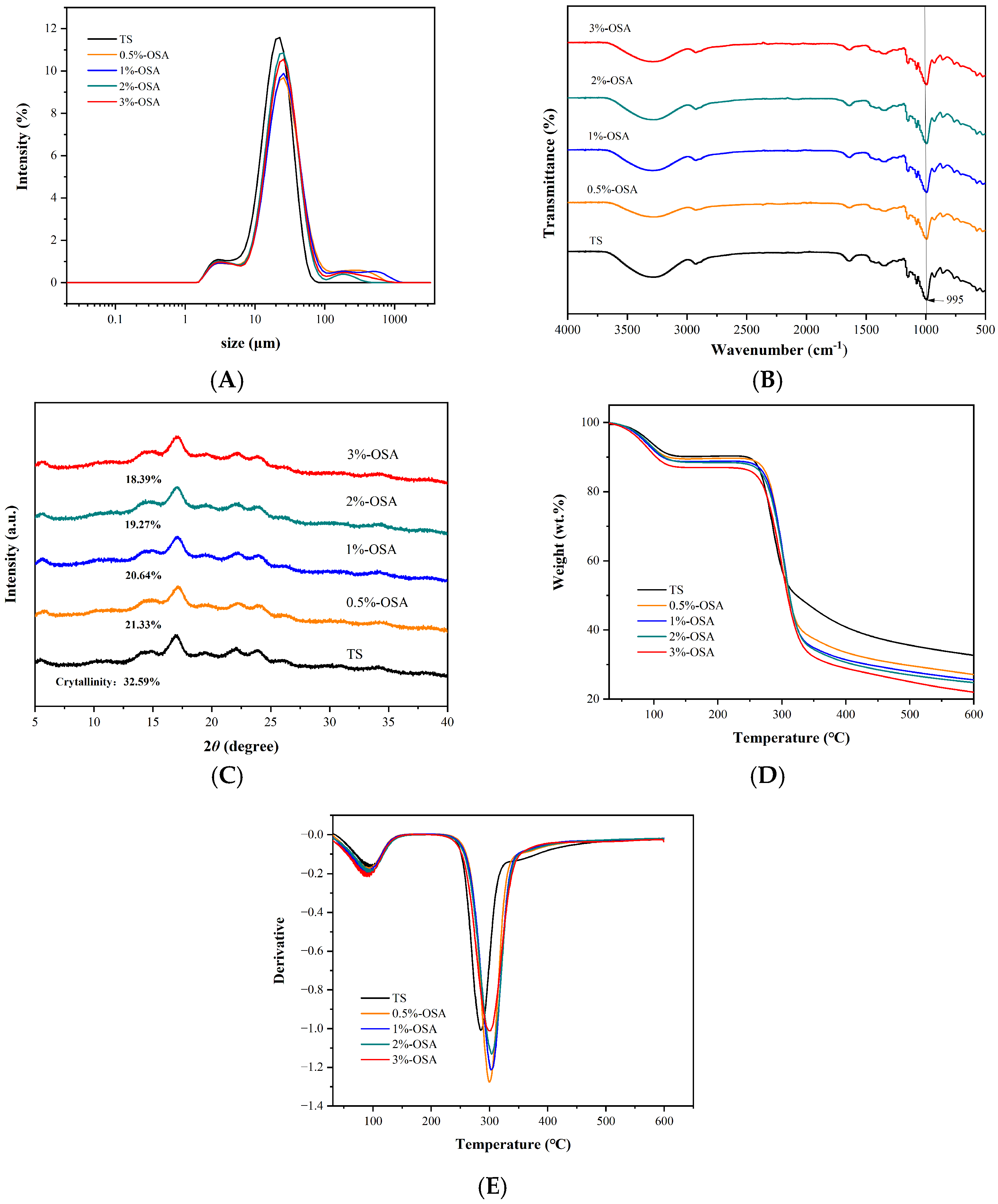

3.6. Changes in Particle Size Analysis

3.7. FT-IR Analysis

3.8. XRD Analysis

3.9. Thermogravimetric Analysis

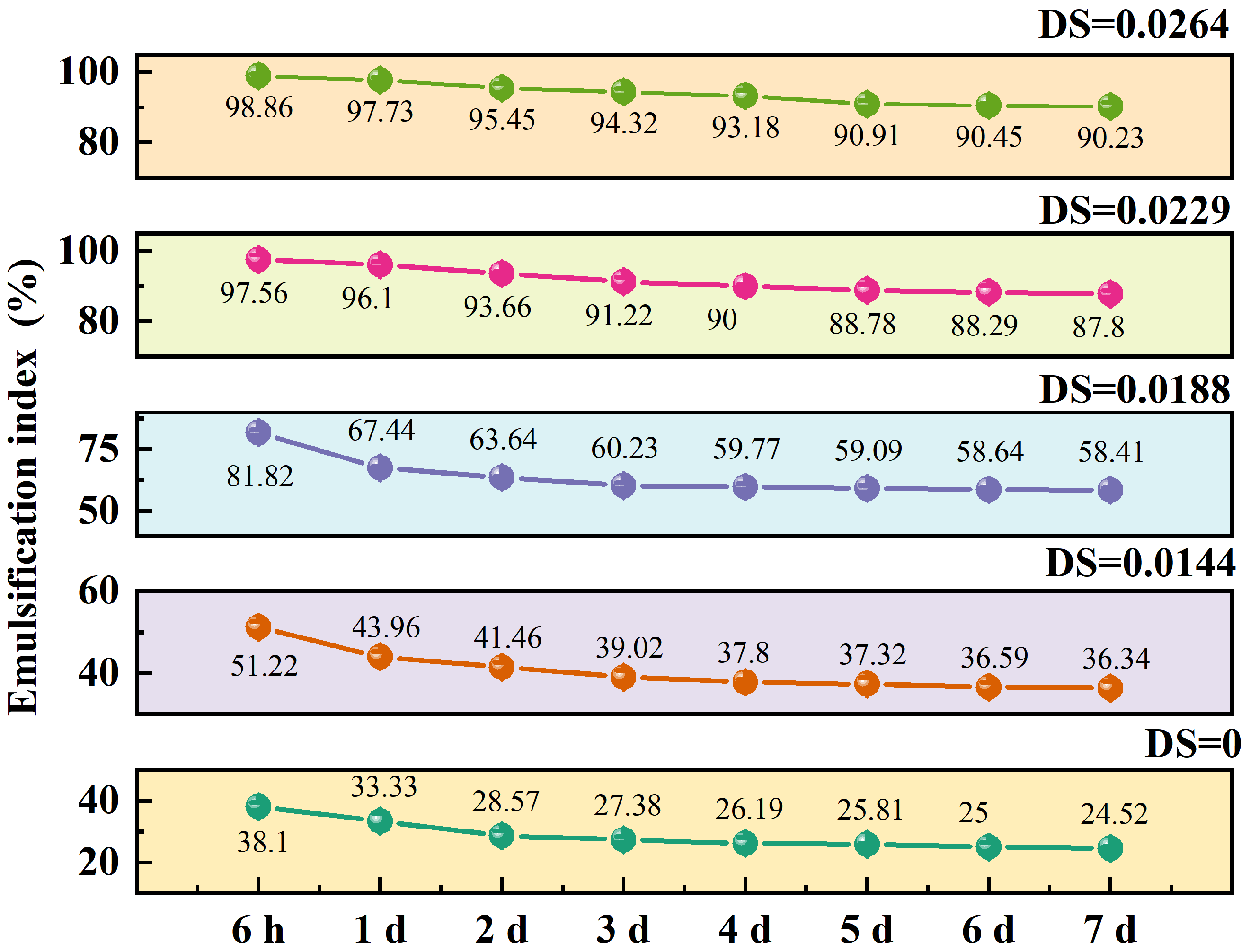

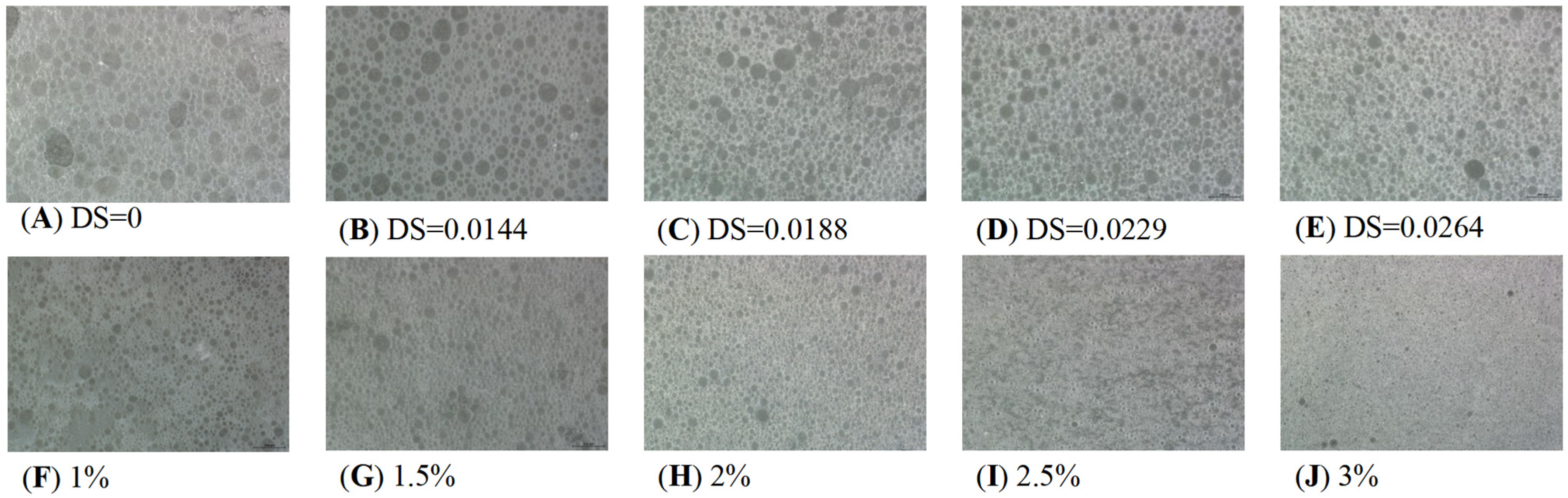

3.10. The Effects of DS Value on Pickering Emulsion Stability

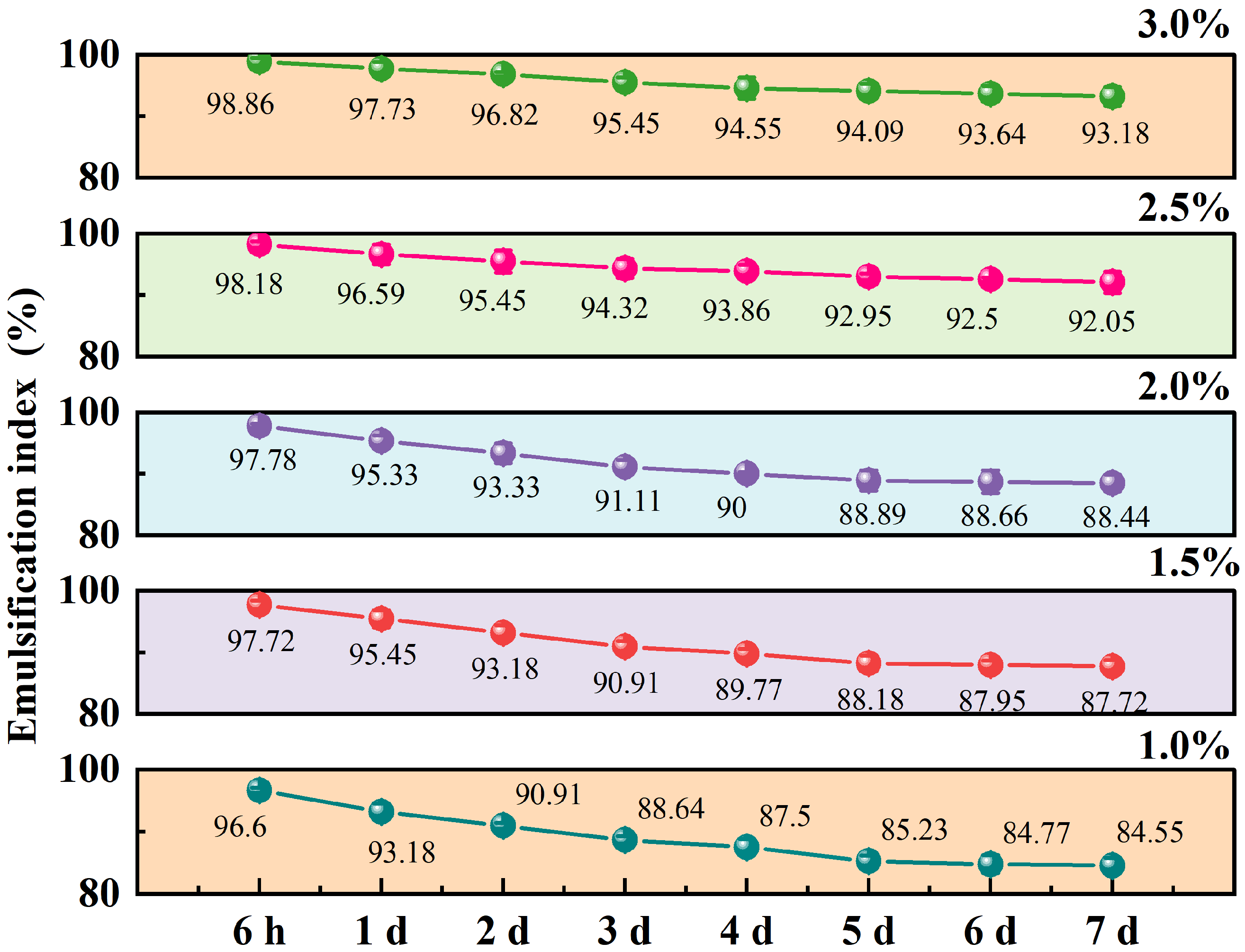

3.11. Effect of Starch Concentration on the Stability of Pickering Emulsion

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| OAS | Octenyl succinic anhydride |

| TSs | Turmeric starches |

| O-MTSs | OSA-modified turmeric starches |

| SEM | Scanning electron microscope |

| XRD | X-ray diffractometer |

| FT-IR | Fourier-transform infrared spectroscopy |

| DS | Degree of substitution |

| EI | Emulsification index |

References

- Lelli, D.; Pedone, C.; Majeed, M.; Sahebkar, A. Curcumin and Lung Cancer: The Role of microRNAs. Curr. Pharm. Des. 2017, 23, 3440–3444. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.Y.; Lin, S.B.; An, S.Y.; Liu, L.; Hu, Y.C. Preparation, characterization, and anti-aflatoxigenic activity of chitosan packaging films incorporated with turmeric essential oil. Int. J. Biol. Macromol. 2019, 131, 420–434. [Google Scholar] [CrossRef] [PubMed]

- Guerrero-Romero, F.; Simental-Mendía, L.E.; Martínez-Aguilar, G.; Sánchez-Meraz, M.A.; Gamboa-Gómez, C.I. Hypoglycemic and antioxidant effects of five commercial turmeric (Curcuma longa) supplements. J. Food Biochem. 2020, 44, e13389. [Google Scholar] [CrossRef] [PubMed]

- Yan, S.; Zhou, M.; Zheng, X.; Xing, Y.; Dong, J.; Yan, M.; Li, R. Anti-inflammatory effect of curcumin on the mouse model of myocardial infarction through regulating macrophage polarization. Mediat. Inflamm. 2021, 2021, 976912. [Google Scholar] [CrossRef]

- Fu, L.J.; Tan, S.; Si, R.R.; Qiang, Y.Y.; Wei, H.; Huang, B.; Shi, M.Z.; Fang, L.; Fu, J.W.; Zeng, S.X. Characterization, stability and antioxidant activity of curcumin nanocomplexes with soy protein isolate and pectin. Curr. Res. Food Sci. 2023, 6, 100530. [Google Scholar] [CrossRef]

- Qiang, Y.Y.; Wei, H.; Huang, B.; Chi, H.H. Inclusion complex of turmeric essential oil with hydroxypropyl-β-cyclodextrin: Preparation, characterization and release kinetics. Curr. Res. Food Sci. 2024, 8, 100668. [Google Scholar] [CrossRef]

- Van Hung, P.; Duyen, V.T.N. Structure, physicochemical characteristics, and functional properties of starches isolated from yellow (Curcuma longa) and black (Curcuma caesia) turmeric rhizomes. Starch-Sträke 2017, 69, 1600285. [Google Scholar] [CrossRef]

- Caldwell, C.G.; Wurzburg, O.B. Polysaccharide Derivatives of Substituted Dicarboxylic Acids. U.S. Patent 2661349 A, 1 December 1953. [Google Scholar]

- Dokić, L.; Krstonošić, V.; Nikolić, I. Physicochemical characteristics and stability of oil-in-water emulsions stabilized by OSA starch. Food Hydrocoll. 2012, 29, 185–192. [Google Scholar] [CrossRef]

- Pan, J.; Chen, J.; Wang, X.; Wang, Y.; Fan, J.B. Pickering emulsion: From controllable fabrication to biomedical application. Interdiscip. Med. 2023, 1, e20230014. [Google Scholar] [CrossRef]

- Linke, C.; Drusch, S. Pickering emulsions in foods-opportunities and limitations. Crit. Rev. Food Sci. Nutr. 2018, 58, 1971–1985. [Google Scholar] [CrossRef]

- Ding, M.; Zhang, T.; Zhang, H. Gelatin moleculastructures affect behaviors of fish oil-oaded traditionaand Pickering emulsions. Food Chem. 2020, 309, 125642. [Google Scholar] [CrossRef] [PubMed]

- Pickering, S.U. Emulsions. J. Chem. Soc. Trans. 1907, 91, 2001–2021. [Google Scholar] [CrossRef]

- Zhang, B.; Mei, J.Q.; Chen, B.; Chen, H.Q. Digestibility, physicochemical and structural properties of octenyl succinic anhydride-modified cassava starches with different degree of substitution. Food Chem. 2017, 229, 136. [Google Scholar] [CrossRef] [PubMed]

- Gong, B.; Xu, M.; Li, B.; Wu, H.; Liu, Y.; Zhang, G.; Ouyang, S.; Li, W. Repeated heat-moisture treatment exhibits superiorities in modification of structural, physicochemical and digestibility properties of red adzuki bean starch compared to continuous heat-moisture way. Food Res. Int. 2017, 102, 776. [Google Scholar] [CrossRef]

- Zhou, Y.G.; Li, D.; Wang, L.J.; Li, Y.; Yang, B.N.; Bhandari, B.; Xiao, D.C.; Mao, Z.H. Effect of water content on thermal behaviors of common buckwheat flour and starch. J. Food Eng. 2009, 93, 242–248. [Google Scholar] [CrossRef]

- Shang, J.; Li, L.; Zhao, B.; Liu, M.; Zheng, X. Comparative studies on physicochemical properties of total, A- and B-type starch from soft and hard wheat varieties. Int. J. Biol. Macromol. 2020, 154, 714–723. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, M.; Zhu, K.; Gang, W.; Tan, L. Functional properties and utilization of Artocarpus heterophyllus Lam seed starch from new species in China. Int. J. Biol. Macromol. 2018, 107 Pt B, 1395–1405. [Google Scholar] [CrossRef]

- Sun, S.W.; Lin, X.; Zhao, B.B.; Wang, B.L.; Guo, Z.B. Structural properties of lotus seed starch prepared by octenyl succinic anhydride esterification assisted by high hydrostatic pressure treatment. LWT-Food Sci. Technol. 2020, 117, 108698. [Google Scholar] [CrossRef]

- Mao, X.H.; Huang, H.H.; Li, X.; Wang, T.T.; Chen, X.T.; Gao, W.Y. Physicochemical characterisation, digestibility and anticonstipation activity of some high-resistant untraditional starches from zingiberaceae plants. Int. J. Food Sci. Technol. 2016, 52, 617–625. [Google Scholar] [CrossRef]

- Yu, Z.Y.; Jiang, S.W.; Zheng, Z.; Cao, X.M.; Hou, Z.G.; Xu, J.J.; Wang, H.L.; Jiang, S.T.; Pan, L.J. Preparation and properties of OSA-modified taro starches and their application for stabilizing Pickering emulsions. Int. J. Biol. Macromol. 2019, 137, 277–285. [Google Scholar] [CrossRef]

- Xiao, J.; Wang, X.; Gonzalez, A.J.P.; Huang, Q. Kafirin nanoparticles-stabilized Pickering emulsions: Microstructure and rheological behavior. Food Hydrocoll. 2016, 54, 30–39. [Google Scholar] [CrossRef]

- Altuna, L.; Herrera, M.L.; Foresti, M.L. Synthesis and characterization of octenyl succinic anhydride modified starches for food applications. A review of recent literature. Food Hydrocoll. 2018, 80, 97–110. [Google Scholar] [CrossRef]

- Miao, M.; Li, R.; Jiang, B.; Cui, S.W.; Zhang, T.; Jin, Z.Y. Structure and physicochemical properties of octenyl succinic esters of sugary maize soluble starch and waxy maize starch. Food Chem. 2014, 151, 154–160. [Google Scholar] [CrossRef] [PubMed]

- Liang, Y.; Zheng, L.; Yang, Y.; Zheng, X.; Xiao, D.; Ai, B.; Sheng, Z. Dielectric barrier discharge cold plasma modifies the multiscale structure and functional properties of banana starch. Int. J. Biol. Macromol. 2024, 264, 130462. [Google Scholar] [CrossRef]

- Sharma, M.; Singh, A.K.; Yadav, D.N.; Arora, S.; Vishwakarma, R.K. Impact of octenyl succinylation on rheological, pasting, thermal and physicochemical properties of pearl millet (Pennisetum typhoides) starch. LWT-Food Sci. Technol. 2016, 73, 52–59. [Google Scholar] [CrossRef]

- Bist, Y.; Kumar, Y.; Saxena, D.C. Enhancing the storage stability of Pickering emulsion using esterified buckwheat starch with improved structure and morphology. LWT 2022, 161, 113329. [Google Scholar] [CrossRef]

- Abiddin, N.F.Z.; Yusoff, A.; Ahmad, N. Effect of octenylsuccinylation on physicochemical, thermal, morphological and stability of octenyl succinic anhydride (OSA) modified sago starch. Food Hydrocoll. 2018, 75, 138–146. [Google Scholar] [CrossRef]

- Simsek, S.; Ovando-Martinez, M.; Marefati, A.; Sj, M.; Rayner, M. Chemical composition, digestibility and emulsification properties of octenyl succinic esters of various starches. Food Res. Int. 2015, 75, 41–49. [Google Scholar] [CrossRef]

- Han, M.; Wu, X.; Peng, Y.; Yu, H. Preparation of low degree of substitution octenyl succinic starch ester by response surface methodology and its property analysis. J. Food Process. Preserv. 2021, 46, e16125. [Google Scholar] [CrossRef]

- Zheng, Y.; Hu, L.; Ding, N.; Liu, P.; Yao, C.; Zhang, H. Physicochemical and structural characteristics of the octenyl succinic ester of ginkgo starch. Int. J. Biol. Macromol. 2017, 94, 566–570. [Google Scholar] [CrossRef]

- Zhang, W.; Cheng, B.; Li, J.; Shu, Z.; Wang, P.; Zeng, X. Structure and properties of octenyl succinic anhydride-modified high-amylose japonica rice starches. Polymers 2021, 13, 493–498. [Google Scholar] [CrossRef] [PubMed]

- Ačkar, Đ.; Babić, J.; Jozinović, A.; Miličević, B.; Jokić, S.; Miličević, R.; Šubarić, D. Starch Modification by Organic Acids and Their Derivatives: A Review. Molecules 2015, 20, 19554–19570. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Fu, X.; Huang, Q.; Zhang, B. Octenylsuccinate starch spherulites as a stabilizer for Pickering emulsions. Food Chem. 2017, 227, 298. [Google Scholar] [CrossRef] [PubMed]

- Shao, P.; Zhang, H.; Niu, B.; Jin, W. Physical stabilities of taro starch nanoparticles stabilized Pickering emulsions and the potential application of encapsulated tea polyphenols. Int. J. Biol. Macromol. 2018, 118, 2032–2039. [Google Scholar] [CrossRef]

- Jia, X.; Xu, R.; Shen, W.; Xie, M.; Abid, M.; Jabbar, S.; Wu, T. Stabilizing oil-in-water emulsion with amorphous cellulose. Food Hydrocoll. 2015, 43, 275–282. [Google Scholar] [CrossRef]

- Lu, Y.; Huang, J.; Ge, L.; Xie, W.; Wu, D. Selective localization of cellulose nanocrystals in the biodegradable poly(vinyl alcohol)/poly(ε-caprolactone) blend composites prepared by Pickering emulsions. Polymer 2018, 156, 136–147. [Google Scholar] [CrossRef]

- Estrada-Fernández, A.G.; Dorantes-Bautista, G.; Román-Guerrero, A.; Campos-Montiel, R.G.; Hernández-Uribe, J.P.; Jiménez-Alvarado, R. Oxalis tuberosa Modification of starch with OSA, characterization and application in food-grade Pickering emulsions. Food Sci. Technol. 2021, 58, 2896–2905. [Google Scholar] [CrossRef]

- Cheng, F.; Ai, Y.F.; Ghosh, S. Utilization of octenyl succinic anhydride-modified pea and corn starches for stabilizing oil-in-water emulsions. Food Hydrocoll. 2021, 118, 106773. [Google Scholar] [CrossRef]

- Zheng, W.X.; Ren, L.; Hao, W.Z.; Wang, L.; Liu, C.H.; Zheng, L. Encapsulation of indole-3-carbinol in Pickering emulsions stabilized by OSA-modified high amylose corn starch: Preparation, characterization and storage stability properties. Food Chem. 2022, 386, 132846. [Google Scholar] [CrossRef]

- Bhosale, R.; Singhal, R. Effect of octenylsuccinylation on physicochemical and functional properties of waxy maize and amaranth starches. Carbohydr. Polym. 2007, 68, 447–456. [Google Scholar] [CrossRef]

- Marefati, A.; Wiege, B.; Haase, N.U.; Matos, M.; Rayner, M. Pickering emulsifiers based on hydrophobically modified small granular starches-Part I: Manufacturing and physico-chemical characterization. Carbohydr. Polym. 2017, 175, 473–483. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.G.; Khalid, N.; Shu, G.F.; Neves, M.A.; Kobayashi, I.; Nakajima, M. Formulation and characterization of O/W emulsions stabilized using octenyl succinic anhydride modified kudzu starch. Carbohydr. Polym. 2017, 176, 91–98. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.S.; Ran, C.; Jiang, X.F.; Dou, J.P. Impact of octenyl succinic anhydride (OSA) esterification on microstructure and physicochemical properties of Sorghum starch. LWT 2021, 152, 112320. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, L.; Chi, H.; Wei, H.; Huang, B.; Qiang, Y.; Shi, M.; Fang, L.; Fu, J. The Preparation, Properties, and Characterization of Octenyl Succinic Anhydride-Modified Turmeric Starches and Their Emulsification for Pickering Emulsions. Foods 2025, 14, 1171. https://doi.org/10.3390/foods14071171

Fu L, Chi H, Wei H, Huang B, Qiang Y, Shi M, Fang L, Fu J. The Preparation, Properties, and Characterization of Octenyl Succinic Anhydride-Modified Turmeric Starches and Their Emulsification for Pickering Emulsions. Foods. 2025; 14(7):1171. https://doi.org/10.3390/foods14071171

Chicago/Turabian StyleFu, Lijuan, Hongfei Chi, Hang Wei, Biao Huang, Yueyue Qiang, Mengzhu Shi, Ling Fang, and Jianwei Fu. 2025. "The Preparation, Properties, and Characterization of Octenyl Succinic Anhydride-Modified Turmeric Starches and Their Emulsification for Pickering Emulsions" Foods 14, no. 7: 1171. https://doi.org/10.3390/foods14071171

APA StyleFu, L., Chi, H., Wei, H., Huang, B., Qiang, Y., Shi, M., Fang, L., & Fu, J. (2025). The Preparation, Properties, and Characterization of Octenyl Succinic Anhydride-Modified Turmeric Starches and Their Emulsification for Pickering Emulsions. Foods, 14(7), 1171. https://doi.org/10.3390/foods14071171