Development of Gluten-Free Cakes Using Protein Concentrate Obtained from Cold-Pressed Terebinth (Pistacia terebinthus L.) Oil By-Products

Abstract

1. Introduction

2. Material and Methods

2.1. Material

2.2. Methods

2.2.1. Formation of Terebinth Seed Protein Concentrate

2.2.2. Production of Cake Samples

2.2.3. Rheological Properties of Cake Batters

2.2.4. Physicochemical Properties of Cakes

2.2.5. Texture Profile Analysis

2.2.6. Oxidation Stability of Cakes

2.2.7. Sensory Analysis

2.2.8. Statistical Analysis

3. Results and Discussion

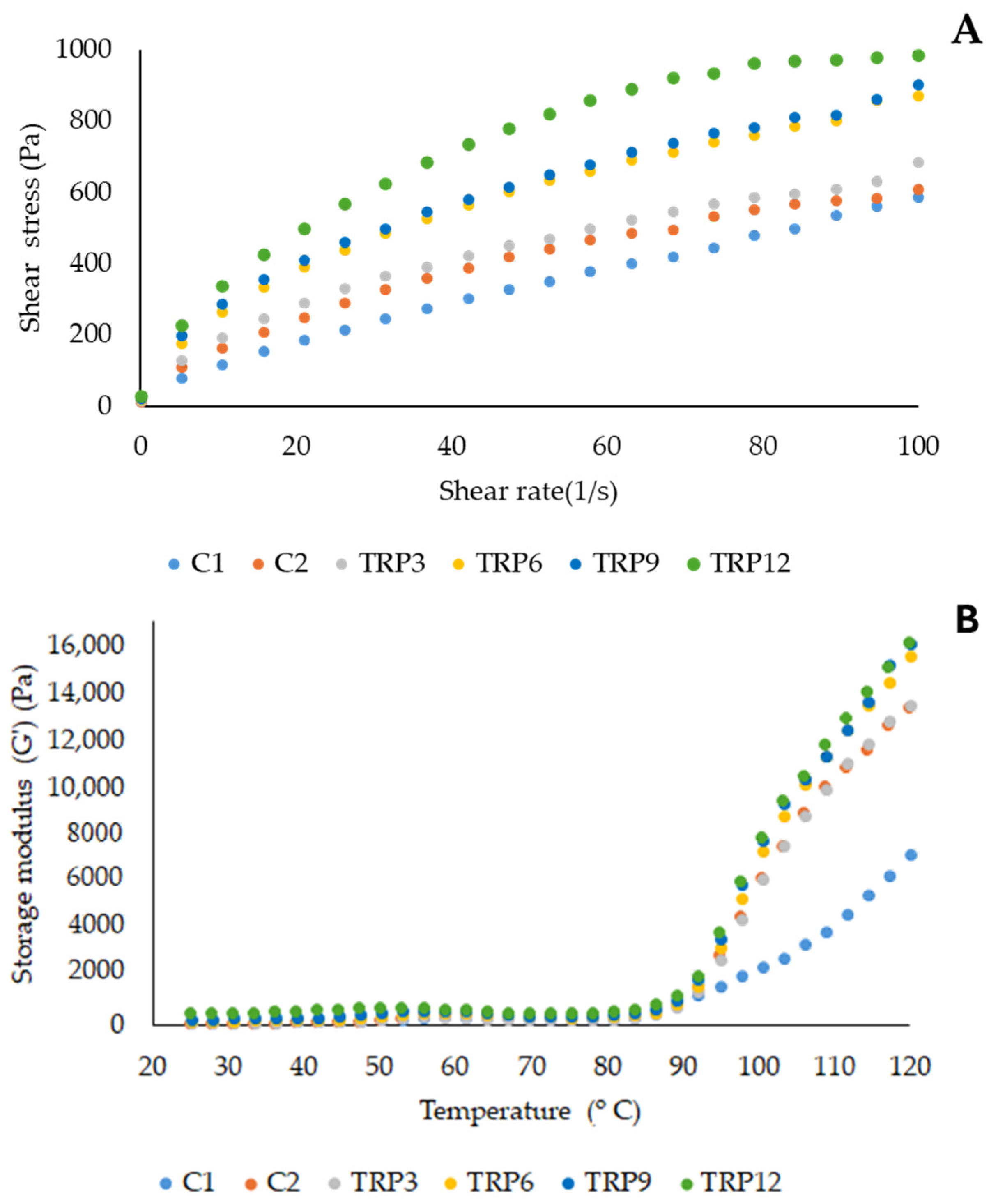

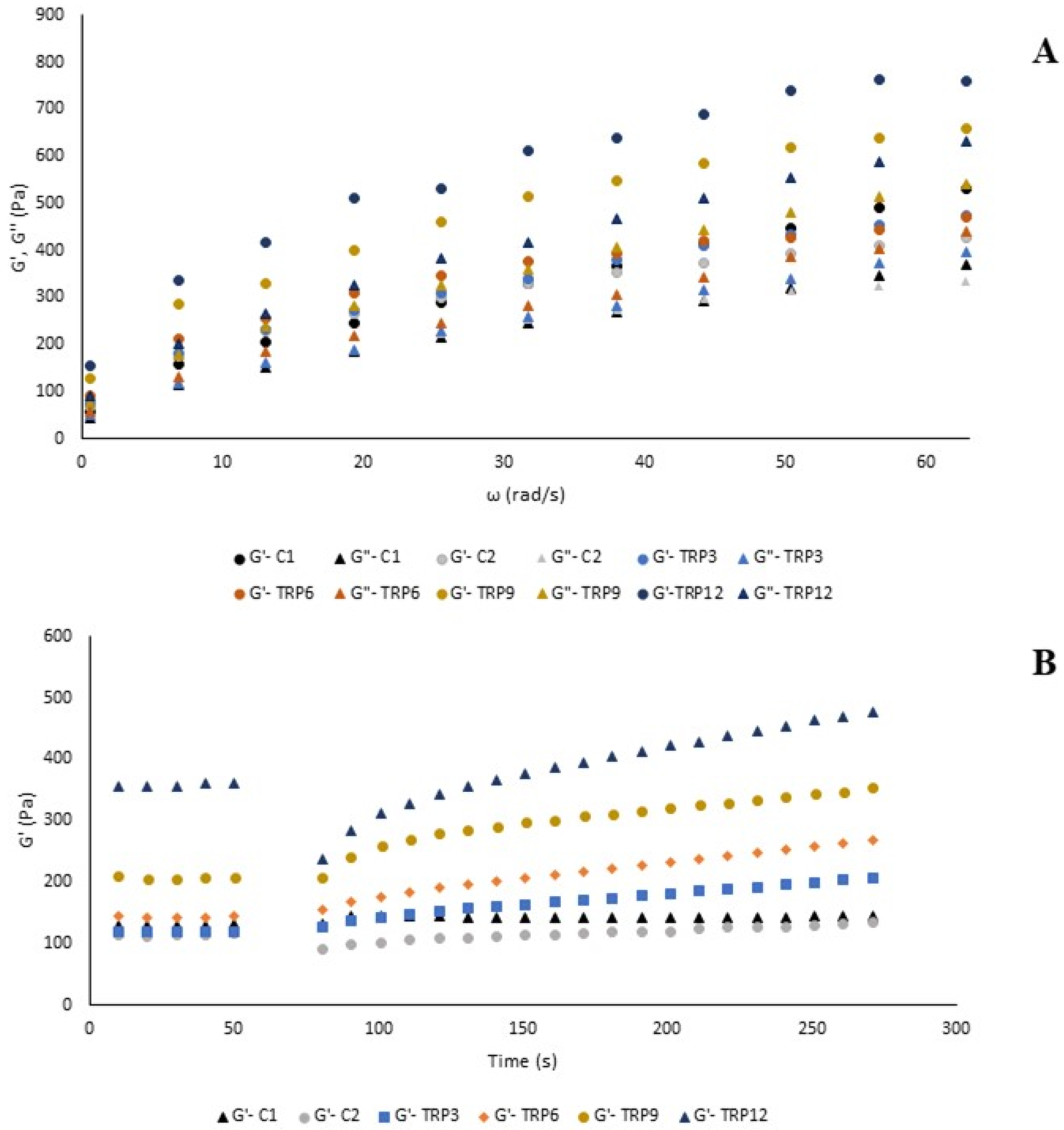

3.1. Rheological Characteristics of Cake Batters

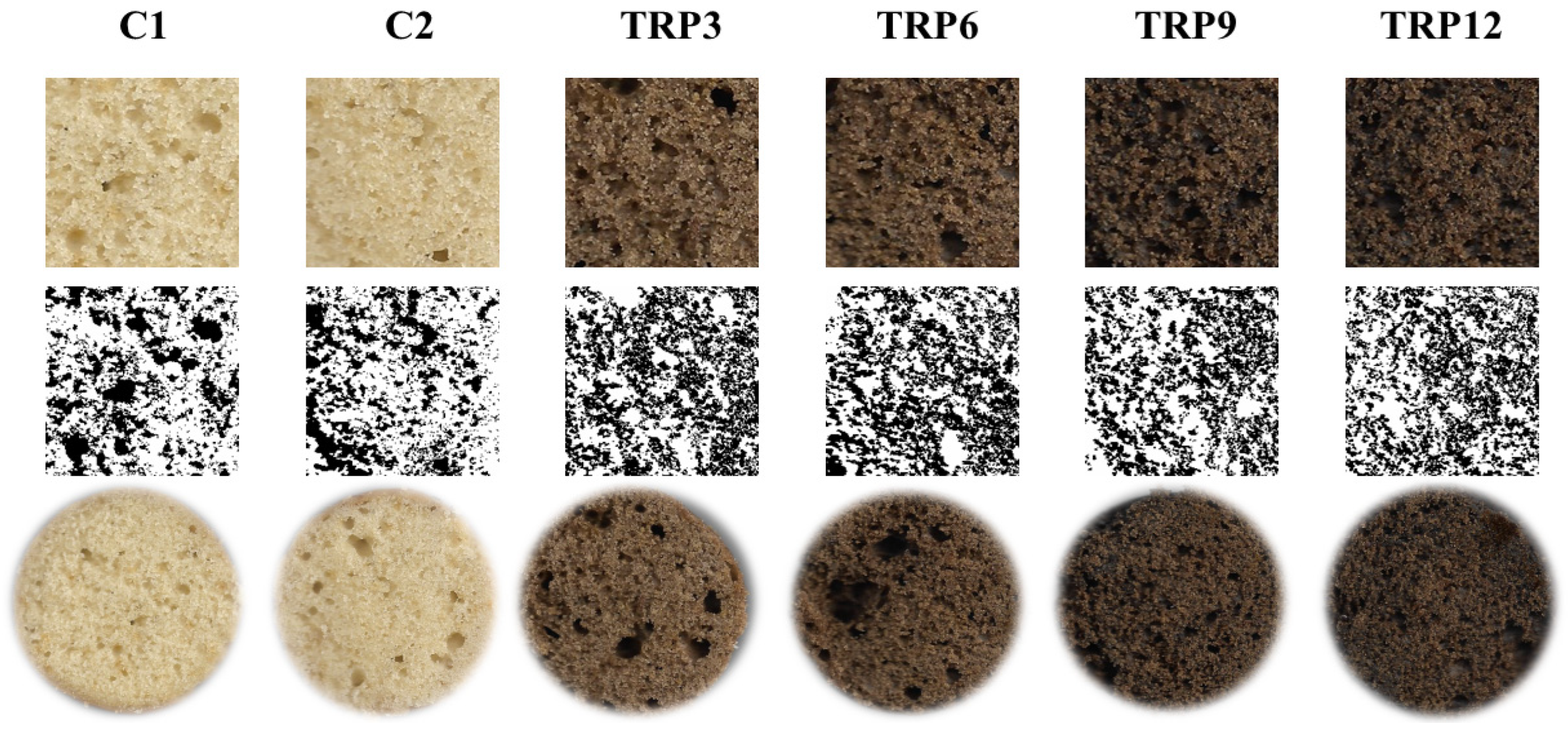

3.2. Cake Samples’ Physicochemical Properties

3.3. Textural Properties of Cake Crumbs

3.4. Oxidative Stability of the Cake Samples

3.5. Sensory Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Petraru, A.; Amariei, S. Oil press-cakes and meals valorization through circular economy approaches: A review. Appl. Sci. 2020, 10, 7432. [Google Scholar] [CrossRef]

- Nevara, G.A.; Giwa Ibrahim, S.a.; Syed Muhammad, S.K.; Zawawi, N.; Mustapha, N.A.; Karim, R. Oilseed meals into foods: An approach for the valorization of oilseed by-products. Crit. Rev. Food Sci. Nutr. 2023, 63, 6330–6343. [Google Scholar] [CrossRef]

- Teh, S.-S.; Bekhit, A.E.-D.A. Utilization of oilseed cakes for human nutrition and health benefits. In Agricultural Biomass Based Potential Materials; Springer: Berlin/Heidelberg, Germany, 2015; pp. 191–229. [Google Scholar]

- Akcicek, A.; Ozgolet, M.; Tekin-Cakmak, Z.H.; Karasu, S.; Duran, E.; Sagdic, O. Cold-Pressed Okra Seed Oil Byproduct as an Ingredient for Muffins to Decrease Glycemic Index, Maillard Reaction, and Oxidation. ACS Omega 2024, 9, 7491–7501. [Google Scholar] [CrossRef]

- Sá, A.G.A.; da Silva, D.C.; Pacheco, M.T.B.; Moreno, Y.M.F.; Carciofi, B.A.M. Oilseed by-products as plant-based protein sources: Amino acid profile and digestibility. Future Foods 2021, 3, 100023. [Google Scholar] [CrossRef]

- Östbring, K.; Nilsson, K.; Ahlström, C.; Fridolfsson, A.; Rayner, M. Emulsifying and anti-oxidative properties of proteins extracted from industrially cold-pressed rapeseed press-cake. Foods 2020, 9, 678. [Google Scholar] [CrossRef]

- Ozgolet, M.; Kasapoglu, M.Z.; Avcı, E.; Karasu, S. Enhancing Gluten-Free Muffins with Milk Thistle Seed Proteins: Evaluation of Physicochemical, Rheological, Textural, and Sensory Characteristics. Foods 2024, 13, 2542. [Google Scholar] [CrossRef] [PubMed]

- Multescu, M.; Marinas, I.C.; Susman, I.E.; Belc, N. Byproducts (flour, meals, and groats) from the vegetable oil industry as a potential source of antioxidants. Foods 2022, 11, 253. [Google Scholar] [CrossRef] [PubMed]

- Gupta, A.; Sharma, R.; Sharma, S.; Singh, B. Oilseed as potential functional food Ingredient. In Trends & Prospects in Food Technology, Processing and Preservation, 1st ed.; Prodyut Kumar, P., Mahawar, M.K., Abobatta, W., Panja, P., Eds.; Today and Tomorrow’s Printers and Publishers: New Delhi, India, 2018; pp. 25–58. [Google Scholar]

- Mansour, E.; Dworschák, E.; Lugasi, A.; Gaál, Ö.; Barna, E.; Gergely, A. Effect of processing on the antinutritive factors and nutritive value of rapeseed products. Food Chem. 1993, 47, 247–252. [Google Scholar] [CrossRef]

- Xiong, Z.; Fu, Y.; Yao, J.; Zhang, N.; He, R.; Ju, X.; Wang, Z. Removal of anti-nutritional factors of rapeseed protein isolate (RPI) and toxicity assessment of RPI. Food Funct. 2022, 13, 664–674. [Google Scholar] [CrossRef]

- Igbinedion, S.O.; Ansari, J.; Vasikaran, A.; Gavins, F.N.; Jordan, P.; Boktor, M.; Alexander, J.S. Non-celiac gluten sensitivity: All wheat attack is not celiac. World J. Gastroenterol. 2017, 23, 7201. [Google Scholar] [CrossRef]

- Knežević, N.; Karlović, S.; Takács, K.; Szűcs, V.; Knežević, S.; Badanjak Sabolović, M.; Brnčić, S.R. Consumer Satisfaction with the Quality and Availability of Gluten-Free Products. Sustainability 2024, 16, 8215. [Google Scholar] [CrossRef]

- Korus, J.; Witczak, M.; Ziobro, R.; Juszczak, L. Hemp (Cannabis sativa subsp. sativa) flour and protein preparation as natural nutrients and structure forming agents in starch based gluten-free bread. LWT 2017, 84, 143–150. [Google Scholar]

- Bozorgi, M.; Memariani, Z.; Mobli, M.; Salehi Surmaghi, M.H.; Shams-Ardekani, M.R.; Rahimi, R. Five Pistacia species (P. vera, P. atlantica, P. terebinthus, P. khinjuk, and P. lentiscus): A review of their traditional uses, phytochemistry, and pharmacology. Sci. World J. 2013, 2013, 219815. [Google Scholar] [CrossRef]

- Özcan, M. Characteristics of fruit and oil of terebinth (Pistacia terebinthus L) growing wild in Turkey. J. Sci. Food Agric. 2004, 84, 517–520. [Google Scholar] [CrossRef]

- Bakirel, T.; Şener, S.; Bakirel, U.; Keleş, O.; Şennazli, G.; Gürel, A. The investigation of the effects of Pistacia terebinthus L. upon experimentally induced hypercholesterolemia and atherosclerosis in rabbits. Turk. J. Vet. Anim. Sci. 2003, 27, 1283–1292. [Google Scholar]

- Uyar, A.; Abdulrahman, N. A histopathological, immunohistochemical and biochemical investigation of the antidiabetic effects of the Pistacia terebinthus in diabetic rats. Biotech. Histochem. 2020, 95, 92–104. [Google Scholar] [CrossRef]

- Türkoğlu, S.; Celik, S.; Keser, S.; Türkoğlu, İ.; Yilmaz, Ö. The effect of Pistacia terebinthus extract on lipid peroxidation, glutathione, protein, and some enzyme activities in tissues of rats undergoing oxidative stress. Turk. J. Zool. 2017, 41, 82–88. [Google Scholar] [CrossRef]

- Najibullah, S.N.M.; Ahamad, J.; Sultana, S.; Zafar, A. Chemical characterization and evaluation of anticancer activity of Pistacia terebinthus Linn. fruits essential oil. J. Essent. Oil Bear. Plants 2022, 25, 180–187. [Google Scholar] [CrossRef]

- Moeini, R.; Memariani, Z.; Asadi, F.; Bozorgi, M.; Gorji, N. Pistacia genus as a potential source of neuroprotective natural products. Planta Medica 2019, 85, 1326–1350. [Google Scholar] [CrossRef]

- Uzun, A.; Sarıkaya, A.G. Random Forest regresyon algoritması ile Pistacia terebinthus L.’nin mevcut ve gelecek potansiyel yayılış alanlarının tahmini. Artvin Çoruh Üniversitesi Orman Fakültesi Derg. 2023, 24, 160–169. [Google Scholar] [CrossRef]

- Uluata, S.; Özdemir, N. Antioxidant activities and oxidative stabilities of some unconventional oilseeds. J. Am. Oil Chem. Soc. 2012, 89, 551–559. [Google Scholar] [CrossRef]

- Ertas, E.; Bekiroglu, S.; Ozdemir, I.; Demirtas, I. Comparison of fatty acid, sterol, and tocol compositions in skin and kernel of turpentine (Pistacia terebinthus L.) fruits. J. Am. Oil Chem. Soc. 2013, 90, 253–258. [Google Scholar] [CrossRef]

- Özkılıç, S.; Arslan, D. Acidic and enzymatic pre-treatment effects on cold-pressed pumpkin, terebinth and flaxseed oils. Grasas Y Aceites 2022, 73, e462. [Google Scholar] [CrossRef]

- Orphanides, A.; Goulas, V.; Gekas, V. Drying Technologies: Vehicle to high-quality herbs. Food Eng. Rev. 2016, 8, 164–180. [Google Scholar] [CrossRef]

- Rauf, A.; Patel, S.; Uddin, G.; Siddiqui, B.S.; Ahmad, B.; Muhammad, N.; Mabkhot, Y.N.; Hadda, T.B. Phytochemical, ethnomedicinal uses and pharmacological profile of genus Pistacia. Biomed. Pharmacother. 2017, 86, 393–404. [Google Scholar] [CrossRef]

- Pieprzyca, E.; Skowronek, R.; Nižnanský, Ľ.; Czekaj, P. Synthetic cathinones–From natural plant stimulant to new drug of abuse. Eur. J. Pharmacol. 2020, 875, 173012. [Google Scholar] [CrossRef]

- Altuntaş, E.; Gül, E.N.; Hüsne, G. Menengiç meyve ve tohumlarının fiziksel, mekanik ve kimyasal özelliklerinin belirlenmesi. Kahramanmaraş Sütçü İmam Üniversitesi Tarım Ve Doğa Derg. 2020, 23, 1518–1528. [Google Scholar] [CrossRef]

- Karakoç, F.B.; Ertaş, N.; Aslan, M. Storage stability, nutritional and qualitative attributes of biscuits enriched with terebinth, flaxseed and sesame seeds. Br. Food J. 2024, 126, 3263–3282. [Google Scholar] [CrossRef]

- Köten, M. Influence of roasted and unroasted terebinth (Pistacia terebinthus) on the functional, chemical and textural properties of wire-cut cookies. Food Sci. Technol. 2020, 41, 245–253. [Google Scholar] [CrossRef]

- Bala, M.; Arun Kumar, T.; Tushir, S.; Nanda, S.; Gupta, R. Quality protein maize based muffins: Influence of non-gluten proteins on batter and muffin characteristics. J. Food Sci. Technol. 2019, 56, 713–723. [Google Scholar] [CrossRef]

- Matos, M.E.; Sanz, T.; Rosell, C.M. Establishing the function of proteins on the rheological and quality properties of rice based gluten free muffins. Food Hydrocoll. 2014, 35, 150–158. [Google Scholar] [CrossRef]

- Shevkani, K.; Kaur, A.; Kumar, S.; Singh, N. Cowpea protein isolates: Functional properties and application in gluten-free rice muffins. LWT-Food Sci. Technol. 2015, 63, 927–933. [Google Scholar] [CrossRef]

- Ozgolet, M.; Cakmak, Z.H.T.; Bozkurt, F.; Sagdic, O.; Karasu, S. Response surface optimization of protein extraction from cold-pressed terebinth (Pistacia terebinthus L.) oil byproducts: Physicochemical and functional characteristics. J. Food Sci. 2024, 89, 7380–7396. [Google Scholar] [CrossRef] [PubMed]

- AACC. Approved Methods of the American Association of Cereal Chemists; American Association of Cereal Chemists: St. Paul, MN, USA, 2000; Volume 1. [Google Scholar]

- Gökşen, G.; Ekiz, H. Use of aniseed cold-pressed by-product as a food ingredient in muffin formulation. LWT–Food Sci Technol. 2021, 148, 111722. [Google Scholar] [CrossRef]

- Preichardt, L.D.; Vendruscolo, C.T.; Gularte, M.A.; Moreira, A.d.S. The role of xanthan gum in the quality of gluten free cakes: Improved bakery products for coeliac patients. Int. J. Food Sci. Technol. 2011, 46, 2591–2597. [Google Scholar] [CrossRef]

- Turabi, E.; Sumnu, G.; Sahin, S. Rheological properties and quality of rice cakes formulated with different gums and an emulsifier blend. Food Hydrocoll. 2008, 22, 305–312. [Google Scholar] [CrossRef]

- Genc, E.; Karasu, S.; Akcicek, A.; Toker, O.S. Fabrication and characterisation of Pickering emulsion-based oleogel stabilised by citrus fibre and whey protein isolate colloidal complex: Application in cookie formulation. Int. J. Food Sci. Technol. 2024, 59, 1709–1723. [Google Scholar] [CrossRef]

- Toker, O.S.; Karasu, S.; Yilmaz, M.T.; Karaman, S. Three interval thixotropy test (3ITT) in food applications: A novel technique to determine structural regeneration of mayonnaise under different shear conditions. Food Res. Int. 2015, 70, 125–133. [Google Scholar] [CrossRef]

- Aranibar, C.; Aguirre, A.; Borneo, R. Utilization of a by-product of chia oil extraction as a potential source for value addition in wheat muffins. J. Food Sci. Technol. 2019, 56, 4189–4197. [Google Scholar] [CrossRef]

- Sahin, M.; Ozgolet, M.; Cankurt, H.; Dertli, E. Harnessing the Role of Three Lactic Acid Bacteria (LAB) Strains for Type II Sourdough Production and Influence of Sourdoughs on Bread Quality and Maillard Reaction Products. Foods 2024, 13, 1801. [Google Scholar] [CrossRef]

- Aksoy, F.S.; Tekin-Cakmak, Z.H.; Karasu, S.; Aksoy, A.S. Oxidative stability of the salad dressing enriched by microencapsulated phenolic extracts from cold-pressed grape and pomegranate seed oil by-products evaluated using OXITEST. Food Sci. Technol. 2021, 42, e57220. [Google Scholar] [CrossRef]

- Alvarez, M.D.; Herranz, B.; Fuentes, R.; Cuesta, F.J.; Canet, W. Replacement of wheat flour by chickpea flour in muffin batter: Effect on rheological properties. J. Food Process Eng. 2017, 40, e12372. [Google Scholar] [CrossRef]

- Ghaemi, P.; Arabshahi-Delouee, S.; Aalami, M.; Hosseini Ghaboos, S.H. The Effect of Whey Protein Concentrate, Soy Protein Isolate, and Xanthan Gum on Textural and Rheological Characteristics of Gluten-Free Batter and Cake. J. Food Process. Preserv. 2024, 2024, 5571107. [Google Scholar] [CrossRef]

- Ronda, F.; Oliete, B.; Gómez, M.; Caballero, P.A.; Pando, V. Rheological study of layer cake batters made with soybean protein isolate and different starch sources. J. Food Eng. 2011, 102, 272–277. [Google Scholar] [CrossRef]

- Sahagún, M.; Bravo-Núñez, Á.; Báscones, G.; Gómez, M. Influence of protein source on the characteristics of gluten-free layer cakes. LWT 2018, 94, 50–56. [Google Scholar] [CrossRef]

- Shevkani, K.; Singh, N. Influence of kidney bean, field pea and amaranth protein isolates on the characteristics of starch-based gluten-free muffins. Int. J. Food Sci. Technol. 2014, 49, 2237–2244. [Google Scholar] [CrossRef]

- Hager, A.-S.; Wolter, A.; Jacob, F.; Zannini, E.; Arendt, E.K. Nutritional properties and ultra-structure of commercial gluten free flours from different botanical sources compared to wheat flours. J. Cereal Sci. 2012, 56, 239–247. [Google Scholar] [CrossRef]

- Kaur, M.; Singh, B.; Kaur, A. Influence of different oilseed cake incorporation on batter rheology, proximate composition, texture, antioxidant and sensory properties of wheat flour muffins. Int. J. Food Sci. Technol. 2022, 57, 7107–7115. [Google Scholar] [CrossRef]

- Kaur, G.; Singh, A.; Khatkar, S. Effect of ultrasonicated corn starch as a fat replacer on muffin quality and sensory characteristics. J. Food Meas. Charact. 2025, 19, 1–11. [Google Scholar]

- Nieto-Calvache, J.; Lorenzo, G.; Califano, A.; Gerschenson, L.; de Escalada Pla, M. Papaya dietary fiber concentrates for providing functionality to muffin formulations. J. Sci. Food Agric. 2023, 103, 1326–1333. [Google Scholar] [CrossRef]

- Jafari, M.; Koocheki, A.; Milani, E. Functional effects of xanthan gum on quality attributes and microstructure of extruded sorghum-wheat composite dough and bread. LWT 2018, 89, 551–558. [Google Scholar] [CrossRef]

- Singh, J.P.; Kaur, A.; Singh, N. Development of eggless gluten-free rice muffins utilizing black carrot dietary fibre concentrate and xanthan gum. J. Food Sci. Technol. 2016, 53, 1269–1278. [Google Scholar] [CrossRef] [PubMed]

- Mukprasirt, A.; Herald, T.J.; Seib, P.A. Pasting characteristics of rice flour-based batter compared to wheat flour-based batter. J. Food Qual. 2002, 25, 139–154. [Google Scholar] [CrossRef]

- Salazar, D.; Arancibia, M.; Silva, D.R.; López-Caballero, M.E.; Montero, M.P. Exploring the potential of andean crops for the production of gluten-free muffins. Agronomy 2021, 11, 1642. [Google Scholar] [CrossRef]

- Soumya, C.; Sudha, M.; Vijaykrishnaraj, M.; Negi, P.S.; Prabhasankar, P. Comparative study on batter, quality characteristics and storage stability of muffins using natural ingredients (preservatives) and synthetic preservatives. J. Food Process. Preserv. 2017, 41, e13242. [Google Scholar] [CrossRef]

- Felfoul, I.; Lopez, C.; Gaucheron, F.; Attia, H.; Ayadi, M. A laboratory investigation of cow and camel whey proteins deposition under different heat treatments. Food Bioprod. Process. 2015, 96, 256–263. [Google Scholar] [CrossRef]

- Rahim Monfared, M.; Nouri, L.; Mohammadi Nafchi, A. The effects of sesame protein isolate and transglutaminase enzyme on the quality characteristics of gluten-free batter and cake. J. Food Meas. Charact. 2023, 17, 4881–4891. [Google Scholar] [CrossRef]

- Shaabani, S.; Yarmand, M.S.; Kiani, H.; Emam-Djomeh, Z. The effect of chickpea protein isolate in combination with transglutaminase and xanthan on the physical and rheological characteristics of gluten free muffins and batter based on millet flour. LWT 2018, 90, 362–372. [Google Scholar] [CrossRef]

- Dhillon, G.K.; Kour, A.; Salazar, B.M. Potential of Pleurotus ostreatus as a novel protein source in rice-millet-based gluten-free muffins. Cogent Food Agric. 2023, 9, 2191888. [Google Scholar] [CrossRef]

- Guo, J.; Lian, X.; Kang, H.; Gao, K.; Li, L. Effects of glutenin in wheat gluten on retrogradation of wheat starch. Eur. Food Res. Technol. 2016, 242, 1485–1494. [Google Scholar] [CrossRef]

- Bravo-Núñez, Á.; Sahagún, M.; Bravo-Núñez, A.; Gómez, M. Optimisation of protein-enriched gluten-free layer cakes using a mixture design. Int. J. Food Sci. Technol. 2020, 55, 2171–2178. [Google Scholar] [CrossRef]

- Kiokias, S.; Gordon, M.H.; Oreopoulou, V. Effects of composition and processing variables on the oxidative stability of protein-based and oil-in-water food emulsions. Crit. Rev. Food Sci. Nutr. 2017, 57, 549–558. [Google Scholar] [CrossRef] [PubMed]

- Faraji, H.; McClements, D.J.; Decker, E.A. Role of continuous phase protein on the oxidative stability of fish oil-in-water emulsions. J. Agric. Food Chem. 2004, 52, 4558–4564. [Google Scholar] [CrossRef]

- Almajano, M.P.; Delgado, M.E.; Gordon, M.H. Albumin causes a synergistic increase in the antioxidant activity of green tea catechins in oil-in-water emulsions. Food Chem. 2007, 102, 1375–1382. [Google Scholar] [CrossRef]

- Rutkowska, J.; Antoniewska, A.; Martinez-Pineda, M.; Nawirska-Olszańska, A.; Zbikowska, A.; Baranowski, D. Black chokeberry fruit polyphenols: A valuable addition to reduce lipid oxidation of muffins containing xylitol. Antioxidants 2020, 9, 394. [Google Scholar] [CrossRef] [PubMed]

- El Sohaimy, S.A.; Brennan, M.A.; Darwish, A.M.; Brennan, C.S. Chickpea protein isolation, characterization and application in muffin enrichment. Int. J. Food Stud. 2021, 10, 57–71. [Google Scholar] [CrossRef]

- Banu, I.; Patrașcu, L.; Vasilean, I.; Dumitrașcu, L.; Aprodu, I. Influence of the Protein-Based Emulsions on the Rheological, Thermo-Mechanical and Baking Performance of Muffin Formulations. Appl. Sci. 2023, 13, 3316. [Google Scholar] [CrossRef]

| K | n | R2 | K′ | n′ | R2 | K″ | n″ | R2 | |

|---|---|---|---|---|---|---|---|---|---|

| C1 | 18.84 ± 1.80 e | 0.74 ± 0.04 a | 0.997 | 44.84 ± 1.00 e | 0.59 ± 0.02 a | 0.995 | 40.97 ± 1.61 d | 0.55 ± 0.03 a | 0.998 |

| C2 | 45.57 ± 3.31 d | 0.53 ± 0.03 b | 0.999 | 80.92 ± 2.53 d | 0.36 ± 0.02 c | 0.997 | 46.71 ± 0.85 c | 0.49 ± 0.03 a | 0.998 |

| TRP3 | 57.10 ± 1.87 c | 0.53 ± 0.02 b | 0.999 | 76.95 ± 1.93 d | 0.43 ± 0.02 b | 0.998 | 39.16 ± 2.30 d | 0.54 ± 0.02 a | 0.996 |

| TRP6 | 80.76 ± 4.77 b | 0.52 ± 0.03 b | 0.999 | 107.97 ± 2.53 c | 0.37 ± 0.01 c | 0.998 | 42.68 ± 1.20 cd | 0.55 ± 0.02 a | 0.994 |

| TRP9 | 90.05 ± 2.84 b | 0.50 ± 0.02 b | 0.999 | 128.25 ± 6.88 b | 0.39 ± 0.03 bc | 0.997 | 63.74 ± 3.16 b | 0.51 ± 0.03 a | 0.997 |

| TRP12 | 128.78 ± 6.95 a | 0.50 ± 0.04 b | 0.991 | 163.21 ± 8.01 a | 0.38 ± 0.02 bc | 0.997 | 71.11 ± 2.45 a | 0.52 ± 0.04 a | 0.997 |

| Sample | G0 | Ge | Ge/G0 | k × 1000 | R2 | %Def | %Rec |

|---|---|---|---|---|---|---|---|

| C1 | 125.62 ± 2.03 d | 148.20 ± 6.60 d | 1.18 ± 0.04 e | 58.6 ± 1.0 a | 0.961 | - | 110.7 |

| C2 | 89.50 ± 3.00 e | 182.48 ± 7.73 c | 2.04 ± 0.02 d | 4.4 ± 0.3 d | 0.988 | 22.8 | 92.2 |

| TRP3 | 126.35 ± 3.19 d | 420.06 ± 5.37 b | 3.32 ± 0.04 b | 1.8 ± 0.3 e | 0.997 | - | 124.4 |

| TRP6 | 153.27 ± 4.78 c | 616.92 ± 7.71 a | 4.03 ± 0.07 a | 1.6 ± 0.2 e | 0.999 | - | 126.2 |

| TRP9 | 196.41 ± 3.12 b | 413.15 ± 6.43 b | 2.10 ± 0.02 d | 11.8 ± 0.5 b | 0.991 | - | 129.2 |

| TRP12 | 223.53 ± 7.55 a | 622.87 ± 7.51 a | 2.79 ± 0.07 c | 7.9 ± 0.7 c | 0.995 | 34.3 | 90.6 |

| Specific Volume (cm3) | Height (cm) | Bake Loss (%) | Porosity (%) | Circularity | Perimeter | Protein (%) | 1st Day | Aw 4th Day | 7th Day | IP (h) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| C1 | 2.51 ± 0.03 a | 45.5 ± 0.8 bc | 11.5 ± 0.5 a | 38.03 ± 1.51 c | 0.849 ± 0.004 b | 18.23 ± 0.23 d | 5.43 ± 0.03 c | 0.78 ± 0.01 a | 0.76 ± 0.02 a | 0.74 ± 0.02 a | 10.60 ± 0.44 c |

| C2 | 2.51 ± 0.04 a | 44.7 ± 0.2 c | 12.2 ± 0.6 a | 37.22 ± 1.79 c | 0.856 ± 0.003 ab | 16.89 ± 0.85 d | 3.67 ± 0.05 e | 0.79 ± 0.01 a | 0.76 ± 0.02 a | 0.75 ± 0.03 a | 10.31 ± 0.16 c |

| TRP3 | 2.54 ± 0.05 a | 46.9 ± 0.5 a | 12.3 ± 0.2 a | 64.41 ± 2.02 a | 0.871 ± 0.007 a | 43.60 ± 2.16 ab | 5.16 ± 0.07 d | 0.78 ± 0.02 a | 0.75 ± 0.01 a | 0.75 ± 0.02 a | 10.30 ± 0.23 c |

| TRP6 | 2.57 ± 0.04 a | 47.7 ± 0.8 a | 12.3 ± 0.1 a | 64.47 ± 3.23 a | 0.801 ± 0.008 c | 44.71 ± 3.11 a | 5.55 ± 0.07 c | 0.78 ± 0.01 a | 0.75 ± 0.02 a | 0.74 ± 0.02 a | 12.27 ± 0.27 b |

| TRP9 | 2.58 ± 0.06 a | 47.9 ± 0.5 a | 12.1 ± 0.6 a | 52.49 ± 2.34 b | 0.799 ± 0.007 c | 39.07 ± 1.40 bc | 6.07 ± 0.05 b | 0.78 ± 0.01 a | 0.75 ± 0.03 a | 0.74 ± 0.02 a | 12.45 ± 0.11 b |

| TRP12 | 2.60 ± 0.05 a | 48.4 ± 0.9 a | 12.3 ± 0.3 a | 50.93 ± 1.70 b | 0.785 ± 0.008 c | 37.21 ± 1.46 c | 6.38 ± 0.07 a | 0.78 ± 0.02 a | 0.74 ± 0.01 a | 0.74 ± 0.03 a | 13.24 ± 0.24 a |

| Parameters | Storage Day | C1 | C2 | TRP3 | TRP6 | TRP9 | TRP12 |

|---|---|---|---|---|---|---|---|

| Hardness (N) | 1 | 7.03 ± 0.09 c | 8.30 ± 0.21 b | 7.93 ± 0.11 b | 8.14 ± 0.28 b | 11.76 ± 0.22 a | 11.46 ± 0.36 a |

| 4 | 15.63 ± 0.36 d | 25.18 ± 0.39 a | 18.07 ± 0.43 c | 22.32 ± 0.43 b | 22.34 ± 0.44 b | 23.99 ± 0.77 a | |

| 7 | 20.56 ± 0.55 d | 28.19 ± 0.86 ab | 22.29 ± 0.43 c | 27.53 ± 0.42 b | 28.38 ± 0.37 ab | 29.50 ± 0.76 a | |

| Springiness | 1 | 0.97 ± 0.02 a | 0.98 ± 0.02 a | 0.96 ± 0.02 a | 0.95 ± 0.02 a | 0.97 ± 0.02 a | 0.95 ± 0.02 a |

| 4 | 0.87 ± 0.02 a | 0.86 ± 0.02 a | 0.89 ± 0.02 a | 0.87 ± 0.03 a | 0.86 ± 0.02 a | 0.85 ± 0.03 a | |

| 7 | 0.85 ± 0.02 a | 0.82 ± 0.02 a | 0.87 ± 0.02 a | 0.85 ± 0.02 a | 0.83 ± 0.02 a | 0.83 ± 0.02 a | |

| Cohesiveness | 1 | 0.69 ± 0.03 a | 0.70 ± 0.02 a | 0.67 ± 0.02 a | 0.65 ± 0.03 a | 0.67 ± 0.03 a | 0.64 ± 0.03 a |

| 4 | 0.56 ± 0.03 a | 0.45 ± 0.02 b | 0.44 ± 0.02 b | 0.48 ± 0.02 b | 0.44 ± 0.02 b | 0.43 ± 0.01 b | |

| 7 | 0.47 ± 0.03 a | 0.34 ± 0.03 b | 0.34 ± 0.01 b | 0.35 ± 0.03 b | 0.32 ± 0.02 b | 0.33 ± 0.01 b | |

| Chewiness | 1 | 4.69 ± 0.19 b | 5.69 ± 0.28 b | 5.10 ± 0.02 b | 5.02 ± 0.17 b | 7.63 ± 0.60 a | 6.98 ± 0.69 a |

| 4 | 7.59 ± 0.76 bc | 9.75 ± 0.51 a | 7.07 ± 0.33 c | 9.32 ± 0.53 a | 8.52 ± 0.50 ab | 8.63 ± 0.22 ab | |

| 7 | 8.23 ± 0.94 a | 7.86 ± 0.74 a | 6.60 ± 0.40 a | 8.18 ± 0.39 a | 7.63 ± 0.64 a | 7.76 ± 0.47 a | |

| Resilience | 1 | 0.36 ± 0.02 a | 0.36 ± 0.03 a | 0.36 ± 0.02 a | 0.33 ± 0.02 a | 0.35 ± 0.02 a | 0.31 ± 0.02 a |

| 4 | 0.23 ± 0.02 a | 0.19 ± 0.02 a | 0.20 ± 0.03 a | 0.20 ± 0.02 a | 0.18 ± 0.03 a | 0.17 ± 0.02 a | |

| 7 | 0.20 ± 0.02 a | 0.17 ± 0.03 a | 0.18 ± 0.01 a | 0.18 ± 0.02 a | 0.16 ± 0.02 a | 0.15 ± 0.02 a |

| Appearance | Flavor | Smell/Odor | Texture | Sweetness | Overall Quality | |

|---|---|---|---|---|---|---|

| C1 | 4.59 ± 0.48 a | 4.36 ± 0.75 a | 4.13 ± 0.59 a | 4.40 ± 0.69 a | 4.31 ± 0.74 a | 4.42 ± 0.67 a |

| C2 | 4.36 ± 0.77 a | 4.03 ± 1.00 a | 4.20 ± 0.73 a | 3.75 ± 1.02 a | 4.13 ± 0.92 a | 4.18 ± 0.83 a |

| TRP3 | 4.08 ± 0.86 a | 4.31 ± 0.75 a | 4.08 ± 0.76 a | 4.15 ± 0.80 a | 4.15 ± 0.90 a | 4.15 ± 0.90 a |

| TRP6 | 4.31 ± 0.75 a | 4.23 ± 0.73 a | 4.23 ± 0.73 a | 4.23 ± 0.60 a | 4.39 ± 0.65 a | 4.39 ± 0.65 a |

| TRP9 | 4.54 ± 0.52 a | 4.15 ± 0.90 a | 4.39 ± 0.65 a | 4.00 ± 0.82 a | 4.15 ± 0.90 a | 4.39 ± 0.65 a |

| TRP12 | 4.54 ± 0.66 a | 4.15 ± 0.80 a | 4.23 ± 0.73 a | 3.92 ± 0.76 a | 4.00 ± 0.91 a | 4.08 ± 0.76 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ozgolet, M.; Karasu, S.; Kasapoglu, M.Z. Development of Gluten-Free Cakes Using Protein Concentrate Obtained from Cold-Pressed Terebinth (Pistacia terebinthus L.) Oil By-Products. Foods 2025, 14, 1049. https://doi.org/10.3390/foods14061049

Ozgolet M, Karasu S, Kasapoglu MZ. Development of Gluten-Free Cakes Using Protein Concentrate Obtained from Cold-Pressed Terebinth (Pistacia terebinthus L.) Oil By-Products. Foods. 2025; 14(6):1049. https://doi.org/10.3390/foods14061049

Chicago/Turabian StyleOzgolet, Muhammed, Salih Karasu, and Muhammed Zahid Kasapoglu. 2025. "Development of Gluten-Free Cakes Using Protein Concentrate Obtained from Cold-Pressed Terebinth (Pistacia terebinthus L.) Oil By-Products" Foods 14, no. 6: 1049. https://doi.org/10.3390/foods14061049

APA StyleOzgolet, M., Karasu, S., & Kasapoglu, M. Z. (2025). Development of Gluten-Free Cakes Using Protein Concentrate Obtained from Cold-Pressed Terebinth (Pistacia terebinthus L.) Oil By-Products. Foods, 14(6), 1049. https://doi.org/10.3390/foods14061049