Whey—A Valuable Technological Resource for the Production of New Functional Products with Added Health-Promoting Properties

Abstract

1. Introduction

- -

- Sweet whey (rennet whey), obtained in the production of hard, semi-hard, and soft cheeses, as well as rennet casein (pH 5.9–6.3).

- -

- Acid whey, produced during the cottage cheese production. Coagulation is achieved mainly by acidification (pH 4.3–4.6) [2].

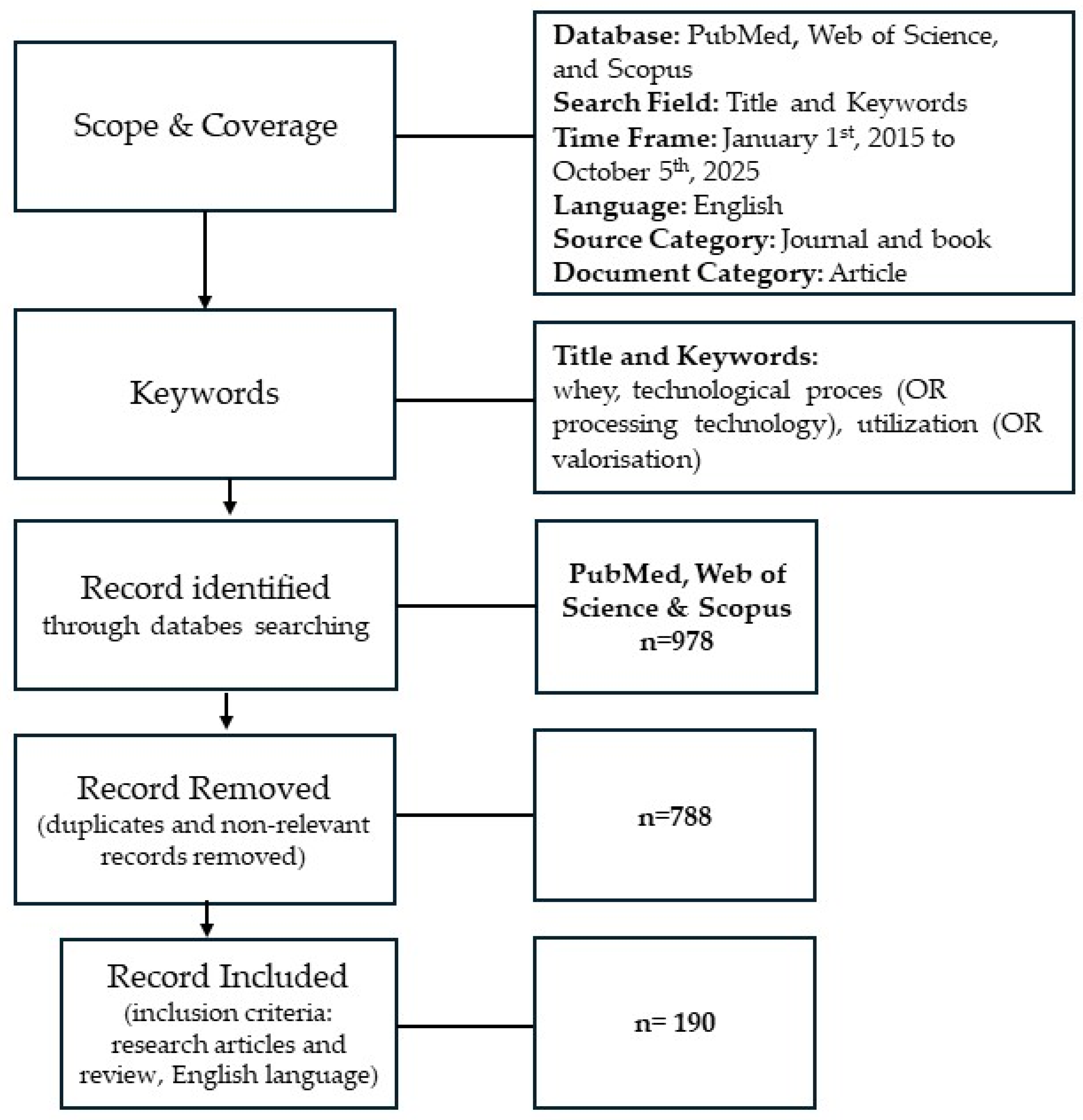

2. Materials and Methods

3. Results

3.1. The Scale of Unused Whey Worldwide and the Associated Environmental Pollution

- -

- solids (gross and finely dispersed/suspended);

- -

- low and high pH levels;

- -

- free edible fat/oil;

- -

- emulsified material, e.g., edible fat/oil;

- -

- soluble biodegradable organic material, e.g., BOD;

- -

- volatile substances, e.g., ammonia and organics;

- -

- plant nutrients, e.g., phosphorus and/or nitrogen;

- -

- pathogens, e.g., from sanitary water;

- -

- dissolved non-biodegradable organics [12].

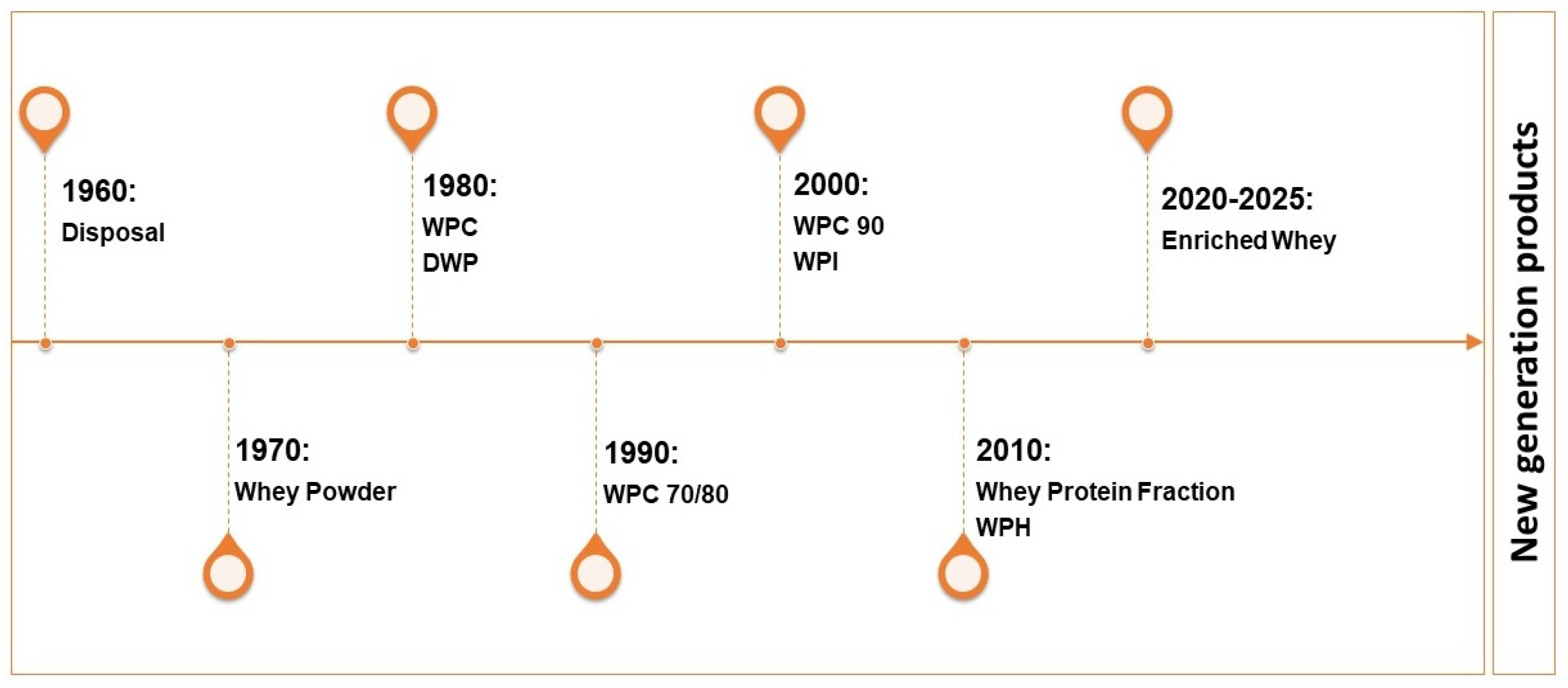

3.2. Whey from a By-Product (Disposal) to a Valuable Dairy Product—Changes from the 1950s to the Present

- 1960s–1970s

- 1980s–1990s—New whey processing techniques

- 21st Century—Next-generation whey products

3.3. Whey: A Microbiological Overview

3.4. Whey Proteins and Other Whey Constituents, and Their Functionality

3.5. Novel Whey Processing Methods

- -

- Thermosonication—used to produce whey beverages, including fermented whey beverages. This method offers better microbiological quality and enhanced antioxidant, antihypertensive, and antidiabetic activities; reduces the degradation of ascorbic acid, improves rheological properties, and provides a more favorable volatile compound profile when compared to beverages treated with short-term thermal heating.

- -

- Ohmic heating and spray drying—used in the production of whey protein, such as WPH, WPI, WPC.

- -

- Cross-flow microfiltration—used for concentrate whey as native powder, deproteinized powder, or delactozed powder.

- -

- Electroactivation—whey lactose is used to produce galactooligosaccharides (GOS), lactitol, lactulose, and lactosucrose.

- -

- Reverse osmosis—whey water for water recovery.

- -

- Membrane technologies (microfiltration, ultrafiltration, nanofiltration, emerging membrane processes, integration of membrane technologies)—used for clarification or fractioning, as well as to increase the concentration of specific components (concentrates whey proteins and decreases non-protein components), or their separation. Moreover, this process leads to a highly efficient separation of phenolic compounds while ensuring bacterial reduction. This results in high-value whey protein concentrates (WPCs) and isolates (WPIs), which are rich in essential amino acids and ideal for sports nutrition and dietary supplements.

- -

- Enzymatic hydrolysis—improves the functional properties of whey proteins through controlled cleavage of peptide bonds, which reduces molecular weight and increases the exposure of polar groups; and improves solubility, emulsification ability, and foam stability. Hydrolysates are ingredients in functional foods, beverages, and products with regenerative properties.

- -

3.6. The Utilization of Whey for the Production of High-Quality Food Products

3.6.1. Whey Cheese Production

3.6.2. The Use of Whey in Meat Preparation

3.6.3. The Valorization of Whey in the Production of Functional Beverages

3.6.4. Other Usage of Whey

Edible Whey Films

Alternatives to Petroleum-Based Plastics

Whey-Derived Alcoholic Beverages

Biohydrogen and Biodiesel

3.7. Technological Problems with the Valorization of Whey

- raw material variability;

- process challenges depending on the type of whey (acid vs. sweet whey);

- microbiological safety/quality;

- economic aspects and scalability;

- environmental/regulatory issues.

- -

- Microbiological stability—Whey provides an environment conducive to microbial growth, so when designing these types of beverages, it is essential to develop effective preservation methods, such as pasteurization, microfiltration, and the use of natural growth inhibitors.

- -

- The sensory quality of the developed whey beverages: The natural flavor and aroma of whey are not always accepted by consumers; therefore, the use of flavorings or fermentation processes to enhance organoleptic qualities is crucial. Fruit additives are particularly effective in this regard.

- -

- The high lactose content limits the consumer group, excluding those with intolerance. Enzymatic hydrolysis of the disaccharide lactose should be considered when planning and selecting production technologies.

- -

- Standardization of the final product—The wide variation in whey composition depending on the type of raw material, the seasonality of the milk, and the cheesemaking process makes it difficult to achieve a uniform final product. Technological costs associated with implementing new whey processing technologies (e.g., ultrafiltration, nanofiltration) are also significant, as they necessitate investments in modern production lines, which may be a barrier for smaller enterprises.

4. Future Perspectives and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- CXS 289-1995; Standard for Whey Powders. International Food Standards. FAO, WHO: Geneva, Switzerland, 2022.

- Buchanan, D.; Martindale, W.; Romeih, E.; Hebishy, E. Recent advances in whey processing and valorisation: Technological and environmental perspectives. Int. J. Dairy Technol. 2023, 76, 291–312. [Google Scholar] [CrossRef]

- Rejdlová, A.; Lorencová, E.; Míšková, Z.; Salek, R.N. Techno-Functional Properties and Recent Advances in the Manufacturing of Whey Beverages: A Review. Appl. Sci. 2025, 15, 1846. [Google Scholar] [CrossRef]

- Menchik, P.; Zuber, T.; Zuber, A.; Moraru, C.I. Short communication: Composition of coproduct streams from dairy processing: Acid whey and milk permeate. J. Dairy Sci. 2019, 102, 3978–3984. [Google Scholar] [CrossRef]

- Lindsay, M.J.; Walker, T.W.; Dumesic, J.A.; Rankin, S.A.; Huber, G.W. Production of monosaccharides and whey protein from acid whey waste streams in the dairy industry. Green Chem. 2018, 20, 1824–1834. [Google Scholar] [CrossRef]

- Pal, P.; Nayak, J. Development and analysis of a sustainable technology in manufacturing acetic acid and whey protein from waste cheese whey. J. Clean. Prod. 2016, 112, 59–70. [Google Scholar] [CrossRef]

- Ziarno, M. Kwaśna serwatka—Nowe kierunki wykorzystania i korzyści zdrowotne. Forum Mlecz. Bizn. 2024, 3, 56. [Google Scholar]

- Khattab, A.M.; Esmael, M.E.; Farrag, A.A.; Ibrahim, M.I.A. Structural assessment of the bioplastic (poly-3-hydroxybutyrate) produced by Bacillus flexus Azu-A2 through cheese whey valorization. Int. J. Biol. Macromol. 2021, 190, 319–332. [Google Scholar] [CrossRef]

- Asunis, F.; De Gioannis, G.; Isipato, M.; Muntoni, A.; Polettini, A.; Pomi, R.; Rossi, A.; Spiga, D. Control of fermentation duration and pH to orient biochemicals and biofuels production from cheese whey. Bioresour. Technol. 2019, 289, 121722. [Google Scholar] [CrossRef]

- Bhusari, A.A.; Mazumdar, B.; Rathid, A.P. Synthesis and characterization of biocatalyst prepared from dairy waste for lactic acid esterification. Int. J. Chem. React. Eng. 2021, 19, 939–948. [Google Scholar] [CrossRef]

- Fancello, F.; Zara, G.; Hatami, F.; Scano, A.E.; Mannazzu, I. Unlocking the potential of second cheese whey: A comprehensive review on valorisation strategies. Rev. Environ. Sci. Bio/Technol. 2024, 23, 411–441. [Google Scholar] [CrossRef]

- Ginger Santonja, G.; Panagiotis Raunkjær Stubdrup, K.K.; Brinkmann, T.; Roudier, S. Best Available Techniques (BAT) Reference Document for the Food, Drink and Milk Industries. Industrial Emissions Directive 2010/75/EU Integrated Pollution Prevention and Control, 2019, EUR 29978 EN, Luxembourg: Publications Office of the European Union, 2019. Available online: https://bureau-industrial-transformation.jrc.ec.europa.eu/sites/default/files/2020-01/JRC118627_FDM_Bref_2019_published.pdf (accessed on 7 September 2025).

- Besediuk, V.; Yatskov, M.; Korchyk, N.; Kucherova, A.; Maletskyi, Z. Whey—From Waste to a Valuable Resource. J. Agric. Food Res. 2024, 18, 101280. [Google Scholar] [CrossRef]

- Abish, Z.A.; Alibekov, R.S.; Tarapoulouzi, M.; Bakhtybekova, A.R.; Kobzhasarova, Z.I. Review in Deep Processing of Whey. Cogent Food Agric. 2024, 10, 2415380. [Google Scholar] [CrossRef]

- Jiang, L.; Zhang, Z.; Qiu, C.; Wen, J. A Review of Whey Protein-Based Bioactive Delivery Systems: Design, Fabrication, and Application. Foods 2024, 13, 2453. [Google Scholar] [CrossRef]

- Sustainable Development Goals 2030. UNDP. Available online: https://sdgs.un.org/goals (accessed on 10 November 2025).

- Mukherjee, P.; Raj, N.; Sivaprakasam, S. Harnessing Valorization Potential of Whey Permeate for D-Lactic Acid Production Using Lactic Acid Bacteria. Biomass Convers. Biorefinery 2023, 13, 15639–15658. [Google Scholar] [CrossRef]

- Pires, A.F.; Marnotes, N.G.; Rubio, O.D.; Garcia, A.C.; Pereira, C.D. Dairy By-Products: A Review on the Valorization of Whey and Second Cheese Whey. Foods 2021, 10, 1067. [Google Scholar] [CrossRef] [PubMed]

- Pandey, S.; Dumont, M.J.; Orsat, V. Comparative Kinetic Study for the Conversion of Lactose and Whey Permeate Powder into 5-Hydroxymethylfurfural. In Proceedings of the 2021 ASABE Annual International Virtual Meeting, Virtual, 12–16 July 2021; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2021. [Google Scholar] [CrossRef]

- Urtasun, N.; Baieli, M.F.; Hirsch, D.B.; Miranda, M.V.; Cascone, O.; Wolman, F.J. Challenges in Dairy Whey Protein Purification. In Handbook on Protein Purification: Industry Challenges and Technological Developments; Nova Science Publishers: Hauppauge, NY, USA, 2022; pp. 1–18. Available online: http://hdl.handle.net/11336/162658 (accessed on 5 November 2025).

- Ergasheva, Z.K.; Sultanov, S.A.; Saparov, J.E. Analysis of Dairy Whey Food Functional Modules Based on Resource-Saving Technologies. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2023; Volume 1231, p. 012042. [Google Scholar] [CrossRef]

- José, N.V.; Orantes, L.A.C.; Gómez-Cruz, L.A.; Vela-Gutiérrez, G. Use of Whey: A Sustainable Alternative for the Cheese Industry. In Integration of Sustainable Development Goals in Water Resource Management and Agricultural Food Production; Apple Academic Press: New York, NY, USA, 2025; pp. 65–81. [Google Scholar]

- Rocha-Mendoza, D.; Kosmerl, E.; Krentz, A.; Zhang, L.; Badiger, S.; Miyagusuku-Cruzado, G.; Mayta-Apaza, A.; Giusti, M.; Jiménez-Flores, R.; García-Cano, I. Invited review: Acid whey trends and health benefits. J. Dairy Sci. 2021, 104, 1262–1275. [Google Scholar] [CrossRef] [PubMed]

- Eurostat Milk and Milk Product Statistics—Statistics Explained—Eurostat. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Milk_and_milk_product_statistics (accessed on 14 October 2025).

- Macwan, S.R.; Dabhi, B.K.; Parmar, S.C.; Aparnathi, K.D. Whey and Its Utilization. Int. J. Curr. Microbiol. Appl. Sci. 2016, 5, 134–155. [Google Scholar] [CrossRef]

- Eurostat Key Figures on the European Food Chain—2024 Edition. Available online: https://ec.europa.eu/eurostat/documents/15216629/20555393/KS-01-24-000-EN-N.pdf (accessed on 15 October 2025).

- National Agricultural Statistics Service Dairy Products—2024 Summary. Available online: https://esmis.nal.usda.gov/sites/default/release-files/jm214p131/r781zd41r/4b29d481c/daryan25.pdf (accessed on 15 October 2025).

- Lappa, I.K.; Papadaki, A.; Kachrimanidou, V.; Terpou, A.; Koulougliotis, D.; Eriotou, E.; Kopsahelis, N. Cheese Whey Processing: Integrated Biorefinery Concepts and Emerging Food Applications. Foods 2019, 8, 347. [Google Scholar] [CrossRef]

- Pescuma, M.; Hébert, E.M.; de Valdez, G.F.; Mozzi, F. Functional Fermented Whey Foods: Their Role in Human Health. In Beneficial Microbes in Fermented and Functional Foods; CRC Press: Boca Raton, FL, USA, 2014; pp. 114–131. [Google Scholar]

- Rajarajan, G.; Irshad, A.; Raghunath, B.V.; Mahesh Kumar, G.; Punnagaiarasi, A. Utilization of Cheese Industry Whey for Biofuel–Ethanol Production. In Environmental Science and Engineering (Subseries: Environmental Science); Springer: Cham, Switzerland, 2016; pp. 59–64. [Google Scholar]

- Uribe-Velázquez, T.; Díaz-Vázquez, D.; Barajas-Álvarez, P.; González-López, M.E.; Gradilla-Hernández, M.S.; García-Amezquita, L.E.; Carrillo-Nieves, D.; García-Cayuela, T. From Waste to Value: Mitigating the Environmental Impact of Whey in Jalisco, Mexico. J. Clean. Prod. 2025, 501, 145334. [Google Scholar] [CrossRef]

- Sirmacekic, E.; Atilgan, A.; Rolbiecki, R.; Jagosz, B.; Rolbiecki, S.; Gokdogan, O.; Niemiec, M.; Kocięcka, J. Possibilities of Using Whey Wastes in Agriculture: Case of Turkey. Energies 2022, 15, 9636. [Google Scholar] [CrossRef]

- Verma, D.K.; Patel, A.R.; Tripathy, S.; Gupta, A.K.; Singh, S.; Shah, N.; Utama, G.L.; Chávez-González, M.L.; Zongo, K.; Banwo, K.; et al. Processing and Formulation Technology of Nutritional and Functional Food Products by Utilizing Cheese and/or Paneer Whey: A Critical Review. J. King Saud Univ.-Sci. 2024, 36, 103508. [Google Scholar] [CrossRef]

- Mutio, C.; Okello, D.; Karanja, S.; Bebe, B.; Bolwig, S. Circular Business Models for Whey Valorization in the Kenyan Dairy Sector through Product Life Extension and Resource Recovery. Discov. Sustain. 2025, 6, 805. [Google Scholar] [CrossRef]

- Arshad, U.E.T.; Hassan, A.; Ahmad, T.; Naeem, M.; Chaudhary, M.T.; Abbas, S.Q.; Randhawa, M.; Colombo Pimentel, T.; da Cruz, A.G.; Aadil, R.M. A recent glance on the valorisation of cheese whey for industrial prerogative: High-value-added products development and integrated reutilising strategies. Int. J. Food Sci. Technol. 2023, 58, 2001–2013. [Google Scholar] [CrossRef]

- Ramos, G.L.D.P.A.; Guimarães, J.T.; Pimentel, T.C.; da Cruz, A.G.; de Souza, S.L.Q.; Vendramel, S.M.R. Whey: Generation, Recovery, and Use of a Relevant by-Product. In Valorization of Agri-Food Wastes and By-Products: Recent Trends, Innovations and Sustainability Challenges; Bhat, R., Ed.; Academic Press: Tartu, Estonia, 2021; pp. 391–414. [Google Scholar] [CrossRef]

- Panagopoulos, V.; Dima, A.; Boura, K.; Bosnea, L.; Nigam, P.S.; Kanellaki, M.; Koutinas, A.A. Cell Factory Models of Non-Engineered S. Cerevisiae Containing Lactase in a Second Layer for Lactose Fermentation in One Batch. Enzym. Microb. Technol. 2021, 145, 109750. [Google Scholar] [CrossRef] [PubMed]

- Xia, J.; He, J.; Xu, J.; Liu, X.; Qiu, Z.; Xu, N.; Su, L. Direct conversion of cheese whey to polymalic acid by mixed culture of Aureobasidium pullulans and permeabilized Kluyveromyces marxianus. Bioresour. Technol. 2021, 337, 125443. [Google Scholar] [CrossRef] [PubMed]

- Sebastián-Nicolás, J.L.; González-Olivares, L.G.; Vázquez-Rodríguez, G.A.; Lucho-Constatino, C.A.; Castañeda-Ovando, A. Valorization of whey using a biorefinery. Biofuels Bioprod. Bioref. 2020, 14, 1010–1027. [Google Scholar] [CrossRef]

- Directive 2006/12/EC of the European Parliament and of the Council of 5 April 2006 on Waste (Text with EEA Relevance). OJ L 114, 27.4.2006, pp. 9–21. Available online: https://eur-lex.europa.eu/eli/dir/2006/12/oj/eng (accessed on 5 September 2025).

- Council Directive 91/271/EEC of 21 May 1991 Concerning Urban Waste-Water Treatment (91/271/EEC). OJ L 135, 30.5.1991, pp. 40–52. Available online: https://eur-lex.europa.eu/eli/dir/1991/271/oj/eng (accessed on 5 September 2025).

- Council Directive 1999/31/EC of 26 April 1999 on the Landfill of Waste. OJ L 182, 16.7.1999, pp. 1–19. Available online: https://eur-lex.europa.eu/eli/dir/1999/31/oj/eng (accessed on 5 September 2025).

- Giulianetti de Almeida, M.P.; Mockaitis, G.; Weissbrodt, D.G. Got Whey? Sustainability Endpoints for the Dairy Industry through Resource Biorecovery. Fermentation 2023, 9, 897. [Google Scholar] [CrossRef]

- Najlepsze Dostępne Techniki (BAT) Wytyczne dla Branży Mleczarskiej; Narodowy Fundusz Ochrony Środowiska i Gospodarki Wodnej, Ministerstwo Środowiska: Warszawa, Poland, 2005. (In Polish)

- Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives (Text with EEA Relevance). Document 02008L0098-20251016. Available online: https://eur-lex.europa.eu/eli/dir/2008/98 (accessed on 5 November 2025).

- Zandona, E.; Blažić, M.; Režek Jambrak, A. Whey Utilization: Sustainable Uses and Environmental Approach. Food Technol. Biotechnol. 2021, 59, 147–161. [Google Scholar] [CrossRef]

- González-García, S.; Hospido, A.; Moreira, M.T.; Feijoo, G.; Arroja, L. Environmental life cycle assessment of a Galician cheese: San Simon da Costa. J. Clean. Prod. 2013, 52, 253–262. [Google Scholar] [CrossRef]

- Finnegan, W.; Yan, M.; Holden, N.M.; Goggins, J. A review of environmental life cycle assessment studies examining cheese production. Int. J. Life Cycle Assess. 2018, 23, 1773–1787. [Google Scholar] [CrossRef]

- Ladha-Sabur, A.; Bakalis, S.; Fryer, P.J.; Lopez-Quiroga, E. Mapping energy consumption in food manufacturing. Trends Food Sci. Technol. 2019, 86, 270–280. [Google Scholar] [CrossRef]

- Price, J. History of the development and application of whey protein products. In Whey Proteins; Academic Press: Cambridge, MA, USA, 2019; pp. 51–95. [Google Scholar] [CrossRef]

- Goyal, C.; Dhyani, P.; Rai, D.C.; Tyagi, S.; Dhull, S.B.; Sadh, P.K.; Duhan, J.S.; Saharan, B.S. Emerging trends and advancements in the processing of dairy whey for sustainable biorefining. J. Food Process. Preserv. 2023, 1, 6626513. [Google Scholar] [CrossRef]

- Ayed, L.; M’hir, S.; Asses, N. Sustainable whey processing techniques: Innovations in derivative and beverage production. Food Biosci. 2023, 53, 102642. [Google Scholar] [CrossRef]

- Paladii, I.V.; Vrabie, E.G.; Sprinchan, K.G.; Bologa, M.K. Whey: Review. Part 2. Treatment Processes and Methods. Surf. Eng. Appl. Electrochem. 2021, 57, 651–666. [Google Scholar] [CrossRef]

- Malos, I.G.; Ghizdareanu, A.-I.; Vidu, L.; Matei, C.B.; Pasarin, D. The Role of Whey in Functional Microorganism Growth and Metabolite Generation: A Biotechnological Perspective. Foods 2025, 14, 1488. [Google Scholar] [CrossRef]

- Yeluri Jonnala, B.R.; McSweeney, P.L.H.; Sheehan, J.J.; Cotter, P.D. Whey microbiota and their significance in dairy processing. Front. Microbiol. 2018, 9, 1942. [Google Scholar] [CrossRef]

- Zhubanova, A.; Abdieva, G.; Ualieva, P.; Akimbekov, N.; Malik, A.; Tastambek, K. Whey-to-bioethanol valorisation: Fermentation with immobilised yeast cells. Eng. Sci. 2024, 27, 995. [Google Scholar] [CrossRef]

- Ohstrom, A.M.; Buck, A.E.; Du, X.; Wee, J. Evaluation of Kluyveromyces spp. for conversion of lactose in different types of whey from dairy processing waste into ethanol. Front. Microbiol. 2023, 14, 1208284. [Google Scholar] [CrossRef]

- Anumudu, C.K.; Miri, T.; Onyeaka, H. Multifunctional Applications of Lactic Acid Bacteria: Enhancing Safety, Quality, and Nutritional Value in Foods and Fermented Beverages. Foods 2024, 13, 3714. [Google Scholar] [CrossRef]

- Del Toro-Barbosa, M.; Uribe-Velázquez, T.; Hurtado-Romero, A.; Rosales-De la Cruz, M.F.; Carrillo-Nieves, D.; Garcia-Amezquita, L.E.; García-Cayuela, T. Evaluation of GABA-Producing Fermented Whey Formulations: From Strain Selection to Raspberry-Enriched Beverages with Psychobiotic Potential. Foods 2025, 14, 2762. [Google Scholar] [CrossRef]

- Delgado-Macuil, R.J.; Perez-Armendariz, B.; Cardoso-Ugarte, G.A.; Tolibia, S.E.M.; Benítez-Rojas, A.C. Recent Biotechnological Applications of Whey: Review and Perspectives. Fermentation 2025, 11, 217. [Google Scholar] [CrossRef]

- Marco, M.L.; Heeney, D.; Binda, S.; Cifelli, C.J.; Cotter, P.D.; Foligne, B.; Ganzle, M.; Kort, R.; Pasin, G.; Pihlanto, A.; et al. Health benefits of fermented foods: Microbiota and beyond. Curr. Opin. Biotechnol. 2017, 44, 94–102. [Google Scholar] [CrossRef]

- Zheng, X.; Shi, X.; Wang, B. A Review on the General Cheese Processing Technology, Flavor Biochemical Pathways, and the Influence of Yeasts in Cheese. Front. Microbiol. 2021, 12, 703284. [Google Scholar] [CrossRef]

- Saubenova, M.; Oleinikova, Y.; Rapoport, A.; Maksimovich, S.; Yermekbay, Z.; Khamedova, E. Bioactive Peptides Derived from Whey Proteins for Health and Functional Beverages. Fermentation 2024, 10, 359. [Google Scholar] [CrossRef]

- Gao, Y.; Gao, L.; Kang, Y.; Yang, G.; Zhao, Z.; Zhao, Y.; Li, S. Non-Targeted Metabolomics Analysis Reveals Metabolite Profiles Change During Whey Fermentation with Kluyveromyces marxianus. Metabolites 2024, 14, 694. [Google Scholar] [CrossRef]

- Conde-Báez, L.; Pineda-Muñoz, C.F.; Conde-Mejía, C.; Mas-Hernández, E.; López-Molina, A. Conversion of Sweet Whey to Bioethanol: A Bioremediation Alternative for Dairy Industry. Biomass 2024, 4, 507–517. [Google Scholar] [CrossRef]

- Chandrapala, J.; Duke, M.C.; Gray, S.R.; Zisu, B.; Weeks, M.; Palmer, M.; Vasiljevic, T. Properties of acid whey as a function of pH and temperature. J. Dairy Sci. 2015, 98, 4352–4363. [Google Scholar] [CrossRef]

- Asunis, F.; De Gioannis, G.; Dessì, P.; Isipato, M.; Lens, P.N.; Muntoni, A.; Spiga, D. The dairy biorefinery: Integrating treatment processes for cheese whey valorisation. J. Environ. Manag. 2020, 276, 111240. [Google Scholar] [CrossRef] [PubMed]

- Praveen, M.; Brogi, S. Microbial Fermentation in Food and Beverage Industries: Innovations, Challenges, and Opportunities. Foods 2025, 14, 114. [Google Scholar] [CrossRef] [PubMed]

- Benitez, R.; Ortero, G. (Eds.) Whey: Types, Composition and Health Implications; Nova Science Publishers Inc.: Hauppauge, NY, USA, 2012. [Google Scholar]

- Yang, S.Y.; Yoon, K.S. Quantitative Microbial Risk Assessment of Listeria monocytogenes and Enterohemorrhagic Escherichia coli in Yogurt. Foods 2022, 11, 971. [Google Scholar] [CrossRef] [PubMed]

- Guanhong, C.; Zonghong, L.; Yao, Z.; Xu, X.; Ting, Z.; Xin, W. Effect and mechanism of eliminating Staphylococcus aureus by electron beam irradiation and reducing the toxicity of its metabolites. Appl. Environ. Microbiol. 2023, 89, e02075-22. [Google Scholar] [CrossRef]

- Briega, I.; Garde, S.; Sánchez, C.; Rodríguez-Mínguez, E.; Picon, A.; Ávila, M. Evaluation of Biofilm Production and Antibiotic Resistance/Susceptibility Profiles of Pseudomonas spp. Isolated from Milk and Dairy Products. Foods 2025, 14, 1105. [Google Scholar] [CrossRef]

- Sumny, E.H.; Kempka, A.P. Bioactive whey peptides: A bibliometric and functional overview. Discov. Food 2025, 5, 138. [Google Scholar] [CrossRef]

- Whey Protein Market (2022–2030); Grand View Research, Inc.: San Francisco, CA, USA, 2025; Available online: https://www.grandviewresearch.com/industry-analysis/whey-protein-market (accessed on 5 September 2025).

- Global Market Insights. Whey Protein Market Size, Share & Trends Report, 2024–2032; Global Market Insights Inc.: Selbyville, DE, USA, 2024; Available online: https://www.gminsights.com/industry-analysis/whey-protein-ingredients-market (accessed on 3 November 2025).

- Ramos, O.L.; Pereira, R.N.; Rodrigues, R.M.; Teixeira, J.A.; Vicente, A.A.; Malcata, F.X. Whey and Whey Powders: Production and Uses. In Encyclopedia of Food and Health; Elsevier: Amsterdam, The Netherlands, 2016; pp. 498–505. [Google Scholar] [CrossRef]

- Allied Market Research. Whey Protein Market by Type (WPC, WPI, WPH): Global Opportunity Analysis and Industry Forecast, 2023–2032. Allied Analytics LLP: Pune, India, 2023. Available online: https://www.alliedmarketresearch.com/press-release/whey-protein-ingredients-market.html (accessed on 5 November 2025).

- G Whey Protein Ingredients Market Size—By Type (Whey Protein Concentrate, Whey Protein Isolate, Hydrolyzed Whey Protein), By Application (Bakery & Confectionery, Dairy Product, Sports Nutrition, Meat Product, Health Supplements) & Forecast 2023–2032; Global Market Insight (GMI), 2023. Report ID: GMI6313. Available online: https://www.gminsights.com/industry-analysis/whey-protein-ingredients-market (accessed on 3 October 2025).

- Euromonitor International. Dairy Proteins: Global Trends and Consumer Insights; Euromonitor International Ltd.: London, UK, 2023; Available online: https://www.euromonitor.com/article/the-key-trends-shaping-dairy-products-and-alternatives-into-2025 (accessed on 5 November 2025).

- Tahir, I.; Foley, C.; Floreani, R. Whey Protein Isolate and β-Lactoglobulin-Modified Alginate Hydrogel Scaffolds Enhance Cell Proliferation for Cultivated Meat Applications. Foods 2025, 14, 2534. [Google Scholar] [CrossRef] [PubMed]

- Dinika, I.; Verma, D.K.; Balia, R.; Utama, G.L.; Patel, A.R. Potential of cheese whey bioactive proteins and peptides in the development of antimicrobial edible film composite: A review of recent trends. Trends Food Sci. Technol. 2020, 103, 57–67. [Google Scholar] [CrossRef]

- Mehra, R.; Kumar, H.; Kumar, N.; Ranvir, S.; Jana, A.; Buttar, H.S.; Telessy, I.G.; Awuchi, C.G.; Okpala, C.O.R.; Korzeniowska, M.; et al. Whey proteins processing and emergent derivatives: An insight perspective from constituents, bioactivities, functionalities to therapeutic applications. J. Funct. Foods 2021, 87, 104760. [Google Scholar] [CrossRef]

- Soumati, B.; Atmani, M.; Benabderrahmane, A.; Benjelloun, M. Whey Valorization- Innovative Strategies for Sustainable Development and Value-Added Product Creation. J. Ecol. Eng. 2023, 24, 86–104. [Google Scholar] [CrossRef]

- Whey Protein Isolate (WPI) Standard v4.0 Effective 07/04/2023. American Dairy Products Institute (ADPI). Available online: https://adpi.org/wp-content/uploads/2023/07/WPI-Standard-v4.0_2023.pdf (accessed on 5 November 2025).

- Bandara, T.A.; Munasinghe-Arachchige, S.P.; Gamlath, C.J. Fermented whey beverages: A review of process fundamentals, recent developments and nutritional potential. Int. J. Dairy Technol. 2023, 76, 737–757. [Google Scholar] [CrossRef]

- Bintsis, T.; Papademas, P. Sustainable approaches in whey cheese production: A review. Dairy 2023, 4, 249–270. [Google Scholar] [CrossRef]

- Papademas, P.; Kotsaki, P. Technological Utilization of Whey towards Sustainable Exploitation. J. Adv. Dairy Res. 2020, 7, 231. [Google Scholar] [CrossRef]

- Reig, M.; Vecino, X.; Cortina, J.L. Use of Membrane Technologies in Dairy Industry: An Overview. Foods 2021, 10, 2768. [Google Scholar] [CrossRef]

- Di Filippo, G.; Melchior, S.; Plazzotta, S.; Calligaris, S.; Innocente, N. Effect of enzymatic hydrolysis with Alcalase or Protamex on technological and antioxidant properties of whey protein hydrolysates. Food Res. Int. 2024, 188, 114499. [Google Scholar] [CrossRef]

- Chang, Y.B.; Kim, H.; Lee, S.K.; Kim, H.-J.; Jeong, A.-H.; Suh, H.J.; Ahn, Y. Characteristics and Absorption Rate of Whey Protein Hydrolysates Prepared Using Flavourzyme after Treatment with Alcalase and Protamex. Molecules 2023, 28, 7969. [Google Scholar] [CrossRef]

- Lans, A.M.; Frelka, J.C.; Paluri, S.; Vodovotz, Y. Physical properties and sensory analysis of galacto-oligosaccharide glassy confections. LWT 2018, 96, 499–506. [Google Scholar] [CrossRef]

- Hansen, M.M.; Hartel, R.W.; Roos, Y.H. Bioactives and extracts affect the physico-chemical properties of concentrated whey protein isolate dispersions. Food Prod. Process. Nutr. 2022, 4, 2. [Google Scholar] [CrossRef]

- Czelej, M.; Garbacz, K.; Czernecki, T.; Rachwał, K.; Wawrzykowski, J.; Waśko, A. Whey Protein Enzymatic Breakdown: Synthesis, Analysis, and Discovery of New Biologically Active Peptides in Papain-Derived Hydrolysates. Molecules 2025, 30, 1451. [Google Scholar] [CrossRef] [PubMed]

- Julmohammad, N.; Roslan, J.; Mohd Razali, U.H.; Chin, S.Y. Physicochemical properties and radical-scavenging activity of whey protein hydrolysate by conjugation with lactose. Food Res. 2024, 8, 62–69. [Google Scholar] [CrossRef] [PubMed]

- Yu, P.; Yan, J.; Kong, L.; Yu, J.; Zhao, X.; Peng, X. Whey Protein Hydrolysate Improved the Structure and Function of Myofibrillar Protein in Ground Pork during Repeated Freeze–Thaw Cycles. Foods 2023, 12, 3135. [Google Scholar] [CrossRef]

- Alvarez-Perez, O.B.; Ventura-Sobrevilla, J.M.; Torres-León, C.; Rojas-Molina, R.; Rodríguez-Herrera, R.; Aguilar-González, M.A.; Aguilar, C.N. Development and characterization of whey protein films incorporated with tarbush polyphenols and candelilla wax. Food Biosci. 2022, 45, 101505. [Google Scholar] [CrossRef]

- Kheto, A.; Adhikary, U.; Dhua, S.; Sarkar, A.; Kumar, Y.; Vashishth, R.; Shrestha, B.B.; Saxena, D.C. A review on advancements in emerging processing of whey protein: Enhancing functional and nutritional properties for functional food applications. Food Saf. Health 2025, 3, 23–45. [Google Scholar] [CrossRef]

- Boey, J.Y.; Mohamad, L.; Khok, Y.S.; Tay, G.S.; Baidurah, S. A Review of the Applications and Biodegradation of Polyhydroxyalkanoates and Poly (lactic acid) and Its Composites. Polymers 2021, 13, 1544. [Google Scholar] [CrossRef] [PubMed]

- Deshmukh, N.; Singh Rao, P.; Sharma, H.; Kumar, S.M.H.; Laxmana Naik, N.; Manoj Kumar, C.T. Waste to nutrition: The evolution of whey, a byproduct to galactooligosaccharides production. Food Chem. Adv. 2024, 4, 100642. [Google Scholar] [CrossRef]

- Zhou, X.; Hua, X.; Huang, L.; Xu, Y. Bioutilization of cheese manufacturing wastes (cheese whey powder) for bioethanol and specific product (galactonic acid) production via a two-step bioprocess. Bioresour. Technol. 2019, 272, 70–76. [Google Scholar] [CrossRef]

- Mei, L.; Fu, Q.; Guo, T.; Ji, Q.; Zhou, Y. Structural changes and cholesterol-lowering in denatured whey protein isolate: Malic acid combined enzymolysis. Food Hydrocoll. 2022, 127, 107502. [Google Scholar] [CrossRef]

- Irazoqui, J.M.; Santiago, G.M.; Mainez, M.E.; Amadio, A.F.; Eberhardt, M.F. Enzymes for production of whey protein hydrolysates and other value-added products. Appl. Microbiol. Biotechnol. 2024, 108, 354. [Google Scholar] [CrossRef] [PubMed]

- Bolla, M.; Pettinato, M.; Ferrari, P.F.; Fabiano, B.; Perego, P. Polyhydroxyalkanoates production from laboratory to industrial scale: A review. Int. J. Biol. Macromol. 2025, 310, 143255. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, Y.; Ma, Z.; Mu, G.; Qian, F. Novel insights into whey protein peptide-iron chelating agents: Structural characterization, in vitro stability, and functional properties. Food Biosci. 2024, 60, 104317. [Google Scholar] [CrossRef]

- Fara, A.; Sabater, C.; Palacios, J.; Requena, T.; Montilla, A.; Zárate, G. Prebiotic galactooligosaccharides production from lactose and lactulose by Lactobacillus delbrueckii subsp. Bulgaricus CRL 450. Food Funct. 2020, 11, 5875–5886. [Google Scholar] [CrossRef]

- Kiran, S.; Sreeja, V.; Kumari Patel, H. The prebiotic potential of lactulose: A review. J. Phytopharm. 2023, 12, 425–429. [Google Scholar] [CrossRef]

- Kandasamy, S.; Yoo, J.; Yun, J.; Kang, H.-B.; Seol, K.-H.; Kim, H.-W.; Ham, J.-S. Application of Whey Protein-Based Edible Films and Coatings in Food Industries: An Updated Overview. Coatings 2021, 11, 1056. [Google Scholar] [CrossRef]

- Khin, M.N.; Ahammed, S.; Kamal, M.M.; Saqib, M.N.; Liu, F.; Zhong, F. Investigating next-generation edible packaging: Protein-based films and coatings for delivering active compounds. Food Hydrocoll. Health 2024, 6, 100182. [Google Scholar] [CrossRef]

- Pires, A.F.; Díaz, O.; Cobos, A.; Pereira, C.D. A Review of Recent Developments in Edible Films and Coatings-Focus on Whey-Based Materials. Foods 2024, 13, 2638. [Google Scholar] [CrossRef]

- Koukoumaki, D.I.; Papanikolaou, S.; Ioannou, Z.; Gkatzionis, K.; Sarris, D. The Development of Novel Edible Films from Single-Cell Protein Produced by the Biotechnological Valorization of Cheese Whey. Appl. Microbiol. 2024, 4, 1030–1041. [Google Scholar] [CrossRef]

- Sarkar, S.; Gupta, S.; Shaw, A.K. Emerging Technology and Management Trends in Environment and Sustainability: Proceedings of the International Conference, EMTES-2022; Taylor & Francis: Abingdon, UK, 2023. [Google Scholar]

- Kumar, N.; Heena; Dixit, A.; Mehra, M.; Daniloski, D.; Trajkovska Petkoska, A. Utilization of whey: Sustainable trends and future developments. In Whey Valorization: Innovations, Technological Advancements and Sustainable Exploitation; Springer Nature: Singapore, 2023; pp. 47–62. [Google Scholar]

- Królczyk, J.B.; Dawidziuk, T.; Janiszewska-Turak, E.; Sołowiej, B. Use of Whey and Whey Preparations in the Food Industry—A Review. Pol. J. Food Nutr. Sci. 2016, 66, 157–165. [Google Scholar] [CrossRef]

- Babenyshev, S.P.; Zhidkov, V.E.; Mamay, D.S.; Utkin, V.P.; Shapakov, N.A. Ultrafiltration of Modified Milk Whey. Food Raw Mater. 2016, 4, 101–110. [Google Scholar] [CrossRef]

- Ferreira, M.V.S.; Cappato, L.P.; Silva, R.; Rocha, R.S.; Guimarães, J.T.; Balthazar, C.F.; Esmerino, E.A.; Freitas, M.Q.; Rodrigues, F.N.; Granato, D.; et al. Ohmic heating for processing of whey-raspberry flavored beverage. Food Chem. 2019, 297, 125018. [Google Scholar] [CrossRef] [PubMed]

- Sathya, R.; Singh, A.; Rasane, P.; Poonia, A.; Singh, J.; Kaur, S.; Gunjal, M.; Kaur, J.; Bhadariya, V. Recent Trends in Membrane Processing of Whey. In Whey Valorization; Poonia, A., Trajkovska Petjoska, A., Eds.; Springer Natura Pte Ltd.: Singapore, 2023; Chapter 16; pp. 323–353. [Google Scholar] [CrossRef]

- Chen, Q.; Zhao, L.; Yao, L.; Chen, Q.; Ahmad, W.; Li, Y.; Qin, Z. The Application of Membrane Separation Technology in the Dairy Industry. In Technological Approaches for Novel Applications in Dairy Processing; IntechOpen: London, UK, 2018; p. 23. [Google Scholar]

- Argenta, A.B.; Scheer, A.D.P. Membrane Separation Processes Applied to Whey: A review. Food Rev. Int. 2019, 36, 1–30. [Google Scholar] [CrossRef]

- Tavares, T.G.; Malcata, F.X. Whey proteins as a source of bioactive peptides against hypertension. In Bioactive Food Peptides in Health and Disease; IntechOpen: London, UK, 2013; p. 75. [Google Scholar]

- Tolkach, A.; Kulozik, U. Fractionation of whey proteins and caseinomacropeptide by means of enzymatic crosslinking and membrane separation techniques. J. Food Eng. 2005, 67, 13–20. [Google Scholar] [CrossRef]

- Cassano, A.; Conidi, C.; Castro-Muñoz, R. Current and Future Applications of Nanofiltration in Food Processing. In Separation of Functional Molecules in Food by Membrane Technology; Elsevier: Amsterdam, The Netherlands, 2019; pp. 305–348. [Google Scholar]

- Abdulstar, A.R.; Altemimi, A.B.; Al-Hilphy, A.R. Exploring the power of thermosonication: A comprehensive review of its applications and impact in the food industry. Foods 2023, 12, 1459. [Google Scholar] [CrossRef]

- Selmi, H.; Presutto, E.; Spano, G.; Capozzi, V.; Fragasso, M. Valorising Whey: From Environmental Burden to Bio-Based Production of Value-Added Compounds and Food Ingredients. Foods 2025, 14, 3646. [Google Scholar] [CrossRef]

- Zheng, Y.; Yang, F.; Yuan, X.; Ji, Y.; Li, H.; Li, H.; Yu, J.; Zulewska, J. Enzymatic hydrolysis of whey proteins by the combination of Alcalase and Neutrase: Kinetic model and hydrolysis control. Int. Dairy J. 2024, 151, 105867. [Google Scholar] [CrossRef]

- Brião, V.B.; Mossmann, J.; Seguenka, B.; Graciola, S.; Piccin, J.S. Integrating whey processing: Ultrafiltration, nanofiltration, and water reuse from diafiltration. Membranes 2024, 14, 191. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.Q.; Qu, Y.; Gras, S.L.; Kentish, S.E. Separation technologies for whey protein fractionation. Food Eng. Rev. 2023, 15, 438–465. [Google Scholar] [CrossRef]

- dos Santos, I.F.; Pimentel, T.C.; da Cruz, A.G.; Stringheta, P.C.; Martins, E.; Campelo, P.H. Ohmic Heating in Food Processing: An Overview of Plant-Based Protein Modification. Processes 2024, 12, 1800. [Google Scholar] [CrossRef]

- Hasan, R.; Islam, M.; Jobair, A.B.; Afrin, S.; Islam, N.; Begum, R. A Comparative Quality Evaluation of Whey Powder Using Spray and Freeze Drying Methods. J. Food Qual. Hazards Control 2025, 12, 201–209. [Google Scholar] [CrossRef]

- Carter, B.G.; Cheng, N.; Kapoor, R.; Meletharayil, G.H.; Drake, M.A. Invited review: Microfiltration-derived casein and whey proteins from milk. J. Dairy Sci. 2021, 104, 2465–2479. [Google Scholar] [CrossRef]

- Nielsen, E.N.; Gøtke, M.; Cordin, U.; Skibsted, L.H.; Velizarov, S.; Crespo, J.G.; Ahrné, L.M. Effect of reverse osmosis pre-processing of acid whey and electrodialysis current density on process performance. Food Bioprod. Process. 2023, 140, 72–83. [Google Scholar] [CrossRef]

- Khalid, M.; Ghasem, N.; Yang, X.; Schroen, K.; Nazir, A. Progress in Membrane Technology for the Enrichment of Individual Whey Proteins. Ind. Eng. Chem. Res. 2025, 64, 19305–19321. [Google Scholar] [CrossRef]

- eAmbrosia. Union Register of Geographical Indications. Database. Available online: https://ec.europa.eu/agriculture/eambrosia/geographical-indications-register/ (accessed on 12 November 2025).

- Papademas, P.; Bintsis, T.; Alichanidis, E.; Ardö, Y. Whey cheeses (Heat coagulated). Chapter 13. In Global Cheesemaking Technology: Cheese Quality and Characteristics; Papademas, P., Bintsis, T., Eds.; John Willey & Sons Ltd.: Chichester, UK, 2017; pp. 446–452. [Google Scholar] [CrossRef]

- Gobbetti, M.; Neviani, E.; Fox, P.; Varanini, G.M. The Cheeses of Italy: Science and Technology; Springer: Cham, Switzerland, 2018; pp. 1–274. [Google Scholar]

- Macit, E. Türkiye’s whey cheeses. Black Sea J. Agric. 2023, 6, 74–86. [Google Scholar] [CrossRef]

- Isipato, M. Application of Microbial Electrochemical Systems for Valorisation of Cheese Whey in Biorefinery Framework. Ph.D. Thesis, Università degli Studi di Cagliari, Scienze E Tecnologie Della Terra E Dell’ambiente (ICAR/03), Cagliari, Italy, 2021. Cycle XXXIII. Available online: https://tesidottorato.depositolegale.it/handle/20.500.14242/69531 (accessed on 3 November 2025).

- Simitzis, P.; Zikou, F.; Progoulakis, D.; Theodorou, G.; Politis, I. A note on the effects of yoghurt acid whey Marination on the tenderness and oxidative stability of different meat types. Foods 2021, 10, 2557. [Google Scholar] [CrossRef]

- Stadnik, J.; Stasiak, D.M. Effect of acid whey on physicochemical characteristics of dry-cured organic pork loins without nitrite. Int. J. Food Sci. Technol. 2016, 51, 970–977. [Google Scholar] [CrossRef]

- Vlahova-Vangelova, D.B.; Balev, D.K.; Dragoev, S.G.; Kirisheva, G.D. Improvement of technological and sensory properties of meat by whey marinating. Sci. Works Univ. Food Technol. 2016, 63, 7–13. Available online: http://uft-plovdiv.bg/site_files/file/scienwork/scienworks_2016/docs/original%20SWUFT201601103%20(final).pdf (accessed on 10 September 2025).

- Latoch, A.; Libera, J. Quality and safety of pork steak marinated in fermented dairy products and sous-vide cooked. Sustainability 2019, 11, 5644. [Google Scholar] [CrossRef]

- Latoch, A.; Czarniecka-Skubina, E.; Moczkowska-Wyrwisz, M. Marinades Based on Natural Ingredients as a Way to Improve the Quality and Shelf Life of Meat: A Review. Foods 2023, 12, 3638. [Google Scholar] [CrossRef] [PubMed]

- Latoch, A.; Moczkowska-Wyrwisz, M.; Sałek, P.; Czarniecka-Skubina, E. Effect of marinating in dairy-fermented products and sous-vide cooking on the protein profile and sensory quality of pork longissimus muscle. Foods 2023, 12, 3257. [Google Scholar] [CrossRef]

- Kim, J. Effects of Acid Whey Marination on Tenderness, Sensory, and Other Quality Parameters of Beef Eye of Round. Master’s of Science, Brigham Young University, Provo, UT, USA, 1 April 2018. Available online: https://scholarsarchive.byu.edu/etd/6758 (accessed on 10 September 2023).

- Augustyńska-Prejsnar, A.; Ormian, M.; Hanus, P.; Kluz, M.; Sokołowicz, Z.; Rudy, M. Effects of marinating breast muscles of slaughter pheasants with acid whey, buttermilk, and lemon juice on quality parameters and product safety. J. Food Qual. 2019, 1, 1–8. [Google Scholar] [CrossRef]

- Augustyńska-Prejsnar, A.; Sokołowicz, Z.; Hanus, P.; Ormian, M.; Kačániová, M. Quality and safety of marinating breast muscles of hens from organic farming after the laying period with buttermilk and whey. Animals 2020, 10, 2393. [Google Scholar] [CrossRef]

- Karageorgou, A.; Paveli, A.; Goliomytis, M.; Theodorou, G.; Politis, I.; Simitzis, P. The effects of yoghurt acid whey marination on quality parameters of pork and chicken meat. Foods 2023, 12, 2360. [Google Scholar] [CrossRef]

- Kęska, P.; Wójciak, K.M.; Stadnik, J. Effect of marination time on the antioxidant properties of peptides extracted from organic dry-fermented beef. Biomolecules 2019, 9, 614. [Google Scholar] [CrossRef]

- Karwowska, M.; Kononiuk, A.D.; Borrajo, P.; Lorenzo, J.M. Comparative studies on the fatty acid profile and volatile compounds of fallow deer and beef fermented sausages without nitrite produced with the addition of acid whey. Appl. Sci. 2021, 11, 1320. [Google Scholar] [CrossRef]

- Kadyan, S.; Rashmi, H.M.; Pradhan, D.; Kumari, A.; Chaudhari, A.; Deshwal, G.K. Effect of lactic acid bacteria and yeast fermentation on antimicrobial, antioxidative, and metabolomic profile of naturally carbonated probiotic whey drink. LWT 2021, 142, 111059. [Google Scholar] [CrossRef]

- Ozer, B.; Evrendilek, G.A. Whey beverages. In Dairy Foods; Woodhead Publishing: London, UK; Elsevier: Amsterdam, The Netherlands, 2022; pp. 117–137. [Google Scholar] [CrossRef]

- Chawla, R.; Roy, S.; Malik, B. Valorisation of whey for development of different types of food products including fermented beverages. In Whey Valorization: Innovations, Technological Advancements and Sustainable Exploitation; Springer Nature: Singapore, 2023; pp. 211–238. [Google Scholar] [CrossRef]

- Altuntaş, S.; Hapoğlu, H. Kefir-type drinks from whey. In Non-Alcoholic Beverages; Grumezescu, A.M., Holban, A.M., Eds.; Woodhead Publishing: Cambridge, UK, 2019; pp. 185–225. [Google Scholar] [CrossRef]

- Saha, P.; Ray, P.R.; Hazra, T. Evaluation of quality and stability of chhana whey beverage fermented with lactic acid bacteria. J. Dairy. Foods Home Sci. 2017, 36, 112–116. [Google Scholar] [CrossRef]

- Rizzolo, A.; Cortellino, G. Ricotta Cheese Whey-Fruit-Based Beverages: Pasteurization Effects on Antioxidant Composition and Color. Beverages 2017, 3, 15. [Google Scholar] [CrossRef]

- Kotsaki, P.; Aspri, M.; Papademas, P. Novel Whey Fermented Beverage Enriched with a Mixture of Juice Concentrates: Evaluation of Antimicrobial, Antioxidant, and Angiotensin I Converting Enzyme Inhibitory (ACE) Activities Before and After Simulated Gastrointestinal Digestion. Microorganisms 2025, 13, 1490. [Google Scholar] [CrossRef]

- Szafrańska, J.O.; Waraczewski, R.; Bartoń, M.; Wesołowska-Trojanowska, M.; Maziejuk, W.; Nowak, P.; Sołowiej, B.G. Effects of organic fruit juices on physicochemical, microbiological, and antioxidative aspects of fermented whey beverages from organic goat and cow milk, produced at laboratory and industrial scales. J. Dairy Sci. 2024, 107, 10481–10496. [Google Scholar] [CrossRef]

- Ganguly, S.; Sabikhi, L.; Singh, A.K. Evaluation of nutritional attributes of whey-cereal based probiotic beverage. LWT 2021, 159, 112292. [Google Scholar] [CrossRef]

- Chavan, R.S.; Shraddha, R.C.; Kumar, A.; Nalawade, T. Whey Based Beverage: Its Functionality, Formulations, Health Benefits, and Applications. J. Food Process. Technol. 2015, 6, 1–8. [Google Scholar] [CrossRef]

- Sar, T.; Bogovic Matijasic, B.; Danilovic, B.; Gamero, A.; Gandía, M.; Krausova, G.; Martínez-Villaluenga, C.; Peñas, E.; Bagherzadehsurbagh, E.; Cemali, Ö.; et al. A systematic review of the promoting effects of consumption of whey-based fermented products on adults. Front. Nutr. 2025, 12, 1651365. [Google Scholar] [CrossRef]

- Ankiel, M.; Halagarda, M.; Piekara, A.; Sady, S.; Żmijowska, P.; Popek, S.; Pachołek, B.; Jefmański, B.; Kucia, M.; Krzywonos, M. Role of Certifications and Labelling in Ensuring Authenticity and Sustainability of Fermented Milk Products. Sustainability 2025, 17, 8398. [Google Scholar] [CrossRef]

- Regulation (EC) No 1924/2006 of the European Parliament and of the Council of 20 December 2006 on Nutrition and Health Claims Made on Foods. L404/9. 30.12.2006. Document 32006R1924. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32006R1924 (accessed on 3 November 2025).

- Garg, V.; Velumani, D.; Lin, Y.C.; Haye, A. A comprehensive review of probiotic claim regulations: Updates from the Asia-Pacific regions, the United States, and Europe. Pharma Nutr. 2024, 30, 100423. [Google Scholar] [CrossRef]

- Mirzakulova, A.; Sarsembaeva, T.; Suleimenova, Z.; Kowalski, Ł.; Gajdzik, B.; Wolniak, R.; Bembenek, M. Whey: Composition, Processing, Application, and Prospects in Functional and Nutritional Beverages A Review. Foods 2025, 14, 3245. [Google Scholar] [CrossRef] [PubMed]

- Freire, P.; Zambrano, A.; Zamora, A.; Castillo, M. Thermal Denaturation of Milk Whey Proteins: A Comprehensive Review on Rapid Quantification Methods Being Studied, Developed and Implemented. Dairy 2022, 3, 500–512. [Google Scholar] [CrossRef]

- Foschi, M.; Biancolillo, A.; Reale, S.; Poles, F.; D’Archivio, A.A. Classification of “Ricotta” Whey Cheese from Different Milk and Designation of Origin-Protected Samples through Infrared Spectroscopy and Chemometric Analysis. J. Food Compos. Anal. 2025, 138, 107019. [Google Scholar] [CrossRef]

- Skryplonek, K. The Use of Acid Whey for the Production of Yogurt-Type Fermented Beverages. Mljekarstvo 2018, 68, 139–149. [Google Scholar] [CrossRef]

- Igualada, C.; Giraldo, J.; Font, G.; Yusà, V. Validation of a Multi-Residue UHPLC-HRMS Method for Antibiotics Screening in Milk, Fresh Cheese, and Whey. J. Food Compos. Anal. 2022, 106, 104265. [Google Scholar] [CrossRef]

- Ramos-Suárez, J.L.; Álvarez-Méndez, S.J.; Padrón Tejera, E.; Ritter, A.; Mata González, J. Temperature Control Effect on Cheese Whey Anaerobic Digestion with Low-Cost Tubular Digesters. Processes 2024, 12, 1452. [Google Scholar] [CrossRef]

- Mahato, J.; Miah, M.; Shovon, M.S.; Roy, N.; Easmin, M.S.; Sharma, S.C.D. Electricity production by microbial fuel cell using cheese whey wastewater of the dairy industry in Rajshahi, Bangladesh. Chem. Biochem. Eng. Q. 2021, 35, 421–430. [Google Scholar] [CrossRef]

- Boudjema, K.; Fazouane-Naimi, F.; Hellal, A. Optimization of the bioethanol production on sweet cheese whey by Saccharomyces cerevisiae DIV13-Z087C0VS using response surface methodology (RSM). Rom. Biotechnol. Lett. 2025, 20, 10814–10825. Available online: https://www.researchgate.net/publication/287521347_Optimization_of_the_Bioethanol_Production_on_Sweet_Cheese_Whey_by_Saccharomyces_cerevisiae_DIV13-Z087C0VS_using_Response_Surface_Methodology_RSM (accessed on 5 September 2025).

- Panghal, A.; Patidar, R.; Jaglan, S.; Chhikara, N.; Khatkar, S.K.; Gat, Y.; Sindhu, N. Whey valorization: Current options and future scenario—A critical review. Nutr. Food Sci. 2018, 48, 520–535. [Google Scholar] [CrossRef]

- Costa, M.A.; Kuhn, D.; Rama, G.R.; Lehn, D.N.; Souza, C.F.V.D. Whey butter: A promising perspective for the dairy industry. Braz. J. Food Technol. 2022, 25, e2021088. [Google Scholar] [CrossRef]

- Athira, S.; Mann, B.; Sharma, R.; Pothuraju, R.; Bajaj, R.K. Preparation and characterization of iron-chelating peptides from whey protein: An alternative approach for chemical iron fortification. Food Res. Int. 2021, 141, 110133. [Google Scholar] [CrossRef]

- Fahrullah, F.; Noersidiq, A.; Kisworo, D.; Maruddin, F. Evaluating Physicochemical Properties of Whey-Chia Seed Edible Films for Biodegradable Packaging. Trop. Anim. Sci. J. 2024, 47, 519–528. [Google Scholar] [CrossRef]

- Pratiwi, D.; Saputri, R.A.; Setiyawan, A.I. Whey edible film enhanced with ginger essential oil: Characterization and antimicrobial activity. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2024; Volume 1377, p. 012036. [Google Scholar] [CrossRef]

- Wulandari, A.; Juliyarsi, I.; Melia, S. Improvement of Physicochemical Properties of Cheese Whey Edible Film through Egg White Addition. J. Ilmu Teknol. Has. Ternak 2024, 19, 139–148. [Google Scholar] [CrossRef]

- Asunis, F.; De Gioannis, G.; Francini, G.; Lombardi, L.; Muntoni, A.; Polettini, A.; Pomi, R.; Rossi, A.; Spiga, D. Environmental lifecycle assessment of polyhydroxyalkanoates production from cheese whey. Waste Manag. 2021, 132, 31–43. [Google Scholar] [CrossRef] [PubMed]

- Dopazo, V.; Luz, C.; Calpe, J.; Vila-Donat, P.; Rodriguez, L.; Meca, G. Antifungal properties of whey fermented by lactic acid bacteria in films for the preservation of cheese slices. Int. J. Dairy Technol. 2022, 75, 619–629. [Google Scholar] [CrossRef]

- Tamošaitis, A.; JaruševičienĖ, A.; StrykaitĖ, M.; Damašius, J. Analysis of antimicrobial whey protein-based biocomposites with lactic acid, tea tree (Melaleuca alternifolia), and garlic (Allium sativum) essential oils for Edam cheese coating. Int. J. Dairy Technol. 2022, 75, 611–618. [Google Scholar] [CrossRef]

- Risner, D.; Tomasino, E.; Hughes, P.; Meunier-Goddik, L. Volatile aroma composition of distillates produced from fermented sweet and acid whey. J. Dairy Sci. 2019, 102, 202–210. [Google Scholar] [CrossRef]

- Krishnan, N.U.; Joseph, M.T.; Shaiha, S.; Vani, P.V.; Raj, J.R.A. Optimization of Bio-Ethanol Production from Whey and the Characterization of Bio-Edible Films from the Fermentation Residue; Springer: Singapore, 2020; pp. 77–84. [Google Scholar] [CrossRef]

- Ferreira, A.; Gouveia, L. Chapter 28—Microalgal biorefineries. In Handbook of Microalgae-Based Processes and Products; Jacob-Lopes, E., Maroneze, M.M., Queiroz, M.I., Zepka, L.Q., Eds.; Academic Press: Cambridge, UK, 2020; pp. 771–798. [Google Scholar] [CrossRef]

- Weide, T.; Peitzmeier, J.; Wetter, C.; Wichern, M.; Brügging, E. Comparison of thermophilic and hyperthermophilic dark fermentation with subsequent mesophilic methanogenesis in expanded granular sludge bed reactors. Int. J. Hydrogen Energy 2021, 57, 29142–29159. [Google Scholar] [CrossRef]

- Aranda-Jaramillo, B.; León-Becerril, E.; Aguilar-Juárez, O.; Castro-Muñoz, R.; García-Depraect, O. Feasibility Study of Biohydrogen Production from Acid Cheese Whey via Lactate-Driven Dark Fermentation. Fermentation 2023, 9, 644. [Google Scholar] [CrossRef]

- Muñoz-Páez, K.M.; Buitrón, G.; Vital-Jácome, M. Predicting metabolic pathways and microbial interactions in dark fermentation systems treating real cheese whey effluents. Bioresour. Technol. 2024, 413, 131536. [Google Scholar] [CrossRef] [PubMed]

- Srivastava, S.; Jhariya, U.; Purohit, H.J.; Dafale, N.A. Synergistic action of lytic polysaccharide monooxygenase with glycoside hydrolase for lignocellulosic waste valorization: A review. Biomass Convers. Biorefin. 2023, 13, 8727–8745. [Google Scholar] [CrossRef]

- Vasilakis, G.; Karayannis, D.; Massouras, T.; Politis, I.; Papanikolaou, S. Biotechnological Conversions of Mizithra Second Cheese Whey by Wild-Type Non-Conventional Yeast Strains: Production of Yeast Cell Biomass, Single-Cell Oil and Polysaccharides. Appl. Sci. 2022, 12, 11471. [Google Scholar] [CrossRef]

- Colacicco, M.; De Micco, C.; Macrelli, S.; Agrimi, G.; Janssen, M.; Bettiga, M.; Pisano, I. Process scale-up simulation and techno-economic assessment of ethanol fermentation from cheese whey. Biotechnol. Biofuels Bioprod. 2024, 17, 124. [Google Scholar] [CrossRef]

- Christensen, A.D.; Kádár, Z.; Oleskowicz-Popiel, P.; Thomsen, M.H. Production of bioethanol from organic whey using Kluyveromyces marxianus. J. Ind. Microbiol. Biotechnol. 2011, 38, 283–289. [Google Scholar] [CrossRef]

- Tarapata, J.; Zieliński, M.; Zulewska, J. Valorization of Dairy By-Products: Efficiency of Energy Production from Biogas Obtained in Anaerobic Digestion of Ultrafiltration Permeates. Energies 2022, 15, 6829. [Google Scholar] [CrossRef]

- Farnocchia, G.; Gómez-Camacho, C.E.; Pipitone, G.; Hischier, R.; Pirone, R.; Bensaid, S. Techno-Economic and Life Cycle Assessments of Aqueous Phase Reforming for the Energetic Valorization of Winery Wastewaters. Sustainability 2025, 17, 7856. [Google Scholar] [CrossRef]

- Khramtsov, A.G.; Borisenko, A.A.; Volodin, D.N.; Borisenko, A.A.; Borisenko, L.A. Problems of processing milk whey as universal agricultural raw material and some ways to solve them. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2022; Volume 981, p. 022093. [Google Scholar] [CrossRef]

- Pirttijärvi, T.S.; Ahonen, L.M.; Maunuksela, L.M.; Salkinoja-Salonen, M.S. Bacillus cereus in a whey process. Int. J. Food Microbiol. 1998, 44, 31–41. [Google Scholar] [CrossRef] [PubMed]

- Paul, S.; Kulkarni, S.; Rao, K.J. Utilisation of concentrated whey in the production of multigrain bread: Optimisation of solid levels in concentrated whey and temperatures of baking. Int. Food Res. J. 2019, 26, 599–606. [Google Scholar]

- Pořízka, J.; Slavíková, Z.; Bidmonová, K.; Vymětalová, M.; Diviš, P. Physiochemical and sensory properties of bread fortified with wheat bran and whey protein isolates. Foods 2023, 12, 2635. [Google Scholar] [CrossRef]

- Liu, X.; Jiang, D.; Peterson, D.G. Identification of bitter peptides in whey protein hydrolysate. J. Agric. Food Chem. 2014, 62, 5719–5725. [Google Scholar] [CrossRef]

- de Aquino, L.F.M.C.; Ribeiro, R.D.O.R.; Simoes, J.S.; Mano, S.B.; M’arsico, E.T.; Junior, C.A.C. Mercury content in whey protein and potential risk for human health. J. Food Compos. Anal. 2017, 59, 141–144. [Google Scholar] [CrossRef]

| Region | Annual Whey Production (Metric Tons) | Notes | Reference |

|---|---|---|---|

| European Union | 52.2 million | Used for human consumption | [24,25] |

| in which; | |||

| Germany | 14.1 million | By-product in the manufacture of cheese | |

| Netherlands | 8.8 million | [26] | |

| Poland | 5.2 million | ||

| United States | n/d (fragmented estimation > 58.2 million *) | Sweet whey estimated from USDA data | [27,28] |

| Argentina | 4.7 million (4700 million liters) | Processed into demineralized powder and whey protein concentrates | [29] |

| India | 3.3–5 million | Estimated from paneer production | [25,30] |

| Jalisco ** (in Mexico) | 0.323 million (322,942 m3) | High organic load, environmental impact | [31] |

| Turkey | 1.1 million | As a possible energy source | [32] |

| Global | 180–200 million | Significant environmental impact due to high biological oxygen demand | [13,19,21,22] |

| Type of Whey Preparation | Processing Methods | Functional Properties | Chemical Properties | Technological Application | Source |

|---|---|---|---|---|---|

| Whey protein concentrate (WPC) | Ultrafiltration, Diafiltration, Spray Drying | Good solubility, high emulsification and foaming capacity, moderate heat stability, mild milky flavor. WPC hydrolysates possess antioxidant and ACE-inhibiting effects. Peptides released from WPC after hydrolysis have bioactive properties. | Protein content 35–80%; moderate amount of lactose and fat; calcium and phosphates content. | Sports nutrition, sauces, milk drinks, baby food, protein bars, functional drinks, confectionery, desserts, meat products, bread | [28,63,75,76,77,78,79,80,81,82,83] |

| Whey protein isolate (WPI) | Ultrafiltration; Microfiltration; Ion exchange; Spray drying | Very good solubility; excellent emulsifying properties; high thermal stability; neutral taste. In soluble WPI dispersions, the addition of bioactive extracts (e.g., polyphenols) can modify the physicochemical properties (viscosity, interactions). | Protein content ≥90%; very low lactose (<1%) and fat content; high purity of β-lactoglobulin and α-lactalbumin fractions | Protein supplements, dietary products (lactose-free), clinical nutrition, functional drinks | [52,77,79,84,85,86,87,88] |

| Whey protein hydrolysate (WPH) | Enzymatic hydrolysis (e.g., papain, trypsin, alcalase); Heat inactivation; Spray drying | They exhibit high solubility, rapid absorption, and bioactive properties, including antioxidant, ACE inhibitor, and immunomodulatory effects. They possess reduced foaming capacity; very good heat stability; a slightly bitter aftertaste; and high biological value (DIAAS > 1.0). Peptide fractions (e.g., <1 kDa) demonstrate stability and bioactivity after simulated digestion. | High protein content (75–85%) and bioactive peptides; very low lactose content | Formulas for infants and the elderly, medical nutrition, regenerative supplements, and also in muscle systems (e.g., improving protein stability in meat). | [89,90,91,92,93,94,95] |

| Demineralized whey powder (DWP) | Nanofiltration, Electrodialysis, Spray drying | Good solubility; improves the taste and structure of products; has stabilizing properties | Low ash content (<5%), moderate lactose level, protein content approx. 12–15% | Production of infant food, dairy desserts, protein bars, instant soups, and sauces. | [52,88,96] |

| Single-cell whey protein (SCP) | Microbiological fermentation (Bacillus, Kluyveromyces), drying, grinding | Highly digestible; nutritional function; possible use as a source of amino acids | Protein content (60–70%); trace element content (Fe, Zn, Mg) | High-protein products, feed, and biotechnology applications | [63,97] |

| Whey permeate powder | A by-product of whey protein ultrafiltration | Nutritional functions, source of protein, and oligosaccharides | Protein content 3–8%, content of lactose, minerals, and oligosaccharides | A cheap raw material for fermentation (lactic acid, bioethanol) and the production of bioplastics, feed, and fertilizers; a source of substrates for biotechnology. | [28,83,98,99,100] |

| Prebiotic products from lactose (GOS, lactulose) | Enzymatic conversion of lactose (β-galactosidase, isomerization) to GOS and lactulose | Prebiotic properties: stimulate the growth of intestinal bacteria (Bifidobacterium, Lactobacilus) | GOS content up to 60%; thermally stable; supports the bioavailability of calcium and magnesium | Used as a functional ingredient for a wide range of products: infant milk powders, dairy products, fruit-based drinks, bakery products, and prebiotic supplements. Lactulose is used as a sweetener for diabetic patients, replacing the sugar in confectionery and yogurts. | [52,99,101,102,103,104,105,106] |

| Whey proteins | They are produced enzymatically or by the isomerization of lactose. | They have prebiotic properties and support intestinal microbiota. WPI/WPC can be used as a film matrix; modifications improve mechanical properties and antimicrobial activity. | They contain: β-lactoglobulin, α-lactalbumin, immunoglobulins, and lactoferrin | Used in the production of meat and meat products, reduced-fat products, yogurts and ice creams, cheeses, bakery products, confectionery and pastry products, infant formulas, and whey drinks. Used as edible films, protective coatings, and biodegradable packaging, is used in functional foods, supplements, protein drinks, and clinical products. | [8,51,52,67,102,107,108,109,110,111,112,113] |

| Country | Types of Cheese | Country | Types of Cheese |

|---|---|---|---|

| Italy | Ricotta salata, Ricottone, Ricotta fresca Ricotta di Bufala Campana *, Ricotta Romana * | Greece | Anthotyros, Myzithra, Manouri, Xynomyzithra, Urda, Xinomyzithra Kritis * |

| Norway | Mysost Gjetost, Brunost | Turkey | Lor Peyniri, Tire Çamur Peyniri |

| Sweden | Mesost, Messmör | Cyprus | Anari |

| Denmark | Myseost | Croatia | Skuta |

| France | Brocciu corse * | Serbia | Skuta, Urda |

| Romania | Urda | Mexico | Requesón |

| Portugal | Requeijão, Requeijão da Beira Baixa *, Requeijão Serra da Estrela * | Iceland | Mysuostur |

| Spain | Requesón |

| Whey Valorisation | Yields and Operating Conditions | Techno-Economic Assessment (TEA)/Life-Cycle Assessments (LCA) Indicator |

|---|---|---|

| Bioethanol | Ethanol fermentations with Kluyveromyces marxianus are often carried out at 30–40 °C with pH ~4.5 (or without strict pH control). Using K. marxianus yields of ~0.50 g ethanol per g lactose have been reported in batch fermentation at 30–40 °C and acidic pH (~4.5), with productivity up to 2.5–4.5 g/L·h in continuous alginate-immobilized systems. It was found that when the initial whey was 18.8 g/L, fermentation with K. marxianus for 12 h reduced the COD content by 82.28%. | The TEA value of a scaled-up whey-to-ethanol facility (developed in a simulation study) showed a strong dependence on the “gate fee” for whey. When whey is treated as a waste stream (negative cost or credit for the processor), the economics improve significantly, giving a minimum ethanol selling price of ~1.43 €/kg for Y_E/L = 0.45 g/g. |

| Biogas (methane) | Anaerobic digestion for methanogenesis typically runs mesophilic (e.g., ~35 °C in UASB reactors) or thermophilic for higher rates. In single-stage anaerobic digestion of whey under thermophilic conditions, methane yields of around 314 L CH4 per kg COD added were observed. Under mesophilic UASB digestion, other studies reported ~120 L CH4/kg COD. | In life-cycle assessments (LCA) and economic modeling of two-stage anaerobic digestion (for H2 + CH4), studies show that on-site systems yield favorable greenhouse gas (GHG) savings compared to conventional disposal, making them attractive for medium-scale dairies. |

| Biohydrogen (H2) | Anaerobic fermentation of whey/lactose has achieved 2.8–3.6 mol H2 per mol lactose under buffered conditions (COD ~9–15 g/L). Theoretically, higher yields (up to 8 mol H2/mol lactose) are possible if acetate is the only end-product For dark hydrogen fermentation, an initial COD of around 9–15 g COD/L, with a buffering system (e.g., MES buffer) to maintain pH ~5–5.5, yields the best H2. | Energetic efficiency (energy consumption) for processes like aqueous-phase reforming (APR) of dairy wastewater has also been studied: for example, producing H2 in a reforming plant gave LCA footprints of 2.57 kg CO2-eq per kg H2, and an energy cost (minimum selling price) of ~USD 7.00/kg H2 in one scenario. |

| Strengths | Weaknesses |

|---|---|

| Whey is a rich source of vitamins, minerals, proteins, and other nutritional values. Therefore, it can be used to develop new, nutritional products. The valorization of whey is the achievement of the UN Sustainable Development Goals, such as Goal 6. Clean Water and Sanitation, Goal 12. Responsible consumption, and Goal 13. Climate Action. This is in line with the principles of a circular economy (Zero waste). | Whey recovery and valorisation from small dairies can be difficult and too expensive. Valorisation processes are not always available or affordable for small-scale producers who do not have the finances, resources, or infrastructure. Some types of whey are difficult to valorize (e.g., acid whey cannot be valorised through membrane filtration). |

| Opportunities | Threats |

| The development of modern processing methods (technologies) may be more effective in the valorisation of whey. Waste whey from small dairies can be sold for further processing. Consumer interest in new products, such as probiotics, whey beverages, and other functional products, may increase the dairy industry’s interest in whey valorisation. | Excessive production of dairy products may result in increased environmental pollution, despite the dairy industry’s growing interest in whey valorisation. Failure to valorize leads to significant economic, nutritional, and environmental losses. Whey processing also creates wastewater and environmental pollution. Due to the fragmented producer structure in the dairy industry, there is a lack of comprehensive, documented data on discharges to wastewater or soil, as well as data on whey valorization. As a result, this leads to a lack of comprehensive solutions for whole industry. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Czarniecka-Skubina, E.; Pielak, M.; Neffe-Skocińska, K.; Kajak-Siemaszko, K.; Karp-Paździerska, S.; Głuchowski, A.; Moczkowska-Wyrwisz, M.; Rosiak, E.; Rutkowska, J.; Antoniewska-Krzeska, A.; et al. Whey—A Valuable Technological Resource for the Production of New Functional Products with Added Health-Promoting Properties. Foods 2025, 14, 4258. https://doi.org/10.3390/foods14244258

Czarniecka-Skubina E, Pielak M, Neffe-Skocińska K, Kajak-Siemaszko K, Karp-Paździerska S, Głuchowski A, Moczkowska-Wyrwisz M, Rosiak E, Rutkowska J, Antoniewska-Krzeska A, et al. Whey—A Valuable Technological Resource for the Production of New Functional Products with Added Health-Promoting Properties. Foods. 2025; 14(24):4258. https://doi.org/10.3390/foods14244258

Chicago/Turabian StyleCzarniecka-Skubina, Ewa, Marlena Pielak, Katarzyna Neffe-Skocińska, Katarzyna Kajak-Siemaszko, Sabina Karp-Paździerska, Artur Głuchowski, Małgorzata Moczkowska-Wyrwisz, Elżbieta Rosiak, Jarosława Rutkowska, Agata Antoniewska-Krzeska, and et al. 2025. "Whey—A Valuable Technological Resource for the Production of New Functional Products with Added Health-Promoting Properties" Foods 14, no. 24: 4258. https://doi.org/10.3390/foods14244258

APA StyleCzarniecka-Skubina, E., Pielak, M., Neffe-Skocińska, K., Kajak-Siemaszko, K., Karp-Paździerska, S., Głuchowski, A., Moczkowska-Wyrwisz, M., Rosiak, E., Rutkowska, J., Antoniewska-Krzeska, A., & Zielińska, D. (2025). Whey—A Valuable Technological Resource for the Production of New Functional Products with Added Health-Promoting Properties. Foods, 14(24), 4258. https://doi.org/10.3390/foods14244258