Physicochemical Characteristics and Flavor Quality Analysis of Fermented Jerky from Yanbian Beef Cattle

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

2.2. Yanbian Yellow Beef Jerky Production

2.3. Determination of General Composition of Beef Jerky

2.4. Determination of Physicochemical Properties of Beef Jerky

2.5. Determination of Flavor Quality of Beef Jerky

2.6. Microbial Community Detection During Beef Fermentation Process

2.7. Data Processing and Statistical Analysis

3. Results and Discussion

3.1. Physicochemical Properties of Beef Jerky

3.2. Free Amino Acid Composition of Beef Jerky

3.3. Free Fatty Acid Composition of Beef Jerky

3.4. Beef Jerky Flavor Quality

3.5. Microbial Community Analysis During Beef Fermentation Process

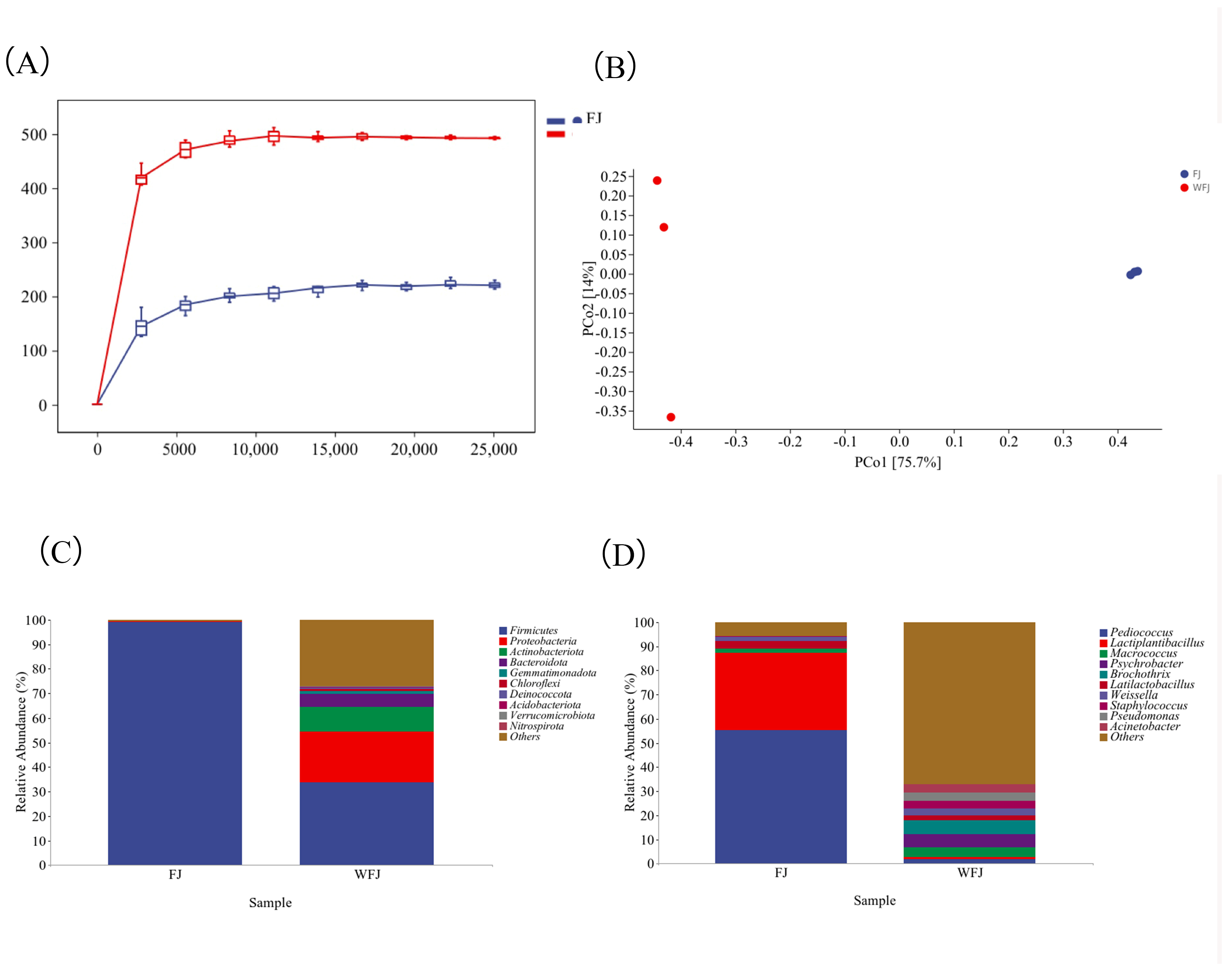

3.5.1. Analysis of Beef Alpha Diversity

3.5.2. Beef Microbial Community Structure

3.5.3. Beef Beta Diversity Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Y.; Li, T.; Chen, F.; Zhao, Y.; Li, Y.; Zhao, C. Research Progress of Meat Jerky Varieties and Meat Jerky Preservation Technology. Sci. Technol. Food Ind. 2021, 42, 9. [Google Scholar] [CrossRef]

- Heres, A.; Mora, L.; Toldrá, F. Bioactive and Sensory Di- and Tripeptides Generated during Dry-Curing of Pork Meat. Int. J. Mol. Sci. 2023, 24, 1574. [Google Scholar] [CrossRef] [PubMed]

- Shen, J.; Hanif, Q.; Cao, Y.; Yu, Y.; Lei, C.; Zhang, G.; Zhao, Y. Whole Genome Scan and Selection Signatures for Climate Adaption in Yanbian Cattle. Front. Genet. 2020, 11, 94. [Google Scholar] [CrossRef] [PubMed]

- Ashaolu, T.; Khalifa, I.; Mesak, M.; Lorenzo, J.; Farag, M. A Comprehensive Review of the Role of Microorganisms on Texture Change, Flavor and Biogenic Amines Formation in Fermented Meat with Their Action Mechanisms and Safety. Crit. Rev. Food Sci. Nutr. 2021, 63, 3538–3555. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, Y.; Chen, Y.; Wang, S. Analysis of Physicochemical Characteristics and Flavor Quality of Fermented Beef Jerky during Its Processing. Food Sci. 2021, 42, 8. [Google Scholar] [CrossRef]

- Kim, J.; Lee, E.; Kim, M. Potential Correlation between Microbial Diversity and Volatile Flavor Compounds in Different Types of Korean Dry-Fermented Sausages. Foods 2022, 11, 3182. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Zhang, G. Recent Progress on the Application of Lactic Acid Bacteria in Fermented Meat Products. Meat Res. 2022, 36, 51–56. [Google Scholar] [CrossRef]

- Bai, B.; Qiu, R.; Wang, Z.; Liu, Y.; Bao, J.; Sun, L.; Liu, T.; Ge, G.; Jia, Y. Effects of Cellulase and Lactic Acid Bacteria on Ensiling Performance and Bacterial Community of Caragana korshinskii Silage. Microorganisms 2023, 11, 337. [Google Scholar] [CrossRef]

- Stangierski, J.; Rezler, R.; Kawecki, K. An Analysis of Changes in the Physicochemical and Mechanical Properties during the Storage of Smoked and Mould Salamis Made in Poland. Molecules 2023, 28, 5122. [Google Scholar] [CrossRef]

- Hu, M.; Yu, J.; Yu, J.; Pan, Y.; Ou, Y. Isolation and Screening of Staphylococcus xylosus P2 from Chinese Bacon: A Novel Starter Culture in Fermented Meat Products. Int. J. Food Eng. 2019, 15, 1–7. [Google Scholar] [CrossRef]

- Hu, Y.; Dong, Z.; Wen, R.; Kong, B.; Yu, W.; Wang, J.; Liu, H.; Chen, Q. Combination of Ultrasound Treatment and Starter Culture for Improving the Quality of Beef Jerky. Meat Sci. 2023, 204, 109240. [Google Scholar] [CrossRef] [PubMed]

- Oppong, D.; Panpipat, W.; Cheong, L.; Chaijan, M. Comparative Effect of Frying and Baking on Chemical, Physical, and Microbiological Characteristics of Frozen Fish Nuggets. Foods 2021, 10, 3158. [Google Scholar] [CrossRef] [PubMed]

- Sam, F.; Ma, T.; Atuna, R.A.; Salifu, R.; Nubalanaan, B.; Amagloh, F.; Han, S. Physicochemical, Oxidative Stability and Sensory Properties of Frankfurter-Type Sausage as Influenced by the Addition of Carrot (Daucus carota) Paste. Foods 2021, 10, 3032. [Google Scholar] [CrossRef]

- Zheng, Z.; Zhou, Q.; Li, D.; Wu, Y.; Zhong, K.; Gao, H. Effects of Enhanced Fermentation with Lactiplantibacillus plantarum WWPC on Physicochemical Characteristics and Flavor Profiles of Radish Paocai and Dried-Fermented Radish. Food Biosci. 2024, 59, 103941. [Google Scholar] [CrossRef]

- Dias, I.; Laranjo, M.; Potes, M.E.; Agulheiro-Santos, A.C.; Ricardo-Rodrigues, S.; Fialho, A.R.; Véstia, J.; Fraqueza, M.J.; Oliveira, M.; Elias, M. Co-Inoculation with Staphylococcus equorum and Lactobacillus sakei Reduces Vasoactive Biogenic Amines in Traditional Dry-Cured Sausages. Int. J. Environ. Res. Public Health 2021, 18, 7100. [Google Scholar] [CrossRef]

- Zavistanaviciute, P.; Klementaviciute, J.; Klupsaite, D.; Zokaityte, E.; Ruzauskas, M.; Buckiuniene, V.; Viskelis, P.; Bartkiene, E. Effects of Marinades Prepared from Food Industry By-Products on Quality and Biosafety Parameters of Lamb Meat. Foods 2023, 12, 1391. [Google Scholar] [CrossRef] [PubMed]

- Rocchetti, G.; Leni, G.; Rebecchi, A.; Dordoni, R.; Giuberti, G.; Lucini, L. The Distinctive Effect of Different Insect Powders as Meat Extenders in Beef Burgers Subjected to Cooking and in Vitro Gastrointestinal Digestion. Food Chem. 2024, 442, 138422. [Google Scholar] [CrossRef]

- Huang, C.; Blecker, C.; Wei, X.; Xie, X.; Li, S.; Chen, L.; Zhang, D. Effects of Different Plant Polysaccharides as Fat Substitutes on the Gel Properties, Microstructure and Digestion Characteristics of Myofibrillar Protein. Food Hydrocoll. 2024, 150, 109717. [Google Scholar] [CrossRef]

- Bal-Prylypko, L.; Danylenko, S.; Mykhailova, O.; Nedorizanyuk, L.; Bovkun, A.; Slobodyanyuk, N.; Omelian, A.; Ivaniuta, A. Influence of Starter Cultures on Microbiological and Physical-Chemical Parameters of Dry-Cured Products. Potravin. Slovak. J. Food Sci. 2024, 18, 313–330. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Zhao, L.; Su, R.; Jin, Y. Effects of Different Starter Culture Combinations on Microbial Counts and Physico-chemical Properties in Dry Fermented Mutton Sausages. Food Sci. Nutr. 2019, 7, 1957–1968. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Liang, S.; Wang, K.; Zi, X.; Zhang, R.; Wang, G.; Kang, J.; Li, Z.; Dou, T.; Ge, C. Physicochemical, Nutritional Properties and Metabolomics Analysis Fat Deposition Mechanism of Chahua Chicken No. 2 and Yao Chicken. Genes 2022, 13, 1358. [Google Scholar] [CrossRef] [PubMed]

- Jeong, C.-H.; Lee, S.-H.; Kim, H.-Y. Microbiological Composition and Sensory Characterization Analysis of Fermented Sausage Using Strains Isolated from Korean Fermented Foods. Food Sci. Anim. Resour. 2022, 42, 928–941. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Shen, J.; Meng, G.; Wang, H.; Liu, C.; Zhu, C.; Zhao, G.; Tong, L. Selection of Yeast Strains in Naturally Fermented Cured Meat as Promising Starter Cultures for Fermented Cured Beef, a Traditional Fermented Meat Product of Northern China. J. Sci. Food Agric. 2024, 104, 883–891. [Google Scholar] [CrossRef]

- Liu, R.; Wu, G.; Li, K.; Ge, Q.; Wu, M.; Yu, H.; Wu, S.; Bao, W. Comparative Study on Pale, Soft and Exudative (PSE) and Red, Firm and Non-Exudative (RFN) Pork: Protein Changes during Aging and the Differential Protein Expression of the Myofibrillar Fraction at 1 h Postmortem. Foods 2021, 10, 733. [Google Scholar] [CrossRef]

- Shikha Ojha, K.; Granato, D.; Rajuria, G.; Barba, F.J.; Kerry, J.P.; Tiwari, B.K. Application of Chemometrics to Assess the Influence of Ultrasound Frequency, Lactobacillus sakei Culture and Drying on Beef Jerky Manufacture: Impact on Amino Acid Profile, Organic Acids, Texture and Colour. Food Chem. 2018, 239, 544–550. [Google Scholar] [CrossRef] [PubMed]

- Kirkyol, M.; Akkose, A. Investigation of Textural and Physicochemical Changes during the Manufacturing Process of Pastirma, a Dry-Cured Meat Product. Food Sci. Technol. Int. 2023, 29, 739–747. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, P.; Xie, Y.; Wang, X. Co-Fermentation with Lactobacillus curvatus LAB26 and Pediococcus pentosaceus SWU73571 for Improving Quality and Safety of Sour Meat. Meat Sci. 2020, 170, 108240. [Google Scholar] [CrossRef]

- Sunesen, L.O.; Stahnke, L.H. Mould Starter Cultures for Dry Sausages-Selection, Application and Effects. Meat Sci. 2003, 65, 935–948. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, M.; Xie, J.; Zhao, M.; Hou, L.; Liang, J.; Wang, S.; Cheng, J. Volatile Flavor Constituents in the Pork Broth of Black-Pig. Food Chem. 2017, 226, 51–60. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Wu, Y.; Xiang, H.; Sun-Waterhouse, D.; Zhao, Y.; Chen, S.; Li, L.; Wang, Y. UHPLC-Q-Exactive Orbitrap MS/MS-Based Untargeted Lipidomics Reveals Molecular Mechanisms and Metabolic Pathways of Lipid Changes during Golden Pomfret (Trachinotus ovatus) Fermentation. Food Chem. 2022, 396, 133676. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Wang, X.; Kang, L.; Liang, J.; Na, Q.; Wang, L.; Zhang, Y. Effects of different starter cultures on the inhibition of harmful biogenic amine content and free fatty acids release of fermented sausages. Food Ferment. Ind. 2018, 44, 71–77. [Google Scholar] [CrossRef]

- Liu, M.; Chen, S.; Zhang, S.; Zhao, B.; Pan, X.; Zhou, H.; Qiao, X.; Zang, M.; Li, S.; Zhu, N. Effect of Light Fermentation on the Flavor of Beef Jerky. Food Sci. 2021, 42, 8. [Google Scholar] [CrossRef]

- Janssens, M.; Myter, N.; De Vuyst, L.; Leroy, F. Species Diversity and Metabolic Impact of the Microbiota Are Low in Spontaneously Acidified Belgian Sausages with an Added Starter Culture of Staphylococcus carnosus. Food Microbiol. 2012, 29, 167–177. [Google Scholar] [CrossRef]

- Sha, K.; Li, S.; Zhang, S.; Zhang, J.; Liu, H. Effect of High Voltage Electrostatic Field on Flavor Quality and Microbial Community of Fermented Beef. Trans. Chin. Soc. Agric. Mach. 2023, 54, 371–380, 398. [Google Scholar]

| Indicator | Unfermented Beef Jerky | Fermented Beef Jerky |

|---|---|---|

| Protein content (%) | 60.60 ± 0.35 a | 58.84 ± 0.42 b |

| Fat content (%) | 3.97 ± 0.21 a | 3.85 ± 0.80 a |

| Moisture content (%) | 19.96 ± 0.40 a | 17.52 ± 0.41 b |

| Ash content (%) | 3.21 ± 0.09 b | 3.89 ± 0.08 a |

| pH value | 5.77 ± 0.03 a | 4.96 ± 0.05 b |

| Aw value | 0.78 ± 0.00 a | 0.76 ± 0.01 b |

| Nitrite residue/(mg/kg) | 0.01 ± 0.00 a | 0.01 ± 0.00 a |

| Histamine/(mg/100 g) | 5.47 ± 0.03 a | 5.49 ± 0.02 a |

| TBRAS value/(mg/100 g) | 0.59 ± 0.06 a | 0.63 ± 0.01 a |

| Hardness/N | 166.22 ± 9.89 b | 201.27 ± 12.76 a |

| Viscosity/mJ | 0.22 ± 0.03 a | 0.21 ± 0.05 a |

| Cohesion | 0.35 ± 0.03 a | 0.30 ± 0.02 a |

| Elasticity/mm | 6.61 ± 0.55 a | 6.97 ± 0.05 a |

| Chewability/mJ | 380.66 ± 19.81 a | 423.45 ± 46.71 a |

| L* | 46.68 ± 0.78 a | 47.83 ± 0.45 a |

| a* | 2.58 ± 0.39 a | 3.13 ± 0.23 a |

| b* | 5.57 ± 0.84 a | 6.79 ± 0.46 a |

| Amino Acid Classification | Amino Acid Name | (mg/kg) | |

|---|---|---|---|

| Unfermented Beef Jerky | Fermented Beef Jerky | ||

| Fresh amino acids | Aspartic acid (Asp) | 14.131 ± 0.536 b | 15.980 ± 0.462 a |

| Glutamine (Glu) | 25.496 ± 0.179 b | 30.627 ± 0.963 a | |

| Total | 39.628 ± 0.716 b | 46.607 ± 1.425 a | |

| Sweet amino acids | Alanine (Ala) | 9.082 ± 0.359 b | 10.299 ± 0.285 a |

| Glycine (Gly) | 6.508 ± 0.030 b | 7.637 ± 0.199 a | |

| Serine (Ser) | 6.378 ± 0.250 b | 7.211 ± 0.208 a | |

| Threonine (Thr) | 7.321 ± 0.467 a | 8.012 ± 0.254 a | |

| Total | 29.289 ± 1.105 b | 33.159 ± 0.946 a | |

| Bitter amino acids | Phenylalanine (Pre) | 6.327 ± 0.239 b | 7.162 ± 0.158 a |

| Methionine (Met) | 4.064 ± 0.164 a | 4.456 ± 0.172 a | |

| Leucine (Leu) | 12.020 ± 0.474 b | 13.539 ± 0.392 a | |

| Isoleucine (Iso) | 5.448 ± 0.224 a | 5.956 ± 0.195 a | |

| Valine (Val) | 5.583 ± 0.228 a | 6.086 ± 0.194 a | |

| Cysteine (Gys) | 0.692 ± 0.014 b | 0.867 ± 0.017 a | |

| Histidine (His) | 4.767 ± 0.191 b | 5.490 ± 0.044 a | |

| Arginine (Arg) | 10.371 ± 0.386 b | 11.535 ± 0.354 a | |

| Total | 49.273 ± 1.919 b | 55.091 ± 1.528 a | |

| Odorless amino acids | Lysine (Lys) | 13.189 ± 0.551 a | 14.587 ± 0.513 a |

| Tyrosine (Tyr) | 5.488 ± 0.227 a | 5.963 ± 0.239 a | |

| Total | 18.677 ± 0.778 a | 20.550 ±0.753 a | |

| Essential amino acid (EAA) | 53.952 ± 2.946 a | 59.798 ± 1.879 a | |

| Non-essential amino acid (NEAA) | 82.914 ± 2.173 b | 95.609 ± 2.722 a | |

| Total amino acid (TAA) | 136.866 ± 4.519 b | 155.408 ± 4.651 a | |

| Fatty Acids | Content (g/100 g) | ||

|---|---|---|---|

| Unfermented Beef Jerky | Fermented Beef Jerky | ||

| Saturated fatty acid (SFA) | Lauric acid C12:0 | 0.002 ± 0.001 a | 0.001 ± 0.000 b |

| Myristic acid C14:0 | 0.045 ± 0.001 a | 0.033 ± 0.002 b | |

| Pentadecanoic acid C15:0 | 0.010 ± 0.000 a | 0.008 ± 0.000 b | |

| Palmitic acid C16:0 | 0.580 ± 0.010 a | 0.449 ± 0.048 b | |

| Heptadecanoic acid C17:0 | 0.019 ± 0.001 a | 0.017 ± 0.001 a | |

| Stearic acid C18:0 | 0.313 ± 0.010 a | 0.249 ± 0.016 b | |

| total | 0.969 ± 0.022 a | 0.757 ± 0.068 b | |

| Monounsaturated fatty acid (MUFA) | Tetradecenoic acid C14:1 | 0.009 ± 0.000 a | 0.007 ± 0.001 b |

| Palmitoleic acid C16:1 | 0.053 ± 0.001 a | 0.039 ± 0.005 b | |

| Heptadecenoic acid C17:1 | ND | 0.010 ± 0.001 | |

| Trans-oleic acid C18:1n9t | ND | 0.005 ± 0.001 | |

| Oleic acid C18:1n9c | 0.651 ± 0.142 a | 0.696 ± 0.074 a | |

| total | 0.714 ± 0.143 a | 0.757 ± 0.080 a | |

| Polyunsaturated fatty acid (PUFA) | Linoleic acid C18:2n6c | 0.213 ± 0.017 a | 0.234 ± 0.011 a |

| Arachidonic acid C20:4n6 | ND | 0.042 ± 0.006 | |

| total | 0.213 ± 0.017 b | 0.276 ± 0.017 a | |

| Total fatty acids | 1.896 ± 0.135 a | 1.789 ± 0.164 a | |

| Sample | Chao1 | Faith_pd | Goods_ Coverage | Observed_ Species | Pielou_e | Shannon | Simpson |

|---|---|---|---|---|---|---|---|

| Unfermented beef jerky | 492.91 | 169.17 | 1.00 | 487.07 | 0.84 | 7.46 | 0.99 |

| Fermented beef jerky | 221.70 | 32.96 | 1.00 | 196.90 | 0.45 | 3.42 | 0.76 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, X.; Liu, C.; Wang, Q.; Cui, E.; Piao, H.; Wen, Y.; Li, G.; Jin, Q. Physicochemical Characteristics and Flavor Quality Analysis of Fermented Jerky from Yanbian Beef Cattle. Foods 2025, 14, 300. https://doi.org/10.3390/foods14020300

Yang X, Liu C, Wang Q, Cui E, Piao H, Wen Y, Li G, Jin Q. Physicochemical Characteristics and Flavor Quality Analysis of Fermented Jerky from Yanbian Beef Cattle. Foods. 2025; 14(2):300. https://doi.org/10.3390/foods14020300

Chicago/Turabian StyleYang, Xiao, Changlei Liu, Qi Wang, Enying Cui, Hongjie Piao, Yuping Wen, Guanhao Li, and Qing Jin. 2025. "Physicochemical Characteristics and Flavor Quality Analysis of Fermented Jerky from Yanbian Beef Cattle" Foods 14, no. 2: 300. https://doi.org/10.3390/foods14020300

APA StyleYang, X., Liu, C., Wang, Q., Cui, E., Piao, H., Wen, Y., Li, G., & Jin, Q. (2025). Physicochemical Characteristics and Flavor Quality Analysis of Fermented Jerky from Yanbian Beef Cattle. Foods, 14(2), 300. https://doi.org/10.3390/foods14020300