Enhanced Peelability and Quality of Whiteleg Shrimp (Litopenaeus vannamei) Using Pulsed Electric Field (PEF) Treatment

Abstract

1. Introduction

2. Materials and Methods

2.1. Shrimp Preparation

2.2. PEF Treatment

2.3. Measurement of Peelability After PEF Treatment

2.4. Measurement of Texture Properties of Treated Shrimp

2.5. Statistical Analysis

3. Results and Discussion

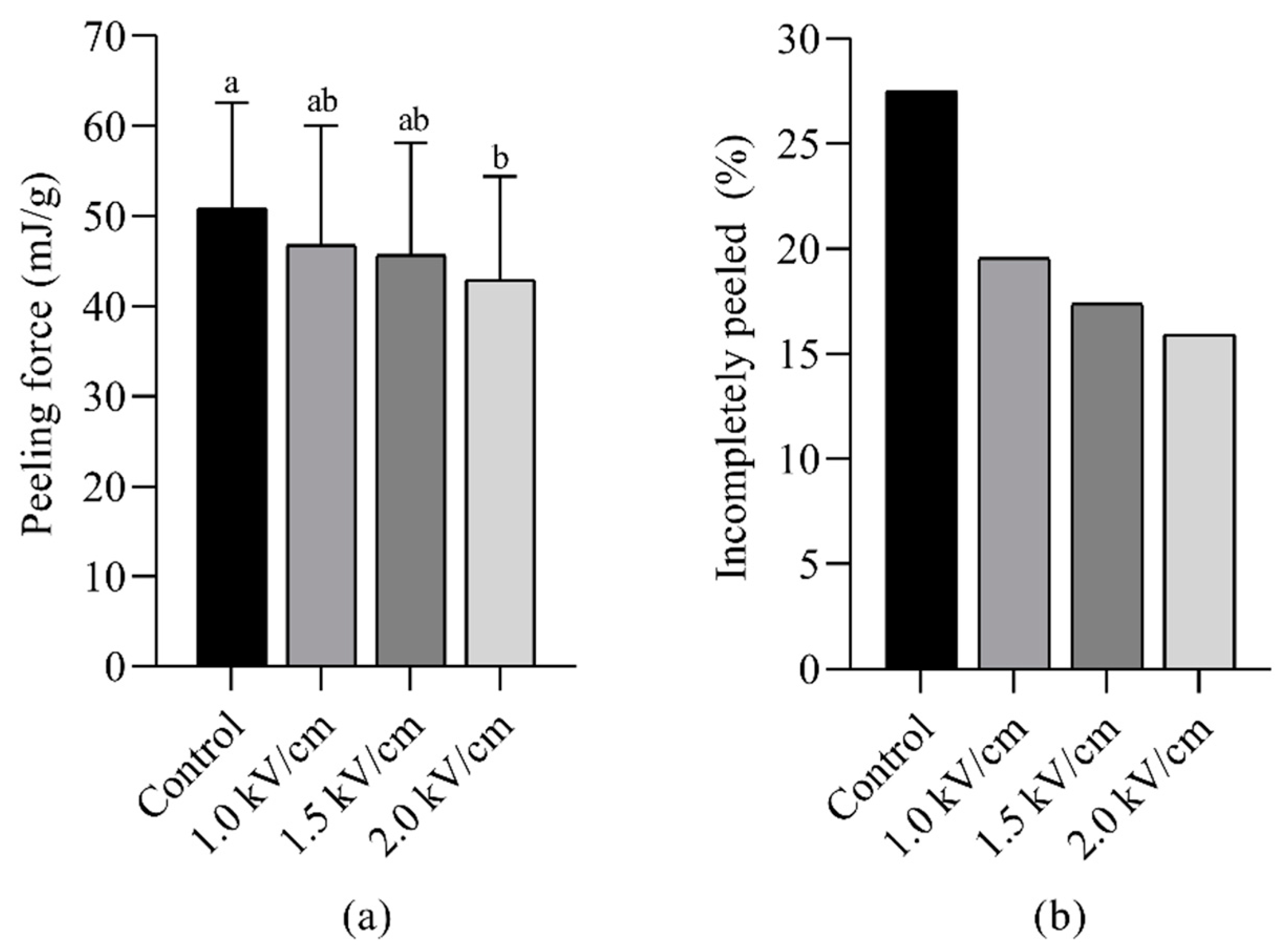

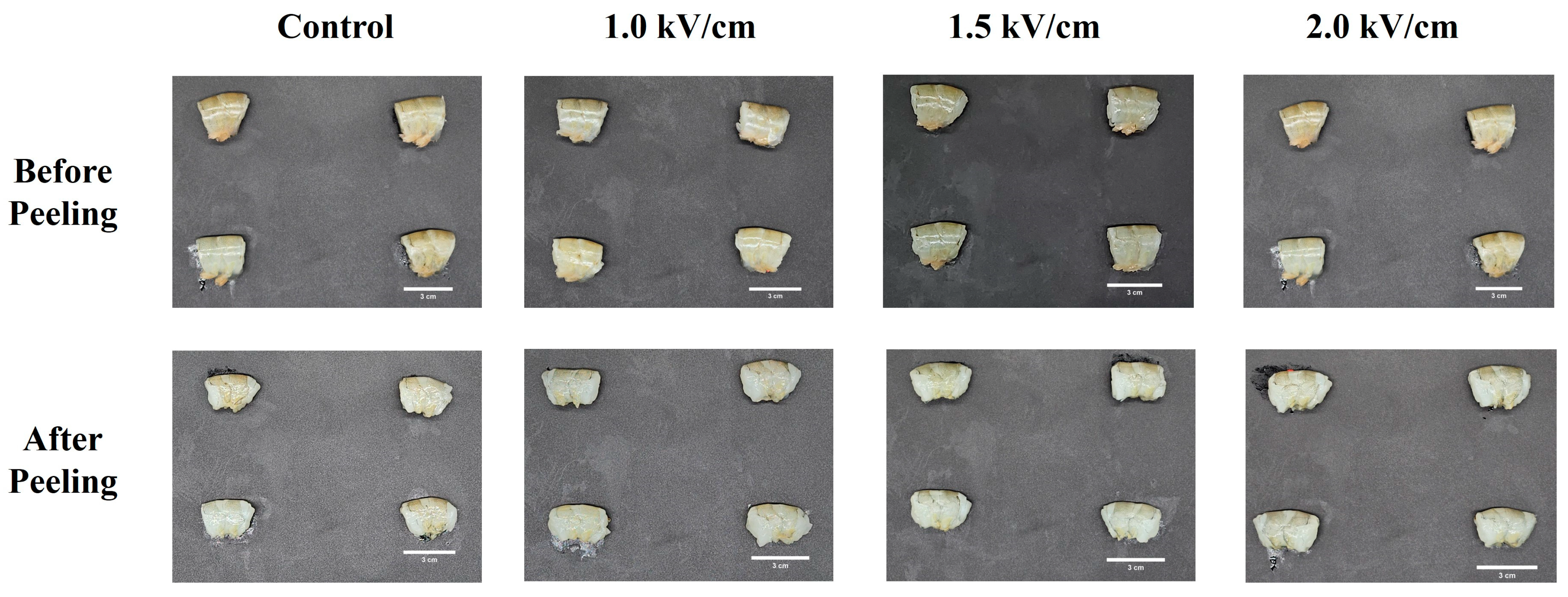

3.1. Effect of PEF on Shrimp Peelability

3.2. Textural Properties of PEF-Treated Shrimp

3.3. Mechanism and Industrial Implications

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hannan, M.A.; Habib, K.A.; Shahabuddin, A.; Haque, M.A.; Munir, M.B. Post-Harvest Processing, Packaging and Inspection of Frozen Shrimp: A Practical Guide; Springer Nature: Berlin, Germany, 2022. [Google Scholar]

- Jory, D. Annual Farmed Shrimp Production Survey: A Slight Decrease in Production Reduction in 2023 with Hopes for Renewed Growth in 2024; Global Seafood Alliance: Portsmouth, NH, USA, 2023. [Google Scholar]

- Yang, X.; Hao, S.; Pan, C.; Li, L.; Huang, H.; Yang, X.; Wang, Y. A quantitative method to analysis shrimp peelability and its application in the shrimp peeling process. J. Food Process. Preserv. 2020, 44, e14882. [Google Scholar] [CrossRef]

- Dang, T.T.; Feyissa, A.H.; Gringer, N.; Jessen, F.; Olsen, K.; Bøknæs, N.; Orlien, V. Effects of high pressure and ohmic heating on shell loosening, thermal and structural properties of shrimp (Pandalus borealis). Innov. Food Sci. Emerg. Technol. 2020, 59, 102246. [Google Scholar] [CrossRef]

- Shuxian, H.; Xiaojie, Y.; Hui, H.; Laihao, L.; Chuang, P.; Xianqing, Y.; Jianwei, C. Status of shrimp peeling and pretreatment technology for facilitating peeling. South China Fish. Sci. 2020, 16, 121–128. [Google Scholar]

- Shen, L.; Qiu, W.; Du, L.; Zhou, M.; Qiao, Y.; Wang, C.; Wang, L. Effects of high hydrostatic pressure on peelability and quality of crayfish (Procambarus clarkii). J. Sci. Food Agric. 2024, 104, 611–619. [Google Scholar] [CrossRef]

- Dang, T.T.; Gringer, N.; Jessen, F.; Olsen, K.; Bøknæs, N.; Nielsen, P.L.; Orlien, V. Facilitating shrimp (Pandalus borealis) peeling by power ultrasound and proteolytic enzyme. Innov. Food Sci. Emerg. Technol. 2018, 47, 525–534. [Google Scholar] [CrossRef]

- Shahbaz, H.M.; Javed, F.; Park, J. Advances in Food Applications for High Pressure Processing Technology; Springer: Berlin/Heidelberg, Germany, 2023. [Google Scholar]

- Basiri, S.; Shekarforoush, S.S.; Aminlari, M.; Akbari, S. The effect of pomegranate peel extract (PPE) on the polyphenol oxidase (PPO) and quality of Pacific white shrimp (Litopenaeus vannamei) during refrigerated storage. LWT-Food Sci. Technol. 2015, 60, 1025–1033. [Google Scholar] [CrossRef]

- Giancaterino, M.; Jaeger, H. Impact of pulsed electric fields (PEF) treatment on the peeling ability of tomatoes and kiwi fruits. Front. Food Sci. Technol. 2023, 3, 1152111. [Google Scholar] [CrossRef]

- Koch, Y.; Witt, J.; Lammerskitten, A.; Siemer, C.; Toepfl, S. The influence of Pulsed Electric Fields (PEF) on the peeling ability of different fruits and vegetables. J. Food Eng. 2022, 322, 110938. [Google Scholar] [CrossRef]

- Niu, D.; Zeng, X.-A.; Ren, E.-F.; Xu, F.-Y.; Li, J.; Wang, M.-S.; Wang, R. Review of the application of pulsed electric fields (PEF) technology for food processing in China. Food Res. Int. 2020, 137, 109715. [Google Scholar] [CrossRef] [PubMed]

- Caminiti, I.M.; Palgan, I.; Noci, F.; Muñoz, A.; Whyte, P.; Cronin, D.A.; Morgan, D.J.; Lyng, J.G. The effect of pulsed electric fields (PEF) in combination with high intensity light pulses (HILP) on Escherichia coli inactivation and quality attributes in apple juice. Innov. Food Sci. Emerg. Technol. 2011, 12, 118–123. [Google Scholar] [CrossRef]

- Alam, M.R.; Lyng, J.G.; Frontuto, D.; Marra, F.; Cinquanta, L. Effect of pulsed electric field pretreatment on drying kinetics, color, and texture of parsnip and carrot. J. Food Sci. 2018, 83, 2159–2166. [Google Scholar] [CrossRef] [PubMed]

- Lin, T.; Wang, J.J.; Li, J.B.; Liao, C.; Pan, Y.J.; Zhao, Y. Use of acidic electrolyzed water ice for preserving the quality of shrimp. J. Agric. Food Chem. 2013, 61, 8695–8702. [Google Scholar] [CrossRef] [PubMed]

- Boonsumrej, S.; Chaiwanichsiri, S.; Tantratian, S.; Suzuki, T.; Takai, R. Effects of freezing and thawing on the quality changes of tiger shrimp (Penaeus monodon) frozen by air-blast and cryogenic freezing. J. Food Eng. 2007, 80, 292–299. [Google Scholar] [CrossRef]

- Xu, N.; Shi, W.; Wang, X.; Wang, Z. Effect of ice water pretreatment on the quality of Pacific White Shrimps (Litopenaeus vannamei). Food Sci. Nutr. 2019, 7, 645–655. [Google Scholar] [CrossRef] [PubMed]

- Gómez, B.; Munekata, P.E.; Gavahian, M.; Barba, F.J.; Martí-Quijal, F.J.; Bolumar, T.; Campagnol, P.C.B.; Tomasevic, I.; Lorenzo, J.M. Application of pulsed electric fields in meat and fish processing industries: An overview. Food Res. Int. 2019, 123, 95–105. [Google Scholar] [CrossRef] [PubMed]

- Arroyo, C.; Eslami, S.; Brunton, N.P.; Arimi, J.M.; Noci, F.; Lyng, J.G. An assessment of the impact of pulsed electric fields processing factors on oxidation, color, texture, and sensory attributes of turkey breast meat. Poult. Sci. 2015, 94, 1088–1095. [Google Scholar] [CrossRef] [PubMed]

- Luo, Q.; Hamid, N.; Oey, I.; Leong, S.Y.; Kantono, K.; Alfaro, A.; Lu, J. Physicochemical changes in New Zealand abalone (Haliotis iris) with pulsed electric field (PEF) processing and heat treatments. LWT 2019, 115, 108438. [Google Scholar] [CrossRef]

- Heu, M.-S.; Kim, J.-S.; Shahidi, F. Components and nutritional quality of shrimp processing by-products. Food Chem. 2003, 82, 235–242. [Google Scholar] [CrossRef]

- Rødde, R.H.; Einbu, A.; Vårum, K.M. A seasonal study of the chemical composition and chitin quality of shrimp shells obtained from northern shrimp (Pandalus borealis). Carbohydr. Polym. 2008, 71, 388–393. [Google Scholar] [CrossRef]

| Field Strength (kV/cm) | Texture Properties | |||||||

|---|---|---|---|---|---|---|---|---|

| Hardness (N) | Adhesiveness | Springiness | Cohesiveness | Gumminess | Chewiness (N) | Resilience | Cutting Force (N) | |

| Control | 46.49 ± 8.19 a | −33.88 ± 12.12 a | 0.62 ± 0.11 a | 0.57 ± 0.12 a | 26.81 ± 7.23 a | 17.39 ± 8.85 a | 0.37 ± 0.07 a | 19.54 ± 2.84 a |

| PEF_1.0 | 47.37 ± 5.63 a | −28.22 ± 6.42 a | 0.56 ± 0.04 ab | 0.50 ± 0.03 a | 23.81 ± 3.95 a | 13.44 ± 2.88 a | 0.35 ± 0.32 a | 17.70 ± 1.75 a |

| PEF_1.5 | 48.95 ± 7.32 a | −33.74 ± 17.25 a | 0.56 ± 0.13 ab | 0.54 ± 0.13 a | 27.35 ± 11.17 a | 16.88 ± 13.58 a | 0.35 ± 0.06 a | 18.84 ± 2.13 a |

| PEF_2.0 | 45.23 ± 7.98 a | −26.31 ± 5.64 a | 0.51 ± 0.05 b | 0.51 ± 0.03 a | 23.28 ± 5.25 a | 12.08 ± 3.41 a | 0.36 ± 0.03 a | 20.00 ± 3.30 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, G.-S.; Seo, H.; Lee, H.-B.; Lee, J.-W.; Shahbaz, H.M.; Jeong, S.-H.; Lee, D.-U. Enhanced Peelability and Quality of Whiteleg Shrimp (Litopenaeus vannamei) Using Pulsed Electric Field (PEF) Treatment. Foods 2025, 14, 148. https://doi.org/10.3390/foods14020148

Park G-S, Seo H, Lee H-B, Lee J-W, Shahbaz HM, Jeong S-H, Lee D-U. Enhanced Peelability and Quality of Whiteleg Shrimp (Litopenaeus vannamei) Using Pulsed Electric Field (PEF) Treatment. Foods. 2025; 14(2):148. https://doi.org/10.3390/foods14020148

Chicago/Turabian StylePark, Gyeong-Seo, Hyeon Seo, Han-Baek Lee, Ji-Won Lee, Hafiz Muhammad Shahbaz, Se-Ho Jeong, and Dong-Un Lee. 2025. "Enhanced Peelability and Quality of Whiteleg Shrimp (Litopenaeus vannamei) Using Pulsed Electric Field (PEF) Treatment" Foods 14, no. 2: 148. https://doi.org/10.3390/foods14020148

APA StylePark, G.-S., Seo, H., Lee, H.-B., Lee, J.-W., Shahbaz, H. M., Jeong, S.-H., & Lee, D.-U. (2025). Enhanced Peelability and Quality of Whiteleg Shrimp (Litopenaeus vannamei) Using Pulsed Electric Field (PEF) Treatment. Foods, 14(2), 148. https://doi.org/10.3390/foods14020148