Multi-Technique Flavoromics for Identifying Key Differential Volatile Compounds Underlying Sensory Profiles in Lager Beers

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Collection

2.2. Materials

2.3. LLE-SAFE and HS-SPME

2.4. Analytical Instrumentation and Conditions

2.4.1. GC-MS Conditions

2.4.2. GC-O-MS Conditions

2.4.3. GC×GC-TOF MS Conditions

2.5. Qualitative and Quantitative Analysis

2.6. Odor Activity Value (OAV) and Taste Activity Value (TAV) Calculation

2.7. Flavor Perception Evaluation of Lager Beers

2.8. Adding Validation Experiment

2.9. Statistical Analysis and Statistical Methods

3. Results and Discussion

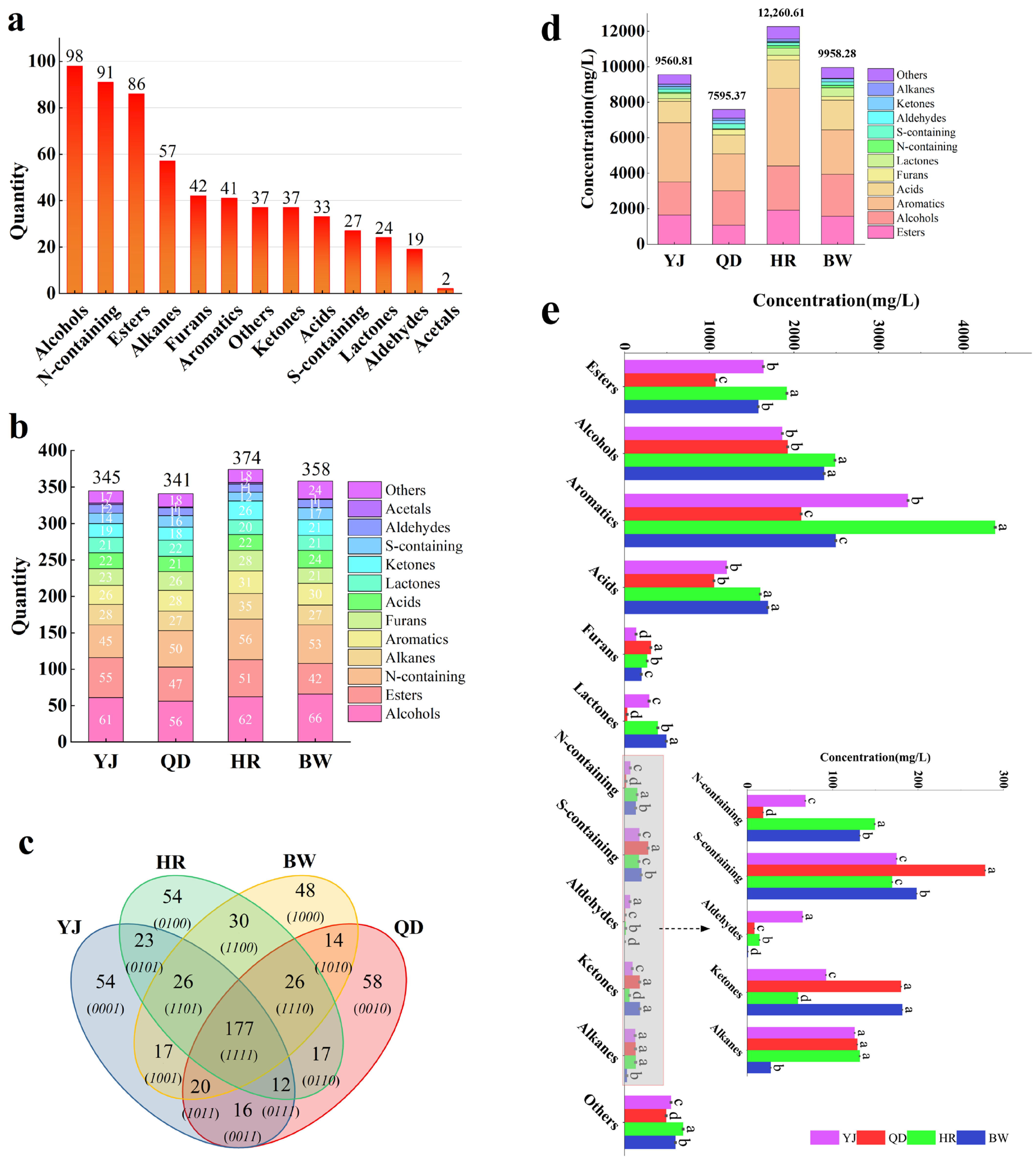

3.1. Analysis of Distribution Characteristics of Volatile Compounds

3.2. Flavor Expression Evaluation

3.3. Flavor Perception Evaluation

3.4. Screening of Potential Differential Compounds by PLS-DA

3.5. Validation Experiment Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| LLE | Liquid–liquid extraction |

| HS-SPME | Headspace solid-phase microextraction |

| SAFE | Solvent-assisted flavor evaporation |

| GC-MS | Gas chromatography–mass spectrometry |

| GC×GC-TOF MS | Comprehensive two-dimensional gas chromatography–time-of-flight mass spectrometry |

| GC-O-MS | Gas chromatography–olfactometry–mass spectrometry |

| OAV | Odor activity value |

| TAV | Taste activity value |

| PLS-DA | Partial least squares discriminant analysis |

| VIP | Variable importance in projection |

| YJ | U8, Beijing Yanjing Brewery Co., Ltd. |

| QD | Classic, Tsingtao Brewery Group Co., Ltd. |

| HR | Brave the World, China Resources Beer (Holdings) Co., Ltd. |

| BW | Ice Beer, Budweiser Asia Pacific Holdings Ltd. |

Appendix A

| Code | Product Name | Manufacturer | Original Wort Concentration | Ingredients |

|---|---|---|---|---|

| YJ | U8 | Beijing Yanjing Brewery Co., Ltd. | 8 °P | Water, malt, rice, hops |

| QD | Classic | Tsingtao Brewery Group Co., Ltd. | 8 °P | Water, malt, rice, hops |

| HR | Brave the World | China Resources Beer (Holdings) Co., Ltd. | 8 °P | Water, malt, brewing syrup, hops |

| BW | Ice Beer | Budweiser Asia Pacific Holdings Ltd. | 8 °P | Water, malt, rice, hop extract, yeast |

| – | Qing Shuang Beer | Beijing Yanjing Brewery Co., Ltd. | 10 °P | Water, malt, rice, hops |

| No. | Compound Name | CAS | Quantifier Ion | Calibration Curve | ||||

|---|---|---|---|---|---|---|---|---|

| n | Slope | Intercept | R2 | Range (mg/L) | ||||

| 1 | Isoamyl acetate | 123-92-2 | 43 | 9 | 0.00005 | −15.2830 | 0.9972 | 2.34–1200.00 |

| 2 | Ethyl hexanoate | 123-66-0 | 88 | 8 | 0.000003 | −0.9841 | 0.9993 | 6.25–800.00 |

| 3 | Ethyl propanoate | 105-37-3 | 29 | 7 | 0.0000005 | 1.2961 | 0.9998 | 0.31–160.00 |

| 4 | Hexyl butanoate | 2639-63-6 | 43 | 9 | 0.000003 | 3.6897 | 0.9974 | 1.25–320.00 |

| 5 | Methyl decanoate | 110-42-9 | 74 | 10 | 0.000003 | 0.8804 | 0.9990 | 0.78–400.00 |

| 6 | Ethyl octanoate | 106-32-1 | 88 | 7 | 0.0000002 | −0.4058 | 0.9976 | 0.43–27.50 |

| 7 | Ethyl decanoate | 110-38-3 | 88 | 8 | 0.0000004 | −0.1858 | 0.9997 | 0.16–40.00 |

| 8 | Isoamyl butyrate | 106-27-4 | 71 | 7 | 0.000004 | −3.6818 | 0.9855 | 3.13–200.00 |

| 9 | Ethyl trans-2-decenoate | 7367-88-6 | 55 | 11 | 0.0000005 | 0.4049 | 0.9996 | 0.16–160.00 |

| 10 | Octyl acetate | 112-14-1 | 43 | 9 | 0.0000007 | −0.3902 | 0.9998 | 0.39–100.00 |

| 11 | Ethyl stearate | 111-61-5 | 88 | 9 | 0.0000004 | −1.2460 | 0.9994 | 0.39–100.00 |

| 12 | Ethyl isovalerate | 108-64-5 | 88 | 6 | 0.000001 | −0.6628 | 0.9988 | 0.39–50.00 |

| 13 | Ethyl myristate | 124-06-1 | 88 | 7 | 0.0000004 | −0.1408 | 0.9999 | 0.39–25.00 |

| 14 | Ethyl lactate | 97-64-3 | 45 | 7 | 0.000002 | −0.6235 | 0.9977 | 0.78–50.00 |

| 15 | Ethyl acetate | 141-78-6 | 43 | 7 | 0.000003 | −1.2344 | 0.9993 | 12.5–800.00 |

| 16 | Ethyl heptanoate | 106-30-9 | 88 | 8 | 0.0000008 | −0.1803 | 0.9992 | 0.16–20.00 |

| 17 | Hexyl acetate | 142-92-7 | 43 | 8 | 0.000003 | 1.0401 | 0.9955 | 1.25–160.00 |

| 18 | Diethyl succinate | 123-25-1 | 101 | 10 | 0.0000009 | 0.1174 | 0.9995 | 0.31–160.00 |

| 19 | Butyl acetate | 123-86-4 | 43 | 9 | 0.000002 | 0.6073 | 0.9928 | 0.08–20.00 |

| 20 | Ethyl 3-hydrobutyrate | 5405-41-4 | 43 | 7 | 0.000002 | 0.0074 | 0.9997 | 0.02–1.25 |

| 21 | Ethyl nonanoate | 123-29-5 | 88 | 8 | 0.0000007 | 0.2045 | 0.9993 | 0.31–40.00 |

| 22 | Ethyl hydrogen succinate | 1070-34-4 | 101 | 6 | 0.000008 | −1.0704 | 0.9992 | 10.00–320.00 |

| 23 | Ethyl valerate | 539-82-2 | 29 | 8 | 0.000002 | 0.3861 | 0.9909 | 0.31–40.00 |

| 24 | Methyl 2-octynate | 111-12-6 | 95 | 9 | 0.000003 | −0.5746 | 0.9981 | 0.78–200.00 |

| 25 | (−)-Ethyl L-lactate | 687-47-8 | 45 | 8 | 0.000003 | −1.9181 | 0.9973 | 0.78–100.00 |

| 26 | 2-Hydroxyethyl acetate | 542-59-6 | 43 | 8 | 0.000002 | 0.1359 | 0.9926 | 0.16–20.00 |

| 27 | Propyl acetate | 109-60-4 | 43 | 8 | 0.000003 | −1.9656 | 0.9971 | 0.16–20.00 |

| 28 | 2,3-Dihydroxypropyl acetate | 106-61-6 | 43 | 9 | 0.000003 | −1.7321 | 0.9967 | 0.16–40.00 |

| 29 | Methyl propionate | 554-12-1 | 29 | 9 | 0.000002 | 0.2601 | 0.9901 | 0.16–40.00 |

| 30 | Isopropyl formate | 625-55-8 | 45 | 8 | 0.000002 | 0.3989 | 0.9995 | 1.25–160.00 |

| 31 | Ethyl dodecanoate | 106-33-2 | 88 | 8 | 0.000002 | 0.6648 | 0.9987 | 0.16–20.00 |

| 32 | Ethyl 3-hexenoate | 2396-83-0 | 29 | 8 | 0.000002 | 1.7706 | 0.9918 | 0.31–40.00 |

| 33 | Ethyl butyrylacetate | 3249-68-1 | 71 | 8 | 0.000003 | 0.7792 | 0.9963 | 0.16–40.00 |

| 34 | Ethyl 3-methylvalerate | 5870-68-8 | 88 | 8 | 0.000001 | −0.4345 | 0.9988 | 0.16–20.00 |

| 35 | Ethyl undecanoate | 627-90-7 | 88 | 8 | 0.000001 | −1.6635 | 0.9984 | 0.16–20.00 |

| 36 | (+)-Diethyl L-tartrate | 87-91-2 | 104 | 8 | 0.000002 | 1.1348 | 0.9984 | 0.16–20.00 |

| 37 | 2,3-Butaneiol | 513-85-9 | 45 | 9 | 0.00003 | 16.4440 | 0.9951 | 4.69–1200.00 |

| 38 | 3-Methyl-1-butanol | 123-51-3 | 55 | 7 | 0.000006 | −32.0320 | 0.9990 | 25.00–1600.00 |

| 39 | 1,2,3-Propanetriol | 56-81-5 | 61 | 7 | 0.000004 | 124.5400 | 0.9992 | 125.00–8000.00 |

| 40 | 2-Methyl-1-propanol | 78-83-1 | 43 | 9 | 0.00001 | −6.9598 | 0.9996 | 4.69–1200.00 |

| 41 | Diisobutylcarbinol | 108-82-7 | 69 | 8 | 0.0000007 | 0.2155 | 0.9941 | 0.39–50.00 |

| 42 | 1-Butanol | 71-36-3 | 56 | 8 | 0.000005 | −0.6615 | 0.9998 | 1.56–200.00 |

| 43 | 1-Octanol | 111-87-5 | 56 | 7 | 0.0000008 | −0.1317 | 0.9995 | 0.31–20.00 |

| 44 | 1-Pentanol | 71-41-0 | 42 | 10 | 0.000001 | −0.4668 | 0.9991 | 0.31–320.00 |

| 45 | 3-Methyl-3-buten-1-ol | 763-32-6 | 41 | 9 | 0.000006 | 0.0446 | 0.9966 | 0.04–10.00 |

| 46 | α-Terpineol | 98-55-5 | 59 | 6 | 0.0000007 | 0.0775 | 0.9993 | 0.16–5.00 |

| 47 | 2-Ethyl-1-hexanol | 104-76-7 | 57 | 8 | 0.0000009 | −0.6655 | 0.998 | 0.31–40.00 |

| 48 | 4-Methyl-1-pentanol | 626-89-1 | 56 | 8 | 0.000003 | 0.7926 | 0.996 | 0.31–80.00 |

| 49 | 1,2-Propylene glycol | 57-55-6 | 45 | 6 | 0.000005 | 1.6696 | 0.9993 | 1.25–40.00 |

| 50 | 2-Hexyl-1-decanol | 2425-77-6 | 57 | 8 | 0.0000009 | −0.6035 | 0.961 | 0.31–40.00 |

| 51 | 1-Hexanol | 111-27-3 | 56 | 7 | 0.000004 | −0.3672 | 0.9996 | 1.56–100.00 |

| 52 | Linalool | 78-70-6 | 71 | 8 | 0.000005 | −0.5625 | 0.9998 | 0.78–100.00 |

| 53 | 1-Decanol | 112-30-1 | 70 | 8 | 0.000005 | −0.5974 | 0.9992 | 0.78–100.00 |

| 54 | Diethylene glycol monoethyl ether | 111-90-0 | 45 | 8 | 0.000005 | −1.2538 | 0.9999 | 1.56–200.00 |

| 55 | (−)-Isolongifolol | 1139-17-9 | 109 | 7 | 0.000004 | −0.0935 | 0.9997 | 1.56–100.00 |

| 56 | Phytol | 150-86-7 | 71 | 7 | 0.000004 | 0.1171 | 0.9996 | 0.39–25.00 |

| 57 | β-Eudesmol | 473-15-4 | 59 | 8 | 0.000001 | 0.0652 | 0.9982 | 3.13–200.00 |

| 58 | Guaiol | 489-86-1 | 161 | 9 | 0.000002 | −0.3251 | 0.9997 | 0.78–200.00 |

| 59 | 2,6-Dimethyl-5,7-octadien-2-ol | 5986-38-9 | 93 | 7 | 0.000001 | 0.0317 | 0.9964 | 1.56–100.00 |

| 60 | Phenethyl alcohol | 60-12-8 | 91 | 9 | 0.000007 | −97.3390 | 0.9851 | 7.81–4000.00 |

| 61 | 2-Phenylethyl acetate | 103-45-7 | 104 | 10 | 0.000003 | −8.9800 | 0.9958 | 0.78–800.00 |

| 62 | Phenol | 108-95-2 | 94 | 10 | 0.000001 | −4.5197 | 0.9993 | 1.17–600.00 |

| 63 | Benzeneacetaldehyde | 122-78-1 | 91 | 7 | 0.00001 | 0.5234 | 0.9916 | 1.25–80.00 |

| 64 | Benzyl alcohol | 100-51-6 | 79 | 7 | 0.0000009 | 0.0445 | 0.9999 | 0.16–10.00 |

| 65 | Ethyl benzoate | 93-89-0 | 105 | 7 | 0.000002 | −0.0393 | 0.9997 | 0.63–40.00 |

| 66 | Benzaldehyde | 100-52-7 | 77 | 6 | 0.000003 | 0.0024 | 0.9904 | 1.25–40.00 |

| 67 | 2,4-Di-tert-butylphenol | 96-76-4 | 191 | 8 | 0.000001 | 2.3582 | 0.9989 | 1.56–200.00 |

| 68 | 2-Methoxy-4-vinylphenol | 7786-61-0 | 135 | 7 | 0.000002 | 5.609 | 0.9955 | 3.13–200.00 |

| 69 | 2,6-Di-tert-butyl-4-methylphenol | 128-37-0 | 205 | 9 | 0.0000004 | 0.4619 | 0.9998 | 2.50–640.00 |

| 70 | Benzoic acid | 65-85-0 | 105 | 6 | 0.000003 | 6.6738 | 0.9964 | 12.5–400.00 |

| 71 | p-Hydroxyphenylethanol | 501-94-0 | 107 | 9 | 0.000001 | 2.0534 | 0.9989 | 0.78–200.00 |

| 72 | Benzeneacetic acid | 103-82-2 | 91 | 6 | 0.000003 | 4.3926 | 0.9943 | 6.25–200.00 |

| 73 | Resorcinol | 108-46-3 | 110 | 6 | 0.000002 | 1.6271 | 0.9992 | 1.56–50.00 |

| 74 | 2,5-Dimethylphenol | 95-87-4 | 122 | 7 | 0.000001 | 1.6717 | 0.9967 | 0.78–50.00 |

| 75 | α-Methylstyrene | 98-83-9 | 118 | 6 | 0.000003 | 0.3579 | 0.9924 | 1.25–40.00 |

| 76 | 1-(2-Hydroxy-5-methylphenyl)ethanone | 1450-72-2 | 135 | 8 | 0.000002 | 0.1579 | 0.9973 | 0.08–10.00 |

| 77 | (R)-(+)-1-Phenylethanol | 1517-69-7 | 107 | 8 | 0.000005 | 0.2135 | 0.9957 | 0.08–10.00 |

| 78 | Toluene | 108-88-3 | 91 | 6 | 0.000004 | −1.9747 | 0.9986 | 7.81–250.00 |

| 79 | Octanoic acid | 124-07-2 | 60 | 8 | 0.000005 | 45.9690 | 0.9888 | 6.25–1600.00 |

| 80 | Hexanoic acid | 142-62-1 | 60 | 8 | 0.000008 | −2.3383 | 0.9990 | 4.69–600.00 |

| 81 | Acetic acid | 64-19-7 | 43 | 6 | 0.00001 | 1.6743 | 0.9987 | 12.5–800.00 |

| 82 | 3-Methylbutanoic acid | 503-74-2 | 60 | 8 | 0.000007 | −0.1555 | 0.9967 | 3.13–400.00 |

| 83 | Decanoic acid | 334-48-5 | 60 | 6 | 0.000003 | 11.6970 | 0.9989 | 12.5–400.00 |

| 84 | Dodecanoic acid | 143-07-7 | 60 | 9 | 0.000004 | 3.1751 | 0.9996 | 3.13–800.00 |

| 85 | Elaidic acid | 112-79-8 | 55 | 8 | 0.000003 | 20.8040 | 0.9958 | 3.13–800.00 |

| 86 | DL-3-Methylvaleric acid | 105-43-1 | 60 | 8 | 0.000001 | 1.7304 | 0.9997 | 1.56–200.00 |

| 87 | Heptanoic acid | 111-14-8 | 60 | 9 | 0.000002 | 3.7580 | 0.9988 | 1.56–400.00 |

| 88 | Tridecanoic acid | 638-53-9 | 73 | 6 | 0.000001 | 1.8894 | 0.9915 | 0.78–50.00 |

| 89 | 2-Methylvaleric acid | 594-61-6 | 59 | 6 | 0.000001 | 1.1722 | 0.9987 | 1.56–50.00 |

| 90 | Pentanoic acid | 109-52-4 | 60 | 7 | 0.000004 | 5.7311 | 0.9998 | 10.00–640.00 |

| 91 | Nonanoic acid | 112-05-0 | 60 | 8 | 0.0000002 | 0.4131 | 0.9962 | 0.31–40.00 |

| 92 | Palmitic acid | 57-10-3 | 43 | 6 | 0.000001 | 10.45 | 0.9993 | 12.5–400.00 |

| 93 | trans-3-Hexenoic acid | 4219-24-3 | 41 | 6 | 0.00001 | 6.6252 | 0.9978 | 0.78–25.00 |

| 94 | 4-Methyl-2-pentenoic acid | 10321-71-8 | 41 | 8 | 0.000001 | 1.5656 | 0.9991 | 0.39–50.00 |

| 95 | Hendecanoic acid | 112-37-8 | 60 | 7 | 0.000002 | 1.1722 | 0.9987 | 0.39–25.00 |

| 96 | Crotonic acid | 3724-65-0 | 86 | 7 | 0.000002 | −1.0557 | 0.9953 | 0.39–25.00 |

| 97 | 2-Methyl-2-pentenoic acid | 3142-72-1 | 41 | 7 | 0.000006 | −2.8264 | 0.9958 | 4.69–300.00 |

| 98 | Furfuryl alcohol | 98-00-0 | 98 | 6 | 0.000007 | 1.2221 | 0.9956 | 1.56–100.00 |

| 99 | 2-Furancarboxylic acid | 88-14-2 | 112 | 6 | 0.000004 | 1.7403 | 0.9987 | 5.00–160.00 |

| 100 | 2-Butylfuran | 4466-24-4 | 81 | 6 | 0.000004 | 1.6517 | 0.9948 | 1.25–80.00 |

| 101 | Furfural | 98-01-1 | 96 | 6 | 0.000002 | 2.345 | 0.9974 | 3.13–100.00 |

| 102 | 2-Acetyl furan | 1192-62-7 | 95 | 11 | 0.000005 | 0.6997 | 0.9985 | 0.08–80.00 |

| 103 | Methyl 2-furoate | 611-13-2 | 95 | 7 | 0.000003 | 0.9577 | 0.9986 | 1.25–80.00 |

| 104 | 5-Hydroxymethyl-2-furaldehyde | 67-47-0 | 97 | 9 | 0.000005 | −7.9761 | 0.9971 | 4.68–1200.00 |

| 105 | 2,5-Dimethyl-4-hydroxy-2H-furan-3-one | 3658-77-3 | 43 | 7 | 0.000006 | 3.1029 | 0.9981 | 1.56–100.00 |

| 106 | 2(5H)-Furanone | 497-23-4 | 55 | 8 | 0.000008 | −0.334 | 0.9933 | 1.56–200.00 |

| 107 | Furfuryl sulfide | 13678-67-6 | 81 | 7 | 0.000002 | −1.394 | 0.9958 | 3.13–200.00 |

| 108 | 2,2′-Difurfuryl ether | 4437-22-3 | 81 | 8 | 0.000003 | −1.8112 | 0.9959 | 1.56–200.00 |

| 109 | (±)-3-Hydroxy-4-butanolide | 5469-16-9 | 44 | 7 | 0.00001 | 19.2420 | 0.9969 | 1.17–1200.00 |

| 110 | γ-Decanolactone | 706-14-9 | 85 | 7 | 0.0000006 | −0.1815 | 0.9998 | 0.39–25.00 |

| 111 | γ-Butyrolactone | 96-48-0 | 42 | 10 | 0.00001 | −7.8209 | 0.998 | 1.56–800.00 |

| 112 | 4-Nonanolide | 104-61-0 | 85 | 6 | 0.000003 | 0.167 | 0.9991 | 0.78–50.00 |

| 113 | γ-Hexanolactone | 695-06-7 | 85 | 8 | 0.000001 | 0.0428 | 0.9999 | 0.08–10.00 |

| 114 | γ-Octalactone | 104-50-7 | 85 | 6 | 0.000004 | −0.6705 | 0.9959 | 1.25–40.00 |

| 115 | δ-Valerolactone | 542-28-9 | 42 | 8 | 0.000001 | 0.1065 | 0.9992 | 0.08–10.00 |

| 116 | γ-Valerolactone | 108-29-2 | 56 | 10 | 0.000005 | 0.7945 | 0.9985 | 0.16–80.00 |

| 117 | Costunolide | 553-21-9 | 81 | 8 | 0.0000007 | −0.4606 | 0.9992 | 0.39–50.00 |

| 118 | 5-Hydroxy-4-pentanolide | 32780-06-6 | 85 | 6 | 0.000004 | −0.3032 | 0.9977 | 2.50–80.00 |

| 119 | 2-Hydroxypyridine | 142-08-5 | 95 | 7 | 0.000002 | 0.6471 | 0.9958 | 0.31–20.00 |

| 120 | (Z)-9-Octadecenamide | 301-02-0 | 59 | 6 | 0.0000007 | 0.0624 | 0.9963 | 2.50–80.00 |

| 121 | 2-Acetyl pyrrole | 1072-83-9 | 94 | 7 | 0.000002 | 0.5324 | 0.9922 | 0.31–20.00 |

| 122 | N-Butyl-acetamide | 1119-49-9 | 30 | 8 | 0.000004 | 0.6875 | 0.9995 | 0.16–20.00 |

| 123 | 2,6-Di-tert-butylpyridine | 585-48-8 | 176 | 9 | 0.000001 | 0.4103 | 0.994 | 0.16–40.00 |

| 124 | 5-Methyl-1H-pyrrole-2-carbaldehyde | 1192-79-6 | 108 | 8 | 0.0000003 | 0.1641 | 0.9996 | 0.08–10.00 |

| 125 | 6-(Ethoxycarbonyl)nicotinic acid | 17874-78-1 | 123 | 7 | 0.000001 | −1.0354 | 0.9992 | 1.25–160.00 |

| 126 | Benzylamine | 100-46-9 | 106 | 7 | 0.000002 | 0.195 | 0.9981 | 0.63–40.00 |

| 127 | Diethylamine | 109-89-7 | 58 | 8 | 0.000003 | 0.2945 | 0.9963 | 0.08–10.00 |

| 128 | 3-Methylthiopropanol | 505-10-2 | 106 | 10 | 0.000006 | −1.3947 | 0.9995 | 1.56–800.00 |

| 129 | Thiophene | 110-02-1 | 84 | 9 | 0.0000005 | −1.7580 | 0.9902 | 0.31–160.00 |

| 130 | Methyl mercaptan | 74-93-1 | 47 | 9 | 0.000006 | −0.711 | 0.9982 | 1.56–100.00 |

| 131 | Dimethyl Sulfoxide | 67-68-5 | 63 | 8 | 0.00002 | 7.776 | 0.9962 | 3.13–400.00 |

| 132 | Dimethyl sulfone | 67-71-0 | 79 | 8 | 0.000007 | 0.5096 | 0.9975 | 0.31–40.00 |

| 133 | Thioacetic acid | 507-09-5 | 43 | 7 | 0.00002 | 9.9358 | 0.9964 | 3.13–200.00 |

| 134 | Tetrahydrothiophene | 110-01-0 | 60 | 7 | 0.00001 | 6.1179 | 0.995 | 1.56–100.00 |

| 135 | 2-Acetyl-2-thiazoline | 29926-41-8 | 43 | 7 | 0.00002 | −0.398 | 0.9984 | 6.25–400.00 |

| 136 | 4-Methyl-5-acetyl thiazole | 38205-55-9 | 126 | 7 | 0.00003 | 0.7128 | 0.9961 | 1.56–100.00 |

| 137 | (E)-2-Nonenal | 18829-56-6 | 43 | 7 | 0.000001 | 0.4996 | 0.9996 | 1.56–100.00 |

| 138 | Isovaleraldehyde | 590-86-3 | 44 | 9 | 0.000001 | −1.3097 | 0.9990 | 1.56–400.00 |

| 139 | Acetaldehyde | 75-07-0 | 29 | 8 | 0.000002 | 0.1996 | 0.9996 | 1.56–50.00 |

| 140 | Hexadecanal | 629-80-1 | 82 | 7 | 0.000001 | 0.2471 | 0.9991 | 0.78–50.00 |

| 141 | 4-Hydroxy-2-butanone | 590–90-9 | 43 | 6 | 0.000002 | 3.5000 | 0.9997 | 5.00–160.00 |

| 142 | (Z)-β-Ionone | 79-77–6 | 177 | 8 | 0.000002 | 2.9139 | 0.9992 | 1.56–200.00 |

| 143 | 3-Hydroxy-2-butanone | 513-86–0 | 45 | 8 | 0.000002 | 1.3398 | 0.9987 | 0.63–160.00 |

| 144 | Cholestane | 481-21-0 | 217 | 8 | 0.000003 | 1.1282 | 0.9989 | 3.13–400.00 |

| 145 | 1-Heptene | 592-76-7 | 56 | 7 | 0.00003 | −10.3550 | 0.9955 | 0.39–50.00 |

| 146 | 1-Undecene | 821-95-4 | 43 | 9 | 0.0000008 | −0.5146 | 0.9998 | 0.16–80.00 |

| 147 | 2-Methyl-2-butene | 513-35-9 | 55 | 7 | 0.000002 | 1.0146 | 0.9972 | 0.78–50.00 |

| 148 | Myrcene | 123-35-3 | 41 | 7 | 0.000002 | 1.0361 | 0.9986 | 0.78–50.00 |

| 149 | Diisopropyl ether | 108-20-3 | 45 | 7 | 0.000002 | 1.8727 | 0.9972 | 0.78–50.00 |

| 150 | 3-Methyl-1-butene | 563-45-1 | 55 | 7 | 0.000003 | 0.0584 | 0.9993 | 0.78–50.00 |

| No. | Compound Name | CAS | RI | Identification Method | Sample Preparation | Presence in Samples | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| DB-WAX | DB-FFAP | YJ | QD | HR | BW | |||||

| Alcohols (98) | ||||||||||

| 1 | 2-Propen-1-ol | 107-18-6 | 1016 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 2 | 1-Methoxy-2-propanol | 107-98-2 | 1028 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 3 | 1-Butanol | 71-36-3 | 1044 | MS, RI, S | LLE-SAFE | √ | √ | √ | √ | |

| 4 | 3-Penten-2-ol | 1569-50-2 | 1070 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 5 | (±)-2-Methyl-1-butanol | 137-32-6 | 1104 | 1145 | MS, RI, S | LLE-SAFE, SPME | √ | √ | √ | √ |

| 6 | (S)-(−)-2-Methyl-1-butanol | 1565-80-6 | 1106 | 1141 | MS, RI | LLE-SAFE, SPME | √ | √ | √ | √ |

| 7 | 3-Methyl-1-butanol | 123-51-3 | 1107 | 1131 | MS, RI, aroma, S | LLE-SAFE, SPME | √ | √ | √ | √ |

| 8 | 3-Butyn-2-ol | 2028-63-9 | 1111 | MS, RI | LLE-SAFE | √ | ||||

| 9 | 3-Methyl-3-buten-1-ol | 763-32-6 | 1147 | MS, RI, S | LLE-SAFE | √ | √ | √ | √ | |

| 10 | 1-Pentanol | 71-41-0 | 1149 | MS, RI, S | LLE-SAFE | √ | √ | √ | √ | |

| 11 | 2-Cyclopropylethanol | 2566-44-1 | 1200 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 12 | 4-Penten-1-ol | 821-09-0 | 1200 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 13 | 4-Methyl-1-pentanol | 626-89-1 | 1213 | 1205 | MS, RI, S | LLE-SAFE, SPME | √ | √ | ||

| 14 | 2-Methyl-2-buten-1-ol | 4675-87-0 | 1219 | MS, RI | LLE-SAFE | √ | ||||

| 15 | 3-Methyl-2-buten-1-ol | 556-82-1 | 1219 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 16 | 2-Pentyn-1-ol | 6261-22-9 | 1235 | MS, RI | LLE-SAFE | √ | ||||

| 17 | Cyclobut-1-enylmethanol | 89182-08-1 | 1235 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 18 | 1,4-Pentadien-3-ol | 922-65-6 | 1235 | MS, RI | LLE-SAFE | √ | ||||

| 19 | 2-Methoxyethanol | 109-86-4 | 1236 | MS, RI | LLE-SAFE | √ | √ | |||

| 20 | 1-Hexanol | 111-27-3 | 1252 | 1227 | MS, RI, S | LLE-SAFE, SPME | √ | √ | √ | √ |

| 21 | 4-Methyl-3-penten-1-ol | 763-89-3 | 1285 | MS, RI | LLE-SAFE | √ | ||||

| 22 | Propargyl alcohol | 107-19-7 | 1294 | MS, RI | LLE-SAFE | √ | ||||

| 23 | 1-Heptanol | 111-70-6 | 1352 | MS, RI, S | LLE-SAFE | √ | ||||

| 24 | (2S)-2-Oxiranylmethanol | 60456-23-7 | 1356 | MS, RI | LLE-SAFE | √ | √ | |||

| 25 | 2-Ethyl-1-hexanol | 104-76-7 | 1387 | 1311 | MS, RI, S | LLE-SAFE, SPME | √ | |||

| 26 | 2-Methylbutane-2,3-diol | 5396-58-7 | 1411 | MS, RI | LLE-SAFE | √ | √ | |||

| 27 | (R)-(−)-2-Hexanol | 26549-24-6 | 1418 | MS, RI | LLE-SAFE | √ | ||||

| 28 | (R)-2-Octanol | 5978-70-1 | 1418 | MS, RI | LLE-SAFE | √ | ||||

| 29 | (2R,3R)-(−)-2,3-Butanediol | 513-85-9 | 1434 | 1541 | MS, RI, aroma, S | LLE-SAFE, SPME | √ | √ | √ | √ |

| 30 | (S,S)-(+)-1,3-Butaneiol | 19132-06-0 | 1435 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 31 | Linalool | 78-70-6 | 1443 | 1332 | MS, RI | LLE-SAFE, SPME | √ | √ | √ | |

| 32 | 1-Octanol | 111-87-5 | 1456 | 1348 | MS, RI, S | LLE-SAFE, SPME | √ | √ | √ | √ |

| 33 | 2-(2-Methoxyethoxy)ethanol | 111-77-3 | 1480 | 1955 | MS, RI | LLE-SAFE, SPME | √ | |||

| 34 | (S)-(+)-1,2-Propanediol | 4254-15-3 | 1484 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 35 | 1,2-Propylene glycol | 57-55-6 | 1484 | 1592 | MS, RI, aroma, S | LLE-SAFE | √ | √ | √ | √ |

| 36 | 3-Ethoxy-1-propanol | 111-35-3 | 1507 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 37 | Ethylene glycol | 107-21-1 | 1516 | 1627 | MS, RI | LLE-SAFE | √ | √ | √ | √ |

| 38 | Cyclopropanemethanol | 2516-33-8 | 1545 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 39 | Cyclobutanol | 2919-23-5 | 1545 | MS, RI | LLE-SAFE | √ | √ | |||

| 40 | 1-Methoxy-2-butanol | 53778-73-7 | 1550 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 41 | 1,2-Butanediol | 584-03-2 | 1550 | MS, RI | LLE-SAFE | √ | ||||

| 42 | α-Terpineol | 98-55-5 | 1593 | 1386 | MS, RI, S | LLE-SAFE, SPME | √ | √ | √ | |

| 43 | 4,5-Octanediol | 22607-10-9 | 1598 | MS, RI | LLE-SAFE | √ | ||||

| 44 | 2-Nonanol | 628-99-9 | 1618 | MS, RI | LLE-SAFE | √ | ||||

| 45 | 1,3-Butaneiol | 107-88-0 | 1634 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 46 | 2-Methyl-3-hexanol | 617-29-8 | 1639 | MS, RI | LLE-SAFE | √ | ||||

| 47 | 1-Decanol | 112-30-1 | 1659 | 1420 | MS, RI | LLE-SAFE, SPME | √ | √ | √ | |

| 48 | 1-Nonanol | 143-08-8 | 1659 | MS, RI, S | LLE-SAFE | √ | √ | √ | ||

| 49 | 5-Methyl-1-hepten-4-ol | 99328-46-8 | 1676 | MS, RI | LLE-SAFE | √ | ||||

| 50 | 2-(2-Butoxyethoxy)ethanol | 112-34-5 | 1688 | MS, RI | LLE-SAFE | √ | ||||

| 51 | 2,2-Dimethyl-1,3-propanediol | 126-30-7 | 1697 | MS, RI | LLE-SAFE | √ | ||||

| 52 | 1,1-Oxydi-2-propanol | 110-98-5 | 1726 | 2389 | MS, RI | LLE-SAFE, SPME | √ | √ | √ | |

| 53 | 2-(2-Hydroxypropoxy)-1-propanol | 106-62-7 | 1777 | MS, RI | LLE-SAFE | √ | ||||

| 54 | Diethylene glycol | 111-46-6 | 1865 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 55 | 1-Nonene-4-ol | 35192-73-5 | 1886 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 56 | 1,2-Heptanediol | 3710-31-4 | 1886 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 57 | 1,6-Heptadien-4-ol | 2883-45-6 | 1978 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 58 | 1-Buten-3-ol | 598-32-3 | 1997 | MS, RI | LLE-SAFE | √ | √ | |||

| 59 | 2-Methyl-1-penten-3-ol | 2088/7/5 | 2012 | MS, RI | LLE-SAFE | √ | ||||

| 60 | 2-Hexen-4-ol | 4798-58-7 | 2012 | MS, RI | LLE-SAFE | √ | ||||

| 61 | 1,2,3-Propanetriol | 56-81-5 | 2197 | 2323 | MS, RI, S | LLE-SAFE | √ | √ | √ | √ |

| 62 | Triethylene glycol | 112-27-6 | 2216 | 1942 | MS, RI | LLE-SAFE, SPME | √ | √ | √ | √ |

| 63 | 2-Methyl-2-propanol | 75-65-0 | 2219 | MS, RI, S | LLE-SAFE | √ | ||||

| 64 | 2E,6E-Farnesol | 106-28-5 | 2249 | MS, RI, S | LLE-SAFE | √ | √ | |||

| 65 | Farnesol | 4602-84-0 | 2249 | MS, RI | LLE-SAFE | √ | ||||

| 66 | 2,2-Dimethyl-5-hexen-3-ol | 19550-89-1 | 2261 | MS, RI | LLE-SAFE | √ | ||||

| 67 | 3-Decyn-2-ol | 69668-93-5 | 2469 | MS, RI | LLE-SAFE | √ | ||||

| 68 | 2,3-Epoxy-1-propanol | 57044-25-4 | 2476 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 69 | 1-Dodecanol | 112-53-8 | 2481 | MS, RI | LLE-SAFE | √ | ||||

| 70 | 3-Methyl-2-hexanol | 2313-65-7 | 2503 | MS, RI | LLE-SAFE | √ | ||||

| 71 | 2-(Vinyloxy)ethanol | 764-48-7 | 2503 | 1685 | MS, RI | LLE-SAFE, SPME | √ | √ | √ | √ |

| 72 | 2-Butene-1,4-diol | 110-64-5 | 2561 | MS, RI | LLE-SAFE | √ | ||||

| 73 | Isopropyl alcohol | 67-63-0 | 2596 | MS, RI, S | LLE-SAFE | √ | ||||

| 74 | Di(ethylene glycol) vinyl ether | 929-37-3 | 2600 | MS, RI | LLE-SAFE | √ | √ | |||

| 75 | (R)-(−)-1,2-Propanediol | 4254-14-2 | 2816 | MS, RI | LLE-SAFE | √ | √ | |||

| 76 | 4-Penten-2-ol | 625-31-0 | 2946 | MS, RI | LLE-SAFE | √ | ||||

| 77 | 2-Eyhoxyethanol | 110-80-5 | 3099 | MS, RI | LLE-SAFE | √ | √ | |||

| 78 | Glycidol | 556-52-5 | 3220 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 79 | 2-Methyl-1-propanol | 78-83-1 | 996 | 682 | MS, RI, S | LLE-SAFE, SPME | √ | √ | √ | √ |

| 80 | 4-Methyl-2-pentanol | 108-11-2 | 2241 | MS, RI | SPME | √ | √ | |||

| 81 | Diisobutylcarbinol | 108-82-7 | 1215 | MS, RI, S | SPME | √ | √ | √ | ||

| 82 | 2,5-Dimethyl-2,5-hexanediol | 110-03-2 | 1269 | MS, RI | SPME | √ | ||||

| 83 | (+)-β-Citronellol | 1117-61-9 | 1340 | MS, RI | SPME | √ | ||||

| 84 | Diethylene glycol monoethyl ether | 111-90-0 | 2248 | MS, RI | SPME | √ | √ | √ | √ | |

| 85 | (−)-Isolongifolol | 1139-17-9 | 2421 | MS, RI | LLE-SAFE | √ | √ | |||

| 86 | Phytol | 150-86-7 | 1061 | MS, RI | SPME | √ | √ | √ | ||

| 87 | 2-Methyl-3-heptanol | 18720-62-2 | 1217 | MS, RI | SPME | √ | √ | √ | ||

| 88 | 4-Methyl-4-nonanol | 23418-38-4 | 2402 | MS, RI | SPME | √ | √ | |||

| 89 | 2-Hexyl-1-decanol | 2425-77-6 | 2377 | MS, RI, aroma, S | LLE-SAFE | √ | √ | |||

| 90 | β-Eudesmol | 473-15-4 | MS, S | LLE-SAFE | √ | √ | √ | √ | ||

| 91 | Pentaethylene glycol | 4792-15-8 | 2006 | MS, RI | SPME | √ | √ | √ | √ | |

| 92 | Guaiol | 489-86-1 | 2203 | MS, RI, S | SPME | √ | √ | √ | ||

| 93 | Octaethylene glycol | 5117-19-1 | 1986 | MS, RI | SPME | √ | √ | √ | √ | |

| 94 | 2,2,4-Trimethyl-3-pentanol | 5162-48-1 | 1261 | MS, RI | SPME | √ | √ | |||

| 95 | Heptaethylene glycol | 5617-32-3 | 2082 | MS, RI | SPME | √ | √ | √ | √ | |

| 96 | 1-Methylcyclohexanol | 590-67-0 | 1050 | MS, RI | SPME | √ | √ | √ | ||

| 97 | 2,6-Dimethyl-5,7-octadien-2-ol | 5986-38-9 | 1387 | MS, RI | SPME | √ | √ | |||

| 98 | 5-Nonanol | 623-93-8 | 1273 | MS, RI | SPME | √ | ||||

| Nitrogen-containing compounds (91) | ||||||||||

| 1 | Triethylamine | 121-44-8 | 1110 | MS, RI | LLE-SAFE | √ | ||||

| 2 | N,N,O-Triacetylhydroxylamine | 17720-63-7 | 1112 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 3 | 2-Methylpyrazine | 109-08-0 | 1162 | MS, RI, S | LLE-SAFE | √ | √ | √ | ||

| 4 | N,N-Dimethylformamide | 1968-12-2 | 1223 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 5 | 2-Oxopropanamide | 631-66-3 | 1531 | MS, RI | LLE-SAFE | √ | √ | |||

| 6 | N-Methylacetamide | 79-16-3 | 1533 | MS, RI | LLE-SAFE | √ | ||||

| 7 | N-Ethylacetamide | 625-50-3 | 1533 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 8 | N-Acetyglycinamide | 2620-63-5 | 1610 | MS, RI | LLE-SAFE | √ | ||||

| 9 | 2,3-Butanedione monoxime | 57-71-6 | 1627 | MS, RI | LLE-SAFE | √ | √ | |||

| 10 | Acetamide | 60-35-5 | 1656 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 11 | Formamide | 1975/12/7 | 1675 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 12 | 3-(Ethoxycarbonyl)pyridine | 614-18-6 | 1706 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 13 | N-Methylsuccinimide | 1121-07-9 | 1793 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 14 | 2-Pyridinecarbaldehyde oxime | 873-69-8 | 1806 | MS, RI | LLE-SAFE | √ | ||||

| 15 | 3-Methylbutyramide | 541-46-8 | 1811 | MS, RI | LLE-SAFE | √ | √ | |||

| 16 | 2-Acetyl pyrrole | 1072-83-9 | 1862 | 1978 | MS, RI, aroma, S | LLE-SAFE | √ | √ | √ | √ |

| 17 | 3-Benzylsydnone | 16844-42-1 | 1862 | MS, RI | LLE-SAFE | √ | ||||

| 18 | 2-Pyrrolecarbaldehyde | 1003-29-8 | 1895 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 19 | 2-Pyrrolidinone | 616-45-5 | 1928 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 20 | 1-Methylpyrrole-2-carboxaldehyde | 1192-58-1 | 1989 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 21 | Butanamide | 541-35-5 | 2000 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 22 | Hexanamide | 628-02-4 | 2000 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 23 | 5-Aminopentanamide | 13023-70-6 | 2021 | MS, RI | LLE-SAFE | √ | ||||

| 24 | 2-Piperidinone | 675-20-7 | 2021 | MS, RI | LLE-SAFE | √ | ||||

| 25 | N-Acetylglycine ethyl ester | 1906-82-7 | 2044 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 26 | ε-Caprolactam | 105-60-2 | 2074 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 27 | 3,5-Dihydroxy-6-methyl-2,3-dihydro-4H-pyran-4-one | 28564-83-2 | 2157 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 28 | Ethosuximide | 77-67-8 | 2252 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 29 | Glutarimide | 1121-89-7 | 2264 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 30 | N,N,3,5-Tetramethylaniline | 4913-13-7 | 2269 | MS, RI | LLE-SAFE | √ | ||||

| 31 | N-Acetylethanolamine | 142-26-7 | 2277 | MS, RI | LLE-SAFE | √ | √ | |||

| 32 | Indole | 120-72-9 | 2329 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 33 | 5H-cyclopenta[b]pyridine | 270-91-7 | 2329 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 34 | Succinimide | 123-56-8 | 2355 | MS, RI | LLE-SAFE | √ | ||||

| 35 | N,S-Diacetylcysteamine | 1420-88-8 | 2411 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 36 | N-(2-Phenylethyl)acetamide | 877-95-2 | 2473 | MS, RI | LLE-SAFE | √ | ||||

| 37 | 1-Methyl-1H-tetrazole | 16681-77-9 | 2475 | MS, RI | LLE-SAFE | √ | ||||

| 38 | 4-Amino-1-butanol | 13325-10-5 | 2479 | MS, RI | LLE-SAFE | √ | ||||

| 39 | DL-Pyroglutamic acid | 149-87-1 | 2497 | MS, RI | LLE-SAFE | √ | ||||

| 40 | Ethyl 5-oxo-L-prolinate | 66183-71-9 | 2497 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 41 | L-Pyroglutamicacid | 98-79-3 | 2500 | MS, RI | LLE-SAFE | √ | ||||

| 42 | Benzamide | 55-21-0 | 2575 | MS, RI | LLE-SAFE | √ | √ | |||

| 43 | Phenylacetamide | 103-81-1 | 2607 | MS, RI | LLE-SAFE | √ | ||||

| 44 | Valeramide | 626-97-1 | 2654 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 45 | Enanthamide | 628-62-6 | 2657 | MS, RI | LLE-SAFE | √ | ||||

| 46 | Octanamide | 629-01-6 | 2657 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 47 | Pent-4-enylamine | 22537-07-1 | 2705 | MS, RI | LLE-SAFE | √ | ||||

| 48 | Cyclobutylamine | 2516-34-9 | 2762 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 49 | 3-Indoleethanol | 526-55-6 | 2767 | MS, RI | LLE-SAFE | √ | ||||

| 50 | (2-Hydroxyethyl)hydrazine | 109-84-2 | 2811 | MS, RI | LLE-SAFE | √ | ||||

| 51 | Dodecanamide | 1120-16-7 | 2883 | MS, RI | LLE-SAFE | √ | √ | |||

| 52 | (Z)-9-Octadecenamide | 301-02-0 | 2887 | 2432 | MS, RI, aroma, S | LLE-SAFE | √ | √ | √ | √ |

| 53 | 2-Propoxyethylamine | 42185-03-5 | 2937 | MS, RI | LLE-SAFE | √ | ||||

| 54 | 2-Methoxyethylamine | 109-85-3 | 2963 | MS, RI | LLE-SAFE | √ | √ | |||

| 55 | 2-Ethoxyethylamine | 110-76-9 | 2968 | MS, RI | LLE-SAFE | √ | ||||

| 56 | Nonanamide | 1120-07-6 | 3105 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 57 | 1,2-Propanediamine | 78-90-0 | 3147 | MS, RI | LLE-SAFE | √ | √ | |||

| 58 | N-Methylisobutylamine | 625-43-4 | 3222 | MS, RI | LLE-SAFE | √ | ||||

| 59 | N-Methyltyramine | 370-98-9 | 884 | MS, RI | LLE-SAFE | √ | √ | |||

| 60 | 4-Hydroxypyrazole | 4843-98-5 | 924 | MS, RI | LLE-SAFE | √ | ||||

| 61 | 4H-1,2,4-Triazol-4-amine | 584-13-4 | 925 | MS, RI | LLE-SAFE | √ | ||||

| 62 | Benzylamine | 100-46-9 | 1188 | MS, RI | SPME | √ | √ | |||

| 63 | 2,4,6-Triamino-5-nitrosopyrimidine | 1006-23-1 | MS | LLE-SAFE | √ | |||||

| 64 | 1,3,5-Trimethylpyrazole | 1072-91-9 | 2157 | MS, RI | LLE-SAFE | √ | √ | |||

| 65 | Diethylamine | 109-89-7 | 597 | MS, RI | SPME | √ | √ | |||

| 66 | N-Butyl-acetamide | 1119-49-9 | 1118 | MS, RI, aroma, S | LLE-SAFE, SPME | √ | √ | √ | ||

| 67 | cis-13-Docosenoamide | 112-84-5 | MS | LLE-SAFE | √ | √ | ||||

| 68 | 5-Methyl-1H-pyrrole-2-carbaldehyde | 1192-79-6 | 2120 | MS, RI, aroma, S | LLE-SAFE | √ | √ | |||

| 69 | Octadecanamide | 124-26-5 | MS | LLE-SAFE | √ | √ | ||||

| 70 | 2-Hydroxypyridine | 142-08-5 | 1468 | MS, RI, aroma, S | LLE-SAFE | √ | √ | |||

| 71 | 6-(Ethoxycarbonyl)nicotinic acid | 17874-78-1 | MS, aroma, S | LLE-SAFE | √ | √ | ||||

| 72 | Diethyl iminodiacetate | 19617-44-8 | 2035 | MS, RI | SPME | √ | √ | √ | √ | |

| 73 | N-Ethylisopropylamine | 19961-27-4 | 1270 | MS, RI | SPME | √ | √ | √ | ||

| 74 | 2-Hydroxy-Propanamide | 2043-43-8 | 667 | MS, RI | SPME | √ | √ | |||

| 75 | 5,6,7,8-Tetrahydro-1-naphthylamine | 2217-41-6 | 2039 | MS, RI | SPME | √ | ||||

| 76 | 4-Hydroxyindole | 2380-94-1 | 2284 | MS, RI | SPME | √ | ||||

| 77 | 5-Amino-1-pentanol | 2508-29-4 | 1043 | MS, RI | SPME | √ | ||||

| 78 | Pyrazole | 288-13-1 | 2243 | MS, RI | LLE-SAFE | √ | ||||

| 79 | 4-Hydroxy-6-methylpyrimidine | 3524-87-6 | 2172 | MS, RI | LLE-SAFE | √ | ||||

| 80 | 2-Amino-1,3,4-thiadiazole | 4005-51-0 | 1294 | MS, RI | SPME | √ | ||||

| 81 | N-Ethylmaleamic acid | 4166-67-0 | 2233 | MS, RI | SPME | √ | √ | √ | √ | |

| 82 | N-Ethyl-pentanamide | 54007-33-9 | 1267 | MS, RI | SPME | √ | √ | √ | ||

| 83 | Isobutyramide | 563-83-7 | 590 | MS, RI | SPME | √ | √ | |||

| 84 | 2,6-Di-tert-butylpyridine | 585-48-8 | 2457 | MS, RI, aroma, S | LLE-SAFE | √ | √ | √ | ||

| 85 | Ethylhydrazine | 624-80-6 | 1710 | MS, RI | SPME | √ | ||||

| 86 | Imidazole-4-acetic acid | 645-65-8 | 1185 | MS, RI | SPME | √ | √ | |||

| 87 | 3-Hydroxypiperidine | 6859-99-0 | 1194 | MS, RI | SPME | √ | ||||

| 88 | N,N-Dimethylthioformamide | 758-16-7 | 1786 | MS, RI | SPME | √ | √ | √ | √ | |

| 89 | N,N-Dimethylpropanamide | 758-96-3 | 664 | MS, RI | SPME | √ | √ | |||

| 90 | Ethyl 3-aminopropanoate | 924-73-2 | 1269 | MS, RI | SPME | √ | ||||

| 91 | 2-Ethyl-4-methylimidazole | 931-36-2 | MS | LLE-SAFE | √ | √ | ||||

| Esters (86) | ||||||||||

| 1 | Isoamyl acetate | 123-92-2 | 1024 | 1014 | MS, RI, aroma, S | LLE-SAFE, SPME | √ | √ | √ | √ |

| 2 | 2-Methylbutyl acetate | 624-41-9 | 1024 | MS, RI | LLE-SAFE | √ | √ | |||

| 3 | Pentyl acetate | 628-63-7 | 1024 | MS, RI, S | LLE-SAFE | √ | √ | |||

| 4 | Ethyl valerate | 539-82-2 | 1038 | 1433 | MS, RI, S | LLE-SAFE | √ | √ | √ | √ |

| 5 | Ethyl hexanoate | 123-66-0 | 1135 | 1157 | MS, RI, aroma, S | LLE-SAFE, SPME | √ | √ | √ | √ |

| 6 | Ethyl Pyruvate | 617-35-6 | 1164 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 7 | Hexyl acetate | 142-92-7 | 1171 | 1183 | MS, RI, S | LLE-SAFE, SPME | √ | √ | √ | √ |

| 8 | Allyl butanoate | 2051-78-7 | 1175 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 9 | Ethyl heptanoate | 106-30-9 | 1232 | 1214 | MS, RI, S | LLE-SAFE, SPME | √ | √ | √ | √ |

| 10 | (−)-Ethyl L-lactate | 687-47-8 | 1238 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 11 | Ethyl lactate | 97-64-3 | 1238 | MS, RI, S | LLE-SAFE | √ | √ | √ | √ | |

| 12 | Hexyl formate | 629-33-4 | 1250 | MS, RI, S | LLE-SAFE | √ | ||||

| 13 | 2-Propenoic acid ethenyl ester | 2177-18-6 | 1294 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 14 | Methyl acrylate | 96-33-3 | 1294 | MS, RI | LLE-SAFE | √ | √ | |||

| 15 | Ethyl octanoate | 106-32-1 | 1332 | 1303 | MS, RI, S | LLE-SAFE, SPME | √ | √ | √ | √ |

| 16 | Heptyl formate | 112-23-2 | 1352 | MS, RI | LLE-SAFE | √ | ||||

| 17 | 3-Methoxybutyl acetate | 4435-53-4 | 1411 | MS, RI | LLE-SAFE | √ | ||||

| 18 | Ethyl 2-hydroxyisobutyrate | 80-55-7 | 1411 | MS, RI | LLE-SAFE | √ | √ | |||

| 19 | Ethyl 3-hydrobutyrate | 5405-41-4 | 1411 | 1876 | MS, RI, S | LLE-SAFE, SPME | √ | √ | ||

| 20 | Octyl formate | 112-32-3 | 1454 | MS, RI | LLE-SAFE | √ | √ | |||

| 21 | 2-Hydroxypropyl acetate | 627-69-0 | 1467 | MS, RI | LLE-SAFE | √ | ||||

| 22 | Ethyl levulinate | 539-88-8 | 1500 | MS, RI | LLE-SAFE | √ | ||||

| 23 | 2-Hydroxyethyl formate | 628-35-3 | 1514 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 24 | 2-Hydroxyethyl acetate | 542-59-6 | 1528 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 25 | Ethyl decanoate | 110-38-3 | 1535 | 1377 | MS, RI, S | LLE-SAFE, SPME | √ | √ | √ | |

| 26 | Diethyl succinate | 123-25-1 | 1570 | MS, RI, S | LLE-SAFE | √ | √ | √ | √ | |

| 27 | Dimethyl glutarate | 1119-40-0 | 1593 | MS, RI | LLE-SAFE | √ | √ | |||

| 28 | Isopropyl isobutyrate | 617-50-5 | 1600 | MS, RI | LLE-SAFE | √ | ||||

| 29 | Propyl acetate | 109-60-4 | 1630 | MS, RI, S | LLE-SAFE | √ | √ | |||

| 30 | 1,3-Diacetoxy-propane | 628-66-0 | 1632 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 31 | Neryl formate | 2142-94-1 | 1744 | MS, RI | LLE-SAFE | √ | ||||

| 32 | 1,1-Ethanediol diacetate | 542-10-9 | 1749 | MS, RI | LLE-SAFE | √ | √ | |||

| 33 | Butyl butyrate | 109-21-7 | 1760 | MS, RI | LLE-SAFE | √ | ||||

| 34 | Butyl 2-methyl propanoate | 97-87-0 | 1760 | MS, RI, S | LLE-SAFE | √ | ||||

| 35 | Pentyl 2-methylprop-2-enoate | 2849-98-1 | 1936 | MS, RI | LLE-SAFE | √ | ||||

| 36 | Allyl propionate | 2408-20-0 | 2012 | MS, RI | LLE-SAFE | √ | ||||

| 37 | Vinyl butyrate | 123-20-6 | 2012 | MS, RI | LLE-SAFE | √ | ||||

| 38 | Allyl isobutyrate | 15727-77-2 | 2015 | MS, RI | LLE-SAFE | √ | √ | |||

| 39 | Ethyl cinnamate | 103-36-6 | 2019 | MS, RI | LLE-SAFE | √ | ||||

| 40 | Vinyl acetate | 108-05-4 | 2038 | MS, RI | LLE-SAFE | √ | ||||

| 41 | Methyl acetate | 79-20-9 | 2102 | MS, RI, S | LLE-SAFE | √ | ||||

| 42 | Methyl tridecanoate | 1731-88-0 | 2112 | MS, RI | LLE-SAFE | √ | ||||

| 43 | Glycidyl acrylate | 106-90-1 | 2139 | MS, RI | LLE-SAFE | √ | √ | |||

| 44 | 2,3-Dihydroxypropyl acetate | 106-61-6 | 2173 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 45 | Ethyl cyclohexanepropionate | 10094-36-7 | 2233 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 46 | Ethyl nonanoate | 123-29-5 | 2233 | 1285 | MS, RI, S | LLE-SAFE, SPME | √ | √ | √ | √ |

| 47 | Allyl propyl ether | 1471-03-0 | 2589 | MS, RI | LLE-SAFE | √ | ||||

| 48 | 2-Oxooctadecanoic acid methyl ester | 2380-18-9 | 2607 | MS, RI | LLE-SAFE | √ | ||||

| 49 | L-Lactide | 4511-42-6 | 2630 | MS, RI | LLE-SAFE | √ | ||||

| 50 | Ethenyl formate | 692-45-5 | 2716 | MS, RI | LLE-SAFE | √ | √ | |||

| 51 | Methyl propionate | 554-12-1 | 2729 | MS, RI, S | LLE-SAFE, SPME | √ | √ | |||

| 52 | Butyl lactate | 138-22-7 | 2751 | MS, RI, S | LLE-SAFE | √ | √ | |||

| 53 | Lactic acid methyl ester | 547-64-8 | 2811 | MS, RI | LLE-SAFE | √ | ||||

| 54 | Isopropyl formate | 625-55-8 | 2939 | MS, RI | LLE-SAFE | √ | √ | |||

| 55 | DL-Lactide | 95-96-5 | 3127 | MS, RI | LLE-SAFE | √ | √ | |||

| 56 | Ethyl acetate | 141-78-6 | 913 | 606 | MS, RI, S | LLE-SAFE, SPME | √ | √ | √ | √ |

| 57 | Isobutyl acetate | 110-19-0 | 990 | MS, RI, S | LLE-SAFE | √ | ||||

| 58 | Butyl acetate | 123-86-4 | 990 | MS, RI, S | LLE-SAFE | √ | √ | |||

| 59 | 2,2-Dimethoxypropionic acid methyl ester | 10076-48-9 | 2237 | MS, RI | SPME | √ | √ | |||

| 60 | sec-Butyl Crotonate | 10371-45-6 | 1304 | MS, RI | SPME | √ | √ | |||

| 61 | Ethyl propanoate | 105-37-3 | 2101 | MS, RI, aroma, S | LLE-SAFE | √ | √ | √ | √ | |

| 62 | Isoamyl butyrate | 106-27-4 | 1102 | MS, RI, S | SPME | √ | ||||

| 63 | Ethyl dodecanoate | 106-33-2 | 2256 | MS, RI | LLE-SAFE | √ | √ | |||

| 64 | Ethyl hydrogen succinate | 1070-34-4 | 2388 | MS, RI, aroma, S | LLE-SAFE | √ | √ | √ | √ | |

| 65 | Ethyl isovalerate | 108-64-5 | 1302 | MS, RI, S | SPME | √ | ||||

| 66 | Methyl decanoate | 110-42-9 | 2215 | MS, RI, aroma, S | LLE-SAFE | √ | √ | √ | √ | |

| 67 | Methyl 2-octynate | 111-12-6 | 2415 | MS, RI, aroma, S | LLE-SAFE | √ | √ | |||

| 68 | Ethyl Stearate | 111-61-5 | 1301 | MS, RI, S | SPME | √ | √ | √ | √ | |

| 69 | Octyl Acetate | 112-14-1 | 1298 | MS, RI, S | SPME | √ | √ | |||

| 70 | Ethyl myristate | 124-06-1 | 1382 | MS, RI, S | SPME | √ | √ | √ | √ | |

| 71 | Ccrotonic acid isopropyl ester | 18060-77-0 | 1263 | MS, RI | SPME | √ | √ | √ | ||

| 72 | Ethyl nonadecanoate | 18281-04-4 | 1299 | MS, RI | SPME | √ | √ | |||

| 73 | Methyl (Z)-3,7-dimethylocta-2,6-dienoate | 1862-61-9 | 1394 | MS, RI | SPME | √ | ||||

| 74 | Ethyl 3-hexenoate | 2396-83-0 | 1206 | MS, RI, S | SPME | √ | √ | √ | ||

| 75 | 2-Ethylhexyl Butyrate | 25415-84-3 | 1320 | MS, RI | SPME | √ | ||||

| 76 | Hexyl butanoate | 2639-63-6 | 2144 | MS, RI, aroma, S | LLE-SAFE | √ | √ | √ | √ | |

| 77 | Ethyl butyrylacetate | 3249-68-1 | 2297 | MS, RI | SPME | √ | √ | √ | ||

| 78 | Heptadecanyl margarate | 36617-50-2 | 1422 | MS, RI | SPME | √ | √ | |||

| 79 | Dimethyl dl-malate | 38115-87-6 | 1197 | MS, RI | SPME | √ | √ | |||

| 80 | Methyl 4-methoxyacetoacetate | 41051-15-4 | 2275 | MS, RI | SPME | √ | ||||

| 81 | Ethyl 3-methylvalerate | 5870-68-8 | 1299 | MS, RI | SPME | √ | ||||

| 82 | Ethyl undecanoate | 627-90-7 | 1271 | MS, RI | SPME | √ | √ | |||

| 83 | Dodecyl isobutyrate | 6624-71-1 | 2332 | MS, RI | SPME | √ | √ | |||

| 84 | Ethyl trans-2-decenoate | 7367-88-6 | 1194 | MS, RI, S | SPME | √ | ||||

| 85 | Isobutyric acid 2-ethyl-3-hydroxyhexyl ester | 74367-31-0 | 677 | MS, RI | SPME | √ | ||||

| 86 | (+)-Diethyl L-tartrate | 87-91-2 | 1526 | MS, RI | SPME | √ | ||||

| Alkanes (57) | ||||||||||

| 1 | 1,1-Dimethyl cyclopropane | 1630-94-0 | 886 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 2 | s-Trioxane | 110-88-3 | 1063 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 3 | Nonane | 111-84-2 | 1105 | MS, RI | LLE-SAFE | √ | ||||

| 4 | 2,4-Dimethyldecane | 2801-84-5 | 1105 | MS, RI | LLE-SAFE | √ | ||||

| 5 | n-Hendecane | 1120-21-4 | 1105 | MS, RI | LLE-SAFE | √ | ||||

| 6 | 2,3-Dimethylbutane | 79-29-8 | 1111 | MS, RI | LLE-SAFE | √ | ||||

| 7 | Decane | 124-18-5 | 1201 | MS, RI | LLE-SAFE | √ | √ | |||

| 8 | 3,7-Dimethyldecane | 17312-54-8 | 1201 | MS, RI | LLE-SAFE | √ | ||||

| 9 | 2-Methylnonane | 871-83-0 | 1201 | MS, RI | LLE-SAFE | √ | ||||

| 10 | Tridecane | 629-50-5 | 1203 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 11 | Propyl cyclopropane | 2415-72-7 | 1250 | MS, RI | LLE-SAFE | √ | ||||

| 12 | Cyclododecane | 294-62-2 | 1659 | MS, RI | LLE-SAFE | √ | ||||

| 13 | 2,3-Dimethyloxirane | 3266-23-7 | 1713 | MS, RI | LLE-SAFE | √ | ||||

| 14 | 1,4- Diacetoxybutane | 628-67-1 | 1769 | MS, RI | LLE-SAFE | √ | ||||

| 15 | trans-1,2-Dimethylcyclopropane | 2402/6/4 | 2039 | MS, RI | LLE-SAFE | √ | ||||

| 16 | 1,2-Epoxyhexane | 1436-34-6 | 2155 | MS, RI | LLE-SAFE | √ | √ | |||

| 17 | Methylcyclobutane | 598-61-8 | 2264 | MS, RI | LLE-SAFE | √ | √ | |||

| 18 | 6-Ethyl-2-methyldecane | 62108-21-8 | 2401 | MS, RI | LLE-SAFE | √ | ||||

| 19 | 2,7-Dimethyloctane | 1072-16-8 | 2491 | MS, RI | LLE-SAFE | √ | ||||

| 20 | Dimethylmethane | 74-98-6 | 2514 | MS, RI | LLE-SAFE | √ | √ | |||

| 21 | 2,6,10-Trimethyldodecane | 3891-98-3 | 2709 | MS, RI | LLE-SAFE | √ | ||||

| 22 | Hexadecane | 544-76-3 | 2805 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 23 | 2-Methylpropane | 75-28-5 | 2996 | MS, RI | LLE-SAFE | √ | √ | |||

| 24 | Butane | 106-97-8 | 3044 | MS, RI | LLE-SAFE | √ | √ | |||

| 25 | 1,3,6-Trioxocane | 1779-19-7 | 3054 | MS, RI | LLE-SAFE | √ | ||||

| 26 | Pentane | 109-66-0 | 881 | MS, RI | LLE-SAFE | √ | ||||

| 27 | Bicyclo[2,1,0]pentane | 185-94-4 | 889 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 28 | Ethylene oxide | 75-21-8 | 893 | MS, RI | LLE-SAFE | √ | √ | |||

| 29 | Isobutylene oxide | 558-30-5 | 910 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 30 | Cyclopropane | 75-19-4 | 998 | MS, RI | LLE-SAFE | √ | √ | |||

| 31 | 1,3-Dimethoxybutane | 10143-66-5 | 2290 | MS, RI | SPME | √ | ||||

| 32 | Acetaldehyde dipropyl acetal | 105-82-8 | 2254 | MS, RI | SPME | √ | √ | √ | ||

| 33 | Methylcyclohexane | 108-87-2 | MS | LLE-SAFE | √ | √ | √ | √ | ||

| 34 | Tetratriacontane | 14167-59-0 | MS, aroma, S | LLE-SAFE | √ | √ | ||||

| 35 | Cycloheptane | 291-64-5 | 1237 | MS, RI | SPME | √ | ||||

| 36 | Cyclooctane | 292-64-8 | 1415 | MS, RI | SPME | √ | ||||

| 37 | 1,2,3,4-Tetramethoxybutane | 3011-85-6 | 2305 | MS, RI | SPME | √ | √ | √ | ||

| 38 | 1,1,3-Trimethylcyclohexane | 3073-66-3 | MS | LLE-SAFE | √ | √ | ||||

| 39 | 1,2-Dicyclohexylethane | 3321-50-4 | MS | LLE-SAFE | √ | √ | √ | |||

| 40 | 2,2-Dimethoxybutane | 3453-99-4 | 2017 | MS, RI | SPME | √ | ||||

| 41 | Cholestane | 481-21-0 | MS, aroma, S | LLE-SAFE | √ | √ | √ | √ | ||

| 42 | 11-Decyl-docosane | 55401-55-3 | MS | LLE-SAFE | √ | |||||

| 43 | 1-(1-ethoxyethoxy)-Butane | 57006-87-8 | 671 | MS, RI | SPME | √ | √ | |||

| 44 | 2,4-Dimethylhexane | 589-43-5 | 1303 | MS, RI | LLE-SAFE | √ | ||||

| 45 | Heptacosane | 593-49-7 | 2304 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 46 | 1-Ethyl-2-propylcyclohexane | 62238-33-9 | MS | LLE-SAFE | √ | |||||

| 47 | n-Pentadecane | 629-62-9 | MS | LLE-SAFE | √ | √ | √ | |||

| 48 | n-Heneicosane | 629-94-7 | MS | LLE-SAFE | √ | |||||

| 49 | n-Pentacosane | 629-99-2 | MS | LLE-SAFE | √ | |||||

| 50 | Hexacosane | 630-01-3 | MS, aroma, S | LLE-SAFE | √ | √ | √ | |||

| 51 | n-Octacosane | 630-02-4 | MS | LLE-SAFE | √ | √ | √ | √ | ||

| 52 | n-Nonacosane | 630-03-5 | MS | LLE-SAFE | √ | √ | √ | |||

| 53 | Hentriacontane | 630-04-6 | 2406 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 54 | n-Triacontane | 638-68-6 | MS | LLE-SAFE | √ | √ | √ | |||

| 55 | Tetracosane | 646-31-1 | MS | LLE-SAFE | √ | √ | √ | |||

| 56 | 1,3,3-Trimethoxybutane | 6607-66-5 | 2367 | MS, RI | SPME | √ | √ | |||

| 57 | Tetratetracontane | 7098-22-8 | MS, aroma, S | LLE-SAFE | √ | √ | ||||

| Furans (42) | ||||||||||

| 1 | 2-Methyltetrahydrofuran-3-one | 3188-00-9 | 1160 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 2 | 2,2,5,5-Tetramethyltetrahydrofuran | 15045-43-9 | 1307 | MS, RI | LLE-SAFE | √ | ||||

| 3 | Furfural | 1998/1/1 | 1354 | 1303 | MS, RI | LLE-SAFE, SPME | √ | √ | √ | √ |

| 4 | 2-Acetyl furan | 1192-62-7 | 1396 | MS, RI, S | LLE-SAFE | √ | √ | √ | √ | |

| 5 | 5-Methyl-2-furaldehyde | 620-02-0 | 1462 | MS, RI, S | LLE-SAFE | √ | ||||

| 6 | 2-Propionylfuran | 3194-15-8 | 1465 | MS, RI | LLE-SAFE | √ | ||||

| 7 | Furfuryl alcohol | 98-00-0 | 1555 | 1375 | MS, RI, aroma, S | LLE-SAFE, SPME | √ | √ | √ | √ |

| 8 | Tetrahydrofuran-2-ylmethylacetat | 637-64-9 | 1566 | MS, RI | LLE-SAFE | √ | ||||

| 9 | 2,2-Di(2-tetrahydrofuryl)propane | 89686-69-1 | 1604 | MS, RI | LLE-SAFE | √ | ||||

| 10 | 3-Methyl-2(5H)-furanone | 22122-36-7 | 1605 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 11 | 2(5H)-Furanone | 497-23-4 | 1639 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 12 | 2,5-Dimethyl-4-hydroxy-2H-furan-3-one | 3658-77-3 | 1749 | 1865 | MS, RI, aroma, S | LLE-SAFE | √ | √ | √ | √ |

| 13 | 2-(1-Oxo-2-hydroxyethyl)furan | 17678-19-2 | 1892 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 14 | 5-Acetyltetrahydrofuran-2-one | 29393-32-6 | 1945 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 15 | 4-Hydroxy-5-methyl-3-furanone | 19322-27-1 | 2009 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 16 | 2H-Pyran-2,6(3H)-dione | 5926-95-4 | 2009 | MS, RI | LLE-SAFE | √ | ||||

| 17 | 2-Furaldehyde diethyl acetal | 13529-27-6 | 2012 | MS, RI | LLE-SAFE | √ | ||||

| 18 | 4-Methoxy-5H-furan-2-one | 69556-70-3 | 2056 | MS, RI | LLE-SAFE | √ | ||||

| 19 | 3-Furanmethanol | 4412-91-3 | 2085 | MS, RI | LLE-SAFE | √ | ||||

| 20 | Ethyl 5-oxooxolane-2-carboxylate | 1126-51-8 | 2116 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 21 | Methyl 5-oxotetrahydrofuran-2-carboxylate | 3885-29-8 | 2116 | MS, RI | LLE-SAFE | √ | ||||

| 22 | Tetrahydrofurfruyl alcohol | 97-99-4 | 2155 | MS, RI, S | LLE-SAFE | √ | √ | |||

| 23 | 2-Furanmethanamine | 617-89-0 | 2170 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 24 | 2-Methyl-4H,5H-furo[3,2-c]pyridin-4-one | 26956-44-5 | 2269 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 25 | 5-Hydroxymethyl-2-furaldehyde | 67-47-0 | 2387 | MS, RI, aroma, S | LLE-SAFE | √ | √ | √ | √ | |

| 26 | 5-(Hydroxymethyl)dihydro-2(3H)-furanone | 10374-51-3 | 2390 | MS, RI | LLE-SAFE | √ | ||||

| 27 | 5-(1-Piperidyl)furan-2-carbaldehyde | 22868-60-6 | 2433 | MS, RI | LLE-SAFE | √ | ||||

| 28 | 5-(Hydroxymethyl)furfuryl alcohol | 1883-75-6 | 2469 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 29 | 3-Furaldehyde | 498-60-2 | 2514 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 30 | 2,3-Dihydrofuran | 1191-99-7 | 1116 | MS, RI | SPME | √ | ||||

| 31 | Furfuryl sulfide | 13678-67-6 | MS | LLE-SAFE | √ | |||||

| 32 | 4,6-Dimethoxy-2,3-dihydrobenzofuran-3-one | 4225-35-8 | 2389 | MS, RI | LLE-SAFE | √ | ||||

| 33 | 2,2′-Difurfuryl ether | 4437-22-3 | 1190 | MS, RI | SPME | √ | √ | √ | ||

| 34 | 2-Butylfuran | 4466-24-4 | 1186 | MS, RI, S | SPME | √ | ||||

| 35 | Phthalan | 496-14-0 | 1371 | MS, RI | SPME | √ | ||||

| 36 | 2,3-Dihydrobenzofuran | 496-16-2 | 2402 | MS, RI | LLE-SAFE | √ | ||||

| 37 | Methyl 2-furoate | 611-13-2 | 2021 | MS, RI, aroma, S | LLE-SAFE | √ | √ | √ | √ | |

| 38 | 2,5-Furandicarboxaldehyde | 823-82-5 | 1999 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 39 | 2-Furancarboxylic acid | 88-14-2 | 2249 | MS, RI, aroma, S | LLE-SAFE | √ | √ | √ | ||

| 40 | 3-Methylfuran | 930-27-8 | 1206 | MS, RI | SPME | √ | √ | |||

| 41 | 5-Methoxy-2,3-dihydrobenzofuran-3-acetic acid | 93198-71-1 | MS | LLE-SAFE | √ | |||||

| 42 | 2-Methyltetrahydrofuran | 96-47-9 | 690 | MS, RI | SPME | √ | ||||

| Aromatic compounds (41) | ||||||||||

| 1 | Styrene | 100-42-5 | 1152 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 2 | Benzocyclobutene | 694-87-1 | 1152 | MS, RI | LLE-SAFE | √ | ||||

| 3 | Benzaldehyde | 100-52-7 | 1411 | MS, RI, S | LLE-SAFE | √ | ||||

| 4 | Benzeneacetaldehyde | 122-78-1 | 1531 | MS, RI, S | LLE-SAFE | √ | √ | √ | √ | |

| 5 | Ethyl benzoate | 93-89-0 | 1558 | MS, RI, S | LLE-SAFE | √ | ||||

| 6 | 2-Phenylethyl acetate | 103-45-7 | 1706 | 1444 | MS, RI, aroma, S | LLE-SAFE, SPME | √ | √ | √ | √ |

| 7 | Benzyl alcohol | 100-51-6 | 1767 | MS, RI, S | LLE-SAFE | √ | √ | √ | √ | |

| 8 | Phenethyl alcohol | 1960/12/8 | 1801 | 1471 | MS, RI, aroma, S | LLE-SAFE, SPME | √ | √ | √ | √ |

| 9 | Toluene | 108-88-3 | 1803 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 10 | 2,6-Di-tert-butyl-4-methylphenol | 128-37-0 | 1807 | MS, RI, S | LLE-SAFE | √ | √ | √ | √ | |

| 11 | DL-β-Ethylphenethyl alcohol | 2035-94-1 | 1876 | MS, RI | LLE-SAFE | √ | ||||

| 12 | Phenol | 108-95-2 | 1894 | 2009 | MS, RI, S | LLE-SAFE | √ | √ | √ | √ |

| 13 | 3-Phenoxypropionic acid | 7170-38-9 | 1964 | MS, RI | LLE-SAFE | √ | ||||

| 14 | 2-Methoxy-4-vinylphenol | 7786-61-0 | 2083 | 1647 | MS, RI, aroma, S | LLE-SAFE, SPME | √ | √ | √ | √ |

| 15 | 3-Hydroxy-4-phenylbutane-2-one | 5355-63-5 | 2146 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 16 | Ethyl 2-hydroxy-3-phenylpropanoate | 15399-05-0 | 2164 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 17 | 1,3-Dioxolane,2-(1-phenylethyl) | 4362-22-5 | 2165 | MS, RI | LLE-SAFE | √ | √ | |||

| 18 | 2,4-Di-tert-butylphenol | 96-76-4 | 2207 | 2309 | MS, RI, aroma, S | LLE-SAFE | √ | √ | √ | √ |

| 19 | 1-Phenyl-2-propanone | 103-79-7 | 2219 | MS, RI | LLE-SAFE | √ | √ | |||

| 20 | 4-Vinylphenol | 2628-17-3 | 2281 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 21 | 1,3-Diphenylpropan-2-ol | 5381-92-0 | 2400 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 22 | 3-Hydroxy-3-phenylbutan-2-one | 3155/1/9 | 2410 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 23 | α-Methylstyrene | 98-83-9 | 2679 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 24 | 4-n-Propylphenol | 645-56-7 | 2703 | MS, RI, S | LLE-SAFE | √ | ||||

| 25 | 4-(2-Acetoxy-ethyl)phenol | 58556-55-1 | 2821 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 26 | p-Hydroxybenzaldehyde | 123-08-0 | 2836 | MS, RI, S | LLE-SAFE | √ | ||||

| 27 | 4-Methoxyresorcinol | 6100-60-3 | 2846 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 28 | 2-Methoxyhydroquinone | 824-46-4 | 2846 | MS, RI, S | LLE-SAFE | √ | √ | √ | ||

| 29 | 4-Hydroxyphenylethanol | 501-94-0 | 2893 | MS, RI, aroma, S | LLE-SAFE | √ | √ | √ | √ | |

| 30 | Benzeneacetic acid | 103-82-2 | MS, aroma, S | LLE-SAFE | √ | √ | √ | √ | ||

| 31 | Resorcinol | 108-46-3 | 2084 | MS, RI, aroma, S | LLE-SAFE | √ | ||||

| 32 | 1-(2-Hydroxy-5-methylphenyl)ethanone | 1450-72-2 | 1647 | MS, RI | SPME | √ | √ | |||

| 33 | (R)-(+)-1-Phenylethanol | 1517-69-7 | 1220 | MS, RI | SPME | √ | √ | √ | ||

| 34 | 4-Phenylbutanal | 18328-11-5 | 1428 | MS, RI | SPME | √ | √ | |||

| 35 | 4-Methoxyphenoxyacetic acid | 1877-75-4 | MS | LLE-SAFE | √ | √ | √ | |||

| 36 | 4-Hydroxyphenoxyacetic acid | 1878-84-8 | MS | LLE-SAFE | √ | |||||

| 37 | 3,5-Dimethoxyphenol | 500-99-2 | MS, S | LLE-SAFE | √ | |||||

| 38 | 2,3,5,6-Tetramethyl-pheno | 527-35-5 | 1645 | MS, RI, S | SPME | √ | √ | |||

| 39 | 2,5-Di-tert-butylphenol | 5875-45-6 | 1701 | MS, RI | SPME | √ | √ | √ | √ | |

| 40 | Benzoic acid | 65-85-0 | 2449 | MS, RI, aroma, S | LLE-SAFE | √ | √ | √ | √ | |

| 41 | 2,5-Dimethylphenol | 95-87-4 | 2196 | MS, RI, aroma, S | LLE-SAFE | √ | ||||

| Ketones (37) | ||||||||||

| 1 | 3-Penten-2-one | 3102-33-8 | 1026 | MS, RI | LLE-SAFE | √ | ||||

| 2 | 3-Penten-2-one | 625-33-2 | 1026 | MS, RI | LLE-SAFE | √ | √ | |||

| 3 | Cyclopentanone | 120-92-3 | 1082 | MS, RI | LLE-SAFE | √ | √ | |||

| 4 | 2,2,5-Trimethylhexane-3,4-dione | 20633-03-8 | 1105 | MS, RI | LLE-SAFE | √ | ||||

| 5 | 3-Hydroxy-2-butanone | 513-86-0 | 1179 | 1277 | MS, RI, S | LLE-SAFE | √ | √ | √ | √ |

| 6 | Hydroxyacetone | 116-09-6 | 1191 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 7 | 2-Cyclopenten-1-one | 930-30-3 | 1248 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 8 | 2-Hydroxy-3-pentanone | 5704-20-1 | 1250 | MS, RI | LLE-SAFE | √ | √ | |||

| 9 | 4-Hydroxy-4-methyl-2-pentanone | 123-42-2 | 1254 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 10 | 4-Hydroxy-3-hexanone | 4984-85-4 | 1302 | MS, RI | LLE-SAFE | √ | ||||

| 11 | 4-Hydroxy-2-pentanone | 4161-60-8 | 1350 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 12 | 2-Butanone | 78-93-3 | 1359 | MS, RI | LLE-SAFE | √ | √ | |||

| 13 | 2,5-Hexanedione | 110-13-4 | 1394 | MS, RI | LLE-SAFE | √ | √ | |||

| 14 | 4-Hydroxy-2-butanone | 590-90-9 | 1427 | 1737 | MS, RI, aroma, S | LLE-SAFE | √ | √ | √ | √ |

| 15 | 3-Hydroxy-3-methyl-2-butanone | 115-22-0 | 1451 | MS, RI | LLE-SAFE | √ | √ | |||

| 16 | Isophorone | 78-59-1 | 1483 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 17 | 3-Methylcyclopentane-1,2-dione | 765-70-8 | 1726 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 18 | 3,4-Dihydroxy-2-butanone | 57011-15-1 | 1819 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 19 | 1,3-Dioxolan-2-one | 96-49-1 | 1827 | MS, RI | LLE-SAFE | √ | √ | |||

| 20 | 1-Hydroxy-2-pentanone | 64502-89-2 | 1978 | MS, RI | LLE-SAFE | √ | ||||

| 21 | 4-Methyl-2,3-pentanedione | 7493-58-5 | 2003 | MS, RI | LLE-SAFE | √ | ||||

| 22 | 2-Ethyl-cyclopentanone | 4971-18-0 | 2009 | MS, RI | LLE-SAFE | √ | ||||

| 23 | 2,3-Butanedione | 431-03-8 | 2038 | MS, RI, S | LLE-SAFE | √ | ||||

| 24 | 4-Acetoxy-2-butanone | 10150-87-5 | 2424 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 25 | 4-Hydroxy-β-damascone | 102488-09-5 | 2425 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 26 | 4-(Hydroxymethyl)-1,3-dioxolan-2-one | 931-40-8 | 2716 | MS, RI | LLE-SAFE | √ | √ | |||

| 27 | Acetone | 67-64-1 | 917 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 28 | 2,3-Pentanedione | 600-14-6 | 982 | MS, RI | LLE-SAFE | √ | √ | |||

| 29 | 2,2,6-Trimethylcyclohexanone | 2408-37-9 | MS | LLE-SAFE | √ | √ | ||||

| 30 | 2-Ethyl-3-methoxy-2-cyclopentenone | 25112-86-1 | MS | LLE-SAFE | √ | |||||

| 31 | 3-Methyl-4-nonanone | 35778-39-3 | 681 | MS, RI | SPME | √ | √ | |||

| 32 | 3,4,5,6-Tetrahydropseudoionone | 4433-36-7 | MS | LLE-SAFE | √ | |||||

| 33 | 5-Methyl-3-heptanone | 541-85-5 | 2215 | MS, RI | SPME | √ | ||||

| 34 | 4-Octanone | 589-63-9 | 1150 | MS, RI | SPME | √ | √ | √ | √ | |

| 35 | 3-Methyl-cyclohexanone | 591-24-2 | 1188 | MS, RI | SPME | √ | ||||

| 36 | (Z)-β-Ionone | 79-77-6 | MS, aroma, S | LLE-SAFE | √ | √ | ||||

| 37 | Verbenone | 80-57-9 | 1645 | MS, RI | SPME | √ | ||||

| Acids (33) | ||||||||||

| 1 | 2-Methylvaleric acid | 594-61-6 | 1411 | MS, RI, S | LLE-SAFE | √ | √ | √ | √ | |

| 2 | Acetic acid | 64-19-7 | 1473 | 1296 | MS, RI, aroma, S | LLE-SAFE, SPME | √ | √ | √ | √ |

| 3 | 4-Methyl-3-pentenoic acid | 504-85-8 | 1478 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 4 | 3-Hydroxypropionic acid | 503-66-2 | 1489 | MS, RI | LLE-SAFE | √ | ||||

| 5 | Malonic acid | 141-82-2 | 1715 | MS, RI | LLE-SAFE | √ | ||||

| 6 | Butanoic acid | 107-92-6 | 1718 | MS, RI | LLE-SAFE | √ | ||||

| 7 | Hexanoic acid | 142-62-1 | 1824 | 1441 | MS, RI, aroma, S | LLE-SAFE, SPME | √ | √ | √ | √ |

| 8 | 4-Methylvaleric acid | 646-07-1 | 1832 | MS, RI | LLE-SAFE | √ | ||||

| 9 | Pentanoic acid | 109-52-4 | 1870 | MS, RI, S | LLE-SAFE | √ | √ | √ | √ | |

| 10 | 4-Methylpent-4-enoic acid | 1001-75-8 | 2006 | MS, RI | LLE-SAFE | √ | ||||

| 11 | Octanoic acid | 124-07-2 | 2006 | 1544 | MS, RI, aroma, S | LLE-SAFE, SPME | √ | √ | √ | √ |

| 12 | 2-Methyl-2-pentenoic acid | 3142-72-1 | 2011 | 1199 | MS, RI, S | LLE-SAFE, SPME | √ | √ | √ | √ |

| 13 | 3-Methylbutanoic acid | 503-74-2 | 2062 | 1379 | MS, RI, aroma, S | LLE-SAFE, SPME | √ | √ | √ | √ |

| 14 | 2-Propynyl acetate | 627-09-8 | 2112 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 15 | 2-Oxopropionic acid | 127-17-3 | 2229 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 16 | Decanoic acid | 334-48-5 | 2322 | 1684 | MS, RI, aroma, S | LLE-SAFE, SPME | √ | √ | √ | √ |

| 17 | Nonanoic acid | 112-05-0 | 2342 | MS, RI, S | LLE-SAFE | √ | ||||

| 18 | L-Lactic acid | 79-33-4 | 2947 | MS, RI | LLE-SAFE | √ | ||||

| 19 | 4-Methyl-2-pentenoic acid | 10321-71-8 | 1955 | MS, RI | LLE-SAFE | √ | √ | |||

| 20 | DL-3-Methylvaleric acid | 105-43-1 | 1373 | MS, RI, S | SPME | √ | ||||

| 21 | Heptanoic acid | 111-14-8 | 1619 | MS, RI, S | SPME | √ | √ | √ | ||

| 22 | Hendecanoic acid | 112-37-8 | 1492 | MS, RI | SPME | √ | √ | √ | ||

| 23 | Elaidic acid | 112-79-8 | MS, aroma, S | LLE-SAFE | √ | √ | √ | |||

| 24 | 3-Ethylheptanoic acid | 14272-47-0 | 1629 | MS, RI | SPME | √ | √ | √ | ||

| 25 | Dodecanoic acid | 143-07-7 | 2486 | MS, RI, aroma, S | LLE-SAFE | √ | √ | √ | √ | |

| 26 | 2-(2-Methoxyethoxy)acetic acid | 16024-56-9 | 2311 | MS, RI | SPME | √ | ||||

| 27 | 4-Methoxybutyric acid | 29006-02-8 | 2321 | MS, RI | SPME | √ | √ | √ | ||

| 28 | Crotonic acid | 3724-65-0 | 2395 | MS, RI | LLE-SAFE | √ | ||||

| 29 | trans-3-Hexenoic acid | 4219-24-3 | 2128 | MS, RI, aroma, S | LLE-SAFE | √ | √ | √ | √ | |

| 30 | 3-Ethoxypropionic acid | 4324-38-3 | 1859 | MS, RI | SPME | √ | √ | |||

| 31 | Palmitic acid | 1957/10/3 | MS, aroma, S | LLE-SAFE | √ | √ | √ | √ | ||

| 32 | Tridecanoic acid | 638-53-9 | 1620 | MS, RI, S | SPME | √ | √ | √ | √ | |

| 33 | Citric acid | 77-92-9 | 1730 | MS, RI | SPME | √ | ||||

| Sulfur-containing compounds (27) | ||||||||||

| 1 | Thiazole | 288-47-1 | 1145 | MS, RI | LLE-SAFE | √ | ||||

| 2 | Acetyl Sulfide | 3232-39-1 | 1164 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 3 | 2-(Methylthio)ethanol | 5271-38-5 | 1422 | MS, RI, S | LLE-SAFE | √ | √ | √ | √ | |

| 4 | Dimethyl sulfoxide | 67-68-5 | 1467 | MS, RI, S | LLE-SAFE | √ | √ | √ | √ | |

| 5 | 3-(Methylthio)-1-propanol | 505-10-2 | 1610 | 1714 | MS, RI, aroma, S | LLE-SAFE, SPME | √ | √ | √ | √ |

| 6 | Thioacetic acid | 507-09-5 | 1630 | MS, RI, S | LLE-SAFE | √ | √ | |||

| 7 | S-Ethyl ethanethioate | 625-60-5 | 1704 | MS, RI, S | LLE-SAFE | √ | ||||

| 8 | Dimethyl sulfone | 67-71-0 | 1785 | MS, RI, S | LLE-SAFE | √ | √ | √ | √ | |

| 9 | 4-methyl-5-hydroxyethyl thiazole | 137-00-8 | 2197 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 10 | Methyl p-tolyl sulfone | 3185-99-7 | 2504 | MS, RI | LLE-SAFE | √ | ||||

| 11 | Methyl mercaptan | 74-93-1 | 893 | MS, RI, S | LLE-SAFE | √ | √ | √ | √ | |

| 12 | Tetrahydrothiophene | 110-01-0 | 1679 | MS, RI | SPME | √ | √ | |||

| 13 | Thiophene | 110-02-1 | 1031 | MS, RI, aroma, S | LLE-SAFE, SPME | √ | √ | √ | √ | |

| 14 | 2,3-Dihydrothiophene | 1120-59-8 | 2395 | MS, RI | LLE-SAFE | √ | ||||

| 15 | 2-Thiopheneacetic acid | 1918-77-0 | 1187 | MS, RI | SPME | √ | √ | √ | ||

| 16 | (Butylthio)acetic acid | 20600-61-7 | 1989 | MS, RI | SPME | √ | ||||

| 17 | [(2-Methylpropyl)thio]acetic acid | 20600-62-8 | 2282 | MS, RI | SPME | √ | ||||

| 18 | 3-(n-Butylsulphanyl)propionic acid | 22002-73-9 | 2383 | MS, RI | SPME | √ | ||||

| 19 | 2-Pyrrolidinethione | 2295-35-4 | 1219 | MS, RI | SPME | √ | √ | |||

| 20 | Isothiazole | 288-16-4 | 652 | MS, RI | LLE-SAFE | √ | √ | |||

| 21 | 2-Acetyl-2-thiazoline | 29926-41-8 | 1631 | MS, RI | SPME | √ | ||||

| 22 | 4-Methyl-5-acetyl thiazole | 38205-55-9 | 1349 | MS, RI | SPME | √ | ||||

| 23 | Thiazolidine-4-carboxylic acid | 444-27-9 | 2219 | MS, RI | SPME | √ | √ | √ | ||

| 24 | Thiazolidine | 504-78-9 | 1893 | MS, RI | SPME | √ | ||||

| 25 | Diethyl sulfite | 623-81-4 | 2166 | MS, RI | SPME | √ | √ | √ | ||

| 26 | 5-Methylthio-1,3,4-thiadiazole-2-thiol | 6264-40-0 | 2158 | MS, RI | SPME | √ | ||||

| 27 | Divinyl sulfide | 627-51-0 | 2399 | MS, RI | LLE-SAFE | √ | ||||

| Lactones (24) | ||||||||||

| 1 | α-Methyl-γ-butyrolactone | 1679-47-6 | 1476 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 2 | 4,4-Dimethylbut-2-en-4-olide | 20019-64-1 | 1496 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 3 | γ-Valerolactone | 108-29-2 | 1496 | MS, RI, S | LLE-SAFE | √ | √ | √ | √ | |

| 4 | 3-Methyl-4-butanolide | 1679-49-8 | 1500 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 5 | γ-Butyrolactone | 96-48-0 | 1512 | MS, RI, S | LLE-SAFE | √ | √ | √ | √ | |

| 6 | γ-Hexanolactone | 695-06-7 | 1589 | MS, RI, S | LLE-SAFE | √ | √ | √ | √ | |

| 7 | δ-Hexanolide | 823-22-3 | 1679 | MS, RI, S | LLE-SAFE | √ | √ | √ | √ | |

| 8 | δ-Valerolactone | 542-28-9 | 1688 | MS, RI, S | LLE-SAFE | √ | √ | √ | √ | |

| 9 | 3-Methyl-2-buten-4-olide | 6124-79-4 | 1769 | 1903 | MS, RI | LLE-SAFE | √ | √ | √ | √ |

| 10 | γ-Octalactone | 104-50-7 | 1803 | MS, RI, S | LLE-SAFE | √ | √ | √ | √ | |

| 11 | 3-Methyl-2-penten-5-olide | 2381-87-5 | 1903 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 12 | 4-Nonanolide | 104-61-0 | 1915 | MS, RI, S | LLE-SAFE | √ | √ | √ | √ | |

| 13 | L-(+)-Pantolactone | 5405-40-3 | 1917 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 14 | D-(−)-Pantolactone | 599-04-2 | 1917 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 15 | DL-Pantoyl Lacyone | 79-50-5 | 1917 | MS, RI | LLE-SAFE | √ | ||||

| 16 | 2-Hydroxy-γ-butyrolactone | 19444-84-9 | 2053 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 17 | Dihydroactinidiolide | 15356-74-8 | 2224 | MS, RI, S | LLE-SAFE | √ | √ | √ | √ | |

| 18 | (R)-Dihydro-actinidiolide | 17092-92-1 | 2224 | MS, RI | LLE-SAFE | √ | ||||

| 19 | 5-Hydroxy-4-pentanolide | 32780-06-6 | 2364 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 20 | DL-Mevalonolactone | 674-26-0 | 2428 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 21 | (±)-3-Hydroxy-4-butanolide | 5469-16-9 | 2479 | MS, RI, aroma, S | LLE-SAFE | √ | √ | √ | √ | |

| 22 | β-Butyrolactone | 3068-88-0 | 2531 | MS, RI | LLE-SAFE | √ | ||||

| 23 | Costunolide | 553-21-9 | MS, aroma, S | LLE-SAFE | √ | √ | ||||

| 24 | γ-Decanolactone | 706-14-9 | 2040 | MS, RI, aroma, S | LLE-SAFE | √ | √ | √ | √ | |

| Aldehydes (19) | ||||||||||

| 1 | 3-Methyl-2-butenal | 107-86-8 | 1096 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 2 | Nonanal | 124-19-6 | 1289 | MS, RI, S | LLE-SAFE | √ | √ | |||

| 3 | 1,3,5,7-Tetroxane | 293-30-1 | 1418 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 4 | Methyl glyoxal | 78-98-8 | 1458 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 5 | Glutaraldehyde | 111-30-8 | 1545 | 2353 | MS, RI | LLE-SAFE, SPME | √ | √ | √ | |

| 6 | (Z)-2-Methyl-2-butenal | 1115-11-3 | 1636 | MS, RI | LLE-SAFE | √ | ||||

| 7 | Methacrolein | 78-85-3 | 1686 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 8 | 2-Ethyl-4-pentenal | 5204-80-8 | 2038 | MS, RI | LLE-SAFE | √ | ||||

| 9 | Methoxy acetaldehyde | 10312-83-1 | 2216 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 10 | cis-6-Nonenal | 2277-19-2 | 2517 | MS, RI | LLE-SAFE | √ | ||||

| 11 | Glyoxylic acid | 298-12-4 | 2643 | MS, RI | LLE-SAFE | √ | ||||

| 12 | 2,2-Dimethylocta-3,4-dienal | 590-71-6 | 2796 | MS, RI | LLE-SAFE | √ | ||||

| 13 | 3-Hydroxybutyraldehyde | 107-89-1 | 2929 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 14 | Acetaldehyde | 75-07-0 | 890 | MS, RI, S | LLE-SAFE | √ | √ | √ | √ | |

| 15 | Hexanal | 66-25-1 | 993 | MS, RI | LLE-SAFE | √ | √ | |||

| 16 | trans-2-Nonenal | 18829-56-6 | 1414 | MS, RI, S | SPME | √ | √ | |||

| 17 | Isovaleraldehyde | 590-86-3 | 2047 | MS, RI, S | SPME | √ | ||||

| 18 | (E,E)-2,4-Nonadienal | 5910-87-2 | 1123 | MS, RI | SPME | √ | √ | |||

| 19 | Hexadecanal | 629-80-1 | MS | LLE-SAFE | √ | √ | ||||

| Acetals (2) | ||||||||||

| 1 | 2-Benzyl-1,3-dioxolane | 101-49-5 | 2165 | MS, RI | LLE-SAFE | √ | √ | |||

| 2 | Tetraethylene glycol | 112-60-7 | 2597 | 2144 | MS, RI | LLE-SAFE, SPME | √ | √ | √ | √ |

| Others (37) | ||||||||||

| 1 | Myrcene | 123-35-3 | 1066 | 1056 | MS, RI, S | LLE-SAFE, SPME | √ | √ | √ | |

| 2 | Dimethyl ether | 115-10-6 | 1110 | MS, RI | LLE-SAFE | √ | √ | |||

| 3 | Acetic anhydride | 108-24-7 | 1134 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 4 | 1,3,5,7-Cyclooctatetraene | 629-20-9 | 1152 | MS, RI | LLE-SAFE | √ | ||||

| 5 | 3,5-Dimethylhex-1-ene | 7423-69-0 | 1659 | MS, RI | LLE-SAFE | √ | ||||

| 6 | Ethoxyacetylene | 927-80-0 | 1676 | MS, RI | LLE-SAFE | √ | ||||

| 7 | 1,5-Heptadien-3-yne | 3511-27-1 | 1806 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 8 | Isobutyl anhydride | 97-72-3 | 2012 | MS, RI | LLE-SAFE | √ | √ | |||

| 9 | 2-Methyl-2-butene | 513-35-9 | 2039 | MS, RI, S | LLE-SAFE | √ | √ | √ | √ | |

| 10 | 3-Methylene-nonane | 51655-64-2 | 2039 | MS, RI | LLE-SAFE | √ | ||||

| 11 | Valeric anhydride | 2082-59-9 | 2116 | MS, RI | LLE-SAFE | √ | ||||

| 12 | 2-Methylsuccinic anhydride | 4100-80-5 | 2264 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 13 | 1-Docosene | 1599-67-3 | 2481 | MS, RI | LLE-SAFE | √ | ||||

| 14 | 1-Hexadecene | 629-73-2 | 2481 | MS, RI | LLE-SAFE | √ | ||||

| 15 | 1,4-Dioxane | 123-91-1 | 2713 | MS, RI | LLE-SAFE | √ | ||||

| 16 | Cyclopentene | 142-29-0 | 889 | MS, RI | LLE-SAFE | √ | ||||

| 17 | Propene | 115-07-1 | 908 | MS, RI | LLE-SAFE | √ | √ | √ | √ | |

| 18 | 1,3-Butadiyne | 460-12-8 | 918 | MS, RI | LLE-SAFE | √ | ||||

| 19 | 1-Buten-3-yne | 689-97-4 | 921 | MS, RI | LLE-SAFE | √ | ||||

| 20 | 1-Nonyne | 3452/9/3 | 1115 | MS, RI | SPME | √ | ||||

| 21 | cis-2-Octene | 7642/4/8 | 1292 | MS, RI | SPME | √ | √ | √ | ||

| 22 | Diisopropyl ether | 108-20-3 | 2325 | MS, RI | SPME | √ | √ | √ | ||

| 23 | 2-Pentene | 109-68-2 | 606 | MS, RI, aroma, S | LLE-SAFE | √ | √ | |||

| 24 | 3-Ethyl-3-hexene | 16789-51-8 | 1282 | MS, RI | SPME | √ | ||||

| 25 | β-Pinene | 18172-67-3 | 1040 | MS, RI, S | SPME | √ | √ | √ | ||

| 26 | 2-Methyl-2-hexene | 2738-19-4 | 1412 | MS, RI | SPME | √ | ||||

| 27 | (E)-2-Hexene | 4050-45-7 | 1175 | MS, RI | SPME | √ | ||||

| 28 | Dodecyl ether | 4542-57-8 | MS | LLE-SAFE | √ | √ | √ | |||

| 29 | 3-Methyl-1-butene | 563-45-1 | 605 | MS, RI | LLE-SAFE | √ | √ | √ | ||

| 30 | 1,2-Butadiene | 590-19-2 | 613 | MS, RI | LLE-SAFE | √ | ||||

| 31 | 1-Heptene | 592-76-7 | 1228 | MS, RI, S | SPME | √ | √ | √ | √ | |

| 32 | 1-Octadecyne | 629-89-0 | MS | LLE-SAFE | √ | √ | √ | |||

| 33 | 1,1-Diethoxy-3,7-dimethylocta-2,6-diene | 7492-66-2 | 1216 | MS, RI | SPME | √ | √ | |||

| 34 | 2-Methyl-1-pentene | 763-29-1 | 1050 | MS, RI | SPME | √ | √ | √ | ||

| 35 | 2-Methyl-1,3-butadiene | 78-79-5 | 605 | MS, RI | LLE-SAFE | √ | ||||

| 36 | 1-Undecene | 821-95-4 | 1349 | MS, RI, S | SPME | √ | √ | √ | √ | |

| 37 | Vinyl isopropyl ether | 926-65-8 | 1044 | MS, RI | SPME | √ | √ | |||

| No. | Compound Name | CAS | Sniffing Description | YJ | BW | HR | QD |

|---|---|---|---|---|---|---|---|

| 1 | 4-Vinylguaiacol | 7786-61-0 | Coffee bean, nut shell, sour | 4 | 3 | 1.5 | 3 |

| 2 | γ-Decalactone | 706-14-9 | Sweet, floral, gardenia, creamy | 4 | 4.5 | 4 | 4 |

| 3 | Phenylacetic acid | 103-82-2 | Floral, rose, sweet, grassy | 3.5 | 4 | 2.5 | 2 |

| 4 | Isovaleric acid | 503-74-2 | Sour, durian-like | 3.5 | 3 | 3.5 | 2.5 |

| 5 | 2-Phenylethyl acetate | 103-45-7 | Sweet, floral, fruity | 3 | 2.5 | 3.5 | 1 |

| 6 | Acetic acid | 64-19-7 | Sour, muddy | 3 | 2.5 | 4 | 3 |

| 7 | Octanoic acid | 124-07-2 | Grassy, vegetal | 3 | 2.5 | 2.5 | 2 |

| 8 | Hexyl butyrate | 2639-63-6 | Sweet, floral, honey-like | 2.5 | 2 | 2 | 1.5 |

| 9 | 6-Methyl-5-hepten-2-one | 3658-77-3 | Caramel, sweet | 2.5 | 3 | 2.5 | 2 |

| 10 | Phenylethanol | 1960/12/8 | Rose-like, sweet | 2.5 | 3.5 | 3.5 | 2.5 |

| 11 | Pineapple alcohol | 505-10-2 | Sour, muddy | 2.5 | 2.5 | 3 | 3 |

| 12 | 2,3-Butanediol | 513-85-9 | Roasted, dark wheat | 2 | 1 | - | - |

| 13 | Hexanoic acid | 142-62-1 | Lemon-like, sour, bitter | 2 | 2 | 2.5 | 0.5 |

| 14 | Decanoic acid | 334-48-5 | Sour, hoppy, grassy | 2 | 1.5 | 1.5 | 0.5 |

| 15 | 2-Acetylpyrrole | 1072-83-9 | Malty, sweet, caramel | 1.5 | 2.5 | 1.5 | 1 |

| 16 | Furoic acid | 88-14-2 | Rooty, wheaty | 1.5 | 2 | - | 1.5 |

| 17 | 4-Hydroxyphenylethanol | 501-94-0 | Floral, sweet, fruity | 1.5 | 2 | 3 | 1 |

| 18 | Ethyl propionate | 105-37-3 | Floral, fruity, strawberry-like | 1 | 2 | 1.5 | 1 |

| 19 | Hexacosane | 630-01-3 | Floral, honey-like | 1 | 2 | 0.5 | - |

| 20 | Resorcinol | 108-46-3 | Burnt, sweet | - | 2 | - | - |

| 21 | trans-Oleic acid | 112-79-8 | Dark wheat | - | 2 | - | 2 |

| 22 | 5-Methylpyrrole-2-carboxaldehyde | 1192-79-6 | Rooty | 1.5 | 1.5 | - | - |

| 23 | trans-3-Hexenoic acid | 4219-24-3 | Floral, sweet, burnt | 1.5 | 1.5 | 1 | - |

| 24 | Isoamyl alcohol | 123-51-3 | Nut shell, roasted | 1 | 1.5 | 2 | 1 |

| 25 | Furfuryl alcohol | 98-00-0 | Sour, putrid | 1 | 1.5 | 0.5 | - |

| 26 | Palmitic acid | 1957/10/3 | Dark wheat | 1 | 1.5 | - | - |

| 27 | (±)-3-Hydroxy-4-butyrolactone | 5469-16-9 | Floral, woody | 1 | 1.5 | 1 | 1.5 |

| 28 | Monoethyl succinate | 1070-34-4 | Malty | - | 1.5 | - | - |

| 29 | 2,4-Di-tert-butylphenol | 96-76-4 | Roasted, nut shell, yeasty | 1 | 1 | 1 | 1.5 |

| 30 | Ethyl hexanoate | 123-66-0 | Sweet, fruity, floral | 0.5 | 1 | 1.5 | 1.5 |

| 31 | 4-Hydroxy-2-butanone | 590-90-9 | Floral, oily, sweet | 0.5 | 1 | 2 | 0.5 |

| 32 | Methyl octanoate | 111-12-6 | Dusty, moldy, bitter | - | 1 | 1 | - |

| 33 | 6-(Ethoxycarbonyl)nicotinic acid | 17874-78-1 | Smoky | - | 1 | - | - |

| 34 | (Z)-β-Ionone | 79-77-6 | Floral, sweet | - | 1 | - | 0.5 |

| 35 | Cholestane | 481-21-0 | Roasted, dark wheat | 1 | 0.5 | - | - |

| 36 | 1,2-Propanediol | 57-55-6 | Nut shell | - | 0.5 | - | - |

| 37 | Isoamyl acetate | 123-92-2 | Floral | - | 0.5 | - | - |

| 38 | Tetratetracontane | 7098-22-8 | Nut shell | - | 0.5 | - | - |

| 39 | Methyl decanoate | 110-42-9 | Apple-like, sweet, floral | 1.5 | - | - | 1 |

| 40 | (Z)-9-Octadecenamide | 301-02-0 | Sweet, yeasty | 1 | - | - | 1 |

| 41 | 2,6-Di-tert-butylpyridine | 585-48-8 | Ashy | 1 | - | - | - |

| 42 | 5-Hydroxymethylfurfural | 67-47-0 | Yeasty | 1 | - | - | - |

| 43 | Benzoic acid | 65-85-0 | Ashy | 1 | - | - | - |

| 44 | Lauric acid | 143-07-7 | Fruity | 1 | - | - | - |

| 45 | 2-Hexyl-1-decanol | 2425-77-6 | Floral | 0.5 | - | 0.5 | - |

| 46 | Thiophene | 110-02-1 | Garlic, oily | - | - | 2.5 | - |

| 47 | 2-Hydroxypyridine | 142-08-5 | Hoppy, bitter | - | - | 2 | - |

| 48 | 2-Pentene | 109-68-2 | Burnt, plastic-like | - | - | 2 | - |

| 49 | 2,5-Dimethylphenol | 95-87-4 | Nut shell | - | - | 1 | - |

| 50 | Methyl furoate | 611-13-2 | Nut shell | - | - | 0.5 | - |

| 51 | N-Butylacetamide | 1119-49-9 | Sweet | - | - | - | 1 |

| 52 | Tetratriacontane | 14167-59-0 | Sweet | - | - | - | 2 |

| 53 | Costunolide | 553-21-9 | Floral | - | - | - | 0.5 |

| No. | Compound Name | Odor Threshold (μg/L) | OAV | Taste Threshold (μg/L) | TAV | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| YJ | QD | HR | BW | YJ | QD | HR | BW | ||||

| 1 | Isoamyl acetate | 0.13 | 2,046,526 | 1,217,009 | 4,338,735 | 2,821,490 | 2.63 | 102,326 | 60,850 | 216,937 | 141,074 |

| 2 | Ethyl hexanoate | 4.35 | 8113 | 6941 | 4690 | 10,366 | 4.35 | 8113 | 6941 | 4690 | 10,366 |

| 3 | Ethyl propanoate | 8.88 | 4468 | 2403 | 6090 | 5094 | 8.88 | 4468 | 2403 | 6090 | 5094 |

| 4 | Hexyl butanoate | 172.75 | 1354 | 718 | 1797 | 1547 | — | — | — | — | — |

| 5 | Methyl decanoate | 3.75 | 19,448 | 16,822 | 29,701 | 45,970 | 871.00 | 84 | 72 | 128 | 198 |

| 6 | Ethyl octanoate | 16.73 | 105 | 30 | 79 | 97 | 0.09 | 20,170 | 5840 | 15,231 | 18,693 |

| 7 | Ethyl decanoate | 4.31 | 249 | — | 320 | 634 | 17.24 | 62 | — | 80 | 158 |

| 8 | Isoamyl butyrate | 12.93 | 3658 | — | — | — | — | — | — | — | — |

| 9 | Ethyl trans-2-decenoate | 10,000.00 | — | — | <1 | — | — | — | — | — | — |

| 10 | Octyl acetate | 0.04 | 99 | 22 | — | — | 182.28 | 22 | 5 | — | — |

| 11 | Ethyl stearate | 0.53 | 26 | 23 | 12 | 27 | — | — | — | — | — |

| 12 | Ethyl isovalerate | 0.10 | — | 31,502 | — | — | 0.17 | — | 17,326 | — | — |

| 13 | Ethyl myristate | 3440.00 | 1 | <1 | <1 | 1 | — | — | — | — | — |

| 14 | Ethyl lactate | 51,550.00 | <1 | <1 | <1 | <1 | 257,750.00 | <1 | <1 | <1 | <1 |

| 15 | Ethyl acetate | 50.00 | 11,099 | 8987 | 10,306 | 7351 | 6765.00 | 82 | 66 | 76 | 54 |

| 16 | Ethyl heptanoate | 1.65 | 350 | 409 | 254 | 623 | 147.90 | 4 | 5 | 3 | 7 |

| 17 | Hexyl acetate | 20.00 | 286 | 392 | 574 | 551 | 34.80 | 164 | 225 | 330 | 317 |

| 18 | Diethyl succinate | 104,700.00 | <1 | <1 | <1 | <1 | 1,094,115.00 | <1 | <1 | <1 | <1 |

| 19 | Butyl acetate | 51.04 | — | — | 13 | 14 | 88.00 | — | — | 8 | 8 |

| 20 | Ethyl 3-hydrobutyrate | 1000.00 | — | — | <1 | <1 | — | — | — | — | — |

| 21 | Ethyl nonanoate | 326.48 | 7 | 2 | 9 | 16 | 1039.20 | 2 | 1 | 3 | 5 |

| 22 | Ethyl hydrogen succinate | 1,141,000.00 | <1 | <1 | <1 | <1 | 1,369,200.00 | <1 | <1 | <1 | <1 |

| 23 | Ethyl valerate | 5.08 | 774 | 679 | 596 | 623 | 787.50 | 5 | 4 | 4 | 4 |

| 24 | Methyl 2-octynate | 23.00 | — | — | 721 | 575 | — | — | — | — | — |

| 25 | (−)-Ethyl L-lactate | — | — | — | — | — | — | — | — | — | — |

| 26 | 2-Hydroxyethyl acetate | — | — | — | — | — | — | — | — | — | — |

| 27 | Propyl acetate | 1776.00 | <1 | <1 | — | — | 710.40 | 1 | <1 | — | — |

| 28 | 2,3-Dihydroxypropyl acetate | — | — | — | — | — | 1,616,040.00 | <1 | <1 | <1 | <1 |

| 29 | Methyl propionate | 4209.00 | — | <1 | — | — | 53.07 | — | 73 | — | — |

| 30 | Isopropyl formate | — | — | — | — | — | — | — | — | — | — |

| 31 | Ethyl dodecanoate | 5091.70 | 1 | — | <1 | — | 284.79 | 24 | — | 17 | — |

| 32 | Ethyl 3-hexenoate | 10,000.00 | 3 | — | <1 | <1 | — | — | — | — | — |

| 33 | Ethyl butyrylacetate | — | — | — | — | — | — | — | — | — | — |

| 34 | Ethyl 3-methylvalerate | — | — | — | — | — | — | — | — | — | — |

| 35 | Ethyl undecanoate | — | — | — | — | — | 859.00 | 56 | — | 3 | — |

| 36 | (+)-Diethyl L-tartrate | — | — | — | — | — | — | — | — | — | — |

| 37 | 2,3-Butaneiol | 100,200.00 | 2 | <1 | 4 | 5 | 50,100.00 | 5 | 1 | 8 | 11 |

| 38 | 3-Methyl-1-butanol | 792.82 | 710 | 531 | 1045 | 913 | 202.25 | 2785 | 2082 | 4098 | 3579 |

| 39 | 1,2,3-Propanetriol | 25,000,000.00 | <1 | <1 | <1 | <1 | 6,562,500.00 | <1 | <1 | <1 | <1 |

| 40 | 2-Methyl-1-propanol | 11.00 | 14,796 | 12,246 | 15,732 | 6183 | 8.83 | 18,426 | 15,251 | 19,592 | 7700 |

| 41 | Diisobutylcarbinol | 1051.70 | — | — | 3 | 2 | — | — | — | — | — |

| 42 | 1-Butanol | 3483.00 | 3 | <1 | <1 | <1 | 162,000.00 | <1 | <1 | <1 | <1 |

| 43 | 1-Octanol | 104.04 | 4 | 5 | 11 | 8 | 44.66 | 10 | 11 | 27 | 18 |

| 44 | 1-Pentanol | 121.81 | 2030 | 1596 | 2460 | 2104 | 64,880.00 | 4 | 3 | 5 | 4 |

| 45 | 3-Methyl-3-buten-1-ol | 466.70 | <1 | <1 | <1 | <1 | — | — | — | — | — |

| 46 | α-Terpineol | 1116.00 | <1 | <1 | <1 | — | 279.00 | 2 | 2 | 1 | — |

| 47 | 2-Ethyl-1-hexanol | 21,227.00 | — | — | — | <1 | — | — | — | — | — |

| 48 | 4-Methyl-1-pentanol | 673.22 | 1 | — | — | 99 | — | — | — | — | — |

| 49 | 1,2-Propylene glycol | 352,240.00 | <1 | <1 | <1 | <1 | 1,450,400.00 | <1 | <1 | <1 | <1 |

| 50 | 2-Hexyl-1-decanol | — | — | — | — | — | — | — | — | — | — |

| 51 | 1-Hexanol | 318.27 | 10 | 24 | 13 | 10 | 162.80 | 20 | 47 | 26 | 20 |

| 52 | Linalool | 941.34 | 71 | 6 | 3 | — | 23.49 | 2854 | 242 | 114 | — |

| 53 | 1-Decanol | 642.48 | — | 16 | 16 | — | 19.07 | — | 548 | 536 | — |

| 54 | Diethylene glycol monoethyl ether | — | — | — | — | — | 47,952.00 | <1 | <1 | <1 | <1 |

| 55 | (−)-Isolongifolol | — | — | — | — | — | — | — | — | — | — |

| 56 | Phytol | — | — | — | — | — | — | — | — | — | — |

| 57 | β-Eudesmol | — | — | — | — | — | — | — | — | — | — |

| 58 | Guaiol | — | — | — | — | — | — | — | — | — | — |

| 59 | 2,6-Dimethyl-5,7-octadien-2-ol | — | — | — | — | — | — | — | — | — | — |

| 60 | Phenethyl alcohol | 397.80 | 5968 | 3462 | 8289 | 4426 | 50,100.00 | 5 | 1 | 8 | 11 |

| 61 | 2-Phenylethyl acetate | 257.58 | 100 | 16 | 231 | 72 | 102,000.00 | 23 | 14 | 32 | 17 |

| 62 | Phenol | 59,000.00 | <1 | <1 | <1 | <1 | 20.64 | 1248 | 205 | 2877 | 894 |

| 63 | Benzeneacetaldehyde | 6.80 | 4206 | 5867 | 990 | 633 | 5890.50 | <1 | <1 | 1 | 1 |

| 64 | Benzyl alcohol | 2660.80 | <1 | <1 | <1 | <1 | 9.71 | 2944 | 4107 | 693 | 443 |

| 65 | Ethyl benzoate | 58.06 | 615 | — | — | — | 5747.50 | <1 | <1 | <1 | <1 |

| 66 | Benzaldehyde | 783.93 | — | — | 2 | — | 313,500.00 | <1 | — | — | — |

| 67 | 2,4-Di-tert-butylphenol | 443.50 | 18 | 157 | 73 | 88 | 313.20 | — | — | 5 | — |