Agaricus bisporus Grown on Sustainable Peat Casing Alternatives—A Systematic Review on Quality Characteristics

Abstract

1. Introduction

1.1. The Casing Layer

1.2. Quality Criteria

2. Materials and Methods

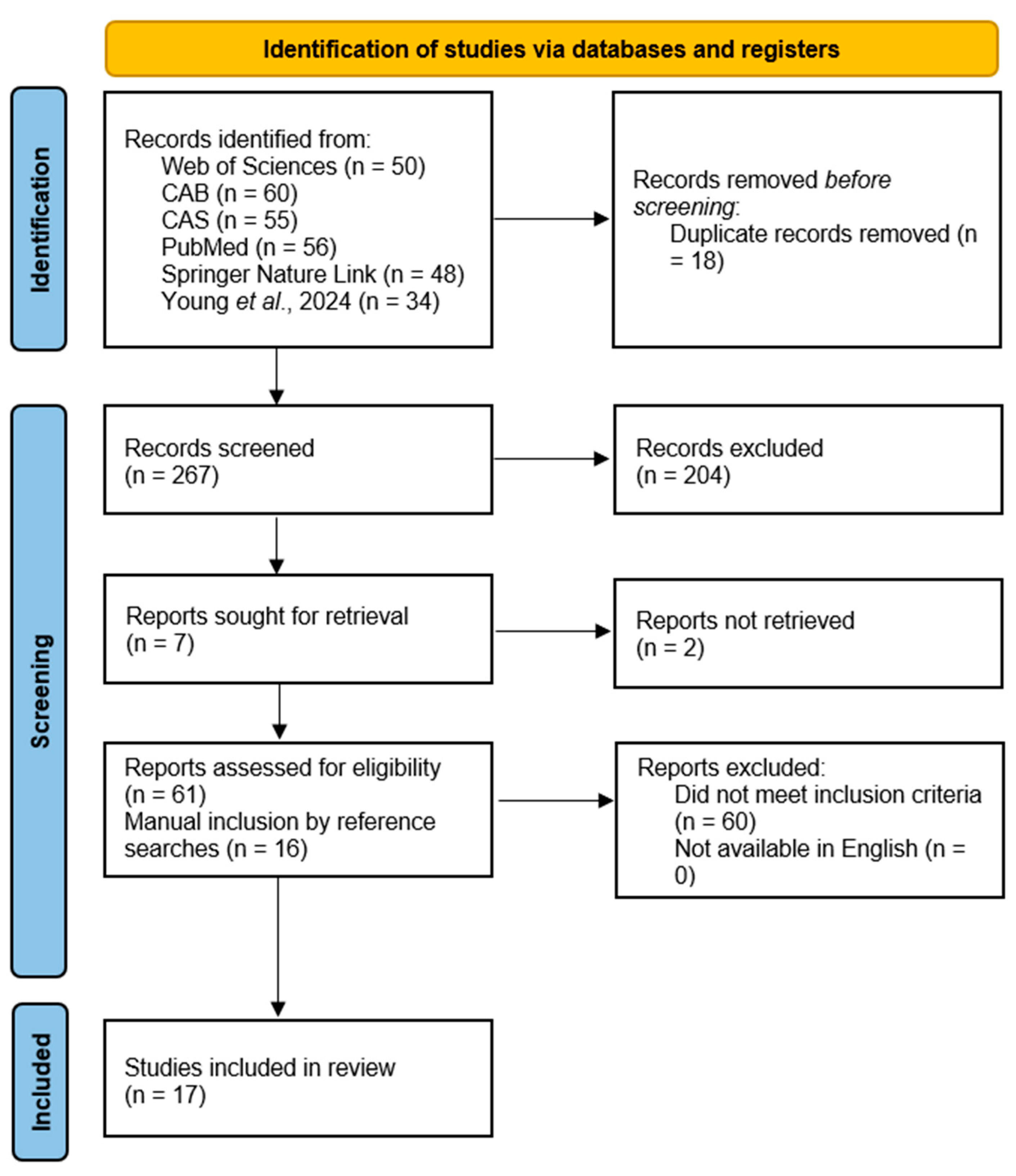

2.1. Search Strategy and Database Creation

2.2. Evaluation of Quality Criteria and Data Extraction

3. Results

3.1. Study Selection

3.2. Overview of the Identified Studies

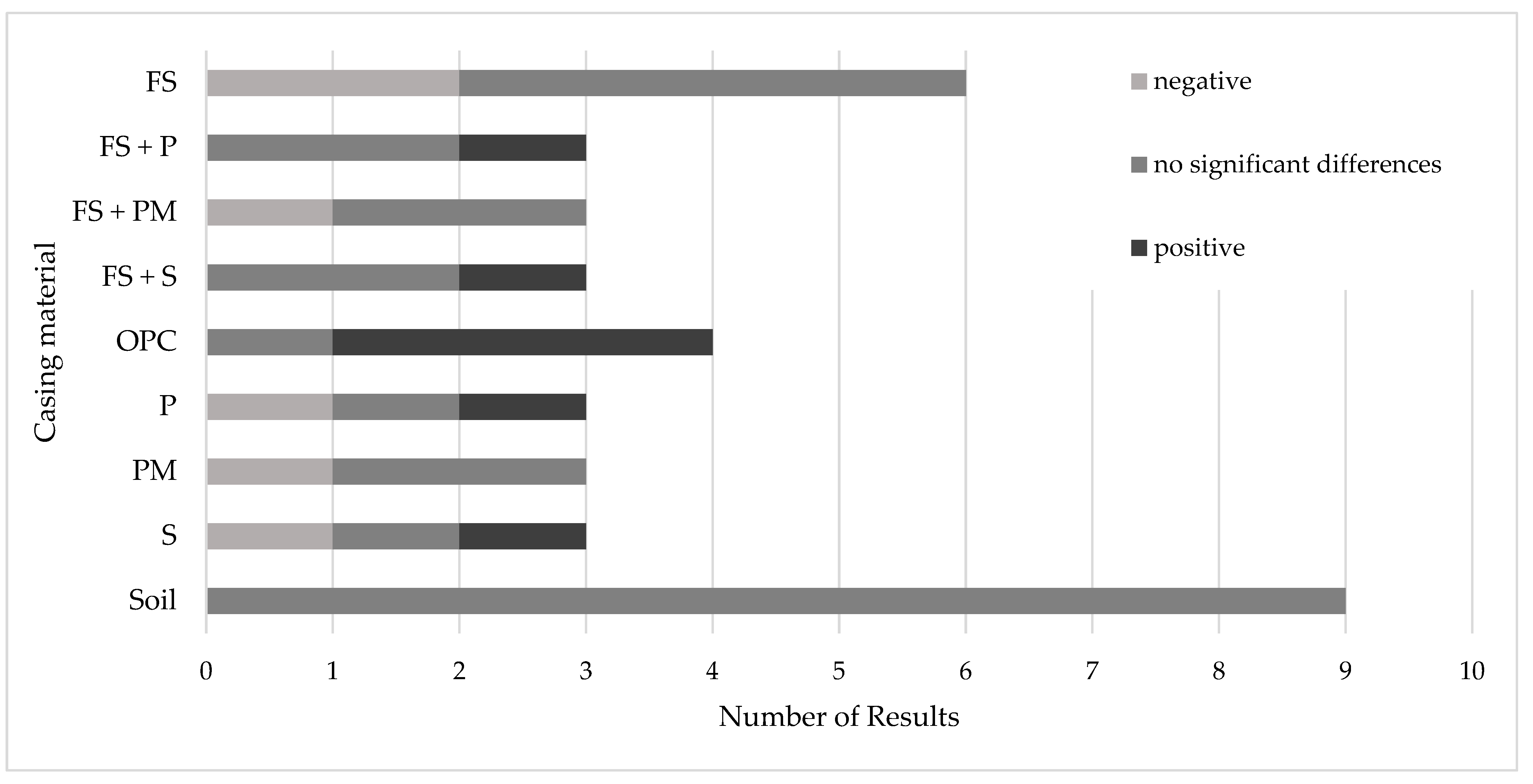

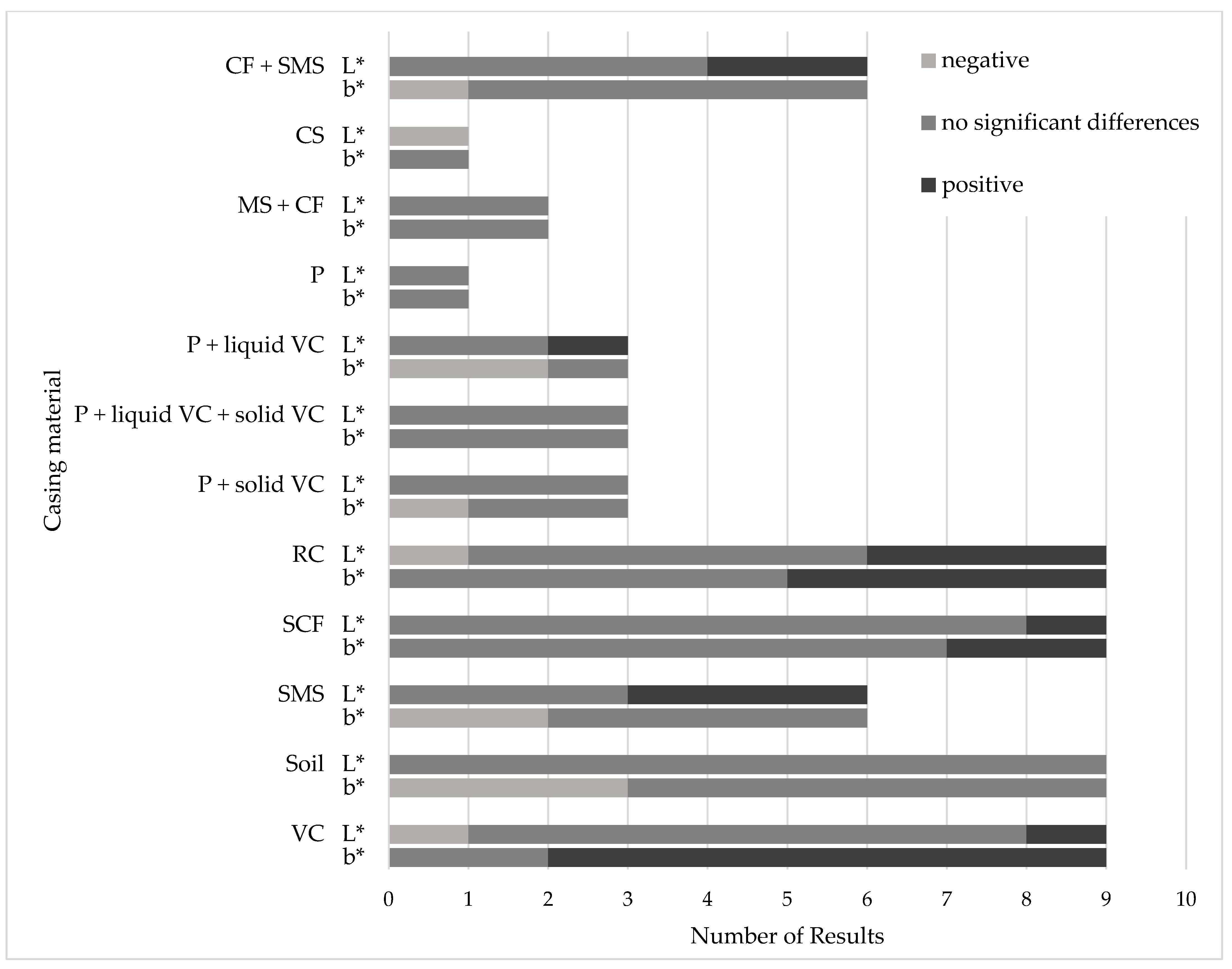

3.3. Peat Substitutes

3.4. Chemical Composition

3.4.1. Organic and Inorganic Matter

3.4.2. Nutrients

3.4.3. Contaminants and Heavy Metals

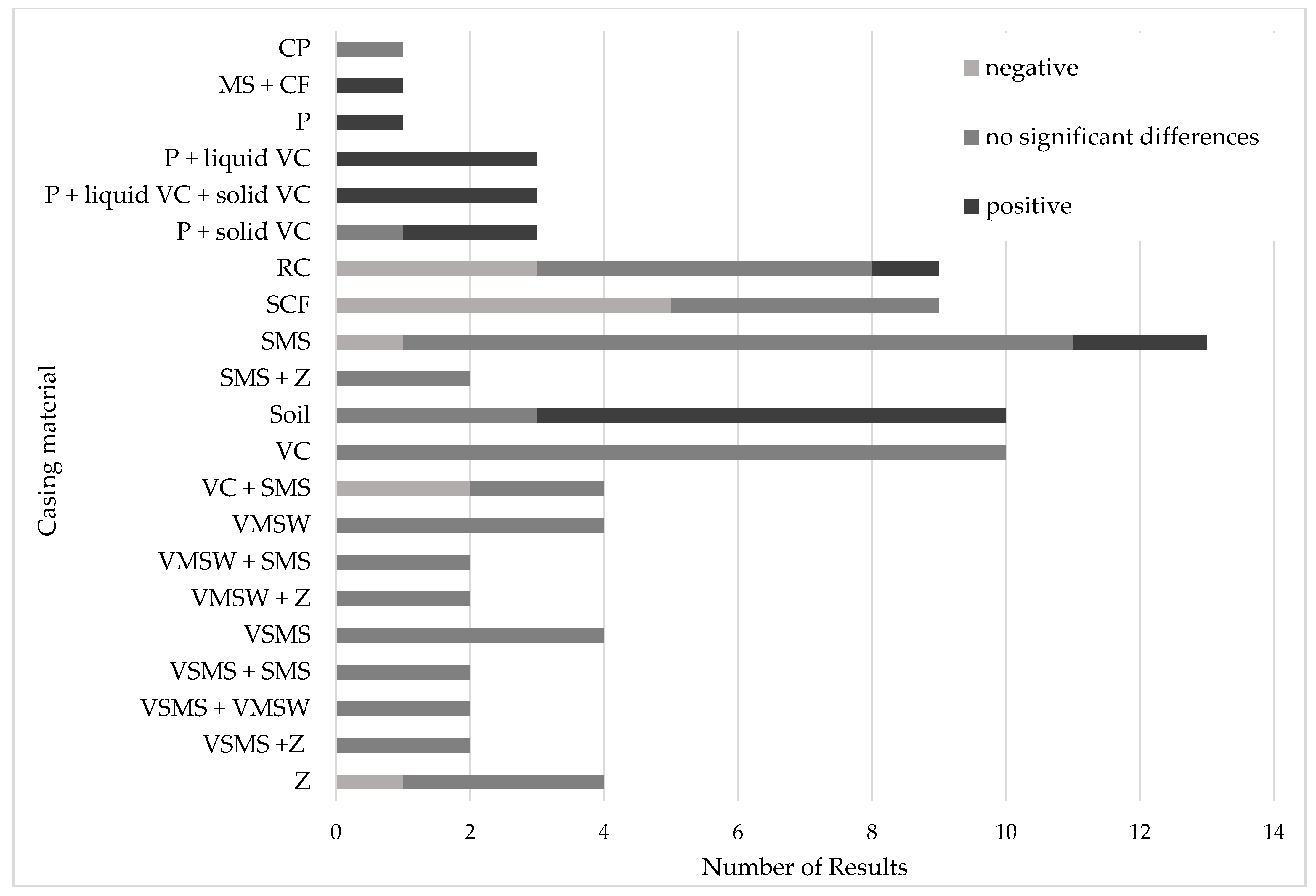

3.5. Phenotypic Features

3.5.1. Size and Weight

3.5.2. Color

3.5.3. Firmness and Texture

3.5.4. Marketability

4. Discussion

4.1. Chemical Composition

4.2. Phenotypic Features

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| A. bisporus | Agaricus bisporus |

| Ca | Calcium |

| CF | Coconut fiber pith |

| CP | Coconut peat |

| CSMS | Spent mushroom substrate compost |

| Cu | Copper |

| Fe | Iron |

| GWC | Green waste compost |

| K | Potassium |

| Mg | Magnesium |

| Mn | Manganese |

| OPC | Olive press cake |

| P | Phosphorus |

| RC | Rose oil processing waste compost |

| SCF | Spent coconut fiber |

| SMS | Spent mushroom substrate |

| UNECE | United Nations Economic Commission for Europe |

| VC | Vermicompost |

| VSMS | Spent mushroom substrate vermicompost |

| VMSW | Municipal solid waste vermicompost |

| Zn | Zinc |

Appendix A

References

- Gow, N.A.R.; Latge, J.P.; Munro, C.A. The Fungal Cell Wall: Structure, Biosynthesis, and Function. Microbiol. Spectr. 2017, 5, 10-1128. [Google Scholar] [CrossRef]

- Singh, M.; Kamal, S.; Sharma, V.P. Status and trends in world mushroom production-III -World Production of Different Mushroom Species in 21st Century. Mush Res. 2021, 29. [Google Scholar] [CrossRef]

- Royse, D.J.; Baars, J.; Tan, Q. Current Overview of Mushroom Production in the World. In Edible and Medicinal Mushrooms; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2017; pp. 5–13. [Google Scholar] [CrossRef]

- Atila, F.; Nadhim Owaid, M.; Ali Shariati, M. The nutritional and medical benefits of Agaricus bisporus: A Review. J. Microbiol. Biotechnol. Food Sci. 2017, 7, 281–286. [Google Scholar] [CrossRef]

- Vetter, J. Chitin content of cultivated mushrooms Agaricus bisporus, Pleurotus ostreatus and Lentinula edodes. Food Chem. 2007, 102, 6–9. [Google Scholar] [CrossRef]

- Zivanovic, S.; Busher, R.W.; Kim, K.S. Textural Changes in Mushrooms (Agaricus bisporus) Associated with Tissue Ultrastructure and Composition. J. Food Sci. 2000, 65, 1404–1408. [Google Scholar] [CrossRef]

- Sajyan, T.K.; Fayssal, S.A.; Bejjani, R.; El-Sebaaly, Z.; Sassine, Y.N. Casing and cropping. In Mushrooms: Agaricus Bisporus; Sassine, Y.N., Ed.; CABI: Wallingford, UK, 2021; pp. 240–296. [Google Scholar]

- De Juan, J.A.; Pardo, J.E.; Pardo, A. Effect of different casing materials on production and quality of the cultivated mushroom. Adv. Hort. Sci. 2003, 17, 141–148. [Google Scholar]

- Noble, R.; Dobrovin-Pennington, A. Partial substitution of peat in mushroom casing with fine particle coal tailings. Sci. Hortic. 2005, 104, 351–367. [Google Scholar] [CrossRef]

- Taparia, T.; Hendrix, E.; Nijhuis, E.; de Boer, W.; van der Wolf, J. Circular alternatives to peat in growing media: A microbiome perspective. J. Clean. Prod. 2021, 327, 129375. [Google Scholar] [CrossRef]

- Harenda, K.M.; Lamentowicz, M.; Samson, M.; Chojnicki, B.H. The Role of Peatlands and their Carbon Storage Function in the Context of Climate Change. In Interdisciplinary Approaches for Sustainable Development Goals. GeoPlanet: Earth and Planetary Sciences; Zielinski, T., Sagan, I., Surosz, W., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 169–187. [Google Scholar] [CrossRef]

- Poudel, P.; Duenas, A.E.K.; Di Gioia, F. Organic waste compost and spent mushroom compost as potential growing media components for the sustainable production of microgreens. Front. Plant Sci. 2023, 14, 1229157. [Google Scholar] [CrossRef]

- Noble, R.; Grogan, H.; Corbett, E.; Seymour, G. The Future of Casing—Review of Casing Materials and Availability of Peat for Mushroom Cultivation. In AMGA Casing Review Report 2023. 2023. Available online: https://Isms.biz/Web/Web/Library/AMGA%20Casing%20Review%20Report%202023.aspx?hkey=ed8c4010-014c-4d47-abc3-c8502276cea2,%20zuletzt%20aktualisiert%20am%2012.11.2024,%20zuletzt%20gepr%C3%BCft%20am%2012.11.2024 (accessed on 13 July 2025).

- Seaby, D. The Influence on Yield of Mushrooms (Agaricus bisporus) of the Casing Layer Pore Space Volume and Ease of Water Uptake. Compost. Sci. Util. 1999, 7, 56–65. [Google Scholar] [CrossRef]

- Siyoum, N.A.; Surridge, K.; Korsten, L. Bacterial profiling of casing materials for white button mushrooms (Agaricus bisporus) using denaturing gradient gel electrophoresis. S. Afr. J. Sci. 2010, 106, 1–6. [Google Scholar] [CrossRef]

- Cetin, M.; Atila, F.; Eren, E. Valorization of olive press cake as a sustainable alternative to peat in white button mushroom (Agaricus bisporus) cultivation. Biomass Conv. Bioref. 2025, 15, 20589–20599. [Google Scholar] [CrossRef]

- Dias, E.S.; Zied, D.C.; Pardo-Gimenez, A. Revisiting the casing layer: Casing materials and management in Agaricus mushroom cultivation. Ciênc. E Agrotecnol. 2021, 45, e0001R21. [Google Scholar] [CrossRef]

- Pardo-Giménez, A.; Pardo González, J.E.; Zied, D.C. Casing Materials and Techniques in Agaricus bisporus Cultivation. In Edible and Medicinal Mushrooms; Zied, D.C., Pardo-Giménez, A., Eds.; John Wiley & Sons Ltd.: West Sussex, UK, 2017; pp. 149–174. [Google Scholar] [CrossRef]

- Commission Delegated Regulation (EU) 2023/2429 of 17 August 2023 supplementing Regulation (EU) No 1308/2013 of the European Parliament and of the Council as regards marketing standards for the fruit and vegetables sector, certain processed fruit and vegetable products and the bananas sector, and repealing Commission Regulation (EC) No 1666/1999 and Commission Implementing Regulations (EU) No 543/2011 and (EU) No 1333/2011. Official Journal of the European Union. L 2023/2429, 03.11.2023. Available online: https://eur-lex.europa.eu/eli/reg_del/2023/2429/oj/eng (accessed on 24 September 2025).

- United Nations Economic Commission for Europe. UNECE Standard FFV-24 Concerning the Marketing and Commercial Quality Control of Cultivated Mushrooms; UNCECE: Geneva, Switzerland, 2023. [Google Scholar]

- Sener, S. Effect of Seagrass Mixed with Casing Soil for the Cultivation of Mushrooms and Study of Bioaccumulation of Heavy Metals. At. Spectrosc. 2019, 40, 188–192. [Google Scholar] [CrossRef]

- Commission Regulation (EU) 2023/915 of 25 April 2023 on maximum levels for certain contaminants in food and repealing Regulation (EC) No 1881/2006. Official Journal of the European Union. L 119/103, 05.05.2023. Available online: https://eur-lex.europa.eu/eli/reg/2023/915/oj/eng (accessed on 24 September 2025).

- Mushrooms Grades and Standards, Agricultural Marketing Service, USDA. Available online: www.ams.usda.gov/grades-standards/mushrooms-grades-and-standards (accessed on 30 July 2025).

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Young, G.; Grogan, H.; Walsh, L.; Noble, R.; Tracy, S.; Schmidt, O. Peat alternative casing materials for the cultivation of Agaricus bisporus mushrooms—A systematic review. Clean. Circ. Bioeconomy 2024, 9, 100100. [Google Scholar] [CrossRef]

- Askari-Khorasgani, O.; Jafarpour, M.; Golparvar, A.R. The effects of various casing materials on yield and quantitative indices of Agaricuss ubrufescens and Agaricuss bisporus. J. Biodivers. Environ. Sci. (JBES) 2015, 6, 60–67. [Google Scholar]

- Colak, M.; Baysal, E.; Simsek, H.; Toker, H.; Yilmaz, F. Cultivation of Agaricus bisporus on wheat straw and waste tea leaves based composts and locally available casing materials Part III: Dry matter, protein, and carbohydrate contents of Agaricus bisporus. Afr. J. Biotechnol. 2007, 6, 2855–2859. [Google Scholar] [CrossRef]

- Duran, H.; Peksen, A.; Eren, E. Vermicompost, rose oil processing waste compost, and spent coconut fiber as casing material in button mushroom cultivation. Biomass Convers. Biorefinery 2022, 13, 4317–4329. [Google Scholar] [CrossRef]

- Ghasemi, K.; Emadi, M.; Bagheri, A.; Mohammadi, M. Casing Material and Thickness Effects on the Yield and Nutrient Concentration of Agaricus bisporus. Sarhad J. Agric. 2020, 36, 958–965. [Google Scholar] [CrossRef]

- Goldwater, A. Recycled green waste compost as an alternative to peat in mushroom casing. In Proceedings of the Nineteenth International Scientific Congress on the Cultivation of Edible Fungi, online, 14–17 September 2021. [Google Scholar]

- Moctezuma-Perez, I.; Dominguez-Gutierrez, M.; Colorado-Moreno, A.; Gaitan-Hernandez, R. Potential use of vermicompost of spent mushroom substrate as casing layer. In Proceedings of the Nineteenth International Scientific Congress on the Cultivation of Edible Fungi, online, 14–17 September 2021. [Google Scholar]

- Pardo, A.; de Juan, A.; Alvarez-Ortí, M.; Pardo, J.E. Screening of Agaricus bisporus (Lange, Imbach) Strains and the Casing Variables for Quality Mushroom Production in Spain. HortScience 2010, 45, 231–235. [Google Scholar] [CrossRef]

- Pardo-Giménez, A.; Pardo-González, J.E. Evaluation of casing materials made from spent mushroom substrate and coconut fibre pith for use in production of Agaricus bisporus (Lange) Imbach. Span. J. Agric. Res. 2008, 6, 683–690. [Google Scholar] [CrossRef]

- Pardo-Giménez, A.; Pardo-González, J.E.; Zied, D.C. Evaluation of harvested mushrooms and viability of Agaricus bisporus growth using casing materials made from spent mushroom substrate. Int. J. Food Sci. Technol. 2011, 46, 787–792. [Google Scholar] [CrossRef]

- Polat, E.; Onel, O. An alternative new casing material in the production of Agaricus bisporus. Mediterr. Agric. Sci. 2021, 34, 261–266. [Google Scholar] [CrossRef]

- Riahi, H.; Zamani, H. Use of spent mushroom compost and composted azolla as an alternative for casing soil. Mushroom Sci. 2008, 17, 333–339. [Google Scholar]

- Sassine, Y.; Ghora, Y.; Kharrat, M.; Boehme, M.; Abdel-Mawgoud, A. Waste Paper as an Alternative for Casing Soil in Mushroom (Agaricus bisporus) Production. J. Appl. Sci. Res. 2005, 1, 277–284. [Google Scholar]

- Shandilya, T.R. Studies on casing soil media during the cultivation of Agaricus bisporus. Mushroom Sci. 1989, 12, 387–400. [Google Scholar]

- Young, L.S.; Chu, J.N.; Young, C.C. Beneficial bacterial strains on Agaricus blazei cultivation. Pesqui. Agropecuária Bras. 2012, 47, 815–821. [Google Scholar] [CrossRef]

- Gupta, S.; Summuna, B.; Gupta, M.; Annepu, S.K. Edible Mushrooms: Cultivation, Bioactive Molecules, and Health Benefits. In Bioactive Molecules in Food; Mérillon, J.M., Ramawat, K.G., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 1–33. [Google Scholar] [CrossRef]

- Budzyńska, S.; Siwulski, M.; Budka, A.; Kalač, P.; Niedzielski, P.; Gąsecka, M.; Mleczek, M. Mycoremediation of Flotation Tailings with Agaricus bisporus. J. Fungi 2022, 8, 883. [Google Scholar] [CrossRef]

- Domínguez-Gutiérrez, M.; Gaitán-Hernández, R.; Moctezuma-Pérez, I.; Barois, I.; Domínguez, J. Composting and vermicomposting of spent mushroom substrate to produce organic fertilizer. Emir. J. Food Agric. 2022, 34, 220–228. [Google Scholar] [CrossRef]

- Noble, R.; Dobrovin-Pennington, A. Physicochemical characterisation of casings in relation to mushroom (Agaricus bisporus) cropping performance. Fungal Biol. 2024, 128, 1698–1704. [Google Scholar] [CrossRef] [PubMed]

- Uccello, A.; Gernon, D.; Grogan, H. Colour quality assessment in white Agaricus bisporus mushrooms. Mushroom Sci. 2024, 20, 14. [Google Scholar]

| Category | Inclusion | Exclusion |

|---|---|---|

| Comparator | Control group using peat casing | Absence of a control group |

| Study Design | Experimental, with controlled growth trials | Study design without replicates |

| Species | Agaricus sp. with no restriction based on variety or size at harvest | Edible or medicinal fungal species that are not members of the genus Agaricus |

| Experiment | Mushrooms grown using peat alternative casing. This can either be a partial or complete substitution, with no limitation on precise composition | Mushrooms grown exclusively on peat |

| Data | The observation of at least one quality parameter was undertaken (e.g., fruiting body color, nutrients of the fruiting body, marketable size of the fruiting body) | Quality parameters of the fruiting body were not addressed |

| References | Organic/ Inorganic Matter | Nutrients | Contaminants/Heavy Metal | Size/Weight | Color | Firmness/ Texture | Marketability |

|---|---|---|---|---|---|---|---|

| Askari-Khorasgani et al. (2015) [26] | X | X | |||||

| Cetin et al. (2025) [16] | X | X | |||||

| Colak et al. (2007) [27] | X | X | |||||

| Duran et al. (2023) [28] | X | X | X | ||||

| Ghasemi et al. (2020) [29] | X | X | |||||

| Goldwater (2021) [30] | X | ||||||

| Moctezuma-Pérez et al. (2021) [31] | X | ||||||

| Noble and Dobrovin-Pennington (2005) [9] | X | X | |||||

| Pardo et al. (2010) [32] | X | X | X | X | X | X | |

| Pardo-Giménez and Pardo-Gonzáles (2008) [33] | X | X | X | X | |||

| Pardo-Gimenéz et al. (2011) [34] | X | X | X | X | |||

| Polat and Onel (2021) [35] | X | X | X | X | |||

| Riahi and Zamani (2008) [36] | X | X | |||||

| Sassine et al. (2005) [37] | X | ||||||

| Seaby (1999) [14] | X | ||||||

| Shandilya (1989) [38] | X | X | X | ||||

| Young et al. (2012) [39] | X | ||||||

| Number of publications. | 11 | 6 | 1 | 10 | 6 | 4 | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dissemond, M.H.; Franken, C.E.; Sari, M. Agaricus bisporus Grown on Sustainable Peat Casing Alternatives—A Systematic Review on Quality Characteristics. Foods 2025, 14, 3348. https://doi.org/10.3390/foods14193348

Dissemond MH, Franken CE, Sari M. Agaricus bisporus Grown on Sustainable Peat Casing Alternatives—A Systematic Review on Quality Characteristics. Foods. 2025; 14(19):3348. https://doi.org/10.3390/foods14193348

Chicago/Turabian StyleDissemond, Mareike Helena, Charlotte Elisabeth Franken, and Miriam Sari. 2025. "Agaricus bisporus Grown on Sustainable Peat Casing Alternatives—A Systematic Review on Quality Characteristics" Foods 14, no. 19: 3348. https://doi.org/10.3390/foods14193348

APA StyleDissemond, M. H., Franken, C. E., & Sari, M. (2025). Agaricus bisporus Grown on Sustainable Peat Casing Alternatives—A Systematic Review on Quality Characteristics. Foods, 14(19), 3348. https://doi.org/10.3390/foods14193348