Evaluating the Impact of Lactobacillus acidophilus on Fusarium Mycotoxins in Raw Vegan Pumpkin–Sunflower Seed Flour Blends

Abstract

1. Introduction

2. Materials and Methods

2.1. Media

2.2. Microbiological Analysis of Ingredients for MHT Blend Production

2.3. Preparation of Inoculum

2.4. The Preparation of MHT Blend and Inoculation of Lactobacillus acidophilus and Fusarium langsethiae

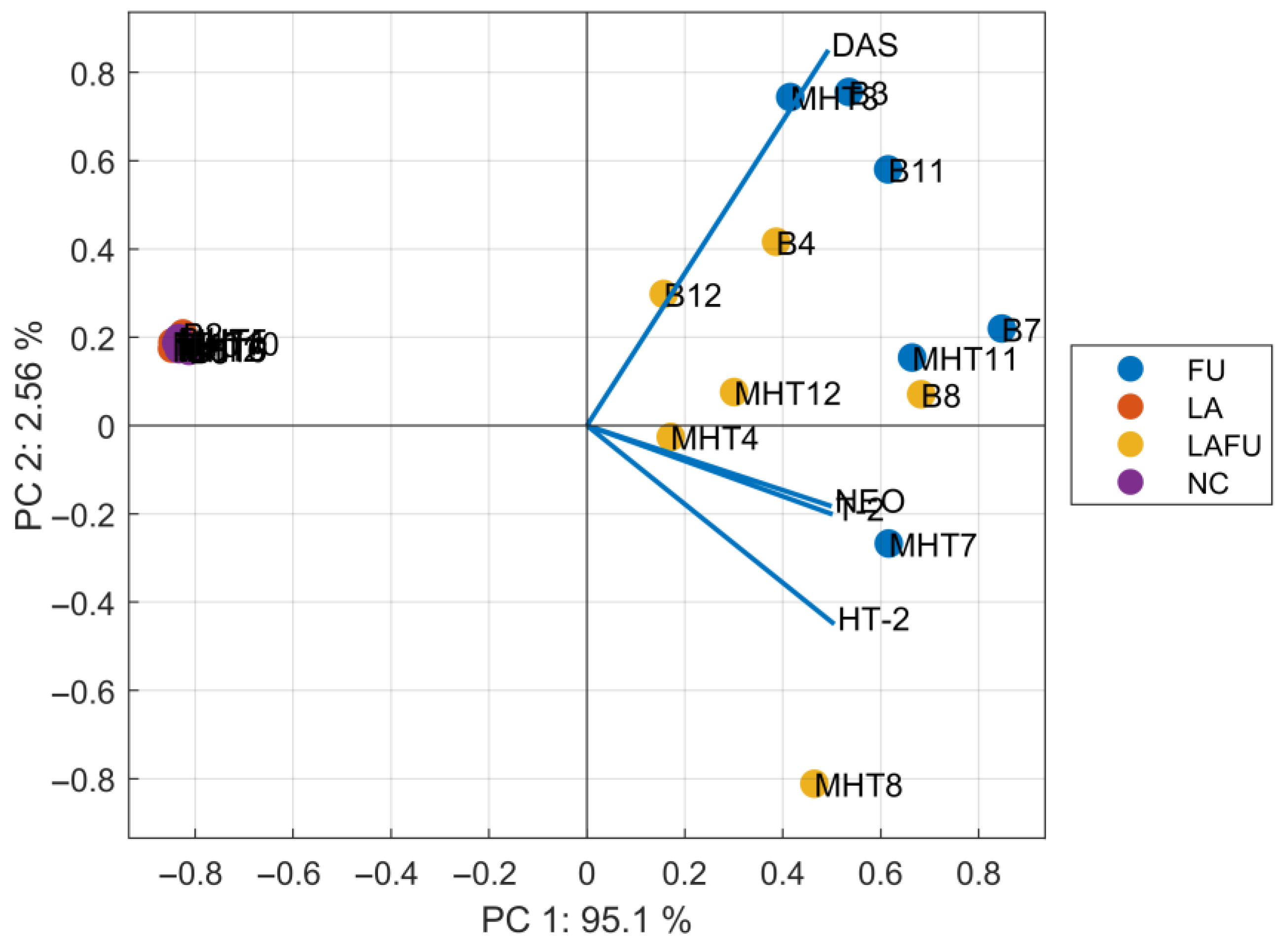

2.5. Analysis of Mycotoxins

2.6. Moisture Content and Water Activity

2.7. Total Phenolic Content and Antioxidant Activity

2.8. Statistical Analysis

3. Results and Discussion

3.1. The Microbial Load in Ingredients for Blend and MHT Blend Production

3.2. Moisture Content and Water Activity of Blends

3.3. Total Phenolic Content and Antioxidant Activity of Blends

3.4. Mycotoxin Content in Blend and HMT Blend

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Desmond, M.A.; Sobiecki, J.G.; Jaworski, M.; Płudowski, P.; Antoniewicz, J.; Shirley, M.K.; Eaton, S.; Książyk, J.; Cortina-Borja, M.; De Stavola, B.; et al. Growth, body composition, and cardiovascular and nutritional risk of 5- to 10-y-old children consuming vegetarian, vegan, or omnivore diets. Am. J. Clin. Nutr. 2021, 113, 1565–1577. [Google Scholar] [CrossRef]

- Marrone, G.; Guerriero, C.; Palazzetti, D.; Lido, P.; Marolla, A.; Di Daniele, F.; Noce, A. Vegan diet health benefits in metabolic syndrome. Nutrients 2021, 13, 817. [Google Scholar] [CrossRef]

- Ferrarová, E.; Faltusová, K.; Goerojová, K.; Kašparová, M.; Matějíčková, P.; Moravcová, A.; Poulová, V.; Vlčková, E. Crisis of cultural patterns and new trends in alimentation in terms of anthropology of food. Anthropol. Integr. 2019, 10, 7–16. [Google Scholar] [CrossRef]

- Raba, D.-N.; Iancu, T.; Bordean, D.-M.; Adamov, T.; Popa, V.-M.; Pîrvulescu, L.C. Pros and cons of raw vegan diet. Adv. Res. Life Sci. 2019, 3, 46–51. [Google Scholar] [CrossRef]

- Fernández-López, J.; Botella-Martínez, C.; Navarro-Rodriguez de Vera, C.; Sayas-Barberá, M.E.; Viuda-Martos, M.; Sánchez-Zapata, E.; Pérez-Álvarez, J.A. Vegetable soups and creams: Raw materials, processing, health benefits, and innovation trends. Plants 2020, 9, 1769. [Google Scholar] [CrossRef]

- Wong, J. Are there benefits to a raw-food diet? New Sci. 2021, 249, 20. [Google Scholar] [CrossRef]

- Pahlavani, N.; Azizi-Soleiman, F. The effects of a raw vegetarian diet from a clinical perspective; review of the available evidence. Clin. Nutr. Open Sci. 2023, 49, 107–112. [Google Scholar] [CrossRef]

- Morelli, G.; Catellani, P.; Miotti Scapin, R.; Bastianello, S.; Conficoni, D.; Contiero, B.; Ricci, R. Evaluation of microbial contamination and effects of storage in raw meat-based dog foods purchased online. J. Anim. Physiol. Anim. Nutr. 2020, 104, 690–697. [Google Scholar] [CrossRef]

- Schelstraete, W.; Devreese, M.; Croubels, S. Comparative toxicokinetics of Fusarium mycotoxins in pigs and humans. Food Chem. Toxicol. 2020, 137, 111140. [Google Scholar] [CrossRef]

- Ekwomadu, T.I.; Mwanza, M. Fusarium fungi pathogens, identification, adverse effects, disease management, and global food security: A review of latest research. Agriculture 2023, 13, 1810. [Google Scholar] [CrossRef]

- Pernica, M.; Kyralová, B.; Svoboda, Z.; Boško, R.; Brožková, I.; Česlová, L.; Benešová, K.; Červenka, L.; Běláková, S. Levels of T-2 toxin and its metabolites, and the occurrence of Fusarium fungi in spring barley in the Czech Republic. Food Microbiol. 2022, 102, 103879. [Google Scholar] [CrossRef] [PubMed]

- Krishnan, S.V.; Nampoothiri, K.M.; Suresh, A.; Linh, N.T.; Balakumaran, P.A.; Pòcsi, I.; Pusztahelyi, T. Fusarium biocontrol: Antagonism and mycotoxin elimination by lactic acid bacteria. Front. Microbiol. 2024, 14, 1260166. [Google Scholar] [CrossRef]

- Brožková, I.; Šmahová, P.; Vytřasová, J.; Moťková, P.; Pejchalová, M.; Šilha, D. Influence of chosen microbes and some chemicals substances on the production of aflatoxins. Slovak J. Food Sci./Potravin. 2015, 9, 9–17. [Google Scholar] [CrossRef][Green Version]

- Mateo, E.M.; Tarazona, A.; Aznar, R.; Mateo, F. Exploring the impact of lactic acid bacteria on the biocontrol of toxigenic Fusarium spp. and their main mycotoxins. Int. J. Food Microbiol. 2023, 387, 110054. [Google Scholar] [CrossRef]

- Joudeikiene, G.; Bartkiene, E.; Cernauskas, D.; Cizeikiene, D.; Zadeike, D.; Lele, V.; Bartkevics, V. Antifungal activity of lactic acid bacteria and their application for Fusarium mycotoxin reduction in malting wheat grains. LWT-Food Sci. Technol. 2018, 89, 307–314. [Google Scholar] [CrossRef]

- Cao, H.; Meng, D.; Zhang, W.; Ye, T.; Yuan, M.; Yu, J.; Wu, X.; Li, Y.; Yin, F.; Fu, C.; et al. Growth inhibition of Fusarium graminearum and deoxynivalenol detoxification by lactic acid bacteria and their application in sourdough bread. Int. J. Food Sci. Technol. 2021, 56, 2304–2314. [Google Scholar] [CrossRef]

- Piotrowska, M. Microbiological decontamination of mycotoxins: Opportunities and limitations. Toxins 2021, 13, 819. [Google Scholar] [CrossRef]

- Alcorta, A.; Porta, A.; Tárrega, A.; Alvarez, M.D.; Vaquero, M.P. Foods for plant-based diets: Challenges and innovations. Foods 2021, 10, 293. [Google Scholar] [CrossRef] [PubMed]

- Kamiński, M.; Skonieczna-Żydecka, K.; Nowak, J.K.; Stachowska, E. Global and local diet popularity rankings, their secular trends, and seasonal variation in Google Trends data. Nutrition 2020, 79–80, 110759. [Google Scholar] [CrossRef] [PubMed]

- ČSN EN ISO 7218 Amd.A1; Microbiology of Food and Animal Feeding Stuffs—General Requirements and Guidance for Microbiological Examinations. Czech Office for Standards, Metrology and Testing: Prague, Czech Republic, 2014.

- Martiník, J.; Boško, R.; Svoboda, Z.; Běláková, S.; Benešová, K.; Pernica, M. Determination of mycotoxins and their dietary exposure assessment in pale lager beers using immunoaffinity columns and UPLC-MS/MS. Mycotoxin Res. 2023, 39, 285–302. [Google Scholar] [CrossRef]

- Červenka, L.; Frühbauerová, M.; Palarčík, J.; Muriqi, S.; Velichová, H. The effect of vibratory grinding time on moisture sorption, particle size distribution, and phenolic bioaccessibility of carob powder. Molecules 2022, 27, 7689. [Google Scholar] [CrossRef]

- Senn, S.; Holford, N.; Hockey, H. The ghosts of departed quantities: Approaches to dealing with observations below the limit of quantification. Stat. Med. 2012, 31, 4280–4290. [Google Scholar] [CrossRef]

- U.S. Environmental Protection Agency (EPA). Data Quality Assessment: Statistical Methods for Practitioners; EPA QA/G-9S; EPA/240/B-06/003; U.S. Environmental Protection Agency: Washington, DC, USA. Available online: https://nepis.epa.gov/Exe/ZyPDF.cgi/900B0D00.PDF?Dockey=900B0D00.PDF (accessed on 24 June 2025).

- Lubin, J.H.; Colt, J.S.; Camann, D.; Davis, S.; Cerhan, J.R.; Severson, R.K.; Bernstein, L.; Hartge, P. Epidemiologic evaluation of measurement data in the presence of detection limits. Environ. Health Perspect. 2004, 112, 1691–1696. [Google Scholar] [CrossRef]

- Ramette, A. Multivariate analyses in microbial ecology. FEMS Microbiol. Ecol. 2007, 62, 142–160. [Google Scholar] [CrossRef]

- Abapihi, B.; Wibawa, G.N.A.; Baharuddin; Mukhsar; Agusrawati; LaOme, L. ANOVA on principal component as an alternative to MANOVA. J. Phys. Conf. Ser. 2021, 1899, 012103. [Google Scholar] [CrossRef]

- Hunaefi, D.; Rahmawati, R.; Saputra, D.; Maulani, R.R.; Muhandri, T. Optimizing the tray dryer temperature and time of white corn flour culture. Food Res. 2021, 5, 95–104. [Google Scholar] [CrossRef] [PubMed]

- Schmidt-Heydt, M.; Parra, R.; Geisen, R.; Magan, N. Modelling the relationship between environmental factors, transcriptional genes and deoxynivalenol mycotoxin production by strains of two Fusarium species. J. R. Soc. Interface 2011, 8, 117–126. [Google Scholar] [CrossRef]

- Mshelia, L.P.; Selamat, J.; Putra Samsudin, N.I.; Rafii, M.Y.; Abdul Mutalib, N.A.; Nordin, N.; Berthiller, F. Effect of temperature, water activity and carbon dioxide on fungal growth and mycotoxin production of acclimatized isolates of Fusarium verticillioides and F. graminearum. Toxins 2020, 12, 478. [Google Scholar] [CrossRef] [PubMed]

- Salah-Abbès, J.B.; Mannai, M.; Belgacem, H.; Zinedine, A.; Abbès, S. Efficacy of lactic acid bacteria supplementation against Fusarium graminearum growth in vitro and inhibition of zearalenone causing inflammation and oxidative stress in vivo. Toxicon 2021, 202, 115–122. [Google Scholar] [CrossRef] [PubMed]

- Akbari, M.; Hadi Razavi, S.; Khodaiyan, F.; Blesa, J.; Esteve, M.J. Fermented corn bran: A by product with improved total phenolic content and antioxidant activity. LWT 2023, 184, 115090. [Google Scholar] [CrossRef]

- Shalapy, N.M.; Kang, W. Fusrium oxysporum & Fusarium solani: Identification, characterization, and differentitation the fungal phenolic profiles by HPLC and the fungal lipid profiles by GC-MS. J. Food Qual. 2022, 2022, 414180. [Google Scholar]

- Kulik, T.; Stuper-Szablewska, K.; Bilska, K.; Buśko, M.; Ostrowska-Kołodziejczak, A.; Załuski, D.; Perkowski, J. trans-cinnamic and chlorogenic acids affect the secondary metabolic profiles and ergosterol biosynthesis by Fusarium culmorum and F. gramenearum sensu stricto. Toxins 2017, 9, 198. [Google Scholar] [CrossRef]

- Coton, M.; Dantigny, P. Mycotoxin migration in moldy foods. Curr. Opin. Food Sci. 2018, 29, 88–93. [Google Scholar] [CrossRef]

- Guo, H.; Ji, J.; Wang, J.S.; Sun, X. Deoxinivalenol: Masked forms, fate during food processing, and potential biological remedies. Compr. Rev. Food Sci. Food Saf. 2020, 19, 895–926. [Google Scholar] [CrossRef]

- Arena, M.P.; Capozzi, V.; Russo, P.; Drider, D.; Spano, G.; Fiocco, D. Immunobiosis and probiosis: Antimicrobial activity of lactic acid bacteria with a focus on their antiviral and antifungal properties. Appl. Microbiol. Biotechnol. 2018, 102, 9949–9958. [Google Scholar] [CrossRef] [PubMed]

- Gardiner, D.M.; Osborne, S.; Kazan, K.; Manners, J.M. Low pH regulates the production of deoxynivalenol by Fusarium graminearum. Microbiology 2009, 155, 3149–3156. [Google Scholar] [CrossRef]

- Cai, L.; Li, L.; Li, D.; Wu, Y.; Bai, J.; Zhong, K.; Gao, H. Citric acid impairs type B trichothecene biosynthesis of Fusarium graminearum but enhances its growth and pigment biosynthesis: Transcriptomic and proteomic analyses. Appl. Environ. Microbiol. 2025, 91, e01531-24. [Google Scholar] [CrossRef]

- Vidal, A.; Sanchis, V.; Ramos, A.J.; Marín, S. Thermal stability and kinetics of degradation of deoxynivalenol, deoxynivalenol conjugates and ochratoxin A during baking of wheat bakery products. Food Chem. 2015, 178, 276–286. [Google Scholar] [CrossRef]

- Li, B.; Duan, J.; Ren, J.; Francis, F.; Li, G. Isolation and characterization of two new deoxynivalenol-degrading strains, Bacillus sp. HN117 and Bacillus sp. N22. Toxins 2022, 14, 781. [Google Scholar] [CrossRef]

- Oluwakayode, A.; Greer, B.; Meneely, J.; Berthiller, F.; Krska, R.; Medina, A. Impact of environmental conditions on the concentrations of trichothecenes, their glucosides, and emerging Fusarium toxins in naturally contaminated, irradiated, and Fusarium langsethiae inoculated oats. Toxins 2024, 16, 166. [Google Scholar] [CrossRef] [PubMed]

| Sample | Viable Count (log CFU/g) | |||||

|---|---|---|---|---|---|---|

| TMC | BCC | TCBC | LBC | TYMC | ||

| NC | blend | 3.3 | <2.0 | 2.5 | <2.0 | <2.0 |

| MHT blend | 3.1 | <2.0 | 2.6 | <2.0 | <2.0 | |

| LA | blend | 3.1 | <2.0 | 2.6 | 4.8 | <2.0 |

| MHT blend | 3.2 | <2.0 | 2.5 | 4.8 | <2.0 | |

| FU | blend | 3.1 | <2.0 | 2.6 | <2.0 | 5.9 |

| MHT blend | 3.3 | <2.0 | 2.6 | <2.0 | 7.5 | |

| LAFU | blend | 3.1 | <2.0 | 2.6 | 4.8 | 5.9 |

| MHT blend | 3.0 | <2.0 | 2.6 | 4.8 | 7.4 | |

| Sample | Water Activity | Dry Matter (%) | TPC (mg GAE/g DW) | AC (mg Trolox/g DW) | |

|---|---|---|---|---|---|

| NC | blend | 0.967 ± 0.009 a | 77.0 ± 1.9 a | 5.38 ± 0.58 d | 14.07 ± 3.62 a |

| MHT blend | 0.934 ± 0.008 b | 78.3 ± 0.8 a | 5.57 ± 1.40 d | 13.65 ± 1.82 a | |

| LA | blend | 0.970 ± 0.003 a | 75.4 ± 1.4 a | 4.11 ± 0.56 e | 13.23 ± 0.93 a |

| MHT blend | 0.936 ± 0.006 b | 76.3 ± 0.6 a | 7.64 ± 0.68 cb | 16.65 ± 1.28 ab | |

| FU | blend | 0.971 ± 0.012 a | 76.5 ± 0.7 a | 6.01 ± 0.28 c | 16.07 ± 3.38 a |

| MHT blend | 0.934 ± 0.008 b | 77.0 ± 0.3 a | 8.59 ± 1.06 a | 19.02 ± 2.53 a | |

| LAFU | blend | 0.966 ± 0.012 a | 75.6 ± 2.3 a | 5.48 ± 0.45 d | 13.93 ± 1.16 a |

| MHT blend | 0.939 ± 0.017 a | 76.8 ± 0.1 a | 6.89 ± 0.70 bc | 15.43 ± 2.41 ab | |

| Sample | DAS | NEO | HT-2 | T-2 | |

|---|---|---|---|---|---|

| blend 1 | FU | <LOD | 5.2 | 1.4 | 2.3 |

| LAFU | <LOD | 3.7 | 1.1 | 1.3 | |

| blend 2 | FU | <LOD | <LOD | 1.4 | 0.2 |

| LAFU | <LOD | <LOD | <LOD | <LOD | |

| blend 3 | FU | 0.17 | 35.6 | 17.1 | 5.7 |

| LAFU | 0.08 | 19.1 | 8.4 | 2.4 | |

| MHT blend 1 | FU | 0.06 | 12.7 | 12.5 | 3.2 |

| LAFU | 0.03 | 9.9 | 9.7 | 3.1 | |

| MHT blend 2 | FU | <LOD | 3.0 | 1.2 | 1.0 |

| LAFU | <LOD | 2.5 | 0.7 | 0.9 | |

| MHT blend 3 | FU | <LOD | 1.0 | 11.3 | 30.3 |

| LAFU | 0.05 | 0.5 | 1.8 | 4.2 | |

| LOD | 0.01 | 0.04 | 0.09 | 0.06 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brožková, I.; Pernica, M.; Běláková, S.; Vydržalová, M.; Moťková, P.; Stará, I.; Husáková, L.; Červenka, L. Evaluating the Impact of Lactobacillus acidophilus on Fusarium Mycotoxins in Raw Vegan Pumpkin–Sunflower Seed Flour Blends. Foods 2025, 14, 3077. https://doi.org/10.3390/foods14173077

Brožková I, Pernica M, Běláková S, Vydržalová M, Moťková P, Stará I, Husáková L, Červenka L. Evaluating the Impact of Lactobacillus acidophilus on Fusarium Mycotoxins in Raw Vegan Pumpkin–Sunflower Seed Flour Blends. Foods. 2025; 14(17):3077. https://doi.org/10.3390/foods14173077

Chicago/Turabian StyleBrožková, Iveta, Marek Pernica, Sylvie Běláková, Markéta Vydržalová, Petra Moťková, Ivana Stará, Lenka Husáková, and Libor Červenka. 2025. "Evaluating the Impact of Lactobacillus acidophilus on Fusarium Mycotoxins in Raw Vegan Pumpkin–Sunflower Seed Flour Blends" Foods 14, no. 17: 3077. https://doi.org/10.3390/foods14173077

APA StyleBrožková, I., Pernica, M., Běláková, S., Vydržalová, M., Moťková, P., Stará, I., Husáková, L., & Červenka, L. (2025). Evaluating the Impact of Lactobacillus acidophilus on Fusarium Mycotoxins in Raw Vegan Pumpkin–Sunflower Seed Flour Blends. Foods, 14(17), 3077. https://doi.org/10.3390/foods14173077