Research Progress on Non-Destructive Testing Technology and Equipment for Poultry Eggshell Quality

Abstract

1. Introduction

2. Characteristics of Poultry Eggshells

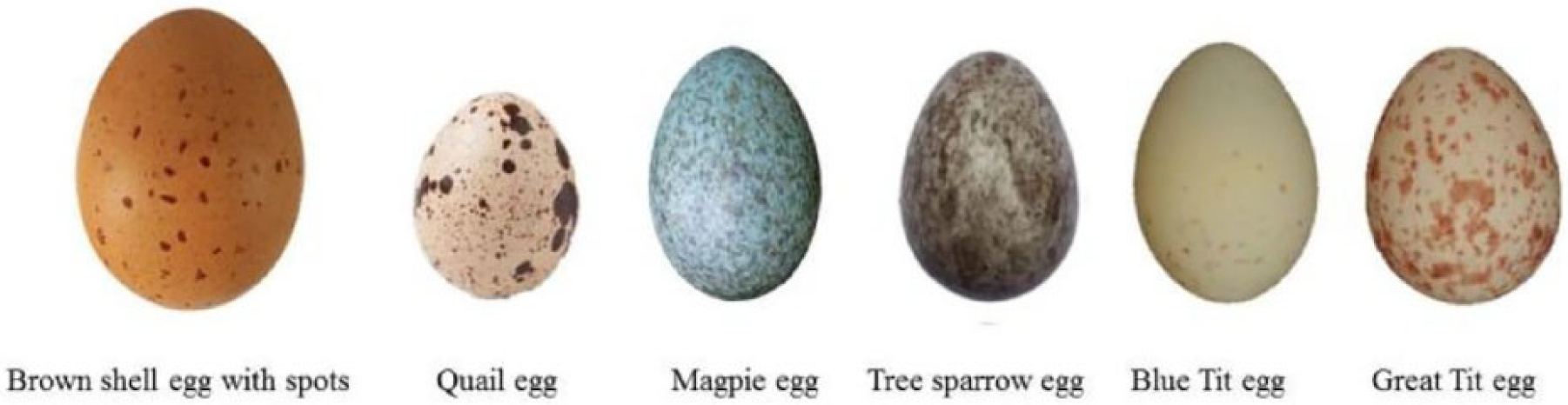

2.1. Surface Characteristics of Poultry Eggshells

2.2. Ultrastructure of Poultry Eggshells

2.3. Mechanical Properties of Poultry Eggshells

3. The Current Research Status of Poultry Eggshell Quality Detection Technology

3.1. Traditional Methods for Eggshell Detection and Evaluation

- (1)

- (2)

- Eggshell Thickness: Measured using tools such as a micrometer, requiring the eggshell to be broken for accurate assessment.

- (3)

- Eggshell Surface Spots: Traditionally identified through sensory evaluation, where human observers classify spots based on predefined grading criteria.

- (4)

- Eggshell Color: Qualitative analysis involves direct visual observation and comparison with standard color charts, whereas quantitative analysis predominantly employs spectrophotometry. A reflectometer is commonly used to measure eggshell color intensity [34].

- (5)

- Eggshell Crack Detection: Typically performed through visual inspection, with manual grading used to assess crack severity.

3.2. Current Research Status and Comparison of Eggshell Non-Destructive Testing Technologies

| Testing Information | Technical Means | Schematics | Algorithms and Models | Performance | Advantages | Disadvantages |

|---|---|---|---|---|---|---|

| Strength (static stiffness) | Acoustic resonance technology [35] |  | Frequency analysis | The correlation coefficients between the resonance frequency of the eggshell and its strength and thickness are 0.97 and 0.91 | Fast and intuitive; strong correlation; capable of simultaneously assessing two information indicators | The resonance effect is highly influenced by environmental factors |

| Acoustic impact signals [36] |  | Hertzian contact theory, time-domain signal analysis. | The static stiffness measured by quasi-static compression tests exhibits a correlation of 0.93 with the average stiffness obtained using this method | Simple structure; good correlation | Acoustic signals are highly influenced by the environment | |

| Hyperspectral imaging [37] |  | Extraction of characteristic wavelengths for regression coefficients and PLSR modeling | The correlation coefficient between the predicted values and eggshell strength is 0.841 | Spectral and image information can enable multi-information detection | The equipment cost is high, and the regression performance is moderate | |

| Non-destructive load technology [38] |  | Multifactorial linear equation | Prediction of maximum shell strength (R ≈ 1) | Good prediction effect | The prediction performance relies on the maximum non-destructive load value, and there is potential for damage | |

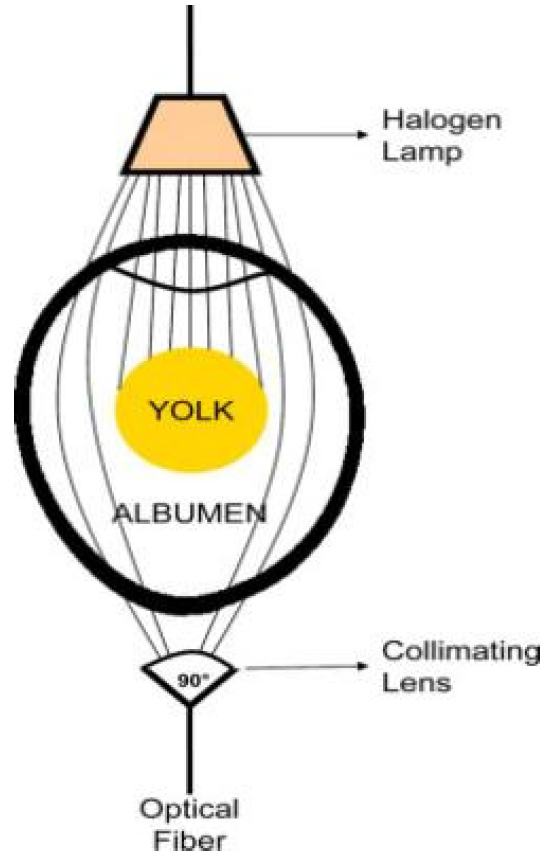

| Thicknesses | Visible/near-infrared transmission spectroscopy [39] | Preprocessing techniques such as standard normal variate transformation, followed by PLSR modeling for regression analysis | The correlation coefficient for the PLSR prediction set is 0.84, with a standard error of 0.01 | The detection is simple and rapid | The shell color has a significant impact; the prediction performance is moderate | |

| Optical coherence tomography [40] | Quantitative measurement of image data | A measurement resolution with a penetration depth ranging from 7 μm to 1.7 mm was achieved | Convenient, non-destructive, and accurate; capable of obtaining variations in thickness | The equipment cost is high | ||

| Terahertz time-domain reflectance spectroscopy [41] |  | Linear regression | The coefficient of determination (R2) of the model is 0.93 | Fast and non-destructive; the model performs excellently | The instrument is expensive, and the maintenance costs are high | |

| Color | Visible/near-infrared transmittance spectroscopy [42] |  | The ratio of relative transmittance at two characteristic spectral wavelengths (TCV) | The TCV value contains more information regarding the actual pigment deposition both inside and on the surface of the eggshell | The obtained pigment information is more comprehensive | It is not possible to fully quantify the external pigment deposition |

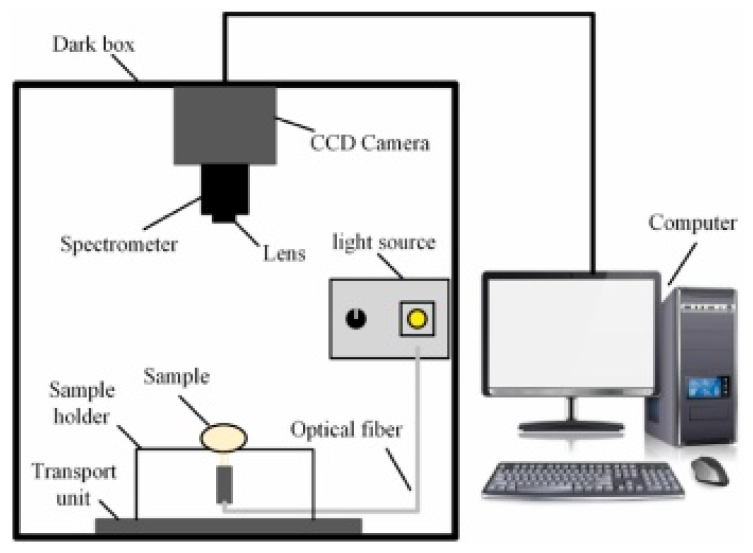

| Visible/near-infrared reflection spectroscopy [43] |  | Principal component analysis for band extraction, BP neural network modeling | The values for the test set are Rv = 0.9975, RMSEP = 0.0277, and SEP = 0.0159 | Fast and non-destructive; while achieving high classification accuracy, it can also provide information on eggshell strength | The implementation of online detection incurs high costs | |

| Speckles | Machine vision [14] |  | Image processing algorithms | The processing speed of the speckle image is 1 frame per 0.5 s | Quickly and accurately calculate the distribution of dark spots and the ratio of the projected area of dark spots | The fit between the calculated number of dark spots and the manual count is slightly poor |

| Crackles | Acoustic vibration [44] |  | Cross-correlation analysis and Bayesian classification method | The crack detection accuracy reaches 97%, with a false rejection rate of 1% | The operation is straightforward, and the classification performance is satisfactory | It is susceptible to environmental noise interference |

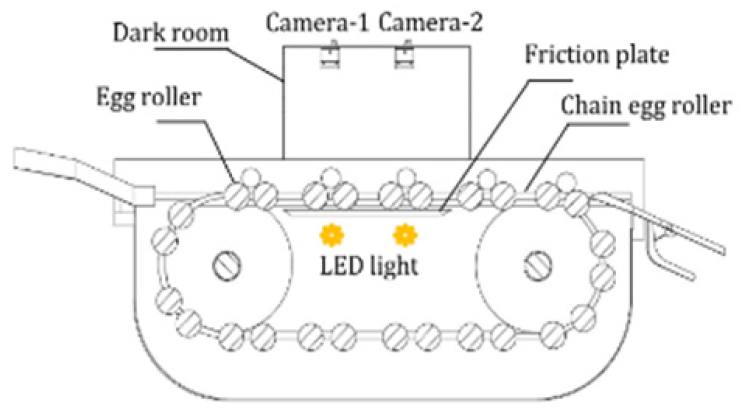

| Machine vision [45] |  | Improved EfficientNetV2 model | The crack recognition accuracy is 98.03%, with a detection time of 6.61 ms | Achieving batch processing of rapid detection for dirty and cracked eggs on the production line, with high classification performance | Sensitive to light source | |

| Visible/near-infrared reflection spectroscopy [43] |  | Principal component analysis for band extraction, followed by modeling using a backpropagation neural network | The crack classification accuracy for brown-shell, green-shell, and white-shell eggs are 100%, 100%, and 98.75% | Fast, non-destructive; high classification accuracy | The influence of eggshell color needs to be considered | |

| Fourier transform near-infrared [46] | selection of VIP feature wavelengths and PLSR modeling for regression | The RMSE, RPD, and R2 of the validation set are 0.82 N, 5.62, and 0.90 | Fast, green, and non-destructive | The color of the eggshell and the glossiness of its surface have a significant impact | ||

| Hyperspectral imaging [47] |  | XGBoost classification model | The crack detection accuracy is 93.33% | While analyzing other information from spectral data, image information was also utilized for crack detection | The instrument cost is high; relying solely on imaging data makes it unsuitable for crack detection | |

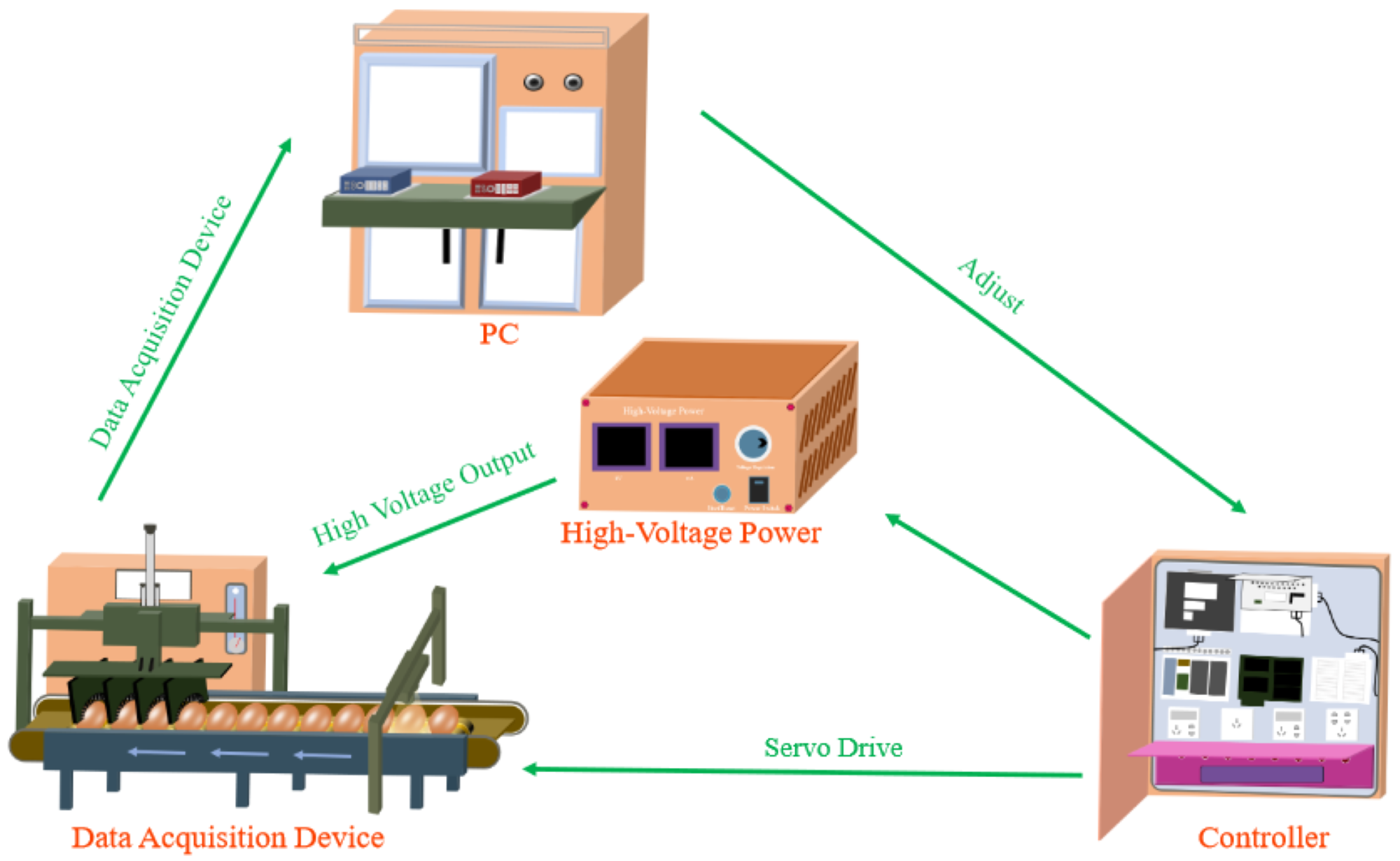

| Bioelectrical signals [48] |  | Wavelet scattering transform for feature extraction and convolutional neural network modeling for classification | The crack detection accuracy exceeds 99% | Fast and real-time; high detection accuracy | Highly influenced by voltage; requires precise control of the voltage range |

3.2.1. Eggshell Strength and Thickness Detection

- (1)

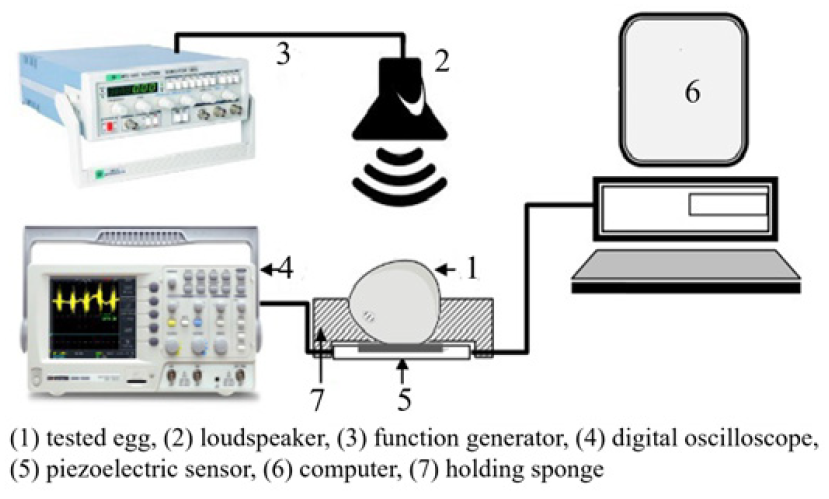

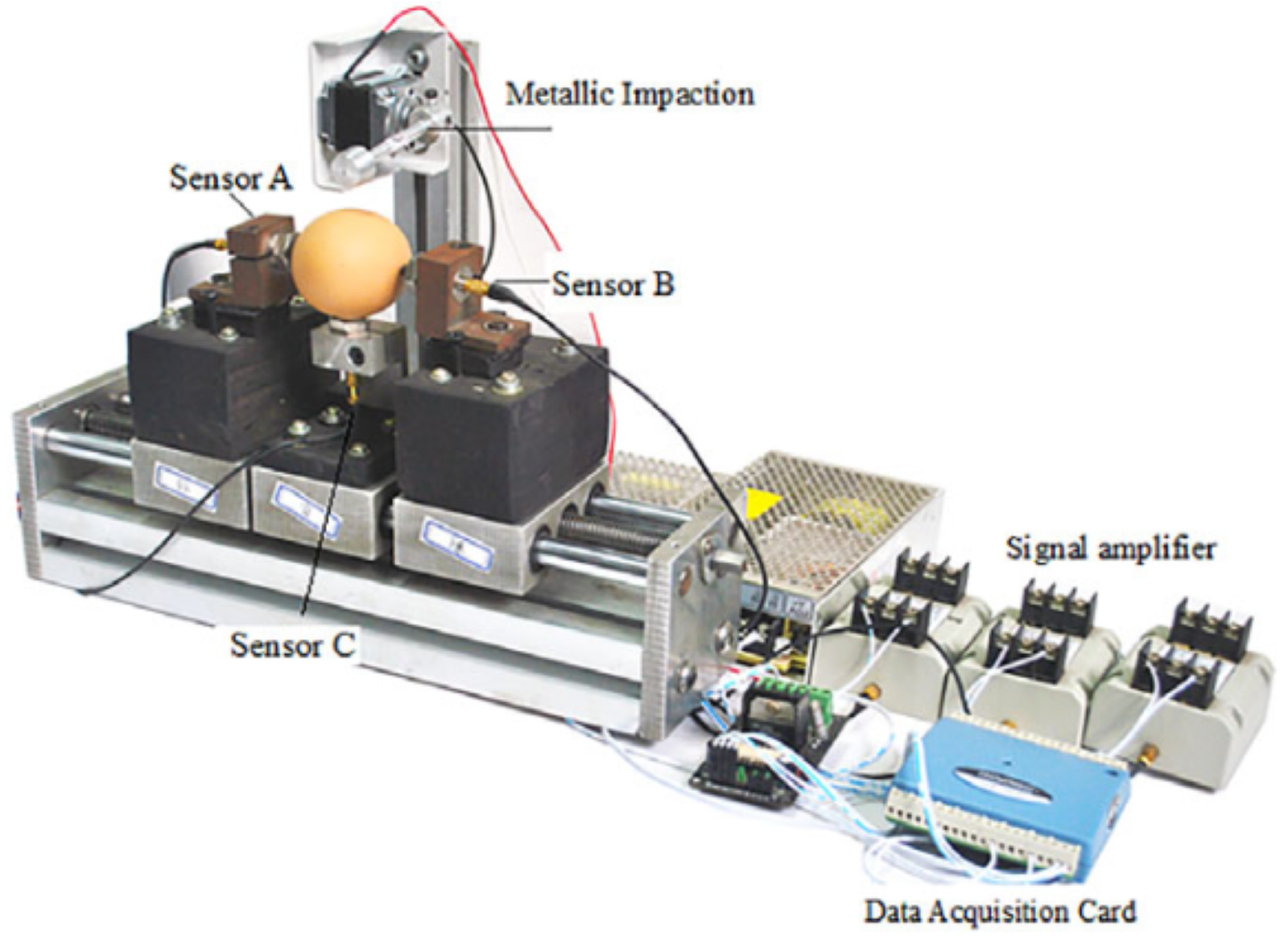

- Acoustic vibration technology

| Signal Acquisition Methods | Sensor | Acquisition Devices | Advantages | Disadvantages |

|---|---|---|---|---|

| Contact type [53] | Acceleration sensor, piezoelectric sensor |  | High detection sensitivity, wide frequency range | The weight of the sensor affects the vibration of the eggs, and can easily cause damage to the eggs |

| Non-contact type [54] | Microphone |  | Simple structure and cost-effective | Highly susceptible to environmental noise |

- (2)

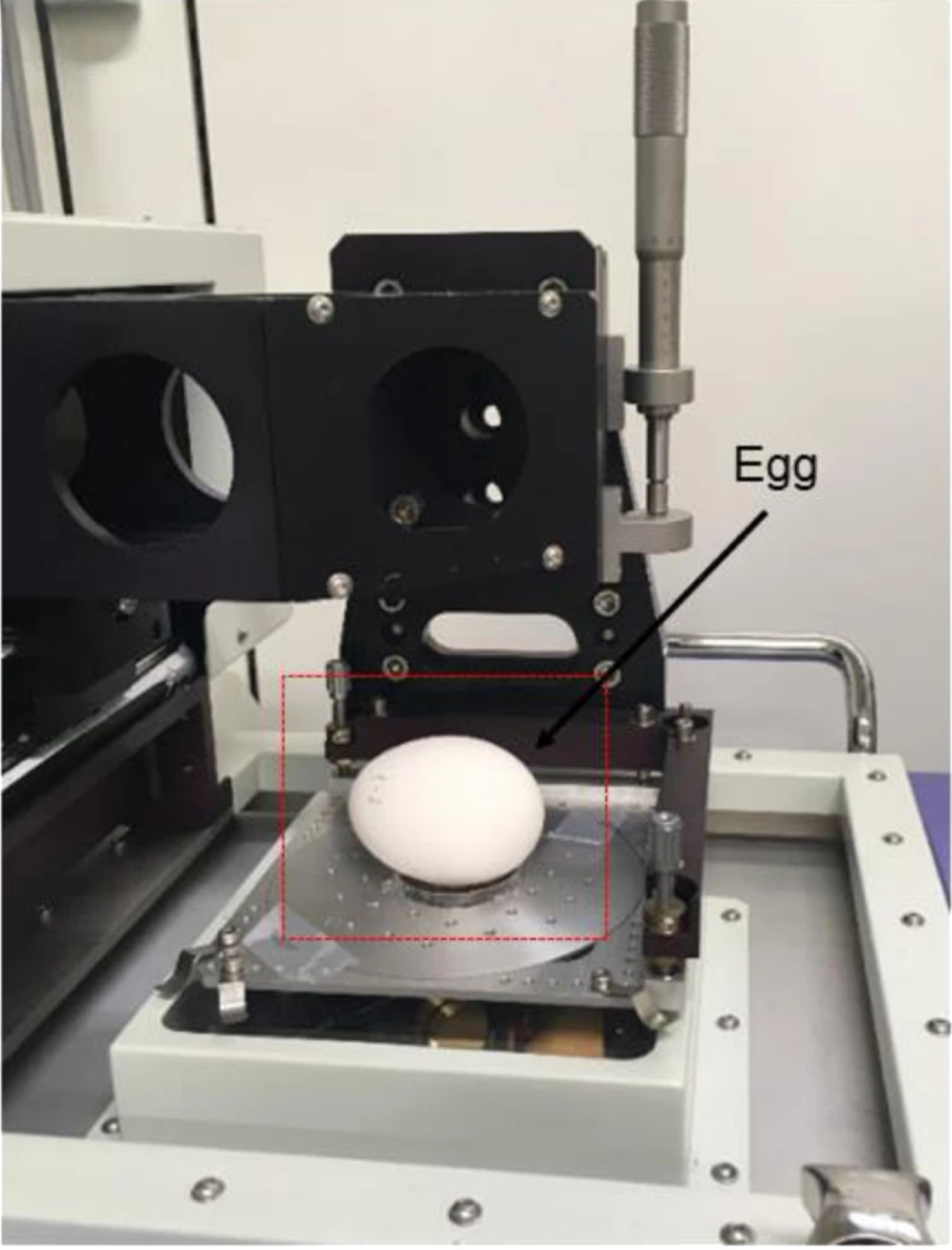

- Ultrasonic technology

- (3)

- Spectral analysis technology

- (4)

- Optical imaging technology

- (5)

- Non-destructive compression technology

3.2.2. Eggshell Crack Detection

- (1)

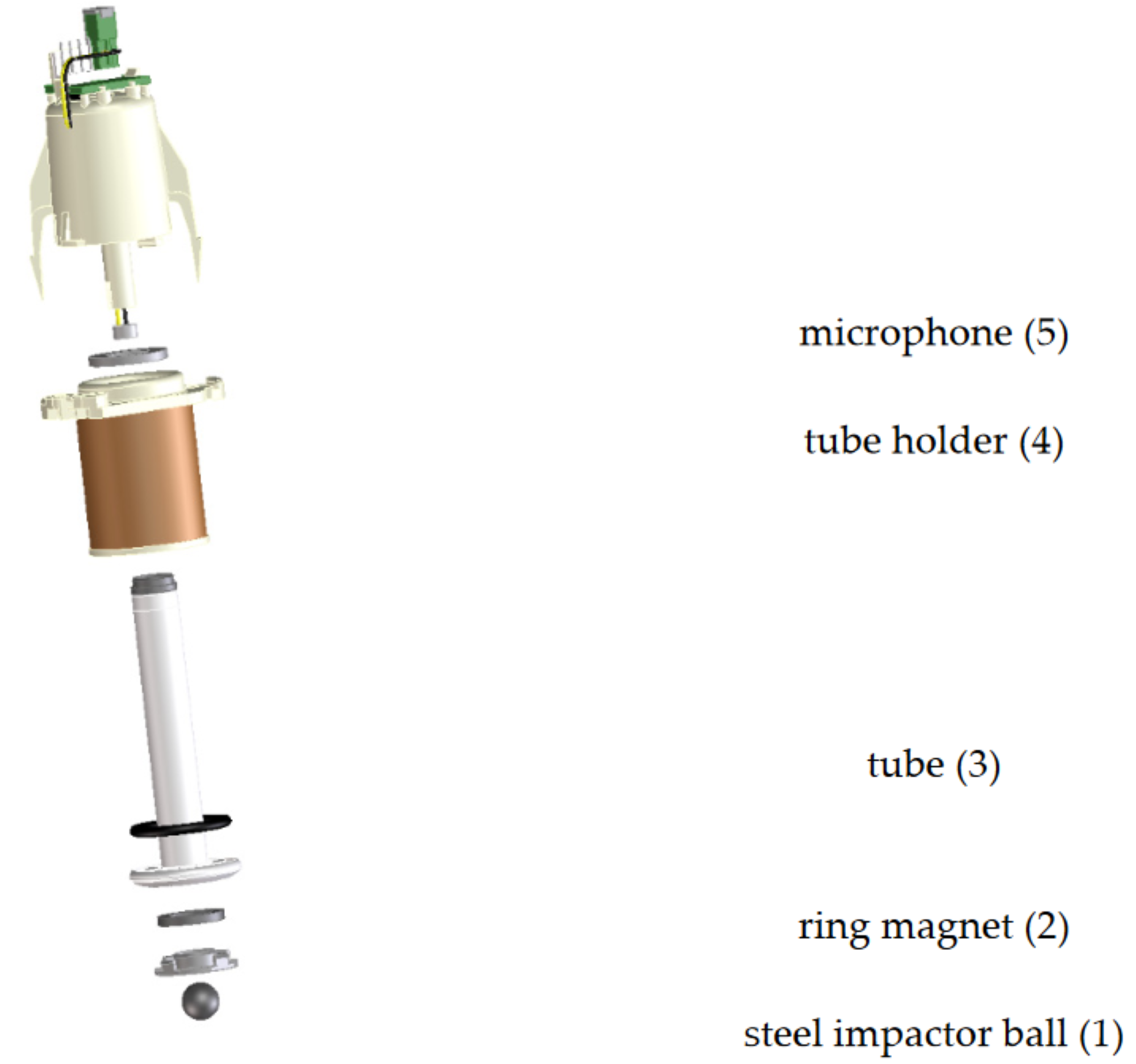

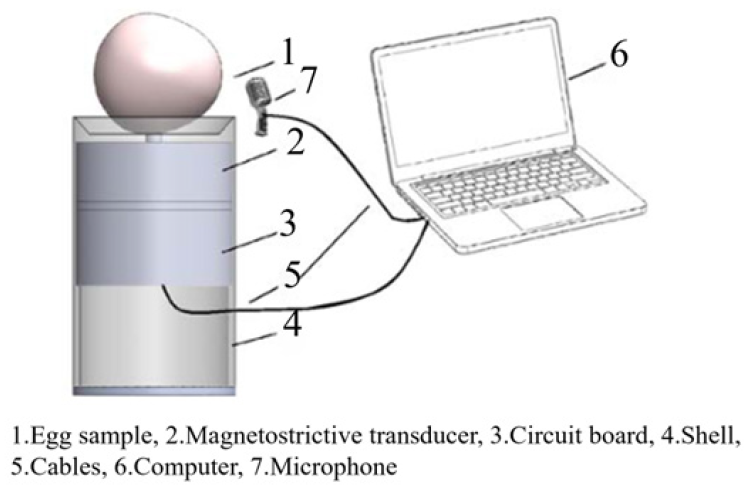

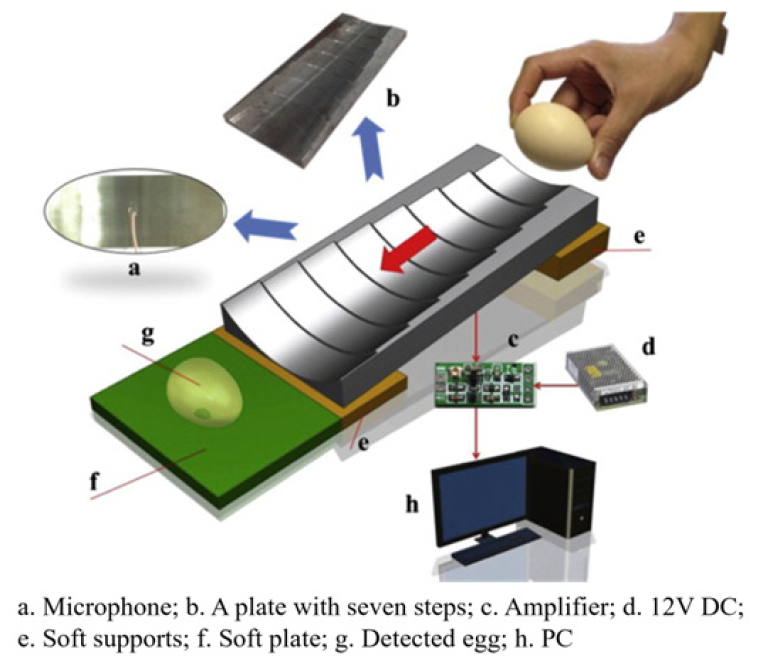

- Acoustic vibration technology

| Incentive Methods | Incentive Devices | Advantages | Disadvantages |

|---|---|---|---|

| Tapping vibration method [72] |  | Short excitation time, simple structure, and low cost | The excitation repeatability is poor, requiring control over the striking force |

| Magnetostrictive frequency sweeping vibration method [80] |  | Good excitation repeatability and a high signal-to-noise ratio | The excitation process is time-consuming |

| Inclined plate rolling vibration method [81] |  | The structure is simple and cost-effective | The damage rate is relatively high, and the time consumption is prolonged |

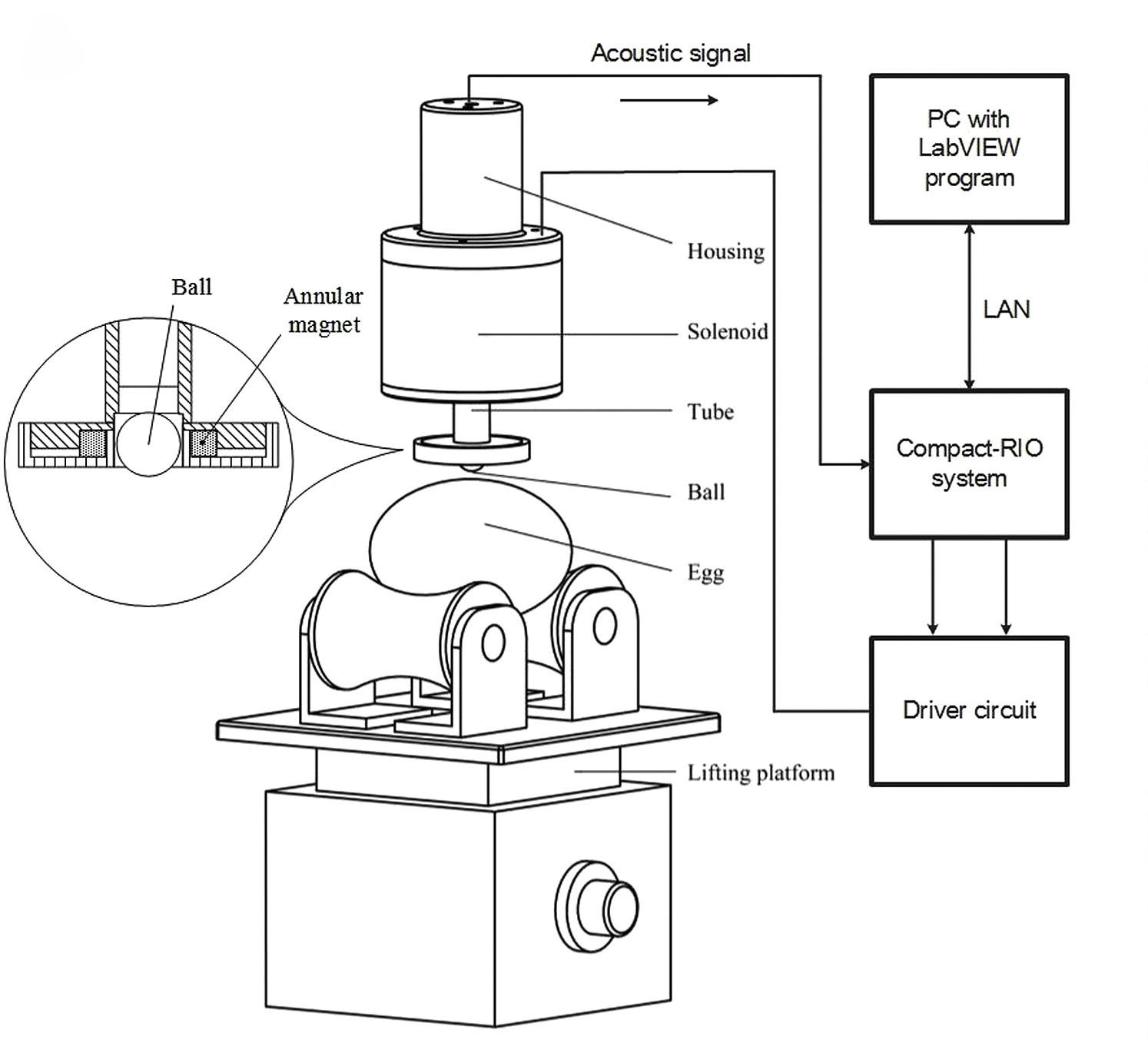

| Electromagnetic excitation method [83] |  | The system features a fast response time, high accuracy, and integrates both the sound collection module and the excitation module into a single unit | Prolonged on/off cycles can lead to heat generation, and the circuit and control system are relatively complex |

- (2)

- Computer vision technology

- (3)

- Spectral analysis technology

- (4)

- Optical imaging technology

- (5)

- Electrical signal analysis technology

3.2.3. Eggshell Color and Spot Detection

- (1)

- Computer vision technology

- (2)

- Spectral analysis technology

3.3. Conformity Assessment of NDT Methodologies with International Eggshell Quality Standards

4. Challenges in the Development of Non-Destructive Testing Equipment for Poultry Eggshell Quality

4.1. Issues in Eggshell Quality Detection

- (1)

- Individual variability of eggs: Different poultry eggs exhibit variations in shape, shell color, and surface texture, which require the detection technology to be adaptable to these individual differences. Technologies with poor adaptability tend to result in lower detection accuracy.

- (2)

- Hardware precision limitations: While visible cracks on the eggshell are relatively easy to identify, detecting small cracks and invisible cracks with complex shapes, which are not discernible to the naked eye, demands higher hardware precision. Therefore, balancing detection accuracy and cost is critical.

- (3)

- Limitations of detection methods: Existing non-destructive testing methods, such as spectral analysis, still struggle to match the precision of destructive tests for measuring eggshell thickness and strength. The performance of different detection techniques varies, making it crucial to select the most appropriate method based on the specific requirements of the task.

- (4)

- Species-specific influences: Unlike other agricultural products such as apples, pears, or kiwis, which experience changes in hardness over time and can be measured at multiple points using destructive testing, the strength of poultry eggs only undergoes a single measurement due to its one-time nature. This makes it challenging to identify inherent natural patterns in the strength of eggs.

4.2. Research Status and Analysis of Detection Equipment

- (1)

- Portable equipment. The colorimeter developed by Konica Minolta (Japan) employs reflective spectral analysis to output standard colorimetric values such as CIELAB, enabling objective quantification of eggshell color. With a measurement area of 8 mm, the device calculates color values based on the characteristics of the reflected spectrum, expressing them as tristimulus values (XYZ) or CIELAB values (Lab*). When paired with a data processor, it allows for data display, transmission, and printing. In China, the Beijing Tianxiang Feiyu Technology Co., Ltd. has designed a digital speckle evaluation instrument that utilizes transmitted imaging from multiple orientations (large end, small end, left side, and right side) of the egg to assess the overall speckle level and achieve digital recording.

- (2)

- Automated sorting equipment. The high-end egg grading machines developed by SANOVO Technology Group (Denmark) are equipped with integrated color recognition modules capable of effectively distinguishing between brown and white eggs. The system automatically directs eggs to corresponding packaging lanes and separates those with undesired shell colors. Furthermore, it can group brown eggs with uniform tonal characteristics, thereby enhancing grading efficiency and consistency.

4.3. Summary of the Current Situation and Challenge Analysis

- (1)

- Paradox between cost and accessibility: Contemporary non-destructive testing systems predominantly remain cost-prohibitive. Hyperspectral implementations incur substantial procurement and maintenance expenses due to core components including full-spectrum illumination sources, cryogenically cooled detectors, and precision control modules. Simplified configurations employing near-infrared (NIR) or multispectral technologies, while structurally streamlined, still necessitate custom-engineered illumination systems with stable performance, uniform irradiance, and extended longevity—yielding considerable lifecycle costs. Even acoustic and vision-based systems require premium data acquisition and processing hardware to achieve high frame rates, micron-scale spatial resolution, or microsecond-scale temporal response, thereby escalating total capital expenditure.

- (2)

- Contradiction between speed and precision: Vision and acoustic technologies achieve industrial-level detection efficiency through hardware innovations (e.g., 1280 fps high-speed cameras, microsecond-level delay acoustic sensors). However, due to the limitations of single-modal perception, there are bottlenecks in analyzing deep indicators such as eggshell thickness distribution and hidden cracks. Although spectral technologies can overcome detection dimensionality through multi-band fusion (e.g., full spectral coverage from 400 to 2500 nm), the complexity of the equipment (requiring integration of spectrometers, temperature control modules, and motion platforms) leads to significantly higher energy consumption and operational costs per test, surpassing the tolerable threshold for industrial scenarios.

- (3)

- Limitations of interference and algorithms: Visual systems are prone to false detection when exposed to fluctuations in lighting or changes in the egg’s position. Acoustic devices, under production line vibrations and background noise, experience a degradation in the effective signal-to-noise ratio. Hyperspectral technologies, with hundreds of feature dimensions, rely on deep neural networks for feature dimensionality reduction, but the time required for model training and the hardware computational demands limit real-time processing. Traditional machine learning algorithms, although computationally efficient, lack sufficient capability for fitting nonlinear relationships.

- (4)

- Disjunction between technology and application scenarios: Current visual and acoustic equipment has significant shortcomings in flexible sorting, miniaturization deployment, and tolerance to extreme environmental conditions. The market urgently requires portable devices that can perform multi-parameter detection (such as simultaneous analysis of cracks, thickness, and strength) with a low operational threshold. However, existing technologies are limited by sensor integration and battery life capabilities.

5. Prospects for the Future of Non-Destructive Testing of Poultry Eggshell Quality

5.1. Emerging Applications of Tactile Sensing Technology

5.2. Breakthrough in AI-Driven X-Ray Imaging Technology

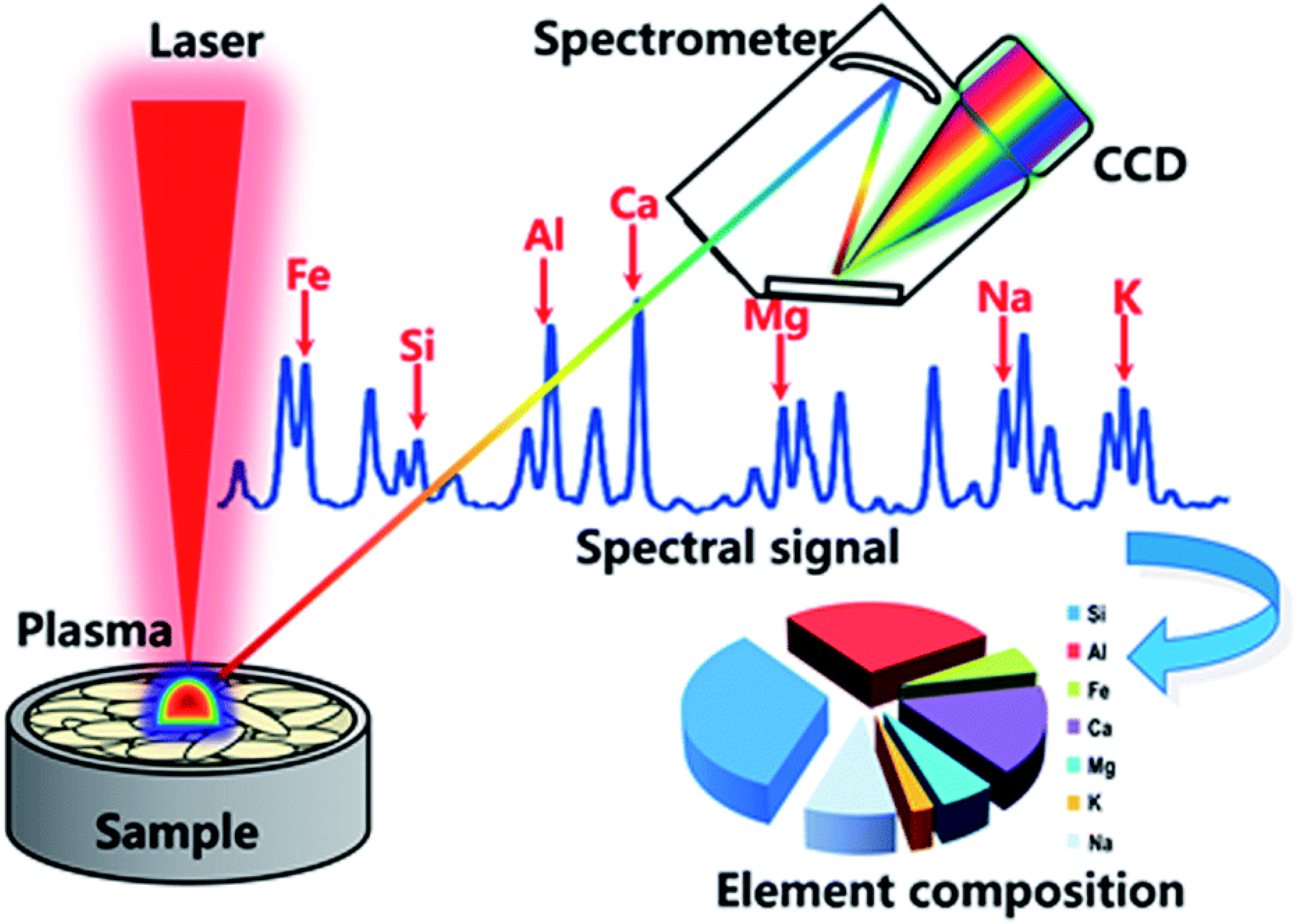

5.3. Exploration of Laser-Induced Breakdown Spectroscopy and Fluorescence Spectroscopy Technologies

5.4. Comprehensive Development Directions and Technological Outlook

- (1)

- Improving technological precision and efficiency: Existing detection equipment may face issues with data accuracy during high-speed operation, especially in micro-crack inspection systems, where it is challenging to ensure high precision while obtaining perfect sound and visual data. Future developments should introduce high-precision, lightweight deep learning algorithms and efficient data analysis methods, combined with hardware optimization, to further accelerate detection speed and enhance data processing capabilities.

- (2)

- Enhancing adaptability in complex environments: Poultry egg production environments may include complex conditions such as noise, dust, and light changes. Visual and optical technologies are susceptible to the influence of ambient light, while acoustic technologies are prone to interference from environmental noise, which can reduce the stability and accuracy of detection technologies and equipment. In the future, integrating visual, acoustic, and optical technologies to form multifunctional, integrated detection systems will improve equipment’s adaptability to complex environments.

- (3)

- Reducing system cost to promote technological adoption: The high overall cost of efficient NDT systems has hindered their widespread adoption and commercialization. Future efforts should focus on developing cost-effective spectral solutions based on low-cost light sources (e.g., LEDs), integrating low-power AI processing modules, and streamlining hardware design. These strategies are expected to significantly reduce system costs and facilitate broader industrial implementation.

- (4)

- Developing portable non-destructive testing instruments: Enterprises typically need to conduct regular sampling inspections of poultry eggs during production to ensure quality control, while research laboratories often require small-batch, diversified sample testing to improve research efficiency. In the future, there will be a need to develop more compact, portable, and easy-to-operate non-destructive testing instruments to meet broader market demands. For example, handheld or miniaturized portable testing instruments can quickly evaluate key indicators such as eggshell thickness and strength.

- (5)

- Establishing multi-model frameworks and integrated databases: Eggshell quality in poultry is influenced by a variety of factors, including breed, rearing environment, and geographical origin. These multidimensional variations introduce significant challenges in model training and generalization across visual, acoustic, and spectral detection modalities. To enhance the robustness and applicability of NDT systems, it is imperative to construct tailored multi-model frameworks and establish integrated databases that encompass diverse breeds, environmental conditions, and production regions.

- (6)

- Building comprehensive traceability systems: As consumer demand for transparency regarding product origins and quality increases, future developments will need to seamlessly integrate eggshell quality information into comprehensive traceability systems. This can be achieved through Internet of Things technologies to record real-time detection data for each egg, linking this information to traceability platforms. This will enable full-quality monitoring of poultry eggs from production to sale, further optimizing supply chain management and enhancing food safety assurance.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cordovil, K.P.S.; Pedroso, I.; Guimarães, A.K.V.; Azevedo, M.M.R.; Fernandes, G.S.T.; Rodrigues, K.F.; Gul, K.; Malik, S.; Taube, P.S. Analysis of the Quality of Eggs Marketed in Santarém, Brazil. Braz. J. Poult. Sci. 2023, 25, eRBCA. [Google Scholar] [CrossRef]

- Damena, A.; Mikru, A.; Adane, M.; Dobo, B. Microbial Profile and Safety of Chicken Eggs from a Poultry Farm and Small-Scale Vendors in Hawassa, Southern Ethiopia. J. Food Qual. 2022, 2022, 7483253. [Google Scholar] [CrossRef]

- Damaziak, K.; Marzec, A.; Riedel, J.; Wójcik, W.; Pstrokoński, P.; Szudrowicz, H.; Gozdowski, D. Effect of Pearl Guinea Fowl Eggshell Ultrastructure and Microstructure on Keets Hatchability. Poult. Sci. 2023, 102, 102733. [Google Scholar] [CrossRef] [PubMed]

- Chen, R.; Jiang, C.; Li, X.; Shi, X.; Zhuang, L.; Zhou, W.; Zhou, C.; Xuan, L.; Xu, G.; Zheng, J. Research on Chinese Consumers’ Shell Egg Consumption Preferences and the Egg Quality of Functional Eggs. Poult. Sci. 2023, 102, 103007. [Google Scholar] [CrossRef]

- Kamanlı, S.; Demirtaş, Ş.E.; Onbaşılar, E.E.; Bakır, B.; Yalçın, S.; Göğer, H.; Taşdemir, A.N.; Şenkal, U.E.; Boyalı, B.; Aygören, H.; et al. The Effects of the Breeder Index Value on the Microscopic Structure of Egg Shells, Hatching Results, and Hybrid Performance. Trop. Anim. Health Prod. 2021, 53, 557. [Google Scholar] [CrossRef]

- Liu, F.; Jiang, X.; Chen, Z.; Wang, L. Mechanical Design Principles of Avian Eggshells for Survivability. Acta Biomater. 2024, 178, 233–243. [Google Scholar] [CrossRef]

- Liu, W.; Lin, J.; Zhang, C.; Yang, Z.; Shan, H.; Jiang, J.; Wan, X.; Wang, Z. Effect of Dietary Casein Phosphopeptide Addition on the Egg Production Performance, Egg Quality, and Eggshell Ultrastructure of Late Laying Hens. Foods 2023, 12, 1712. [Google Scholar] [CrossRef]

- Indirapriyadharshini, J.; Sivaranjani, T.; Santhosh, P. A Novel Measurement Method for Egg Quality Identification. Mater. Today Proc. 2023, 81, 584–588. [Google Scholar] [CrossRef]

- Lu, M.-Y.; Xu, L.; Qi, G.-H.; Zhang, H.-J.; Qiu, K.; Wang, J.; Wu, S.-G. Mechanisms Associated with the Depigmentation of Brown Eggshells: A Review. Poult. Sci. 2021, 100, 101273. [Google Scholar] [CrossRef]

- Samiullah, S.; Roberts, J.R.; Chousalkar, K. Eggshell Color in Brown-Egg Laying Hens—A Review. Poult. Sci. 2015, 94, 2566–2575. [Google Scholar] [CrossRef]

- Rosenbeger, J.; Pytlak, K.; Łukaszewicz, E.; Kowalczyk, A. Variation in Bird Eggs—Does Female Factor, Season, and Laying Order Impact the Egg Size, Pigmentation, and Eggshell Thickness of the Eggs of Capercaillie? Animals 2021, 11, 3454. [Google Scholar] [CrossRef] [PubMed]

- Song, X.; Li, S.; He, S.; Zheng, H.; Li, R.; Liu, L.; Geng, T.; Zhao, M.; Gong, D. Integration of Whole-Genome Resequencing and Transcriptome Sequencing Reveals Candidate Genes in High Glossiness of Eggshell. Animals 2024, 14, 1141. [Google Scholar] [CrossRef] [PubMed]

- Drabik, K.; Karwowska, M.; Wengerska, K.; Próchniak, T.; Adamczuk, A.; Batkowska, J. The Variability of Quality Traits of Table Eggs and Eggshell Mineral Composition Depending on Hens’ Breed and Eggshell Color. Animals 2021, 11, 1204. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Zhou, J.; Wu, H.; Li, J.; Chunjiang, Z.; Liu, R. Research on the Evaluation Method of Eggshell Dark Spots Based on Machine Vision. IEEE Access 2020, 8, 160116–160125. [Google Scholar] [CrossRef]

- Chen, Z.; He, P.; He, Y.; Wu, F.; Rao, X.; Pan, J.; Lin, H. Eggshell Biometrics for Individual Egg Identification Based on Convolutional Neural Networks. Poult. Sci. 2023, 102, 102540. [Google Scholar] [CrossRef]

- Gosler, A.G.; Higham, J.P.; James Reynolds, S. Why Are Birds’ Eggs Speckled? Ecol. Lett. 2005, 8, 1105–1113. [Google Scholar] [CrossRef]

- Attard, M.R.G.; Bowen, J.; Corado, R.; Hall, L.S.; Dorey, R.A.; Portugal, S.J. Ecological Drivers of Eggshell Wettability in Birds. J. R. Soc. Interface 2021, 18, 20210488. [Google Scholar] [CrossRef]

- Cheng, X.; Ning, Z. Research Progress on Bird Eggshell Quality Defects: A Review. Poult. Sci. 2023, 102, 102283. [Google Scholar] [CrossRef]

- Patel, V.A.; Pandey, A.B.; Nandarvawala, B.T. Eggshell Particulate Reinforced Polymer Composite—A Review. J. Adv. Res. Appl. Mech. 2024, 125, 116–136. [Google Scholar] [CrossRef]

- Hincke, M.; Nys, Y.; Gautron, J.; Mann, K.; Rodriguez-Navarro, A.; McKee, M. The Eggshell: Structure, Composition and Mineralization. Front. Biosci. J. Virtual Libr. 2012, 17, 1266–1280. [Google Scholar] [CrossRef]

- Bain, M.M. Eggshell Strength: A Relationship between the Mechanism of Failure and the Ultrastructural Organisation of the Mammillary Layer. Br. Poult. Sci. 1992, 33, 303–319. [Google Scholar] [CrossRef]

- Rodríguez-Navarro, A.B.; Domínguez-Gasca, N.; Athanasiadou, D.; Le Roy, N.; González-Segura, A.; Reznikov, N.; Hincke, M.T.; McKee, M.D.; Checa, A.G.; Nys, Y.; et al. Guinea Fowl Eggshell Structural Analysis at Different Scales Reveals How Organic Matrix Induces Microstructural Shifts That Enhance Its Mechanical Properties. Acta Biomater. 2024, 178, 244–256. [Google Scholar] [CrossRef] [PubMed]

- Nys, Y.; Gautron, J.; Rodriguez-Navarro, A.B.; Hincke, M. Chapter 32—Mechanisms and Hormonal Regulation of Shell Formation: Supply of Ionic and Organic Precursors, Shell Mineralization. In Sturkie’s Avian Physiology, 7th ed.; Scanes, C.G., Dridi, S., Eds.; Academic Press: San Diego, CA, USA, 2022; pp. 833–879. ISBN 978-0-12-819770-7. [Google Scholar]

- Chen, X.; Ma, X.; Yang, C.-W.; Jiang, S.; Huang, L.; Li, Y.; Zhang, F.; Jiao, N.; Yang, W. Low Level of Dietary Organic Trace Elements Improve the Eggshell Strength, Trace Element Utilization, and Intestinal Function in Late-Phase Laying Hens. Front. Vet. Sci. 2022, 9, 903615. [Google Scholar] [CrossRef]

- Zhang, Y.; Deng, Y.; Jin, Y.; Wang, S.; Huang, X.; Li, K.; Xia, W.; Ruan, D.; Wang, S.; Chen, W.; et al. Age-Related Changes in Eggshell Physical Properties, Ultrastructure, Calcium Metabolism-Related Serum Indices, and Gene Expression in Eggshell Gland during Eggshell Formation in Commercial Laying Ducks. Poult. Sci. 2022, 101, 101573. [Google Scholar] [CrossRef]

- Tang, X.; Lin, J.; Yang, H.; Yang, Z.; Wang, Z. Shell Structure and Composition of Poultry Eggs. Fjnyxb 2022, 37, 156–163. [Google Scholar] [CrossRef]

- Ketelaere, B.D.; Govaerts, T.; Coucke, P.; Dewil, E.; Visscher, J.; Decuypere, E.; Baerdemaeker, J.D. Measuring the Eggshell Strength of 6 Different Genetic Strains of Laying Hens: Techniques and Comparisons. Br. Poult. Sci. 2002, 43, 238–244. [Google Scholar] [CrossRef]

- Coucke, C. Comparative Analysis of the Static and Dynamic Mechanical Eggshell Behaviour of a Chicken Egg. In Proceedings of the ISMA23, International Conference on Noise and Vibration Engineering, Leuven, Belgium, 16–18 September 1998; pp. 1497–1502. [Google Scholar]

- Coucke, P.; Dewil, E.; Decuypere, E.; De Baerdemaeker, J. Measuring the Mechanical Stiffness of an Eggshell Using Resonant Frequency Analysis. Br. Poult. Sci. 1999, 40, 227–232. [Google Scholar] [CrossRef]

- Bain, M.M. Recent Advances in the Assessment of Eggshell Quality and Their Future Application. World’s Poult. Sci. J. 2005, 61, 268–277. [Google Scholar] [CrossRef]

- Rodriguez-Navarro, A.; Kalin, O.; Nys, Y.; Garcia-Ruiz, J.M. Influence of the Microstructure on the Shell Strength of Eggs Laid by Hens of Different Ages. Br. Poult. Sci. 2002, 43, 395–403. [Google Scholar] [CrossRef]

- Hao, E.-Y.; Wang, D.-H.; Chen, Y.-F.; Zhou, R.-Y.; Chen, H.; Huang, R.-L. The Relationship between the mTOR Signaling Pathway and Ovarian Aging in Peak-Phase and Late-Phase Laying Hens. Poult. Sci. 2021, 100, 334–347. [Google Scholar] [CrossRef]

- Zhang, H.-D.; Zhao, X.-F.; Ren, Z.-Z.; Tong, M.-Q.; Chen, J.-N.; Li, S.-Y.; Chen, H.; Wang, D.-H. Comparison between Different Breeds of Laying Hens in Terms of Eggshell Translucency and Its Distribution in Various Ends of the Eggshell. Poult. Sci. 2021, 100, 101510. [Google Scholar] [CrossRef] [PubMed]

- Samiullah, S.; Roberts, J.; Chousalkar, K. Oviposition Time, Flock Age, and Egg Position in Clutch in Relation to Brown Eggshell Color in Laying Hens. Poult. Sci. 2016, 95, 2052–2057. [Google Scholar] [CrossRef] [PubMed]

- Attar, M.Z.; Fathi, M.M. Non-Destructive Acoustic Resonance Method for Evaluating Eggshell Strength and Thickness. Int. J. Biophys. 2014, 4, 9–15. [Google Scholar]

- De Ketelaere, B.; Corion, M.; Adriaens, I.; Van Liedekerke, P.; Saeys, W. Non-Destructive Eggshell Strength Assessment Using Hertz Contact Theory—Part II: Implementation and Validation. Foods 2023, 12, 1340. [Google Scholar] [CrossRef]

- Xie, C.; He, Y. External Characteristic Determination of Eggs and Cracked Eggs Identification Using Spectral Signature. Sci. Rep. 2016, 6, 21130. [Google Scholar] [CrossRef]

- Narushin, V.G.; Chausov, M.G.; Shevchenko, L.V.; Pylypenko, A.P.; Davydovych, V.A.; Romanov, M.N.; Griffin, D.K. Shell, a Naturally Engineered Egg Packaging: Estimated for Strength by Non-Destructive Testing for Elastic Deformation. Biosyst. Eng. 2021, 210, 235–246. [Google Scholar] [CrossRef]

- Dong, X.; Tang, X.; Peng, Y.; Dong, J. Nondestructive Assessment of Eggshell Thickness by VIS/NIR Spectroscopy. In Proceedings of the 2017 ASABE Annual International Meeting, Spokane, WA, USA, 16–19 July 2017; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2017. [Google Scholar]

- Sabuncu, M.; Akdoğan, M. Utilizing Optical Coherence Tomography in the Nondestructive and Noncontact Measurement of Egg Shell Thickness. Sci. World J. 2014, 2014, e205191. [Google Scholar] [CrossRef]

- Khaliduzzaman, A.; Konagaya, K.; Suzuki, T.; Kashimori, A.; Kondo, N.; Ogawa, Y. A Nondestructive Eggshell Thickness Measurement Technique Using Terahertz Waves. Sci. Rep. 2020, 10, 1052. [Google Scholar] [CrossRef]

- Mertens, K.; Vaesen, I.; Loffel, J.; Kemps, B.; Kamers, B.; Perianu, C.; Zoons, J.; Darius, P.; Decuypere, E.; De Baerdemaeker, J.; et al. The Transmission Color Value: A Novel Egg Quality Measure for Recording Shell Color Used for Monitoring the Stress and Health Status of a Brown Layer Flock. Poult. Sci. 2010, 89, 609–617. [Google Scholar] [CrossRef]

- Han, X.; Liu, Y.-H.; Zhang, X.; Zhang, Z.; Yang, H. Study on Egg Sorting Model Based on Visible-near Infrared Spectroscopy. Syst. Sci. Control Eng. 2022, 10, 733–741. [Google Scholar] [CrossRef]

- Sun, L.; Zhang, P.; Feng, S.; Qiang, M.; Cai, J. Eggshell Crack Detection Based on the Transient Impact Analysis and Cross-Correlation Method. Curr. Res. Food Sci. 2021, 4, 716–723. [Google Scholar] [CrossRef]

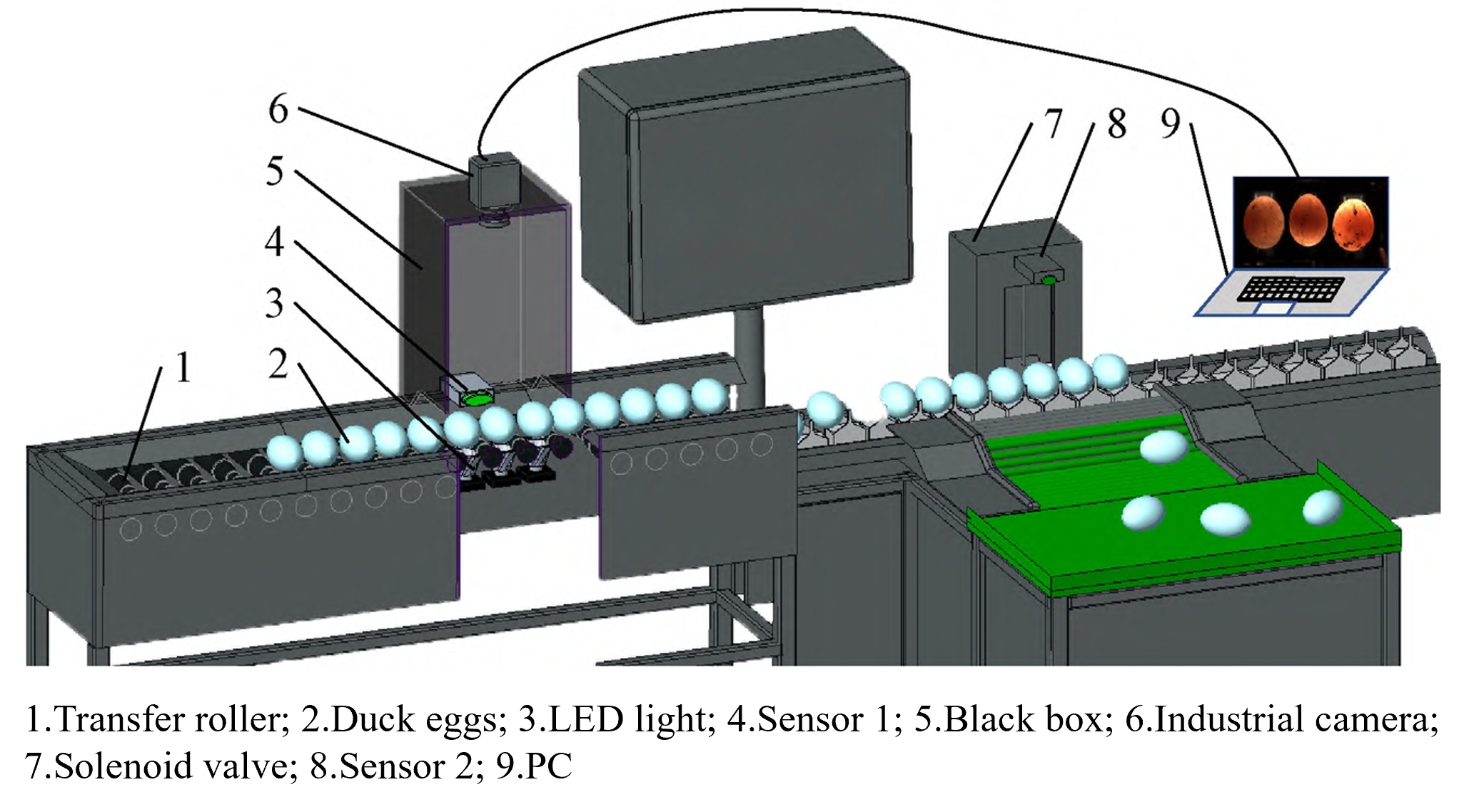

- Wang, Q.; Xu, B.; Tian, W.; Chen, Y.; Fan, W.; Liu, S. Online nondestructive detection of the external quality of pre-incubation duck eggs based on image processing and deep learning. Trans. Chin. Soc. Agric. Eng. 2023, 39, 233–241. [Google Scholar] [CrossRef]

- Ahmed, M.W.; Khaliduzzaman, A.; Emmert, J.L.; Kamruzzaman, M. Non-Destructive Prediction of Eggshell Strength Using FT-NIR Spectroscopy Combined with PLS Regression. In Proceedings of the 2024 ASABE Annual International Meeting, Anaheim, CA, USA, 28–31 July 2024; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2024. [Google Scholar]

- Yao, K.; Sun, J.; Chen, C.; Xu, M.; Zhou, X.; Cao, Y.; Tian, Y. Non-Destructive Detection of Egg Qualities Based on Hyperspectral Imaging. J. Food Eng. 2022, 325, 111024. [Google Scholar] [CrossRef]

- Shi, C.; Cheng, Y.; Zhang, C.; Yuan, J.; Wang, Y.; Jiang, X.; Zhu, C. Wavelet Scattering Convolution Network-Based Detection Algorithm on Nondestructive Microcrack Electrical Signals of Eggs. Agriculture 2023, 13, 730. [Google Scholar] [CrossRef]

- Xu, S.; Wang, H.; Liang, X.; Lu, H. Research Progress on Methods for Improving the Stability of Non-Destructive Testing of Agricultural Product Quality. Foods 2024, 13, 3917. [Google Scholar] [CrossRef]

- Lin, H.; Zhao, J.; Sun, L.; Chen, Q.; Sun, Z.; Zhou, F. Stiffness Measurement of Eggshell by Acoustic Resonance and PLS Models. J. Food Eng. 2011, 103, 351–356. [Google Scholar] [CrossRef]

- Sun, L.; Cai, J.; Lin, H.; Zhao, J.; Bi, X. On-Line Estimation of Eggshell Strength Based on Acoustic Impulse Response Analysis. Innov. Food Sci. Emerg. Technol. 2013, 18, 220–225. [Google Scholar] [CrossRef]

- De Ketelaere, B.; Corion, M.; Adriaens, I.; Van Liedekerke, P.; Saeys, W. Non-Destructive Eggshell Strength Assessment Using Hertz Contact Theory Part I: Theory and Applicability. Foods 2023, 12, 1189. [Google Scholar] [CrossRef]

- Lin, H.; Xu, P.-T.; Sun, L.; Bi, X.; Zhao, J.; Cai, J. Identification of Eggshell Crack Using Multiple Vibration Sensors and Correlative Information Analysis. J. Food Process Eng. 2018, 41, e12894. [Google Scholar] [CrossRef]

- Lai, C.-C.; Li, C.-H.; Huang, K.-J.; Cheng, C.-W. Duck Eggshell Crack Detection by Nondestructive Sonic Measurement and Analysis. Sensors 2021, 21, 7299. [Google Scholar] [CrossRef] [PubMed]

- Siddiqui, H.; Sultan, Z.; Yousuf, O.; Malik, M.; Younis, K. A Review of the Health Benefits, Functional Properties, and Ultrasound-Assisted Dietary Fiber Extraction. Bioact. Carbohydr. Diet. Fibre 2023, 30, 100356. [Google Scholar] [CrossRef]

- Voisey, P.W.; Hamilton, R.M.G. Ultrasonic Measurement of Egg Shell Thickness. Poult. Sci. 1976, 55, 1319–1324. [Google Scholar] [CrossRef]

- Guo, Y.; Huang, S.; Zhao, L.; Zhang, J.; Ji, C.; Ma, Q. Pine (Pinus massoniana Lamb.) Needle Extract Supplementation Improves Performance, Egg Quality, Serum Parameters, and the Gut Microbiome in Laying Hens. Front. Nutr. 2022, 9, 810462. [Google Scholar] [CrossRef]

- Liu, M.; Geng, S.; Wang, Q.; Mi, J.; Zhao, L.; Zhang, J.; Ji, C.; Wang, H.; Ma, Q.; Huang, S. Using Low-Protein Diet in Egg Production for Win-Win of Productivity and Environmental Benefits Should Be Prudent: Evidence from Pilot Test. Sci. Total Environ. 2024, 912, 169148. [Google Scholar] [CrossRef]

- Ma, M.; Geng, S.; Liu, M.; Zhao, L.; Zhang, J.; Huang, S.; Ma, Q. Effects of Different Methionine Levels in Low Protein Diets on Production Performance, Reproductive System, Metabolism, and Gut Microbiota in Laying Hens. Front. Nutr. 2021, 8, 739676. [Google Scholar] [CrossRef]

- Ergun, O.F.; Yamak, U.S. The Effect of Eggshell Thickness on Hatchability of Quail Eggs. Vet World 2017, 10, 1114–1117. [Google Scholar] [CrossRef]

- Arslan, A.; Yamak, U. Comparison of Different Eggshell Thickness Measurement Methods. Turk. J. Vet. Anim. Sci. 2020, 44, 1150–1153. [Google Scholar] [CrossRef]

- Amini, S.; MohamadZamani, D.; Javidan, S.M. Investigation of the Relationship Between Egg Shell Strength and Thickness Using Non-Destructive Ultrasound Method. J. Biosyst. Eng. 2022, 47, 263–269. [Google Scholar] [CrossRef]

- Kibala, L.; Rozempolska-Rucinska, I.; Kasperek, K.; Zieba, G.; Lukaszewicz, M. Ultrasonic Eggshell Thickness Measurement for Selection of Layers. Poult. Sci. 2015, 94, 2360–2363. [Google Scholar] [CrossRef]

- Xiong, H.; Xu, H.; Zhou, W.; Yao, Y.; Chen, H. Detection of Intact Egg Eggshell Quality Based on NIR Spectra. Trans. Chin. Soc. Agric. Eng. 2013, 29, 264–269. [Google Scholar]

- Voisey, P.W.; Hunt, J.R. Effect of Compression Speed on the Behaviour of Eggshells. J. Agric. Eng. Res. 1969, 14, 40–46. [Google Scholar] [CrossRef]

- Voisey, P.W.; Hamilton, R.M.G. Observations on The Relationship Between Non-Destructive Egg Shell Deformation and Resistance to Fracture by Quasi-Static Compression for Measurement of Egg Shell Strength1. Poult. Sci. 1977, 56, 1463–1467. [Google Scholar] [CrossRef]

- Voisey, P.W.; MacDONALD, D.C. Laboratory Measurements of Eggshell Strength: 1. An Instrument for Measuring Shell Strength by Quasi-Static Compression, Puncture, and Non-Destructive Deformation1. Poult. Sci. 1978, 57, 860–869. [Google Scholar] [CrossRef]

- Xu, P.; Zhao, J.; Zhang, D.; Gao, W.; Lin, H. Eggshell crack detection based on vibration mechanics. J. Food Saf. Qual. 2014, 5, 718–724. [Google Scholar] [CrossRef]

- Wang, Q.; Deng, X.; Wen, Y. Egg-shell crack multi-level detection based on the singularity feature of dynamic resonance. Trans. Chin. Soc. Agric. Mach. 2008, 39, 127–131. [Google Scholar]

- Xu, B.; Sun, L.; Cai, J.; Dai, Q. Multi Channel Detection System of Eggshell Crack Based on DSP. Food Mach. 2018, 34, 130–132. [Google Scholar] [CrossRef]

- Yumurtaci, M.; Balci, Z.; Ergiïn, S.; Yabanova, İ. The Detection of Eggshell Cracks Using Different Classifiers. Eskişehir Tech. Univ. J. Sci. Technol. A Appl. Sci. Eng. 2022, 23, 161–172. [Google Scholar] [CrossRef]

- Balci, Z.; Yabanova, İ. Artificial Intelligence Based Determination of Cracks in Eggshell Using Sound Signals. Sak. Univ. J. Sci. 2022, 26, 579–589. [Google Scholar] [CrossRef]

- Cheng, C.-W.; Feng, P.-H.; Xie, J.-H.; Weng, Y.-K. Eggshell Crack Detection and Egg Classification Using Resonance and Support Vector Machine Methods. Appl. Eng. Agric. 2019, 35, 23–30. [Google Scholar] [CrossRef]

- Sun, L.; Feng, S.; Chen, C.; Liu, X.; Cai, J. Identification of Eggshell Crack for Hen Egg and Duck Egg Using Correlation Analysis Based on Acoustic Resonance Method. J. Food Process Eng. 2020, 43, e13430. [Google Scholar] [CrossRef]

- Kertész, I.; Zsom-Muha, V.; András, R.; Horváth, F.; Németh, C.; Felföldi, J. Development of a Novel Acoustic Spectroscopy Method for Detection of Eggshell Cracks. Molecules 2021, 26, 4693. [Google Scholar] [CrossRef] [PubMed]

- Lashgari, M.; Mohammadigol, R. Assessment of Effective Variables on the Acoustic Response for Eggshell Crack. Agric. Mech. Syst. Res. 2016, 17, 1–14. [Google Scholar] [CrossRef]

- Ding, T.; Lu, W.; Zhang, C.; Du, J.; Ding, W.; Zhao, X. Eggshell crack identification based on Welch power spectrum and generalized regression neural network (GRNN). Food Sci. 2015, 36, 156–160. [Google Scholar]

- Zhang, C.; Lu, W.; Ding, W.; Luo, H.; Zhao, X. Study on egg cracks detection method based on the sweep frequency vibration. Food Ferment. Ind. 2015, 41, 181–186. [Google Scholar] [CrossRef]

- Luo, H.; Yan, S.; Lu, W.; Zhang, C.; Dai, D. Micro-cracked Eggs Online Detection Method Based on Force-Acoustic Features. Trans. Chin. Soc. Agric. Eng. 2016, 47, 224–230. [Google Scholar]

- Lu, W.; Zhang, C.; Luo, H.; Ding, W.; Wang, L. Micro-Cracks Detection of Eggshells Based on a Magnetostrictive Transducer. Sens. Transducers 2015, 186, 49–54. [Google Scholar]

- Jin, C.; Xie, L.; Ying, Y. Eggshell Crack Detection Based on the Time-Domain Acoustic Signal of Rolling Eggs on a Step-Plate. J. Food Eng. 2015, 153, 53–62. [Google Scholar] [CrossRef]

- Lashgari, M.; Mohammadigol, R. Comparative Study of Acoustic Signals of Rolling Eggs on Inclined Plate and Impulse Response in Eggshell Crack Detection. Agric. Eng. Int. CIGR J. 2018, 20, 150–156. [Google Scholar]

- Wang, H.; Mao, J.; Zhang, J.; Jiang, H.; Wang, J. Acoustic Feature Extraction and Optimization of Crack Detection for Eggshell. J. Food Eng. 2016, 171, 240–247. [Google Scholar] [CrossRef]

- Sun, K.; Ma, L.; Pan, L.; Tu, K. Sequenced Wave Signal Extraction and Classification Algorithm for Duck Egg Crack On-Line Detection. Comput. Electron. Agric. 2017, 142, 429–439. [Google Scholar] [CrossRef]

- Guanjun, B.; Mimi, J.; Yi, X.; Shibo, C.; Qinghua, Y. Cracked Egg Recognition Based on Machine Vision. Comput. Electron. Agric. 2019, 158, 159–166. [Google Scholar] [CrossRef]

- Chen, H.; Ma, J.; Zhuang, Q.; Zhao, S.; Xie, Y. Submillimeter Crack Detection Technology of Eggs Based on Improved Light Source. IOP Conf. Ser. Earth Environ. Sci. 2021, 697, 012018. [Google Scholar] [CrossRef]

- Sun, K.; Zhang, W.; Pan, L.; Tu, K. Recognition of a Cracked Hen Egg Image Using a Sequenced Wave Signal Extraction and Identification Algorithm. Food Anal. Methods 2018, 11, 1223–1233. [Google Scholar] [CrossRef]

- Zhang, J.; Cui, Y. Egg Crack Detection Based on Improved Particle Swarm Optimization. Food Mach. 2020, 36, 136–139. [Google Scholar] [CrossRef]

- Tu, W.; Cai, L.; Li, X. Egg Crack Image Detection Method Based on Improved Grasshopper Optimization Algorithm and Canny Operator. Food Mach. 2022, 38, 167–172. [Google Scholar] [CrossRef]

- Priyadumkol, J.; Kittichaikarn, C.; Thainimit, S. Crack Detection on Unwashed Eggs Using Image Processing. J. Food Eng. 2017, 209, 76–82. [Google Scholar] [CrossRef]

- Abbaspour-Gilandeh, Y.; Azizi, A. Identification of Cracks in Eggs Shell Using Computer Vision and Hough Transform. Yuz. Yıl Univ. J. Agric. Sci. 2018, 28, 375–383. [Google Scholar] [CrossRef]

- Sun, L.; Sun, Q.; Cai, J.; Wu, Z.; Ding, W. Online Detection of Eggshell Cracks Using Adaptive Light-Source Intensity. J. Food Process Eng. 2024, 47, e14566. [Google Scholar] [CrossRef]

- Abdullah, M.H.; Nashat, S.; Anwar, S.A.; Abdullah, M.Z. A Framework for Crack Detection of Fresh Poultry Eggs at Visible Radiation. Comput. Electron. Agric. 2017, 141, 81–95. [Google Scholar] [CrossRef]

- Wu, L.; Wang, Q.; Jie, D.; Wang, S.; Zhu, Z.; Xiong, L. Detection of Crack Eggs by Image Processing and Soft-Margin Support Vector Machine. J. Comput. Methods Sci. Eng. 2018, 18, 21–31. [Google Scholar] [CrossRef]

- Haoran, C.; Chuchu, H.; Minlan, J.; Xiaoxiao, L. Egg Crack Detection Based on Support Vector Machine. In Proceedings of the 2020 International Conference on Intelligent Computing and Human-Computer Interaction (ICHCI), Sanya, China, 4–6 December 2020; pp. 80–83. [Google Scholar]

- Mota-Grajales, R.; Torres-Peña, J.C.; Camas-Anzueto, J.L.; Pérez-Patricio, M.; Grajales Coutiño, R.; López-Estrada, F.R.; Escobar-Gómez, E.N.; Guerra-Crespo, H. Defect Detection in Eggshell Using a Vision System to Ensure the Incubation in Poultry Production. Measurement 2019, 135, 39–46. [Google Scholar] [CrossRef]

- Botta, B.; Gattam, S.S.R.; Datta, A.K. Eggshell Crack Detection Using Deep Convolutional Neural Networks. J. Food Eng. 2022, 315, 110798. [Google Scholar] [CrossRef]

- Wong, H.C.; Ng, E.Y.; Cheng, L.-H.; Gun, S.; Yen, K.S. Classification of Inhomogeneous Eggshell-Mottling Patterns Using a Pretrained Convolutional Neural Network. J. Electron. Imaging 2020, 29, 013013. [Google Scholar] [CrossRef]

- Li, S.; Tang, M.; Tong, S.; Sun, K. Research on Image Recognition of Cracked Eggs Based on Convolutional Neural Network Model. Food Mach. 2023, 39, 63. [Google Scholar] [CrossRef]

- Botta, B.; Datta, A.K. Deep Transfer Learning-Based Approach for Detection of Cracks on Eggs. J. Food Process Eng. 2023, 46, e14425. [Google Scholar] [CrossRef]

- Tang, W.; Hu, J.; Wang, Q. High-Throughput Online Visual Detection Method of Cracked Preserved Eggs Based on Deep Learning. Appl. Sci. 2022, 12, 952. [Google Scholar] [CrossRef]

- Tang, W.; Chen, Z.; Wang, D.; Fan, W.; Wang, Q. Crack Detection Method for Preserved Eggs Based on Improved YOLO v5 for Online Inspection. Trans. Chin. Soc. Agric. Mach. 2024, 55, 384–392. [Google Scholar]

- Turkoglu, M. Defective Egg Detection Based on Deep Features and Bidirectional Long-Short-Term-Memory. Comput. Electron. Agric. 2021, 185, 106152. [Google Scholar] [CrossRef]

- Shi, C.; Wang, Y.; Zhang, C.; Yuan, J.; Cheng, Y.; Jia, B.; Zhu, C. Nondestructive Detection of Microcracks in Poultry Eggs Based on the Electrical Characteristics Model. Agriculture 2022, 12, 1137. [Google Scholar] [CrossRef]

- Joe, S.Y.; So, J.H.; Oh, S.E.; Jun, S.; Lee, S.H. Development of Cracked Egg Detection Device Using Electric Discharge Phenomenon. Foods 2024, 13, 2989. [Google Scholar] [CrossRef] [PubMed]

- Martínez-de la Puente, J.; Merino, S.; Moreno, J.; Tomás, G.; Morales, J.; Lobato, E.; García-Fraile, S.; Martínez, J. Are Eggshell Spottiness and Colour Indicators of Health and Condition in Blue Tits Cyanistes Caeruleus? J. Avian Biol. 2007, 38, 377–384. [Google Scholar] [CrossRef]

- Gómez, J.; Liñán-Cembrano, G. SpotEgg: An Image-Processing Tool for Automatised Analysis of Colouration and Spottiness. J. Avian Biol. 2017, 48, 502–512. [Google Scholar] [CrossRef]

- Jiang, M.; Wu, P.; Li, F. Detecting Dark Spot Eggs Based on CNN GoogLeNet Model. In Proceedings of the Simulation Tools and Techniques: 15th EAI International Conference, SIMUtools 2023, Seville, Spain, 14–15 December 2023; Springer International Publishing: Cham, Switzerland, 2021; pp. 116–126. [Google Scholar]

- Poole, H.K. Spectrophotometric Identification of Eggshell Pigments and Timing of Superficial Pigment Deposition in the Japanese Quail. Proc. Soc. Exp. Biol. Med. 1965, 119, 547–551. [Google Scholar] [CrossRef]

- Cassey, P.; Hauber, M.E.; Maurer, G.; Ewen, J.G. Sources of Variation in Reflectance Spectrophotometric Data: A Quantitative Analysis Using Avian Eggshell Colours. Methods Ecol. Evol. 2011, 3, 450–456. [Google Scholar] [CrossRef]

- Holveck, M.-J.; Doutrelant, C.; Guerreiro, R.; Perret, P.; Gomez, D.; Grégoire, A. Can Eggs in a Cavity Be a Female Secondary Sexual Signal? Male Nest Visits and Modelling of Egg Visual Discrimination in Blue Tits. Biol. Lett. 2010, 6, 453–457. [Google Scholar] [CrossRef]

- Holveck, M.-J.; Grégoire, A.; Staszewski, V.; Guerreiro, R.; Perret, P.; Boulinier, T.; Doutrelant, C. Eggshell Spottiness Reflects Maternally Transferred Antibodies in Blue Tits. PLoS ONE 2012, 7, e50389. [Google Scholar] [CrossRef]

- Shimizu, T.; Shikida, M.; Sato, K.; Itoigawa, K. A New Type of Tactile Sensor Detecting Contact Force and Hardness of an Object. In Proceedings of the Technical Digest. MEMS 2002 IEEE International Conference. Fifteenth IEEE International Conference on Micro Electro Mechanical Systems (Cat. No.02CH37266), Las Vegas, NV, USA, 24 January 2002; pp. 344–347. [Google Scholar]

- Dargahi, J.; Najarian, S.; Liu, B. Sensitivity Analysis of a Novel Tactile Probe for Measurement of Tissue Softness with Applications in Biomedical Robotics. J. Mater. Process. Technol. 2007, 183, 176–182. [Google Scholar] [CrossRef]

- Romano, J.M.; Hsiao, K.; Niemeyer, G.; Chitta, S.; Kuchenbecker, K.J. Human-Inspired Robotic Grasp Control With Tactile Sensing. IEEE Trans. Robot. 2011, 27, 1067–1079. [Google Scholar] [CrossRef]

- Song, A.; Han, Y.; Hu, H.; Li, J. A Novel Texture Sensor for Fabric Texture Measurement and Classification. IEEE Trans. Instrum. Meas. 2014, 63, 1739–1747. [Google Scholar] [CrossRef]

- Kawamura, T.; Inaguma, N.; Nejigane, K.; Tani, K.; Yamada, H. Measurement of Slip, Force and Deformation Using Hybrid Tactile Sensor System for Robot Hand Gripping an Object. Int. J. Adv. Robot. Syst. 2013, 10, 83. [Google Scholar] [CrossRef]

- Wang, C.; Hwang, D.; Yu, Z.; Takei, K.; Park, J.; Chen, T.; Ma, B.; Javey, A. User-Interactive Electronic Skin for Instantaneous Pressure Visualization. Nat. Mater. 2013, 12, 899–904. [Google Scholar] [CrossRef] [PubMed]

- Ramuz, M.; Tee, B.C.-K.; Tok, J.B.-H.; Bao, Z. Transparent, Optical, Pressure-Sensitive Artificial Skin for Large-Area Stretchable Electronics. Adv. Mater. 2012, 24, 3223–3227. [Google Scholar] [CrossRef]

- Bandyopadhyaya, I.; Babu, D.; Kumar, A.; Roychowdhury, J. Tactile Sensing Based Softness Classification Using Machine Learning. In Proceedings of the 2014 IEEE International Advance Computing Conference (IACC), Gurgaon, India, 21–22 February 2014; pp. 1231–1236. [Google Scholar]

- Zhang, Z.; Zhou, J.; Yan, Z.; Wang, K.; Mao, J.; Jiang, Z. Hardness Recognition of Fruits and Vegetables Based on Tactile Array Information of Manipulator. Comput. Electron. Agric. 2021, 181, 105959. [Google Scholar] [CrossRef]

- Erukainure, F.E.; Parque, V.; Hassan, M.A.; FathElbab, A.M.R. Towards Estimating the Stiffness of Soft Fruits Using a Piezoresistive Tactile Sensor and Neural Network Schemes. In Proceedings of the 2022 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Sapporo, Japan, 11–15 July 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 290–295. [Google Scholar]

- Erukainure, F.E.; Parque, V.; Hassan, M.A.; FathEl-Bab, A.M.R. Estimating the Stiffness of Kiwifruit Based on the Fusion of Instantaneous Tactile Sensor Data and Machine Learning Schemes. Comput. Electron. Agric. 2022, 201, 107289. [Google Scholar] [CrossRef]

- He, L.; Tao, L.; Ma, Z.; Du, X.; Wan, W. Cherry Tomato Firmness Detection and Prediction Using a Vision-Based Tactile Sensor. Food Meas. 2024, 18, 1053–1064. [Google Scholar] [CrossRef]

- Lin, J.; Zhang, Y.; Liang, Q.; Chen, Y.; Zhu, M.; Li, S. Non-destructive Firmness Testing of Kiwifruit Based on Visioned-based Tactile Sensor and Fusion Learning. Trans. Chin. Soc. Agric. Eng. 2023, 54, 390–398. [Google Scholar]

- Kotwaliwale, N.; Singh, K.; Kalne, A.; Jha, S.N.; Seth, N.; Kar, A. X-Ray Imaging Methods for Internal Quality Evaluation of Agricultural Produce. J. Food Sci. Technol. 2014, 51, 1–15. [Google Scholar] [CrossRef]

- Ray, A.; Roberts, J.R.; Flavel, R.; Chousalkar, K.K. Eggshell Penetration by Salmonella Typhimurium in Table Eggs: Examination of Underlying Eggshell Structures by Micro-Computed Tomography and Scanning Electron Microscopy. Food Res. Int. 2015, 78, 34–40. [Google Scholar] [CrossRef]

- Hsiao, W.-T.; Lin, H.-H.; Lai, L.-H. Application of Visual Radiographic Analysis of Quality Grade of Table Eggs. Appl. Sci. 2021, 11, 2815. [Google Scholar] [CrossRef]

- Lell, M.; Kachelrieß, M. Computed Tomography 2.0: New Detector Technology, AI, and Other Developments. Investig. Radiol. 2023, 58, 587. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Tolok, G.; Fu, Y.; Xu, L.; Li, L.; Gao, H.; Zhou, Y. Application and Research Progress of Laser-Induced Breakdown Spectroscopy in Agricultural Product Inspection. ACS Omega 2024, 9, 24203–24218. [Google Scholar] [CrossRef]

- Ali, L.M.; El-Saeid, R.H.; Abdel-Harith, M. Utilizing Laser Spectrochemical Analytical Methods for Assessing the Ripening Progress of Tomato. J. Food Meas. Charact. 2022, 16, 3054–3061. [Google Scholar] [CrossRef]

- Putri, A.; Mitaphonna, R.; Rajibussalim; Lahna, K.; Idris, N. Elemental Analysis of “Kampong” Chicken Egg Shell Content Using a Nd-YAG Laser Induced Breakdown Spectroscopy. IOP Conf. Ser. Earth Environ. Sci. 2024, 1356, 012120. [Google Scholar] [CrossRef]

- Yang, P.; Fu, G.; Wang, J.; Luo, Z.; Yao, M. A Tutorial Review on Methods of Agricultural Product Sample Pretreatment and Target Analysis by Laser-Induced Breakdown Spectroscopy. J. Anal. At. Spectrom. 2022, 37, 1948–1960. [Google Scholar] [CrossRef]

- Ostertag, E.; Scholz, M.; Klein, J.; Rebner, K.; Oelkrug, D. Pigmentation of White, Brown, and Green Chicken Eggshells Analyzed by Reflectance, Transmittance, and Fluorescence Spectroscopy. ChemistryOpen 2019, 8, 1084–1093. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Yang, Z.; Liu, C.; Sun, R.; Yue, S. Research Progress on Non-Destructive Testing Technology and Equipment for Poultry Eggshell Quality. Foods 2025, 14, 2223. https://doi.org/10.3390/foods14132223

Wang Q, Yang Z, Liu C, Sun R, Yue S. Research Progress on Non-Destructive Testing Technology and Equipment for Poultry Eggshell Quality. Foods. 2025; 14(13):2223. https://doi.org/10.3390/foods14132223

Chicago/Turabian StyleWang, Qiaohua, Zheng Yang, Chengkang Liu, Rongqian Sun, and Shuai Yue. 2025. "Research Progress on Non-Destructive Testing Technology and Equipment for Poultry Eggshell Quality" Foods 14, no. 13: 2223. https://doi.org/10.3390/foods14132223

APA StyleWang, Q., Yang, Z., Liu, C., Sun, R., & Yue, S. (2025). Research Progress on Non-Destructive Testing Technology and Equipment for Poultry Eggshell Quality. Foods, 14(13), 2223. https://doi.org/10.3390/foods14132223